Fujitsu MHL2300AT, MHM200AT, MHM215OAT, MHM2100AT User Manual

C141-E104-02EN

MHL2300AT, MHM2200AT,

MHM2150AT, MHM2100AT

DISK DRIVES

PRODUCT MANUAL

C141-E104-02EN

FOR SAFE OPERATION

Handling of This Manual

This manual contains important information for using this product. Read thoroughly before using

the product. Use this product only after thoroughly reading and understanding especially the

section “Important Alert Items” in this manual. Keep this manual handy, and keep it carefully.

FUJITSU makes every effort to prevent users and bystanders from being injured or from suffering

damage to their property. Use the product according to this manual.

IMPO R TANT NOTE TO USER S

READ THE ENTIRE MANUAL CAREFULLY BEFORE USING THI S PRODUCT.

INCORRECT USE OF THE PRO DUCT MAY RESULT IN INJURY OR DAMAGE TO

USERS, BYSTANDERS OR PROPERTY.

While FUJITSU has sought to ensure the accuracy of all information in this manual, FUJITSU

assumes no liability to any party for any damage caused by any error or omission contained in this

manual, its updates or supplements, whether such errors or omissions result from negligence,

accident, or any other cause. In addition, FUJITSU assumes no liability with respect to the

application or use of any product or system in accordance with the descriptions or instructions

contained herein; including any liability for incidental or consequential damages arising therefrom.

FUJITSU DISCLAIMS ALL WARRANTIES REGARDING THE INFORMATION CONTAINED

HEREIN, WHETHER EXPRESSED, IMPLIED, OR STATUTORY.

FUJITSU reserves the right to make changes to any products described herein without further

notice and without obligation.

The contents of this manual may be revised without prior notice.

The contents of this manual shall not be disclosed in any way or reproduced in any media without

the express written permission of Fujitsu Limited.

All Rights Reserved, Copyright FUJITSU LIMITED 2000

This page is intentionally left blank.

C141-E104-02EN

Revision History

(1/1)

Edition Date Revised section (*1)

(Added/Deleted/Altered)

Details

01 2000-02-15 — —

02 2000-09-20 -Table 1.1

- Table 1.2

- (16) SET MAX in Section

5.3.2

- Table 5.17

- Specification (Number of Sections for

MHL2300AT) was altered.

- Order No. was changed.

- SET MAX commands are added.

- Values of host termination for DIOR-,

DIOW- and DMACK- signals are

changed.

*1 Section(s) with asterisk (*) refer to the previous edition when those were deleted.

This page is intentionally left blank.

C141-E104-02EN i

Preface

This manual describes the MHL Series and MHM Series, 2.5-inch hard disk drives.

These drives have a built-in controller that is compatible with the ATA interface.

This manual describes the specifications and functions of the drives and explains in

detail how to incorporate the drives into user systems. This manual assumes that

the reader has a basic knowledge of hard disk drives and their implementations in

computer systems.

This manual consists of seven chapters and sections explaining the special

terminology and abbreviations used in this manual:

Overview of Manual

CHAPTER 1 Device Overview

This chapter gives an overview of the MHL Series and MHM Series and describes

their features.

CHAPTER 2 Device Configuration

This chapter describes the internal configurations of the MHL Series and MHM

Series and the configuration of the systems in which they operate.

CHAPTER 3 Installation Condit ions

This chapter describes the external dimensions, installation conditions, and switch

settings of the MHL Series and MHM Series.

CHAPTER 4 Theory of Device Operation

This chapter describes the operation theory of the MHL Series and MHM Series.

CHAPTER 5 Interface

This chapter describes the interface specifications of the MHL Series and MHM

Series.

CHAPTER 6 Operations

This chapter describes the operations of the MHL Series and MHM Series.

Terminology

This section explains the special terminology used in this manual.

Abbreviation

This section gives the meanings of the definitions used in this manual.

Preface

ii C141-E104-02EN

Conventions for Alert Messages

This manual uses the following conventions to show the alert messages. An alert

message consists of an alert signal and alert statements. The alert signal consists of

an alert symbol and a signal word or just a signal word.

The following are the alert signals and their meanings:

CAUTION

This indicates a hazardous situation could result in

minor or moderate personal injury if the user does

not perform the procedure correctly. This alert

signal also indicates that damages to the product or

other property may occur if the user does not perform

the procedure correctly.

IMPORTANT

This indicates information that could help the user

use the product more efficiently.

In the text, the alert signal is centered, followed below by the indented message. A

wider line space precedes and follows the alert message to show where the alert

message begins and ends. The following is an example:

(Example)

CAUTION

Data corruption: Avoid mounting the disk drive near strong

magnetic sources such as loud speakers. Ensure that the disk drive is

not affected by external magnetic fields.

The main alert messages in the text are also listed in the “Important Alert Items.”

Operating Environment

This product is designed to be used in offices or computer rooms.

For details regarding the operating environment of use, refer to the

(Cnnn-Xnnn) and the

(Cnnn-Xnnn).

Attention

Please forward any comments you may have regarding this manual.

To make this manual easier for users to understand, opinions from readers are

needed. Please write your opinions or requests on the Comment at the back of this

manual and forward it to the address described in the sheet.

Preface

C141-E104-02EN iii

Liability Exception

“Disk drive defects” refers to defects that involve adjustment, repair, or

replacement.

Fujitsu is not liable for any other disk drive defects, such as those caused by user

misoperation or mishandling, inappropriate operating environments, defects in the

power supply or cable, problems of the host system, or other causes outside the

disk drive.

This page is intentionally left blank.

C141-E104-02EN v

Important Alert Items

Important Alert Messages

The important alert messages in this manual are as follows:

CAUTION

A hazardous situation could result in minor or moderate personal

injury if the user does not perform the procedure correctly. Also,

damage to the predate or other property, may occur if the user does not

perform the procedure correctly.

Task Alert message Page

Normal Operation

Data corruption: Avoid mounting the disk near strong

magnetic sources such as loud speakers. Ensure that the disk

drive is not affected by external magnetic fields.

Damage: Do not press the cover of the disk drive. Pressing

it too hard, the cover and the spindle motor contact, which

may cause damage to the disk drive.

Static: When handling the device, disconnect the body

ground (500 kΩ or greater). Do not touch the printed circuit

board, but hold it by the edges.

3-8

This page is intentionally left blank.

C141-E104-02EN vii

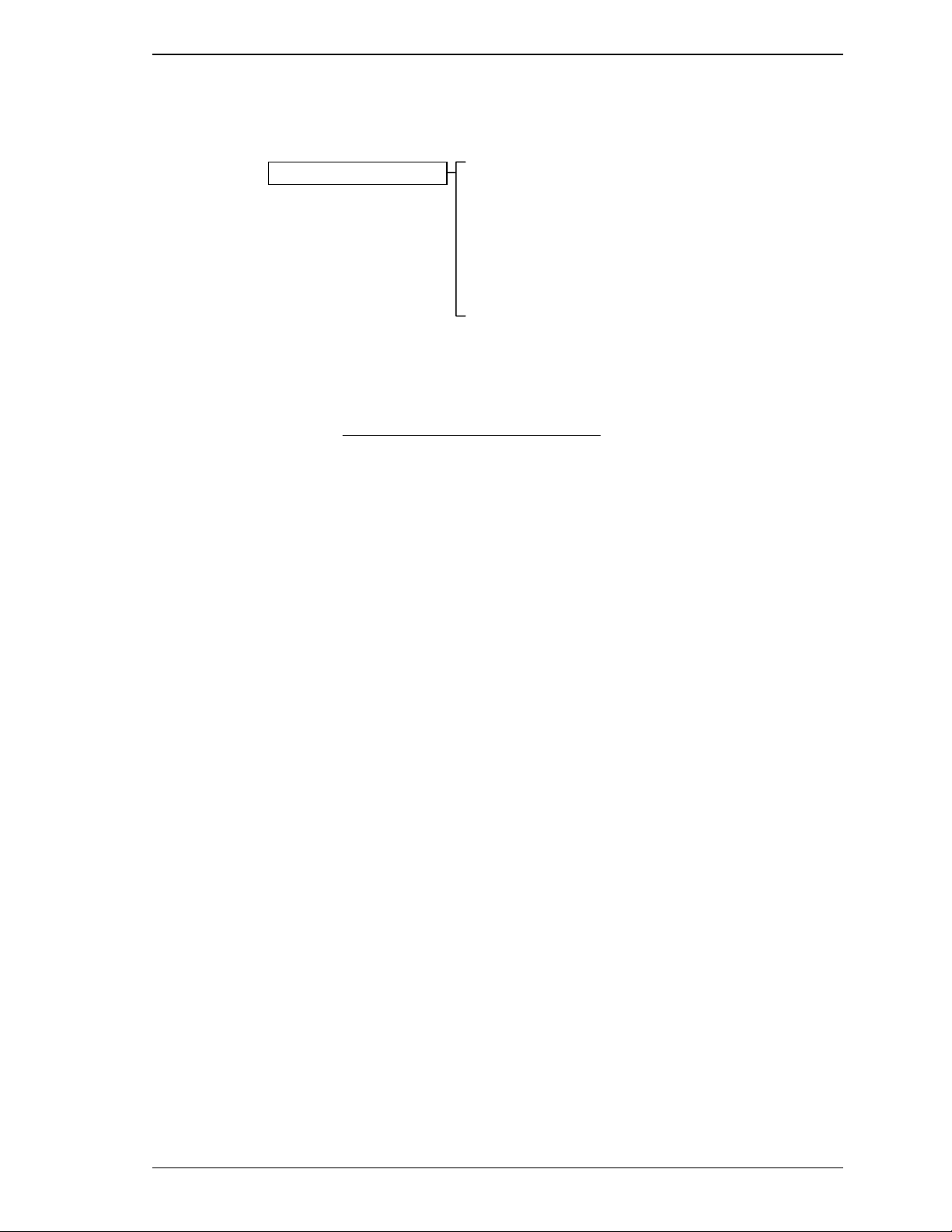

Manual Organization

MHL2300AT, MHM2200AT,

MHM2150AT, MHM2100AT

DISK DRIVES

PRODUCT MANUAL

(C141-E104)

<This manual>

• Device Overview

• Device Configuration

• Installation Conditions

• Theory of Device Operation

• Interface

• Operations

MHL2300AT, MHM2200AT,

MHM2150AT, MHM2100AT

DISK DRIVES

MAINTENANCE MANUAL

(C141-F043)

• Maintenance and Diagnosis

• Removal and Replacement Procedure

This page is intentionally left blank.

C141-E104-02EN ix

Contents

CHAPTER 1 Device Overview ....................................................................... 1-1

1.1 Features 1-2

1.1.1 Functions and performance 1-2

1.1.2 Adaptability 1-2

1.1.3 Interface 1-3

1.2 Device Specifications 1-4

1.2.1 Specifications summary 1-4

1.2.2 Model and product number 1-5

1.3 Power Requirements 1-5

1.4 Environmental Specifications 1-7

1.5 Acoustic Noise 1-8

1.6 Shock and Vibration 1-8

1.7 Reliability 1-9

1.8 Error Rate 1-10

1.9 Media Defects 1-10

CHAPTER 2 Device Configuration................................................................ 2-1

2.1 Device Configuration 2-2

2.2 System Configuration 2-4

2.2.1 ATA interface 2-4

2.2.2 1 drive connection 2-4

2.2.3 2 drives connection 2-4

Contents

x C141-E104-02EN

CHAPTER 3 Installation Conditions..............................................................3-1

3.1 Dimensions 3-2

3.2 Mounting 3-4

3.3 Cable Connections 3-10

3.3.1 Device connector 3-10

3.3.2 Cable connector specifications 3-11

3.3.3 Device connection 3-11

3.3.4 Power supply connector (CN1) 3-12

3.4 Jumper Settings 3-12

3.4.1 Location of setting jumpers 3-12

3.4.2 Factory default setting 3-13

3.4.3 Master drive-slave drive setting 3-13

3.4.4 CSEL setting 3-14

CHAPTER 4 Theory of Device Operation......................................................4-1

4.1 Outline 4-2

4.2 Subassemblies 4-2

4.2.1 Disk 4-2

4.2.2 Head 4-2

4.2.3 Spindle 4-3

4.2.4 Actuator 4-3

4.2.5 Air filter 4-3

4.3 Circuit Configuration 4-4

4.4 Power-on Sequence 4-7

4.5 Self-calibration 4-8

4.5.1 Self-calibration contents 4-8

4.5.2 Execution timing of self-calibration 4-9

4.5.3 Command processing during self-calibration 4-10

4.6 Read/write Circuit 4-10

4.6.1 Read/write preamplifier (HDIC) 4-10

Contents

C141-E104-02EN xi

4.6.2 Write circuit 4-11

4.6.3 Read circuit 4-13

4.6.4 Digital PLL circuit 4-14

4.7 Servo Control 4-15

4.7.1 Servo control circuit 4-15

4.7.2 Data-surface servo format 4-18

4.7.3 Servo frame format 4-20

4.7.4 Actuator motor control 4-21

4.7.5 Spindle motor control 4-22

CHAPTER 5 Interface..................................................................................... 5-1

5.1 Physical Interface 5-2

5.1.1 Interface signals 5-2

5.1.2 Signal assignment on the connector 5-3

5.2 Logical Interface 5-6

5.2.1 I/O registers 5-7

5.2.2 Command block registers 5-8

5.2.3 Control block registers 5-13

5.3 Host Commands 5-13

5.3.1 Command code and parameters 5-14

5.3.2 Command descriptions 5-16

5.3.3 Error posting 5-83

5.4 Command Protocol 5-85

5.4.1 Data transferring commands from device to host 5-85

5.4.2 Data transferring commands from host to device 5-87

5.4.3 Commands without data transfer 5-89

5.4.4 Other commands 5-90

5.4.5 DMA data transfer commands 5-90

5.5 Ultra DMA Feature Set 5-92

5.5.1 Overview 5-92

5.5.2 Phases of operation 5-93

Contents

xii C141-E104-02EN

5.5.2.1 Ultra DMA burst initiation phase 5-93

5.5.2.2 Data transfer phase 5-94

5.5.2.3 Ultra DMA burst termination phase 5-94

5.5.3 Ultra DMA data in commands 5-95

5.5.3.1 Initiating an Ultra DMA data in burst 5-95

5.5.3.2 The data in transfer 5-96

5.5.3.3 Pausing an Ultra DMA data in burst 5-96

5.5.3.4 Terminating an Ultra DMA data in burst 5-97

5.5.4 Ultra DMA data out commands 5-100

5.5.4.1 Initiating an Ultra DMA data out burst 5-100

5.5.4.2 The data out transfer 5-100

5.5.4.3 Pausing an Ultra DMA data out burst 5-101

5.5.4.4 Terminating an Ultra DMA data out burst 5-102

5.5.5 Ultra DMA CRC rules 5-104

5.5.6 Series termination required for Ultra DMA 5-106

5.6 Timing 5-107

5.6.1 PIO data transfer 5-107

5.6.2 Multiword DMA data transfer 5-109

5.6.3 Transfer of Ultra DMA data 5-110

5.6.3.1 Starting of Ultra DMA data In Burst 5-110

5.6.3.2 Ultra DMA data burst timing requirements 5-111

5.6.3.3 Sustained Ultra DMA data in burst 5-113

5.6.3.4 Host pausing an Ultra DMA data in burst 5-114

5.6.3.5 Device terminating an Ultra DMA data in burst 5-115

5.6.3.6 Host terminating an Ultra DMA data in burst 5-116

5.6.3.7 Initiating an Ultra DMA data out burst 5-117

5.6.3.8 Sustained Ultra DMA data out burst 5-118

5.6.3.9 Device pausing an Ultra DMA data out burst 5-119

5.6.3.10 Host terminating an Ultra DMA data out burst 5-120

5.6.3.11 Device terminating an Ultra DMA data in burst 5-121

5.6.4 Power-on and reset 5-122

CHAPTER 6 Operations .................................................................................6-1

6.1 Device Response to the Reset 6-2

Contents

C141-E104-02EN xiii

6.1.1 Response to power-on 6-2

6.1.2 Response to hardware reset 6-4

6.1.3 Response to software reset 6-5

6.1.4 Response to diagnostic command 6-6

6.2 Address Translation 6-7

6.2.1 Default parameters 6-7

6.2.2 Logical address 6-8

6.3 Power Save 6-9

6.3.1 Power save mode 6-9

6.3.2 Power commands 6-11

6.4 Defect Management 6-11

6.4.1 Spare area 6-12

6.4.2 Alternating defective sectors 6-12

6.5 Read-Ahead Cache 6-14

6.5.1 Data buffer configuration 6-14

6.5.2 Caching operation 6-14

6.5.3 Usage of read segment 6-16

6.5.3.1 Mis-hit (no hit) 6-16

6.5.3.2 Sequential read 6-17

6.5.3.3 Full hit (hit all) 6-20

6.5.3.4 Partially hit 6-21

6.6 Write Cache 6-22

Glossary ..................................................................................................GL-1

Acronyms and Abbreviations......................................................................... AB-1

Contents

xiv C141-E104-02EN

Illustrations

Figures

Figure 1.1 Current fluctuation (Typ.) at +5V when power is turned on 1-7

Figure 2.1 Disk drive outerview (the MHL Series and MHM Series) 2-2

Figure 2.2 Configuration of disk media heads 2-3

Figure 2.3 1 drive system configuration 2-4

Figure 2.4 2 drives configuration 2-4

Figure 3.1 Dimensions (MHL/MHM series) 3-2

Figure 3.2 Orientation (Sample: MHL2300AT) 3-4

Figure 3.3 Mounting frame structure 3-5

Figure 3.4 Location of breather 3-6

Figure 3.5 Surface temperature measurement points

(Sample: MHL2300AT) 3 -7

Figure 3.6 Service area (Sample: MHL2300AT) 3-8

Figure 3.7 Handling cautions 3-9

Figure 3.8 Connector locations (Sample: MHL2300AT) 3-10

Figure 3.9 Cable connections 3-11

Figure 3.10 Power supply connector pins (CN1) 3-12

Figure 3.11 Jumper location 3-12

Figure 3.12 Factory default setting 3-13

Figure 3.13 Jumper setting of master or slave device 3-13

Figure 3.14 CSEL setting 3-14

Figure 3.15 Example (1) of Cable Select 3-14

Figure 3.16 Example (2) of Cable Select 3-15

Figure 4.1 Head structure 4-3

Figure 4.2 Power Supply Configuration 4-5

Figure 4.3 Circuit Configuration 4-6

Figure 4.4 Power-on operation sequence 4-8

Figure 4.5 Read/write circuit block diagram 4-12

Figure 4.6 Frequency characteristic of programmable filter 4-13

Figure 4.7 Block diagram of servo control circuit 4-15

Figure 4.8 Physical sector servo configuration on disk surface 4-19

Figure 4.9 Servo frame format 4-20

Figure 5.1 Interface signals 5-2

Figure 5.2 Execution example of READ MULTIPLE command 5-20

Contents

C141-E104-02EN xv

Figure 5.3 Read Sector(s) command protocol 5-86

Figure 5.4 Protocol for command abort 5-87

Figure 5.5 WRITE SECTOR(S) command protocol 5-88

Figure 5.6 Protocol for the command execution without data transfer 5-90

Figure 5.7 Normal DMA data transfer 5-91

Figure 5.8 An example of generation of parallel CRC 5-105

Figure 5.9 Ultra DMA termination with pull-up or pull-down 5-106

Figure 5.10 Data transfer timing 5-108

Figure 5.11 Multiword DMA data transfer timing (mode 2) 5-109

Figure 5.12 Starting of Ultra DMA data In Burst transfer 5-110

Figure 5.13 Sustained Ultra DMA data in burst 5-113

Figure 5.14 Host pausing an Ultra DMA data in burst 5-114

Figure 5.15 Device terminating an Ultra DMA data in burst 5-115

Figure 5.16 Host terminating an Ultra DMA data in burst 5-116

Figure 5.17 Initiating an Ultra DMA data out burst 5-117

Figure 5.18 Sustained Ultra DMA data out burst 5-118

Figure 5.19 Device pausing an Ultra DMA data out burst 5-119

Figure 5.20 Host terminating an Ultra DMA data out burst 5-120

Figure 5.21 Device terminating an Ultra DMA data out burst 5-121

Figure 5.22 Power on Reset Timing 5-122

Figure 6.1 Response to power-on 6-3

Figure 6.2 Response to hardware reset 6-4

Figure 6.3 Response to software reset 6-5

Figure 6.4 Response to diagnostic command 6-6

Figure 6.5 Address translation (example in CHS mode) 6-8

Figure 6.6 Address translation (example in LBA mode) 6-9

Figure 6.7 Sector slip processing 6-12

Figure 6.8 Alternate cylinder assignment 6-13

Figure 6.9 Data buffer configuration 6-14

Tables

Table 1.1 Specifications 1-4

Table 1.2 Model names and product numbers 1-5

Table 1.3 Current and power dissipation 1-6

Table 1.4 Environmental specifications 1-7

Table 1.5 Acoustic noise specification 1-8

Table 1.6 Shock and vibration specification 1-8

Table 3.1 Surface temperature measurement points and standard values 3-7

Table 3.2 Cable connector specifications 3-11

Contents

xvi C141-E104-02EN

Table 4.1 Self-calibration execution timechart 4-10

Table 4.2 Write precompensation algorithm 4-11

Table 5.1 Signal assignment on the interface connector 5-3

Table 5.2 I/O registers 5-7

Table 5.3 Command code and parameters 5-14

Table 5.4 Information to be read by IDENTIFY DEVICE command 5-32

Table 5.5 Features register values and settable modes 5-41

Table 5.6 Diagnostic code 5-52

Table 5.7 Features Register values (subcommands) and functions 5-64

Table 5.8 Format of device attribute value data 5-68

Table 5.9 Format of insurance failure threshold value data 5-68

Table 5.10 SMART error log data format 5-72

Table 5.11 SMART self test log data format 5-74

Table 5.12 Contents of security password 5-76

Table 5.13 Contents of SECURITY SET PASSWORD data 5-80

Table 5.14 Relationship between combination of Identifier and Security level,

and operation of the lock function 5-80

Table 5.15 Command code and parameters 5-83

Table 5.16 Parallel generation equation of CRC polynomial 5-105

Table 5.17 Recommended series termination for Ultra DMA 5-106

Table 5.18 Ultra DMA data burst timing requirements 5-111

Table 6.1 Default parameters 6-7

C141-E104-02EN 1-1

CHAPTER 1 Device Overview

1.1 Features

1.2 Device Specifications

1.3 Power Requirements

1.4 Environmental Specifications

1.5 Acoustic Noise

1.6 Shock and Vibration

1.7 Reliability

1.8 Error Rate

1.9 Media Defects

Overview and features are described in this chapter, and specifications and power

requirement are described.

The MHL Series and MHM Series are 2.5-inch hard disk drives with built-in disk

controllers. These disk drives use the AT-bus hard disk interface protocol and are

compact and reliable.

Device Overview

1-2 C141-E104-02EN

1.1 Features

1.1.1 Functions and performance

The following features of the MHL Series and MHM Series are described.

(1) Compact

The MHL2300AT has 3 built-in disks (the diameter is 65mm[2.5inch]), and its

height is 12.5 mm (0.492 inch). The MHM2200AT, MHM2150AT and

MHM2100AT have 1 disk or 2 disks of 65 mm (2.5 inches) diameter, and its

height is 9.5 mm (0.374 inch).

(2) Large capacity

The disk drive can record up to 10 GB (formatted) on one disk using the 16/17

MTR recording method and 15 recording zone technology. The MHL Series and

MHM Series have a formatted capacity of 30 GB (MHL2300AT), 20 GB

(MHM2200AT), 15 GB (MHM2150AT) and 10 GB (MHM2100AT) respectively.

(3) High-speed Transfer rate

The disk drives (the MHL Series and MHM Series) have an internal data rate up

to 28.7 MB/s. The disk drive supports an external data rate up to 66.6 MB/s (U-

DMA mode 4).

(4) Average positioning time

Use of a rotary voice coil motor in the head positioning mechanism greatly

increases the positioning speed. The average positioning time is 12 ms (at read).

1.1.2 Adaptability

(1) Power save mode

The power save mode feature for idle operation, stand by and sleep modes makes

The disk drives (the MHL Series and MHM Series) ideal for applications where

power consumption is a factor.

(2) Wide temperature range

The disk drives (the MHL Series and MHM Series) can be used over a wide

temperature range (5°C to 55°C).

(3) Low noise and vibration

In Ready status, the noise of the disk drives (the MHL Series and MHM Series) is

only about 30 dBA (measured at 1 m apart from the drive under the idle mode).

1.1 Features

C141-E104-02EN 1-3

1.1.3 Interface

(1) Connection to interface

With the built-in ATA interface controller, the disk drives (the MHL Series and

MHM Series) can be connected to an ATA interface of a personal computer.

(2) 2 MB data buffer

The disk drives (the MHL Series and MHM Series) uses a 2 MB data buffer to

transfer data between the host and the disk media.

In combination with the read-ahead cache system described in item (3) and the

write cache described in item (7), the buffer contributes to efficient I/O

processing.

(3) Read-ahead cache system

After the execution of a disk read command, the disk drive automatically reads the

subsequent data block and writes it to the data buffer (read ahead operation). This

cache system enables fast data access. The next disk read command would

normally cause another disk access. But, if the read ahead data corresponds to the

data requested by the next read command, the data in the buffer can be transferred

instead.

(4) Master/slave

The disk drives (the MHL Series and MHM Series) can be connected to ATA

interface as daisy chain configuration. Drive 0 is a master device, drive 1 is a

slave device.

(5) Error correction and retry by ECC

If a recoverable error occurs, the disk drives (the MHL Series and MHM Series)

themselves attempt error recovery. The ECC has improved buffer error correction

for correctable data errors.

(6) Self-diagnosis

The disk drives (the MHL Series and MHM Series) have a diagnostic function to

check operation of the controller and disk drives. Executing the diagnostic

command invokes self-diagnosis.

(7) Write cache

When the disk drives (the MHL Series and MHM Series) receive a write

command, the disk drives post the command completion at completion of

transferring data to the data buffer completion of writing to the disk media. This

feature reduces the access time at writing.

Device Overview

1-4 C141-E104-02EN

1.2 Device Specifications

1.2.1 Specifications summary

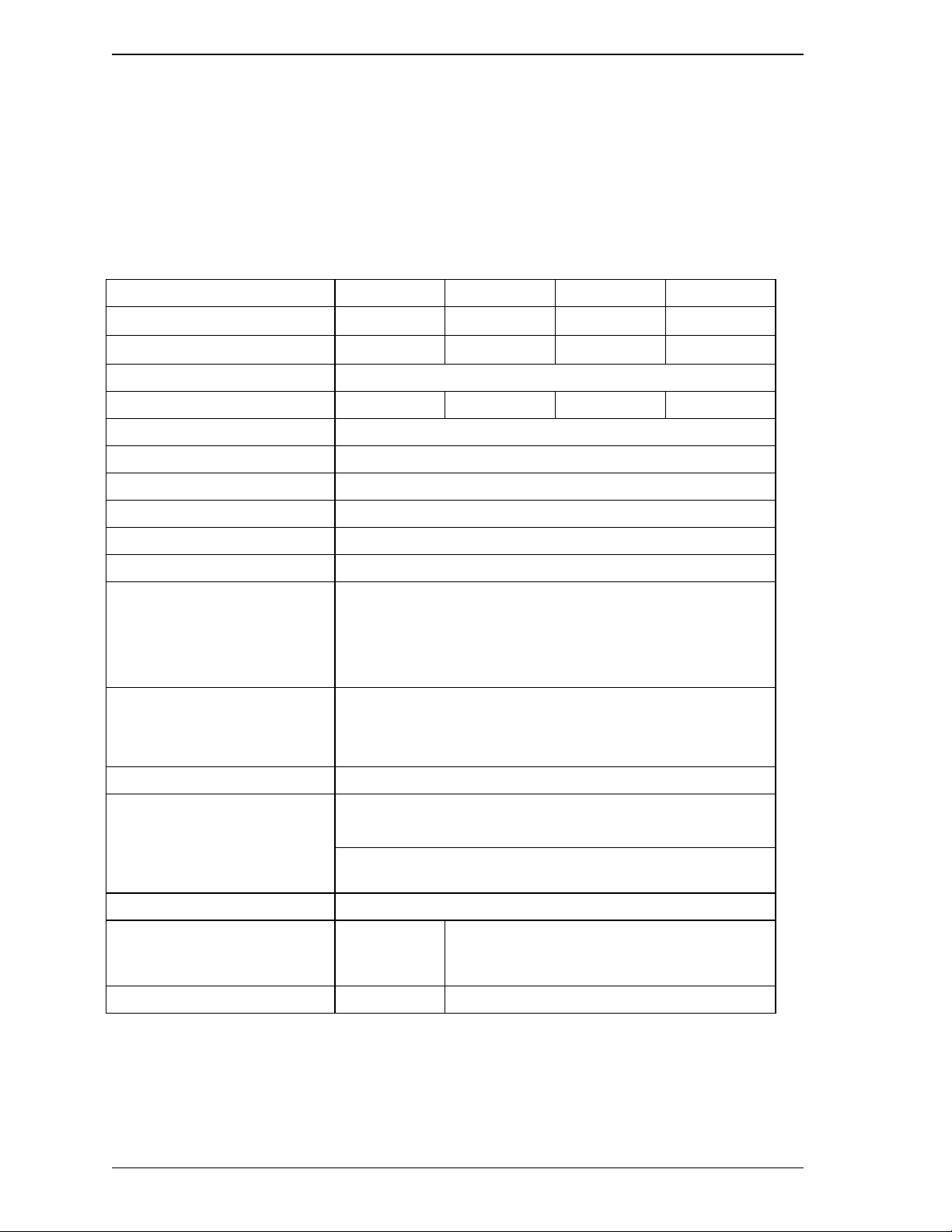

Table 1.1 shows the specifications of the disk drives (MHL Series and MHM Series).

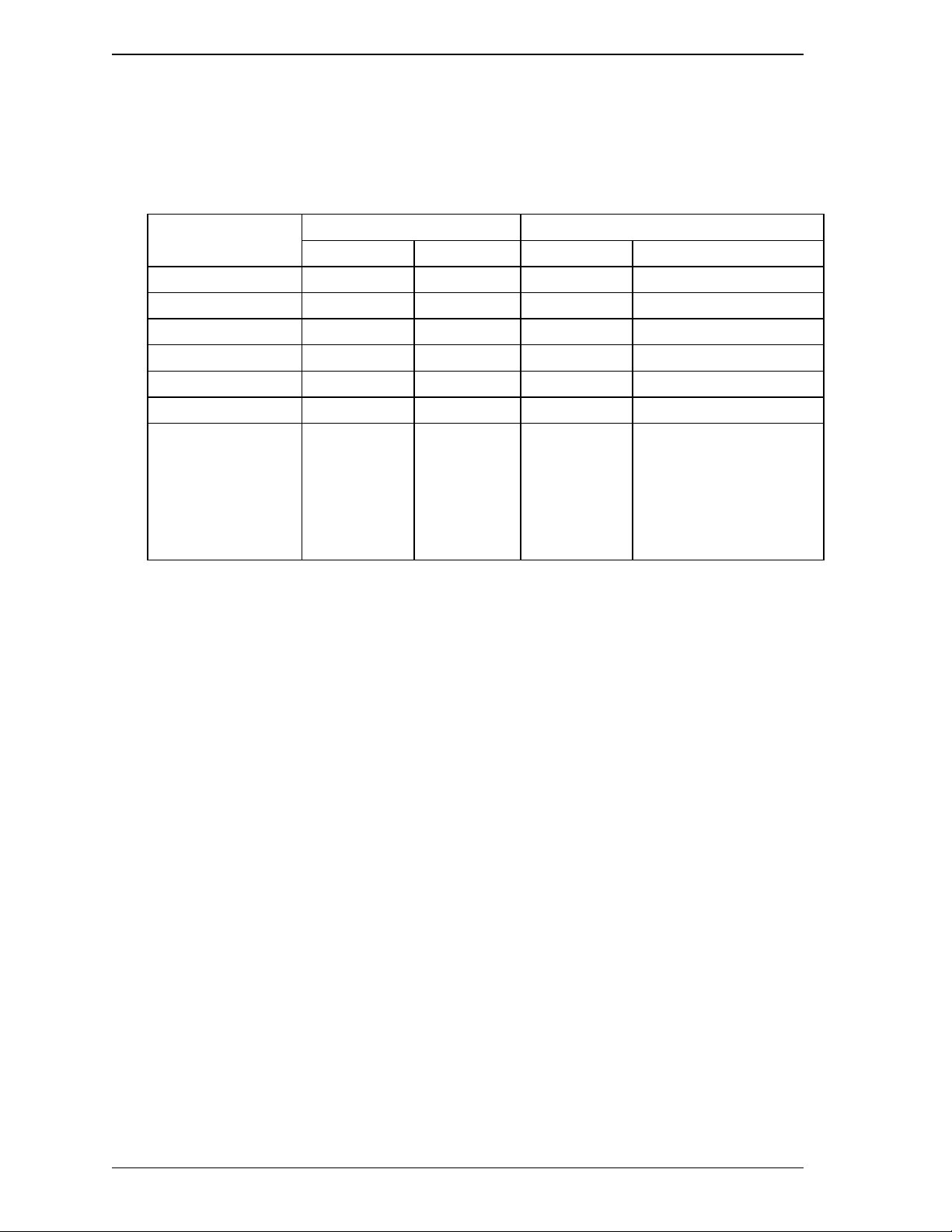

Table 1.1 Specifications ( 1/ 2)

MHL2300AT MHM2200AT MHM2150AT MHM2100AT

Format Capacity (*1) 30 GB 20 GB

15 GB 10 GB

Number of Heads 6 4

32

Number of Cylinders (User) 19,904

Number of Sectors (User) 58,605,120 39,070,080 29,498,112 19,640,880

Bytes per Sector 512

Recording Method 16/17 MTR

Track Density 32,300 TPI (1271 track/mm)

Bit Density 499.7 Kbpi (19.67 k bit/m m )

Rotational Speed 4,200 rpm ± 1%

Average Latency 7.14 ms

Positioning time (read and seek)

• Minimum (Track to Track)

• Average

• Maximum (Full)

1.5 ms (typ.)

Read: 12 ms (typ.)

22 ms (typ.)

Start/Stop time

• Start (0 rpm to Drive Read)

• Stop (at Power Down)

Typ.: 5 sec

Typ.: 5 sec

Interface ATA-5 (Max. Cable length: 0.46 m)

Data Transfer Rate

• To/From Media 16.4 to 28.7 MB/s

• To/From Host 66.6 MB/s Max.

(U-DMA mode 4)

Data Buffer Size 2 MB

Physical Dimensions

(Height × Width × Depth)

12.5 mm ×

100.0 mm ×

70.0 mm

9.5 mm × 100.0 mm ×70.0 mm

Weight 134 g 98 g

*1: Capacity under the LBA mode.

1.3 Power Requirements

C141-E104-02EN 1-5

Under the CHS mode (normal BIOS specification), formatted capacity,

number of cylinders, number of heads, and number of sectors are as

follows.

Table 1.1 Specifications ( 2/ 2)

Model Capacity No. of Cylinder No. of Heads No. of Sectors

MHL2300AT 8.45 GB 16,383 16 63

MHM2200AT 8.45 GB 16,383 16 63

MHM2150AT 8.45 GB 16,383 16 63

MHM2100AT 8.45 GB 16,383 16 63

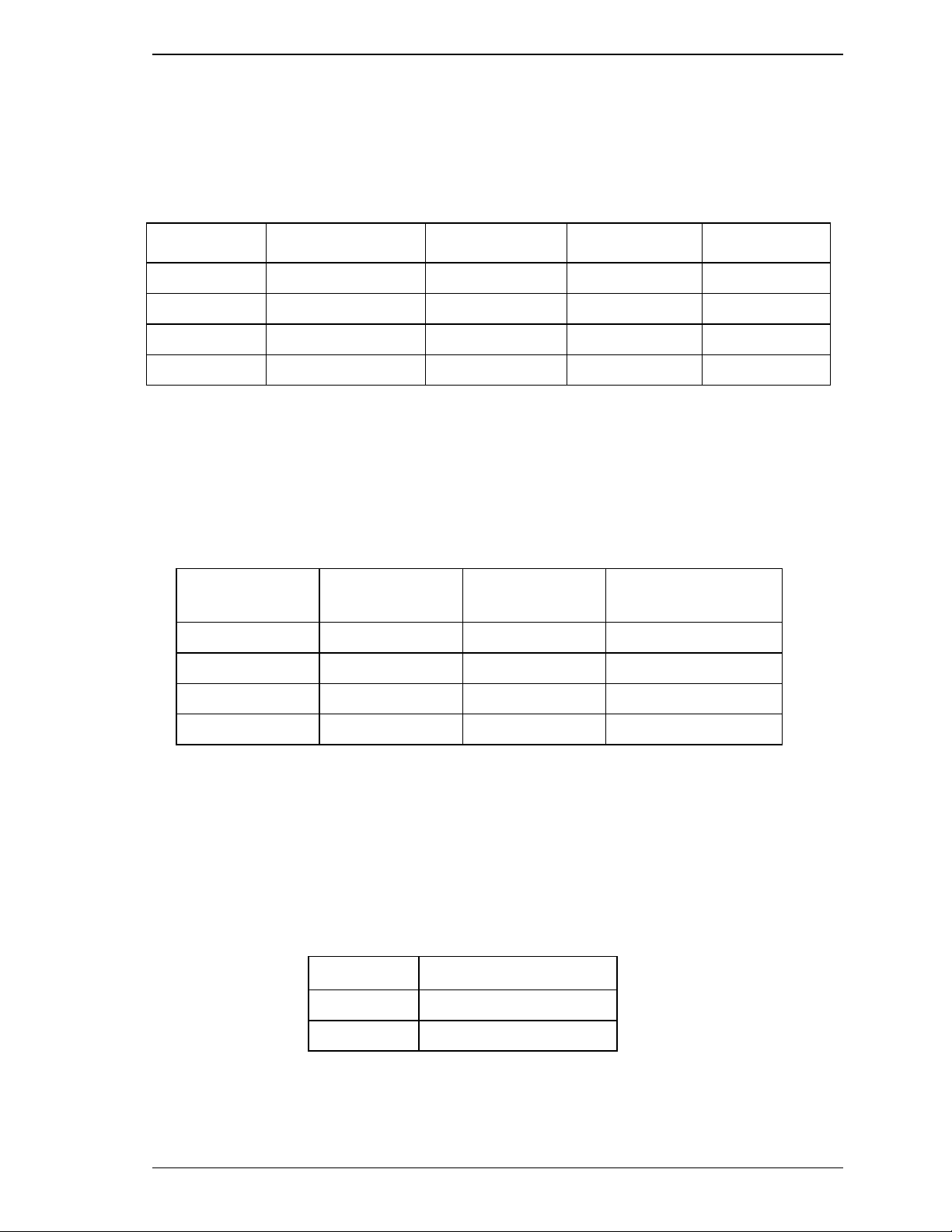

1.2.2 Model and product number

Table 1.2 lists the model names and product numbers of the MHL Series and

MHM Series.

Table 1.2 Model names and product numbers

Model Name Capacity

(user area)

Mounting screw Order No.

MHL2300AT 30 GB M3, depth 3 CA05428-B061

MHM2200AT 20 GB M3, depth 3 CA05429-B041

MHM2150AT 15 GB M3, depth 3 CA05429-B031

MHM2100AT 10 GB M3, depth 3 CA05429-B021

1.3 Power Requirements

(1) Input Voltage

• + 5 V ± 5 %

(2) Ripple

+5 V

Maximum 100 mV (peak to peak)

Frequency DC to 1 MHz

Device Overview

1-6 C141-E104-02EN

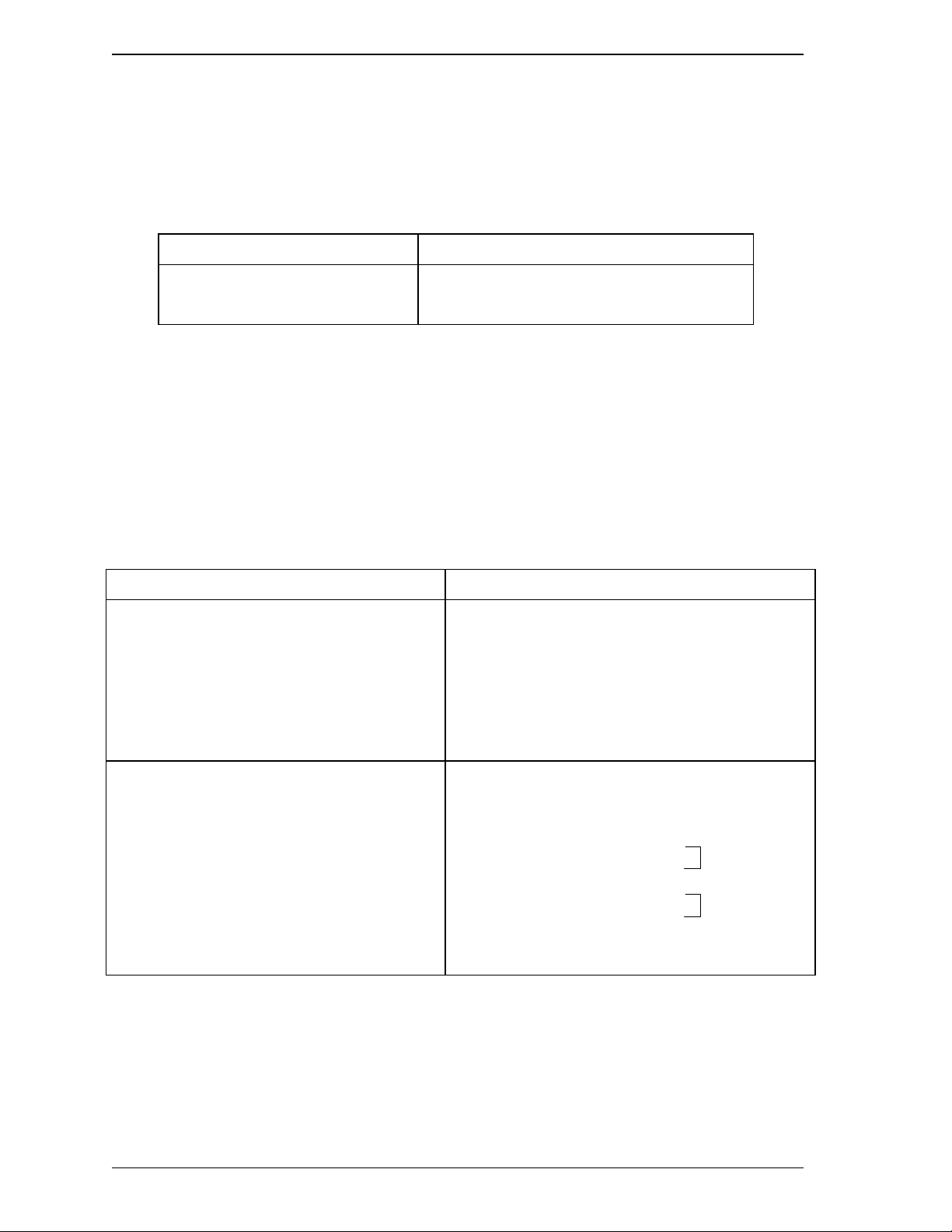

(3) Current Requirements and Power Dissipation

Table 1.3 lists the current and power dissipation.

Table 1.3 Current and power di ssi pat i on

Typical RMS Current Typical Power (*3)

MHL Series MHM Series MHL Series MHM Series

Spin up (*1) 0.9 A 0.9 A 4.5 W 4.5 W

Idle 190 mA 160 mA 0.95 W 0.8 W

R/W (on track) (*2) 520 mA 500 mA 2.6 W 2.5 W

Seek (*5) 490 mA 460 mA 2.45 W 2.3 W

Standby 50 mA 50 mA 0.25 W 0.25 W

Sleep 20 mA 20 mA 0.1 W 0.1 W

Energy

Efficiency (*4)

— — 0.032 W/GB

(rank E)

0.040 W/GB

(rank E / MHM2200AT)

0.040 W/GB

(rank E / MHM2150AT)

0.080 W/GB

(rank D / MHM2100AT)

*1 Current at starting spindle motor.

*2 At 30% disk accessing.

*3 Power requirements reflect nominal values for +5V power.

*4 Energy efficiency based on the Law concerning the Rational Use of Energy

indicates the value obtained by dividing power consumption by the storage

capacity. (Japan only)

*5 The seek average current is specified based on three operations per 100

msec.

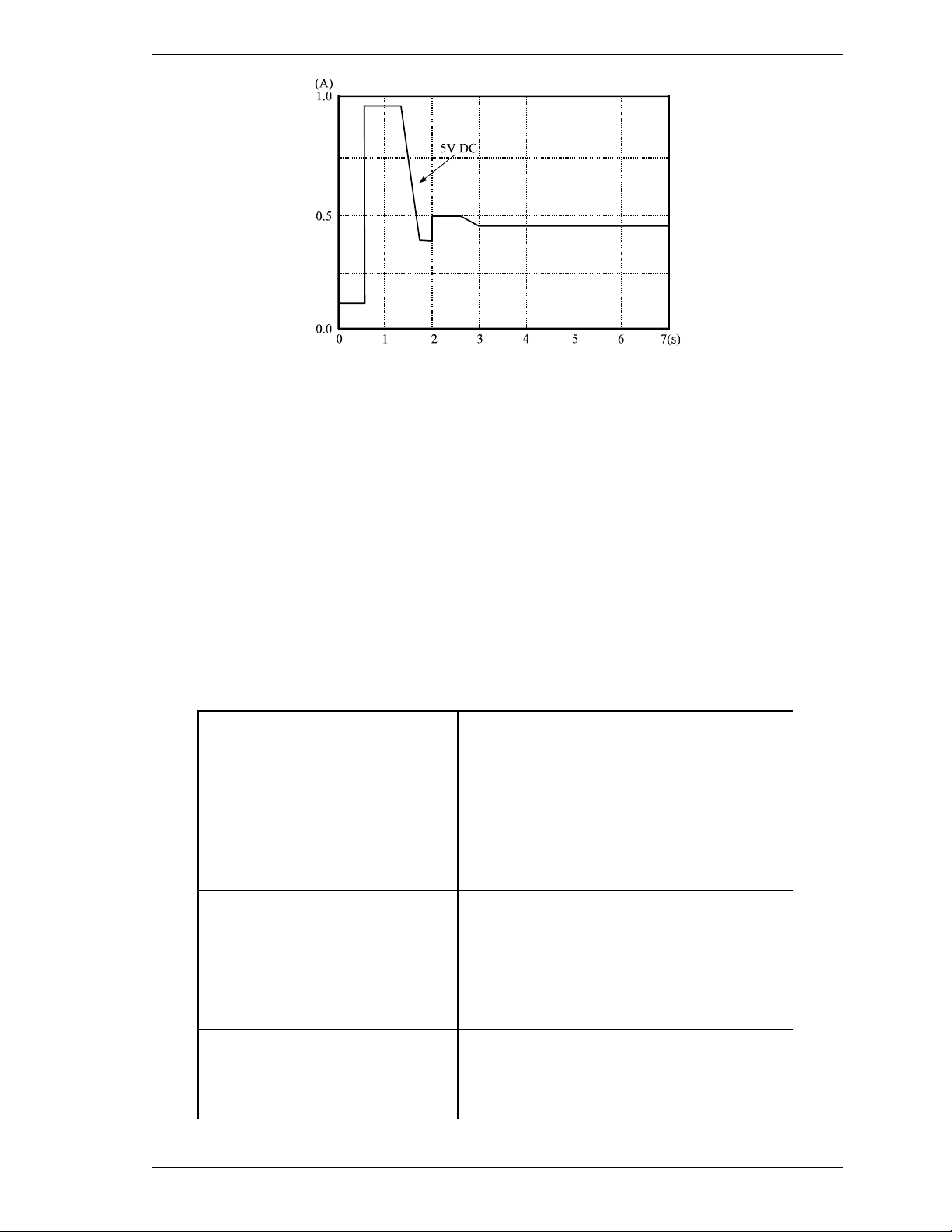

(4) Current fluctuation (Typ.) at +5V when power is turned on

1.4 Environmental Specifications

C141-E104-02EN 1-7

Figure 1.1 Current fluctuation (Typ.) at +5V when power is turned on

(5) Power on/off sequence

The voltage detector circuits (the MHL Series and MHM Series) monitor +5 V.

The circuits do not allow a write signal if either voltage is abnormal. These

prevent data from being destroyed and eliminates the need to be concerned with

the power on/off sequence.

1.4 Environmental Specifications

Table 1.4 lists the environmental specifications.

Table 1.4 Environmental specifications

Item Specification

Temperature

• Operating

• Non-operating

• Thermal Gradient

5°C to 55°C (ambient)

5°C to 60°C (disk enclosure surface)

–40°C to 65°C

20°C/h or less

Humidity

• Operating

• Non-operating

• Maximum Wet Bulb

8% to 90% RH (Non-condensing)

5% to 95% RH (Non-condensing)

29°C (Operating)

40°C (Non-operating)

Altitude (relative to sea level)

• Operating

• Non-operating

–300 to 3,000 m

–300 to 12,000 m

Device Overview

1-8 C141-E104-02EN

1.5 Acoustic Noise

Table 1.5 lists the acoustic noise specification.

Table 1.5 Acoustic noise specification

Item Specification

Sound Pressure

• Idle mode (DRIVE READY) 30 dBA typical at 1 m

Note:

Measure the noise from the cover top surface.

1.6 Shock and Vibration

Table 1.6 lists the shock and vibration specification.

Table 1.6 Shock and vibration specificati on

Item Specification

Vibration (swept sine, one octave per minute)

• Operating

• Non-operating

5 to 500 Hz, 1.0G 0-peak (MHL series)

5 to 400 Hz, 1.0G 0-peak (MHM series)

(without non-recovered errors) (9.8 m/s

2

0-peak)

5 to 500 Hz, 5G 0-peak (MHL series)

5 to 400 Hz, 5G 0-peak (MHM series)

(no damage) (49 m/s

2

0-peak)

Shock (half-sine pulse)

• Operating

• Non-operating

175G 0-peak (1,715 m/s

2

0-peak)

2 ms duration (without non-recovered errors)

600G 0-peak (5,880 m/s

2

0-peak)

2 ms duration (no damage)

700G 0-peak (6,860 m/s

2

0-peak)

2 ms duration (no damage)

120G 0-peak (1,176 m/s

2

0-peak)

11 ms duration (no damage)

MHM series

MHL series

1.7 Reliability

C141-E104-02EN 1-9

1.7 Reliability

(1) Mean time between failures (MTBF)

Conditions of 300,000 h Power-on time 250H/month or less 3000H/years

or less

Operating time 20% or less of power-on time

CSS operations 50/day or less

Total 50,000 or less

Power on/off 1/day or more needed.

Environment 5 to 55°C/8 to 90%

But humidity bulb temperature

29°C or less

MTBF is defined as follows:

Total operation time in all fields

MTBF= (H)

number of device failure in all fields (*1)

*1 “Disk drive defects” refers to defects that involve repair, readjustment, or

replacement. Disk drive defects do not include failures caused by external

factors, such as damage caused by handling, inappropriate operating

environments, defects in the power supply host system, or interface cable.

(2) Mean time to repair (MTTR)

The mean time to repair (MTTR) is 30 minutes or less, if repaired by a specialist

maintenance staff member.

(3) Service life

In situations where management and handling are correct, the disk drive requires

no overhaul for five years when the DE surface temperature is less than 48°C.

When the DE surface temperature exceeds 48°C, the disk drives requires no

overhaul for five years or 20,000 hours of operation, whichever occurs first.

Refer to item (3) in Subsection 3.2 for the measurement point of the DE surface

temperature. Also the operating conditions except the environment temperature

are based on the MTBF conditions.

(4) Data assurance in the event of power failure

Except for the data block being written to, the data on the disk media is assured in

the event of any power supply abnormalities. This does not include power supply

abnormalities during disk media initialization (formatting) or processing of

defects (alternative block assignment).

Loading...

Loading...