Frymaster M3000 Installation Manual

FRYMASTER MANUAL LOV™ M3000 CONTROLLER

OPERATION MANUAL

This equipment chapter is to be installed in the Fryer Section of the

Equipment Manual.

MANUFACTURED

BY

8700 Line Ave.

SHREVEPORT, LOUISIANA 71106

PHONE: 1-318-865-1711

TOLL FREE: 1-800-551-8633

1-800-24 FRYER

FAX: 1-318-219-7135

TABLE OF CONTENTS |

|

INSTALLATION INSTRUCTIONS ....................................................................................... |

Page 1-1 |

MANUAL LOV™ M3000 OPERATING INSTRUCTIONS..................................................... |

Page 2-1 |

OPERATOR TROUBLESHOOTING..................................................................................... |

Page 3-1 |

Frymaster L.L.C., 8700 Line Avenue, Shreveport, LA 71106 |

|

|||

|

PHONE 318-865-1711 |

FAX 318-219-7135 |

|

|

PRINTED IN THE UNITED STATES |

SERVICE HOTLINE 1-800-24-FRYER |

|

JULY 2012 |

|

www.frymaster.com |

Email: service@frymaster.com |

*8196964* |

||

|

|

|||

NOTICE

IF, DURING THE WARRANTY PERIOD, THE CUSTOMER USES A PART FOR THIS MANITOWOC FOOD SERVICE EQUIPMENT OTHER THAN AN UNMODIFIED NEW OR RECYCLED PART PURCHASED DIRECTLY FROM FRYMASTER DEAN, OR ANY OF ITS FACTORY AUTHORIZED SERVICERS, AND/OR THE PART BEING USED IS MODIFIED FROM ITS ORIGINAL CONFIGURATION, THIS WARRANTY WILL BE VOID. FURTHER, FRYMASTER DEAN AND ITS AFFILIATES WILL NOT BE LIABLE FOR ANY CLAIMS, DAMAGES OR EXPENSES INCURRED BY THE CUSTOMER WHICH ARISE DIRECTLY OR INDIRECTLY, IN WHOLE OR IN PART, DUE TO THE INSTALLATION OF ANY MODIFIED PART AND/OR PART RECEIVED FROM AN UNAUTHORIZED SERVICE CENTER.

NOTICE

This appliance is intended for professional use only and is to be operated by qualified personnel only. A Frymaster Dean Factory Authorized Servicer (FAS) or other qualified professional should perform installation, maintenance, and repairs. Installation, maintenance, or repairs by unqualified personnel may void the manufacturer’s warranty.

NOTICE

This equipment must be installed in accordance with the appropriate national and local codes of the country and/or region in which the appliance is installed.

NOTICE

Drawings and photos used in this manual are intended to illustrate operational, cleaning and technical procedures and may not conform to onsite management operational procedures.

NOTICE TO OWNERS OF UNITS EQUIPPED WITH CONTROLLERS

U.S.

This device complies with Part 15 of the FCC rules. Operation is subject to the following two conditions: 1) This device may not cause harmful interference, and 2) This device must accept any interference received, including interference that may cause undesired operation. While this device is a verified Class A device, it has been shown to meet the Class B limits.

CANADA

This digital apparatus does not exceed the Class A or B limits for radio noise emissions as set out by the ICES-003 standard of the Canadian Department of Communications.

Cet appareil numerique n’emet pas de bruits radioelectriques depassany les limites de classe A et B prescrites dans la norme NMB-003 edictee par le Ministre des Communcations du Canada.

DANGER

DANGER

Improper installation, adjustment, maintenance or service, and unauthorized alterations or modifications can cause property damage, injury, or death. Read the installation, operating, and service instructions thoroughly before installing or servicing this equipment.

NOTICE

The instructions in this manual for using a bulk oil system for filling and discarding oil are for an RTI system. These instructions may not be applicable to other bulk oil systems.

MANUAL LOV™ M3000 CONTROLLER

CHAPTER 1: INSTALLATION INSTRUCTIONS

1.1Installation

Before attempting to operate your unit, read the instructions in this manual thoroughly before installation. Installation of the Manual LOV™ (Low Oil Volume) M3000 controller requires some extra steps prior to use. This controller uses network cables for communication between controllers. The controllers also require locator connectors which identify the position of the controllers in the bank of fryers. Finally the network must be terminated on the far left controller and the far right controller of the network.

1.2Controller Information for the M3000 Controllers

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC rules. While this device is a verified Class A device, it has been shown to meet the Class B limits. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of the equipment in a residential area is likely to cause harmful interference in which case the user will be required to correct the interference at their own expense.

The user is cautioned that any changes or modifications not expressly approved by the party responsible for compliance could void the user's authority to operate the equipment.

If necessary, the user should consult the dealer or an experienced radio and television technician for additional suggestions.

The user may find the following booklet prepared by the Federal Communications Commission helpful: "How to Identify and Resolve Radio-TV Interference Problems". This booklet is available from the U.S. Government Printing Office, Washington, DC 20402, Stock No. 004-000-00345-4.

1.3Shipping Damage Claim Procedure

What to do if your equipment arrives damaged:

Please note that this equipment was carefully inspected and packed by skilled personnel before leaving the factory. The freight company assumes full responsibility for safe delivery upon acceptance of the equipment.

1.File Claim for Damages Immediately - regardless of extent of damage.

2.Inspect For and Record All Visible Loss or Damage, and ensure that this information is noted on the freight bill or express receipt and is signed by the person making the delivery.

3.Concealed Loss or Damage- If damage is unnoticed until equipment is unpacked, notify the freight company or carrier immediately upon discovery and file a concealed damage claim.

1-1

This must be submitted within 15 days of date of delivery. Be sure to retain container for inspection.

Frymaster DOES NOT ASSUME RESPONSIBILITY FOR DAMAGE OR LOSS

INCURRED IN TRANSIT.

1.4Service Information

For non-routine maintenance or repairs, or for service information, contact your local Frymaster Authorized Servicer (FAS). In order to assist you quickly, the Frymaster Authorized Servicer (FAS) or Service Department representative requires certain information about your equipment. Most of this information is printed on a data plate affixed to the inside of the fryer door. Part numbers are found in the Service and Parts Manual. Parts orders may be placed directly with your local FAS or distributor. A list of Frymaster Factory Authorized Servicers (FAS’s) is located on the Frymaster website at www.frymaster.com. If you do not have access to this list, contact the Frymaster Service Department at 1-800-551-8633 or 1-318-865-1711 or by email at service@frymaster.com.

The following information will be needed in order to assist you efficiently:

Model Number _________________________

Serial Number__________________________

Voltage _______________________________

Gas Type _____________________________

Nature of the Problem____________________

_____________________________________

_____________________________________

RETAIN AND STORE THIS MANUAL IN A SAFE PLACE FOR FUTURE USE.

1-2

CHAPTER 2: MANUAL LOV™ M3000 CONTROLLER

OPERATION INSTRUCTIONS

2.1M3000 General Information

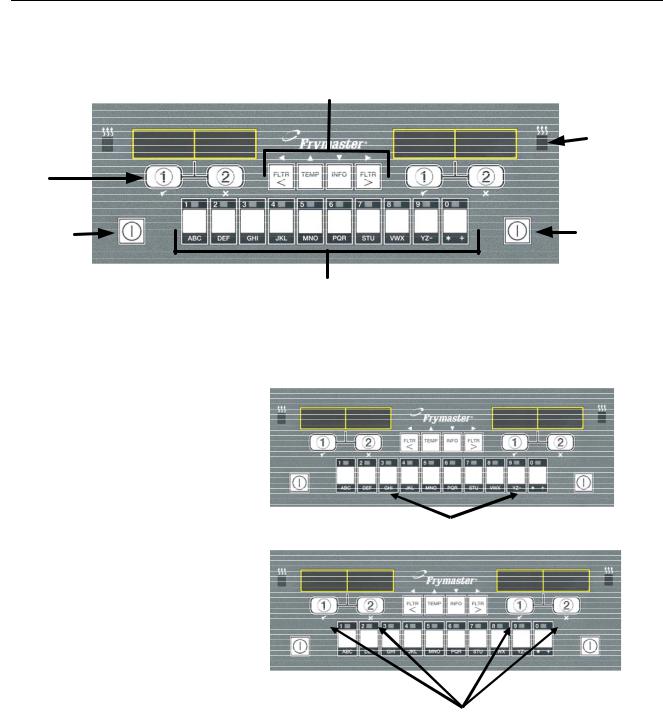

Welcome to the Manual LOV™ M3000, a controller that retains the one-button ease of the M2000 and 100B and the utility of 40-product menu capability. The controller is easy to use. One button push starts a cook cycle for an item cooked in a dedicated vat. The same flexible controller on a multi-product vat requires only two

button pushes to launch a cook cycle. Just choose a menu item on a product button and press, and then press a cook channel button under the display showing the desired item. The controller can move seamlessly from McNuggets to Crispy Chicken to any added menu item.

In a typical store setting, the M3000s on the three-vat fry station display FR FRIES (shown above) and will launch a cook cycle with one push of a cook channel button. On the chicken/filet station, the LED display shows dashed lines. To launch a cook cycle, press a product button and then press the cook channel button that corresponds with the location of the

dropped basket. By pressing the product button for McChicken, McChick will appear in the display. Just press the cook channel button corresponding to the location of the appropriate dropped basket.

The M3000 will operate with electric and gas fryers, both fulland split-vat.

2-1

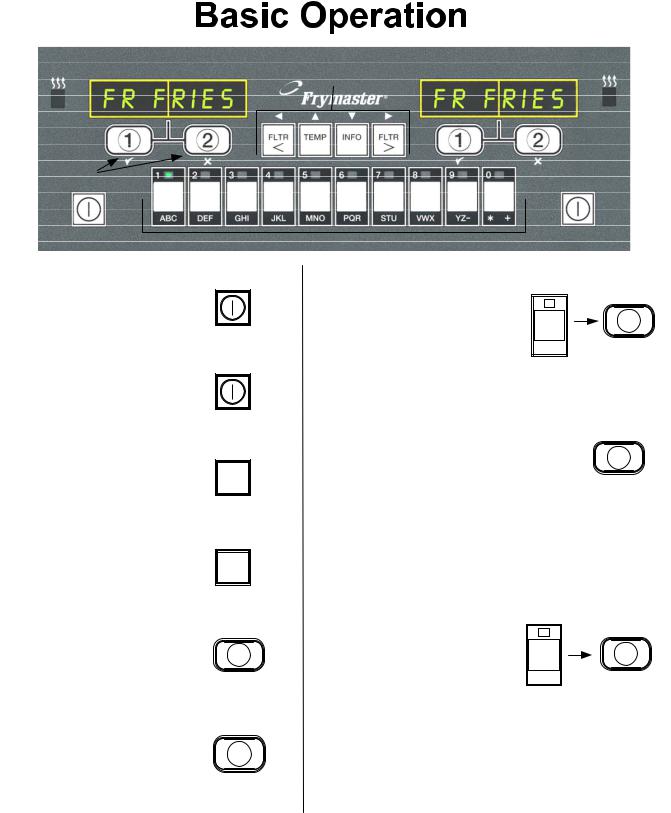

2.2Basic Operation

2-2

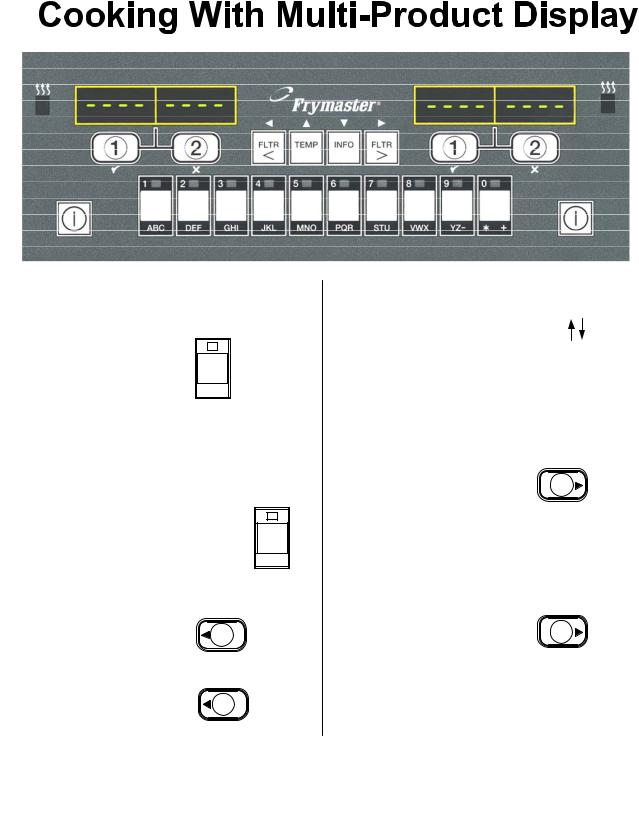

2.3Cooking with Multi-Product Display

2-3

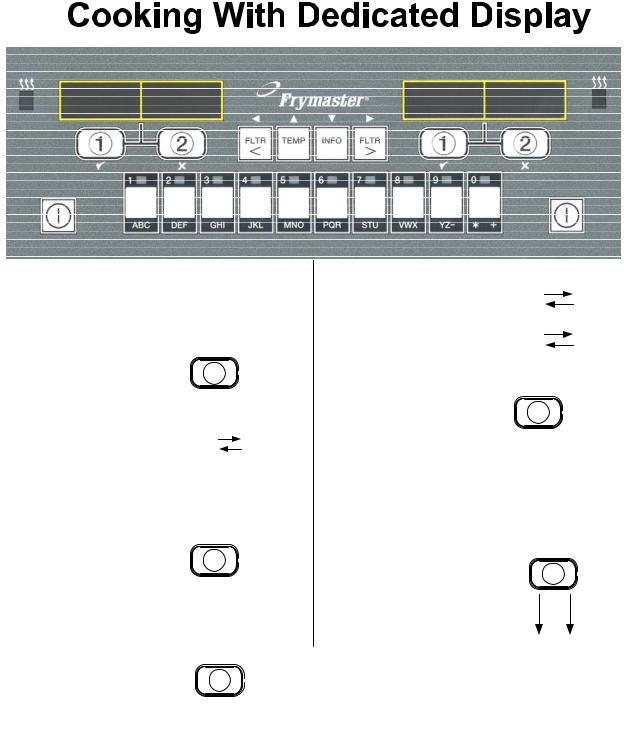

2.4Cooking with Dedicated Display

2-4

2.5Changing from Breakfast Setup to Lunch

2-5

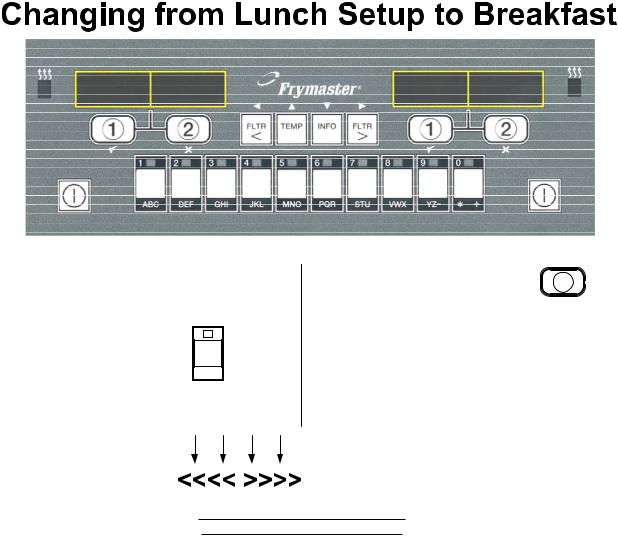

2.6Changing from Lunch Setup to Breakfast

2-6

2.7M3000 Button Description and Functions

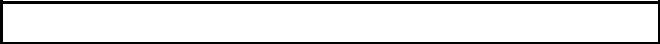

2.7.1 Navigation Buttons

The menu on the M3000 uses 34and tu buttons to navigate the various menus and submenus.

When programming, the left screen shows a menu or

submenu item. The right screen is for data entry. Data is

entered with alpha-numeric characters, scrolling through Left Display Right Display lists or by toggling between choices.

During programming if a button is not pushed within one minute, the controller returns to operation mode.

2.7.2 Filter, Temperature and Info Buttons

The < FLTR and FLTR > buttons (see Figure 1) are used to filter the left and right vats of a split vat or a full vat fryer on demand. The FLTR buttons, if pressed once displays the number of cook cycles remaining until a filtration prompt. When the FLTR button is pressed twice, the date and time of the last filter is displayed. The TEMP button, if pressed once while the fryer is on,

displays current vat temperature on both sides. If the TEMP button is pressed twice while the fryer is on, it shows the setpoint temperatures of the vats. If the fryer is off, the display shows the current

versions of software. The INFO button (see Figure 1), if pressed once when the fryer is on, shows the recovery time for each vat from the last test. Recovery is the time required for the fryer to raise the temperature of the oil 50°F (28°C) between 250°F (121°C) and 300°F (149°C). Maximum

recovery time should not exceed 1:40 for electric or 2:25 for gas. If the INFO button is pressed and held for three seconds it shows information such as usage, filter statistics and last cook cycles (see page 2-31 for more details on the INFO button).

2.7.3 Cook Channel and Selection Buttons

The |

buttons are dual-function buttons shared with |

the number 1 and 2 buttons. They are located directly below the LED displays. Use these buttons to select or

cancel functions. The button is used to back out of and exit submenus.

2-7

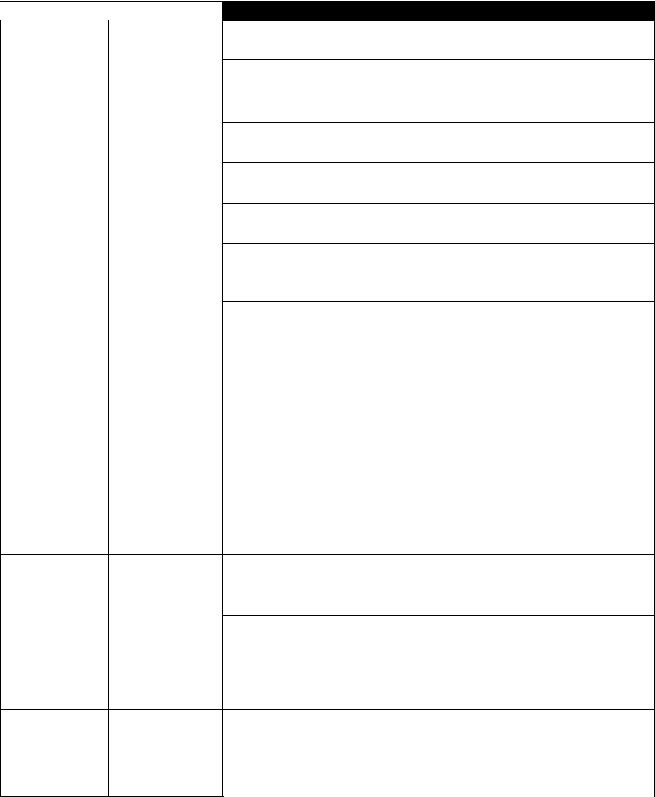

2.8Manual LOV™ M3000 Menu Summary Tree

Reflected below are the major programming sections in the M3000 and the order in which submenu headings will be found under the sections in the controller operation chapter.

Adding New Product Menu Items (Product Selection) |

See section |

2.10.2 |

Storing Product Menu Items in Product Buttons |

See section |

2.10.3 |

Draining, Refilling, and Disposing of Oil |

See section |

2.10.4 |

Filter Menu ………………………………………………………………………………………………………….. 2.11

[Press and hold ◄ FLTR or FLTR ►]

Quick Filter

Maint Filter Dispose Drain to Pan

Fill Vat from Drain Pan

Programming

Level 1 Program…….……………….....………………………………………………………….. 2.12

[Press and hold TEMP and INFO buttons, 2 beeps, displays Level 1, enter 1234]

Product Selection ..…….....………………………………………………………….. 2.10.2

Name Cook Time Temp Cook ID Duty Time 1 Duty Time 2 Qual Tmr AIF Disable Assign Btn

AIF Clock (Suppress Filter Prompt) …………………………………… 2.12.1 Disabled

Enabled

Deep Clean Mode ……..……………………...…………………………………….. 2.12.2 High-Limit Test …………….…………………….…………………………………….. 2.12.3

Fryer Setup …………………….……………………………………………………………….. 2.9

Level 2 Program (Manager Level) ……………………………………………….. 2.13

[Press and hold TEMP and INFO buttons, 3 beeps, displays Level 2, enter 1234]

Prod Comp Sensitivity for product …………………………………….. 2.13.1 E-Log Log of last 10 error codes ….……...…………………………….. 2.13.2 Password Setup Change passwords ..……………………………… 2.13.3

Setup [enter 1234] Usage [enter 4321] Level 1 [enter 1234] Level 2 [enter 1234]

Alert Tone Volume and Tone ...………………………………………….. 2.13.4 Volume 1-9

Tone 1-3

Top Off After Sets number of cooks before top off prompt …….. 2.13.5 Filter After Sets number of cooks before filter prompt ………….. 2.13.6 Filter Time Sets amount of time between filter cycles ………….. 2.13.7

Info Mode ………………...………………………...………………………………………..……………………….. 2.14

[Press and hold INFO for 3 seconds, displays Info Mode]

Full/Split Vat Configuration

Filter Stats ..……………….……………………………………………………………….. 2.14.1

Review Usage ………….……………………………………………………………….. 2.14.2

Last Load ………………….……………………………………………………………….. 2.14.3

2-8

2.9Fryer Setup Mode Programming

Ensure the fryer is OFF and follow the steps below to navigate the options. The setup mode sets the time, date, date format, language, fryer type, vat type, oil system type and the temperature scale. These settings should only be changed by a technician.

Left Display |

Right Display |

|

OFF |

OFF |

|

|

|

|

ENTER |

Blank |

|

CODE |

||

|

||

LEVEL 1 |

PROGRAM |

|

Product |

Blank |

|

Selection |

||

|

||

FRYER |

Blank |

|

SETUP |

||

|

||

ENTER |

Blank |

|

CODE |

||

|

||

LANGUAGE |

ENGLISH |

|

|

|

|

TEMP |

F |

|

Format |

||

|

||

|

|

|

TIME |

12 HR |

|

FORMAT |

|

|

|

|

|

ENTER |

hh:MM |

|

TIME |

|

DATE |

US |

FORMAT |

|

|

|

enter |

MM-DD-YY or |

date |

DD-MM-YY |

fryer |

Elec |

type |

|

|

|

VAT type |

SPLIT |

Action

Press the TEMP and INFO buttons simultaneously for THREE seconds until LEVEL 1 is displayed.

Enter 1234.

None required.

Press the t button once to scroll to FRYER SETUP.

Press the |

(1) button. |

Enter 1234.

Use the 3and 4buttons to scroll through the language menu. With the desired language selection displayed, press the u button.

Press the 3and 4buttons to toggle between F and C temperature scales.

NOTE: F is used for Fahrenheit, C is used for Celsius. With the desired format displayed, press the u button. Press the 3and 4 buttons to toggle between 12hr and

24hR.

With the desired format displayed, press the u button.

Enter time in hours and minutes using the number buttons 0-9.

Example:

7:30 AM is entered 0730 if using the 12 hour format. 2:30 is entered 1430 if using 24 hour format. To change AM and PM use the tu buttons.

With the correct time displayed, press the u button. Press the 3and 4 buttons to toggle between US and interntl.

With the desired format displayed, press the u button. Enter the date using the number buttons 0-9.

Example:

US Format – Dec. 5, 2010 is entered as 120510. International Format – 5 Dec. 2010 is entered as 051210 With the correct date displayed, press the u button.

Press the 3and 4buttons to toggle between elec and gas. With the fryer type displayed, press the u button.

Press the 3and 4buttons to toggle between split and full. With the vat type displayed, press the u button.

2-9

Loading...

Loading...