Frymaster 11814EF Installation Manual

Manual Operation & Installation |

Series 1814E Frymaster Fryer Electric |

|

|

Frymaster, a member of the Commercial Food Equipment Service Association, recommends using CFESA Certified Technicians.

|

24-Hour Service Hotline 1-800-551-8633 |

JANUARY 2012 |

|

|

|

www.frymaster.com |

E-mail: service@frymaster.com *8196887A* |

|

NOTICE

IF, DURING THE WARRANTY PERIOD, THE CUSTOMER USES A PART FOR THIS MANITOWOC FOOD SERVICE EQUIPMENT OTHER THAN AN UNMODIFIED NEW OR RECYCLED PART PURCHASED DIRECTLY FROM FRYMASTER, OR ANY OF ITS AUTHORIZED SERVICE CENTERS, AND/OR THE PART BEING USED IS MODIFIED FROM ITS ORIGINAL CONFIGURATION, THIS WARRANTY WILL BE VOID. FURTHER, FRYMASTER AND ITS AFFILIATES WILL NOT BE LIABLE FOR ANY CLAIMS, DAMAGES OR EXPENSES INCURRED BY THE CUSTOMER WHICH ARISE DIRECTLY OR INDIRECTLY, IN WHOLE OR IN PART, DUE TO THE INSTALLATION OF ANY MODIFIED PART AND/OR PART RECEIVED FROM AN UNAUTHORIZED SERVICE CENTER.

NOTICE

This appliance is intended for professional use only and is to be operated by qualified personnel only. A Frymaster Factory Authorized Servicer (FAS) or other qualified professional should perform installation, maintenance, and repairs. Installation, maintenance, or repairs by unqualified personnel may void the manufacturer’s warranty. See Chapter 1 of this manual for definitions of qualified personnel.

NOTICE

This equipment must be installed in accordance with the appropriate national and local codes of the country and/or region in which the appliance is installed. See NATIONAL CODE REQUIREMENTS in Chapter 2 of this manual for specifics.

NOTICE TO U.S. CUSTOMERS

This equipment is to be installed in compliance with the basic plumbing code of the Building Officials and Code Administrators International, Inc. (BOCA) and the Food Service Sanitation Manual of the U.S. Food and Drug Administration.

NOTICE

Drawings and photos used in this manual are intended to illustrate operational, cleaning and technical procedures and may not conform to onsite management operational procedures.

NOTICE TO OWNERS OF UNITS EQUIPPED WITH CONTROLLERS

U.S.

This device complies with Part 15 of the FCC rules. Operation is subject to the following two conditions: 1) This device may not cause harmful interference, and 2) This device must accept any interference received, including interference that may cause undesired operation. While this device is a verified Class A device, it has been shown to meet the Class B limits.

CANADA

This digital apparatus does not exceed the Class A or B limits for radio noise emissions as set out by the ICES-003 standard of the Canadian Department of Communications.

Cet appareil numerique n’emet pas de bruits radioelectriques depassany les limites de classe A et B prescrites dans la norme NMB-003 edictee par le Ministre des Communcations du Canada.

DANGER

DANGER

Improper installation, adjustment, maintenance or service, and unauthorized alterations or modifications can cause property damage, injury, or death. Read the installation, operating, and service instructions thoroughly before installing or servicing this equipment.

DANGER

DANGER

The front ledge of this appliance is not a step! Do not stand on the appliance. Serious injury can result from slips or contact with the hot oil.

DANGER

DANGER

Do not store or use gasoline or other flammable liquids or vapors in the vicinity of this or any other appliance.

DANGER

DANGER

The crumb tray in fryers equipped with a filter system must be emptied into a fireproof container at the end of frying operations each day. Some food particles can spontaneously combust if left soaking in certain shortening material.

WARNING

WARNING

Do not bang fry baskets or other utensils on the fryer’s joiner strip. The strip is present to seal the joint between the fry vessels. Banging fry baskets on the strip to dislodge shortening will distort the strip, adversely affecting its fit. It is designed for a tight fit and should only be removed for cleaning.

DANGER

DANGER

Adequate means must be provided to limit the movement of this appliance without depending on or transmitting stress to the electrical conduit. A restraint kit is provided with single nonfilter fryers. If the restraint kit is missing contact your local KES.

DANGER

DANGER

Prior to movement, testing, maintenance and any repair on your Frymaster fryer, disconnect all electrical power from the fryer.

WARNING

WARNING

No structural material on the fryer should be altered or removed to accommodate placement of the fryer under a hood. Questions? Call the Frymaster Service Hotline at 1-800-551-8633.

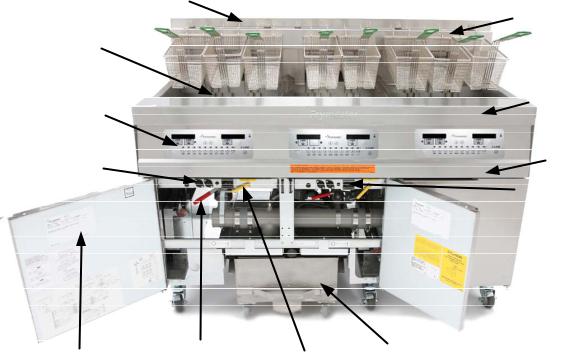

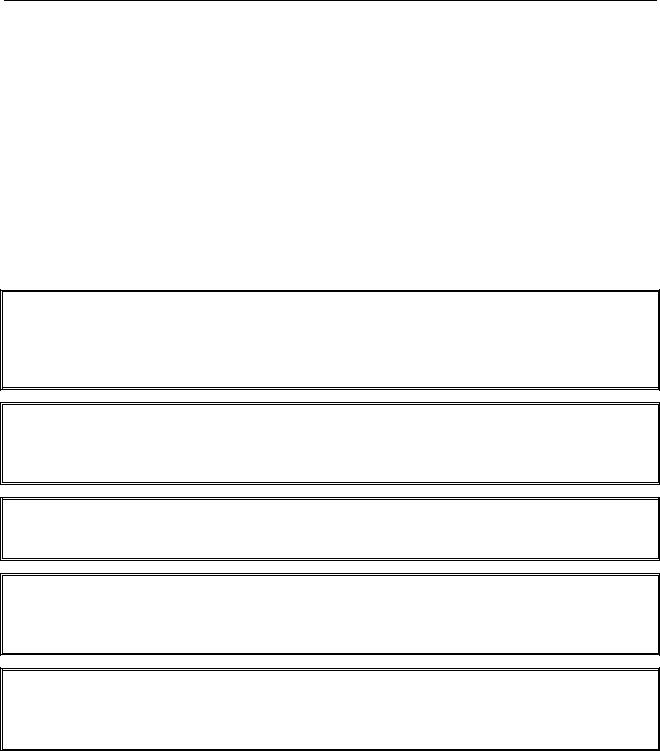

FINDING YOUR WAY AROUND THE FRYMASTER 1814E SERIES

ELECTRIC FRYER

Tilt Housing |

Basket |

|

|

Elements |

Hanger |

|

|

Control Panel |

|

(GM2000 |

Top Cap |

Controllers |

|

Shown) |

|

Fuse |

Bezel |

|

Power |

|

Switch |

|

(Domestic |

|

Only) |

Drain Handle |

Filter Handle |

Filter Pan |

Fryer Identification |

|

|

|

|

|

Data Labels (Model |

|

|

and Serial Number) |

|

|

TYPICAL CONFIGURATION (31814E SHOWN)

NOTE: The appearance of your fryer may differ slightly from that shown depending upon the configuration and date of manufacture.

1814E SERIES ELECTRIC FRYER

Installation and Operation Manual

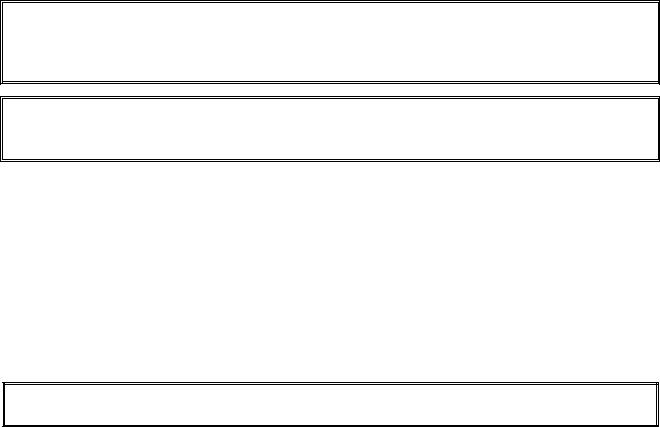

TABLE OF CONTENTS

CHAPTER 1: Introduction |

|

|

1.1 |

General Information .......................................................................................................... |

1-1 |

1.2 |

Safety Information............................................................................................................. |

1-1 |

1.3 |

Controller Information ...................................................................................................... |

1-1 |

1.4 |

European Community (CE) Specific Information............................................................. |

1-2 |

1.5 |

Installation, Operating and Service Personnel .................................................................. |

1-2 |

1.6 |

Definitions ......................................................................................................................... |

1-2 |

1.7 |

Shipping Damage Claim Procedure ................................................................................. |

1-3 |

1.8 |

Service Information........................................................................................................... |

1-3 |

CHAPTER 2: Installation Instructions |

|

|

2.1 |

General Installation Requirements .................................................................................... |

2-1 |

2.2 |

Power Requirements.......................................................................................................... |

2-3 |

2.3 |

Positioning the Fryer Station............................................................................................. |

2-3 |

2.4 |

Frypot Boil Out ................................................................................................................. |

2-4 |

CHAPTER 3: Operating Instructions |

|

|

3.1 |

Equipment Setup and Shutdown Procedures..................................................................... |

3-1 |

3.2 |

Controllers ......................................................................................................................... |

3-2 |

CHAPTER 4: Filtration Instructions |

|

|

4.1 |

Draining and Manual Filtering .......................................................................................... |

4-1 |

4.2 |

General Filter Information................................................................................................. |

4-2 |

4.3 |

Filter Preparation............................................................................................................... |

4-2 |

4.4 |

Daily Filter Operation ....................................................................................................... |

4-6 |

4.5 |

Operating the Filter ........................................................................................................... |

4-8 |

4.6 |

Draining and Disposing of Waste Oil ............................................................................. |

4-11 |

CHAPTER 5: Preventive Maintenance |

|

|

5.1 |

Cleaning the Fryer ............................................................................................................. |

5-1 |

5.2 |

Annual/Periodic System Inspection .................................................................................. |

5-2 |

5.3 |

Stainless Steel Care ........................................................................................................... |

5-4 |

CHAPTER 6: Operator Troubleshooting |

6-1 |

|

6.1 |

Introduction ...................................................................................................................... |

|

6.2 |

Troubleshooting................................................................................................................. |

6-2 |

6.3 |

User Replaceable Parts...................................................................................................... |

6-4 |

i

FRYMASTER 1814E SERIES ELECTRIC FRYER

CHAPTER 1: INTRODUCTION

1.1General

This manual covers all configurations of 1814E series electric fryers. The fryers in this model family have most parts in common, and when discussed as a group, will be referred to as “1814E” electric fryers.

The 1814E electric fryers are open frypots that feature a rotating element with an enhanced design. Fryers in this series come in full pot arrangements, and can be purchased as single units without filters or grouped in batteries of up to three fryers with filtration.

1.2Safety Information

Before attempting to operate your unit, read the instructions in this manual thoroughly.

Throughout this manual, you will find notations enclosed in double-bordered boxes similar to the one below.

DANGER

DANGER

Hot cooking oil causes severe burns. Never attempt to move a fryer containing hot oil or to transfer hot oil from one container to another.

CAUTION boxes contain information about actions or conditions that may cause or result in a malfunction of your system.

CAUTION boxes contain information about actions or conditions that may cause or result in a malfunction of your system.

WARNING boxes contain information about actions or conditions that may cause or result in damage to your system, and which may cause your system to malfunction.

WARNING boxes contain information about actions or conditions that may cause or result in damage to your system, and which may cause your system to malfunction.

DANGER boxes contain information about actions or conditions that may cause or result in injury to personnel, and which may cause damage to your system and/or cause your system to malfunction.

DANGER boxes contain information about actions or conditions that may cause or result in injury to personnel, and which may cause damage to your system and/or cause your system to malfunction.

Fryers in this series are equipped with the following automatic safety features:

1.Two high-temperature detection features shut off power to the elements should the temperature controls fail.

2.A safety switch built into the drain valve prevents the elements from heating with the drain valve even partially open.

1.3Controller Information

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC rules. While this device is a verified Class A device, it has been shown to meet the Class B limits. These limits are designed to provide reasonable protection against

1-1

harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of the equipment in a residential area is likely to cause harmful interference in which case the user will be required to correct the interference at their own expense.

The user is cautioned that any changes or modifications not expressly approved by the party responsible for compliance could void the user's authority to operate the equipment.

If necessary, the user should consult the dealer or an experienced radio and television technician for additional suggestions.

The user may find the following booklet prepared by the Federal Communications Commission helpful: "How to Identify and Resolve Radio-TV Interference Problems". This booklet is available from the U.S. Government Printing Office, Washington, DC 20402, Stock No. 004-000-00345-4.

1.4European Community (CE) Specific Information

The European Community (CE) has established certain specific standards regarding equipment of this type. Whenever a difference exists between CE and non-CE standards, the information or instructions concerned are identified by means of shadowed boxes similar to the one below.

CE Standard

Example of box used to distinguish CE and

Non-CE specific information.

1.5Installation, Operating, and Service Personnel

Operating information for Frymaster equipment has been prepared for use by qualified and/or authorized personnel only, as defined in Section 1.6. All installation and service on Frymaster equipment must be performed by qualified, certified, licensed, and/or authorized installation or service personnel, as defined in Section 1.6.

1.6Definitions

QUALIFIED AND/OR AUTHORIZED OPERATING PERSONNEL

Qualified/authorized operating personnel are those who have carefully read the information in this manual and have familiarized themselves with the equipment functions, or who have had previous experience with the operation of the equipment covered in this manual.

QUALIFIED INSTALLATION PERSONNEL

Qualified installation personnel are individuals, firms, corporations, and/or companies which, either in person or through a representative, are engaged in and are responsible for the installation of electrical appliances. Qualified personnel must be experienced in such work, be familiar with all

1-2

electrical precautions involved, and have complied with all requirements of applicable national and local codes.

QUALIFIED SERVICE PERSONNEL

Qualified service personnel are those who are familiar with Frymaster equipment and who have been authorized by Frymaster, L.L.C. to perform service on the equipment. All authorized service personnel are required to be equipped with a complete set of service and parts manuals, and to stock a minimum amount of parts for Frymaster equipment. A list of Frymaster Factory Authorized Servicers (FAS’s) is located on the Frymaster website at www.frymaster.com. Failure to use qualified service personnel will void the Frymaster warranty on your equipment.

1.7Shipping Damage Claim Procedure

What to do if your equipment arrives damaged:

Please note that this equipment was carefully inspected and packed by skilled personnel before leaving the factory. Frymaster does not assume responsibility for damage or loss incurred in transit. The freight company assumes full responsibility for safe delivery upon acceptance of the equipment.

1.File Claim for Damages Immediately—Regardless of extent of damage.

2.Visible Loss or Damage—Be sure this is noted on the freight bill or express receipt and is signed by the person making the delivery.

3.Concealed Loss or Damage—If damage is unnoticed until equipment is unpacked, notify the freight company or carrier immediately and file a concealed damage claim. This should be done within 15 days of date of delivery. Be sure to retain container for inspection.

1.8Service Information

For non-routine maintenance or repairs, or for service information, contact your local Frymaster Authorized Servicer (FAS). Service information may also be obtained by calling the Frymaster Technical Services Department (1-800-24FRYER) or by e-mail at service@frymaster.com. The following information will be needed in order to assist you efficiently:

Model Number_________________________

Serial Number _________________________

Voltage ______________________________

Nature of the Problem ___________________

____________________________________

____________________________________

RETAIN AND STORE THIS MANUAL IN A SAFE PLACE FOR FUTURE USE.

1-3

FRYMASTER 1814E SERIES ELECTRIC FRYER

CHAPTER 2: INSTALLATION INSTRUCTIONS

2.1General

Proper installation is essential for the safe, efficient, trouble-free operation of this appliance.

Qualified, licensed, and/or authorized installation or service personnel, as defined in Section 1.6 of this manual, should perform all installation and service on Frymaster equipment.

Failure to use qualified, licensed, and/or authorized installation or service personnel (as defined in Section 1.6 of this manual) to install or otherwise service this equipment will void the Frymaster warranty and may result in damage to the equipment or injury to personnel.

Where conflicts exist between instructions and information in this manual and local or national codes or regulations, installation and operation shall comply with the codes or regulations in force in the country in which the equipment is installed.

Service may be obtained by contacting your local Factory Authorized Servicer.

NOTICE

All fryers shipped without factory supplied cords and plug assemblies must be hardwired using flexible conduit to the terminal block located on the rear of the fryer. These fryers should be wired to NEC specifications. Hardwired units must include installation of restraint devices.

NOTICE

If this equipment is wired directly into the electrical power supply, a means for disconnection from the supply having a contact separation of at least 3-mm in all poles must be incorporated in the fixed wiring.

NOTICE

This equipment must be positioned so that the plug is accessible unless other means for disconnection from the power supply (e.g., a circuit breaker) is provided.

NOTICE

If the electrical power supply cord is damaged, it must be replaced by a Frymaster Factory Authorized Servicer or a similarly qualified person in order to avoid a hazard.

DANGER

DANGER

All wiring connections for this appliance must be made in accordance with the wiring diagram(s) furnished with the appliance. Refer to the wiring diagram(s) affixed to the inside of the appliance door when installing or servicing this equipment.

2-1

DANGER

DANGER

Do not attach an apron drainboard to a single fryer. The fryer may become unstable, tip over and cause injury. The appliance area must be kept free and clear of combustible material at all times.

DANGER

DANGER

Building codes prohibit a fryer with its open tank of hot oil being installed beside an open flame of any type, including those of broilers and ranges.

In the event of a power failure, the fryer(s) will automatically shut down. If this occurs, turn the power switch OFF. Do not attempt to start the fryer(s) until power is restored.

2.1.1 Clearance and Ventilation

This appliance must be kept free and clear of combustible material.

A clearance of 6 inches (15cm) must be provided at both sides and back adjacent to combustible construction. A minimum of 24 inches (61cm) should be provided at the front of the equipment for servicing and proper operation.

WARNING

WARNING

Do not block the area around the base or under the fryers.

2.1.2 Electrical Grounding Requirements

All electrically operated appliances must be grounded in accordance with all applicable national and local codes, and, where applicable, CE codes. All units (cord connected or permanently connected) should be connected to a grounded power supply system. A wiring diagram is located on the inside of the fryer door. Refer to the rating plate on the inside of the fryer door for proper voltages.

2.1.3 Australian Requirements

To be installed in accordance with AS 5601 / AG 601, local authority, gas, electricity, and any other relevant statutory regulations.

2-2

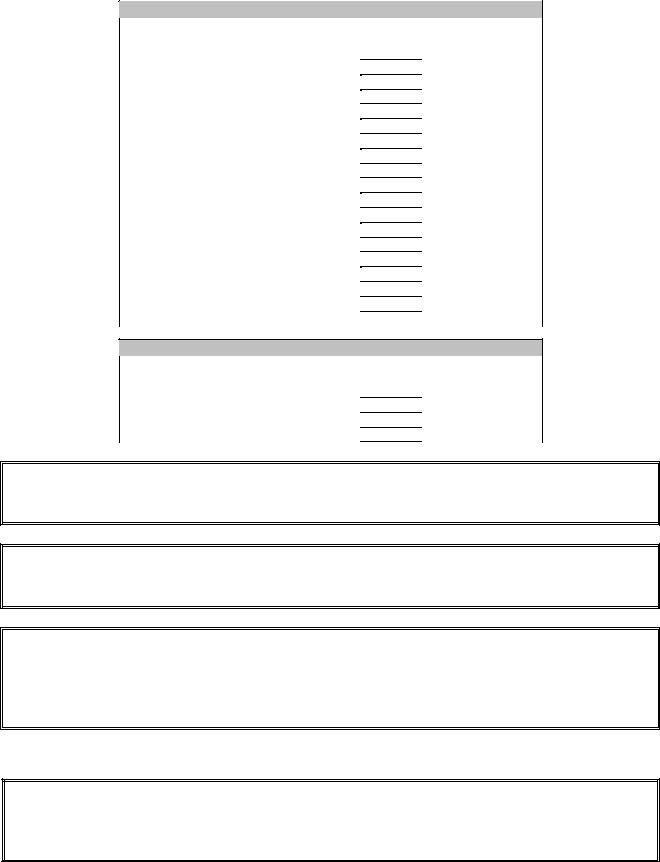

2.2Power Requirements

Three (3) Phase Requirements

|

|

|

WIRE |

MINIMUM WIRE |

AMPS |

||

|

MODEL |

VOLTAGE |

|

SIZE |

|||

|

SERVICE |

|

(per leg) |

||||

|

|

|

AWG |

|

(mm) |

||

|

|

|

|

|

|

||

|

1814E 14kW |

208 |

3 |

6 |

|

(4.11) |

39 |

|

1814E 14kW |

240 |

3 |

6 |

|

(4.11) |

34 |

|

1814E 14kW |

480 |

3 |

8 |

|

(2.59) |

17 |

|

1814E 14kW |

220/380 |

4 |

6 |

|

(4.11) |

21 |

|

|||||||

|

1814E 14kW |

240/415 |

4 |

6 |

|

(4.11) |

20 |

|

|||||||

|

1814E 14kW |

230/400 |

4 |

6 |

|

(4.11) |

21 |

|

|||||||

|

1814E 17kW |

208 |

3 |

6 |

|

(4.11) |

48 |

|

1814E 17kW |

240 |

3 |

6 |

|

(4.11) |

41 |

|

1814E 17kW |

480 |

3 |

6 |

|

(4.11) |

21 |

|

1814E 17kW |

220/380 |

4 |

6 |

|

(4.11) |

26 |

|

|||||||

|

1814E 17kW |

240/415 |

4 |

6 |

|

(4.11) |

24 |

|

|||||||

|

1814E 17kW |

230/400 |

4 |

6 |

|

(4.11) |

25 |

|

|||||||

|

1814E 22kW |

208 |

3 |

4 |

|

(5.19) |

61 |

|

1814E 22kW |

240 |

3 |

4 |

|

(5.19) |

53 |

|

1814E 22kW |

480 |

3 |

6 |

|

(4.11) |

27 |

|

1814E 22kW |

220/380 |

4 |

6 |

|

(4.11) |

34 |

|

|||||||

|

1814E 22kW |

240/415 |

4 |

6 |

|

(4.11) |

31 |

|

|||||||

|

1814E 22kW |

230/400 |

4 |

6 |

|

(4.11) |

32 |

|

|||||||

Single Phase Requirements

|

|

|

WIRE |

MINIMUM WIRE |

AMPS |

|||

|

MODEL |

VOLTAGE |

|

SIZE |

||||

|

SERVICE |

|

(per leg) |

|||||

|

|

|

AWG |

|

|

(mm) |

||

|

|

|

|

|

|

|

||

|

1814E 14kW |

208 |

2 |

3 |

|

|

(5.83) |

68 |

|

1814E 14kW |

240 |

2 |

4 |

|

|

(5.19) |

59 |

|

1814E 14kW |

480 |

2 |

8 |

|

|

(3.26) |

30 |

NOTICE

If this appliance is permanently connected to fixed wiring, it must be connected by means of copper wires having a temperature rating of not less than 167°F (75°C).

DANGER

DANGER

This appliance must be connected to a power supply having the same voltage and phase as specified on the rating plate located on the inside of the appliance door.

DANGER

DANGER

All wiring connections for this appliance must be made in accordance with the wiring diagram(s) furnished with the appliance. Refer to the wiring diagram(s) affixed to the inside of the appliance door when installing or servicing this equipment.

2.3Positioning the Fryer

DANGER

DANGER

No structural material on the fryer should be altered or removed to accommodate placement of the fryer under a hood. Questions? Call the Frymaster Service Hotline at 1-800-551-8633.

2-3

Loading...

Loading...