Friedrich El36n35b-a, Sl28n30b-a, Sl24n30c-a, Sl28n30c-a, Sl24n30b-a Owner's Manual

...

SYSTEM FAN MODE

SCHEDULEFAN SPEED

AUTO

AUTO

AUTO

CONTINUOUS

°F°C

2012 Service/Parts Manual

93001402_00

Service Manual

Service Manual

Room Air Conditioners

Room Air Conditioners

AUTO FAN

CONTINUOUS

AUTO

F

C

SYSTEM

FAN MODE

POWER

FAN SPEED

SCHEDULE

Standard Chassis Models

Standard Chassis Models

Cool Only

Cool Only

115 -Volt:

115-Volt:

208-230-Volt:

208-230-Volt:

Cool

208-230-Volt: ES12N33*, ES15N33*, EM18N34*, EM24N34*, EL36N35*

208-230-Volt:

Electric Heat

208-230-Volt: YS12N33*, YM18N34*, YL24N35*

208-230-Volt:

Heat Pump

115 -Volt:

115-Volt: YS10N10*

Kuhl-Serv/PartsMan (9-12) *Last character may vary

SS08N10*, SS10N10*, SS12N10*, SS14N10*, SM15N10*

SS08M10, SS10M10, SS12M10, SS14M10

SS12N30*, SS15N30*, SM18N30*, SM21N30*

SS12M30, SS15M30, SM18M30, SM21M30

SM24N30*,SL22N30*, SL24N30*, SL28N30*, SL36N30*

Cool with Electric Heat

Cool with Electric Heat

Heat Pump with Electric Heat

Heat Pump with Electric Heat

Heat Pump

Heat Pump

Table Of Contents

Important Safety Information ..................................................................................................................................... 2-4

Introduction ................................................................................................................................................................... 5

Model and Serial Number Location .............................................................................................................................. 5

Unit Identication .......................................................................................................................................................... 6

Performance Data and Specications .......................................................................................................................... 7

Installation Information/Sleeve Dimensions/Circuit Rating ........................................................................................... 8

Electrical Data ............................................................................................................................................................... 9

Before Operating the Unit ............................................................................................................................................10

Kuhl Control Options ....................................................................................................................................................11

Control Panel and Display Identication ......................................................................................................................12

Control Panel Operation Instructions ......................................................................................................................13-19

Remote Control Operation ...................................................................................................................................... 20-21

Unit Operation ............................................................................................................................................................ 22

Electronic Control Sequence of Operation ............................................................................................................ 23-27

Fan Operation ............................................................................................................................................................. 28

Removing the Front Cover and Unit Chassis ................................................................................................................ 29

Replacing the ID Coil Thermistor ................................................................................................................................ 30

Replacing the Control Board ....................................................................................................................................... 30

Airow Selection and Adjustment ............................................................................................................................... 31

Components Testing .............................................................................................................................................. 32-33

Testing the User Interface and Control Board ........................................................................................................... 34

..

Refrigeration Sequence of Operation .......................................................................................................................... 35

R410A Sealed System Repair Considerations ........................................................................................................... 36

Sealed Refrigeration System Repairs .................................................................................................................... 37-40

Hermetics Components Check ................................................................................................................................... 41

Reversing Valve Description/Operation ...................................................................................................................... 42

Testing the Coil ........................................................................................................................................................... 43

Checking the Reversing Valve ............................................................................................................................... 43-44

Compressor Checks .............................................................................................................................................. 45-46

Compressor Replacement ..................................................................................................................................... 47-48

Routine Maintenance ............................................................................................................................................. 49-52

Service and Assistance/Avalaible Accessories .......................................................................................................... 53

How to Check and Erase the Diagnostic Codes ........................................................................................................... 54

Error Codes and Alarm Status .................................................................................................................................... 55

Test Mode ................................................................................................................................................................... 56

Thermistors' Resistance Values .................................................................................................................................. 57

Performance Test Data Sheet ..................................................................................................................................... 58

Troubleshooting ..................................................................................................................................................... 59-68

Electronic Control Board Components Identication & Thermistor Voltage ................................................................... 69

Electronic Control Conguration Instructions .............................................................................................................. 70

Wiring Diagrams .................................................................................................................................................... 71-79

Remote Control Replacement Instructions ........................................................................................................... 80-81

User Interface Service Kit ........................................................................................................................................... 82

Parts Section ......................................................................................................................................................... 83-90

Addendum 1 ............................................................................................................................................................... 91

Warranty ...................................................................................................................................................................... 92

Authorized Parts Depots .............................................................................................................................................. 93

Technical Support Contact Information.........................................................................................................................93

1

IMPORTANT SAFETY INFORMATION

The information contained in this manual is intended for use by a qualied service technician who is familiar

with the safety procedures required for installation and repair, and who is equipped with the proper tools

and test instruments required to service this product.

Installation or repairs made by unqualied persons can result in subjecting the unqualied person making

such repairs as well as the persons being served by the equipment to hazards resulting in injury or

electrical shock which can be serious or even fatal.

Safety warnings have been placed throughout this manual to alert you to potential hazards that may be

encountered. If you install or perform service on equipment, it is your responsibility to read and obey these

warnings to guard against any bodily injury or property damage which may result to you or others.

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read

and obey all safety messages.

This is a Safety Alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol with the word “WARNING”

or “CAUTION”. These words mean:

WARNING

CAUTION

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury,

and tell you what will happen if the instructions are not followed.

NOTICE

You can be killed or seriously injured if you do not follow instructions.

You can receive minor or moderate injury if you do not follow instructions.

A message to alert you of potential property damage will have the

word “NOTICE”. Potential property damage can occur if instructions

are not followed.

PERSONAL INJURY OR DEATH HAZARDS

ELECTRICAL HAZARDS:

• Unplug and/or disconnect all electrical power to the unit before performing inspections,

maintenance, or service.

• Make sure to follow proper lockout/tag out procedures.

• Always work in the company of a qualied assistant if possible.

• Capacitors, even when disconnected from the electrical power source, retain an electrical charge

potential capable of causing electric shock or electrocution.

• Handle, discharge, and test capacitors according to safe, established, standards, and approved

procedures.

• Extreme care, proper judgment, and safety procedures must be exercised if it becomes necessary

to test or troubleshoot equipment with the power on to the unit.

2

• Do not spray or pour water on the return air grille, discharge air grille, evaporator coil, control panel,

and sleeve on the room side of the air conditioning unit while cleaning.

• Electrical component malfunction caused by water could result in electric shock or other electrically

unsafe conditions when the power is restored and the unit is turned on, even after the exterior is dry.

• Never operate the A/C unit with wet hands.

• Use air conditioner on a single dedicated circuit within the specied amperage rating.

• Use on a properly grounded outlet only.

• Do not remove ground prong of plug.

• Do not cut or modify the power supply cord.

• Do not use extension cords with the unit.

• Follow all safety precautions and use proper and adequate protective safety aids such as: gloves,

goggles, clothing, adequately insulated tools, and testing equipment etc.

• Failure to follow proper safety procedures and/or these warnings can result in serious injury or death.

REFRIGERATION SYSTEM REPAIR HAZARDS:

• Use approved standard refrigerant recovering procedures and equipment to relieve pressure before

opening system for repair.

• Do not allow liquid refrigerant to contact skin. Direct contact with liquid refrigerant can result in minor

to moderate injury.

• Be extremely careful when using an oxy-acetylene torch. Direct contact with the torch’s ame or hot

surfaces can cause serious burns.

• Make sure to protect personal and surrounding property with re proof materials.

• Have a re extinguisher at hand while using a torch.

• Provide adequate ventilation to vent off toxic fumes, and work with a qualied assistant whenever

possible.

• Always use a pressure regulator when using dry nitrogen to test the sealed refrigeration system for

leaks, ushing etc.

• Make sure to follow all safety precautions and to use proper protective safety aids such as: gloves,

safety glasses, clothing etc.

• Failure to follow proper safety procedures and/or these warnings can result in serious injury or death.

MECHANICAL HAZARDS:

• Extreme care, proper judgment and all safety procedures must be followed when testing,

troubleshooting, handling, or working around unit with moving and/or rotating parts.

• Be careful when, handling and working around exposed edges and corners of the sleeve, chassis,

and other unit components especially the sharp ns of the indoor and outdoor coils.

• Use proper and adequate protective aids such as: gloves, clothing, safety glasses etc.

• Failure to follow proper safety procedures and/or these warnings can result in serious injury or death.

3

PROPERTY DAMAGE HAZARDS

FIRE DAMAGE HAZARDS:

• Read the Installation/Operation Manual for the air conditioning unit prior to operating.

• Use air conditioner on a single dedicated circuit within the specied amperage rating.

• Connect to a properly grounded outlet only.

• Do not remove ground prong of plug.

• Do not cut or modify the power supply cord.

• Do not use extension cords with the unit.

• Be extremely careful when using acetylene torch and protect surrounding property.

• Failure to follow these instructions can result in re and minor to serious property damage.

WATER DAMAGE HAZARDS:

• Improper installation, maintenance or servicing of the air conditioner unit can result in water damage

to personal items or property.

• Insure that the unit has a sufcient pitch to the outside to allow water to drain from the unit.

• Do not drill holes in the bottom of the drain pan or the underside of the unit.

• Failure to follow these instructions can result in damage to the unit and/or minor to serious property

damage.

4

INTRODUCTION

This service manual is designed to be used in conjunction with the installation and operation manuals provided with

each air conditioning system.

This service manual was written to assist the professional RAC (Room Air Conditioner) service technician to quickly

and accurately diagnose and repair malfunctions.

This manual will deal with subjects in a general nature.

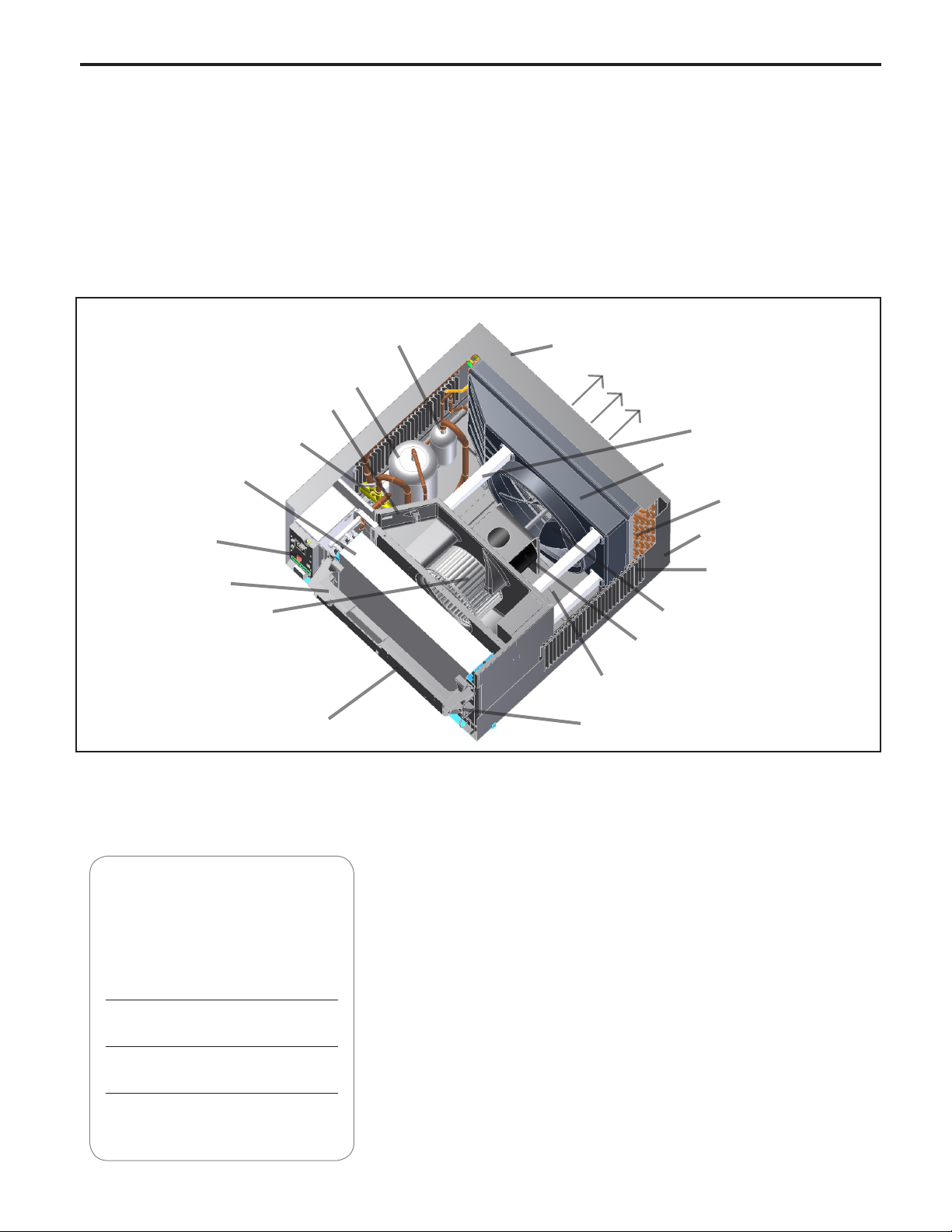

COMPONENTS IDENTIFICATION

Accumulator

Compressor

Outdoor Grille

Discharge Air

Fresh Air Vent

Reversing Valve

Evaporator Coil

Shroud brace

Condense/Fan Shroud

Condenser Coil

Electronic Control

Board

Control Key Pad

Support Bar

Blower Wheel

Air Intake From

Sides and Bottom

Control Key Pad

(User Interface)

IMPORTANT: It will be necessary for you to accurately identify the unit you are servicing, so you can be certain of a

proper diagnosis and repair (See Unit Identication code on page 6).

Chassis Pull

Out Handle

Fan/Blower Motor

Base Pan

Sleeve

Air Intake Vents

Fan Blade

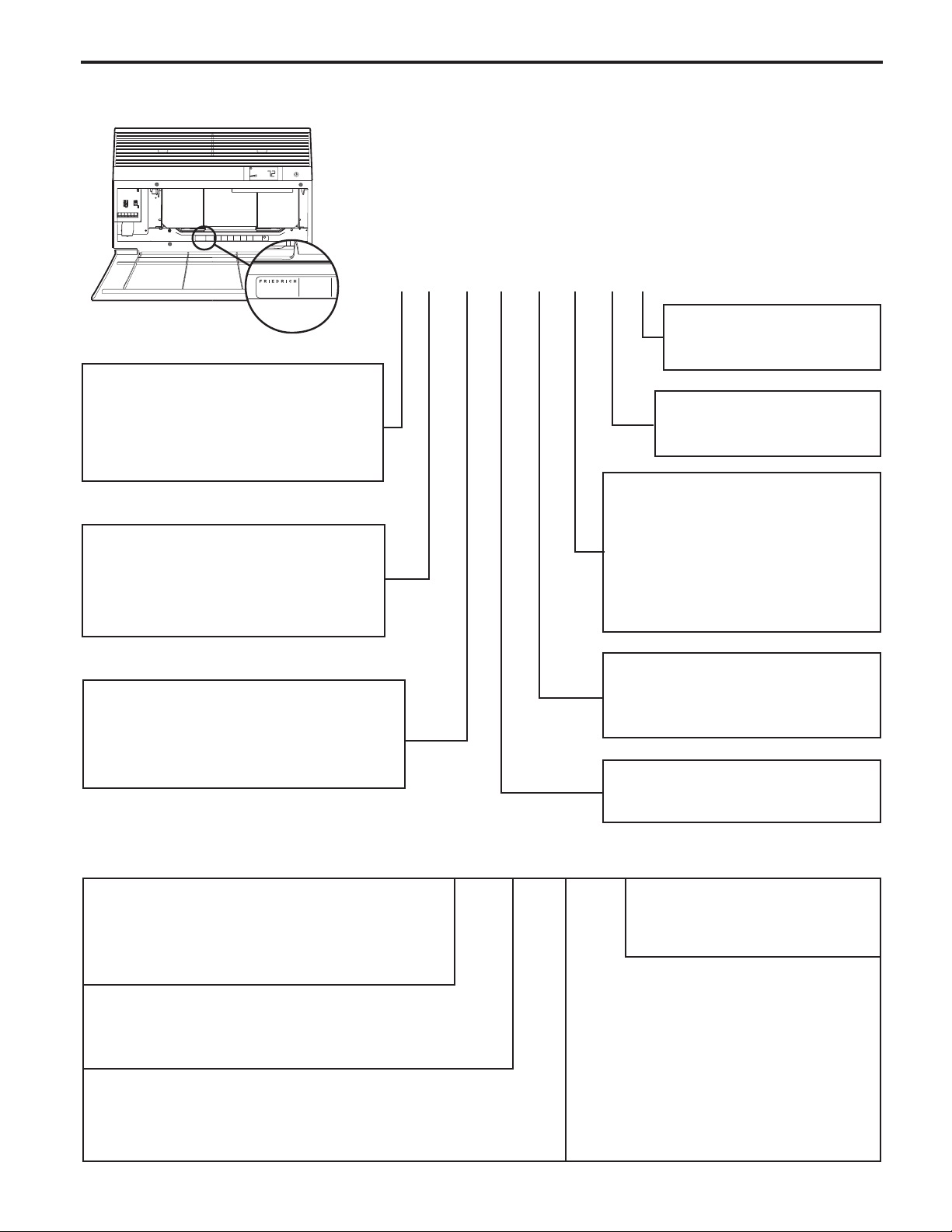

MODEL AND SERIAL NUMBER LOCATION

Register your air conditioner

Model information can be found on the name

plate behind the front cover.

For your future convenience, record the model

information here.

MODEL NUMBER

SERIAL NUMBER

PURCHASE DATE

5

UNIT IDENTIFICATION

COOLING

VOLTS 115

MODEL NUMBER

HEATING

REFRIGERANT

XXXXXXXXX

XXXXXXXXXX

FUSE PROTECTED

U

L

BTH/HR 6500

60 HZ / 1 PH

YS10M10A

BTH/HR 6500

30.1 OZ R410A

600 PSIG HS

XXXXXXXXX

CIRCUITS USE 15A

AIR CONDITIONING CO.

VOLTS MIN 108

SERIAL NUMBER

SAN ANTONIO, TEXAS

LICY00008

ASSEMBLED IN MEXICO

X XX

EER 12.0

EER 10.4

300 PSIG LS

XXXXXXXXXX

TIME DELAY FUSE

XXXXX

AMPS 8.0

AMPS 7.0

XXXXXXXXXX

XXXXXXXXXX

Model Number Code

MODEL NUMBER

YS10M10A

AIR CONDITIONING CO.

SERIAL NUMBER

SAN ANTONIO, TEXAS

LICY00008

ASSEMBLED IN MEXICO

1st Digit – Function

S = Straight Cool, Value Series

Y = Heat Pump

E = Electric Heat

2nd Digit

S = Small Chassis

M = Medium Chassis

L = Large Chassis

3rd and 4th Digit - Approximate

BTU/HR in 1000s (Cooling)

Heating BTU/Hr capacity listed in the

Specication/Performance Data Section

S S 08 M 1 0 B A

9th Digit, Engineering Sufx

Major modication

Subject to change

8th Digit, Marketing Sufx

Indicates modication

Subject to change

7th Digit – Options

0 = Straight Cool &

Heat Pump Models

3 = 3 KW Heat Strip, Nominal

4 = 4 KW Heat Strip, Nominal

5 = 5 KW Heat Strip, Nominal

6th Digit – Voltage

1 = 115 Volts

3 = 230-208 Volts

5th Digit

Alphabetical Modier

RAC Serial Number Identication Guide

Serial Number

Decade Manufactured

L=0 C=3 F=6 J=9

A=1 D=4 G=7

B=2 E=5 H=8

Year Manufactured

A=1 D=4 G=7 K=0

B=2 E=5 H=8

C=3 F=6 J=9

Month Manufactured

A=Jan D=Apr G=Jul K=Oct

B=Feb E=May H=Aug L=Nov

C=Mar F=Jun J=Sept M=Dec

6

A B A R 00001

Production Run Number

Product Line

R = RAC

LISTED

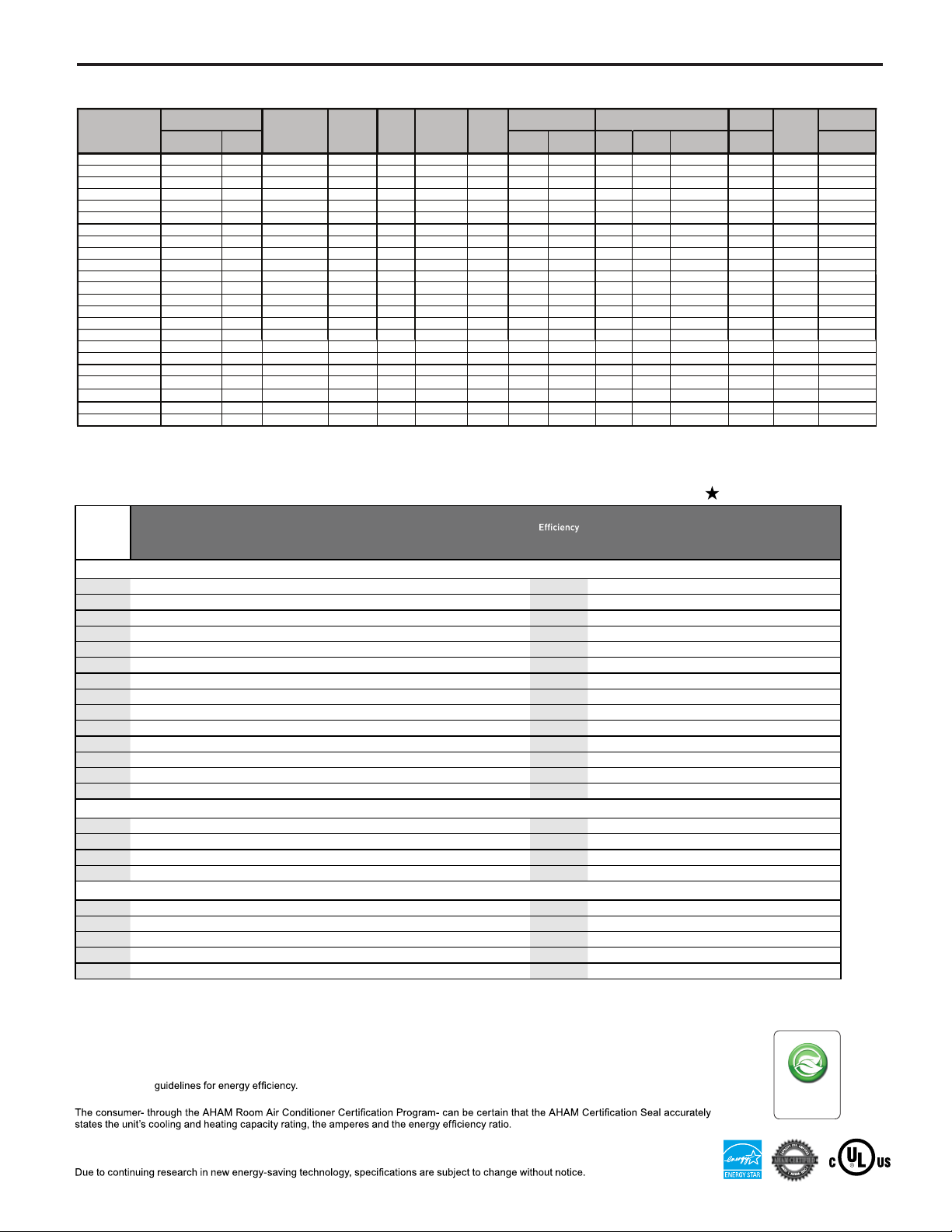

REFRIGERATION SYSTEM PERFORMANCE DATA

COOLING

PERFORMANCE

DATA*

SS08N10-A 54 26 114 153 65 7 19 151 400 6.1 32.0 26.0 115 15

YS10N10-A 59 21 115 155 67 12 14 147 395 7.8 7.6 50.0 26.5 115 15

SS10N10-A 54 26 114 157 68 16 17 137 392 7.7 50.0 27.0 115 15

SS12N10-A 56 24 119 170 60 14 25 135 423 10.0 55.0 30.0 115 15

SS14N10-A 55 25 120 171 62 14 23 141 390 12.0 63.0 31.0 115 15

SS12N30-A 47 33 114 155 58 10 18 134 393 4.8 30.0 31.5 230/208v 15

YS12N30-A 61 19 118 169 69 18 21 137 413 5.2 26.0 32.0 230/208v 20

SS15N30-A 54 26 119 174 59 12 34 127 420 6.4 32.0 33.5 230/208v 15

ES15N33-A 54 26 119 174 59 12 34 127 420 6.4 16.0 32.0 33.5 230/208v 20

SM15N10-A 55 25 118 153 58 10 18 140 410 12.

SM18N30-A 57 23 120 169 61 14 22 136 422 7.4 42.0 39.5 230/208v 15

SM21N30-A 60 20 123 175 65 10 20 130 448 9.4 46.0 40.0 230/208v 15

SM24N30-A 45 35 127 175 50 10 28 119 457 11.2 60.5 43.6 230/208v 20

EM24N34-A 45 35 127 175 50 10 28 119 457 11.2 19.5 60.5 43.5 230/208v 30

YL24N35-A 58 22 119 174 64 22 20 124 417 11.1 12.2 47.0 73.0 230/208v 30

SL22N30-A 54 26 119 159 59 10 20 139 409 9.4 48.0 57.0 230/208v 15

SL24N30-A 54 26 123 163 58 16 19 132 435 11.2 47.0 69.0 230/208v 20

SL28N30-A 54 26 122 173 60 11 26 139 445 12.7 60.0 70.5 230/208v 20

SL36N30-A 52 28 130 190 56 13 33 126 480 18.0 88.0 72.0 230/208v 30

EL36N35-A 52 28 130 190 56 13 33 126 480 18.0 24.0 88.0 72.0 230/208v 30

EVAP. AIR TEMP. DEG.

F

Discharge Air

Temp.

Drop F.

CONDENSER

TEMP DEG. F

Discharge

120 169 61 14 22 136 422 7.4 42.0 39.5 230/208v 30

Temp

Suction

Temp

Super Heat

Sub-

Cooling

OPERATING

PRESSURES

Suction Discharge

ELECTRICAL RATINGS

Amps

Cool

6 63.0 37.0 115 15

Locked Rotor

Amps

Heat

16.0ES12N33-A 47 33 114 155 58 10 18 135 393 4.8 30.0 31.5 230/208v 20

19.5EM18N34-A 57 23

8.5YM18N34-A 48 32 118 169 53 10 21 126 413 8.5 44.0 40.0 230/208v 30

Amps

5.6

R-410A

REF.

Charge in

OZ.

*Rating Conditions: 80 degrees F, room air temp. & 50% relative humidity, with 95 degree F, outside air temp & 40% relative humidity, all

systems use R-410A. Test done at highest unit fan speed.

Voltage

BREAKER

60 Hertz

FUSE

Amps

SPECIFICATIONS

Energy

Volts

MODEL Cooling Btu Heating Btu

®

Kühl

SS08N10 7900 - 115 6.1 677 - - 11.7 $54 - 1.0 265 S 99 121

*

SS10N10 9500 - 115 7.7 848 - - 11.2 $67 - 2.0 260 S 106 136

*

SS12N10 12000 - 115 10.0 1111 - - 10.8 $88 - 3.0 300 S 112 136

*

SS14N10 14000 - 115 12.0 1444 - - 9.7 $115 - 3.5 325 S 116 133

SS12N30 11500/11200 - 230/208 4.8/4.9 1055/1027 - - 10.9/10.9 $84 - 2.8 275 S 112 134

*

SS15N30 14500/14300 - 230/208 6.4/6.8 1480/1459 - - 9.8/9.8 $112 - 3.5 360 S 116 136

SM15N10 14800 - 115 12.0 1358 - - 10.9 $109 - 3.5 360 M 141 154

*

SM18N30 17500/17200 - 230/208 7.4/8.0 1635/1607 - - 10.7/10.7 $131 - 4.6 350 M 140 158

*

SM21N30 20500/20000 - 230/208 9.4/10.3 2181/2128 - - 9.4/9.4 $173 - 6.0 425 M 132 153

*

SM24N30 22300/22000 - 230/208 11.2/11.9 2590/2550 - - 8.6/8.6 $206 - 10.0 390 M 152 167

SL22N30 21000/20500 - 230/208 9.6/10.2 2188/2092 - - 9.6/9.8 $174 - 6.0 625 L 191 212

*

SL24N30 24000/23800 - 230/208 11.2/12.0 2553/2532 - - 9.4/9.4 $207 - 7.0 640 L 192 213

*

SL28N30 27500/27000 - 230/208 13.5/14.4 2926/2872 - - 9.4/9.4 $229 - 8.5 600 L 193 214

*

SL36N30 36000/35700 - 230/208 19.0/20.5 4235/4200 - - 8.5/8.5 $338 - 12.0 725 L 212 227

®

+ Heat Pump

Kühl

YS10N10* 9400 7500 115 7.8 855 7.6 743 11.0 $68 3.0 1.9 285 S 109 131

*

YS12N33 11500/11300 9400/9000 230/208 5.2/5.4 1095/1076 5.6/5.8 1132/1139 10.5/10.5 $87 2.4/2.3 3.0 265 S 115 136

*

YM18N34 18200/17800 17900/17700 230/208 8.5/8.9 1808/1788 8.5/8.7 1833/1761 9.9/9.9 $147 2.5/2.6 5.4 370 M 141 152

*

YL24N35 23500/23000 23500/23000 230/208 11.1/12.0 2500/2447 12.2/14.3 2610/2575 9.4/9.4 $199 2.6/2.6 7.0 600 L 197 212

*

®

Kühl

+ Electric Heat

ES12N33 11500/11200 10700/8900 230/208 4.8/4.9 1055/1027 16.0/14.7 3500/2900 10.9/10.9 $84 - 2.8 275 S 113 128

ES15N33 14500/14300 10700/8900 230/208 6.4/6.8 1480/1459 16.0/14.7 3500/2900 9.8/9.8 $112 - 3.5 360 S 117 133

EM18N34 17500/17200 13000/10600 230/208 7.4/8.0 2590/2550 19.5/17.

EM24N34 22300/22000 13000/10600 230/208 11.2/11.9 2590/2550 19.5/17.0 4200/3500 8.6/8.6 $207 - 10.0 390 M 153 166

EL36N35 36000/35700 17300/14300 230/208 19.0/20.5 4235/4200 24.0/22.4 5500/4650 8.5/8.5 $338 - 12.0 725 L 213 225

* Operates on 115 volt and is not equipped with supplemental heat. Will not provide heat at temperatures below 40°F.

Friedrich room air conditioners are designed to operate in outdoor temperatures from 60°

Kühl+ Heat Pump heating information (shown in red) indicates heat pump per formance. Kühl+ and Chill+ Electric Heat heating information

(shown in red) indicates electric heat strip performance. For Kühl+ Heat Pump electric heating performance

Electric Heat model.

®

As an ENERGY STAR

ENERGY STAR

partner, Friedrich Air Conditioning Co. has determined that the selected ENERGY STAR® models meet the

®

Rated

Cooling

Amps

Cooling

Watts

Heating

Amps

Heating

Watts

0 4200/3500 8.6/8.6 $131 - 4.6 350 M 141 158

F to 115° F.

Ratio

Estimated

Yearly

Operating

EER

Cost COP

refer to corresponding Kühl+

ENERGY STAR

Moisture

Removal -

Pints/HR CFM Sleeve

All models use

environmentally

friendly R-410A

®

models

Net WtShip

R-410A

refrigerant.

Wt.

Estimated yearly operating cost based on a 2007 national average electricity cost of 10.65 cents per kWh.

7

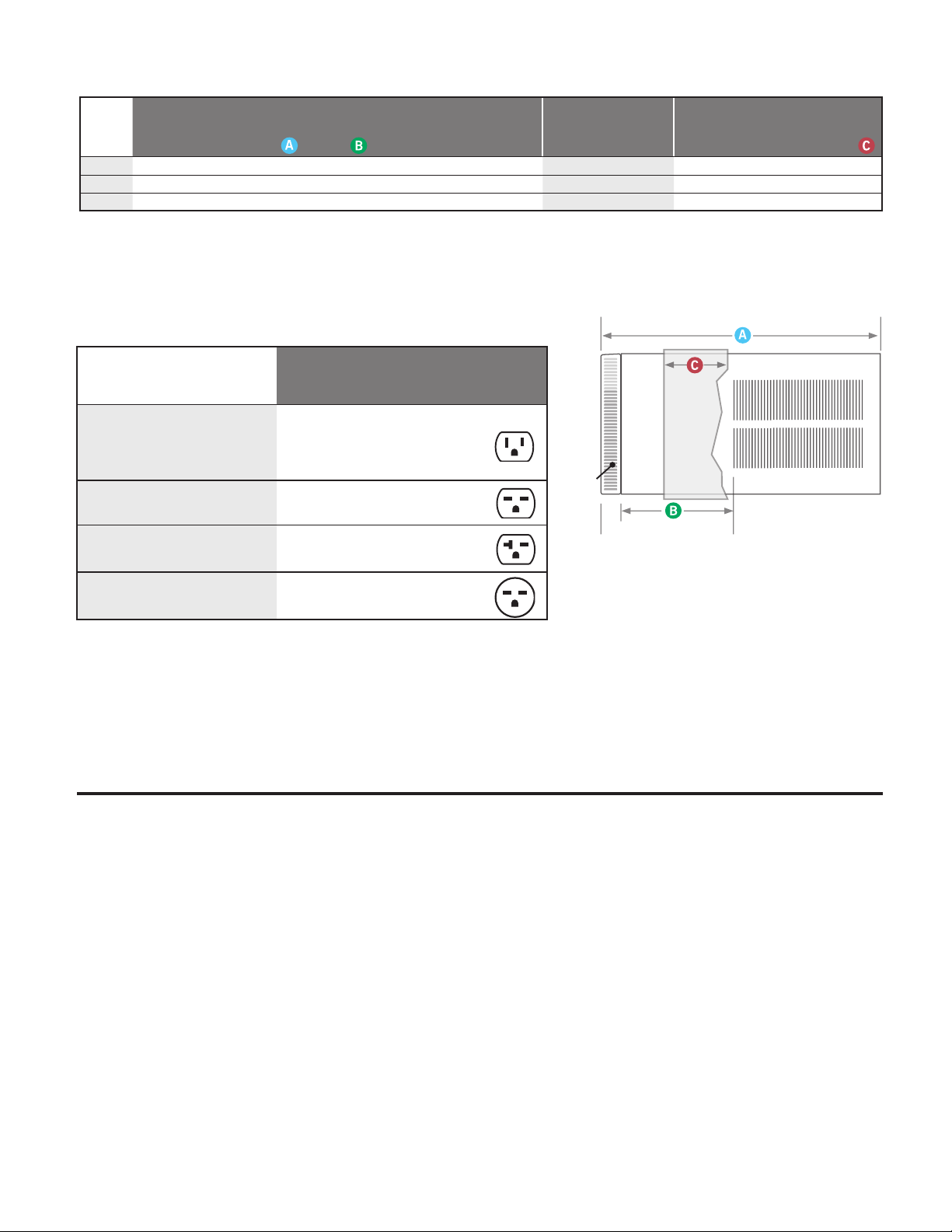

Installation Information / Sleeve Dimensions

Sleeve

Height Width

Depth

with Front

Shell Depth to

Louvers

Minimum

Extension

Into Room*

Minimum

Extension

Outside*

Window Width

Thru-the-wall Installation

Finished Hole

Minimum** Maximum Height Width Max. Depth

S 15

15

/16

" 25

15

/16

" 29"

8

¾"

5

¾”

16

15

/16

” 27

3

/8

" 42 " 16

3

/16”

26

3

/16”

7

3

/8

"

M 17

15

/16

" 25

15

/16

" 29"

8

¾"

5 ¾”

16

15

/16

” 27

3

/8

" 42 " 18

3

/16”

26

3

/16”

7

3

/8

”

L 20

3

/16"

28" 35 ½”

16

½"

5

3

/8

” 18

15

/16

” 29

7

/8

” 42" 20

3

/8

" 28 ¼" 15

1

/8

”

For the best cooling performance and highest energy efficiency

* Minimum ex tensions when mounted in a window.

** Minimum widths achieved using one side curtain assembly as opposed to both in a standard installation.

NOTE: S,M and L sleeves may be installed in window with no side kits if properly installed.

Circuit Rating/ Breaker

Model

SS08N10, SS10N10, SS12N10 and

SS14N10, SM15N10, YS10N10

SS12N30, SS15N30, SM18N30 and

SM21N30, S L22N30

SM24N3 0, SL24N30,SL28N3 0,

ES12N33, ES15N33, YS12N33

SL36N30, EM18N34, EM24N34,

EL36N 35, YM18N34 and YL24N35

Circuit Rating

Breaker or

T-D Fuse

125V - 15A 5 - 15P 6

250V - 15A 6 - 15P 4

250V - 20A 6 - 20 P 4

250V - 30A 6 - 30P 4

Plug

Face

(NEMA#)

Power Cord

Length (f t.)

Wall Outlet

Appearance

Front

(C)

(B)

SIDE VIEW

Keep the filter clean

Make sure that your air conditioner is always in top performing condition

.ylralugerretlifehtgninaelcyb

Provide good air flow

Make sure the airflow to and from the unit is clear. Your air conditioner puts the

conditioned air out at the top of the unit, and takes in unconditioned air at the

bottom. Airflow is critical to good operation. It is just as important on the outside

.dekcolbtonsiroiretxetinuehtdnuorawolfriaehttahtgnidliubehtfo

Unit placement

If your air conditioner can be placed in a window or wall that is shaded by a tree

Insulation

Good insulation will be a big help in maintaining desirable comfort levels.

Doors should have weather stri

pping.

windows.

Proper installation of seal gasket

Make sure the seal gasket has been installed properly to minimize noise

and improve effi ciency. If the seal gasket has not been installed, please

refer to the installation instructions.

rosepardgnisU.yltneiciffeeromneveetarepolliwtinueht,gnidliubre hto naro

blinds on the sunny side of the dwelling will also add to your unit’s efficiency.

8

Be sure to caulk around doors and

LISTED

ELECTRICAL DATA

Not following the above WARNING could result in re or

electically unsafe conditions which could cause moderate

or serious property damage.

Read, understand and follow the above warning.

WARNING

ELECTRIC SHOCK HAZARD

Turn off electric power before service or

installation.

All electrical connections and wiring MUST be

installed by a qualied electrician and conform to

the National Electrical Code and all local codes

which have jurisdiction.

Failure to do so can result in personal injury or

death.

NOTICE

FIRE HAZARD

Wire Size Use ONLY wiring size recommended for single outlet branch circuit.

Fuse/Circuit Breaker Use ONLY the correct HACR type and size fuse/circuit breaker. Read electrical ratings on unit’s

rating plate. Proper circuit protection is the responsibiity of the homeowner.

Grounding Unit MUST be grounded from branch circuit through service cord to unit, or through separate

ground wire provided on permanently connected units. Be sure that branch circuit or general

purpose outlet is grounded.

Receptacle The eld supplied outlet must match plug on service cord and be within reach of service cord.

Do NOT alter the service cord or plug. Do NOT use an extension cord. Refer to the table above

for proper receptacle and fuse type.

The consumer - through the AHAM Room Air Conditioner Certication Program - can

be certain that the AHAM Certication Seal accurately states the unit’s cooling and

heating capacity rating, the amperes and the energy efciency ratio.

*HACR: Heating Air Conditioning and Refrigeration

9

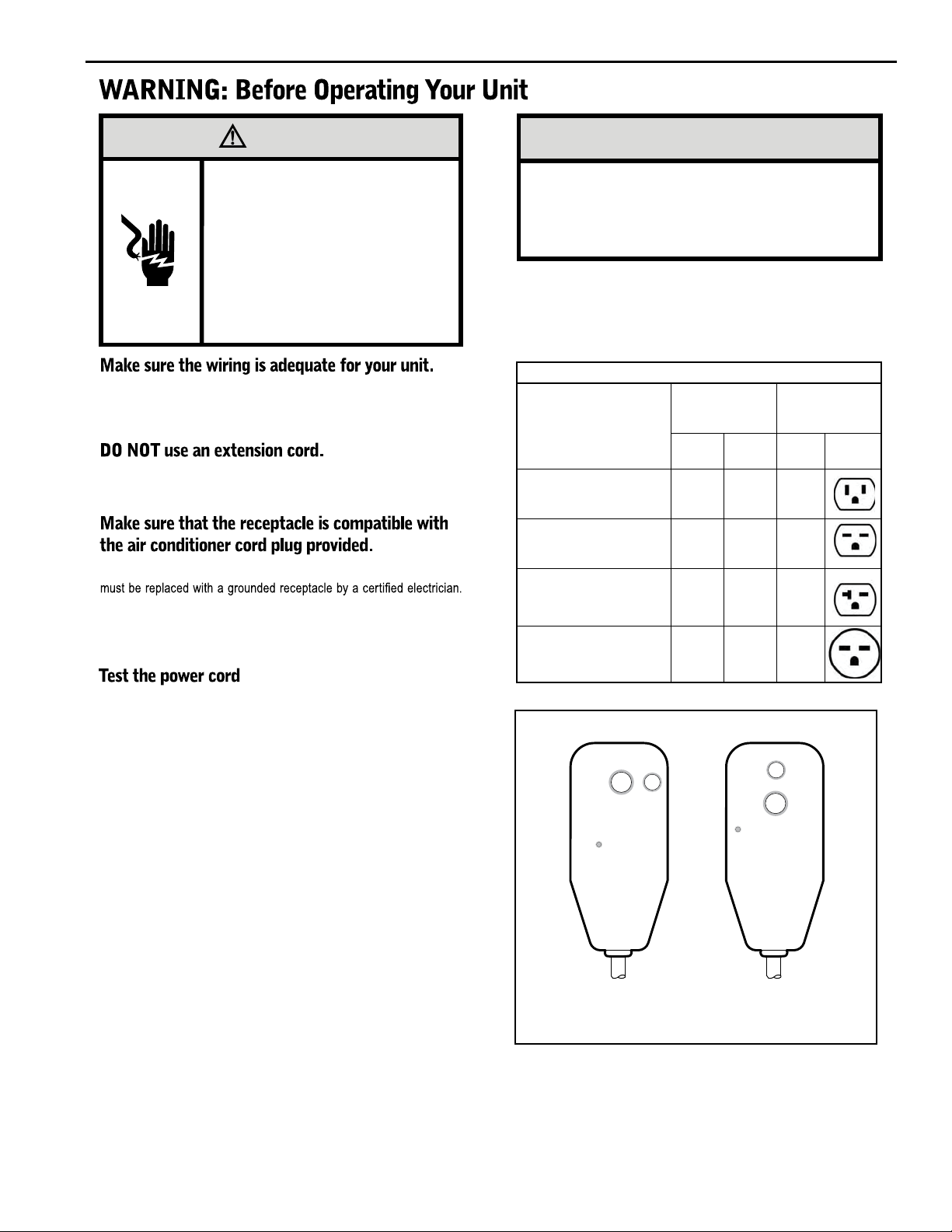

WARNING

NOTICE

Electrical Shock Hazard

Make sure your electrical receptacle has the

same configuration as your air conditioner’s

plug. If different, consult a Licensed Electrician.

Do not use plug adapters.

Do not use an extension cord.

Do not remove ground prong.

Always plug into a grounded 3 prong oulet.

Failure to follow these instructions can result in

death, fire, or electrical shock.

If you have fuses, they should be of the time delay type. Before you install

or relocate this unit, be sure that the amperage rating of the circuit breaker

or time delay fuse does not exceed the amp rating listed in Table 1.

The cord provided will carry the proper amount of electrical power to the

unit; an extension cord may not.

Proper grounding must be maintained at all times. Two prong receptacles

The grounded receptacle should meet all national and local codes and

ordinances. You must use the three prong plug furnished with the air

conditioner. Under no circumstances should you remove the ground

prong from the plug.

Do not use the LCDI device as an ON/OFF switch.

Failure to adhere to this precaution may cause

premature equipment malfunction.

Once plugged in, the unit will operate normally without the need to reset

the LCDI device. If the LCDI device fails to trip when tested or if the power

supply cord is damaged, it must be replaced with a new power supply cord

from the manufacturer. Contact our Technical Assistance Line at (800)

541-6645. To expedite service, please have your model number available.

Table 1.

MODEL

SS08N10, SS10N10,

SS12N10, SS14N10,

SM15N10,

YS10M10

SS12N30, SS15N30,

SM18N30,

SM21N30

SL22N30

SL24N30, SL28N30,

ES12N33, ES15N33,

YS12N33

SL36N30, EM18N34,

EL36N35,

EM24N34, 30 250 6-30R

YM18N34, YL24N35

CIRCUIT RATING

OR TIME DELAY

FUSE

AMP VOLT

15 125 5 -15R

15 250 6-15R

20 250 6-20R

REQUIRED

WALL

RECEPTACLE

NEMA

NO.

All Friedrich room air conditioners are shipped from the factory with a

Leakage Current Detection Interrupter (LCDI) equipped power cord. The

LCDI device on the end of the cord meets the UL and NEC requirements

for cord connected air conditioners.

To test your power supply cord:

1. Plug power supply cord into a grounded 3 prong outlet.

2. Press RESET (See Figure 1).

3. Press TEST, listen for click; the RESET button trips and pops out.

4. Press

and release RESET (Listen for click; RESET button latches

and remains in). The power cord is ready for use.

Note: in case of power failure, unit will resume operation

according to the last input settings.

Figure 1

RESET

TEST

WARNING

TEST BEFORE EACH USE

1. PRESS RESET BUTTON

2. PLUG LCDI INTO POWER

RECEPTACLE

3. PRESS TEST BUTTON,

RESET BUTTON SHOULD

POP UP

4. PRESS TEST BUTTON,

FOR USE

DO NOT USE IF ABOVE TEST

FAILS

WHEN GREEN LIGHT IS ON

IT IS WORKING PROPERLY

15/20A LCDI Device 30A LCDI Device

TEST

RESET

WARNING

TEST BEFORE EACH USE

1. PRESS RESET BUTTON

2. PLUG LCDI INTO POWER

RECEPTACLE

3. PRESS TEST BUTTON,

RESET BUTTON SHOULD

POP UP

4. PRESS TEST BUTTON,

FOR USE

DO NOT USE IF ABOVE TEST

FAILS

WHEN GREEN LIGHT IS ON

IT IS WORKING PROPERLY

FRR001

10

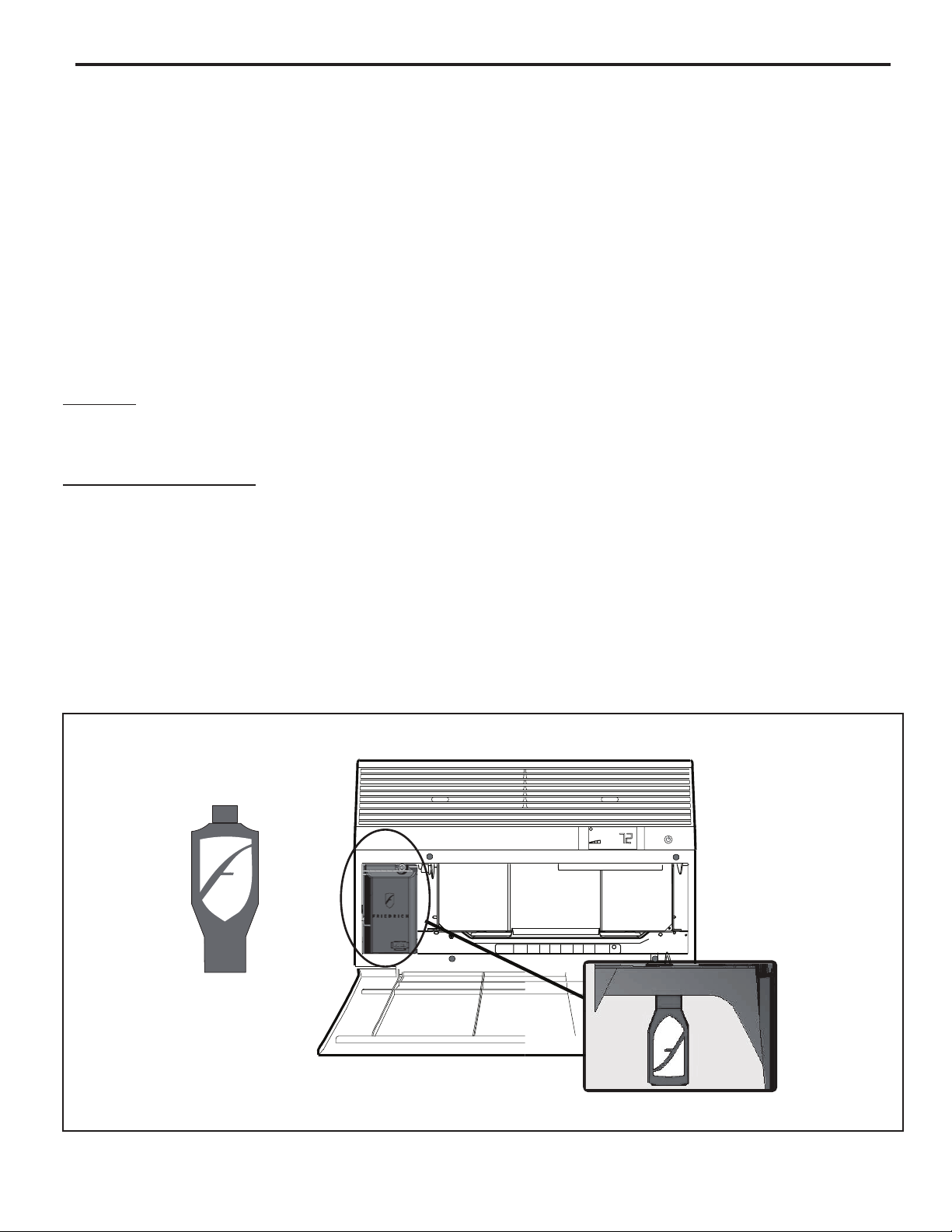

Kuhl Control Options

Kühl Control Options

The

Kühl gives you a variety of options for control, programming, and

scheduling including wireless capabilities

Wireless Programming and Control:

The new FriedrichLink™ Adapter (sold seperately) allows you to conviently

control, program and monitor your air conditioning unit remotely from a

smartphone or computer.

FriedrichLink™ Adapter accessory available through Friedrich authorized

retailers or www.friedrich.com. See FriedrichLink™ Adapter section on

www.friedrich.com for complete details.

Pre-Programmed Scheduling Options:

Your unit’s digital control comes equipped with a 24-hour timer and two preprogrammed 7-day energy management options.

24-Hour Timer

The 24-hour timer allows you to turn the unit off and on at pre-set times by

setting an on and off time on the unit control panel. (See page 11 for details on

timer set-up.)

Pre-programmed Energy Management

Your unit comes from the factory with two (2) Pre-programmed

Management settings are shown in Addendum 1 (Residential & Commercial

Schedule Table).

Energy Management Schedule Options are:

1. Residential Schedule – 40 Hr. Work Week

2. Commercial Schedule – 7-Day Business Week

E

nergy

The “Residential” (40 Hr. Work Week) Schedule has four (4) time periods: 06:00,

08:00, 18:00, and 22:00. This option will cause your Kühl Q unit to raise the room

temperature temporarily to 85°F during the hours wh

en most people are away

at work, lower them again to 78°F prior to the time when most people will return

home, and then raise slightly to 82°F to maintain a comfortable temperature

overnight.

The “Commercial” (7-Day Business Week) Schedule has two (2) time periods:

07:00 and 18:00. This option will cause your air conditioner

to raise temperatures

to 84°F after typical working hours and on weekends when commercial spaces

ar

e ty

pically unoccupied.

(See Control Panel Operation Instructions Section)

Customizable Programming Options:

Customizable schedules, with up to four temperature adjustments per day, can

either be uploaded to the unit via the air conditioner’s built-in micro USB interface

or conveniently transmitted wirelessly using the new FriedrichLink™ Adapter

accessory, greatly simplifying the programming of one or multiple units.

See Figure 2.

See www.friedrich.com for complete Customizable

Programming instructions.

Smart Grid

The Kuhl Unit is also able to be controlled by a Smart Grid.

Smart Grid is a network that brings electricity from power stations to

consumers using new technologies that allow power companies to adjust

electrical loads of residential users. Check with your local electric company

to learn more about Smart Grid programs in your area.

Figure 2

FriedrichLink™ Adapter

AIR CONDITIONING CO.

SAN ANTONIO, TEXAS

ASSEMBLED IN MEXICO

MODEL NUMBER

HEATING

REFRIGERANT

XXXXXXXXX

XXXXXXXXXX

VOLTS 115

COOLING

YS10M10A

60 HZ / 1 PH

BTH/HR 6500

SERIAL NUMBER

VOLTS MIN 108

EER 12.0

LICY00008

AMPS 8.0

FUSE PROTECTED

U

L

BTH/HR 6500

30.1 OZ R410A

EER 10.4

AMPS 7.0

X XX

600 PSIG HS

XXXXXXXXX

CIRCUITS USE 15A

XXXXX

300 PSIG LS

XXXXXXXXXX

TIME DELAY FUSE

XXXXXXXXXX

XXXXXXXXXX

11

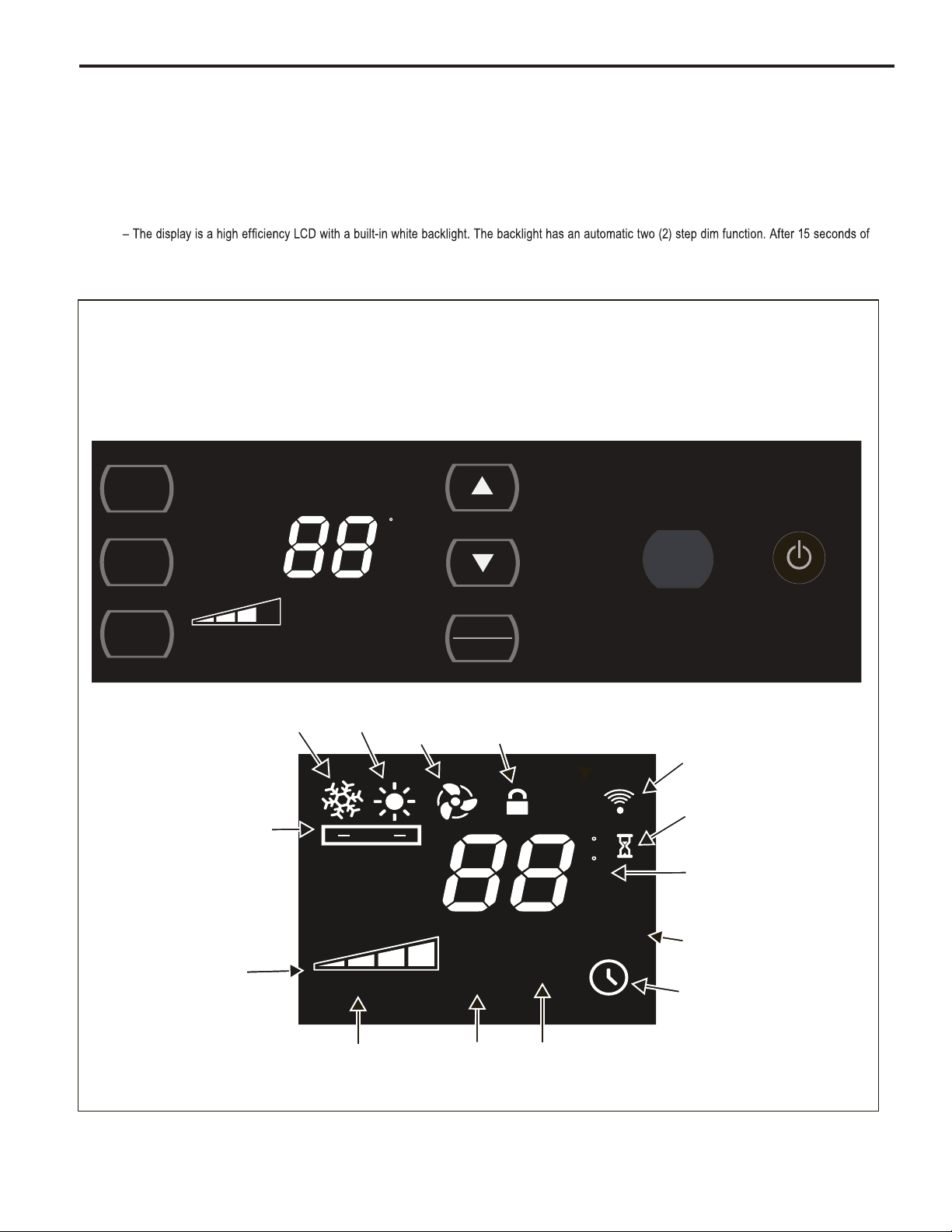

Control Panel and Display Identication

Let’s check out how to control your air conditioner. On the control panel, just above the POWER , is a liquid crystal display (LCD). All of the control panel function

buttons and mode icons can be viewed in Figure 3.

Power On – Press the button to turn on the air conditioner. The power button illuminates to indicate that the power is on. The backlight on the power switch

will automatically dim to 20

% intensity after 15 s

Display

inactivity, the display dims to 20% intensity. After an additional 120 seconds, the display switches off. Touching any button automatically changes the display

to full brightness.

There are three control push buttons on each side of the display.

Figure 3

econds of inactivity. The remote control can also be used to turn power ON / OFF (See Remote Control).

SYSTEM

Cycles between

AUTO, HEAT,

COOL, or FAN

ONLY

(if equipped)

SYSTEM

FAN

MODE

FAN

SPEED

AUTO

Automatically switches

between cool & heat

FAN MODE

Sets fan to either:

- Cycle automatically

- Run continuously

AUTO SPEED

COOL FAN

FAN SPEED

Sets fan speed:

LOW, MED,

HIGH or AUTO

(if equipped)

SET POINT

HEAT

AUTO

AUTO FAN

CONTINUOUS

TEMPERATURE

Increment UP

TEMPERATURE:

Increment DOWN

F

TIMER

SCHEDULE

ONLY

CONTROL

LOCKED

SET POINT

ROOM TEMP

TIMER / SCHEDULE

Turns ON or OFF

F

C

AM

PM

ON OFF

SCHEDULE

:

IR WINDOW

Do not block

ON / OFF

Turns unit on/off

WI-FI

OPERATING

(if equipped)

WAIT

(3 minutes compressor time delay)

2 DIGIT DISPLAY

Shows Setting for:

- Set Point (Temperature)

- Room Temperature

- Clock (AM/PM)

SCHEDULE ON

12

FAN SPEED

Manually selected

fan speed

AUTO SPEED

AUTO SPEED

Automatically selects

best fan cooling or

heating speed

CHECK

FILTER

FILTER

Check / Clean

$MART

TIMER ON

$MART OPERATING

(if equipped)

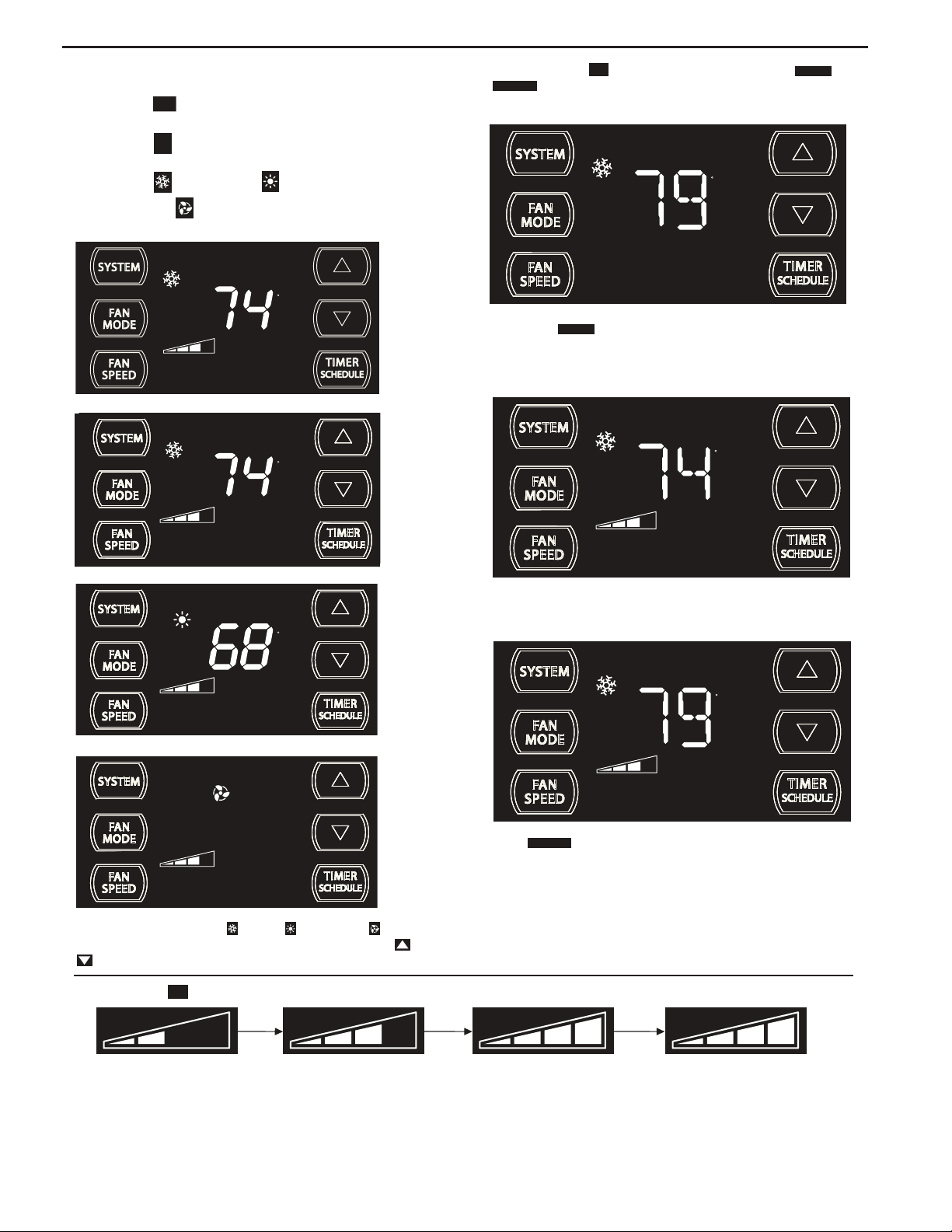

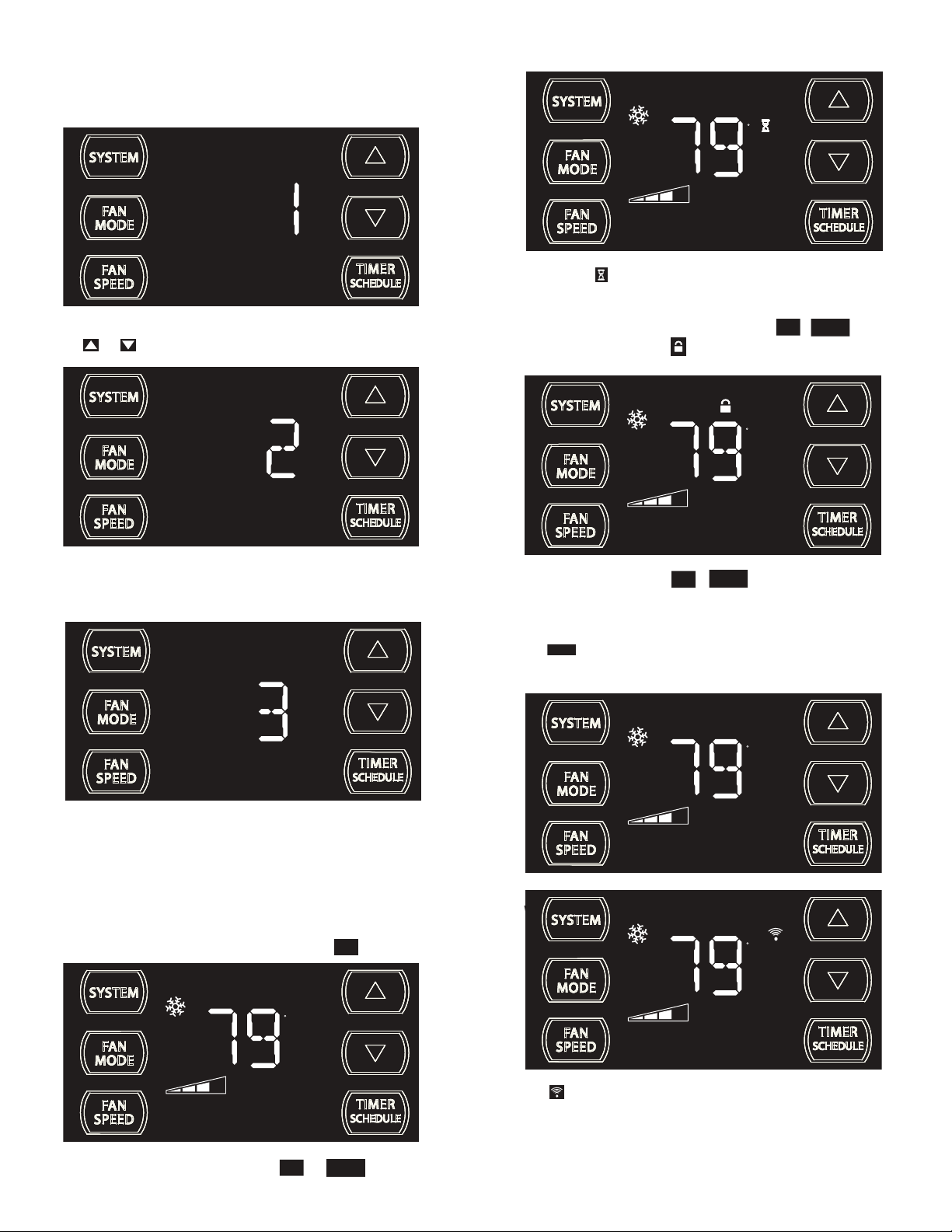

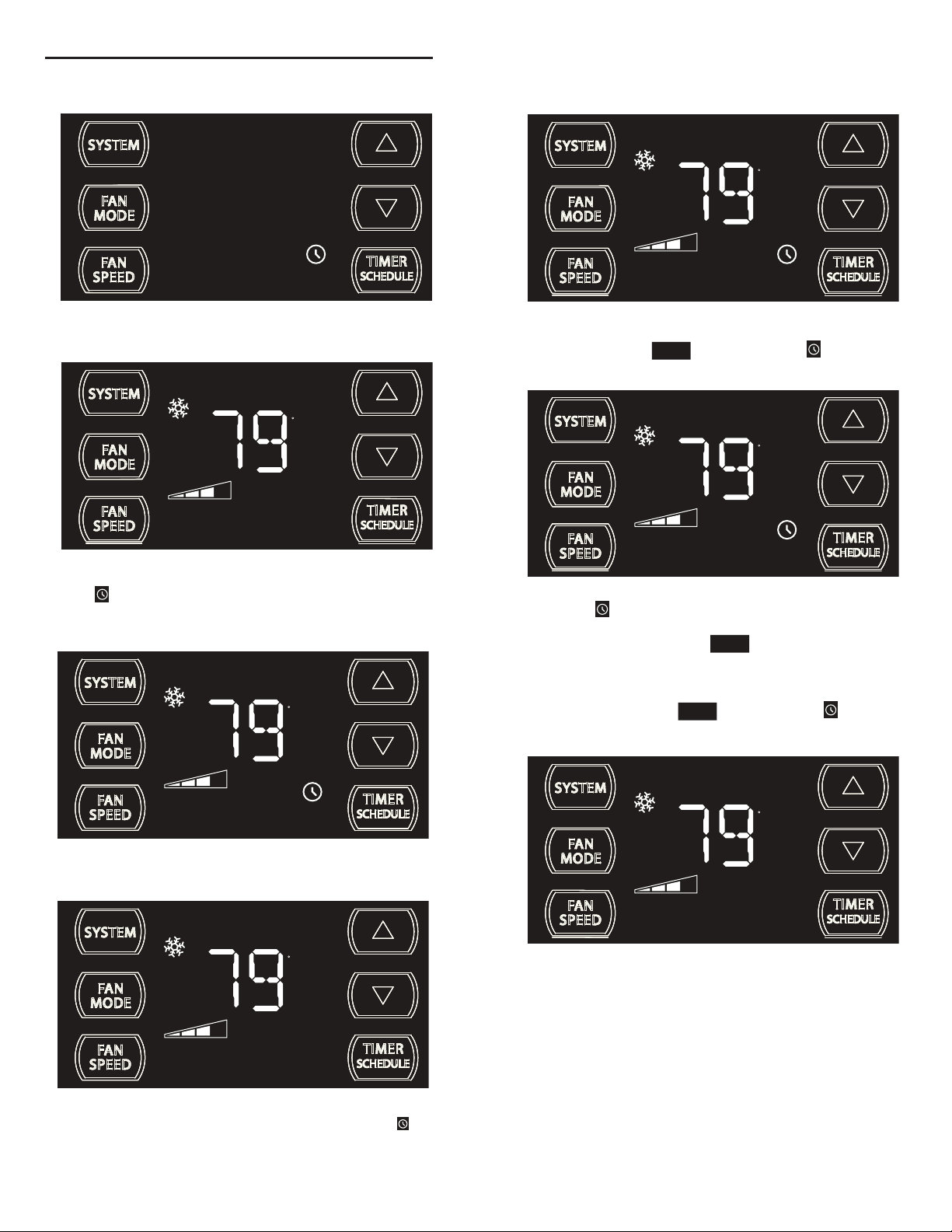

Control Panel Operation Instructions

SYSTEM - The

of operation. To select, press once and let go.

SYSTEM

button allows you to sequentially select the modes

FAN

FAN MODE – The

CONTINUOUS

modes. To select, press once and let go.

MODE

button allows you to select between

AUTO FAN

and

AUTO MODE

COOL MODE

F

AN ONLY MODE

Automatically changes between HEAT and COOL

(HEAT and COOL ONLY Units)

HEAT MODE N

AUTO MODE COOL

- AUTO -

AUTO FAN

SET POINT

COOL ONLY MODE

AUTO FAN

SET POINT

HEAT MODE

AUTO FAN

ot available on some models

F

FRR204

F

FRR103

F

F

AUTO FAN

SET POINT

FRR112

When in the

AUTO FAN

mode, the fan operates only when the system has

a demand to cool or heat the room. Note: the fan is off (no fan speed icon),

indicating no command for cooling or heating.

AUTO FAN (Cooling Demand)

F

AUTO FAN

SET POINT

FRR106

System has a demand for cooling. The fan is operating at a medium speed.

CONTINUOUS

SET POINT

F

CONTINUOUS

SET POINT

FRR113

fan mode, the fan operates all the time. The system

FAN ONLY MODE

FRR104

In the

CONTINUOUS

periodically cools or heats the fan's airfl ow but the fl ow of air does not stop.

When in the SYSTEM COOL or HEAT or FAN ONLY mode, you

FRR105

FAN SPEED - Cooling only units have 4 fan speeds, except models

SL28 and SL36. All Cool+Heat units only have 3 fans speeds.

can also select FAN MODE, FAN SPEED, TIMER SCHEDULE, and

. The SYSTEM MODE does not change.

FAN SPEED - The

FAN

button allows you to toggle between four speeds: LOW, MEDIUM, HIGH, MAX and AUTO speed operation. Press once and let go each time.

SPEED

AUTO

4 Speed

FRR095

During the (SYSTEM mode COOL or HEAT), the fan speed automatically varies depending on the difference between the unit's set point on the control

panel and the actual room temperature. Let me explain. Say for example, you’re working in your garage and you open the big door for several minutes. The

system will sense a wide difference between the set point and the actual room temperature. When this occurs, the system fan speed increases to HIGH for

iod of time. The fan speed decreases, in step, as the temperature difference decreases. When the room temperature matches the system's set point,

a per

fan speed returns to the lowest setting, and if the fan mode is on AUTO FAN, the fan will stop.

13

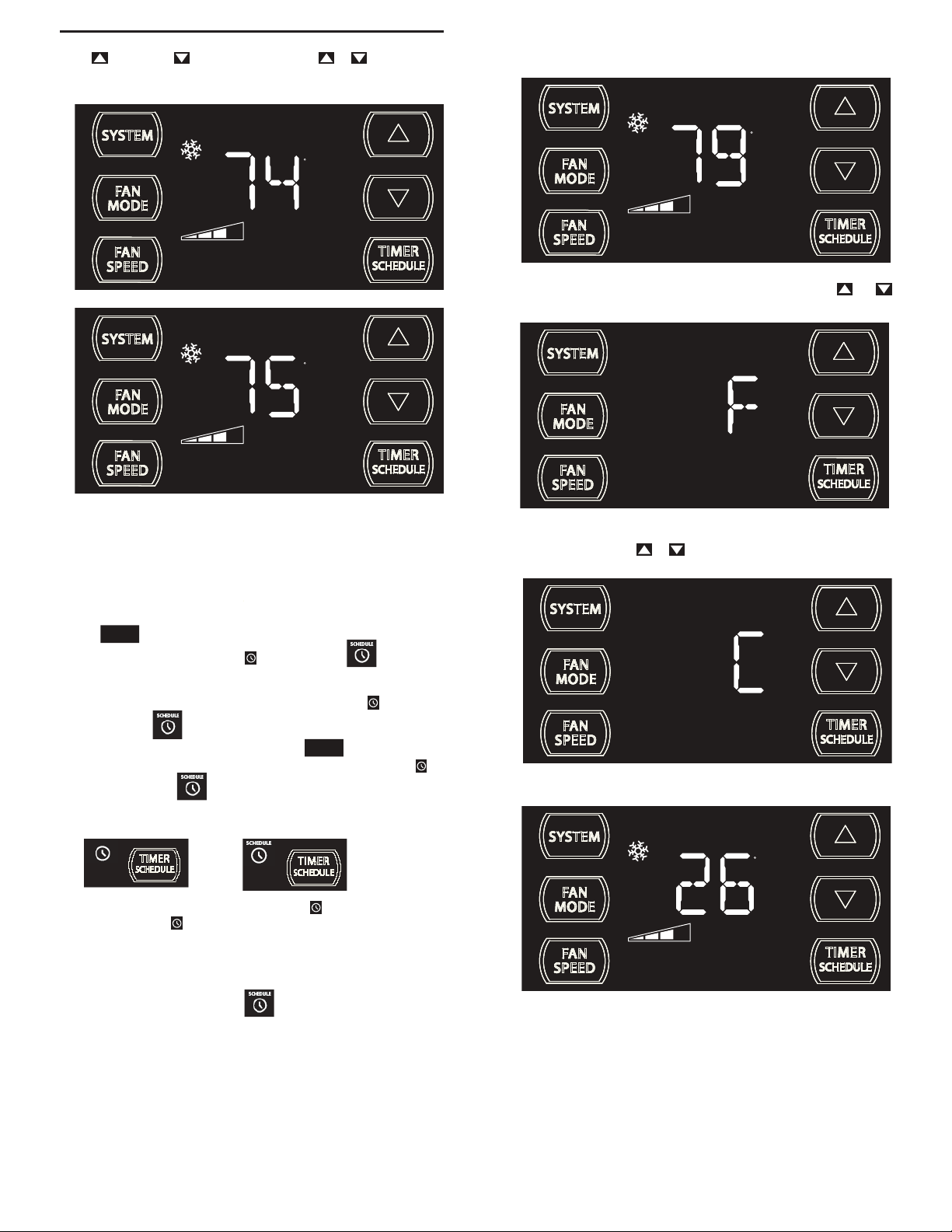

UP and DOWN - arrows - Pressing either or button changes

the system's set point (desired room temperature). These buttons are also

used for setting the Timer and other programming.

F

AUTO FAN

SET POINT

FRR100

F

AUTO FAN

SET POINT

ºF - ºC Select

F

AUTO FAN

SET POINT

FRR132

To switch from degrees Fahrenheit (F) to Celsius (C), press and

buttons simultaneously for three seconds.

FRR101

One press equals 1 degree of change. Holding the button down for more

than 0.6 seconds starts the fast increment/decrement change of the set

point.

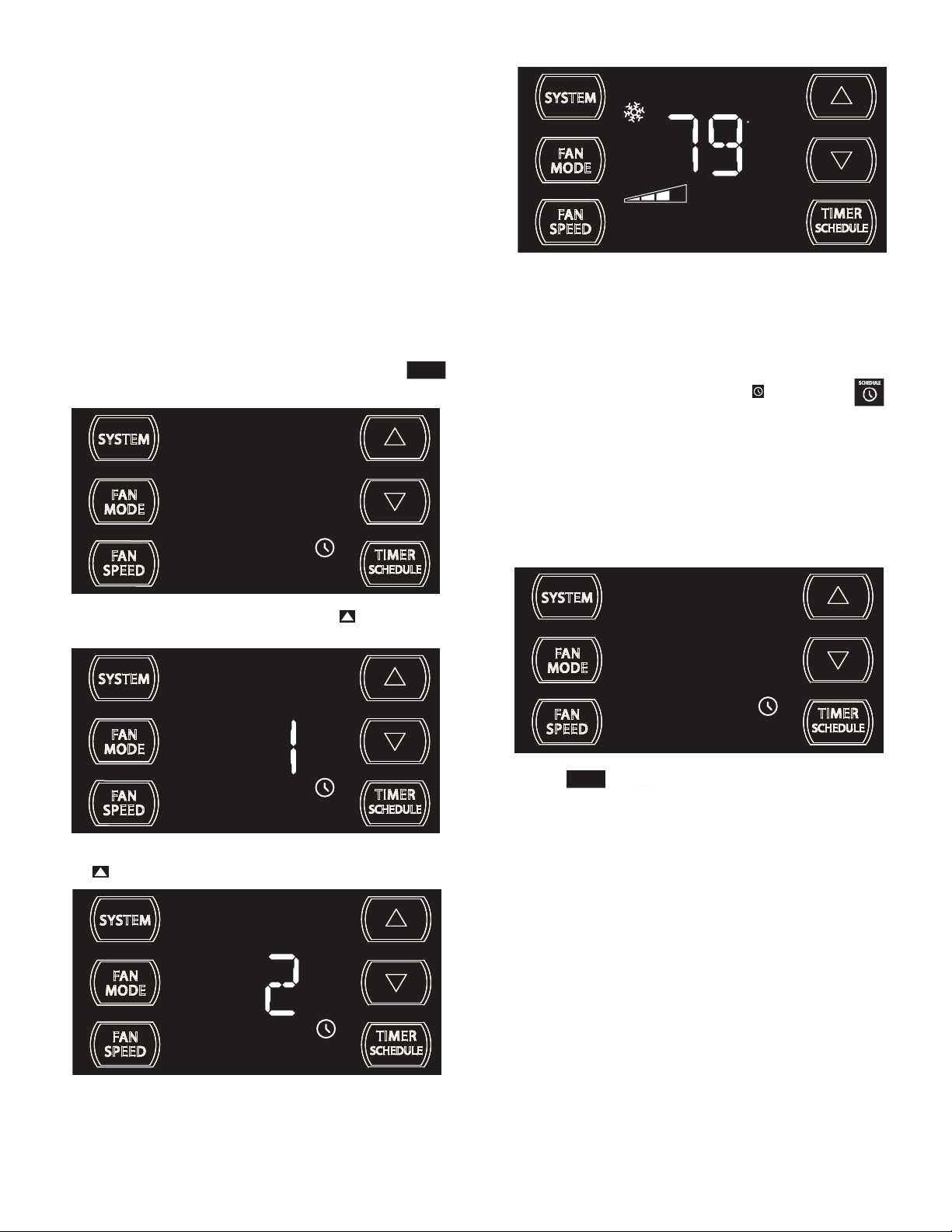

TIMER SCHEDULE BUTTON -

TIMER

SCHEDULE

The button has two main uses:

1.Used to preselect a TIMER or SCHEDULE function. (For

pre-selection instructions, please see page 17.)

2. Used to turn on or activate the pre-selected TIMER or

SCHEDULE .

3. To turn on your pre-selction, press the button once and let

TIMER

SCHEDULE

go. The display at bottom right will show the TIMER icon or

SCHEDULE icon .

Example:

TIMER is turned ON SCHEDULE is turned ON

TIMER (FACTORY DEFAULT) - The TIM

ER is the default on new

units. The TIMER function allows you to turn the unit one time ON

and one time OFF daily at the times that you select. For example, you

can command the system to turn ON at 8:15 am and to turn OFF at

1:30 pm everyday. (To set the timer, see page 18.)

SCHEDULE- The SCHEDULE has two options with factory

pre-programmed energy management settings: temperature, system

and time settings (see addendum) (for more information, see page 17).

FRR133

An “F” will flash for 5 seconds and then revert to a normal display. To change

from F to C, press the

or button within 5 seconds.

FRR134

A “C” will fl ash for 5 seconds and then revert to a normal display.

C

AUTO FAN

SET POINT

FRR135

The ºF icon goes away and the ºC icon illuminates on the normal display.

Schedule options are:

1. Residential Schedule - 40 hour work week

2. Commercial Schedule - 5 day business week

(These factory pre-programmed settings can only be changed by using

the WiFi FriedrichLink™ adaptor, or with an upload via the mirco USB

port, with which you can create your own custom program. See page 11.)

14

DIM Function

There are three separate display brightness levels, AUTO, 20% and full

(100%). To change the DIM setting, press the Power button for three

seconds.

Wait Icon

F

AUTO FAN

SET POINT

FRR120

The wait icon illuminates when the compressor lockout is active.

FRR192

The 1 indicates a DIM setting of Auto (factory default on new units). Use

the or buttons to change the setting.

FRR193

The 2 indicates a DIM setting of 20%. Press the TIMER SET button within

15 seconds to save the setting. Button inactivity for more than 15 seconds

causes the display to time out and return to the normal operating display.

Control Panel Lock

FAN

To lock the front panel controls, press and hold the

for 3 seconds. The lock icon

illuminates to indicate the locked status.

TIMER

+ buttons

SPEED

SCHEDULE

During lockout, none of the control panel buttons will operate.

F

AUTO FAN

SET POINT

FRR116

To unlock, press and hold the

TIMER

FAN

+ buttons simultaneously for 3

SCHEDULE

SPEED

seconds.

External Control Status

$MART

The icon illuminates to indicate that the system is being controlled

remotely, such as from a smart grid from a power company (for more

information, see page 10).

SMART

F

AUTO FAN

FRR194

The 3 indicates a DIM setting of 100% (full brightness). Press the TIMER

SET (Refer to Figure 8) button within 15 seconds to save the setting.

Button inactivity for more than 15 seconds causes the display to time out

and return to the normal operating display.

Alerts

Check Filter

When the fi lter needs to be cleaned or replaced, the

F

AUTO FAN

SET POINT

CHECK

FILTER

FAN

The alert can be dismissed by pressing the

MODE

15

CHECK

icon displays.

FILTER

TIMER

SCHEDULE

and for 3 seconds.

FRR118

SET POINT

$MART

FRR125

WiFi Connection

F

AUTO FAN

SET POINT

FRR126

The icon illuminates to indicate that the system is receiving a Wi-Fi

connection (for more information, see page 10).

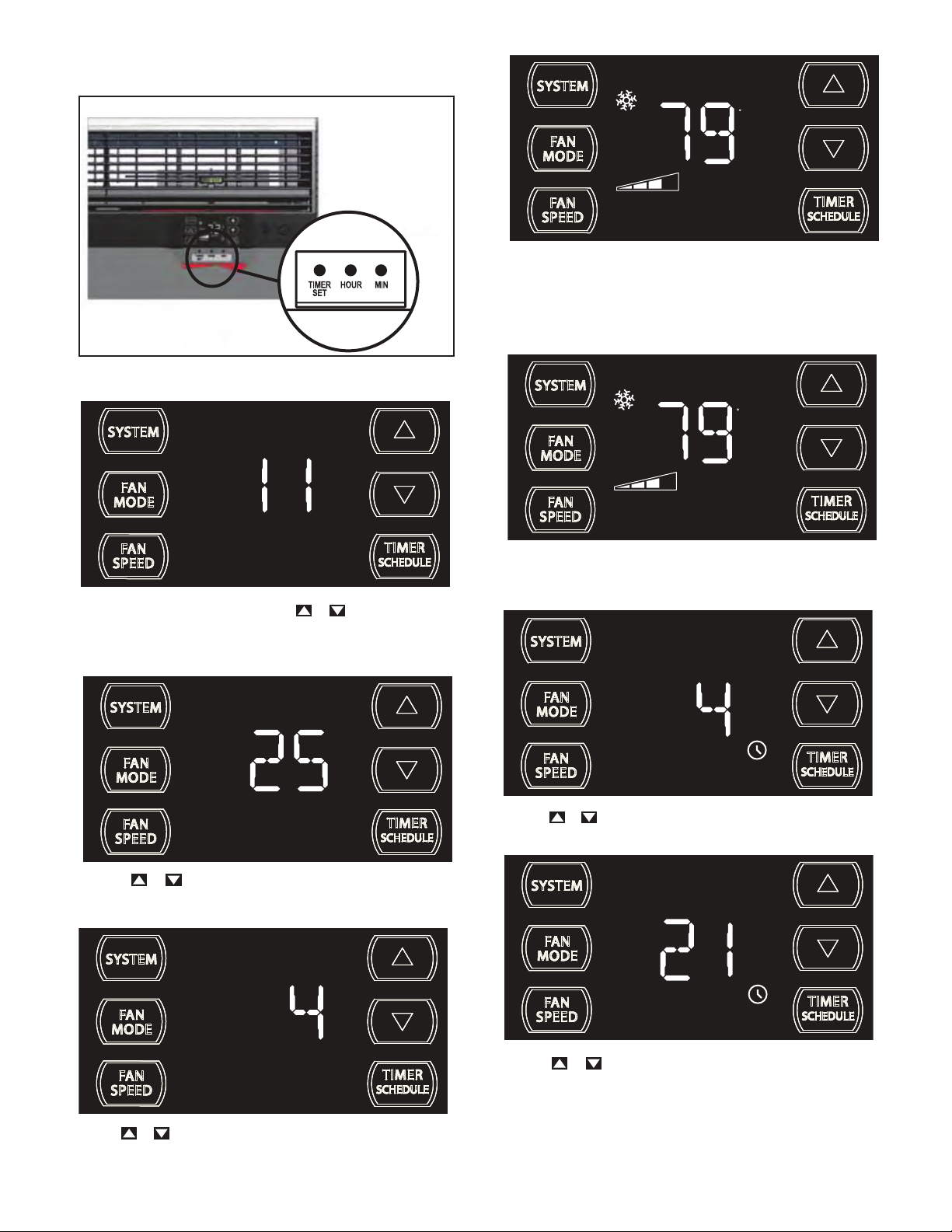

TIMER OR SCHEDULE OPTIONS 1 OR 2 SELECTION

The control system has one Timer and two Schedule functions:

A. Timer (factory default) - Allows you to command the unit to turn

ON and OFF at a time you program. Setting the start, stop and day

can be found latter in this manual on page 18.

B.

Residential Schedule - When selection #1 is selected, the unit

follows a pre-programmed set of operational parameters that

covers 5 days of the week with 4 time windows during each day.

Each time window has it's own set of 8 operating parameters.

Refer to Addendum 1.

C.

Commercial Schedule - When selection #2 is selected, the unit

follows a pre-programmed set of operational parameters that

covers 7 days of the week with 2 time windows during each day.

Each time window has it's own set of 8 operating parameters.

Refer

to Addendum 1.

To change the TIMER/SCHEDULE selection, press and hold the

button for 3 sec, then let go.

TIMER

SCHEDULE

F

AUTO FAN

SET POINT

FRR136

The display reverts to the normal display.

NOTE: The schedule options 1 and 2 have factory pre-programmed

settings which can only be changed by using the WiFi FriedrichLink™

adaptor (an accessory). With it, you can create your own custom

schedule program. See page 10 for more information.

NOTE: Once you have selected the TIMER or SCHEDULE

we must first set the following before turning it on.

1. Set time and day

2. Set start time

3. Set stop time

See timer settings on next page.

FRR139

The display shows the TIMER is selected. Press the button once and

let go.

SCHEDULE

FRR137

The display shows option 1 (Residential Schedule) is selected. Press

the button once and let go.

To Turn On the Timer or Schedule Selected

TIMER

Press the button and let go. The system will operate in the mode

SCHEDULE

option (1, 2 or Timer) you selected. At the above image, TIMER is selected

and turned on.

FRR139

SCHEDULE

The display shows option 2 (Commercial Schedule) is selected.

To save and exit selection, press the TIMER SET button (Figure 4, Page

18).

16

FRR138

TIMER SETTINGS

1. Set time and day 2. Set start time 3. Set stop time

Figure 4

SET TIME AND DAY - To adjust the unit's time press and hold the HOUR

and the MIN buttons for three seconds (Refer to Figure 4).

AM

F

AUTO FAN

SET POINT

FRR131

Press TIMER SET (Refer to Figure 4) button to exit and save the SET

TIME function. The TIMER SET button must be pressed within 15 second.

Button inactivity for more than 15 seconds causes the display to time out

and return to the normal operating display.

Timer Start Time

F

AUTO FAN

SET POINT

FRR128

The unit's current hour displays. Use the or buttons to adjust the

hour. To change from AM to PM continue to increment (roll) the display.

Press TIMER SET (Refer to Figure 4) button to save the hour and display

the unit’s current minutes.

Use the

or buttons to adjust the minutes. The clock is now set

FRR129

for 11:25 AM. Press TIMER SET (Refer to Figure 4) button to display the

unit's day setting.

FRR140

The display shows a normal system. Press and hold the HOUR button

(Figure 4) for 3 seconds. Note: The Timer start-stop times may be set even

when the system is in the Timer or Schedule mode.

AM

ON

FRR141

Use the or button to adjust the hour. Press the TIMER SET button

(Figure 4) to adjust the minutes.

ON

Use the or buttons to adjust the day (1 to 7). The day setting is up

to the user. If you set the current day = 1. So if today is Tuesday, then

Day 1 = Tuesday, select 1.

17

FRR130

FRR142

Use the or button to adjust the minutes. Press the TIMER SET

button (Figure 4) within 15 seconds to exit and save the setting. The timer

is now set to start at 4:21 AM.

The display will return to normal.

Set theTimer Stop Time

F

AUTO FAN

SET POINT

FRR144

The display shows a normal system. Press and hold the MIN button (Figure

4) for 3 seconds. Note the Timer start - stop times may be set even when

the system is in the Schedule mode.

AM

OFF

Timer ON Scenarios

Scenario 1

F

AUTO FAN

SET POINT

FRR156

The display shows a normal operating system.

FRR145

Use the or button to adjust the hour. Press the TIMER SET button

(Figure 4) to advance to the Minutes section.

OFF

FRR146

Use the or button to adjust the minutes. Press the TIMER SET

button (Figure 4) within 15 seconds to exit and save the setting. The timer

is now set to stop at 11:55 AM. The display returns to normal.

Turning the TIMER ON once the time and day, the start and top times

have been set:

TIMER

Press the button once and let go.

SCHEDULE

NOTE: See the following TIMER ON/OFF scenarios.

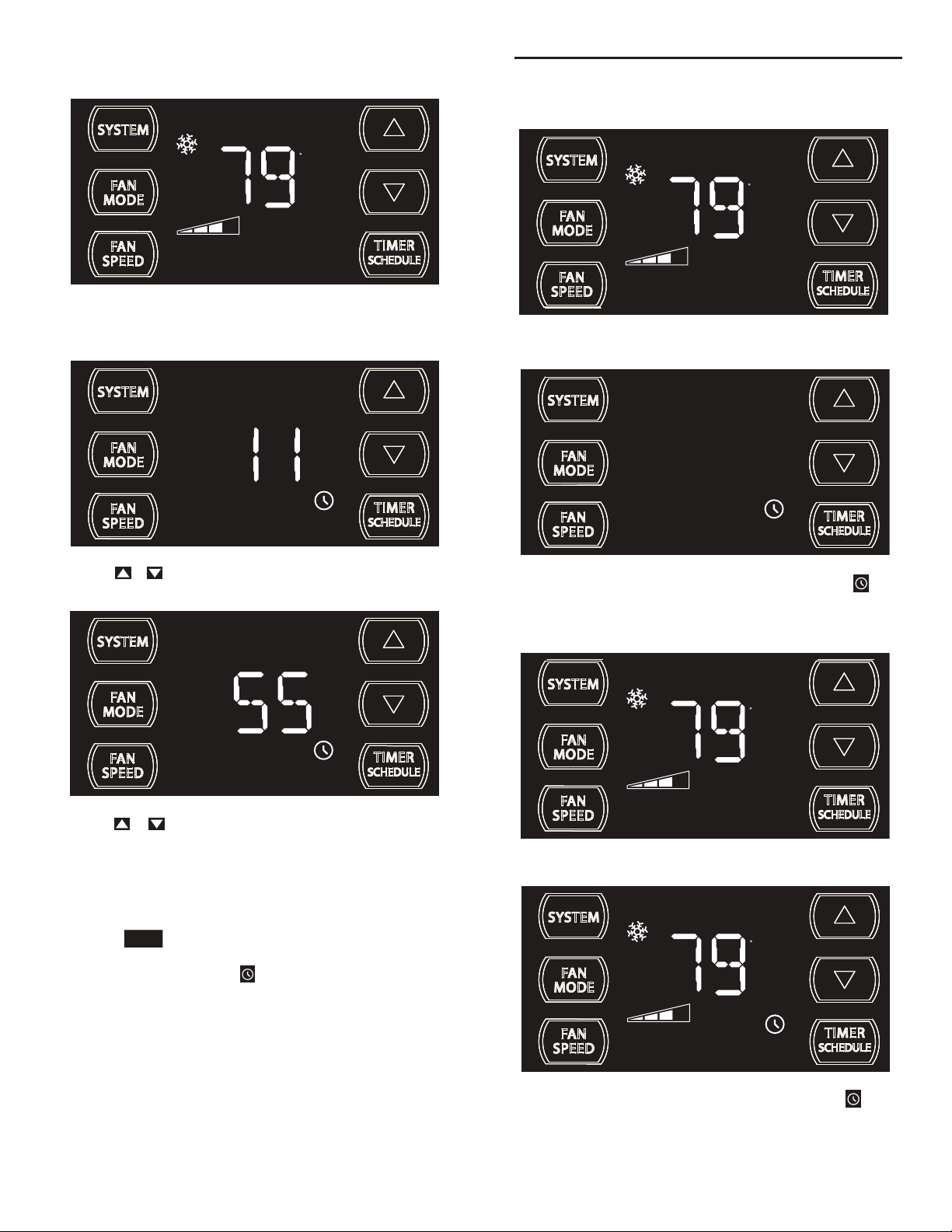

FRR157

If the Timer function is turned ON during the Timer’s OFF time, the icon

illuminates. The control system immediately turns the unit OFF.

Scenario 2

F

AUTO FAN

SET POINT

FRR158

The display shows a normal operating system.

F

AUTO FAN

18

SET POINT

FRR159

If the Timer function is turned ON during the Timer’s ON time, the icon

illuminates. The control system immediately turns the unit OFF.

Timer OFF Scenarios

Scenario 1

Timer - Schedule Control Block

F

AUTO FAN

FRR166

The display shows the unit in Timer mode during an in-active (OFF) period.

F

AUTO FAN

SET POINT

FRR167

If the Timer function is turned OFF during an in-active (OFF) period, the

Timer

icon turns off. The display shows a normal system.

Scenario 2

SET POINT

If the unit is operating in the TIMER or SCHEDULE mode, and you press

any bytton except the button, the TIMER icon begins to

TIMER

SCHEDULE

SCHEDULE

FRR148

blink. All button action is blocked.

F

AUTO FAN

SET POINT

SCHEDULE

FRR149

The TIMER icon stops blinking after 3 seconds. You must turn the

active TIMER or SCHEDULE mode OFF before making changes. Once

the changes are made, press the button to re-activate TIMER

TIMER

SCHEDULE

or SCHEDULE mode.

F

AUTO FAN

SET POINT

FRR168

The display shows the unit in Timer mode during an active (ON) period.

F

AUTO FAN

SET POINT

FRR169

If the Timer function is turned OFF during the ON time. The Timer icon

turns off. The control stays in the current state.

The display shows a normal system.

19

If the unit is operating in the TIMER or SCHEDULE mode, and then you

press any button except the button, the TIMER icon begins

TIMER

SCHEDULE

to blink.

F

AUTO FAN

SET POINT

FRR150

All button action is blocked.

Remote Control Operation

Remote Control - Refer to Figures 12 and 13 during operation description.

Getting Started - Install two (2) AAA batteries in the battery compartment

located on the back of the unit.

Operation - The remote control should be within 25 feet of the air

conditioner for operation. (Refer to Figure 11 for effectiveness). Press the

power button to turn the remote on. The remote will automatically power

off aft

er 15 seconds if the buttons are not being pressed. The remote must

be on to cont

POWER Button - Turns remote and unit on and off.

SYSTEM Button - Allows the user to sequentially select the

following: AUTO - AUTO -, COOL

operations. When the button is pressed, the display indicates which mode

has been selected via a display message.Note that when the heating

function is not available, the system will

FAN MODE Button - Selects between automatic (

operation. In the

NOTE:

rol the unit.

HEAT

,

automatically skip the HEAT mode.

AUTO FAN

mode, the fan only turns on and off when the

compressor operates or the heat function is enabled.

AUTO FAN

is not available in the FAN ONLY Mode, the display

indicates

CONTINUOUS

. In the

CONTINUOUS

determined by your selection on the

, and FAN ONLY

AUTO FAN

) or

mode, fan speed is

FAN

button.

SPEED

CONTINUOUS

FAN SPEED Button - Used to sequentially select new fan speed, plus

AUTO operation. When the

FAN

button is pressed, the fan speed icon

SPEED

(triangle) changes to indicate the new speed level. Fan speed automatically

varies depending on the set temperature on the control panel and the actual

room temperature. For example if there is a big difference between your

set temperature and the actual room temperature, the system fan speed

increases to HIGH. It remains at this speed until the room temperature

matches the set temperatur

TIMER/SCHEDULE Button - The button turns the schedule

e.

TIMER

SCHEDULE

function on and off. Press the Schedule button once to turn on the

Schedule (Residential, Commercial, or Timer) that has already been

selected on your unit. Pressing the button a second time turns

TIMER

SCHEDULE

the schedule function off.

UP and DOWN Arrows - Pressing either the

(UP) or (DOWN)

button changes the desired room temperature. The factory preset lower

and upper limits are 60°F (16°C) and 99°F (37°C). These buttons are also

used to navigate between function options when using the User Menu or

Maintenance Mode.

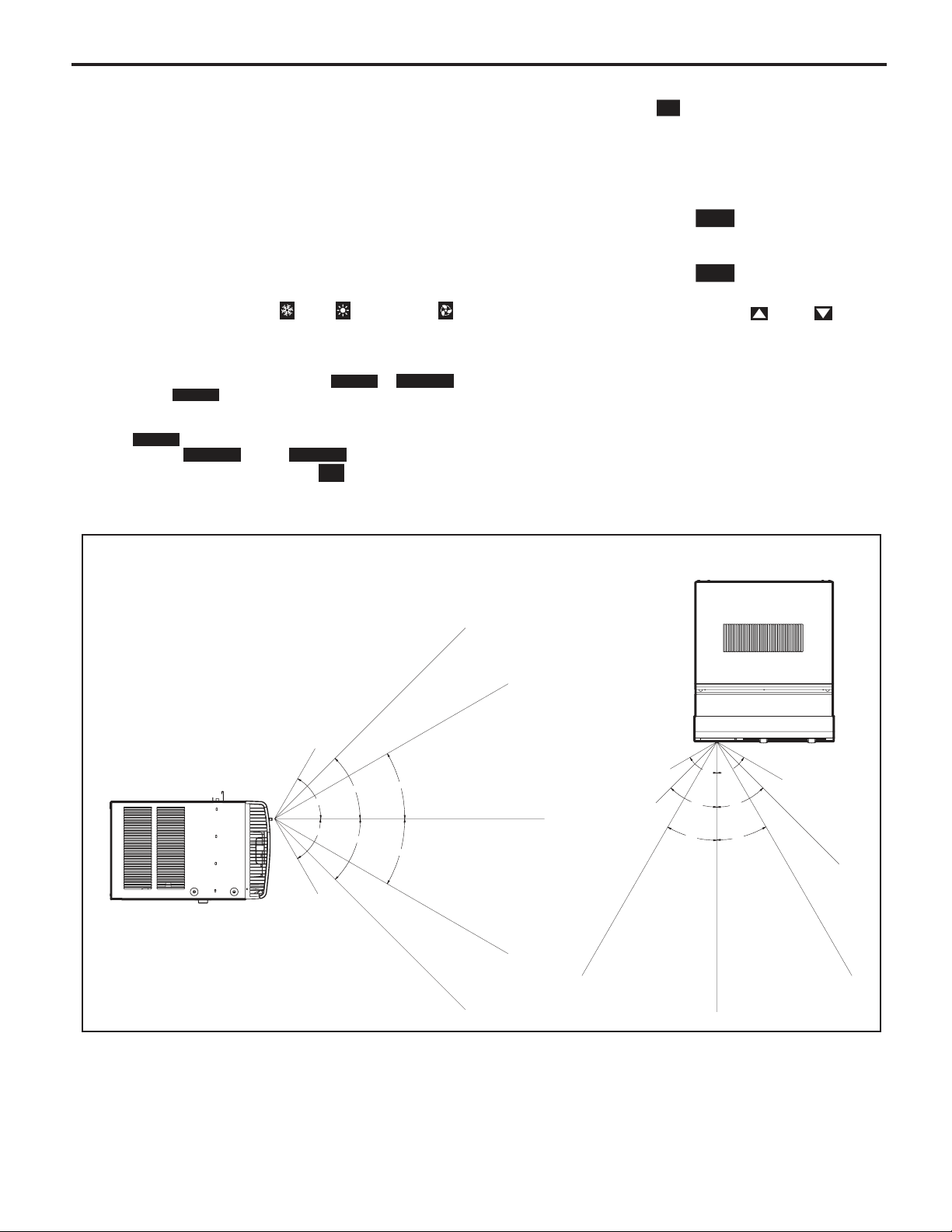

Remote Effectiveness

Hand Held Remote - Has an operating range of up to 25 ft. The infrared

remote control signal must have a clear path to transmit the command to

the air conditioning unit. The remote signal has some ability to "bounce"

off of walls and furniture similar to a television remote control. The diagram

below shows the typical operating range of the control in

with 8 ft high ceilings.

a standard room

Figure 11

SIDE VIEW

TOP VIEW

25ft

25ft

7.5ft

30°

45°

60°

60°

45°

30°

8ft

25ft

25ft

25ft

4ft

8ft

60°

60°

45°

45°

30°

30°

6ft

16ft

25ft

25ft

25ft

Changing Temperature from F˚ (Fahrenheit) To C˚ (Celsius) or Reverse

Be within 25' of unit with the remote control. Press the SYSTEM and FAN MODE buttons at the same time and hold for

3 seconds. The display will show the temperature in Celcius. Do the same to reverse temperature to F

(The remote control operation overrides manual settings on unit)

20

˚ (Fahrenheit).

FRR080

Remote Control Operation (Continued)

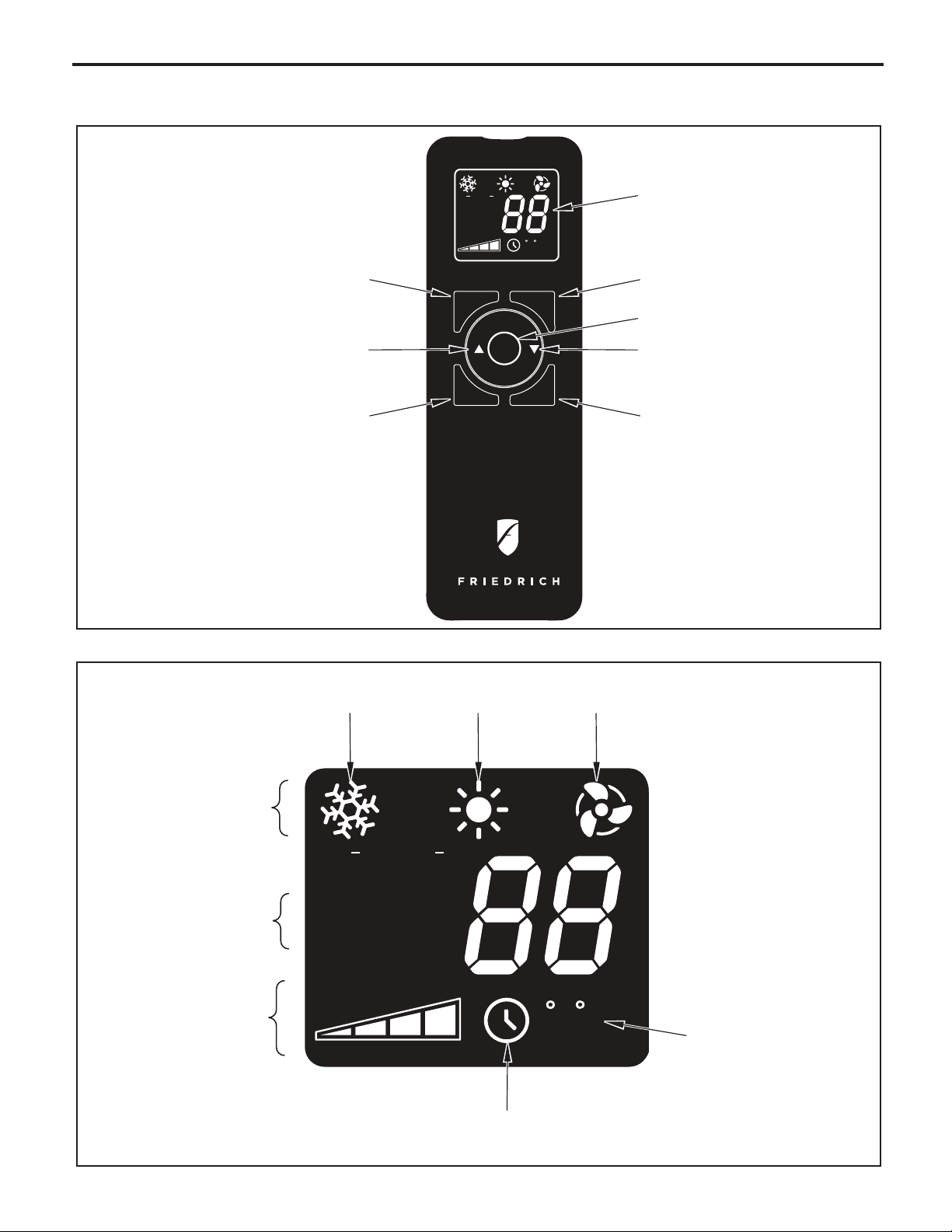

Figure 12

SYSTEM

TEMPERATURE

UP

FAN SPEED

AUTO

AUTO FAN

CONTINUOUS

AUTO

SYSTEM

FAN SPEED

POWER

F

C

FAN MODE

SCHEDULE

DISPLAY

FAN MODE

POWER

TEMPERATURE

DOWN

SCHEDULE

FRR081

Figure 13

SYSTEM

MODE

FAN

MODE

FAN

SPEED

COOL

ICON

AUTO

AUTO FAN

CONTINUOUS

AUTO

HEAT

ICON

SCHEDULE

ICON

FAN ONLY

ICON

F

C

°F / °C

ICONs

FRR082

21

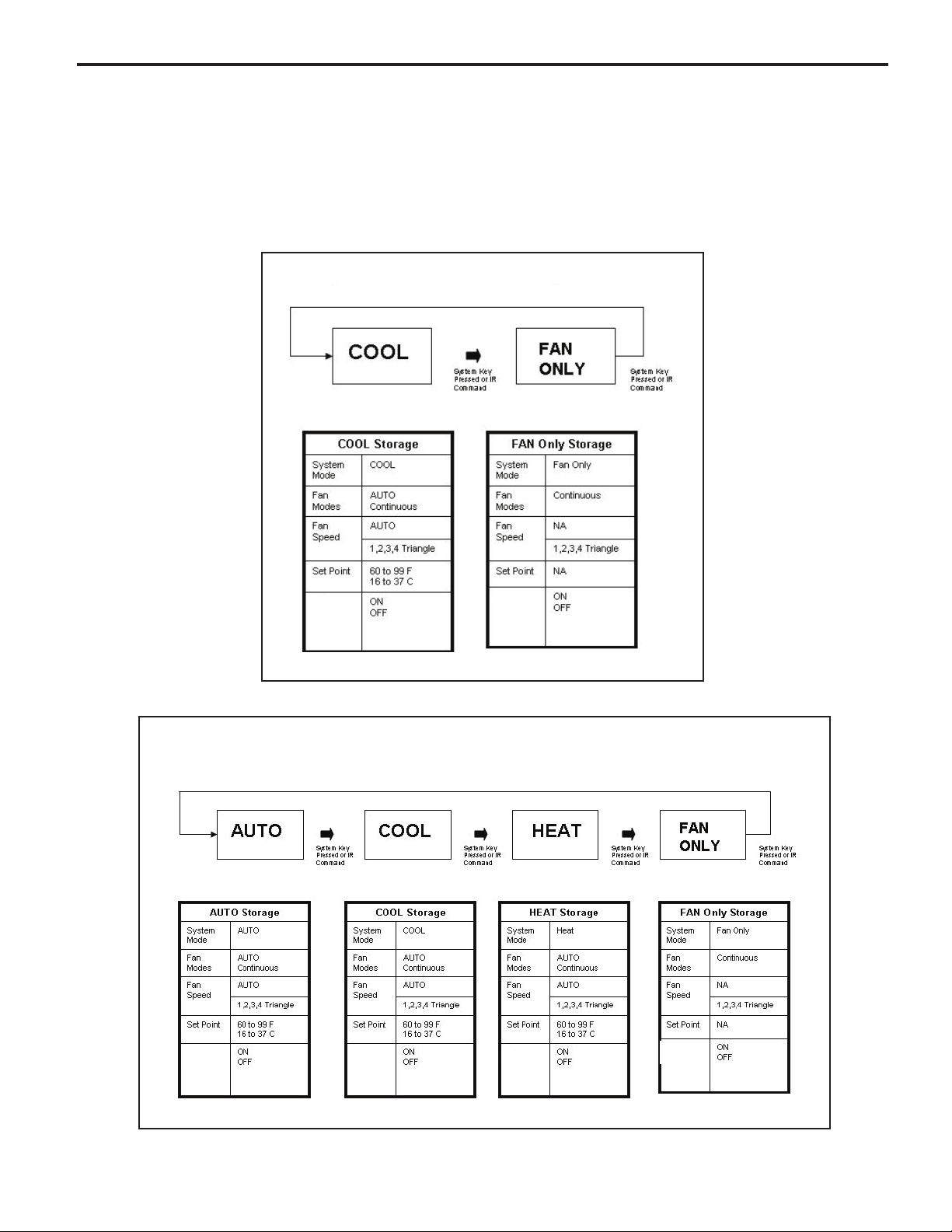

UNIT OPERATION

Front Panel

System Mode Sequence (TIMER/SCHEDULE = OFF)

There are two system modes of operation. One for a cool only unit (see figure 1) and one for a heat-cool unit (see figure 2).

System parameters for each system mode are saved when exiting a system mode, and retrieved when entering a new

system mode.

Figure 1

System Mode: Cool Only Units

Timer/

Schedule

Figure 2

System Mode: Heat - Cool Units

Timer/

Schedule

Timer/

Schedule

Timer/

Schedule

Timer/

Schedule

Timer/

Schedule

22

ELECTRONIC CONTROL SEQUENCE OF OPERATION

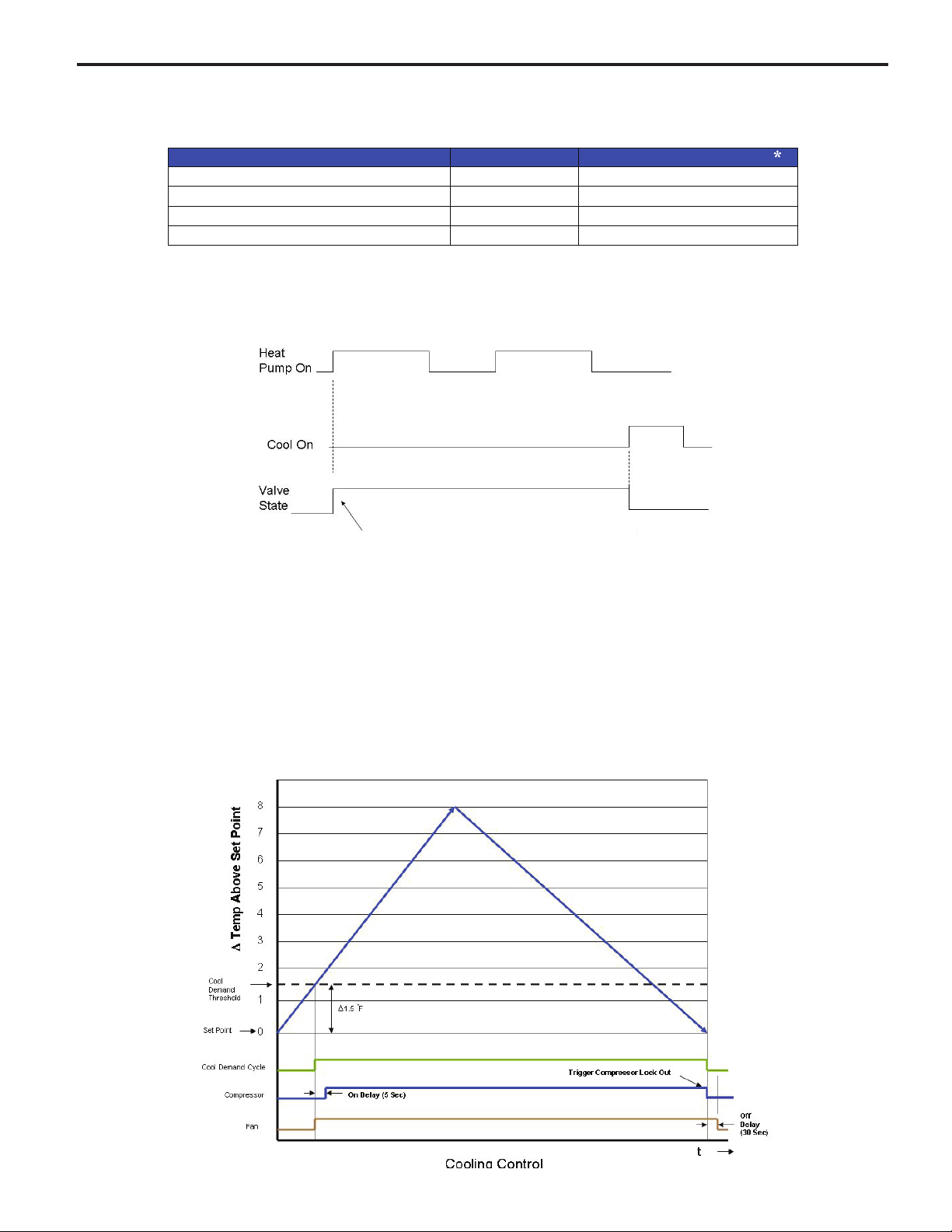

Compressor and Reversing Valve Control

Active Mode Compressor

Cooling De-Energized

Heat - Heat Pump

Heat - Electric

Fan Only

* The Reversing valve stays in the last state until a call for heat or cooling (see gure below)

On

On

Off

Off

Reversing Valve State

Energized

Compressor Operation:

The reversing valve only changes when required

to provide cooling or heat pump. The RV valve

stays in it's last state until required to change.

Cooling Mode

Once the ambient temperature rises past the cool demand threshold (Cool Set Point + 1.5 ˚F) (see gure below), and

the compressor is not locked out, the cooling cycle begins. As shown in the gure below, the fan is started 5 seconds

prior to the compressor. Once the ambient temperature has been lowered to the cool set point (Cool Set Point minus

.25 ˚F), the cooling cycle starts to terminate by shutting off the compressor. After a 30 seconds delay, the fan is shut

off. (See gure below for graphic details)

23

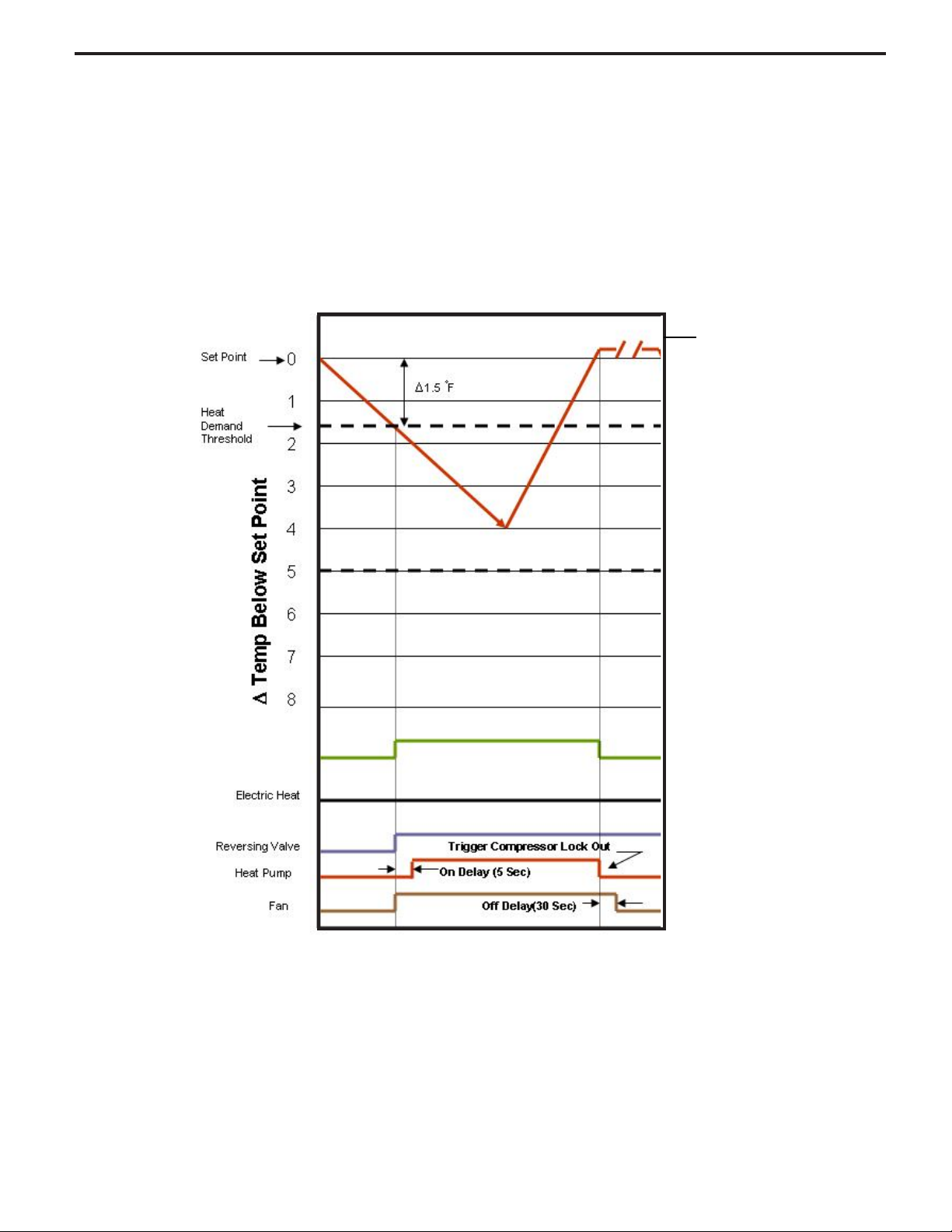

Heating Mode Control Operation

There are two heating methods: Heat Pump and Electric Resistance Heat.

There are 3 types of units that provide heating: Heat Pump Only (Model YS10M10)

Heat Pump with Electric Heat and Cool with Electric Heat.

Heat Control Operation Heat Pump Only Unit (YS10M10 has no electric heat back-up)

Once the ambient temperature falls below the Heating Demand Threshold

(1.5 ˚F Below the Heat Set Point Temperature), the heating cycle begins. The fan is turned on 5 seconds before.

Once the ambient temperature has been raised to the Heat Satised Point (Set point + .25 ˚F), the compressor is

turned off. The fan is turned off 15 seconds later. The gure below illustrates the basic heat pump operation.

Satised Point

Heat Control (Heat Pump Only)

YS10M10 Heat Pump Defrost Cycle Operation

The defrost in this unit is an active reverse cycle. The defrost control runs in the background and determines when a

defrost cycle is required. Once initiated, the defrost cycle runs to completion.

The defrost cycle can only be initiated when the heat pump is in operation. The compressor will not be turned off to

avoid activating the compressor's time delay. The reversing valve will be switched to the cool mode position. The

indoor fan/blower will be turned off. Once the defrost cycle is nished, the system should re-enter a heating demand

cycle if required.

When the heat pump run time is 60 minutes or greater with an outdoor coil temperature of 26F degrees or lower, the

control will run an active defrost for up to 6 minutes. When the temperature at the outdoor coil reaches 54F degrees,

the heat pump heat will resume.

24

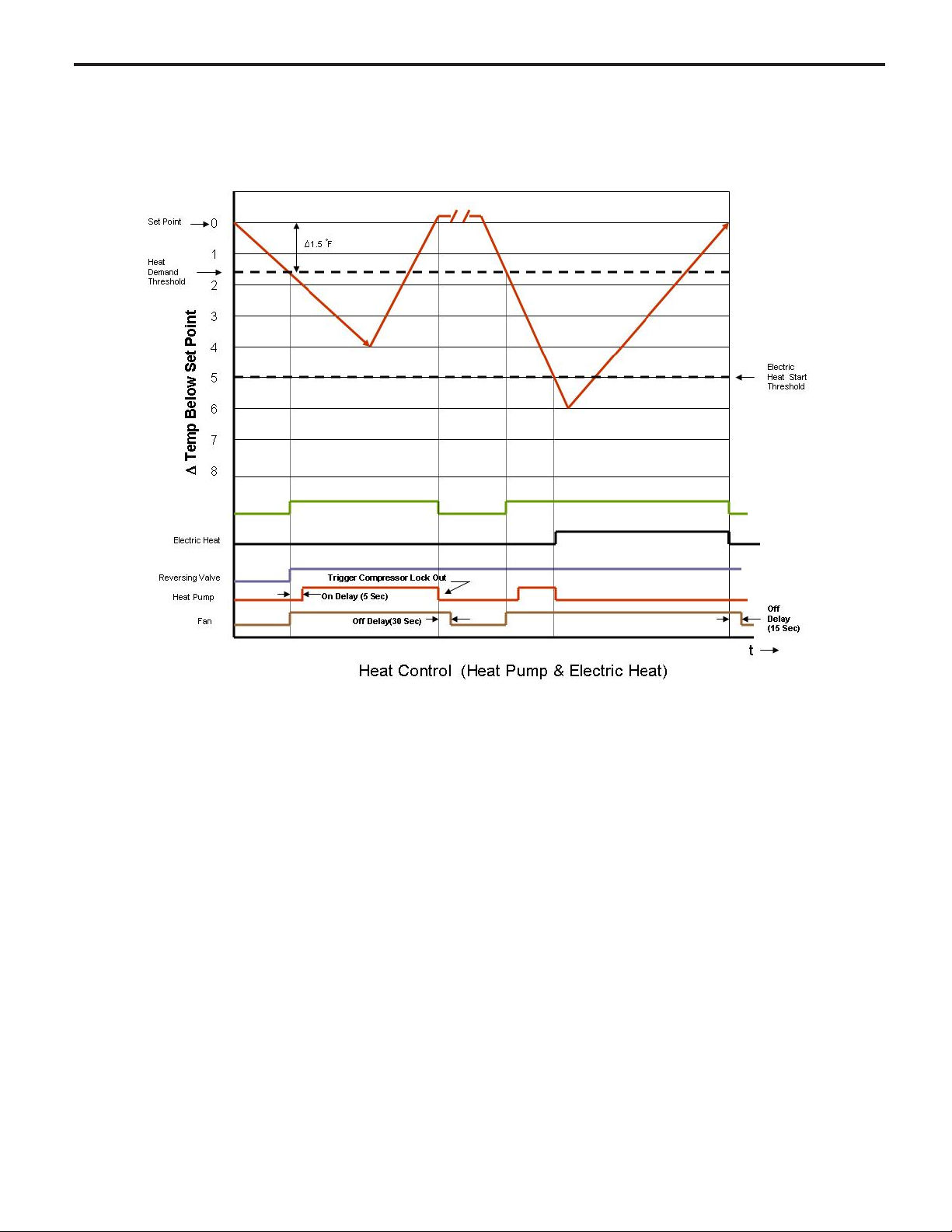

Heat Pump With Electric Heat Operation

This heating is more complex due to the possibility of two heating methods. If the ambient indoor temperature is below the heat demand threshold (1.5˚F below the heat set point temperature), and the compressor is not locked out,

turn on compressor. If the ambient indoor temperature is 0.25˚F above the heat set point turn off the compressor.

If the compressor is locked out & electric heat is available:

1. Turn on the electric heat until the compressor is not locked out.

2. After lockout, turn off the electric heat, wait 5 seconds, then turn on the compressor.

If Electric Heat is Available

After the Heat button is initially pressed, the unit will run the electric heater rst until the initial set point is satised (Hot

Start Feature). After the initial start, the unit will switch to Heat Pump heat and decide between Heat Pump heat and

Electric heat based on the following two monitored conditions:

Condition 1

If the outdoor coil temperature sensor drops to 30 ˚F or less for 2 consecutive minutes, the unit will switch to electric heat

if available. Thereafter, the unit will switch back to Heat Pump heat if the outdoor coil temperature sensor rises to 45 ˚F or

greater.

If Electric Heat is not available (out of order) and the outdoor coil temperature sensor drops to 30 ˚F or less for 2

consecutive minutes, then the compressor and fan will turn off. Thereafter, the unit will switch back to Heat Pump heat if

the outdoor coil temperature rises to 45 ˚F or greater.

25

Heat Pump With Electric Heat Operation (Continued)

Condition 2

If the Δ (delta) (set point temperature minus the ambient indoor temperature) is greater than 5 ˚F, then the unit will switch

to electric heat, if available. The unit will continue to operate with electric heat until the heat demand is satised. Note that

the electric heat switches on after the Δ temp passes 5°F and the heat pump switches off. Also note that the electric heat

will run until the heat demand is satised. When another heat demand cycle is initiated, the heat pump will run unless the Δ

temp is greater than the electric heat threshold.

Automatic Emergency Heat

If the sealed system fails with a bad reversing valve or anything that causes the indoor coil to get colder than the indoor

ambient temperature:

1) If the indoor coil thermistor senses a 5 degree temperature drop as compared to the ambient temperature thermistor

and this lasts up to 5 minutes, the control board will switch the unit to electric heat and continue heating with it.

2) At this point, error code 15 is generated; heat pump failure. Indoor coil temperature lower than indoor ambient

temperature for 5 or more degrees for 5 consecutive minutes.

Note: It is Ok to continue to use the unit with the electric heater until the heat pump is repaired.

Electric Heat Operation in Cool with Electric Heat Units

When in the Heat mode, with and without Fan Mode Auto (Fan cycling):

If the indoor ambient temperature is below the Heat Demand Threshold (Heat Set Point minus 1.5 ˚F), turn on electric heat.

If Ambient is 0.3 ˚F above the Heat Set Point turn off the electric heat.

System Mode Auto

This mode provides automatic change over between cool and heat. The auto mode runs based on the room ambient

temperature vs. the Demand Thresholds. It is only available in Heat-Cool Unit.

Notes:

There is a buffer zone between the cool and heat set points where no heating or cooling is allowed to occur. It is critical

that the Cool Demand Threshold be greater than the Heat Demand Threshold by a minimum of 3° while in the Auto

System Mode. For example, if a user enters a value for the Auto Cooling Set Point that violates the minimum Δ 3° rule, the

Auto Heating Set Point will adjust accordingly.

Automatic Change Over Delay (Cool with Heat Units)

The change over delay ensures that any system heating or cooling over shoot does not trigger an opposite demand cycle.

The change over delay = 15 min. This timer blocks the opposite demand cycle from running until the timer expires. As an

example, if the last demand was a cool cycle, and another cool cycle is requested, the timer will not block the request.

However, if the last demand cycle was a cool cycle, and heat cycle is requested, the timer will block the request until the

change over delay is expired.

26

Compressor Lock Out Time

The lockout feature ensures that the compressor is de-energized for a period of time. The timer varies randomly

from 180 to 240 seconds

The compressor lockout is initiated every time the compressor is “off” due to:

(1) Satisfying the temperature set point

(2) Changing mode to fan only or heat

(3) Turning the unit off

(4) Control is rst plugged in or power is restored after failure

(5) Line power is restored from a brown out condition

Wait ICON (Hour Glass )

The wait icon will be turned on when the compressor is locked out and during demand for cooling or heat pump

compressor operation. The Wait ICON will be turned off when the condition clears.

Cooling Fan Delay

Fan cycle/Auto mode only

When unit cycles cooling ON – starts the fan 5 seconds EARLY. When unit cycles cooling OFF – DELAYS the fan

off for 30 seconds

Note: this fan delay is disabled during Test Mode

Heating Fan Delay

This is only for fan Mode Auto (Fan cycles with cool/heat operation) and not for continuous fan mode. When unit

cycles Heating ON – starts the fan 5 seconds EARLY. When unit cycles Heating OFF – DELAYS the fan off for 15

seconds

Note: the fan delay is disabled during Test Mode

Fan Speed Change Delay

Relay activation is delayed by a minimum number of seconds. The default for this value is 2 seconds and is used to

eliminate relay chatter.

Fan Only System Mode

The fan is turned on and runs at the specied manually set speed.

Only the Fan is turned on. Cool or Heat operation are off.

(This is different than FAN MODE CONTINUOUS where the fan is on with the cool or heat operation).

Fan Only Rules

1. If the SYSTEM FAN ONLY MODE is selected, the Auto fan mode is disabled, and the fan mode is forced to

continuous. In addition, the auto fan speed is disabled. If the user presses the fan speed key, the menu will skip over

the auto selection. The set point temperature display is off.

2. Any fan speed may be manually selected during Fan Only Mode.

27

Fan Operation (Front Panel Mode)

Mode

Heat – Cool – Auto – Fan Only

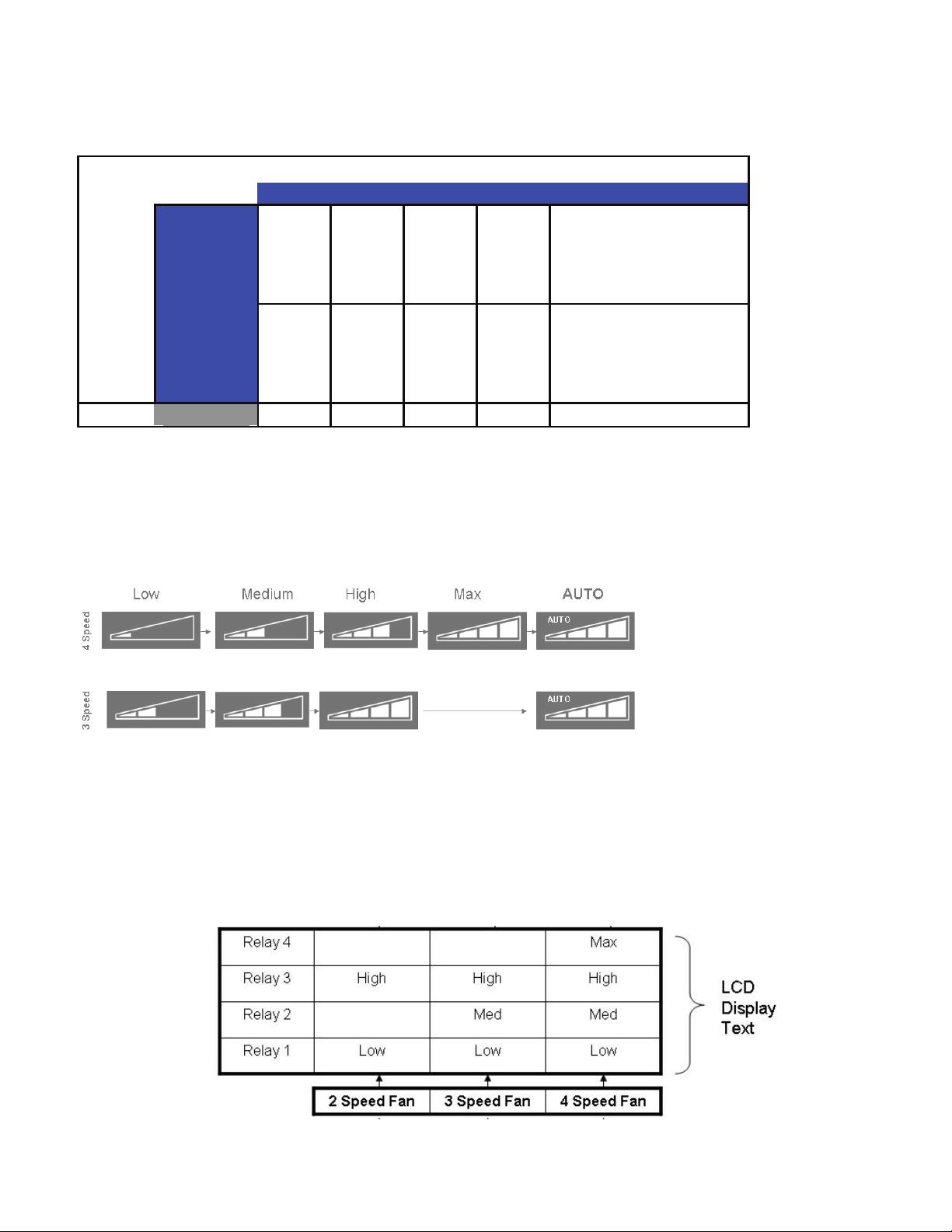

Models starting with SS, SM have 4 speeds. Models with SL, and all Kuhl+ have 3 speeds

Speed Selection

1 2 3 4 AUTO

AUTO Operation, but never

turns Off. Uses cool set point

or heat set point vs. ambient

temperature. When there is

no demand, operate at the

lowest available speed.

AUTO operation turns On or

Off with heat or cool demand

Uses cool set point or heat

set point vs. ambient

temperature

Fan

Continuous

AUTO

Fan Only

"On" " On" "On" " On"

Turns

On or

Off with

heat or

cool

demand

"On" " On" "On" " On" Disabled

Turns

On or

Off with

heat or

cool

demand

Turns

On or

Off with

heat or

cool

demand

Turns

On or

Off with

heat or

cool

demand

Tabl e

Fan ICON Detail

The system may have a 3 or 4 speed fan. The Fan Speed ICON will Display as per the table below.

Note that in the AUTO mode, the speed of the fan will be shown by illuminating the number of bars in the speed triangle.

Fan Relay Operation

Using the

Front Panel

28

Loading...

Loading...