Flowserve ESP3 User Manual

Automax Valve Automation Systems

3-Position Control/Dribble Control

SR Limit Switch Method

Installation, Operation and Maintenance Instructions

Flowserve Corporation |

765 South 100 East |

Phone: 801 373 3028 |

Flow Control Division |

Provo, Utah 84606 |

Facsimile: 801 489 2228 |

Automation Business Unit |

www.flowserve.com |

Email: actuators@flowserve.com |

|

|

|

|

ESP3 Electronic Servo Positioner |

|

Automax electric actuators with servo control are factory adjusted for 90 degree operation and shipped in the full clockwise (CW) position as viewed from the motor side.

WARNING (SEE NOTE 6 ON PAGE 4)

DO NOT CONNECT SHORT CIRCUIT TO MOTOR LEADS WHILE MOTOR IS CONNECTED TO ESP3 - SERIOUS DAMAGE WILL RESULT AND WARRANTY VOIDED.

Specifications

Power |

110-125V, 50/60 Hz |

Requirement* |

5W @ 115 VAC |

Temperature** |

-40° F (-40° C) to 160° F (70° C) |

Approvals |

UL recognized |

|

CSA certified |

Range Of |

30° to 180° rotational span |

Adjustability |

|

|

|

*Options availability for 240 VAC or 12/24 VDC applications.

**Options available for high humidity/outdoor use.

Servo Control Input Options

1.Connect input signal to TB1 terminals marked +IN and -IN (4-20mA configuration is supplied as standard).

Type of |

Signal |

Board Adjustment |

|

Input |

|

|

|

CURRENT |

(250OhmShunt) |

4 to 20 mAdc |

Input Jumper JP1 to the left |

|

|

||

1 to 5 mAdc |

Input Jumper JP1 to the right |

||

|

|

||

10 to 50 mAdc |

Requires special board. |

||

|

|

|

Consult factory. |

|

|

|

|

VOLTAGE |

|

0 to 5 Vdc |

Input Jumper Removed |

|

|

|

|

|

2 to 10 Vdc |

Input Jumper Removed |

|

|

|

|

|

|

1 to 10 Vdc |

Input Jumper Removed |

|

|

|

||

|

|

|

|

RESISTIVE |

(seenotesonp.2) |

1.5 to 135 Ohm |

Requires special board. |

|

Consult factory. |

||

|

|

||

1.5 to 1000 Ohm |

Input Jumper Removed |

||

|

|

||

|

|

|

|

Direct or Reverse Acting

Make sure valve and actuator rotate in the same direction and are in the same position, i.e. valve full CW, actuator full CW. 1. Standard units are direct acting:

Low input (e.g. 4 mA) = CW High input (e.g. 20 mA) = CCW

2.To make reverse acting, place jumpers JP2 and JP3 to ‘R’ positions on ESP3 and proceed with Valve Alignment and Servo Calibration. For reverse action with ESP3 Transmitter, see notes on page 2.

Valve Alignment and Servo Calibration

Note: Standard units are calibrated for 0 to 90 degree operation. Units may be recalibrated for 180 degree operation.

1.Connect 115Vac/60hz power to terminals marked L1, N, and GND. Power should be fused with an in-line 5 amp slowblow fuse. ESP3 may be run on 50hz, but actuator may be affected. See specific actuator I.O.M.

2.Safety overtravel switches disconnect the motor if the actuator overtravels approximately 5 degrees past the full CW or CCW position. On valves with mechanical stops, the safety overtravel switches need to be set so that the motor will not disconnect prior to hitting a mechanical valve stop. See notes 3 and 6 under “Trouble Shooting” on page 4 before adjustment.

3.Minimum Position Adjustment:

•For Direct Acting: Apply minimum input signal to ESP3 terminals +IN and -IN and adjust zero ‘Z’ potentiometer until actuator stops at full CW position and CW LED turns off. Turn the ‘Z’ adjustment CW to move actuator CW.

•For Reverse Acting: Apply minimum input signal to ESP3 terminals +IN and -IN and adjust zero ‘Z’ potentiometer until actuator stops at full CCW position and CCW LED turns off. Turn the ‘Z’ potentiometer CCW to move actuator CW.

4.The voltage at test point ‘A’ referenced to test point ‘G’ should be approximately 0.75 Vdc. If not, see note #4 under “Trouble Shooting”.

5.Maximum Position Adjustment:

•For Direct Acting: Apply maximum input signal to ESP3 and adjust span ‘S’ potentiometer until actuator stops at full CCW position and CCW LED turns off.

•For Reverse Acting: Apply maximum input signal to ESP3 and adjust span ‘S’ potentiometer until actuator stops at full CCW position and CCW LED turns off.

6.Due to Zero-Span interaction, repeat steps 3 and 5 until actuator positions repeat at both ends of travel (usually 2 to 3 times).

LMP0003-1 |

(AUTO-42) |

04/01 |

Page 1 of 4 |

© 2001, Flowserve Corporation, Provo, Utah

Automax Valve Automation Systems

3-Position Control/Dribble Control

SR Limit Switch Method

Installation, Operation and Maintenance Instructions

Flowserve Corporation |

765 South 100 East |

Phone: 801 373 3028 |

Flow Control Division |

Provo, Utah 84606 |

Facsimile: 801 489 2228 |

Automation Business Unit |

www.flowserve.com |

Email: actuators@flowserve.com |

|

|

|

Resistive Inputs (optional)

3 wire: Clockwise rotation of input potentiometer increases signal (increase resistance). Connect potentiometer’s clockwise lead to terminal marked IS. Connect counter-clockwise lead to terminal marked -IN. Connect potentiometer’s wiper lead to terminal marked +IN. Remove JP1 input select jumper.

Note: If clockwise rotation of potentiometer does not rotate actuator in an increasing signal direction, reverse potentiometer leg leads.

RESISTIVE INPUT CONFIGURATIONS

Heater & Thermostat (optional)

1.115 Vac heater and thermostat are connected to TB1 terminals L1 and N on the ESP3 servo board (see Wiring Diagram on page 3).

ESP3 Transmitter (optional)

Note: If the ESP3 Transmitter is used, the servo calibration (p.1) must be completed with the 4-20mA transmitter installed Servo calibration should be performed before transmitter calibration.

1.Connect 4-20mAdc output leads to transmitter terminals marked ‘+’ and ‘-’.

2.Place transmitter JP1 jumpers to positions 1-3 and 2-4 for 90 degree operation,or positions 1-2 and 3-4 for actuators calibrated for 180 degree operation.

3.Drive actuator to the full CCW position and adjust ‘S’ span adjustment for 20mA output.

4.Drive actuator to the CW position and adjust ‘Z’ zero adjustment for 4mA output.

5.Repeat steps 3 and 4 until the desired output is achieved in both positions.

6.Standard ESP3 transmitters are direct acting. A low output signal indicates CW position and high output signal indicates CCW position. For reverse acting see below.

7.The transmitter is self powered and optically isolated from the AC motor drive circuits.

Important Notes About Reverse Acting ESP3 with Transmitter

Note: Reverse acting transmitter means a 4mA output for full CCW, and a 20mA output for full CW position.

1.The BLUE and GREEN feedback potentiometer wires have been reversed on TB1 (see chart below).

2.The feedback potentiometer voltages as measured from test points ‘A’ to ‘G’ on the ESP3 card are as follows:

CCW |

~ |

0 .75 Vdc |

CW |

~ |

4.70 Vdc |

3.JP2 and JP3 (Direct / Reverse acting jumpers) are to be on ‘D’ Direct (left two posts).

4.The RED and BLACK motor drive leads on TB2 have been reversed (see chart below).

5.The drive LED’s will now indicate the opposite of the actual drive travel.

|

Reverse |

Standard |

Wire |

Transmitter |

Transmitter |

|

Position |

Position |

BLUE (Feedback Pot.) |

P1 |

P3 |

|

|

|

GREEN (Feedback Pot.) |

P3 |

P1 |

|

|

|

RED (Motor Drive) |

CW |

CCW |

|

|

|

BLACK (Motor Drive) |

CCW |

CW |

|

|

|

Performance Data (Centura/ESP3)

|

CE2ATA |

CE4ATA |

CE7ATA |

CE1ATA |

LINEARITY |

+/-1% |

+/-1% |

+/-1% |

+/-1% |

RESOLUTION |

2.0° |

1.8° |

1.8° |

1.5° |

DEADBAND |

+/-0.8% |

+/-0.7% |

+/-0.5% |

+/-0.3% |

HYSTERESIS |

+/-1.0% |

+/-0.8% |

+/-0.5% |

+/-0.5% |

|

|

|

|

|

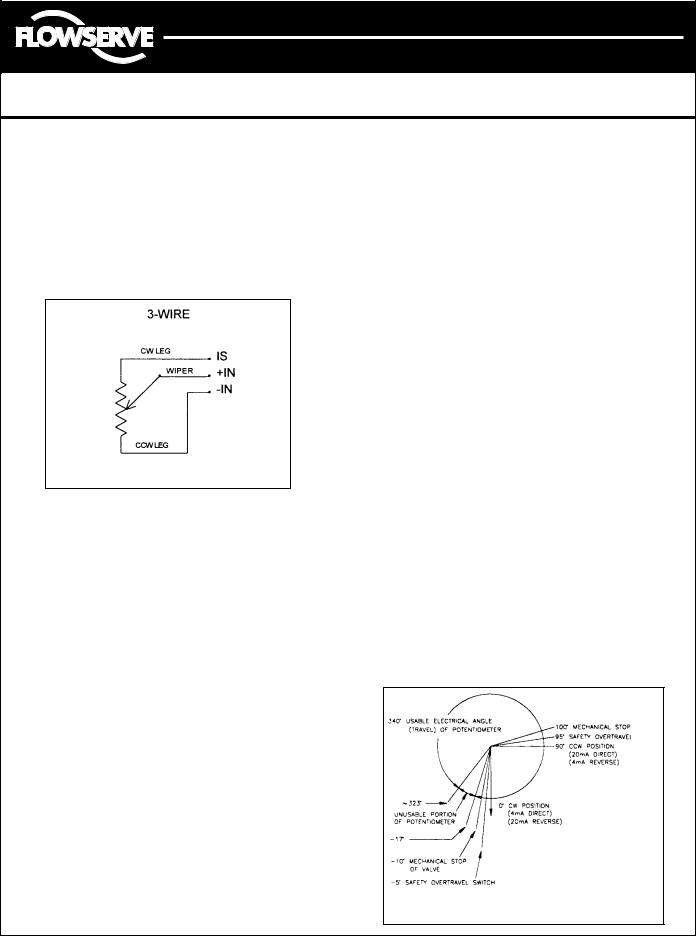

ACTUATOR ANGLE |

FEEDBACK VOLTAGE |

(DEGREES) |

OF POTENTIOMETER |

|

(TPA TO TPG) |

-5° PAST CW |

~0.53 VOLTS |

0° CW POS. |

~0.75 VOLTS |

90° CCW POS. |

~4.70 VOLTS |

ESP3 FEEDBACK POTENTIOMETER

LMP0003-1 |

(AUTO-42) |

04/01 |

Page 2 of 4 |

© 2001, Flowserve Corporation, Provo, Utah

Loading...

Loading...