Festool ETS 150-5 EQ, ETS 150-3 EQ User Manual

ETS 150/3 EQ

ETS 150/5 EQ

Instruction manual |

Eccentric sander |

Page 2 - 6

IMPORTANT: Read and understand all instructions before using.

464 760_004

Guide d’utilisation |

Ponceuse excentrique |

Page 7 - 11

IMPORTANT: Lire et comprendre toutes les instructions avant de démarrer les travaux.

Manual de instrucciones |

Lijadora excéntrica |

Página 12 - 16

IMPORTANTE: Lea y comprende todas las instrucciones antes de usar.

1

GENERAL SAFETY RULES

WARNING! Read and understand all instructions. Failure to follow all instructions listed below, may result in electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS Work area

1Keep your work area clean and well lit.

Cluttered benches and dark areas invite accidents.

2Do not operate power tools in explosive atmospheres, such as in the presence of flammable liquids, gases, or dust. Power tools create sparks which may ignite the dust or fumes.

3Keep bystanders, children, and visitors away while operating a power tool.

Distractions can cause you to lose control.

Electrical safety

4a Grounded tools must be plugged into an outlet properly installed and grounded in accordance with all codes and ordinances. Never remove the grounding prong or modify the plug in any way. Do not use any adapter plugs. Check with a qualified electrician if you are in doubt as to whether the outlet is properly grounded. If the tools should electrically malfunction or break down, grounding provides a low resistance path to carry electricity away from the user.

4b Double insulated tools are equipped with a polarized plug (one blade is wider than the other.) This plug will fit in a polarized outlet only one way. If the plug does not fit fully in the outlet, reverse the plug. If it still does not fit, contact a qualified electrician to install a polarized outlet. Do not change the plug in any way. Double insulation

eliminates the need for the three wire grounded power cord and grounded power supply system.

eliminates the need for the three wire grounded power cord and grounded power supply system.

5Avoid body contact with grounded surfaces such as pipes, radiators, ranges and refrigerators. There is an increased risk of electric shock if your body is grounded.

6Don’t expose power tools to rain or wet conditions. Water entering a power tool will increase the risk of electric shock.

7Do not abuse the cord. Never use the cord to carry the tools or pull the plug from an outlet. Keep cord away from heat, oil, sharp edges or moving parts. Replace damaged cords immediately. Damaged cords increase the risk of electric shock.

8When operating a power tool outside, use an outdoor extension cord marked ”W-

A” or ”W”. These cords are rated for outdoor use and reduce the risk of electric shock.

Personal safety

9 Stay alert, watch what you are doing and use common sense when operating a power tool. Do not use while tired or under the influence of drugs, alcohol, or medication. A moment of inattention while operating power tools may result in serious personal injury.

10 Dress properly. Do not wear loose clothing or jewellery. Contain long hair. Keep your hair, clothing, and gloves away from moving parts. Loose clothes, jewellery, or long hair can be caught in moving parts.

11 Avoid accidental starting. Be sure switch is off before plugging in. Carrying tools with your finger on the switch or plugging in tools that have the switch on invites accidents.

12 Remove adjusting keys or switches before turning the tool on. A wrench or key that is left attached to a rotating part of the tool may result in personal injury.

13Do not overreach. Stand on both feet an keep proper footing and balance at all times. Proper footing and balance enables better control of the tool in unexpected situations.

14Use safety equipment. Always wear eye protection. Dust mask, non-skid safety shoes, hard hat, or hearing protection must be used for

appropriate conditions.

Tool use and care

15 Use clamps or other practical way to secure and support the workpiece to a stable platform. Holding the work by hand or against your body is unstable and may lead to loss of control.

16 Do not force tool. Use the correct tool for your application. The correct tool will do the job better and safer at the rate for which it is designed.

17Do not use tool if switch does not turn it on or off. Any tool that cannot be controlled with the switch is dangerous and must be repaired.

18Disconnect the plug from the power source before making any adjustments, changing accessories, or storing the tool.

Such preventive safety measures reduce the risk of starting the tool accidentally.

19Store idle tools out of reach of children and other untrained persons. Tools are dangerous in the hands of untrained users.

20Maintain tools with care. Keep cutting tools sharp and clean. Properly maintained tools, with sharp cutting edges are less likely to bind and are easier to control.

2

21 Check for misalignment or binding of moving parts, breakage of parts, and any other condition that may affect the tools operation. If damaged, have the tool serviced before using. Many accidents are caused by poorly maintained tools.

22 Use only accessories that are recommended by the manufacturer for your model. Accessories that may be suitable for one tool, may become hazardous when used on another tool.

Service

23Tool service must be performed only by qualified repair personnel. Service or maintenance performed by unqualified personnel could result in a risk of injury.

24When servicing a tool, use only identical replacement parts. Follow instructions in the Maintenance section of this manual. Use of unauthorised parts or failure to follow Maintenance instructions may create a risk of electric shock or injury.

Various dust created by power sanding, sawing, grinding, drilling and other

construction activities contains chemicals known (to the State of California) to cause cancer, birth defects or other reproductive harm. Some examples of these chemicals are: •lead from lead-based paints,

•crystalline silica from bricks and cement and other masonry products, and

•arsenic and chromium from chemicallytreated lumber.

The risk from these exposures varies, depending on how often you do this type of work.

To reduce your exposure to these chemicals: work in a well ventilated area, and work with approved safety equipment, such as dust masks that are specially designed to filter out microscopic particles.

Technical data |

|

ETS 150/3 EQ |

ETS 150/5 EQ |

Wattage |

W |

310 |

310 |

No load speed |

rpm |

6 000 - 10 500 |

6 000 - 10 500 |

No. of strokes |

spm |

12 000 - 21 000 |

12 000 - 21 000 |

Sanding stroke |

mm (in.) |

3.0 (0.12) |

5.0 (0.20) |

Sanding base, Ø |

mm (in.) |

150 (5.9) |

150 (5.9) |

Weight |

kg (lbs) |

1.8 (4.0) |

1.8 (4.0) |

Safety level |

UL 745, CSA C22.2 No. 745 |

||||

|

|

|

|

|

|

|

Symbols |

|

The user bears sole responsibility |

||

V |

Volts |

for any damage or accidents resulting from |

|||

incorrect use. |

|||||

A |

Amperes |

||||

|

|

|

|||

Hz |

Hertz |

|

|

|

|

|

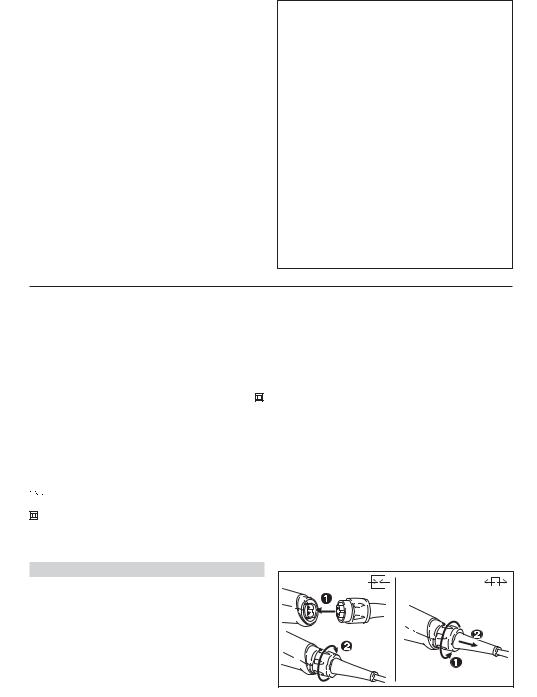

Electrical connection and operation |

||||

W |

Watt |

The mains voltage must correspond with the |

|||

|

Alternating current |

||||

|

voltage on the rating plate! |

||||

n0 |

No load speed |

||||

See the following figure for connection and dis- |

|||||

|

Class II Construction |

||||

|

connection of the power cable. |

||||

rpm |

Revolutions per minute |

||||

|

Always switch the machine off |

||||

spm |

Strokes per minute |

|

|||

Ø |

Diameter |

before connecting or disconnecting the power |

|||

Intended use |

cable! |

|

|

The sanders are designed for sanding wood, |

|

plastic, composite materials, paint / varnish, |

|

filling material and similar materials. |

|

Metal and materials with an asbestos content |

|

must not be processed with these tools. |

|

The machines must not be damp nor operated |

|

in a damp environment for electrical safety |

|

reasons. The machines may only be used for |

|

dry sanding. |

|

3

Switch (2.1) is an on/off switch. For continuous use it can be engaged with the lateral locking button (2.2). Pressing the switch again releases the lock.

Electronic control

The ETS 150/3 EQ, ETS 150/5 EQ has an ELECTRONIC electronic control with which the rotational speed can be varied step-free.

This allows the sanding speed to be adapted to the optimum level according to the material concerned. The speed is set using the rotary control button (2.3).

The numbers on the rotary control button represent approximately the following strokes per minute:

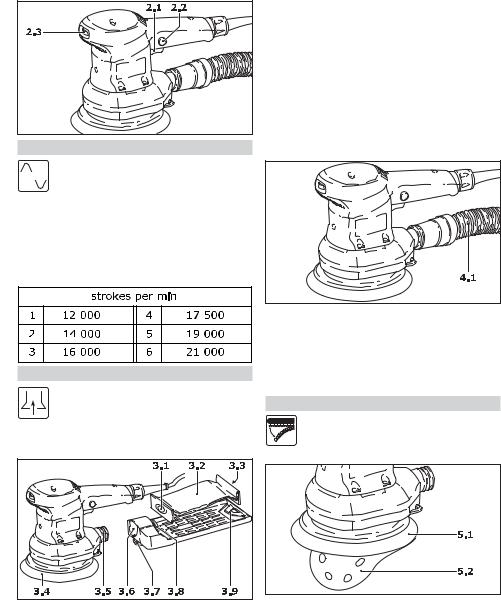

Dust extraction

Dust extractors prevent large accumulations of dust in the air in the working environment and dirt collecting in the workplace.

Inboard extraction

The machines are fitted with inbuilt extraction as standard. The sanding dust is extracted through suction openings in the sanding base (3.4) and trapped in the turbo-filter (3.2).

The turbo-filter has to be changed when it is so full of dust that the extraction power diminishes.

Inserting a turbo-filter

-Push the front cardboard section of the tur- bo-filter with the sealing lip (3.1) onto the extraction nozzle (3.8) of the filter holder

-Insert rear cardboard section with slot (3.3) onto the retaining strip (3.9) of the filter holder

-Push the filter holder with its opening (3.6) as far as it will go onto the extraction nozzle (3.5) of the machine and clamp tight by turning rotary knob (3.7).

External extraction by an extraction unit

In order to avoid frequent changing of the tur- bo-filter when carrying longer sanding jobs, it is possible to connect a Festool extractor to the unit instead of using inbuilt extraction.

In this case, the extraction pipe (Ø 27 mm (4.1)) of the extraction unit is connected to the suction nozzle.

Attaching sanding material

The appropriate Stickfix sanding paper and Stickfix sanding felt can be fastened quickly and easily onto the Stickfix sanding base.

The self-adhesive sanding material (5.2) is simply pressed onto the sanding base (5.1) and held safely in place by the Stickfix sanding base velcro surface.

4

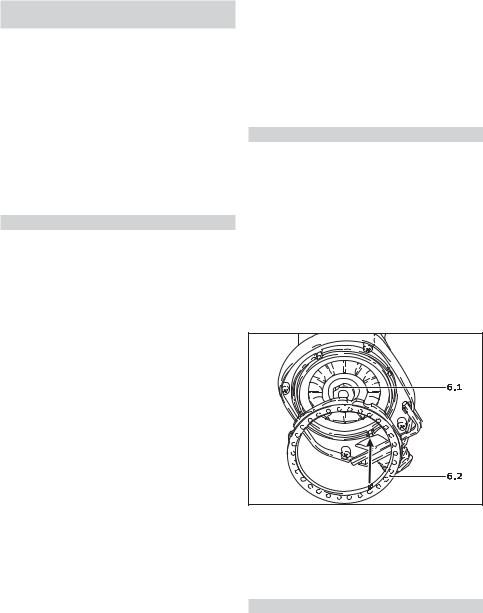

Choice and installation of the grinding disks

The appliance can be fitted with three grinding disks (5.1) of different hardness depending on the surface to be treated.

-Hard: coarse grinding on surfaces, grinding at edges.

-Soft: universal for coarse and fine grinding, for flat and curved surfaces.

-Super-soft: fine grinding on formed parts, curves, radii. Do not use on edges!

The grinding disks and the tool-holding fixture on the appliance are equipped with a positive holder (6.1).

Make sure the grinding disk is correctly positioned before screwing it tight.

Make sure the grinding disk is correctly positioned before screwing it tight.

Working with the machine

Never overload the tool by using too much pressure! The best sanding results

are achieved when applying moderate pressure.

The ETS 150/3 EQ gives the best surface quality and low abrasion. The ETS 150/5 EQ provides high abrasion with good surface quality. The sanding performance and quality depend mainly on the choice of the right sanding material. Festool offers the appropriate sanding material for all applications (see Festool catalogue or on the Internet under "www.festool.com").

We recommend the following settings on the rotary control (2.3) for electronic machines:

5 - 6

-sanding with max. drive

-sanding old paint

-sanding wood and veneer prior to painting

-interim sanding of paint on surfaces

4 - 5

-sanding of thinly applied primer

-sanding of wood with sanding vlies

-sanding edges on wooden parts

-smoothing primed wooden surfaces.

3 - 4

-sanding full wooden and veneer edges

-sanding in the grooves/rebates of windows and doors

-interim paint sanding on edges

-pre-sanding natural wood windows with sanding vlies

-smoothing wood surfaces with sanding felt prior to staining

-rubbing down stained surfaces with sanding vlies

-rubbing down or removing excess lime paste with sanding vlies

2 - 3

-interim paint sanding on stained surfaces

-cleaning natural wood window grooves with sanding felt

1 - 2

-sanding stained edges

-sanding thermoplastic synthetics

Maintenance and care

Any maintenance or repair work requiring the motor housing to be opened may

only be carried out by an authorised service workshop. Maintenance or repair work carried out by an unauthorised person can lead to the wrong connection of the power leads or other components, which in turn can lead to accidents with serious consequences.

Always remove the plug from the mains supply socket before carrying out any

work on the machine!

Always keep the machine and the ventilation slots clean.

Sanding base brakes

The sanding base is braked by a collar (6.2) in order to prevent any uncontrolled excessive speed of the sanding base. Because the collar wears down in the course of time, it has to be replaced by a new one (order no. 453 388) as soon as there is any reduction in the braking effect.

Accessories, tools

For safety reasons, only use original Festool accessories and tools!

For safety reasons, only use original Festool accessories and tools!

The accessory and tool order number can be found in the Festool catalogue or on the Internet under “www.festool-usa.com”.

5

Loading...

Loading...