Page 1

< > !

R-30+A/R-30+A Mate/R-30+B CONTROLLER

EtherNet/IP

OPERATOR'S MANUAL

B-82854EN/02

Page 2

• Original Instructions

Before using the Robot, be sure to read the "FANUC Robot Safety Manual (B-80687EN)" and

understand the content.

• No part of this manual may be reproduced in any form.

• All specifications and designs are subject to change without notice.

The products in this manual are controlled based on Japan’s “Foreign Exchange and

Foreign Trade Law”. The export from Japan may be subject to an export license by the

government of Japan.

Further, re-export to another country may be subject to the license of the government of

the country from where the product is re-exported. Furthermore, the product may also be

controlled by re-export regulations of the United States government.

Should you wish to export or re-export these products, please contact FANUC for advice.

In this manual we have tried as much as possible to describe all the various matters.

However, we cannot describe all the matters which must not be done, or which cannot be

done, because there are so many possibilities.

Therefore, matters which are not especially described as possible in this manual should be

regarded as ”impossible”.

Page 3

B-82854EN/02 SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

Thank you for purchasing FANUC Robot.

This chapter describes the precautions which must be observed to ensure the safe use of the robot.

Before attempting to use the robot, be sure to read this chapter thoroughly.

Before using the functions related to robot operation, read the relevant operator's manual to become

familiar with those functions.

If any description in this chapter differs from that in the other part of this manual, the description given in

this chapter shall take precedence.

For the safety of the operator and the system, follow all safety precautions when operating a robot and its

peripheral devices installed in a work cell.

In addition, refer to the “FANUC Robot SAFETY HANDBOOK (B-80687EN)”.

1 WORKING PERSON

The personnel can be classified as follows.

Operator:

Turns robot controller power ON/OFF

•

Starts robot program from operator’s panel

•

Programmer or teaching operator:

Operates the robot

•

Teaches robot inside the safety fence

•

Maintenance engineer:

Operates the robot

•

Teaches robot inside the safety fence

•

Maintenance (adjustment, replacement)

•

- An operator cannot work inside the safety fence.

- A programmer, teaching operator, and maintenance engineer can work inside the safety fence. The

working activities inside the safety fence include lifting, setting, teaching, adjusting, maintenance,

etc.

- To work inside the fence, the person must be trained on proper robot operation.

During the operation, programming, and maintenance of your robotic system, the programmer, teaching

operator, and maintenance engineer should take additional care of their safety by using the following

safety precautions.

- Use adequate clothing or uniforms during system operation

- Wear safety shoes

- Use helmet

s-1

Page 4

SAFETY PRECAUTIONS B-82854EN/02

2 DEFINITION OF WARNING, CAUTION AND

NOTE

To ensure the safety of user and prevent damage to the machine, this manual indicates each precaution on

safety with "Warning" or "Caution" according to its severity. Supplementary information is indicated by

"Note". Read the contents of each "Warning", "Caution" and "Note" before attempting to use the

oscillator.

WARNING

Applied when there is a danger of the user being injured or when there is a

danger of both the user being injured and the equipment being damaged if the

approved procedure is not observed.

CAUTION

Applied when there is a danger of the equipment being damaged, if the

approved procedure is not observed.

NOTE

Notes are used to indicate supplementary information other than Warnings and

Cautions.

• Read this manual carefully, and store it in a sales place.

3 WORKING PERSON SAFETY

Working person safety is the primary safety consideration. Because it is very dangerous to enter the

operating space of the robot during automatic operation, adequate safety precautions must be observed.

The following lists the general safety precautions. Careful consideration must be made to ensure

working person safety.

(1) Have the robot system working persons attend the training courses held by FANUC.

FANUC provides various training courses. Contact our sales office for details.

(2) Even when the robot is stationary, it is possible that the robot is still in a ready to move state, and is

waiting for a signal. In this state, the robot is regarded as still in motion. To ensure working

person safety, provide the system with an alarm to indicate visually or aurally that the robot is in

motion.

(3) Install a safety fence with a gate so that no working person can enter the work area without passing

through the gate. Install an interlocking device, a safety plug, and so forth in the safety gate so that

the robot is stopped as the safety gate is opened.

The controller is designed to receive this interlocking signal of the door switch. When the gate

is opened and this signal received, the controller stops the robot (Please refer to "STOP

TYPE OF ROBOT" in SAFETY PRECAUTIONS for detail of stop type). For connection, see

Fig.3 (a) and Fig.3 (b).

s-2

Page 5

B-82854EN/02 SAFETY PRECAUTIONS

(4) Provide the peripheral devices with appropriate grounding (Class A, Class B, Class C, and Class D).

(5) Try to install the peripheral devices outside the work area.

(6) Draw an outline on the floor, clearly indicating the range of the robot motion, including the tools

such as a hand.

(7) Install a mat switch or photoelectric switch on the floor with an interlock to a visual or aural alarm

that stops the robot when a working person enters the work area.

(8) If necessary, install a safety lock so that no one except the working person in charge can turn on the

power of the robot.

The circuit breaker installed in the controller is designed to disable anyone from turning it on

when it is locked with a padlock.

(9) When adjusting each peripheral device independently, be sure to turn off the power of the robot

(10) Operators should be ungloved while manipulating the operator’s panel or teach pendant. Operation

with gloved fingers could cause an operation error.

(11) Programs, system variables, and other information can be saved on memory card or USB memories.

Be sure to save the data periodically in case the data is lost in an accident.

(12) The robot should be transported and installed by accurately following the procedures recommended

by FANUC. Wrong transportation or installation may cause the robot to fall, resulting in severe

injury to workers.

(13) In the first operation of the robot after installation, the operation should be restricted to low speeds.

Then, the speed should be gradually increased to check the operation of the robot.

(14) Before the robot is started, it should be checked that no one is in the area of the safety fence. At the

same time, a check must be made to ensure that there is no risk of hazardous situations. If detected,

such a situation should be eliminated before the operation.

(15) When the robot is used, the following precautions should be taken. Otherwise, the robot and

peripheral equipment can be adversely affected, or workers can be severely injured.

- Avoid using the robot in a flammable environment.

- Avoid using the robot in an explosive environment.

- Avoid using the robot in an environment full of radiation.

- Avoid using the robot under water or at high humidity.

- Avoid using the robot to carry a person or animal.

- Avoid using the robot as a stepladder. (Never climb up on or hang from the robot.)

(16) When connecting the peripheral devices related to stop(safety fence etc.) and each signal (external

emergency , fence etc.) of robot. be sure to confirm the stop movement and do not take the wrong

connection.

(17) When preparing trestle, please consider security for installation and maintenance work in high place

according to Fig.3 (c). Please consider footstep and safety bolt mounting position.

s-3

Page 6

SAFETY PRECAUTIONS B-82854EN/02

RP1

Pulsecoder

RI/RO,XHBK,XROT

RM1

Motor power/brake

EARTH

Dual chain

Single chain

Safety fence

Interlocking device and safety plug that are activated if the

gate is opened.

Fig. 3 (a) Safety fence and safety gate

Emergency stop board

Panel board

or Panel board

EAS1

EAS11

EAS2

EAS21

Panel board

FENCE1

FENCE2

(Note)

(Note)

In case of R-30iB

In case of R-30iA

Terminals EAS1,EAS11,EAS2,EAS21 are provided on the

Terminals EAS1,EAS11,EAS2,EAS21 or FENCE1,FENCE2

emergency stop board.

are provided on the operation box or on the terminal block

of the printed circuit board.

In case R-30iA

In case of R-30iA Mate

Terminals EAS1,EAS11,EAS2,EAS21 are provided on the

Terminals EAS1,EAS11,EAS2,EAS21 are provided

emergency stop board or connector panel

on the emergency stop board or connector panel.

(in case of Open air type)

In case R-30iA Mate

Terminals EAS1,EAS11,EAS2,EAS21 or FENCE1,FENCE2

Termianls FENCE1,FENCE2 are provided

on the emergency stop board.

are provided on the emergency stop board or in the connector

panel of CRM65 (Open air type).

Refer to controller maintenance manual for details.

Refer to the ELECTRICAL CONNCETIONS Chapter

of CONNECTION of controller maintenance manual for details.

Fig. 3 (b) Limit switch circuit diagram of the safety fence

s-4

Page 7

B-82854EN/02 SAFETY PRECAUTIONS

Hook for safety belt

Fence

Steps

Trestle

Footstep

for maintenance

Fig.3 (c) Footstep for maintenance

3.1 OPERATOR SAFETY

The operator is a person who operates the robot system. In this sense, a worker who operates the teach

pendant is also an operator. However, this section does not apply to teach pendant operators.

(1) If you do not have to operate the robot, turn off the power of the robot controller or press the

EMERGENCY STOP button, and then proceed with necessary work.

(2) Operate the robot system at a location outside of the safety fence

(3) Install a safety fence with a safety gate to prevent any worker other than the operator from entering

the work area unexpectedly and to prevent the worker from entering a dangerous area.

(4) Install an EMERGENCY STOP button within the operator’s reach.

The robot controller is designed to be connected to an external EMERGENCY STOP button.

With this connection, the controller stops the robot operation (Please refer to "STOP TYPE

OF ROBOT" in SAFETY PRECAUTIONS for detail of stop type), when the external

EMERGENCY STOP button is pressed. See the diagram below for connection.

Dual chain

External stop button

Single chain

External stop button

Emergency stop board

Panel board

or Panel board

EES1

EES11

EES2

EES21

Panel board

EMGIN1

EMGIN2

Fig.3.1 Connection diagram for external emergency stop button

(Note)

Connect EES1 and EES11, EES2 and EES21 or EMGIN1

and EMGIN2

(Note)

In case R-30iB

Connect EES1and EES11,EES2 and EES21or EMGIN1and EMGIN2.

EES1,EES11,EES2,EES21 are on the emergency stop board

In case of R-30iA

EES1,EES11,EES2,EES21 or EMGIN1,EMGIN2 are on the panel board.

In case R-30iA

EES1,EES11,EES2,EES21 or EMGIN1, EMGIN2 are on the

In case of R-30iA Mate

panel board.

EES1,EES11,EES2,EES21 are on the emergency stop board

or connector panel (in case of Open air type).

EMGIN1,EMGIN2 are on the emergency stop board.

In case R-30iA Mate

Terminals EAS1,EAS11,EAS2,EAS21 or FENCE1,FENCE2

Refer to the maintenance manual of the controller for details.

are provided on the emergency stop board or in the connector

panel of CRM65 (Open air type).

Refer to the ELECTRICAL CONNCETIONS Chapter

of CONNECTION of controller maintenance manual for details.

s-5

Page 8

SAFETY PRECAUTIONS B-82854EN/02

3.2 SAFETY OF THE PROGRAMMER

While teaching the robot, the operator must enter the work area of the robot. The operator must ensure

the safety of the teach pendant operator especially.

(1) Unless it is specifically necessary to enter the robot work area, carry out all tasks outside the area.

(2) Before teaching the robot, check that the robot and its peripheral devices are all in the normal

operating condition.

(3) If it is inevitable to enter the robot work area to teach the robot, check the locations, settings, and

other conditions of the safety devices (such as the EMERGENCY STOP button, the DEADMAN

switch on the teach pendant) before entering the area.

(4) The programmer must be extremely careful not to let anyone else enter the robot work area.

(5) Programming should be done outside the area of the safety fence as far as possible. If programming

needs to be done in the area of the safety fence, the programmer should take the following

precautions:

- Before entering the area of the safety fence, ensure that there is no risk of dangerous situations

in the area.

- Be prepared to press the emergency stop button whenever necessary.

- Robot motions should be made at low speeds.

- Before starting programming, check the entire system status to ensure that no remote instruction

to the peripheral equipment or motion would be dangerous to the user.

Our operator panel is provided with an emergency stop button and a key switch (mode switch) for selecting the

automatic operation mode (AUTO) and the teach modes (T1 and T2). Before entering the inside of the safety

fence for the purpose of teaching, set the switch to a teach mode, remove the key from the mode switch to prevent

other people from changing the operation mode carelessly, then open the safety gate. If the safety gate is opened

with the automatic operation mode set, the robot stops (Please refer to "STOP TYPE OF ROBOT" in SAFETY

PRECAUTIONS for detail of stop type). After the switch is set to a teach mode, the safety gate is disabled. The

programmer should understand that the safety gate is disabled and is responsible for keeping other people from

entering the inside of the safety fence. (In case of R-30iA Mate Controller standard specification, there is no mode

switch. The automatic operation mode and the teach mode is selected by teach pendant enable switch.)

Our teach pendant is provided with a DEADMAN switch as well as an emergency stop button. These button and

switch function as follows:

(1) Emergency stop button: Causes an emergency stop (Please refer to "STOP TYPE OF ROBOT" in SAFETY

PRECAUTIONS for detail of stop type) when pressed.

(2) DEADMAN switch: Functions differently depending on the teach pendant enable/disable switch setting

status.

(a) Disable: The DEADMAN switch is disabled.

(b) Enable: Servo power is turned off when the operator releases the DEADMAN switch or when the

operator presses the switch strongly.

Note) The DEADMAN switch is provided to stop the robot when the operator releases the teach pendant or

presses the pendant strongly in case of emergency. The R-30iB/R-30iA/ R-30iA Mate employs a

3-position DEADMAN switch, which allows the robot to operate when the 3-position DEADMAN switch is

pressed to its intermediate point. When the operator releases the DEADMAN switch or presses the

switch strongly, the robot stops immediately.

The operator’s intention of starting teaching is determined by the controller through the dual operation of setting the

teach pendant enable/disable switch to the enable position and pressing the DEADMAN switch. The operator

should make sure that the robot could operate in such conditions and be responsible in carrying out tasks safely.

Based on the risk assessment by FANUC, number of operation of DEADMAN SW should not exceed about 10000

times per year.

s-6

Page 9

B-82854EN/02 SAFETY PRECAUTIONS

The teach pendant, operator panel, and peripheral device interface send each robot start signal. However the

validity of each signal changes as follows depending on the mode switch and the DEADMAN switch of the operator

panel, the teach pendant enable switch and the remote condition on the software.

In case of R-30iB/R-30iA controller or CE or RIA specification of R-30iA Mate controller

Mode

AUTO

mode

T1, T2

mode

T1,T2 mode: DEADMAN switch is effective.

Teach pendant enable switch Software remote condition Teach pendant Peripheral device

Teach pendant

enable switch

On

Off

On

Off

In case of standard specification of R-30iA Mate controller

On Ignored Allowed to start Not allowed

Software

remote

condition

Local Not allowed Not allowed Not allowed

Remote Not allowed Not allowed Not allowed

Local Not allowed Allowed to start Not allowed

Remote Not allowed Not allowed Allowed to start

Local Allowed to start Not allowed Not allowed

Remote Allowed to start Not allowed Not allowed

Local Not allowed Not allowed Not allowed

Remote Not allowed Not allowed Not allowed

Teach pendant Operator panel Peripheral device

Local Not allowed Not allowed Off

Remote Not allowed Allowed to start

(6) (Only when R-30iB/R-30iA Controller or CE or RIA specification of R-30iA Mate controller is

selected.) To start the system using the operator’s panel, make certain that nobody is the robot work

area and that there are no abnormal conditions in the robot work area.

(7) When a program is completed, be sure to carry out a test operation according to the procedure

below.

(a) Run the program for at least one operation cycle in the single step mode at low speed.

(b) Run the program for at least one operation cycle in the continuous operation mode at low

speed.

(c) Run the program for one operation cycle in the continuous operation mode at the intermediate

speed and check that no abnormalities occur due to a delay in timing.

(d) Run the program for one operation cycle in the continuous operation mode at the normal

operating speed and check that the system operates automatically without trouble.

(e) After checking the completeness of the program through the test operation above, execute it in

the automatic operation mode.

(8) While operating the system in the automatic operation mode, the teach pendant operator should

leave the robot work area.

3.3 SAFETY OF THE MAINTENANCE ENGINEER

For the safety of maintenance engineer personnel, pay utmost attention to the following.

(1) During operation, never enter the robot work area.

(2) A hazardous situation may arise when the robot or the system, are kept with their power-on during

maintenance operations. Therefore, for any maintenance operation, the robot and the system should

be put into the power-off state. If necessary, a lock should be in place in order to prevent any other

person from turning on the robot and/or the system. In case maintenance needs to be executed in the

power-on state, the emergency stop button must be pressed.

(3) If it becomes necessary to enter the robot operation range while the power is on, press the

emergency stop button on the operator panel, or the teach pendant before entering the range. The

s-7

Page 10

SAFETY PRECAUTIONS B-82854EN/02

maintenance personnel must indicate that maintenance work is in progress and be careful not to

allow other people to operate the robot carelessly.

(4) When entering the area enclosed by the safety fence, the maintenance worker must check the entire

system in order to make sure no dangerous situations exist. In case the worker needs to enter the

safety area whilst a dangerous situation exists, extreme care must be taken, and entire system status

must be carefully monitored.

(5) Before the maintenance of the pneumatic system is started, the supply pressure should be shut off

and the pressure in the piping should be reduced to zero.

(6) Before the start of teaching, check that the robot and its peripheral devices are all in the normal

operating condition.

(7) Do not operate the robot in the automatic mode while anybody is in the robot work area.

(8) When you maintain the robot alongside a wall or instrument, or when multiple workers are working

nearby, make certain that their escape path is not obstructed.

(9) When a tool is mounted on the robot, or when any moving device other than the robot is installed,

such as belt conveyor, pay careful attention to its motion.

(10) If necessary, have a worker who is familiar with the robot system stand beside the operator panel

and observe the work being performed. If any danger arises, the worker should be ready to press

the EMERGENCY STOP button at any time.

(11) When replacing a part, please contact FANUC service center. If a wrong procedure is followed, an

accident may occur, causing damage to the robot and injury to the worker.

(12) When replacing or reinstalling components, take care to prevent foreign material from entering the

system.

(13) When handling each unit or printed circuit board in the controller during inspection, turn off the

circuit breaker to protect against electric shock.

If there are two cabinets, turn off the both circuit breaker.

(14) A part should be replaced with a part recommended by FANUC. If other parts are used, malfunction

or damage would occur. Especially, a fuse that is not recommended by FANUC should not be used.

Such a fuse may cause a fire.

(15) When restarting the robot system after completing maintenance work, make sure in advance that

there is no person in the work area and that the robot and the peripheral devices are not abnormal.

(16) When a motor or brake is removed, the robot arm should be supported with a crane or other

equipment beforehand so that the arm would not fall during the removal.

(17) Whenever grease is spilled on the floor, it should be removed as quickly as possible to prevent

dangerous falls.

(18) The following parts are heated. If a maintenance worker needs to touch such a part in the heated

state, the worker should wear heat-resistant gloves or use other protective tools.

- Servo motor

- Inside the controller

- Reducer

- Gearbox

- Wrist unit

(19) Maintenance should be done under suitable light. Care must be taken that the light would not cause

any danger.

(20) When a motor, reducer, or other heavy load is handled, a crane or other equipment should be used to

protect maintenance workers from excessive load. Otherwise, the maintenance workers would be

severely injured.

(21) The robot should not be stepped on or climbed up during maintenance. If it is attempted, the robot

would be adversely affected. In addition, a misstep can cause injury to the worker.

When perform

(22)

ing maintenance work in high place, secure a footstep and wear safety belt.

(23) After the maintenance is completed, spilled oil or water and metal chips should be removed from the

floor around the robot and within the safety fence.

(24) When a part is replaced, all bolts and other related components should put back into their original

places. A careful check must be given to ensure that no components are missing or left not mounted.

(25) In case robot motion is required during maintenance, the following precautions should be taken :

s-8

Page 11

B-82854EN/02 SAFETY PRECAUTIONS

- Foresee an escape route. And during the maintenance motion itself, monitor continuously the

whole system so that your escape route will not become blocked by the robot, or by peripheral

equipment.

- Always pay attention to potentially dangerous situations, and be prepared to press the emergency

stop button whenever necessary.

(26) The robot should be periodically inspected. (Refer to the robot mechanical manual and controller

maintenance manual.) A failure to do the periodical inspection can adversely affect the performance

or service life of the robot and may cause an accident

(27) After a part is replaced, a test operation should be given for the robot according to a predetermined

method. (See TESTING section of “Controller operator’s manual”.) During the test operation, the

maintenance staff should work outside the safety fence.

4 SAFETY OF THE TOOLS AND

PERIPHERAL DEVICES

4.1 PRECAUTIONS IN PROGRAMMING

(1) Use a limit switch or other sensor to detect a dangerous condition and, if necessary, design the

program to stop the robot when the sensor signal is received.

(2) Design the program to stop the robot when an abnormal condition occurs in any other robots or

peripheral devices, even though the robot itself is normal.

(3) For a system in which the robot and its peripheral devices are in synchronous motion, particular care

must be taken in programming so that they do not interfere with each other.

(4) Provide a suitable interface between the robot and its peripheral devices so that the robot can detect

the states of all devices in the system and can be stopped according to the states.

4.2 PRECAUTIONS FOR MECHANISM

(1) Keep the component cells of the robot system clean, and operate the robot in an environment free of

grease, water, and dust.

(2) Don’t use unconfirmed liquid for cutting fluid and cleaning fluid.

(3) Employ a limit switch or mechanical stopper to limit the robot motion so that the robot or cable does

not strike against its peripheral devices or tools.

(4) Observe the following precautions about the mechanical unit cables. When theses attentions are not

kept, unexpected troubles might occur.

• Use mechanical unit cable that have required user interface.

• Don’t add user cable or hose to inside of mechanical unit.

• Please do not obstruct the movement of the mechanical unit cable when cables are added to

outside of mechanical unit.

• In the case of the model that a cable is exposed, Please do not perform remodeling (Adding a

protective cover and fix an outside cable more) obstructing the behavior of the outcrop of the

cable.

• Please do not interfere with the other parts of mechanical unit when install equipments in the

robot.

(5) The frequent power-off stop for the robot during operation causes the trouble of the robot. Please

avoid the system construction that power-off stop would be operated routinely. (Refer to bad case

example.) Please execute power-off stop after reducing the speed of the robot and stopping it by

hold stop or cycle stop when it is not urgent. (Please refer to "STOP TYPE OF ROBOT" in

SAFETY PRECAUTIONS for detail of stop type.)

(Bad case example)

s-9

Page 12

SAFETY PRECAUTIONS B-82854EN/02

• Whenever poor product is generated, a line stops by emergency stop.

• When alteration was necessary, safety switch is operated by opening safety fence and

power-off stop is executed for the robot during operation.

• An operator pushes the emergency stop button frequently, and a line stops.

• An area sensor or a mat switch connected to safety signal operate routinely and power-off stop

is executed for the robot.

(6) Robot stops urgently when collision detection alarm (SRVO-050) etc. occurs. The frequent urgent

stop by alarm causes the trouble of the robot, too. So remove the causes of the alarm.

5 SAFETY OF THE ROBOT MECHANISM

5.1 PRECAUTIONS IN OPERATION

(1) When operating the robot in the jog mode, set it at an appropriate speed so that the operator can

manage the robot in any eventuality.

(2) Before pressing the jog key, be sure you know in advance what motion the robot will perform in the

jog mode.

5.2 PRECAUTIONS IN PROGRAMMING

(1) When the work areas of robots overlap, make certain that the motions of the robots do not interfere

with each other.

(2) Be sure to specify the predetermined work origin in a motion program for the robot and program the

motion so that it starts from the origin and terminates at the origin.

Make it possible for the operator to easily distinguish at a glance that the robot motion has

terminated.

5.3 PRECAUTIONS FOR MECHANISMS

(1) Keep the work areas of the robot clean, and operate the robot in an environment free of grease, water,

and dust.

5.4 PROCEDURE TO MOVE ARM WITHOUT DRIVE POWER

IN EMERGENCY OR ABNORMAL SITUATIONS

For emergency or abnormal situations (e.g. persons trapped in or by the robot), brake release unit can be

used to move the robot axes without drive power.

Please refer to controller maintenance manual and mechanical unit operator’s manual for using method of

brake release unit and method of supporting robot.

s-10

Page 13

B-82854EN/02 SAFETY PRECAUTIONS

6 SAFETY OF THE END EFFECTOR

6.1 PRECAUTIONS IN PROGRAMMING

(1) To control the pneumatic, hydraulic and electric actuators, carefully consider the necessary time

delay after issuing each control command up to actual motion and ensure safe control.

(2) Provide the end effector with a limit switch, and control the robot system by monitoring the state of

the end effector.

7 STOP TYPE OF ROBOT

The following three robot stop types exist:

Power-Off Stop (Category 0 following IEC 60204-1)

Servo power is turned off and the robot stops immediately. Servo power is turned off when the robot is

moving, and the motion path of the deceleration is uncontrolled.

The following processing is performed at Power-Off stop.

- An alarm is generated and servo power is turned off.

- The robot operation is stopped immediately. Execution of the program is paused.

Controlled stop (Category 1 following IEC 60204-1)

The robot is decelerated until it stops, and servo power is turned off.

The following processing is performed at Controlled stop.

- The alarm "SRVO-199 Controlled stop" occurs along with a decelerated stop. Execution of the

program is paused.

- An alarm is generated and servo power is turned off.

Hold (Category 2 following IEC 60204-1)

The robot is decelerated until it stops, and servo power remains on.

The following processing is performed at Hold.

- The robot operation is decelerated until it stops. Execution of the program is paused.

WARNING

The stopping distance and stopping time of Controlled stop are longer than the

stopping distance and stopping time of Power-Off stop. A risk assessment for

the whole robot system, which takes into consideration the increased stopping

distance and stopping time, is necessary when Controlled stop is used.

When the emergency stop button is pressed or the FENCE is open, the stop type of robot is Power-Off

stop or Controlled stop. The configuration of stop type for each situation is called stop pattern. The stop

pattern is different according to the controller type or option configuration.

s-11

Page 14

SAFETY PRECAUTIONS B-82854EN/02

There are the following 3 Stop patterns.

Stop

pattern

AUTO P-Stop P-Stop C-Stop C-Stop P-Stop

A T1 P-Stop P-Stop - C-Stop P-Stop

T2 P-Stop P-Stop - C-Stop P-Stop

AUTO P-Stop P-Stop P-Stop P-Stop P-Stop

B T1 P-Stop P-Stop - P-Stop P-Stop

T2 P-Stop P-Stop - P-Stop P-Stop

AUTO C-Stop C-Stop C-Stop C-Stop C-Stop

C T1 P-Stop P-Stop - C-Stop P-Stop

T2 P-Stop P-Stop - C-Stop P-Stop

Mode

Emergency

stop

button

External

Emergency

stop

FENCE open SVOFF input

Servo

disconnect

P-Stop: Power-Off stop

C-Stop: Controlled stop

-: Disable

The following table indicates the Stop pattern according to the controller type or option configuration.

Option

Standard A (*)

Controlled stop by E-Stop (A05B-2600-J570) C (*)

R-30iB

(*) R-30iB does not have servo disconnect.

R-30iA R-30iA Mate

Option

Standard B (*) A A A A (**) A A

Stop type set (Stop pattern C)

(A05B-2500-J570)

Standard

(Single)

N/A N/A C C N/A C C

Standard

(Dual)

RIA

type

CE

type

Standard

RIA

type

CE

type

(*) R-30iA standard (single) does not have servo disconnect.

(**) R-30iA Mate Standard does not have servo disconnect, and the stop type of SVOFF input is

Power-Off stop.

The stop pattern of the controller is displayed in "Stop pattern" line in software version screen. Please

refer to "Software version" in operator's manual of controller for the detail of software version screen.

"Controlled stop by E-Stop" option

When "Controlled stop by E-Stop" (A05B-2600-J570) option (In case of R-30iA/R-30iA Mate, it is Stop

type set (Stop pattern C) (A05B-2500-J570)) is specified, the stop type of the following alarms becomes

Controlled stop but only in AUTO mode. In T1 or T2 mode, the stop type is Power-Off stop which is

the normal operation of the system.

Alarm Condition

SRVO-001 Operator panel E-stop Operator panel emergency stop is pressed.

SRVO-002 Teach pendant E-stop Teach pendant emergency stop is pressed.

SRVO-007 External emergency stops External emergency stop input (EES1-EES11, EES2-EES21) is

open. (R-30iA/R-30iB controller)

SRVO-194 Servo disconnect Servo disconnect input (SD4-SD41, SD5-SD51) is open.

(R-30iA controller)

SRVO-218 Ext.E-stop/Servo Disconnect External emergency stop input (EES1-EES11, EES2-EES21) is

open. (R-30iA Mate/R-30iB controller)

SRVO-408 DCS SSO Ext Emergency Stop In DCS Safe I/O connect function, SSO[3] is OFF.

SRVO-409 DCS SSO Servo Disconnect In DCS Safe I/O connect function, SSO[4] is OFF.

s-12

Page 15

B-82854EN/02 SAFETY PRECAUTIONS

Controlled stop is different from Power-Off stop as follows:

- In Controlled stop, the robot is stopped on the program path. This function is effective for a system

where the robot can interfere with other devices if it deviates from the program path.

- In Controlled stop, physical impact is less than Power-Off stop. This function is effective for

systems where the physical impact to the mechanical unit or EOAT (End Of Arm Tool) should be

minimized.

- The stopping distance and stopping time of Controlled stop is longer than the stopping distance and

stopping time of Power-Off stop, depending on the robot model and axis. Please refer to the

operator's manual of a particular robot model for the data of stopping distance and stopping time.

In case of R-30iA or R-30iA Mate, this function is available only in CE or RIA type hardware.

When this option is loaded, this function cannot be disabled.

The stop type of DCS Position and Speed Check functions is not affected by the loading of this option.

WARNING

The stopping distance and stopping time of Controlled stop are longer than the

stopping distance and stopping time of Power-Off stop. A risk assessment for

the whole robot system, which takes into consideration the increased stopping

distance and stopping time, is necessary when this option is loaded.

s-13

Page 16

Page 17

B-82854EN/02 TABLE OF CONTENTS

TABLE OF CONTENTS

SAFETY PRECAUTIONS............................................................................s-1

1 INTRODUCTION .....................................................................................1

2 SYSTEM OVERVIEW..............................................................................3

2.1 OVERVIEW ...................................................................................................3

2.2 SPECIFICATION OVERVIEW.......................................................................3

2.3 ETHERNET CONNECTION AND IP ADDRESS ASSIGNMENT...................4

2.4 ADAPTER MODE CONFIGURATION OUTLINE...........................................5

2.5 SCANNER MODE CONFIGURATION OUTLINE..........................................5

3 ADAPTER CONFIGURATION................................................................7

3.1 OVERVIEW ...................................................................................................7

3.2 SETTING UP YOUR ROBOT........................................................................7

3.2.1 Configuring the Robot I/O Size................................................................................7

3.2.2 Configuring the Remote Scanner .............................................................................9

3.2.3 Common Errors......................................................................................................13

4 SCANNER CONFIGURATION..............................................................14

4.1 OVERVIEW .................................................................................................14

4.2 SETTING UP YOUR ROBOT......................................................................14

4.2.1 Overview................................................................................................................14

4.2.2 Configure the Adapter Device................................................................................15

4.2.3 Configure the Robot Scan List ...............................................................................15

4.2.4 Advanced EtherNet/IP Scanner Configuration ......................................................19

4.2.4.1 Quick connect feature........................................................................................ 21

4.2.5 Analog I/O..............................................................................................................24

4.2.5.1 Overview ........................................................................................................... 24

4.2.5.2 Examples ........................................................................................................... 25

4.2.6 Common Errors......................................................................................................25

5 ETHERNET/IP TO DEVICENET ROUTING..........................................26

5.1 OVERVIEW .................................................................................................26

5.2 GUIDELINES...............................................................................................26

5.3 SETTING UP ETHERNET/IP TO DEVICENET ROUTING..........................26

5.4 USING ETHERNET/IP TO DEVICENET ROUTING....................................27

6 I/O CONFIGURATION...........................................................................32

6.1 OVERVIEW .................................................................................................32

6.1.1 I/O Size of Each Connection and I/O Configuration..............................................32

c-1

Page 18

TABLE OF CONTENTS B-82854EN/02

6.2 MAPPING I/O ON THE ROBOT..................................................................32

6.3 BACKING UP AND RESTORING ETHERNET/IP AND I/O CONFIGURATION

.....................................................................................................................33

7 EXPLICIT MESSAGING........................................................................35

7.1 OVERVIEW .................................................................................................35

7.2 ROBOT EXPLICIT MESSAGING CLIENT...................................................36

7.2.1 Overview................................................................................................................36

7.2.2 Creating a Configuration File for the Batch File Method ......................................38

7.3 REMOTE EXPLICIT MESSAGING CLIENT CONFIGURATION.................39

7.4 VENDOR SPECIFIC REGISTER OBJECTS...............................................39

7.4.1 Numeric Register Objects (0x6B and 0x6C)..........................................................40

7.4.1.1 Instance attributes.............................................................................................. 41

7.4.1.2 Common services...............................................................................................41

7.4.1.3 Errors................................................................................................................. 42

7.4.1.4 Read single register............................................................................................42

7.4.1.5 Read all registers................................................................................................43

7.4.1.6 Read a block of registers....................................................................................44

7.4.1.7 Write single register...........................................................................................45

7.4.1.8 Write all registers...............................................................................................46

7.4.1.9 Write a block of registers...................................................................................47

7.4.2 String Register Object (0x6D)................................................................................48

7.4.2.1 Instance attributes.............................................................................................. 48

7.4.2.2 Common services...............................................................................................49

7.4.2.3 Errors................................................................................................................. 50

7.4.2.4 Read single register............................................................................................50

7.4.2.5 Read all register.................................................................................................50

7.4.2.6 Read a block of register.....................................................................................51

7.4.2.7 Write single register...........................................................................................52

7.4.2.8 Write all registers...............................................................................................52

7.4.2.9 Write a block of registers...................................................................................53

7.4.3 Position Register Object (0x7B, 0x7C, 0x7D, 0x7E).............................................54

7.4.3.1 Instance attributes.............................................................................................. 54

7.4.3.2 Common services...............................................................................................56

7.4.3.3 Errors................................................................................................................. 57

7.4.3.4 Read single register............................................................................................57

7.4.3.5 Read all registers................................................................................................58

7.4.3.6 Read a block of registers....................................................................................59

7.4.3.7 Read current position (CURPOS or CURJPOS)............................................... 60

7.4.3.8 Write single register...........................................................................................61

7.4.3.9 Write all registers...............................................................................................62

7.4.3.10 Write a block of registers................................................................................... 62

c-2

Page 19

B-82854EN/02 TABLE OF CONTENTS

7.5 VENDOR SPECIFIC ACTIVE ALARM OBJECT (0xA0)..............................63

7.5.1 Instance Attributes..................................................................................................63

7.5.2 Common Services...................................................................................................64

7.5.2.1 Get_Attribute_All Response.............................................................................. 64

7.5.3 Errors......................................................................................................................65

7.5.4 Examples................................................................................................................65

7.5.4.1 Read most recent active alarm cause code......................................................... 65

7.5.4.2 Read all alarm information from the second most recent active alarm..............65

7.6 VENDOC SPECIFIC ALARM HISTORY OBJECT (0xA1)...........................66

7.6.1 Instance Attributes..................................................................................................66

7.6.2 Common Services...................................................................................................66

7.6.3 Errors......................................................................................................................66

7.6.4 Examples................................................................................................................66

7.6.4.1 Read most recent alarm cause code................................................................... 66

7.6.4.2 Real all alarm information from the second most recent alarm.........................66

7.7 VENDOR SPECIFIC MOTION ALARM OBJECT (0xA2).............................67

7.7.1 Instance Attributes..................................................................................................67

7.7.2 Common Services...................................................................................................67

7.7.3 Errors......................................................................................................................67

7.7.4 Examples................................................................................................................67

7.7.4.1 Read most recent motion alarm cause code.......................................................67

7.7.4.2 Read all alarm information from the second most recent motion alarm............ 67

7.8 VENDOR SPECIFIC SYSTEM ALARM OBJECT (0xA3)............................68

7.8.1 Instance Attributes..................................................................................................68

7.8.2 Common Services...................................................................................................68

7.8.3 Errors......................................................................................................................68

7.8.4 Examples................................................................................................................68

7.8.4.1 Read most recent system alarm cause code....................................................... 68

7.8.4.2 Read all alarm information from the second most recent system alarm............69

7.9 VENDOR SPECIFIC APPLICATION ALARM OBJECT (0xA4) ...................69

7.9.1 Instance Attributes..................................................................................................69

7.9.2 Common Services...................................................................................................69

7.9.3 Errors......................................................................................................................69

7.9.4 Examples................................................................................................................69

7.9.4.1 Read most recent application alarm cause code.................................................69

7.9.4.2 Read all alarm information from the second most recent application alarm......70

7.10 VENDOR SPECIFIC RECOVERY ALARM OBJECT (0xA5).......................70

7.10.1 Instance Attributes..................................................................................................70

7.10.2 Common Services...................................................................................................70

c-3

Page 20

TABLE OF CONTENTS B-82854EN/02

7.10.3 Errors......................................................................................................................70

7.10.4 Examples................................................................................................................71

7.10.4.1 Read most recent recovery alarm cause code ....................................................71

7.10.4.2 Read all alarm information from the second most recent recovery alarm......... 71

7.11 VENDOR SPECIFIC COMMUNICATIONS ALARM OBJECT (0xA6)..........71

7.11.1 Instance Attributes..................................................................................................71

7.11.2 Common Services...................................................................................................71

7.11.3 Errors......................................................................................................................72

7.11.4 Examples................................................................................................................72

7.11.4.1 Read most recent communication alarm cause code..........................................72

7.11.4.2 Read all alarm information from the second most recent communications alarm

...........................................................................................................................72

7.12 ACCESSING I/O USING EXPLICIT MESSAGING......................................72

7.12.1 Accessing I/O Specific to an Implicit EtherNet/IP Connection .............................72

7.12.2 Accessing General I/O............................................................................................75

7.13 USING EXPLICIT MESSAGING IN RSLogix 5000......................................76

8 NETWORK DESIGN AND PERFORMANCE........................................80

8.1 NETWORK DESIGN CONSIDERATIONS...................................................80

8.2 I/O RESPONSE TIME .................................................................................81

9 DIAGNOSTICS AND TROUBLESHOOTING........................................84

9.1 VERIFYING NETWORK CONNECTIONS...................................................84

9.1.1 Ethernet Status LEDs .............................................................................................84

9.1.2 PING Utility ...........................................................................................................84

9.2 ERROR CODES..........................................................................................86

APPENDIX

A THIRD-PARTY CONFIGURATION TOOLS..........................................91

A.1 TOOLS OVERVIEW....................................................................................91

B KAREL PROGRAMS FOR ETHERNET/IP Scanner Quick Connect..94

B.1 OVERVIEW .................................................................................................94

B.2 KAREL PROGRAM DESCRIPTIONS AND PARAMETERS........................94

B.3 USING KAREL PROGRAMS IN TEACH PENDANT PROGRAMS .............95

B.4 EXAMPLES USING ETHERNET/IP MACROS............................................96

B.4.1 Overview................................................................................................................96

B.4.2 Individual Examples...............................................................................................96

B.4.3 Advanced Examples...............................................................................................97

c-4

Page 21

B-82854EN/02 1.INTRODUCTION

1 INTRODUCTION

The EtherNet/IP interface supports an I/O exchange with other EtherNet/IP enabled devices over an

Ethernet network. The EtherNet/IP specification is managed by the Open DeviceNet Vendors Association

(www.odva.org).

From the EtherNet/IP Specification (Release 1.0) Overview :

EtherNet/IP (Ethernet/Industrial Protocol) is a communication system suitable for use in industrial

environments. EtherNet/IP allows industrial devices to exchange time-critical application information.

These devices include simple I/O devices such as sensors/actuators, as well as complex control devices

such as robots, programmable logic controllers, welders, and process controllers.

EtherNet/IP uses CIP (Control and Information Protocol), the common network, transport and application

layers also shared by ControlNet and DeviceNet. EtherNet/IP then makes use of standard Ethernet and

TCP/IP technology to transport CIP communications packets. The result is a common, open application

layer on top of open and highly popular Ethernet and TCP/IP protocols.

EtherNet/IP provides a producer/consumer model for the exchange of time-critical control data. The

producer/consumer model allows the exchange of application information between a sending device (e.g.,

the producer) and many receiving devices (e.g., the consumers) without the need to send the data multiple

times to multiple destinations. For EtherNet/IP, this is accomplished by making use of the CIP network

and transport layers along with IP Multicast technology. Many EtherNet/IP devices can receive the same

produced piece of application information from a single producing device.

EtherNet/IP makes use of standard IEEE 802.3 technology; there are no non-standard additions that

attempt to improve determinism. Rather, EtherNet/IP recommends the use of commercial switch

technology, with 100 Mbps bandwidth and full-duplex operation, to provide for more deterministic

performance.

The terms adapter and scanner are used throughout this manual. Although EtherNet/IP is a

producer/consumer network, these terms are still appropriate to describe a device which creates the I/O

connection (the scanner), and a device which responds to connection requests (the adapter). The scanner

can also be called the connection originator. The adapter can also be called the connection target.

The following steps are necessary to configure EtherNet/IP with the robot as the adapter:

1. Design and install the network. It is critical to follow good network design and installation

practices for a reliable network. Refer to Section 8.1 .

2. Set the IP addresses. All devices on the network require a valid IP address. Refer to Section 2.3 for

additional information for the robot.

3. Configure the adapter devices. Adapter devices might require configuration such as setting I/O

sizes. Refer to Section 3.2.1 to configure the robot as an adapter.

4. Configure the scanner devices. Scanners must be configured with a list of devices (adapters) to

connect to along with parameters for each connection. Refer to Section 3.2.2 to configure an Allen

Bradley ControlLogix PLC to connect to the robot.

5. Map EtherNet/IP I/O to digital, group, or UOP I/O points within the robot. Refer to Section 6.2

for more information. Scanner connections can also be mapped to analog. Refer to Section 4.2.5 .

6. Backup the configuration. Refer to Section 6.3 for details on doing this for the robot.

NOTE

If you need to perform diagnostics or troubleshooting, refer to Chapter 9 .

- 1 -

Page 22

1.INTRODUCTION B-82854EN/02

NOTE

For EtherNet/IP Safety function that exchanges safety signals on EtherNet/IP,

please read “R-30iA/R-30iA Mate controller Dual Check Safety Function (ISO

13849-1:2006 compliant) operator’s manual (B-83104EN)” or “R-30iB controller

Dual Check Safety Function operator’s manual (B-83184EN) in addition to this

manual.

- 2 -

Page 23

B-82854EN/02 2.SYSTEM OVERVIEW

2 SYSTEM OVERVIEW

2.1 OVERVIEW

The robot supports 32 connections. Each connection can be configured as either a Scanner connection, or

as an Adapter connection. Adapter connections are normally to a cell controller or PLC to exchange cell

interface I/O data. The EtherNet/IP Adapter option must be loaded to support this functionality.

Each Scanner connection can be configured to exchange I/O with a remote device capable of acting as an

adapter on an EtherNet/IP network. The EtherNet/IP Scanner option must be loaded to support this

functionality (the EtherNet/IP Scanner option includes the adapter functionality as well).

The EtherNet/IP interface corresponds to Rack 89 in the robot for I/O mapping. The slot number reflects

the connection number from the EtherNet/IP interface user interface screen. Any amount of I/O can be

mapped within EtherNet/IP, up to the maximum supported on the robot. Analog I/O is supported on

scanner connections.

Good network design is critical to having reliable communications. Excessive traffic and collisions must

be avoided or managed. Refer to Section 8.1 for details.

2.2 SPECIFICATION OVERVIEW

Table 2.2(a) and table 2.2(b) provides an overview of specifications for EtherNet/IP.

Table 2.2(a) R-30iA/R-30iA Mate specification overview

Item Specification

Number Adapter

Connections

Number Scanner

Connections

Minimum RPI

Maximum Number of

Input bytes per

connection (combination

of Digital and Analog)

Maximum Number of

Output bytes per

connection (combination

of Digital and Analog)

Supported Signal Types

0–32

32 minus the number of adapter connections

8 msec

64 Words (1Word = 16 bits) or 128 Bytes (1Bytes = 8bits)

64 Words (1Word = 16 bits) or 128 Bytes (1Bytes = 8bits)

Digital, Group, UOP, Analog (for scanner connections only)

Table 2.2(b) R-30iB specification overview

Item Specification

Number Adapter

Connections

Number Scanner

Connections

Minimum RPI

0–32

32 minus the number of adapter connections

8 msec

- 3 -

Page 24

2.SYSTEM OVERVIEW B-82854EN/02

Item Specification

Maximum Number of

Input bytes per

connection (combination

of Digital and Analog)

Maximum Number of

Output bytes per

connection (combination

of Digital and Analog)

Supported Signal Types

248 Words (1Word = 16 bits) or 496 Bytes (1Bytes = 8bits)

248 Words (1Word = 16 bits) or 496 Bytes (1Bytes = 8bits)

Digital, Group, UOP, Analog (for scanner connections only)

NOTE

The maximum number of Input/Output bytes per connection in table 2.2(a) and

table 2.2(b) is the range of value that can be set as the data size of EtherNet/IP

connection. On the other hand, the maximum number fo I/O that can be used in

a robot controller differs according to the application software and other option

software configuration.

NOTE

In order for the scanner to work, the EtherNet/IP Scanner option must be loaded.

NOTE

For EtherNet/IP Safety function that exchanges safety signals on EtherNet/IP,

please read “R-30iA/R-30iA Mate controller Dual Check Safety Function (ISO

13849-1:2006 compliant) operator’s manual (B-83104EN)” or “R-30iB controller

Dual Check Safety Function operator’s manual (B-83184EN) in addition to this

manual.

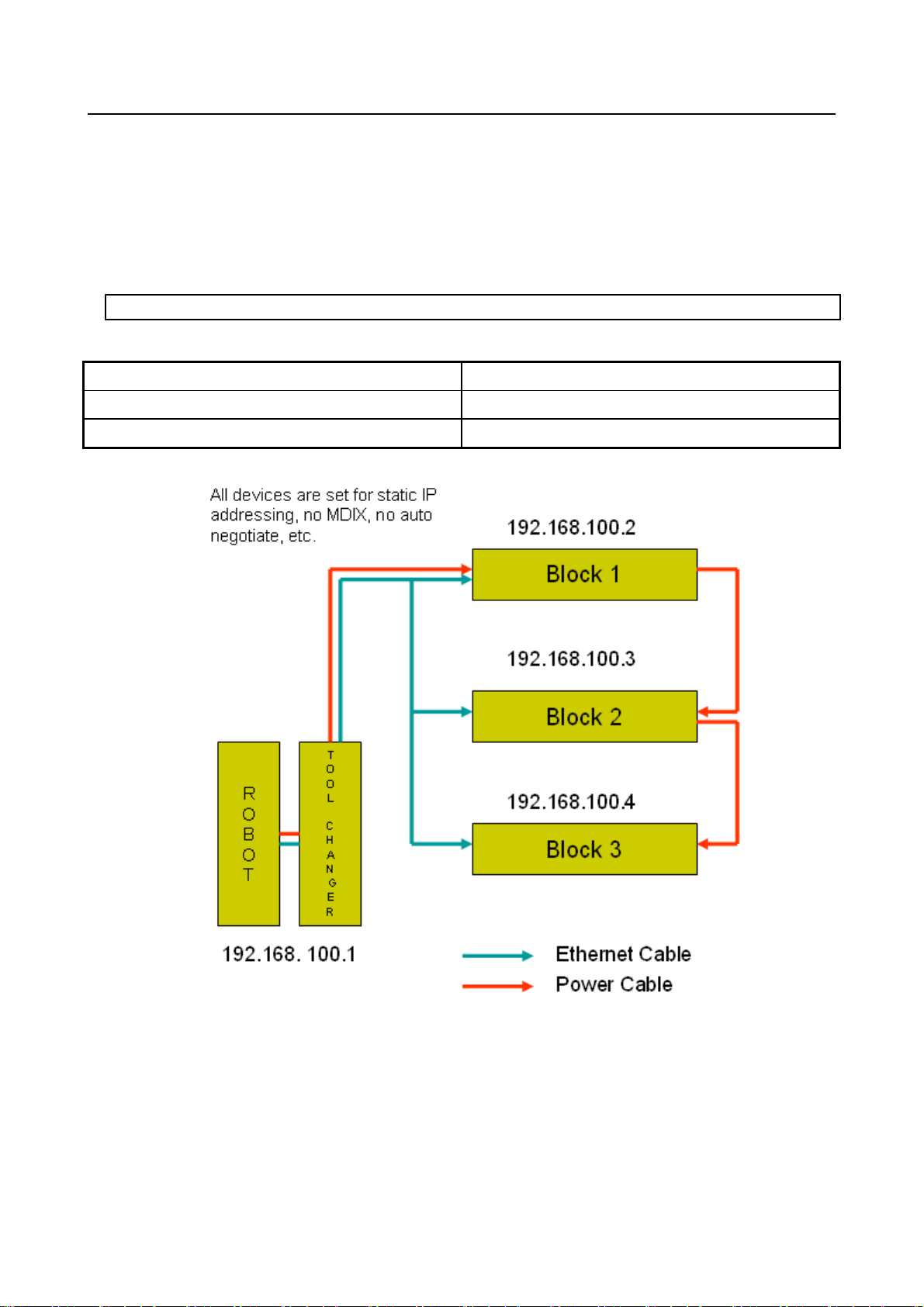

2.3 ETHERNET CONNECTION AND IP ADDRESS

ASSIGNMENT

The robot must have a valid IP (Internet protocol) address and subnet mask to operate as an EtherNet/IP

node.

The Ethernet interface supports 10Mbps and 100Mbps baud rates, along with half and full duplex

communication. By default both interfaces will auto-negotiate and should be connected to a switch which

supports 100Mbps full duplex connections. The LEDs located near the RJ45 connectors on the main CPU

board are useful in confirming link establishment.

The IP address(es) can be configured in the following ways :

Manually configured on the robot teach pendant

DHCP (Dynamic Host Configuration Protocol)

NOTE

DHCP is an optional software component. It is important to utilize static or infinite

lease IP addresses when using EtherNet/IP.

Either one or both Ethernet ports can be configured for use with EtherNet/IP. Note that in order to use

both ports at the same time they must be properly configured on separate subnets. Also note that port 2

(CD38B) is optimized for Ethernet I/O protocols such as EtherNet/IP. The preferred setup is to connect

- 4 -

Page 25

B-82854EN/02 2.SYSTEM OVERVIEW

port 1 (CD38A) to your building network to access the robot through HTTP, FTP, and so forth , and to

connect port 2 (CD38B) to an isolated network for use by EtherNet/IP.

NOTE

Be sure that all EtherNet/IP node IP addresses are configured properly before

you perform the functions in this manual. The PING utility can be used to verify

basic communications. Refer to Chapter 9 for more information.

2.4 ADAPTER MODE CONFIGURATION OUTLINE

Perform the following steps to configure the adapter connection on the robot:

Configure the I/O size on the robot. Refer to Section 3.2.1 .

Map the physical EtherNet/IP I/O to logical I/O points (digital, group, or UOP) on the robot. Refer

to Section 6.2 .

Configure the remote scanner (for example, ControlLogix PLC). Refer to Section 3.2.2 .

Table 2.4 provides a summary of the adapter configuration. This information is used in the scanner device

(for example, PLC) configured to communicate with the robot EtherNet/IP Adapter interface.

Table 2.4 Adapter configuration summary

ITEM DESCRIPTION

Vendor ID 356

Product Code 2

Device Type 12

Communication Format Data – INT

Input Assembly Instance 101–132

Input Size User Configurable, Set in 16-bit W ords

Output Assembly Instance 151–182

Output Size User Configurable, Set in 16-bit Words

Configuration Instance 100

Configuration Size 0

The default I/O size for the adapter connection is four words for both inputs and outputs. This

corresponds to 64 I/O points based on a 16-bit word. This size must be configured on the robot teach

pendant, as well as on the remote scanner (for example, PLC).

Refer to Chapter 3 for details.

2.5 SCANNER MODE CONFIGURATION OUTLINE

The robot must be configured to initiate EtherNet/IP connections. Up to 32 scanner connections are

supported. Perform the following steps to configure the scanner connection on the robot :

Configure the robot scan list on the teach pendant. Refer to Section 4.2.3 .

Map the physical EtherNet/IP I/O to logical I/O points (for example, digital, group, analog, or UOP)

on the robot. Refer to Section 6.2 .

For each connection the following data must be provided on the robot teach pendant. (Refer to the manual

that applies to the adapter device being configured for more information.)

- 5 -

Page 26

2.SYSTEM OVERVIEW B-82854EN/02

Name/IP address

Vendor ID

DeviceType

Product Code

Input Size (16-bit words or 8-bit byes)

Output Size (16-bit words or 8-bit byes)

RPI (ms)

Input assembly instance

Output assembly instance

Configuration instance

NOTE

The robot currently cannot be configured for devices with a non-zero

configuration size from the teach pendant. Refer to Appendix A for information

on third party configuration tools.

- 6 -

Page 27

B-82854EN/02 3.ADAPTER CONFIGURATION

3 ADAPTER CONFIGURATION

3.1 OVERVIEW

The robot supports up to 32 adapter connections. These connections are normally to a cell controller or

PLC to exchange cell interface I/O data. The EtherNet/IP Adapter Option must be loaded to support this

functionality.

The following steps are required to configure the adapter connection on the robot :

Configure I/O size on the robot. Refer to Section 3.2.1 .

Map the physical EtherNet/IP I/O to logical I/O points (digital, group, or UOP) on the robot. Refer

to Section 6.2 .

Configure the remote scanner (for example, ControlLogix PLC). Refer to Section 3.2.2 .

3.2 SETTING UP YOUR ROBOT

3.2.1 Configuring the Robot I/O Size

The Input size and Output size are set in 16-bit word sizes. This means if 32 bits of input and 32 bits of

output are needed then the Input size and Output Size would be set to 2 words each. The default size of

the adapter connection is 4 words (64 bits) of input and 4 words (64 bits) of output. Changes in I/O size

require you to turn off and turn on the robot to take effect.

Refer to Procedure 3-1 to configure I/O size on the robot.

Table 3.2.1(a) describes the items displayed on the EtherNet/IP Status screen.

Table 3.2.1(b) describes the items on the EtherNet/IP Configuration screen.

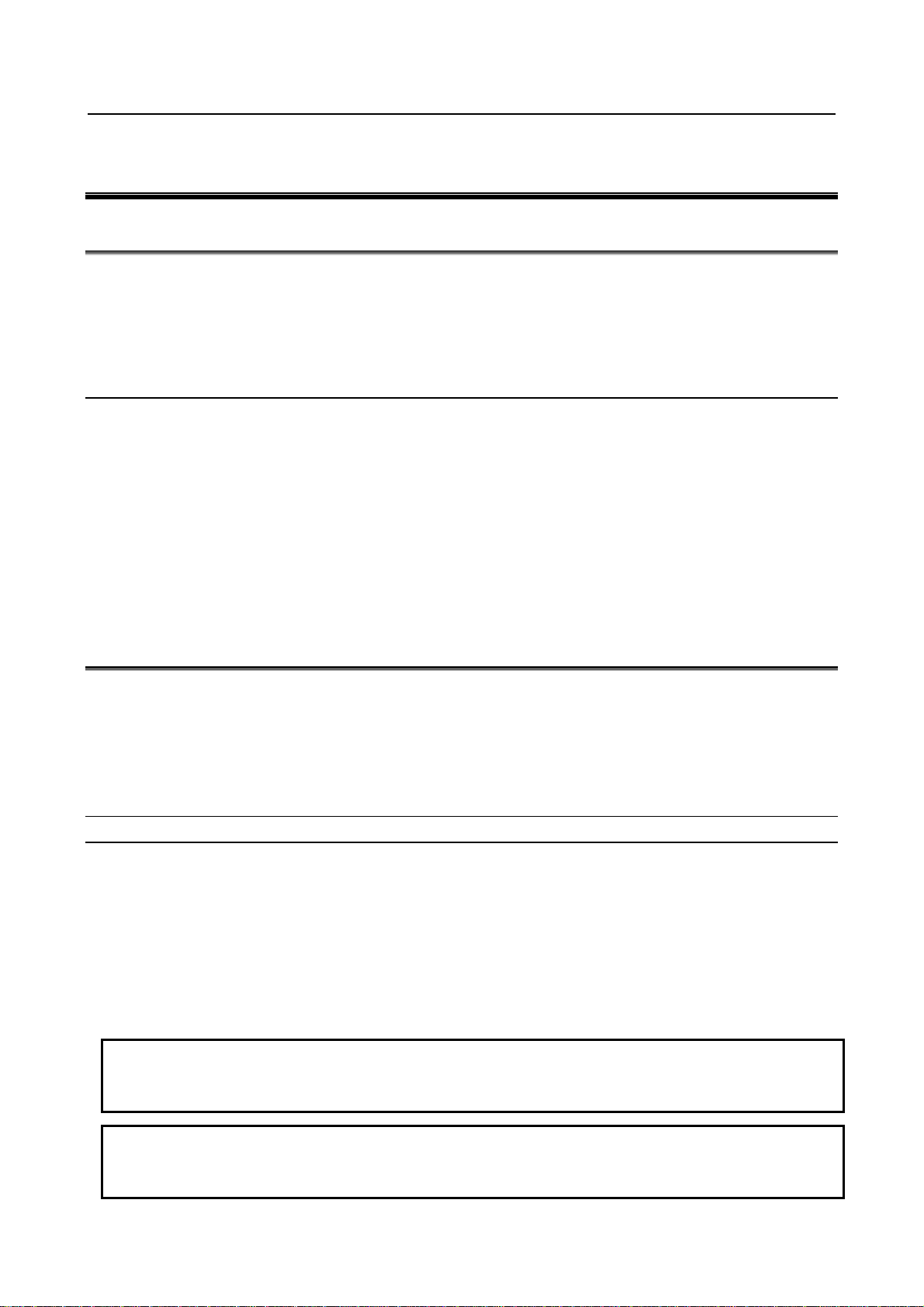

Table 3.2.1(a) EtherNet/IP status screen descriptions

ITEM DESCRIPTION

Description

Default: ConnectionX where

X is the slot number of the

Adapter.

TYP

Default: ADP

Enable

Default: TRUE (for Adapter 1,

FALSE for Adapters 2–32)

Status The Status field can have the following values :

This item is the description of the adapter or scanner. This can be set as desired to

coordinate with your equipment.

This item indicates whether the connection is configured as an Adapter, or as a

Scanner.

This item indicates whether the adapter or scanner is enabled (TRUE) or disabled

(FALSE).

OFFLINE– the connection is disabled.

ONLINE – the connection is enabled but is not active (for example,

waiting for a connection).

RUNNING - the connection is enabled and active (I/O is being

exchanged).

<RUNNING> - the connection is enabled and active (I/O is being

exchanged), and auto-reconnect is enabled. See Table 4.2.4 for more

information on the auto-reconnect setting.

PENDING – changes have taken place in configuration. You must

turn off the robot, then turn it on again.

- 7 -

Page 28

3.ADAPTER CONFIGURATION B-82854EN/02

ITEM DESCRIPTION

Slot

This item is the value used when mapping EtherNet/IP I/O to digital, group, or UOP

I/O signals.

Table 3.2.1(b) EtherNet/IP configuration screen descriptions

ITEM DESCRIPTION

Description

Input size (words)

Default:

Output size (words)

Default:

Alarm Severity

Default: WARN

Scanner IP

API 0 => T

API T => 0

This item is the comment that shows up on the Status screen. It is set on the Status

screen as well.

This item is the number of 16 bit words configured for input.

This item is the number of 16 bit words configured for output.

This item indicates the severity of alarm that will be posted by the adapter

connection. The valid choices are STOP, WARN, and PAUSE.

The IP address of the connected scanner.

Actual Packet Interval at which the scanner/originator is producing.

Actual Packet Interval at which the adapter/target is producing.

Procedure 3-1 Configuring I/O Size on the Robot

Steps

1. Press MENUS.

2. Select I/O.

3. Press F1, [TYPE], and select EtherNet/IP. You will see a screen similar to the following.

I/O EtherNet/IP JOINT 10 %

EtherNet/IP List(Rack 89) 1/8

Description TYP Enable Status Slot

Connection1 ADP TRUE ONLINE 1

Connection2 ADP FALSE OFFLINE 2

Connection3 ADP FALSE OFFLINE 3

Connection4 ADP FALSE OFFLINE 4

Connection5 ADP FALSE OFFLINE 5

Connection6 ADP FALSE OFFLINE 6

Connection7 ADP FALSE OFFLINE 7

Connection8 ADP FALSE OFFLINE 8

Refer to Table 3.2.1(a) for descriptions of these screen items.

4. Move the cursor to select a connection. If the connection is configured as a scanner, move the cursor

to the TYP column and press F5. This configures the connection as an adapter.

5. Move the cursor to select the desired adapter. If you plan to make changes to the adapter

configuration, you must first disable the connections. Otherwise, the configuration screen is

read-only.

NOTE

If the adapter connection is Enabled, the first line of the adapter configuration

screen will display “Adapter config (Read-only)” and the items on the screen

cannot be modified. To make changes to the adapter configuration screen, you

must disable the adapter connection on the EtherNet/IP Status screen.

6. To change adapter status:

- 8 -

Page 29

B-82854EN/02 3.ADAPTER CONFIGURATION

a. Move the cursor to highlight the field in the Enable column for the adapter.

b. To disable the adapter and change the status to OFFLINE, press F5, FALSE.

To enable the adapter and change the status to ONLINE, press F4, TRUE.

7. Move the cursor to the Description column. Press F4, CONFIG. You will see a screen similar to the

following.

Adapter configuration :

Description : Connection1

Input size (words) : 4

Output size(words) : 4

Alarm Severity : WARN

Scanner IP : ****************

API O=>T : 0

API T=>O : 0

Refer to Table 3.2.1(b) for descriptions of these screen items.

8. To change the I/O size:

a. Move the cursor to select "Input size (words)."

b. Type the value you want and press Enter.

c. Move the cursor to select "Output size (words)."

d. Type the value you want and press Enter.

e. Move the cursor to select the alarm severity.

f. Pres F4, [CHOICE], and select the desired severity.

g. To return to the previous screen, press F3, [PREV].

9. After modifying the adapter configuration, you must enable the connection on the EtherNet/IP status

screen. If any changes were made, the status will show as “PENDING”. This indicates that you must

cycle power in order for the changes to take effect.

NOTE

To map EtherNet/IP I/O to digital, group, or UP I/O, refer to Section 6.2 .

3.2.2 Configuring the Remote Scanner

The EtherNet/IP Interface status screen should show that the adapter connection is ONLINE. This means

it is available and waiting for a request from a scanner (for example, PLC) to exchange I/O. If the adapter

status is not ONLINE, refer to Procedure 3-1 , Step 6 .

Table 3.2.2(a) provides a summary of the adapter configuration. This information is used to configure the

remote scanner (for example, PLC).

Table 3.2.2(a) Adapter configuration summary

ITEM DESCRIPTION

Vendor ID 356

Product Code 2

Device Type 12

Communication Format Data – INT

Input Assembly Instance 101–132

Input Size User Configurable, Set in 16-bit Words

Output Assembly Instance 151–182

Output Size User Configurable, Set in 16-bit Words

Configuration Instance 100

Configuration Size 0

- 9 -

Page 30

3.ADAPTER CONFIGURATION B-82854EN/02

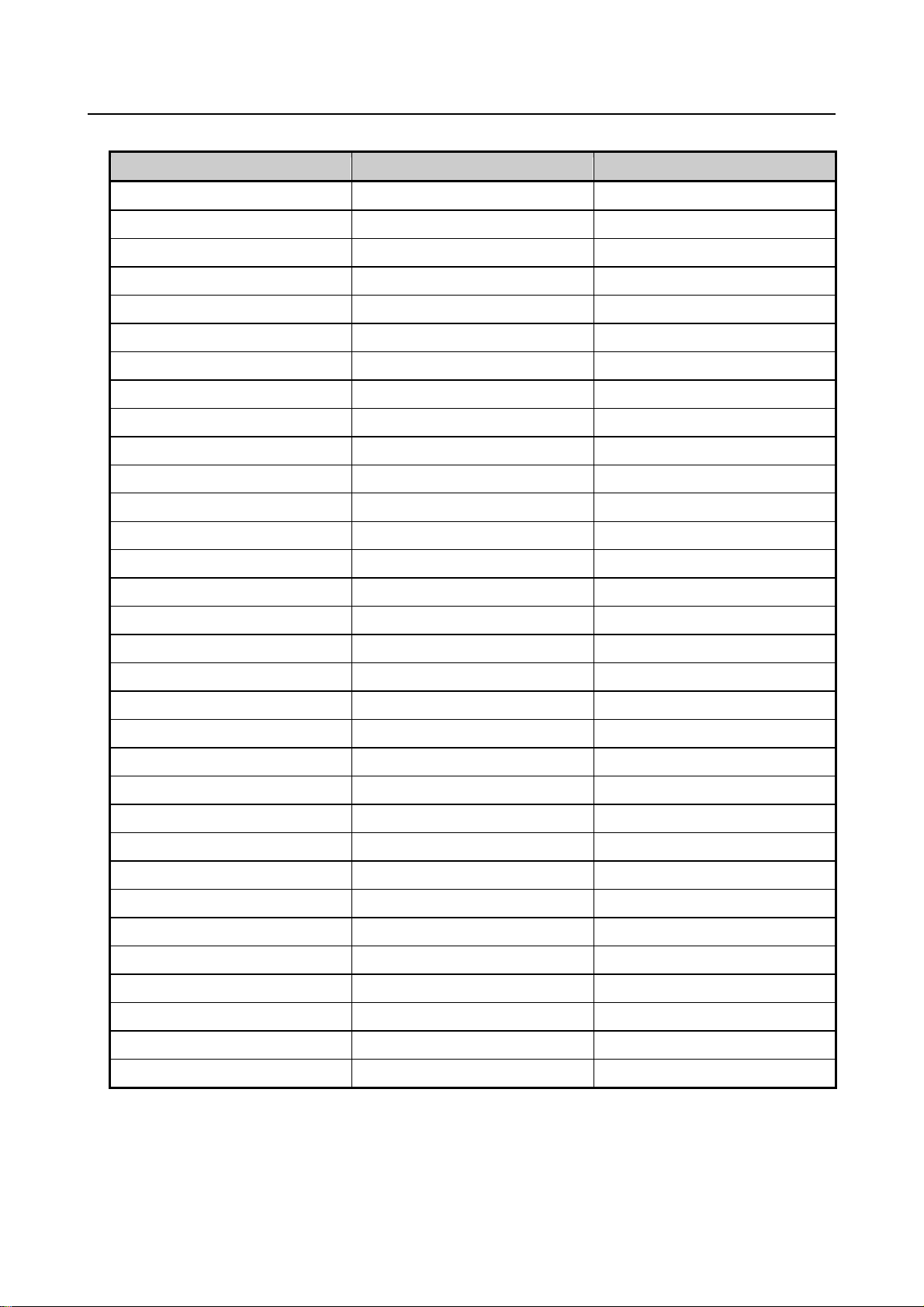

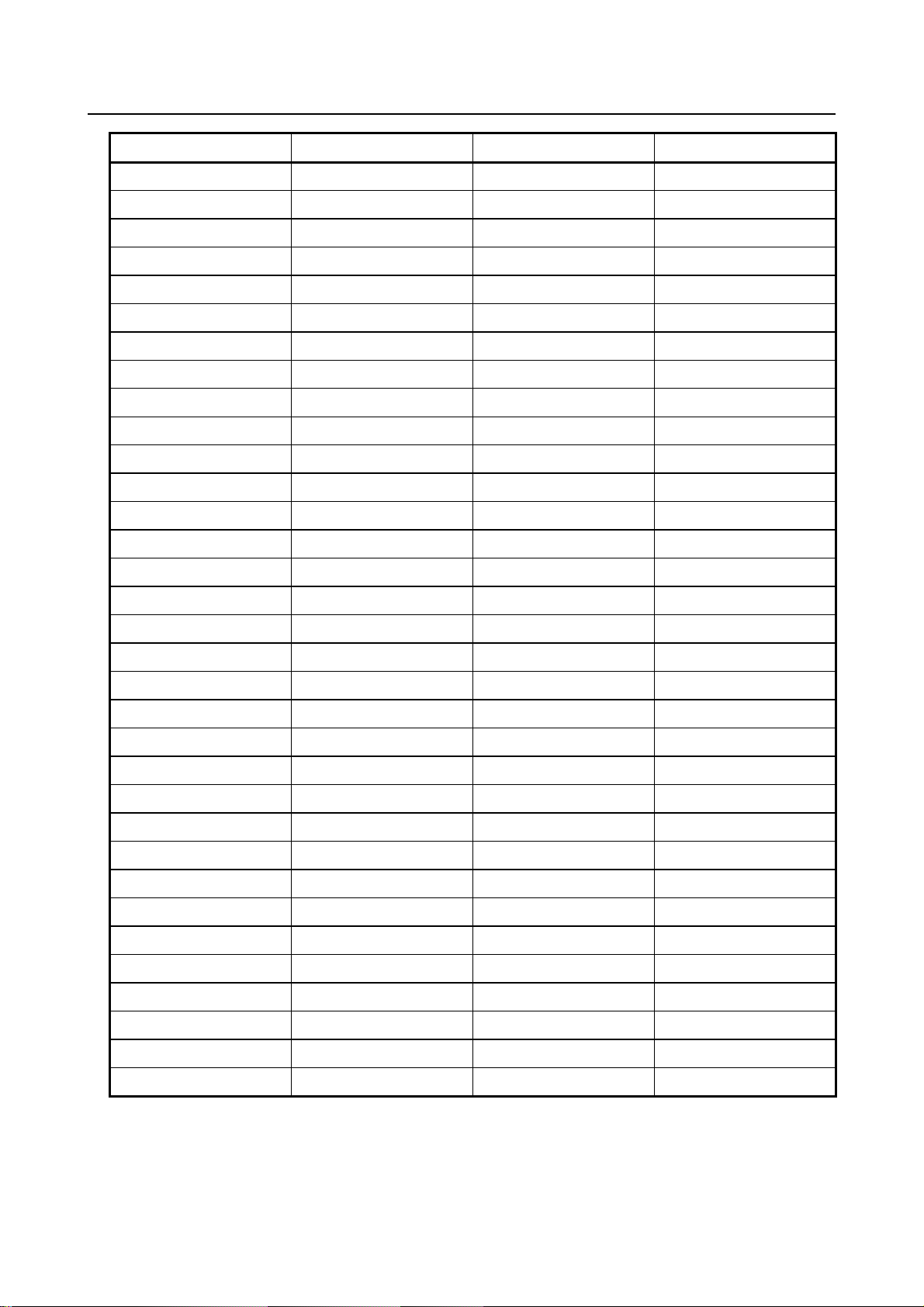

Table 3.2.2(b) Connection points

Slot Number Input Assembly Instance Output Assembly Instance

1 101 151

2 102 152

3 103 153

4 104 154

5 105 155

6 106 156

7 107 157

8 108 158

9 109 159

10 110 160

11 111 161

12 112 162

13 113 163

14 114 164

15 115 165

16 116 166

17 117 167

18 118 168

19 119 169

20 120 170

21 121 171

22 122 172

23 123 173

24 124 174

25 125 175

26 126 176

27 127 177

28 128 178

29 129 179

30 130 180

31 131 181

32 132 182

Use Procedure 3-2 to configure the Allen Bradley ControlLogix PLC. for other scanners, refer to their

configuration software in conjunction with Table 3.2.2(a) .

- 10 -

Page 31

B-82854EN/02 3.ADAPTER CONFIGURATION

Procedure 3-2 Configuring the Scanner Using RS-Logix5000 Software

Steps

NOTE

The following screens show how to configure the scanner using RS-Logix5000

software, which is used with the Allen Bradley ControlLogix PLC. This example

assumes that an EtherNet/IP Bridge module has been added to the configuration

in the ControlLogix PLC.

1. To add the robot adapter connection to the configuration, right-click the EtherNet/IP Bridge module

in the PLC, and select“ New Module”.

2. Select “Generic Ethernet Module,” and click OK. You will see a screen similar to the following.

3. In the next screen, RSLogix will ask for information regarding the communication to the robot. Type

a name for the robot adapter connection.

In the example below we call the module “Example_Robot”. This name will create a tag in RSLogix,

which can be used to access the memory location in the PLCs memory where the data for the

Example_Robot will be stored. A description can also be added if desired (optional).

4. Select the “Comm_Format,” which tells RSLogix the format of the data.

In this example we select Data-INT, which will represent the data in the robot as a field of 16-bit

words.

5. Set connection parameters as follows:

Each of the 32 Connections have different Connection parameters, which are based on the slot

number. Refer to Table 3.2.2(b) to determine the correct parameters. The size of the input

connection and the output connection must correspond to the size that we have configured for the

robot. In this example we configured the robot for 4 (16 bit) words of input data and output data.

The configuration instance should be set to 100 and size of the configuration instance is set to 0.

In the following example, we will be setting up connection parameters corresponding to the adapter

in slot 1.

6. Type the IP address that we have configured for the module.

This could be the Host Name if the DNS (Domain Name Service) is configured and available for the

PLC to resolve names to IP addresses (if names are used be sure the DNS server is very reliable and

always available to the PLC during operation). You will see a screen similar to the following.

- 11 -

Page 32

3.ADAPTER CONFIGURATION B-82854EN/02

7. The RPI (requested packet interval) is set on the next screen. This sets the rate for I/O updates. In the

following example the RPI is set to 32ms. This means the PLC will send its outputs to the robot

every 32ms, and the robot will send its inputs to the PLC every 32ms. You will see a screen similar

to the following.

8. Press Finish to complete this step.

9. To download the new configuration to the ControlLogix PLC, select Download from the

Communications menu. You will see a screen similar to the following.

- 12 -

Page 33

B-82854EN/02 3.ADAPTER CONFIGURATION

10. If there are any errors, a warning triangle will be present on the Example_Robot in the I/O

configuration listing. Double click the module to view any error that is reported.

3.2.3 Common Errors

The robot will post an alarm indicating that the adapter connection is idle if it is enabled but no scanner

has connected to it. This is an informational alarm (warning level) by default. This message is reposted

whenever the robot RESET button is pressed and the adapter connection is idle. If desired, the error

severity level of EtherNet/IP adapter alarms can be increased. See Step 8 of Procedure 3-1 for more

details.

If the adapter connection is lost the values of any mapped inputs will be zeroed out (by default). The last

state behavior can be changed by setting the following system variable : $EIP_CFG.$KEEP_IO_ADP.

The values are :

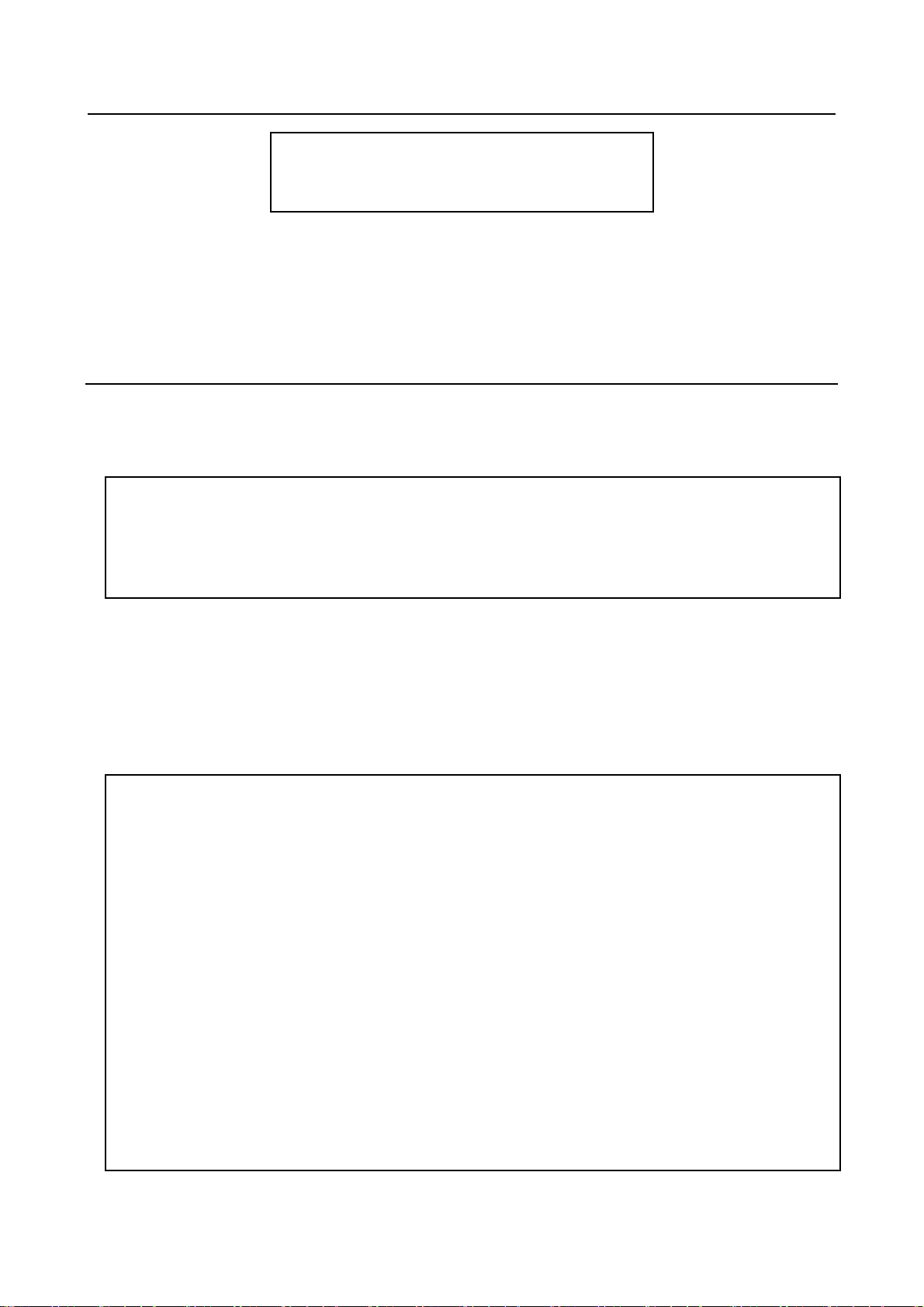

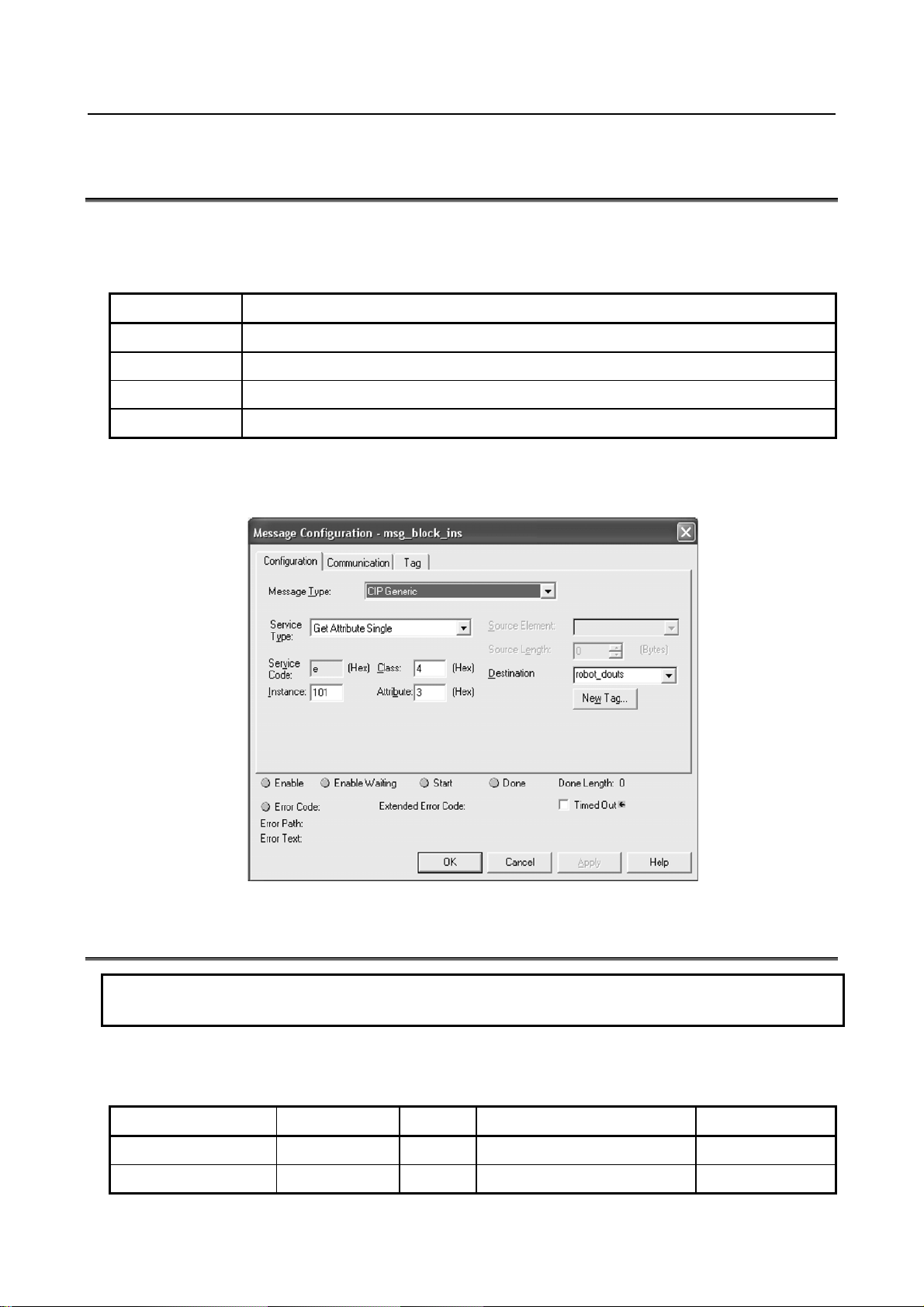

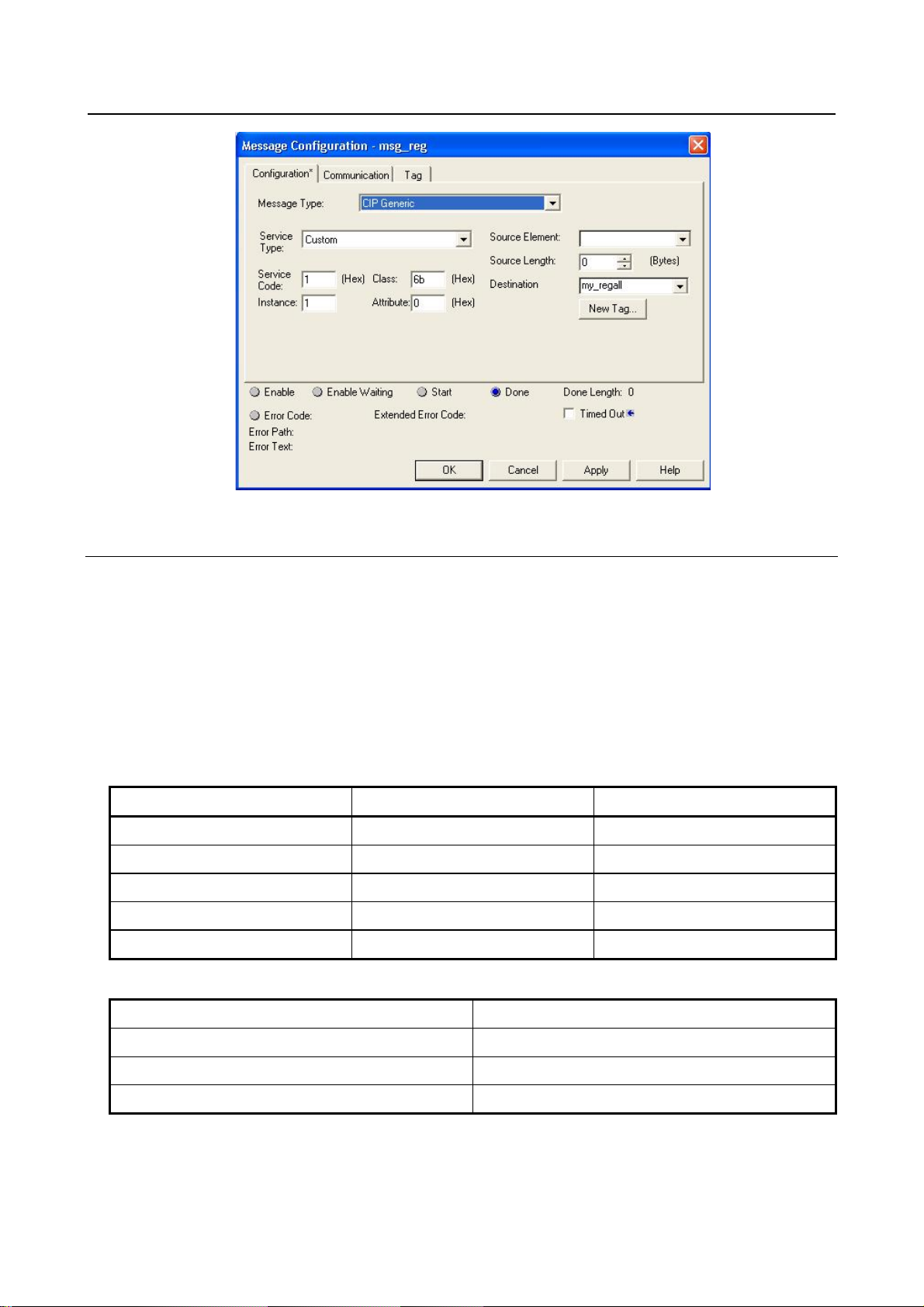

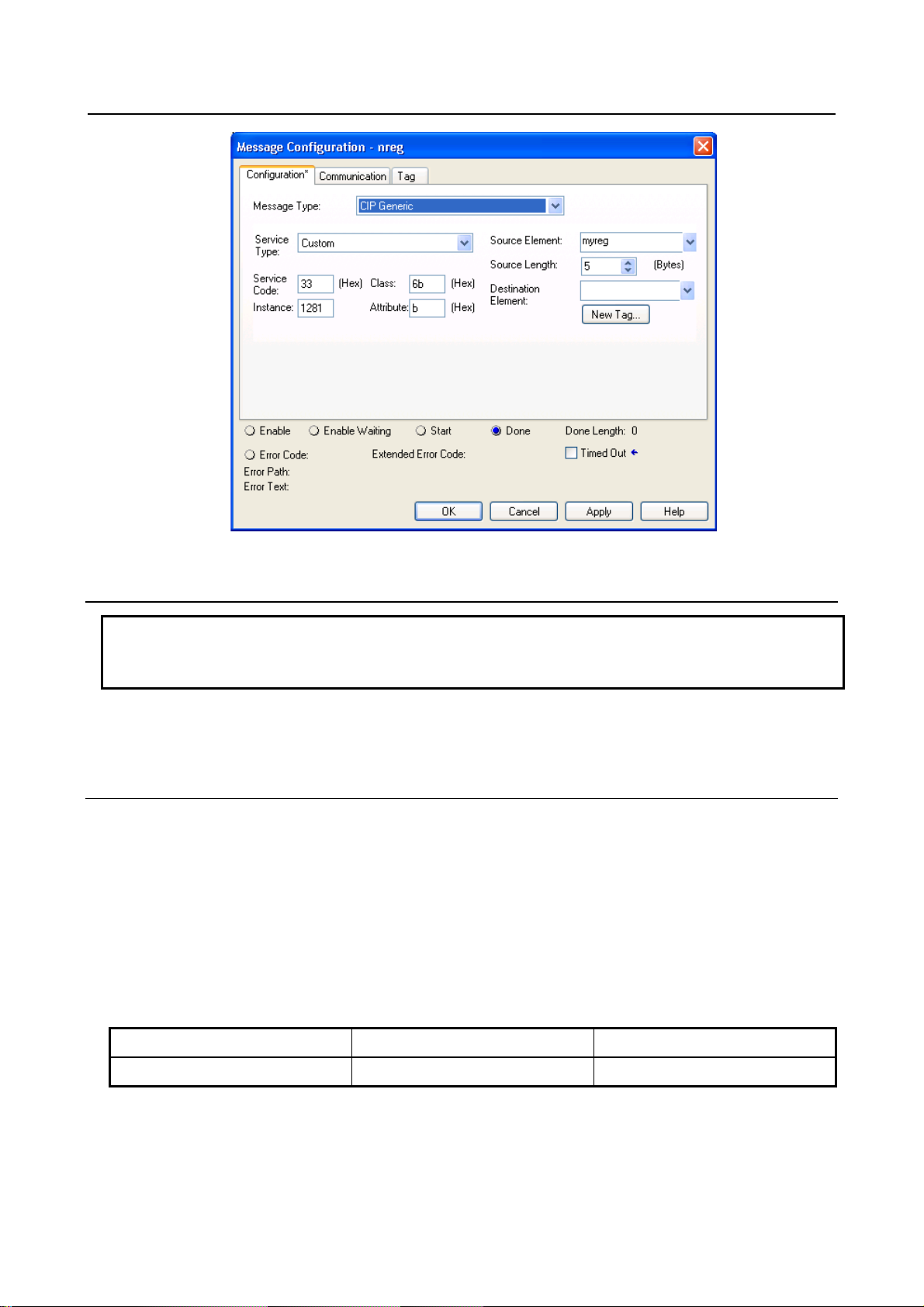

FALSE : The last state values of the adapter inputs will be zero (default)