Industrial 10/100BaseTX to

100BaseFX Media Converter

RUE-111 (multimode) RUE-113 (singlemode)

User Manual

Rev. 2.00

15-September-2006

FCC Warning

This Equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC rules. These limits

are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates, uses

and can radiate radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not

occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by

turning the equipment off and on, the user is encouraged to try to correct

the interference by one or more of the following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a circuit different from that to

which the receiver is connected.

Consult the dealer or an experienced radio/TV technician for help.

Contents

Introduction.........................................................1

Features................................................................... 1

Package Contents....................................................2

Hardware Description.........................................3

Physical Dimension..................................................3

Front Panel............................................................... 3

Bottom View............................................................. 4

Ports......................................................................... 4

Cabling..................................................................... 6

LED Indicators.......................................................... 7

DIP-switch................................................................ 8

Wiring the Power Inputs......................................... 10

Wiring the Fault Alarm Contact.............................. 11

Mounting Installation ........................................12

DIN-Rail Mounting.................................................. 12

Wall Mount Plate Mounting.................................... 14

Hardware Installation........................................15

Troubleshooting................................................18

Technical Specifications...................................19

Introduction

The Industrial 10/100BaseTX to 100BaseFX Media Converter is a costeffective solution for the converting 10/100Base-TX (Auto MDI/MDIX) to

100Base-FX cabling. It provides two power inputs that can be connected

simultaneously to two DC power sources. If one power input fails, the

other one acts as a backup.

The Industrial 10/100BaseTX to 100BaseFX Media Converter also

provides relay alarm outputs to warn when the port link failure, so the

technician can respond quickly with appropriate emergency operation

procedures.

IP- switches are used to set the operation mode for relay alarm, Fiber

ports, link loss forwarding function, and UTP operation mode.

Features

UTP to Fiber Media converter

Auto Negotiation Speed and Half/Full Duplex

12 to 48VDC power inputs

TX port supports Auto MDI/MDI-X

Relay alarm output for port link failure

IEEE 802.3x flow control support

¾ Flow control on full-duplex

¾ Back pressure on half-duplex

Built-in Link Loss Forwarding Technology

DIN-Rail or wall mountable

DIP-switches to set the operation mode and Link- Lost-Forwarding

function.

Redundant dual DC power Inputs

1

Package Contents

Please refer to the package content list below to verify them against the

checklist.

Industrial 10/100BaseTX to 100BaseFX Media Converter

One DIN-Rail (screwed on the converter)

One wall mount plate and six screws

User manual

Industrial 10/100BaseTX to 100BaseFX User Manual

Media Converter

Wall Mount Plate Screws DIN-Rail

Compare the contents of your industrial media converter with the standard

checklist above. If any item is damaged or missing, please contact your

local dealer for service.

2

Hardware Description

In this paragraph, we will introduce the Industrial media converter’s

hardware spec, port, cabling information, and wiring installation.

Physical Dimension

Industrial 10/100BaseTX to 100BaseFX Media Converter dimensions (W

x H x D) are 54mm x 135mm x 105mm

Front Panel

The Front Panel of the Industrial 10/100BaseTX to 100BaseFX Media

Converter is showed below.

LED Indicator

Fiber Port

DIP Switch

UTP Port

Front Panel of the Industrial 10/100BaseTX to 100BaseFX Media Converter

3

Bottom View

The bottom view of the Industrial 10/100BaseTX to 100BaseFX Media

Converter consists one terminal block connector within two DC power

inputs and one DC IN power jack.

Bottom Panel of Industrial 10/100BaseTX to 100BaseFX Media Converter

Ports

RJ-45 Port

The UTP ports will auto-sense for 10Base-T or 100Base-TX connections.

Auto MDI/MDIX means that you can connect to another Switch or

workstation without changing straight through or crossover cabling. See

the Figure C and C-1 for straight through and crossover cabling

schematic.

RJ-45 Pin Assignments

Pin Number Assignment

1 Tx+

2 Tx-

4

3 Rx+

6 Rx-

[NOTE] “+” and “-” signs represent the polarity of the wires that make up

each wire pair.

All UTP ports on this Industrial media converter support automatic

MDI/MDI-X operation, you can use straight-through cables (See Figure)

for all network connections to PCs or servers, or to other switches or hubs.

In straight-through cable, pins 1, 2, 3, and 6, at one end of the cable, are

connected straight through to pins 1, 2, 3 and 6 at the other end of the

cable. The table below shows the 10BASE-T/ 100BASE-TX MDI and

MDI-X port pin outs.

Pin MDI-X Signal Name MDI Signal Name

1 Receive Data plus (RD+) Transmit Data plus (TD+)

2 Receive Data minus (RD-) Transmit Data minus (TD-)

3 Transmit Data plus (TD+) Receive Data plus (RD+)

6 Transmit Data minus (TD-) Receive Data minus (RD-)

Straight Through Cable Schematic

Cross over Cable Schematic

5

Fiber Port

This port is for 100Base-FX connections. We provide SC fiber connector

in multi mode (2Km) or single mode (30Km) for different model number.

When you connect the fiber port to another fiber port, please follow the

below Figure D to connect it. Wrong connection will cause the port cannot

work normally.

ATTENTION

This is a Class 1 Laser/LED product. Don’t stare into

the Laser/LED Beam.

Cabling

Use the four twisted-pair, Category 5 cables for RJ-45 port

connections. The cable between the converter and the link partner

(switch, hub, workstation, etc.) must be less than 100 meters (328 ft.)

6

long.

The Fiber segment using the single-mode connector type must use a

8/125 or 9/125 um single-mode fiber cable. You can connect two

devices up to 30 Kilometers (Available on single mode fiber

model only).

The Fiber segment using a multi-mode connector type must use 50

or 62.5/125 um multi-mode fiber cables. You can connect two devices

up to 2Km distances (Available on multi mode fiber model only).

LED Indicators

There are 8 diagnostic LEDs located on the Front panel of industrial media

converter. They provide real-time information of system and optional

status. The following table provides description of the LED status and their

meanings for the industrial media converter.

LED Status Meaning

Green

When the industrial switch has

power input s the LED will light on

Power

Off No power

Green Power on

Power 1

Off No power

Green Power on

Power 2

Off No power

Orange

Power failure or UTP port failure or

Fiber port failure

Fault

Off

No Power failure or UTP port

failure or Fiber port failure occurs

or the port alarm is disabled

7

Green

The port is linking with its link

partner.

Blinks

The port is transmitting or receiving

packets from the FX device.

LNK/ACT

(Fiber)

Off No device attached

Orange

The port is operating in full-duplex

mode.

FDX (Fiber)

Off

Half-duplex mode or no device

attached

Green In 100Mbps transmitting speed

10/100(UTP)

Off In 10Mbps transmitting speed

Green

The port is linking with its link

partner.

Blinks

The unit is transmitting or receiving

packets from the devices.

LNK/ACT

(UTP)

Off No device attached

Orange

The port is operating in full-duplex

mode.

FDX (UTP)

Off

Half-duplex mode or no device

attached

DIP-switch

The DIP-switch is used to configure operation mode for LLF (Link Loss

Forwarding) operation mode for UTP/Fiber port and the relay alarm

operation mode. The default value of the DIPswitch is OFF.

8

DIP Switch No Status Description

ON

Enable Port Alarm. If the port’s link

fails, the fault LED will light up.

1

OFF Disable Port Alarm

ON LLF Enable

2

OFF LLF Disable

ON 100Base-FX Half Duplex mode

3

OFF 100Base-FX Full Duplex mode

ON 100Base-TX Full Duplex mode

4

OFF UTP Auto-Negotiation

Link Loss Forwarding: When LLF is enabling, allow UTP link failures to

be reported to the fiber side and also allow Fiber link failure to be reported

to the UTP side. Therefore, A link lost forward feature is provided in both

UTP and Fiber side.

[NOTE] Please don’t change the DIP-switch setting when UTP or fiber

port is transmitting or receiving data. It may cause some data error. After

changing the DIP-switch setting, a Power OFF/ON must be executed

to enable new configuration.

9

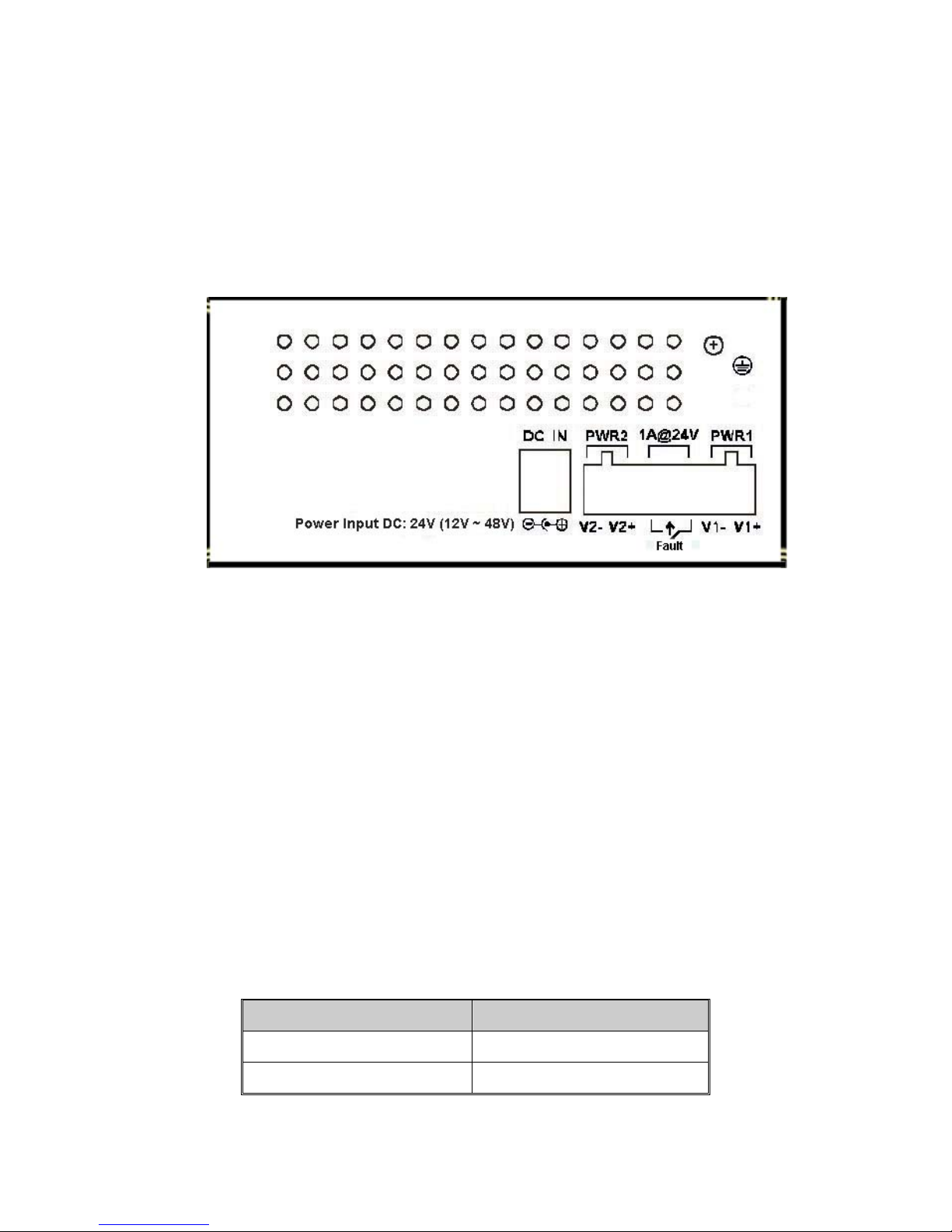

Wiring the Power Inputs

Please follow below steps to insert the power wire.

V- V+ V- V+

1. Insert the positive and negative wires into the V+ and Vconnector on the terminal block connector.

2. Tighten the wire-clamp screws for preventing the DC wires

from loosening.

[NOTE] The wire range of terminal block is from 12~ 24 AWG.

10

Wiring the Fault Alarm Contact

The fault alarm contact is in the middle of terminal block connector as

below figure shows. By inserting the wires and set the DIPswitch at “ON”

status, it will detect when power is failure or port link failure and form an

open circuit. And, the following figure shows an application example for

the fault alarm contact.

[NOTE] The wire range of terminal block is from 12~ 24 AWG.

Insert the wires into the fault alarm contact

1A@24

V

Fault Alarm Contact

24V DC Buzzer 24V Battery

The open circuit will form when the

power failure or port link failure.

The fault alarm device will send a

warning signal to warn the user, ex:

alarm sound or flash light.

11

Mounting Installation

DIN-Rail Mounting

The DIN-Rail is screwed on converter when out of factory. If the DIN-Rail

is not screwed on the converter, please see the following Figure F to

screw the DIN-Rail on the converter. Follow the below steps to hang the

converter.

1. Use the screws to screw on the DIN-Rail on the converter.

2. To remove the DIN-Rail, reverse the step 1.

Rear Panel of

the converter

DIN-Rail

Figure F

12

1. First, insert the top of DIN-Rail into the track.

2. Then, lightly push the button of DIN-Rail into the track.

3. Check the DIN-Rail is tightly on the track.

4. To remove the converter from the track, reverse step 2 and step1

above.

13

Wall Mount Plate Mounting

Follow the below steps to mount the Industrial media converter with wall

mount plate.

1. Remove the DIN-Rail from the Industrial media converter; loose the

screws to remove the DIN-Rail.

2. Place the wall mount plate on the bottom side of the Industrial media

converter.

3. Use the screws to screw the wall mount plate on the Industrial media

converter.

4. Use the hook holes at the corners of the wall mount plate to hang the

Industrial media converter on the wall.

5. To remove the wall mount plate, reverse steps above.

Screws to screw the wall mount plate on the Industrial media

converter

14

Hardware Installation

In this section, we will describe how to install the 10/100BaseTX to

100BaseFX Media Converter and the installation points for the attention.

In Figure, it is an example application for the Industrial converter.

Installation Steps

1. Unpacked the Industrial media converter.

2. Check the DIN-Rail is screwed on the Industrial media converter. If the

DIN-Rail is not screwed on the Industrial media converter. Please refer

to DIN-Rail Mounting section for DIN-Rail installation. If you want to

wall mount the Industrial media converter, then please refer to Wall

15

Mount Plate Mounting section for wall mount plate installation.

3. To insert the Industrial media converter into the track or hang on the

wall, please refer to the Mounting Installation section.

4. Power on the Industrial media converter. How to wire the power;

please refer to the Wiring the Power Inputs section. The power LED

on the Industrial media converter will light up. Please refer to the LED

Indicators section for meaning of LED lights.

5. Prepare the twisted-pair, straight through Category 5 cable for

Ethernet connection and optic fiber cable for fiber connection.

[NOTE] The Fiber port has single-mode and multi-mode. To check

your Industrial media converter fiber connector type, look for

the sticker on the Industrial media converter.

The single-mode connector type must use 8/125 or 9/125 um

single-mode fiber cable. The connect distance between two

devices is up to 30 Km.

The multi-mode connector type must use 50 or 62.5/125 um

multi-mode fiber cable. The connect distance between two

devices is up to 2Km.

6. Insert one side of Category 5 cables into the Industrial media converter

Ethernet port (RJ-45 port) and another side of category 5 cables to the

network switch’s Ethernet port (RJ-45 port). The UTP port (RJ-45) LED

on the Industrial media converter will light up when the cable

connected with the switch. Please refer to the LED Indicators section

for LED light meaning.

[NOTE] Be sure the connected local switch’s Ethernet port support

MDI/MDI-X. If it does not support then use the crossover category-5

cable.

7. Insert one side of fiber cable into the Industrial media converter fiber

port and another side to the convert in the opposite side connection.

The fiber port LED on the converter will light up when the cable

16

connected. Please refer to the LED Indicators section for LED light

meaning.

8. When all connections are all set and LED lights all show in normal, the

installation is complete.

17

Troubleshooting

Verify that you are using the right power cord/adapter (DC 12-48V).

Do not use a power adapter with DC output larger than 48V, or it will

damage the device.

Check the configuration of the DIP-switch. It must be sett in the same

operation mode with the link partner.

Select the proper UTP/Fiber cable to construct your network. The

single-mode converter must use single-mode fiber cable. Please

check that you are using the right cable.

Don’t both use multi-mode and single mode cables.

If the Industrial media converter LED indicators are normal and the

connected cables are correct and the packets still cannot transmit.

Please check your system’s Ethernet devices’ configuration or status.

18

Technical Specifications

Industrial 10/100BaseTX to 100BaseFX Media Converter technical

specification are following.

Standard

IEEE802.3 10BASE-T

IEEE802.3u 100BASE-TX/100BASE-FX

IEEE802.3x Flow Control and Back pressure

Connector

Fiber: SC (Multi-Mode model), SC

(Single-mode model, 30Km)

RJ-45 Socket: CAT-3/5 (10/100Mbps) Twisted

Pair cable Auto MDI/MDI-X and

Auto-Negotiation Function Support

Switch

architecture

Store and Forward

Fiber parameters

Fiber Core: Multi-Mode (62.5/125um,

50/125um)

Single-Mode (8/125um,

10/125um)

Wavelength: 1310nm

Fiber Distance: Multi-Mode Fiber 2Km

(Available on Multi mode

model)

Single-Mode Fiber 30Km

(Available on Single mode

model)

19

Link Lost Forward

TX ÎFiber: If TX port link down, the media

converter will force Fiber port to link down

Fiber ÎTX: If Fiber port link down, the media

converter will force TX port to link down.

DIP Switch

DIP Switch 1:

ON: Enables Port Alarm

OFF: Disables Port Alarm

DIP Switch 2:

ON: Enables LLF (Link Lose Forwarding)

OFF: Disables LLF (Link Lose Forwarding)

DIP Switch 3:

ON: 100Base-FX Half-mode

OFF: 100Base-FX Full-mode

DIP Switch 4:

ON: 100Base-TX Full-duplex mode

OFF: Auto-Negotiation

LED

Power (Green), Power1 (Green), Power2

(Green), Fault (Orange)

Fiber: Link/Activity (Green)

Half/Full Duplex (Orange)

TX: 10/100(Green)

Link (Green)

Half/Full Duplex (Orange)

Power

Input Voltage: 12 to 48VDC; Redundant inputs

Power

consumption

4.6 Watts

Reserve polarity

protection

Present

20

Overload current

protection

Present

Operation

Temperature

0 to 60°C (32 to 140°F)

Storage

Temperature

-40 to 85°C

Ambient Relative

Humidity

5 to 90%(non-condensing)

Dimension

54 mm (W) x 135 mm (H) x 105mm (D)

EMI

FCC Class A, CE EN6100-4-2, CE

EN6100-4-3, CE EN-6100-4-4, CE

EN6100-4-5, CE EN6100-4-6

Safety

UL, cUL, CE/EN60950

Shock

IEC 60068-2-27

Free fall

IEC 60068-2-32

Vibration

IEC 60068-2-6

21

Loading...

Loading...