Ergotron StyleView SV41, StyleView SV42 LiFe, StyleView SV42 SLA, StyleView SV31, StyleView SV32 User Manual

Page 1

User's Guide

StyleView® Camera Shelf

For the latest User Installation Guide please visit: www.ergotron.com

English, Español, Français, Deutsch, Nederlands, Italiano, Svenska, 日本語, 汉语

www.ergotron.com |

888-97-320-W-00 rev. B • 08/19

USA: 1-800-888-8458

|

Europe: +31 (0)33-45 45 600

|

China: 400-120-3051

|

NOTE: camera is

supplied by customer.

English

Japan: japansupport@ergotron.com

1 of 7

Page 2

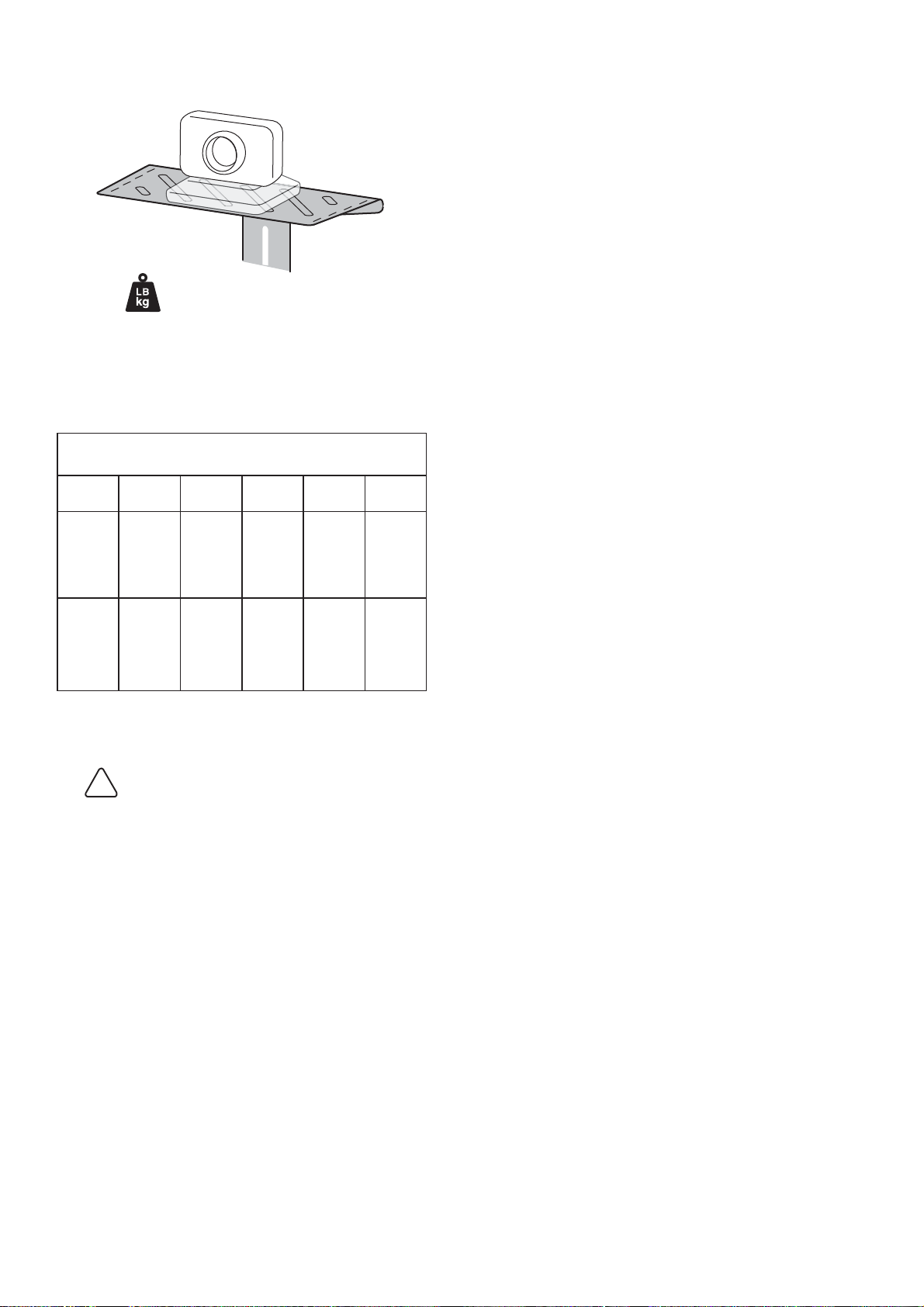

Features & Specifi cations

Max weight: 2 lbs (1 kg)

Weight Capacity Limitations for Carts

with Added Camera Shelf

LCD Arm

or 5” Lift

Pivot

without

lock-out

SV41

10 lbs.

(4.5 kg)

SV42

SLA

10 lbs.

(4.5 kg)

SV42

LiFe

7 lbs. (3.2

kg)

SV31 SV32

12 lbs.

(5.4 kg)

12 lbs.

(5.4 kg)

5” Lift with

lock-out

16 lbs.

(7.3 kg)

16 lbs.

(7.3 kg)

16 lbs.

(7.3 kg)

16 lbs.

(7.3 kg)

CAUTION: Do Not Exceed Maximum Listed Weight

Capacity. Failure to heed this caution may cause serious

Injury or property damage to occur.

16 lbs.

(7.3 kg)

2 of 7

888-97-320-W-00 rev. B • 08/19

Page 3

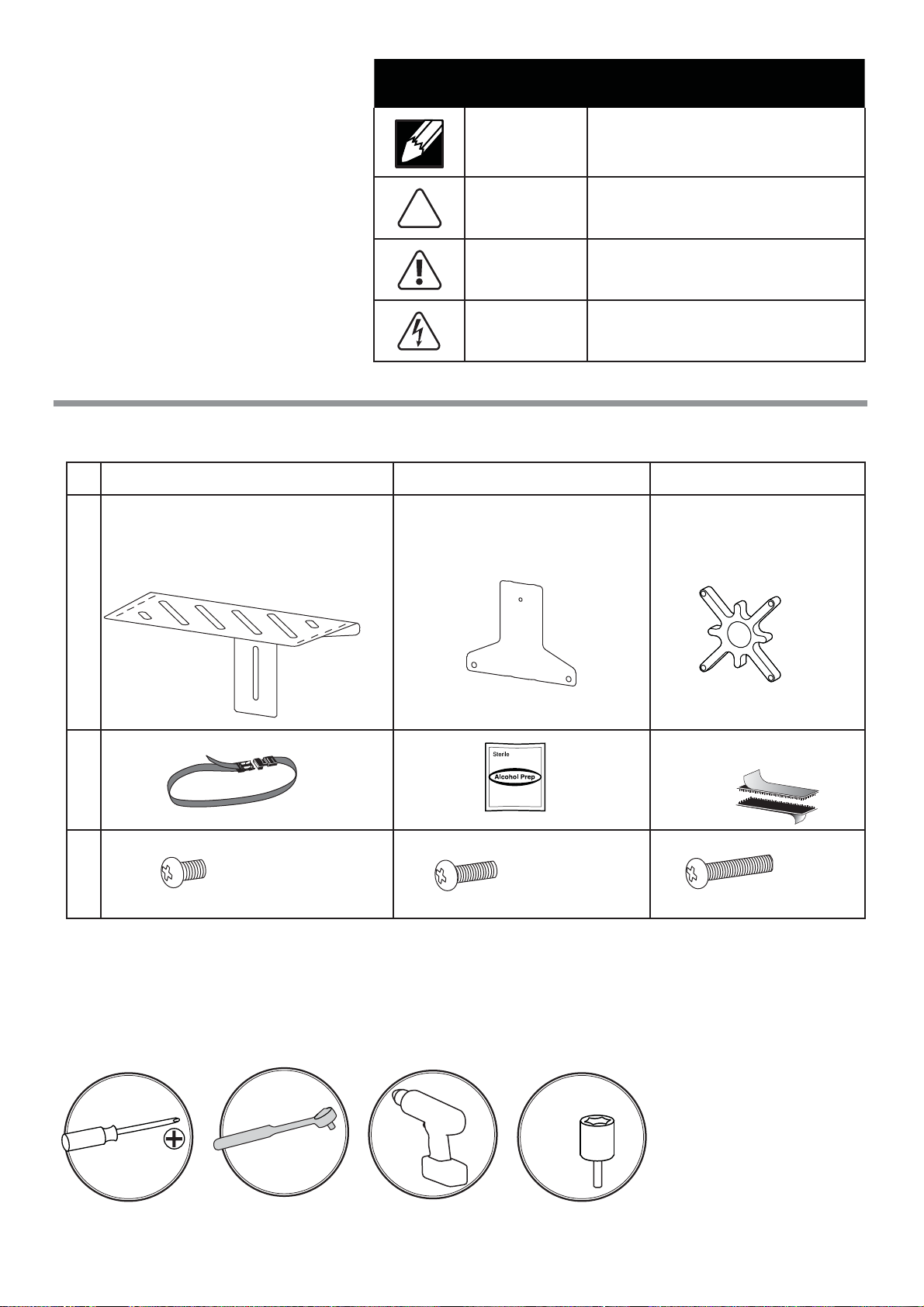

1/4”

Hazard Symbols Review

Symbol Signal Word Level of Hazard

These symbols alert users of a safety condition that

demands attention. All users should be able to

recognize and understand the signi cance of the following Safety Hazards if encountered on the product

or within the documentation. Children who are not

able to recognize and respond appropriately to Safety

Alerts should not use this product without adult

supervision!

Components

ABC

1x 1x 1x

NOTE

CAUTION

WARNING

ELECTRICAL

A NOTE indicates important information that helps you

make better use of this product.

A CAUTION indicates either potential damage to

hardware or loss of data and tells you how to avoid the

problem.

A WARNING indicates either potential for property damage, personal injury, or death.

An Electrical indicates an impending electrical hazard

which, if not avoided, may result in personal injury, re

and/or death.

1

2

3

1x

Tools Needed

M4 x 6mm

2x

M4 x 14mm

1x1x1x

4x

M4 x 25mm

888-97-320-W-00 rev. B • 08/19

14mm

3 of 7

Page 4

CAUTION: Do Not Exceed Maximum SV LCD Cart Weight Capacity 35 lbs. (16 kg). This is

the sum of LCD monitor, CPU, keyboard/mouse, camera and any worksurface load, including drawers, if present. Failure to heed this caution may cause serious Injury or property damage to occur.

1

a. Attach shelf to

bracket using the

provided M4x6mm

Phillips screw.

If your monitor has recessed mounting holes,

you need to add the provided spacer between

the monitor and the mounting plate.

a. Remove the monitor from the cart and set aside on a clean and level surface.

The monitor screws can be discarded.

b. Attach the spacer to the monitor with the four provided M4x25mm Phillips screws.

1x

M4 x 6mm

c. Reattach the monitor to the cart.

d. When following step 2 instructions on next page, DO NOT discard the M4x25mm

screws. The should be used to mount the shelf/bracket assembly.

4 of 7

888-97-320-W-00 rev. B • 08/19

Page 5

a. Remove the top, left screw and discard. (If using spacer, do not discard the screw!)

2

b. Slip the shelf/bracket assembly behind the monitor plate and insert one of the provided

M4x14mm Phillips screw into the top, left hole. (If using spacer, reinsert the M4x25mm

screw removed in step 2a, above.) Allow screw to be secure but not tight.

c. Remove the top, right screw and discard. (If using spacer, do not discard the screw!)

d. Slip the other end of the shelf/bracket assembly behind the monitor plate and insert a

M4x14mm Phillips screw into the top, right hole. (If using spacer, reinsert the M4x25mm

screw removed in step 2c, above.) Tighten both top screws.

a

c

b

d

2x

M4 x 14mm

2x

M4 x 14mm

888-97-320-W-00 rev. B • 08/19

5 of 7

Page 6

3

3 Mounting Options

a

b

a

b

c

6 of 7

d

888-97-320-W-00 rev. B • 08/19

Page 7

4

Adjustment Step

Lift – Up and down

bc

Once the camera has been mounted to the shelf, it is important that

you adjust the lift tension for the additional weight. Test the lift tension

by moving the head unit up and down. If it travels smoothly and easily

through the full range of motion, and does not drift up or sag down from

the place you set it, the tension is good. If not, adjust as directed below:

To change lift tension:

a. Remove cap.

b. Turn adjustment nut with a 14mm (9/16”) socket head.

c. Test lift tension by lifting head unit up and down.

d. When desired lift tension has been achieved, replace cap.

14mm (9/16")

NOTE: Adjustment

may require 40 - 60

revolutions.

For Warranty visit: www.ergotron.com/warranty

For Service visit: www.ergotron.com

For local customer care phone numbers visit: http://contact.ergotron.com

www.ergotron.com |

© 2013 Ergotron, Inc. All rights reserved.

888-97-320-W-00 rev. B • 08/19

USA: 1-800-888-8458

|

Europe: +31 (0)33-45 45 600

|

China: 400-120-3051

|

Japan: japansupport@ergotron.com

7 of 7

Loading...

Loading...