Epson NX125, NX127, TX120, TX125, TX123 Service manual

...

SERVICE MANUAL

CONFIDENTIAL

Color Inkjet Printer

Epson Stylus NX125/NX127/TX120/TX125/TX123/

SX125/TX121/TX121x/TX129/

Epson ME 320/ME 330/ME 350

Epson Stylus T13/T13x/T12/N10/N11/T22/T25/S22/

T22E/

Epson ME 10/ME 32/ME 33/ME 35

Epson Stylus NX130/TX130/TX133/TX135/SX130

ME 340

SEMF09-013

SEIJ09-007

Confidential

Notice:

All rights reserved. No part of this manual may be reproduced, stored in a retrieval system, or transmitted in

any form or by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior

written permission of SEIKO EPSON CORPORATION.

All effort have been made to ensure the accuracy of the contents of this manual. However, should any errors

be detected, SEIKO EPSON would greatly appreciate being informed of them.

The contents of this manual are subject to change without notice.

The above not withstanding SEIKO EPSON CORPORATION can assume no responsibility for any errors in

this manual or the consequences thereof.

EPSON is a registered trademark of SEIKO EPSON CORPORATION.

Note :Other product names used herein are for identification purpose only and may be trademarks or r egistered

trademarks of their respective owners. EPSON disclaims any and all rights in those marks.

Copyright 2010 SEIKO EPSON CORPORATION

IJP CS Quality Assurance Department

Confidential

Safety Precautions

All safety procedures described here shall be strictly adhered to by all parties servicing and maintaining this

product.

DANGER

Strictly observe the following cautions. Failure to comply could result in serious bodily injury or loss of life.

1. Always disconnect the product from the power source and peripheral devices when servicing the product or

performing maintenance.

2. When performing works described in this manual, do not connect to a power source until instructed to do so.

Connecting to a power source causes high voltage in the power supply unit and some electronic components

even if the product power switch is off. If you need to perform the work with the power cable connected to a

power source, use extreme caution to avoid electrical shock.

WARNING

Strictly observe the following cautions. Failure to comply may lead to personal injury or loss of life.

1. Always wear protective goggles for disassembly and reassembly to protect your eyes from ink in working. If

any ink gets in your eyes, wash your eyes with clean water and consult a doctor immediately.

2. When using compressed air products; such as air duster, fo r cleaning during repair and maintenance, the use

of such products containing flammable gas is prohibited.

PRECAUTIONS

Strictly observe the following cautions. Failure to comply may lead to personal injury or damage of the product.

1. Repairs on Epson product should be performed only by an Epson certified repair technician.

2. No work should be performed on this product by persons unfamiliar with basic safety knowledge required for

electrician.

3. The power rating of this product is indicated on the serial number/rating plate. Never connect this product to

the power source whose voltages is different from the rated voltage.

4. Replace malfunctioning components only with those components provided or approved by Epson;

introduction of second-source ICs or other non-approved components may damage the product and void any

applicable Epson warranty.

5. In order to protect sensitive microprocessors and circuitry, use static discharge equipment, such as anti-static

wrist straps, when accessing internal components.

6. Do not tilt this product immediately after initial ink charge, especially after performing the ink charge several

times. Doing so may cause ink to leak from the product because it may take some time for the waste ink pads

to completely absorb ink wasted due to the ink charge.

7. Never touch the ink or wasted ink with bare hands. If ink comes into contact with your skin, wash it off with

soap and water immediately. If you have a skin irritation, consult a doctor immediately.

Confidential

8. When disassembling or assembling this product, make sure to wear gloves to avoid injuries from metal parts

with sharp edges.

9. Use only recommended tools for disassembling, assembling or adjusting the printer.

10. Observe the specified torque when tightening screws.

11. Be extremely careful not to scratch or contaminate the following parts.

Nozzle plate of the printhead

CR Scale

PF Scale

Coated surface of the PF Roller

Gears

Rollers

LCD

Scanner Sensor

Exterior parts

12. Never use oil or grease other than those specified in this manual. Use of different types of oil or grease may

damage the component or give bad influence on the printer function.

13. Apply the specified amount of grease described in this manua l .

14. Make the specified adjustments when you disassemble the printer.

15. When cleaning this product, follow the procedure described in this manual.

16. When transporting this product after filling the ink in the printhead, pack the printer without removing the

ink cartridges in order to prevent the printhead from drying out.

17. Make sure to install antivirus software in the computers used for the service support activities.

18. Keep the virus pattern file of antivirus software up-to-date.

Confidential

About This Manual

This manual, consists of the following chapters, is intended for repair service personnel and includes information

necessary for properly performing maintenance and servicing the product.

CHAPTER 1. DISASSEMBLY / ASSEMBLY

Describes the disassembly/reassembly procedures for main parts/units of the product, and provides the

standard operation time for servicing the product.

CHAPTER 2. ADJUSTMENT

Describes the required adjustments for servicing the product.

CHAPTER 3. MAINTENANCE

Describes maintenance items and procedures for servicing the product.

CHAPTER 4. APPENDIX

Provides the following additional information for reference:

Power-On Sequence

Connector Summary

Symbols Used in this Manual

Various symbols are used throughout this manual either to provide additional information on a specific topic or

to warn of possible danger present during a procedure or an action. Pay attention to all symbols when they are

used, and always read explanation thoroughly and follow the instructions.

Indicates an operating or maintenance procedure, practice or condition that, if not strictly observed,

could result in serious injury or loss of life.

Indicates an operating or maintenance procedure, practice, or condition that, if not strictly observed,

could result in bodily injury, damage or malfunction of equipment.

May indicate an operating or maintenance procedure, practice or condition that is necessary to

accomplish a task efficiently. It may also provide additional information that is related to a specific

subject, or comment on the results achieved through a previous action.

For Chapter 1 “Disassembly/Assembly”, symbols other than indicated above are used to show additional

information for disassembly/reassembly. For the details on those symbols, see " 1.2 Disassembly/Assembly

Procedures (p10)".

Confidential

Revision Status

Revision Date of Issue Description

A April 28, 2010 First Release

B August 19, 2010 Revised Contents

[Chapter 1]

- 1.2.1Standard Operation Time for servicing the product Table 1-2 on page 11-12

Standard Operation Time(NX125 series) is added.

- 1.2.1Standard Operation Time for servicing the product Table 1-3 on page 12

Standard Operation Time(T13 series) is added.

[Chapter 3]

- 3-1 Overview on page 28-30.

Greese name is added.

C October 12, 2010 [Chapter 3]

- 3-1 Overview on page 28-30.

Greese name is TBD.

D February 22, 2011 [All chapters]

The model name”EPSON Stylus TX121x/TX13x/EPSON ME 350/

EPSON ME 35 are added.

E March 25, 2011 Revised Contents

[All chapters]

- The model name ”EPSON Stylus NX130 series” are added, and revision is changed.

[Chapter 5]

- Information for “EPSON Stylus NX130/TX130/TX133/TX135/SX130/ME340” is

added.

F May 26, 2011 Revised Contents

[chapter 3]

- 3-1 Overview on page 28.

Grease name: G-94

- 3-2 Overview on page 29.

<Grease Lubrication Point>

Shaft on the Scanner Housing ---> Greese name is G-94.

- 3-2 Overview on page 30.

<Grease Lubrication Point>

Contacting points (x2) with the Driven Pulley ---> Greese name is G-71.

7

Epson Stylus NX125/T13/NX130 series Revision F

Confidential

Contents

Chapter 1 Disassembly/Assembly

1.1 O verview ................................................................................................................................................................... 9

1.1.1 Tools ................................................................................................................................................................. 9

1.2 D isassembly/Assembly Procedures......................................................................................................................... 10

1.2.1 Standard Operation Time for servicing the product ....................................................................................... 11

1.2.2 D isassembling/Assembling Flowchart ........................................................................................................... 13

1.2.2.1 Housing Part .................................. .................................... ... ................................................................. 13

1.2.2.2 Printer Mechanism Part ......................................................................................................................... 14

1.3 Details of Disassembling/Assembling by Parts/Unit .............................................................................................. 16

1.4 Routing FFC/cables................................................................................................................................................. 21

Chapter 2 Adjustment

2.1 Required Adjustments ............................................................................................................................................. 24

2.2 Revision EDetails of Adjustments .......................................................................................................................... 26

2.2.1 TOP Margin Adjustment ................................................................................................................................ 26

Chapter 3 Maintenance

3.1 O verview ................................................................................................................................................................. 28

3.1.1 Cleaning.......................................................................................................................................................... 28

3.1.2 Lubrication...................................................................................................................................................... 28

3.2 Lubrication Point.............................. ..................................... ..................................... ............................................. 29

Chapter 4 Appendix

4.1 Power-On Sequence ................................................................................................................................................ 32

4.2 Connector Summary................................................................................................................................................ 34

Chapter 5 Stylus NX130 Series

5.1 O verview ................................................................................................................................................................. 36

Confidential

CHAPTER 1

DISASSEMBLY/ASSEMBLY

Confidential

Disassembly/Assembly Overview 9

Epson Stylus NX125/T13/NX130 series Revision F

1.1 Overview

This chapter describes procedures for disassembling the main components of NX125, T13 and NX130 series.

Unless otherwise specified, disassembled units or components can be reassembled by reversing the disassembly

procedure. Refer to " 1.3 Details of Disassembling/Assembling by Parts/Unit (p16)" for cautions and such if

necessary when disassembling and assembling.

Read the " Safety Precautions (p3)" before disassembling and assembling.

When you have to remove components or parts that are not described in this chapter, see the exploded diagrams

of SPI (Service Parts Information).

1.1.1 Tools

Use only specified tools to avoid damaging the printer.

Note *: All of the tools listed above are commercially available.

EPSON provides the tools listed with EPSON part code.

In this chapter, the product names are called as follows:

NX125 series: Epson Stylus NX125/NX127/TX120/TX125/TX123/SX125/TX121/TX121x/

TX129/Epson ME 320/ME 330/ME 350

T13 series: Epson Stylus T13/T13x/T12/N10/N11/T22/T25/S22/T22E/Epson ME 10/

ME 32/ME 33/ME 35

NX130 series: Epson Stylus NX130/TX130/TX133/TX135/SX130/Epson ME 340

Table 1-1. Tools

Name EPSON Part Code*

(+) Phillips screwdriver #1 1080530

(+) Phillips screwdriver #2 ---

Flathead screwdriver ---

Flathead Precision screwdriver #1 ---

Tweezers ---

Longnose pliers ---

Acetate tape 1003963

Nippers ---

Confidential

Disassembly/Assembly Disassembly/Assembly Procedures 10

Epson Stylus NX125/T13/NX130 series Revision F

1.2 Disassembly/Assembly Procedures

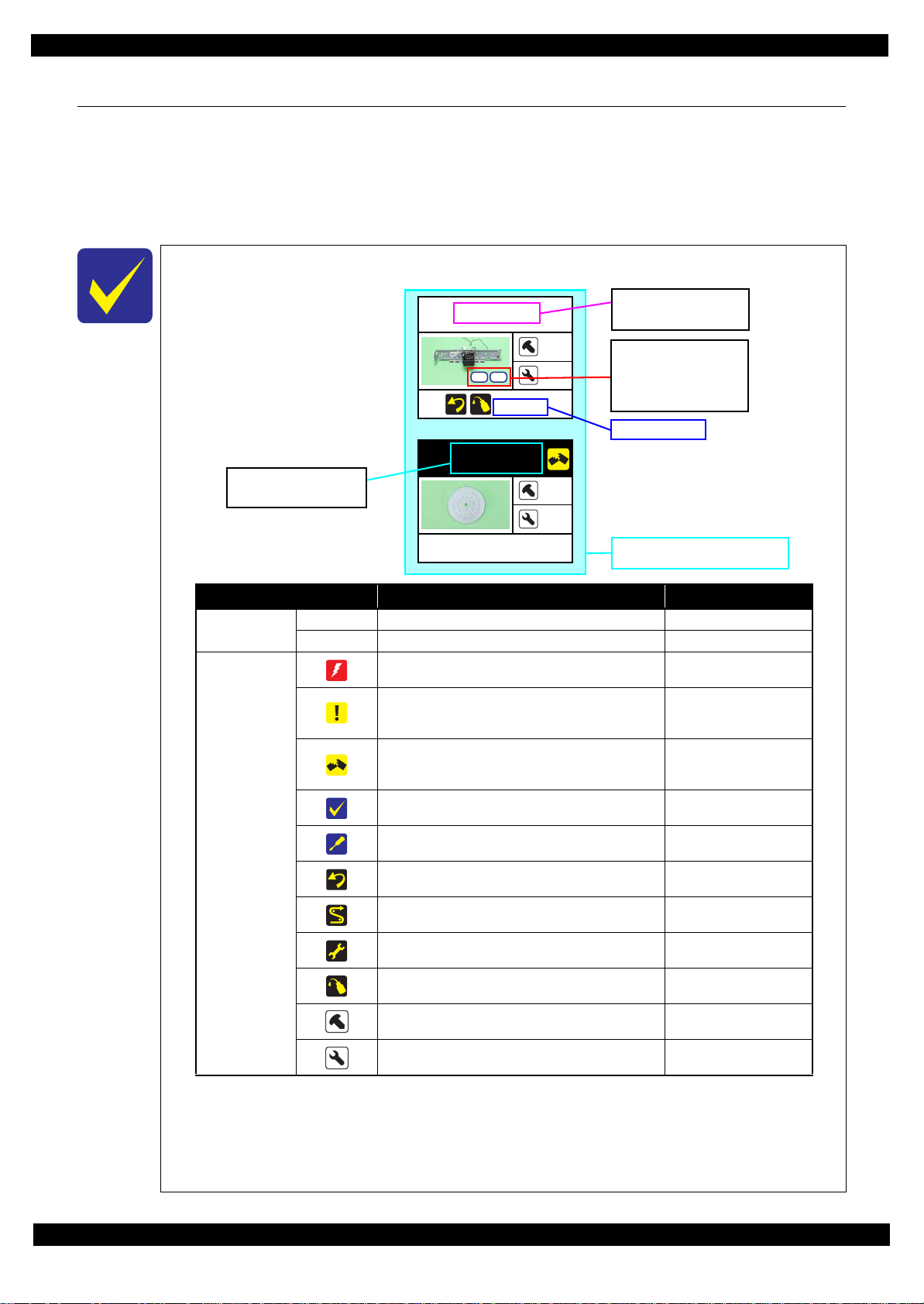

This section describes procedures for disassembling the parts/units in a flowchart form. For some parts/units,

detailed procedures or precautions are provided (accordingly indicated by icons and cell's color). Refer to the

explanations in the example chart below and perform an appropriate disassembling and assembling procedure.

(See" 1.3 Details of Disassembling/Assembling by Parts/Unit (p16)".)

For routing cables, see " 1.4 Routing FFC/cables (p21)"

The example below shows how to see the charts on the following pages.

Main Frame

4

5

(p 17, p 29)

S1

S5

EJ Roller Gear

---

---

---

Item Description Reference

Parts/unit name

White-letter

Parts/units supplied as an ASP ---

Black-letter

Parts/units not supplied as an ASP ---

Icon

Indicates a practice or condition that could result in

injury or loss of life if not strictly observed.

Indicates the reference

page in blue-letter

Indicates a practice or condition that could result in

damage to, or destruction of equipment if not strictly

observed.

Indicates the reference

page in blue-letter

Indicates the parts that are inevitably broken in the

disassembling procedure, and should be replaced with

a new one for reassembly.

---

Indicates necessary check items in the disassembling/

assembling procedure.

Indicates the reference

page in blue-letter

Indicates supplementary explanation for disassembly

is given.

Indicates the reference

page in blue-letter

Indicates particular tasks to keep quality of the

components are required.

Indicates the reference

page in blue-letter

Indicates particular routing of cables is required.

Indicates the reference

page in blue-letter

Indicates particular adjustment(s) is/are required.

Chapter 2 " Adjustment

(p23)"

Indicates lubrication is required.

Chapter 3 " Maintenance

(p27)"

Indicates the number of screws securing the parts/

units.

---

Indicates the points secured with other than a screw

such as a hook, rib, dowel or the like.

---

Shows removal/installation as a

unit/assy. is available.

Reference page

White letters indicate a

part/unit supplied as an

ASP.

Black letters indicate a

part/unit not supplied

as an ASP.

Shows the

correspondence to the

screw types and the

specified torque in the

"Screw type/torque list".

Confidential

Disassembly/Assembly Disassembly/Assembly Procedures 11

Epson Stylus NX125/T13/NX130 series Revision F

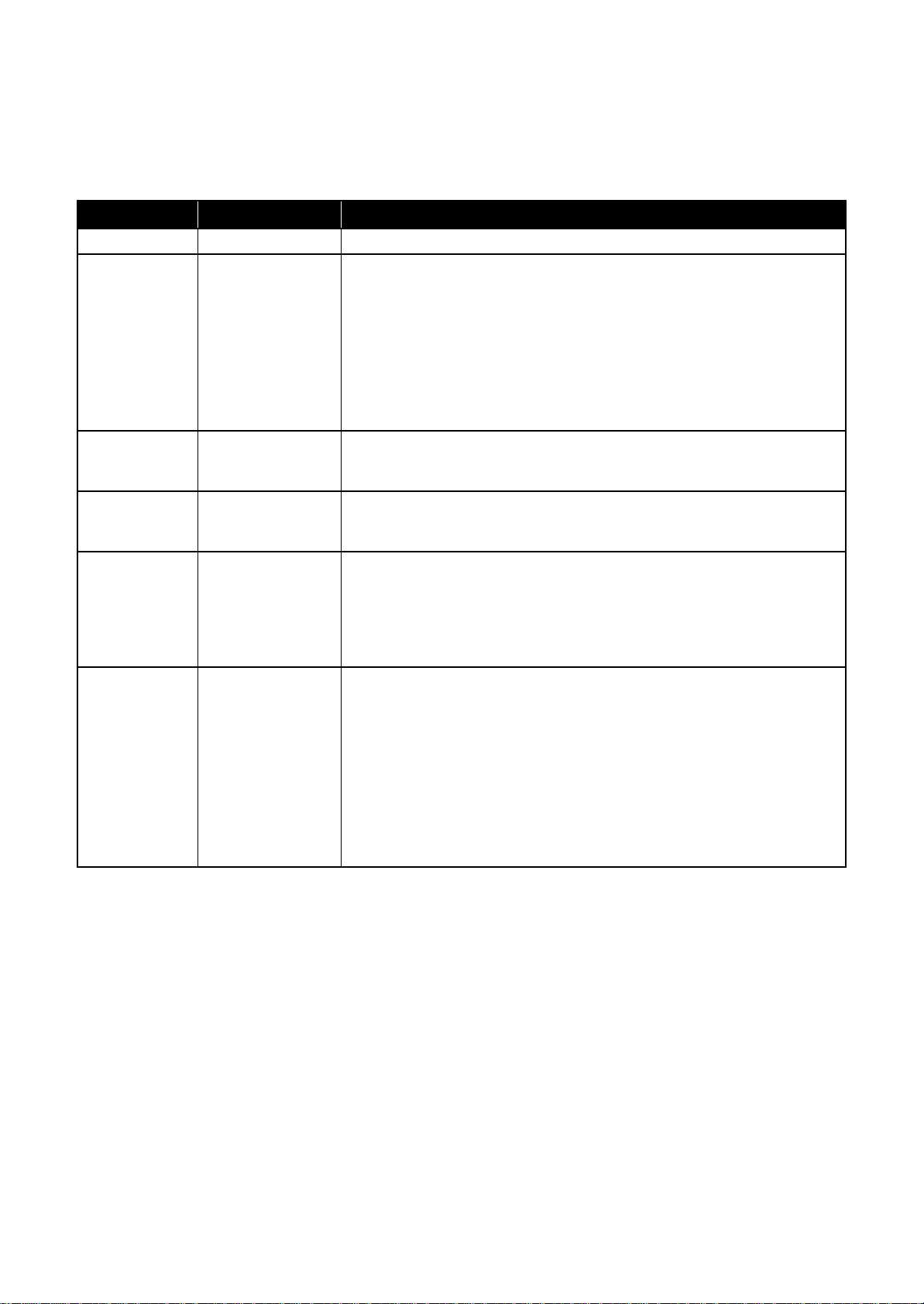

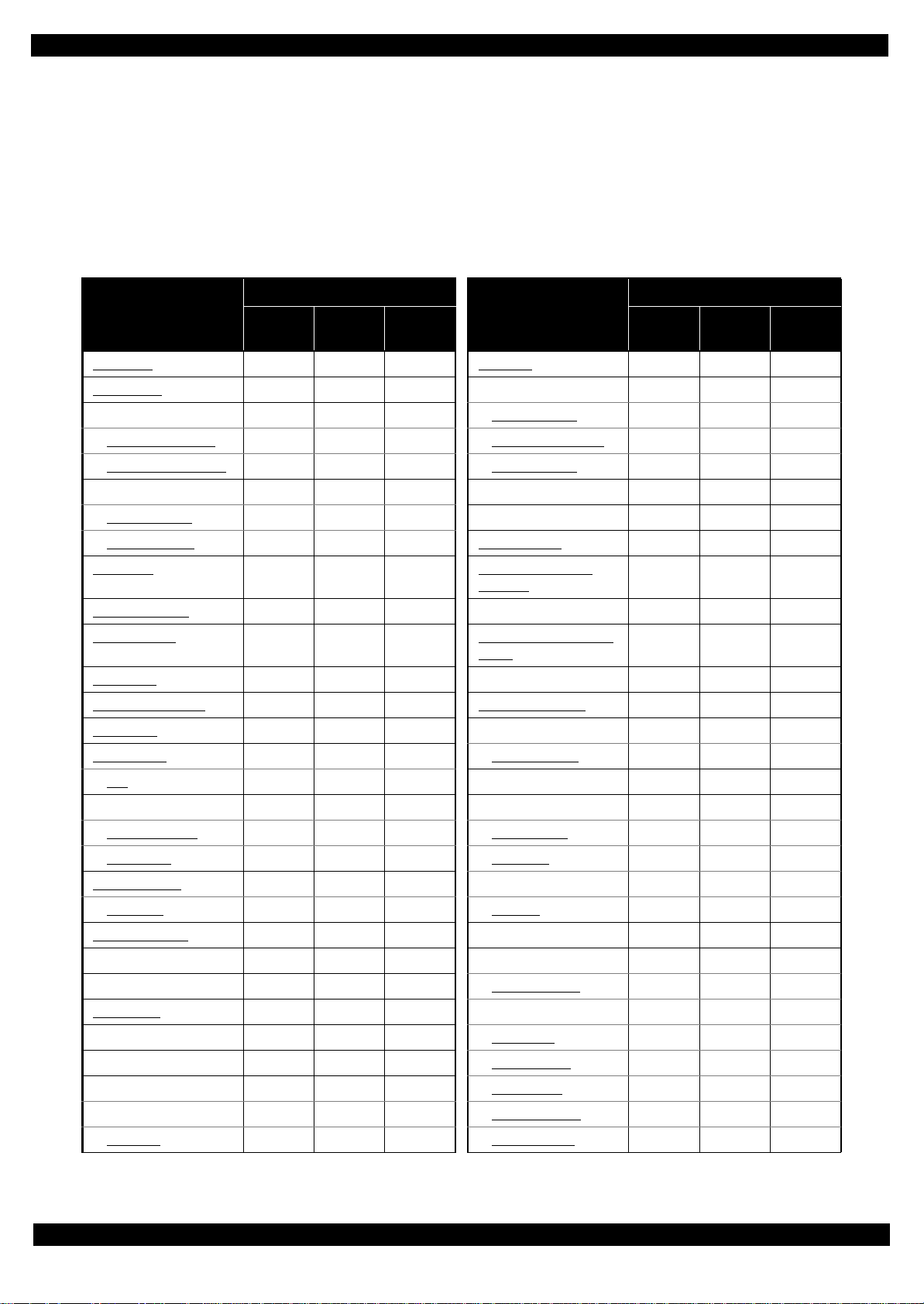

1.2.1 Standard Operation Time for servicing the product

The following are the standard operation time for servicing the product. Those are based on the MTTR result

measured using a prototype.

The underlined parts/units are supplied as After Service Parts.

Standard Operation Time for servicing NX125/NX130 series :See Table 1-2.

Standard Operation Time for servicing T13 series:: :::: :See Table 1-3.

Table 1-2. Standard Operation Time (NX125/NX130 series)

Parts/Unit

Time (second)

Parts/Unit

Time (second)

Replace-

ment

Adjust-

ment

Total

Replace-

ment

Adjust-

ment

Total

Panel Unit

14519Printhead 364 1027 1391

Panel Board

29 5 34 Holder Contact Assy 179 1027 1206

Paper Support Assy 12 5 17 CSIC Terminal

221 1027 1248

Paper Support Tray

20 5 25 CR Contact Module 194 1027 1221

Paper Support Tray 2

26 5 31 Holder Contact 293 1027 1320

Stacker Assy 12 5 17 EJ Frame Assy 149 5 154

Tray Exit Inner

15 5 20 EJ Roller 170 768 938

Tray Exit Outer

18523EJ Roller Gear 134 768 902

Jam Cover

18523

Waste Ink Pads (for

flushing)

230 768 998

Document Cover

9 5 14 Cover Flushing 195 768 963

Document Pad

20525

Porous Pad Front Paper

Guide

159 5 164

ASF Cover

5 5 10 CR Motor 235 768 1003

Ink Cartridge Cover

18 5 23 Power Supply Unit 129 768 897

Rear Cover

10 5 15 Waste Ink Tray Assy 163 822 985

Scanner Unit

79 5 84 Waste Ink Pads 239 822 1061

CIS

245 5 250 Main Frame 501 768 1269

Middle Housing Assy 126 5 131 Carriage Assy 906 768 1674

Middle Housing

146 5 151 PCB Encoder 953 768 1721

USB Cover

146 5 151 Head FFC 939 768 1707

LD Roller Assy

186 768 954 Timing Belt 915 768 1683

LD Roller

227 768 995 Carriage 995 768 1763

Housing Buckler

183 5 188 Upper Paper Guide 269 768 1037

Roller Idler Pick Assy 160 5 165 Pump Assy 791 768 1559

CR Scale 181 5 186 Gear Pump Idle

797 768 1565

Main Board

150 1027 1177 Lever Pick Clutch 798 768 1566

Driven Pulley Assy 363 768 1131 Gear Pump

811 768 1579

Pick Assy 376 768 1144 Bracket Pump

832 768 1600

Cap Unit 481 768 1249 Roller Pump

827 768 1595

Lever Cleaner 175 768 943 Waste Ink Tube

892 768 1640

Cap Assy

449 768 1217 Pump Housing 892 768 1660

Loading...

Loading...