Emerson Mass Flow Transmitter 00825-0100-4716, Mass Flow Transmitter 3095 User Manual

Quick Installation Guide

Start

End

Step 1: Mount the Transmitter

Step 2: Transmitter Installation

Step 3: Software Installation

Step 4: Connect the Wiring and Power Up (HART or Fieldbus)

Step 5: Configure the Transmitter (HART or Fieldbus)

Step 6: Trim the Transmitter

Product Certifications

Product Discontinued

00825-0100-4716, Rev DA

October 2009

Rosemount 3095 MultiVariable

Rosemount 3095 MultiVariable™ Mass Flow

®

Transmitter with HART

or FOUNDATION™

Fieldbus Protocol

Rosemount 3095MF Series Flowmeter Transmitter

www.rosemount.com

¢00825-0100-4716/¤

Quick Installation Guide

IMPORTANT NOTICE

WARNING

00825-0100-4716, Rev DA

Rosemount 3095 MultiVariable

© 2009 Rosemount Inc. All rights reserved. All marks property of owner. Rosemount and the Rosemount logotype are

registered trademarks of Rosemount Inc.

Rosemount Inc.

8200 Market Boulevard

Chanhassen, MN USA 55317

T (US) (800) 999-9307, F (952) 949-7001

T (International) (952) 90 6-8888

Emerson Process Management Asia Pacific

Private Limited

1 Pandan Crescent

Singapore 128461

T (65) 6777 8211, F (65) 6777 0947

This installation guide provides basic guidelines for the Rosemount 3095 MultiVariable

Mass Flow Transmitter (reference manual document number 00809-0100-4716). It also

provides the basic electronics guidelines for the 3095MFA (reference manual document

number 00809-0100-4809), the 3095MFC (reference manual document number

00809-0100-4810) and the 3095MFP (reference manual document number

00809-0100-4686). It does not provide instructions for configuration, diagnostics,

maintenance, service, or troubleshooting. Refer to the appropriate reference manual for

more instruction. These manuals are also available electronically on

www.rosemount.com.

Emerson Process Management GmbH & Co. OHG

Argelsrieder Feld 3

82234 Wessling

Germany

T 49 (8153) 9390, F49 (8153) 939172

Beijing Rosemount Far East Instrument Co.,

Limited

No. 6 North Street,

Hepingli, Dong Cheng District

Beijing 100013, China

T (86) (10) 6428 2233, F (86) (10) 6422 8586

October 2009

Explosions could result in death or serious injury:

Installation of this transmitter in an explosive environment must be in accordance with the

appropriate local, national, and international standards, codes, and practices.

• Before connecting a HART-based communicator in an explosive atmosphere, make

sure the instruments in the loop are installed in accordance with intrinsically safe or

non-incendive field wiring practices.

• In an Explosion-Proof/Flame-Proof installation, do not remove the transmitter covers

when power is applied to the unit.

• Do not remove the transmitter covers in explosive environments when circuit is live.

• Both transmitter covers must be fully engaged to meet explosion-proof requirements.

Process leaks may cause harm or result in death.

• To avoid process leaks, only use the o-ring designed to seal with the corresponding

flange adapter.

Electrical shock can result in death or serious injury.

• Avoid contact with the leads and the terminals. High voltage that may be present on

leads can cause electrical shock.

2

Quick Installation Guide

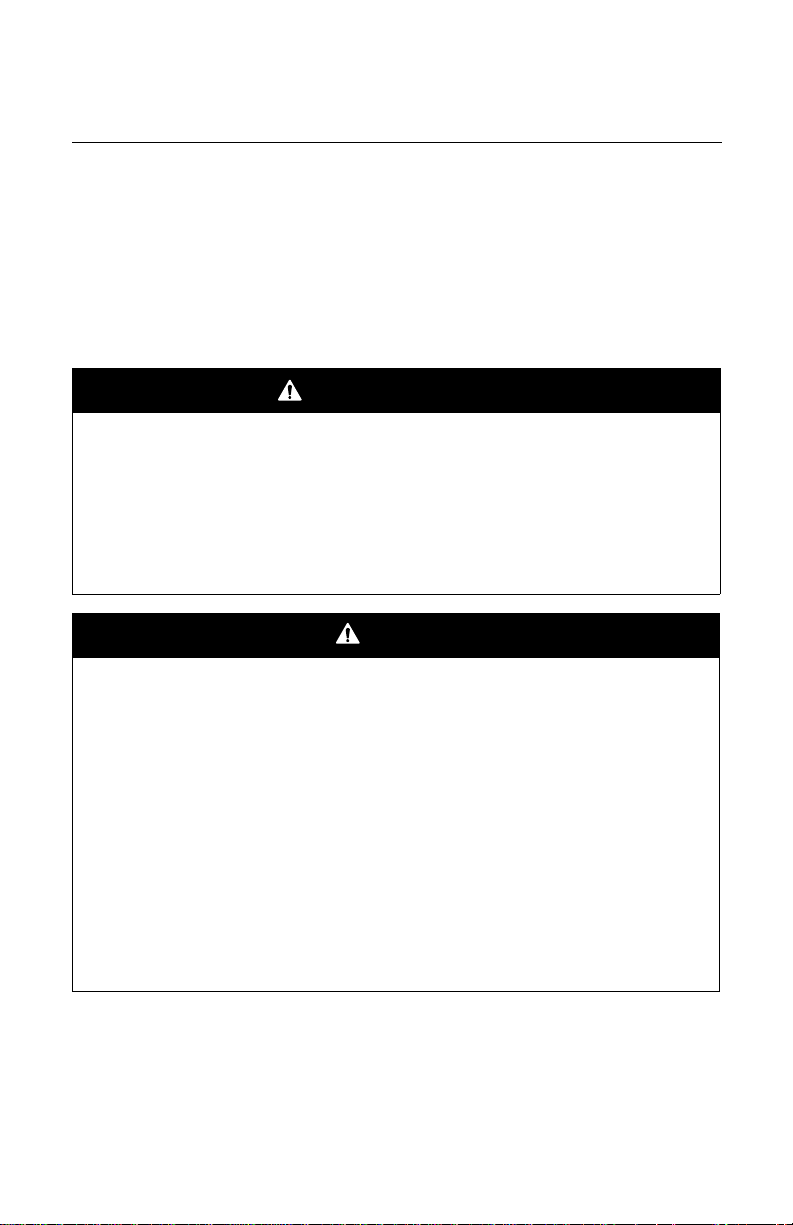

TRANSMITTER EXPLODED VIEW

Housing

O-ring

Cover

Housing Locking Screw

RTD Connector

Process Adapter O-ring

Electronics Board

Nameplate

Module O-ring

Sensor Module

Drain/Vent Valve

Flange Adapter O-ring

Optional Flange Adapters

Bolts

Coplanar Flange

Certification Label

LCD Display Assembly

LCD Display

Cover

Terminal Block

(HART)

Terminal Block (Fieldbus)

00825-0100-4716, Rev DA

October 2009

Rosemount 3095 MultiVariable

3

Rosemount 3095 MultiVariable

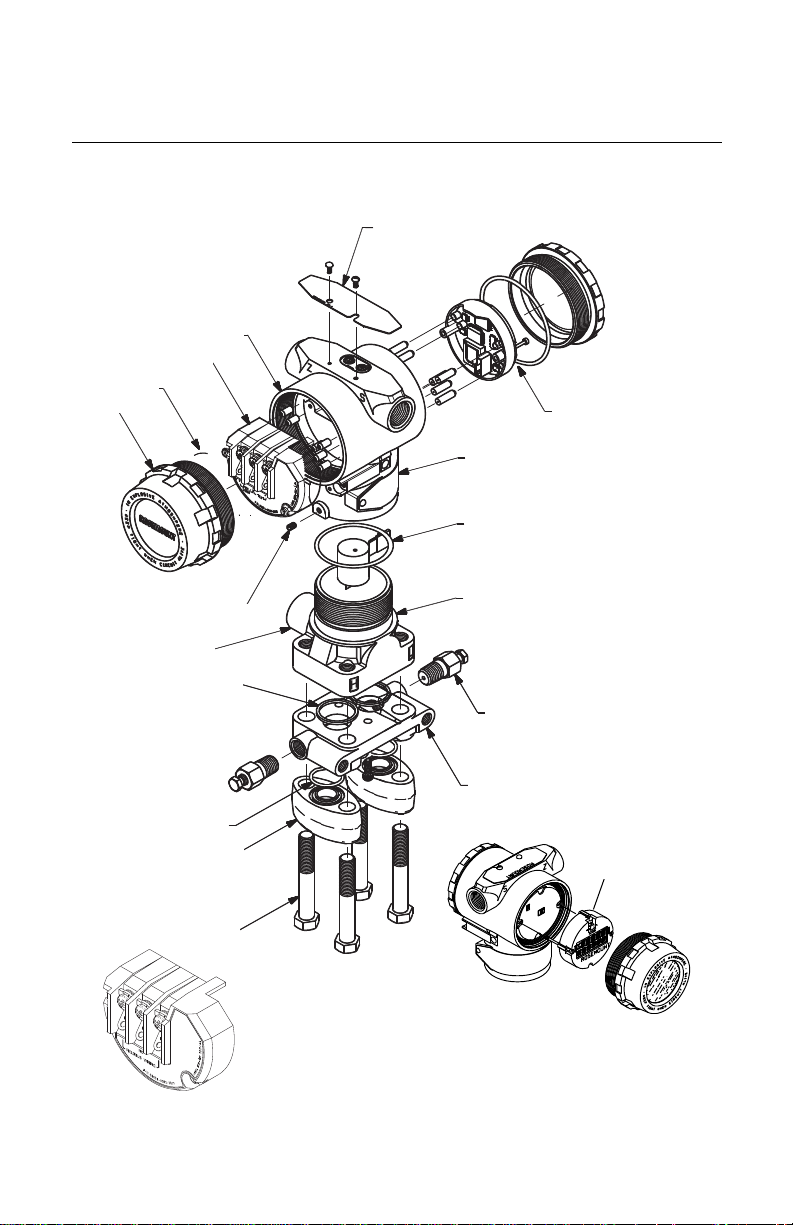

STEP 1: MOUNT THE TRANSMITTER

Flow

Flow

Flow

Flow

Liquid Flow Applications

1. Place taps to the side of the line.

2. Mount beside or below the taps.

3. Mount the transmitter so that the drain/vent

valves are oriented upward.

Gas Flow Applications

1. Place taps in the top or side of the line.

2. Mount beside or above the taps.

Steam Flow Applications

1. Place taps to the side of the line.

2. Mount beside or below the taps.

3. Fill impulse lines with water.

Quick Installation Guide

00825-0100-4716, Rev DA

October 2009

Figure 1. Using a Mounting Bracket

Panel Mount

(1) Panel bolts are customer supplied.

4

(1)

Pipe Mount

Quick Installation Guide

STEP 2: TRANSMITTER INSTALLATION

Housing Rotation Set

Screw (9/64-inch)

00825-0100-4716, Rev DA

October 2009

Rosemount 3095 MultiVariable

Consider Housing Rotation

To improve field access or to better view the optional LCD display:

1. Loosen the housing rotation set screw.

2. Rotate the housing clockwise to the desired position – up to 180° from its original

position. Over rotating will damage the transmitter.

3. If the desired position is attained, tighten the housing rotation set screw.

4. If the desired position cannot be reached because the housing will not rotate further,

rotate the housing counterclockwise until in the desired position is attained (up to 180°

from its original position).

5. Tighten the housing rotation set screw.

Field Installation

1. Mount the transmitter

a.Install the flange or flange/adapter bolt finger-tight.

b.Torque bolts to initial torque value using a cross pattern (see Table 1). When

installing to a mounting bracket, torque bolts to 125 in./lb (169 N/m)

Table 1. Torque Cross Pattern

Bolt Material Initial Value Final Value

Carbon Steel (CS) 300 in./lb (34 N/m) 650 in./lb (73 N/m)

Stainless Steel (SST) 150 in./lb (17 N/m) 300 in./lb (34 N/m)

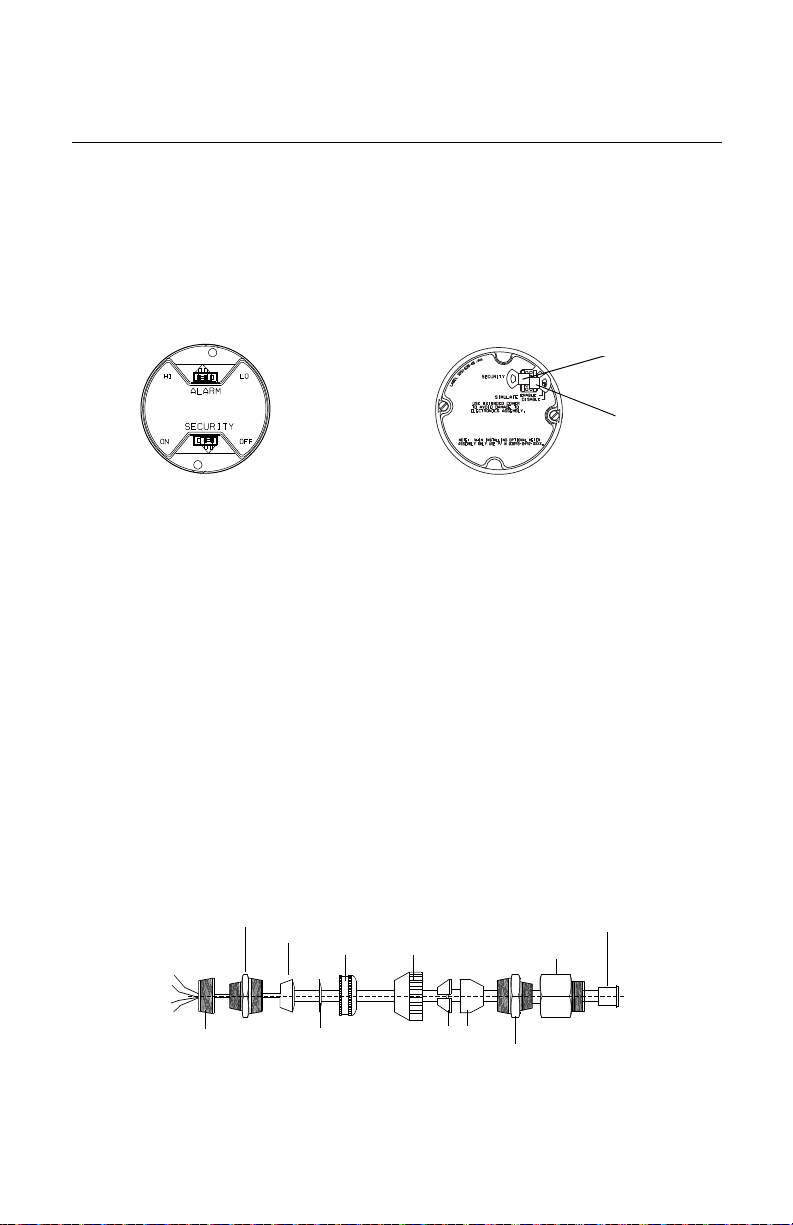

2. Set the Security Jumper, which is located on the front of the electronics board inside the

electronics housing cover. Putting the Security Jumper in the ON position will protect

against configuration change from being unintentionally made. The transmitter operates

normally if the jumpers are not installed. The Security default is OFF.

5

Quick Installation Guide

STEP 2 CONTINUED...

HART Electronics Board

F

OUNDATION fieldbus Electronics Board

Simulate Jumper

Security Jumper

Washer

Cap

Black Cable Connector

RTD Cap

Conductive Bushing

Connect

to RTD

Compression Fitting

Compression Fitting

Cable Adapter

3

/4 to 1/2-14 NPTAdapter

Bushing

00825-0100-4716, Rev DA

Rosemount 3095 MultiVariable

3. Set the Failure Mode Alarm (HART devices), which is located on the front of the

electronics board inside the electronics housing cover. The Alarm Jumper position

determines if the output is driven high or low when a failure is detected. The transmitter

operates normally if the jumpers are not installed and the Alarm default fail is HI.

Figure 2. Alarm Jumper Location

4. Set the Simulate Jumper (FOUNDATION fieldbus devices), which is located on the front of

the electronics board inside the electronics housing cover. The jumper is used to

simulate the measurement and is used as a lock-out feature for the AI function block. To

enable the simulate feature, insert the jumper across ENABLE while the transmitter is

powered. The default position for the Simulate Jumper is DISABLE. Enable the simulate

feature after power is applied to the device. Simulate is automatically disabled

regardless of jumper position if power is cycled.

5. Connect the transmitter to the process.

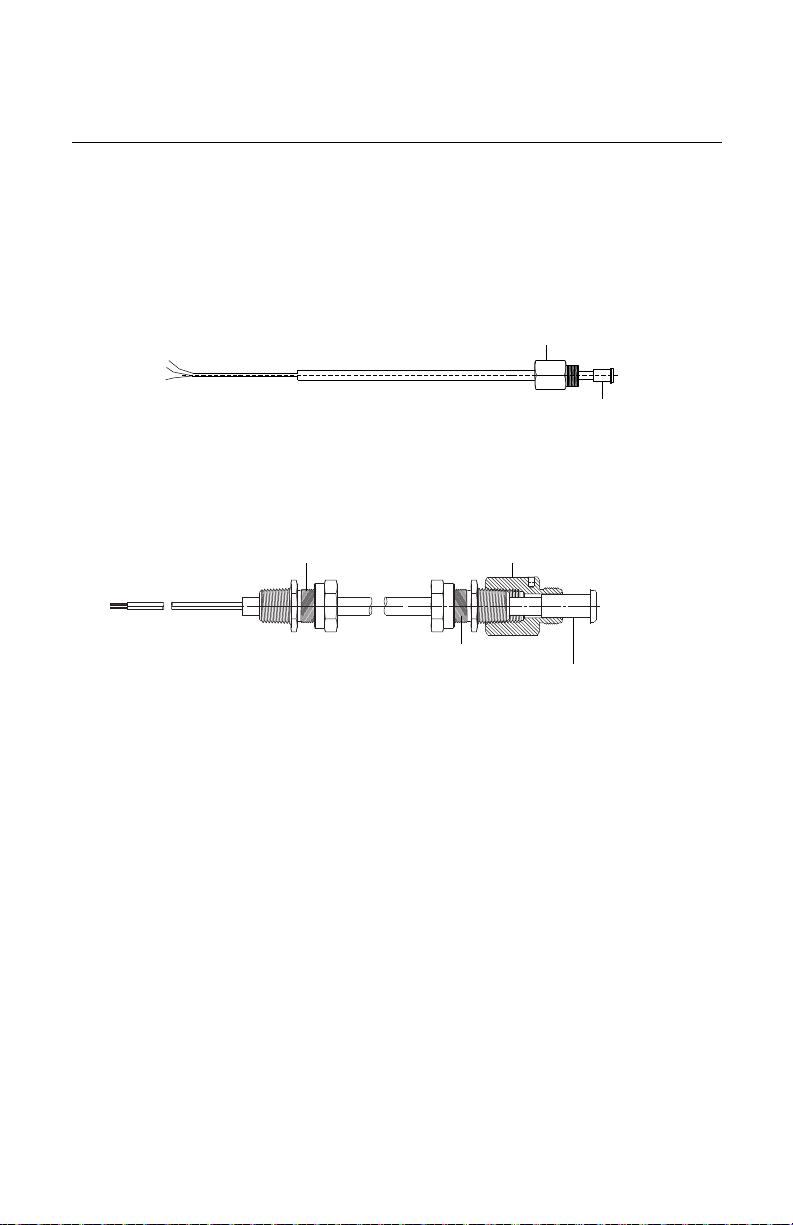

6. Install the RTD Cable Assembly (optional). All RTD 3095 Cable Assemblies use the

3095 RTD Cable Connector. Identify the cable type being installed and follow the steps

below.

• Installing an Armored Shielded RTD Cable (See Figure 3)

a.Fully engage the black cable connector to the 3095 RTD connector.

b.Tighten the cable adapter until metal contacts metal.

c.Install the compression fitting.

d.Tighten the cap onto the compression fitting.

October 2009

Figure 3. Armored Shielded RTD Cable

6

Quick Installation Guide

STEP 2 CONTINUED...

Cable Adapter 1/2–14 NPT

Black Cable Connector

Black Cable Connector/ RTD Connector

Cable Adapter

Cable Gland

RTD Cable Gland CM20

00825-0100-4716, Rev DA

October 2009

• Installing a Shielded 3095 RTD Cable (See Figure 4)

Note: Shielded cable is intended for use in a conduit.

a.Fully engage the black cable connector to the 3095 RTD Connector.

b.Tighten the cable adapter until metal contacts metal.

Figure 4. Shielded RTD Cable

• Installing a ATEX/IECEx Flameproof 3095 RTD Cable (See Figure 5)

a.Fully engage the black cable connector to the 3095 RTD Connector.

b.Tighten the cable adapter and cable gland until metal contacts metal.

Figure 5. ATEX/IE CEx Flameproof RTD Cable

Rosemount 3095 MultiVariable

7. Check all process connections for leaks.

8. Connect the appropriate wiring (see Step 5). Ground the transmitter according to

national and local electrical codes. Install field wiring grounding (optional).

7

Quick Installation Guide

STEP 2 CONTINUED...

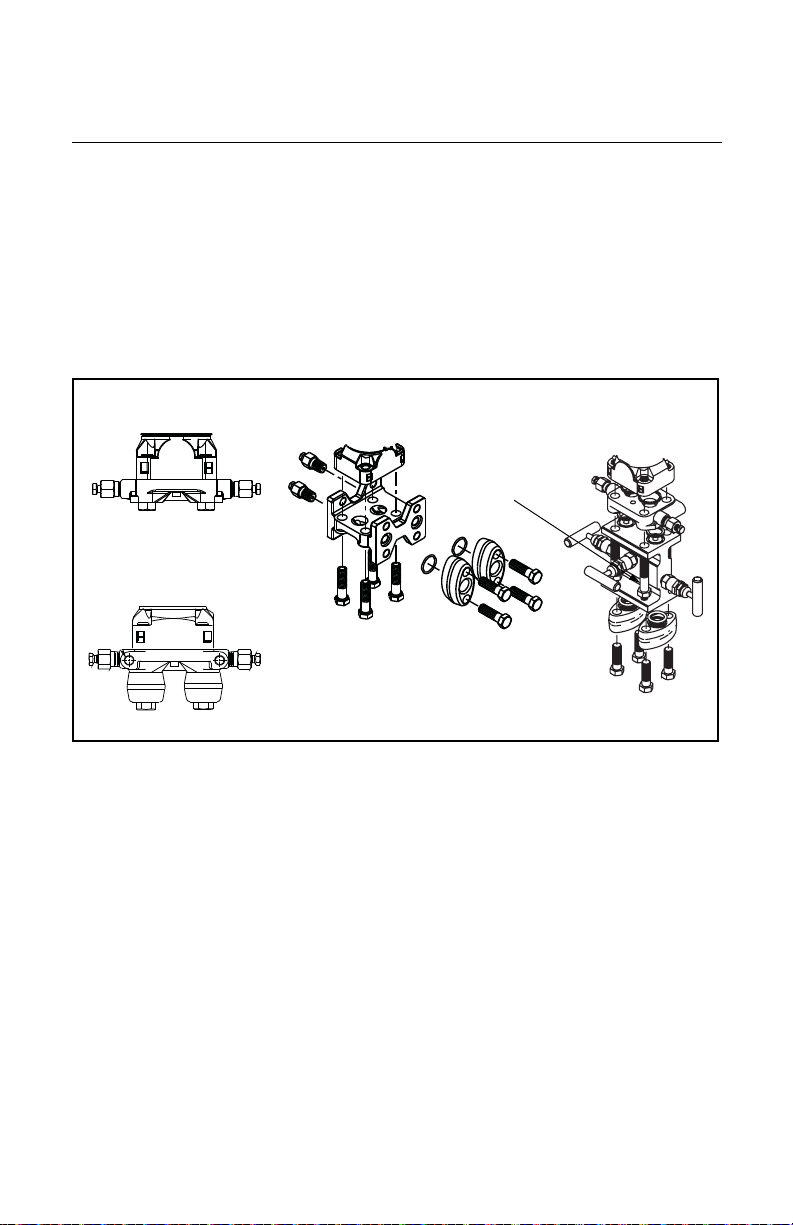

4 x 1.75-in. (44 mm)

4 x 2.88-in. (73 mm)

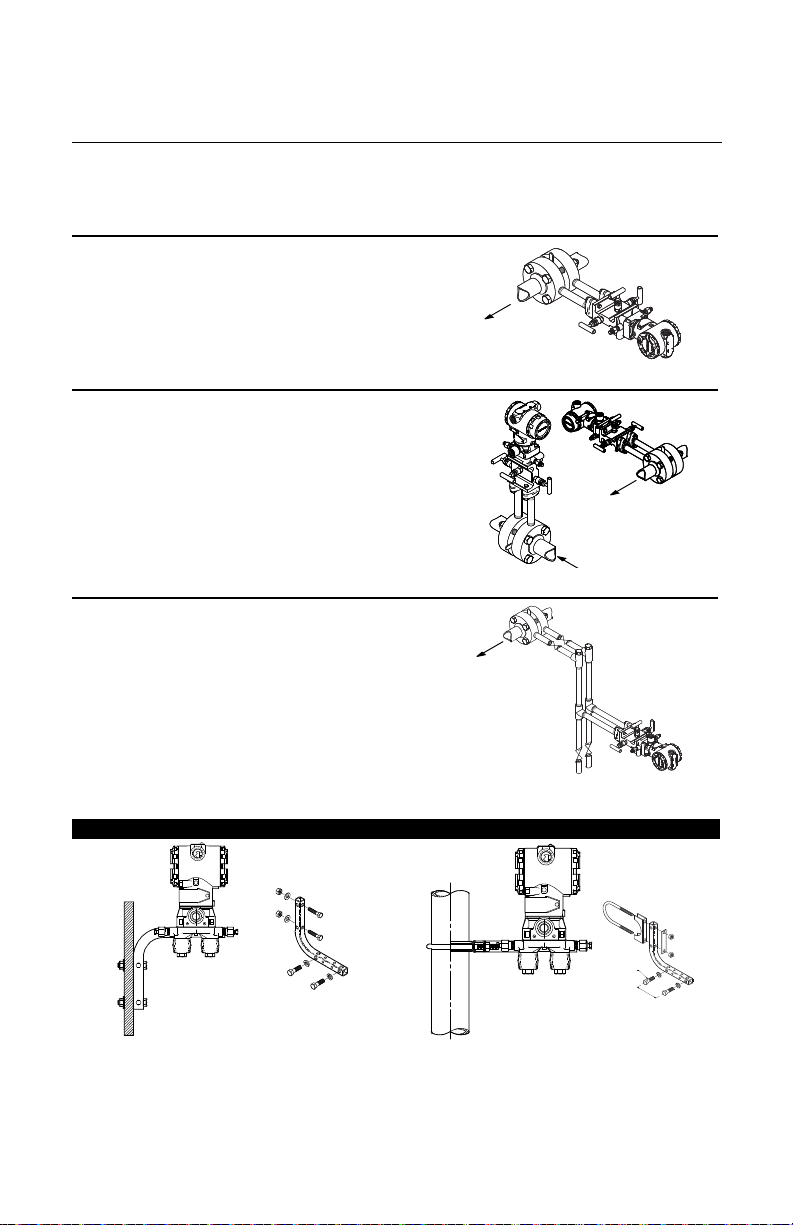

A. Transmitter with

Coplanar Flange

B. Transmitter with Copla nar

Flange and Optional

Flange Adapters

C. Transmitter with Traditional

Flange and Optional Flange

Adapters

D. Transmitter with

Coplanar Flange and

Optional Manifold and

Flange Adapters

4 x 1.75-in. (44 mm)

4 x 1.50-in. (38 mm)

4 x 1.75-in. (44 mm)

4 x 2.25-in. (57 mm)

00825-0100-4716, Rev DA

Rosemount 3095 MultiVariable

October 2009

Bolting Considerations

If the transmitter installation requires assembly of the process flanges, manifolds, or flange

adapters, follow these assembly guidelines to ensure a tight seal for optimal performance

characteristics of the transmitters. Use only bolts supplied with the transmitter or sold by

Emerson as spare parts. Figure 6 illustrates common transmitter assemblies with the bolt

length required for proper transmitter assembly.

Figure 6. Common Transmitter Assemblies

Bolts are typically carbon steel or stainless steel. Confirm the material by viewing the

markings on the head of the bolt and referencing Figure 7. If bolt material is not shown in

Figure 7, contact the local Emerson Process Management representative for more

information.

Use the following bolt installation procedure:

1. Carbon steel bolts do not require lubrication and the stainless steel bolts are coated with

a lubricant to ease installation. However, no additional lubricant should be applied when

installing either type of bolt.

2. Finger-tighten the bolts.

3. T orque the bolt s to the initial torque value using a crossing pattern. See Figure 7 for initial

torque value.

4. Torque the bolts to the final torque value using the same crossing pattern. See Figure 7

for final torque value.

5. Verify that the flange bolts are protruding through the isolator plate before applying

pressure.

8

Quick Installation Guide

STEP 2 CONTINUED...

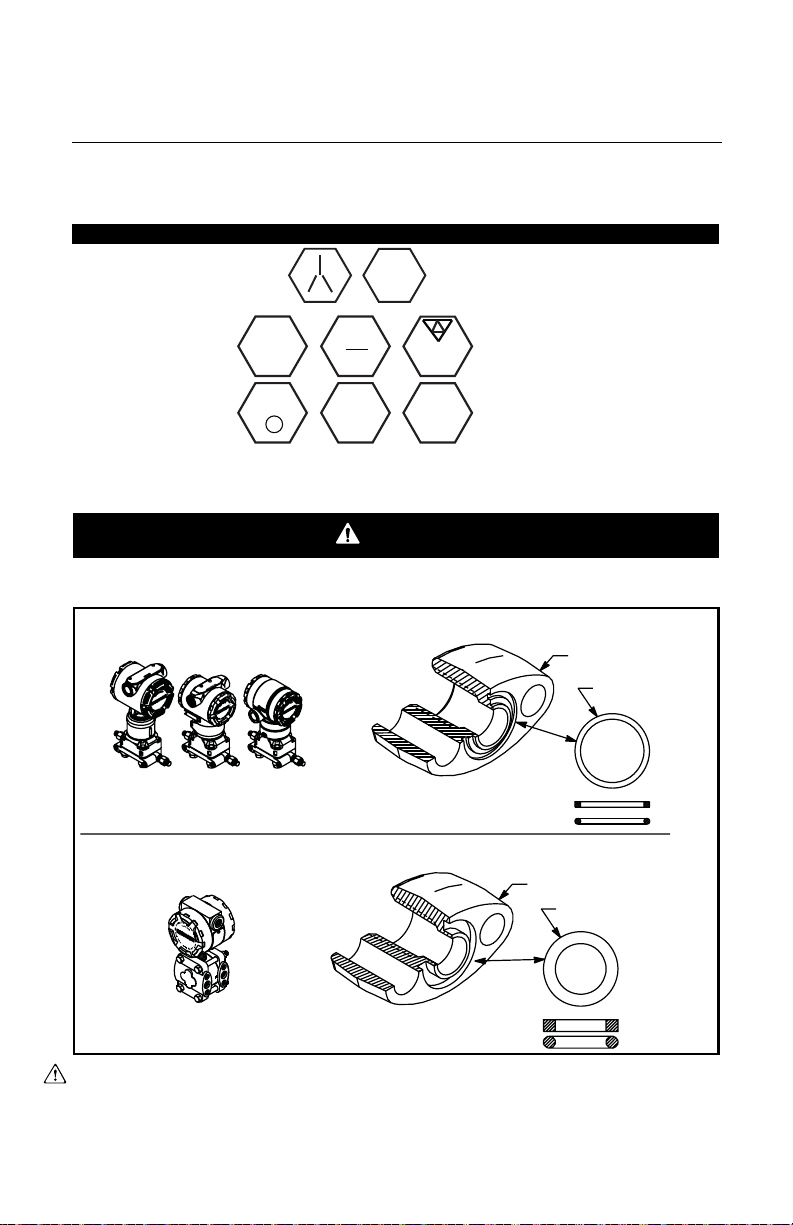

WARNING

B7M

316

316

316

SW

316

STM

316

R

B8M

Rosemount 3051S / 3051 / 2051 / 3095

Rosemount 1151

Flange Adapter

O-ring

Flange Adapter

O-ring

PTFE Based

Elastomer

PTFE

Elastomer

00825-0100-4716, Rev DA

October 2009

Figure 7. Torque values for the flange and flange adapter bolts

Bolt Material Head Markings Initial Torque Final Torque

Carbon Steel (CS) 300 in.-lbs. 650 in.-lbs.

Stainless Steel (SST) 150 in.-lbs. 300 in.-lbs.

Rosemount 3095 MultiVariable

O-rings with Flange Adapters

Failure to install proper flange adapter O-rings may cause process leaks, which can result in death or

serious injury. The two flange adapters are distinguished by unique O-ring grooves. Only use the O-ring

that is designed for its specific flange adapter, as shown below.

Whenever the flanges or adapters are removed, visually inspect the o-rings. Replace them if

there are any signs of damage, such as nicks or cuts. If the o-rings are replaced, re-torque

the flange bolts and alignment screws after installation to compensate for seating of the

PTFE o-ring.

9

Quick Installation Guide

STEP 3: SOFTWARE INSTALLATION

00825-0100-4716, Rev DA

Rosemount 3095 MultiVariable

The 3095 Engineering Assistant (EA) for HART and 3095 Engineering Assistant (EA) for

FOUNDATION Fieldbus software programs can be installed on the same computer. The

applications cannot be open simultaneously.

October 2009

3095 Engineering Assistant (EA) for HART Software Installation

1. Install the Program

a.Place the CD-ROM in the drive and run setup.exe from Windows NT, 2000, or XP.

b.After installing the software, install the HART Modem (see “Installing the HART

Modem” on page 11).

2. Upgrade the previous versions of Engineering Assistant program (if required)

a.Place the CD-ROM disk 2 into the drive and run the EAUpgrade.exe from Windows

98, NT, 2000, or XP. To properly install, the program will first uninstall Engineering

Assistant from the computer. (Upgrades also are available at www.rosemount.com.)

b.Remove the installation disk and reboot the computer to complete installation.

c.To install the upgraded program, run the EAupgrade.exe from Windows 95,98, or

NT again.

3. Connect the computer to the 3095 transmitter.

a.Connect the HART modem cable to the computer using the 9-pin serial or USB

communications port on the computer.

b.Open the cover above the side marked Field Terminals, and connect the

mini-grabbers to the two 3095 terminals marked COMM.

4. Select Engineering Assistant for HART from the program menu.

On-Line Mode: EA communicates directly with the 3095 through AMS.

a.In AMS Explorer view or AMS Connection view, right-mouse click on a 3095 device

tag or icon.

b.Select SNAP-ON/Linked Apps > Engineering Assistant.

Off-Line Mode: Engineering Assistant does not communicate directly with the 3095.

Instead, the EA configuration is sent to a 3095 later when Engineering Assistant is in

on-line mode. In the off-line mode a future device needs to be created in order to launch

Engineering Assistant.

a.In AMS Explorer view or AMS Device Connection view, left click on Plant Database

to the Area folder.

b.Left click on Area to the Unit folder.

c.Left click on Unit to the Equipment Module folder.

d.Left click on Equipment Module to the Control Module folder.

e.right-mouse click on Control Module to the pop-up context menu.

f. Select Add Future Device.

g.Select 3095MV Template and click OK.

h.Right-mouse click on Future device to pop-up context menu.

i. Select SNAP-ON/Linked Apps > Engineering Assistant.

10

Loading...

Loading...