Emerson Hy-Line, Large-Part Vibration Welding Systems, M624HL, Mini II, VW4O-2 Technical Information

Vibration Welding

Vibration Welding

Material Compatibility

Virtually all thermoplastic polymers can be welded to themselves utilizing the vibration welding technique. Vibration welding also offers the largest range of welding of dissimilar materials, as well as the ability to weld different molding grades (injection molded, extruded, etc.) to each other. Since it uses mechanical friction to weld, the process puts as much energy as required at the interface to melt the plastic. As long as the parts are able to be vibrated relative to each other in the plane of the joint, the process may be used.

This method of assembly, when compared with ultrasonic assembly, is particularly advantageous for semi-crystalline resins such as acetal, nylon, thermoplastic polyester, polyethylene, and polypropylene, as well as PVC, cellulosics, thermoplastic rubber, and elastomers, filled and reinforced resins, and those exhibiting

hygroscopic properties. Fillers such as glass, minerals, talc, and mica do not present a problem for the process, as long as the percentage is kept under 40%. Different grades of a material can be welded to each other.

Vibration welding replaces ultrasonic welding in many troublesome applications, since the ultrasonic process relies on transmitting energy through the part to the joint interface. For example, the ability to transmit weld energy is dependent upon the grade of material, as well as part shape and size, the percentage of regrind, the heat history of the plastic, as well as the color additives, melt flow index and filler content. Vibration welding is not subject to the same constraints, since energy is not transmitted through the part, but rather it is generated directly at the interface.

Equipment Configurations

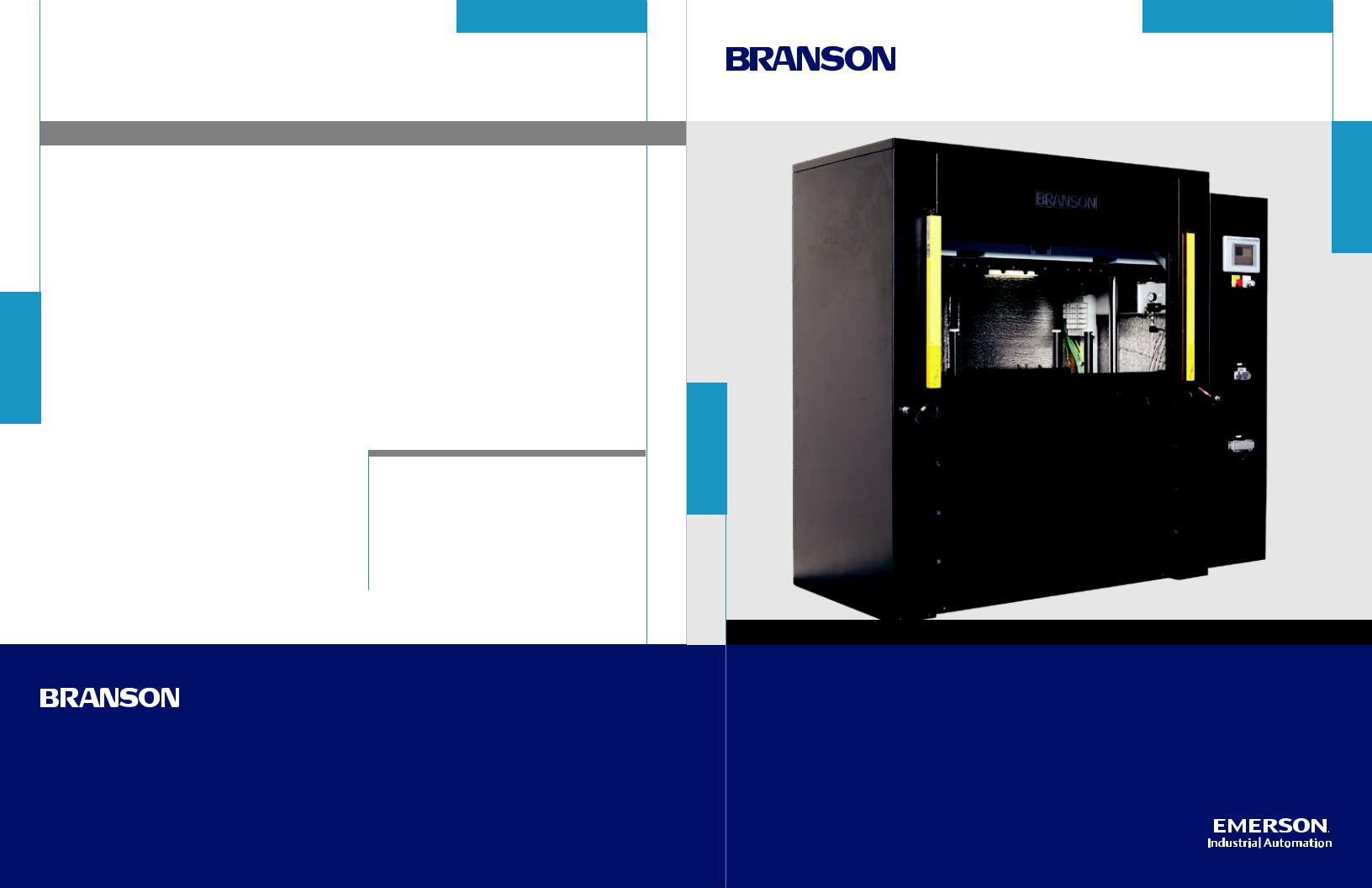

Branson vibration welders are available for part sizes up to 70” x 36” and larger. The smallest vibration welder has a footprint of 36” by 38”. The modular component design allows components to be integrated into automated production lines. Multiple control levels are available, and many units are capable of remote monitoring and diagnostics.

Branson Ultrasonics Corporation

41 Eagle Road, Danbury, CT 06813-1961

(203) 796-0400 • Fax: (203) 796-9838 www.bransonultrasonics.com

e-mail: info@bransonultrasonics.com

475 Quaker Meeting House Rd.,

Honeoye Falls, NY 14472

(585) 624-8000 • Fax: (585) 624-1262

Vibration Welding © Branson Ultrasonics Corporation 1999

The Emerson logo is a trademark and service mark of Emerson

Electric Co. Revised and printed in the U.S.A. 4/11

Vibration Welding

WELDING l STAKING l INSERTION l SWAGING l FORMING l SPOT WELDING l DEGATING l CUTTING AND SEALING

Vibration Welding

Traditional Vibration Welding and “Clean”

Vibration Welding

Loading...

Loading...