Emerson Fisher Vee-Ball V150, Fisher Vee-Ball V200, Fisher Vee-Ball V300 User Guide

www.Fisher.com

Fisher

High-Capacity Rotary

Valves for General or Fibrous

Slurry Service

W9415

Figure 1. Fisher High-Capacity Rotary Valve

Rotary valve efficiency with globe valve ruggedness for general gas, steam, or liquid

service and for fibrous slurry applications

DN 25 to DN 300 and NPS 1 to 24 x 20

Choice of seal types and materials—composition, flat metal, heavy-duty metal, or

flow ring

Temperatures to 427C

Pressures to PN40 and CL600

ENVIRO-SEAL

packing systems to help ensure compliance with environmental

emissions requirements

FIELDVUE

digital valve controllers offer digital control and remote diagnostics. The

proven line of Fisher positioners, controllers, transmitters, and switches also is

available.

Product Flier

PF51.3:Vee-Ball

D102429X012

May 2009

High-Capacity Rotary Valves

High-Capacity Rotary Valves

Product Flier

PF51.3:Vee-Ball

May 2009

2

The Fisher Vee-Ball Valve Family

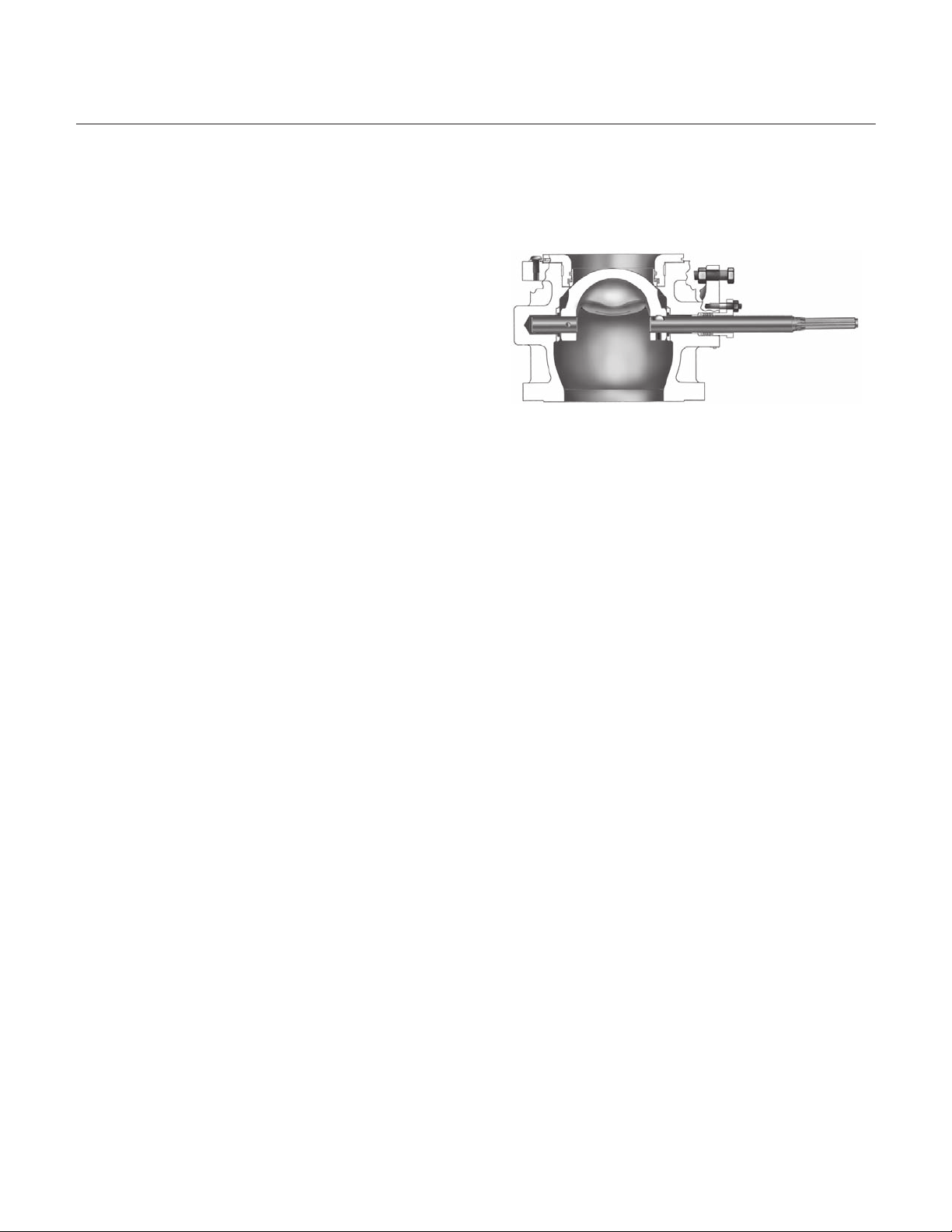

Vee-Ball rotary valves combine the features and

performance you need. These features are made

available through expertise in applications, valve

design, and manufacturing.

The valves are suitable for throttling or on-off

service. They are often used with a full 0 to 90

degree ball rotation.

Fisher V150, V200, and V300 Vee-Ball valves use

the time-proven V-notch ball that provides

high-capacity control of liquid, gas, steam, and

fibrous slurries. The shearing action of the ball

allows smooth, non-clogging operation, and the

unrestricted, straight-through flow ensures high

capacity.

Easy Installation . . . Fisher V150 and V300 integral

flanges eliminate exposed flange studs, and the

V200 features line-centering lugs to simplify

alignment.

High Rangeability . . . Flow coefficient ratio is 300

to 1.

Reduced Maintenance Costs . . . The V150, V200,

and V300 valves have interchangeable trim parts to

reduce spare parts inventory and cost and simplify

maintenance procedures and training. Metal and soft

seals are interchangeable within a valve body.

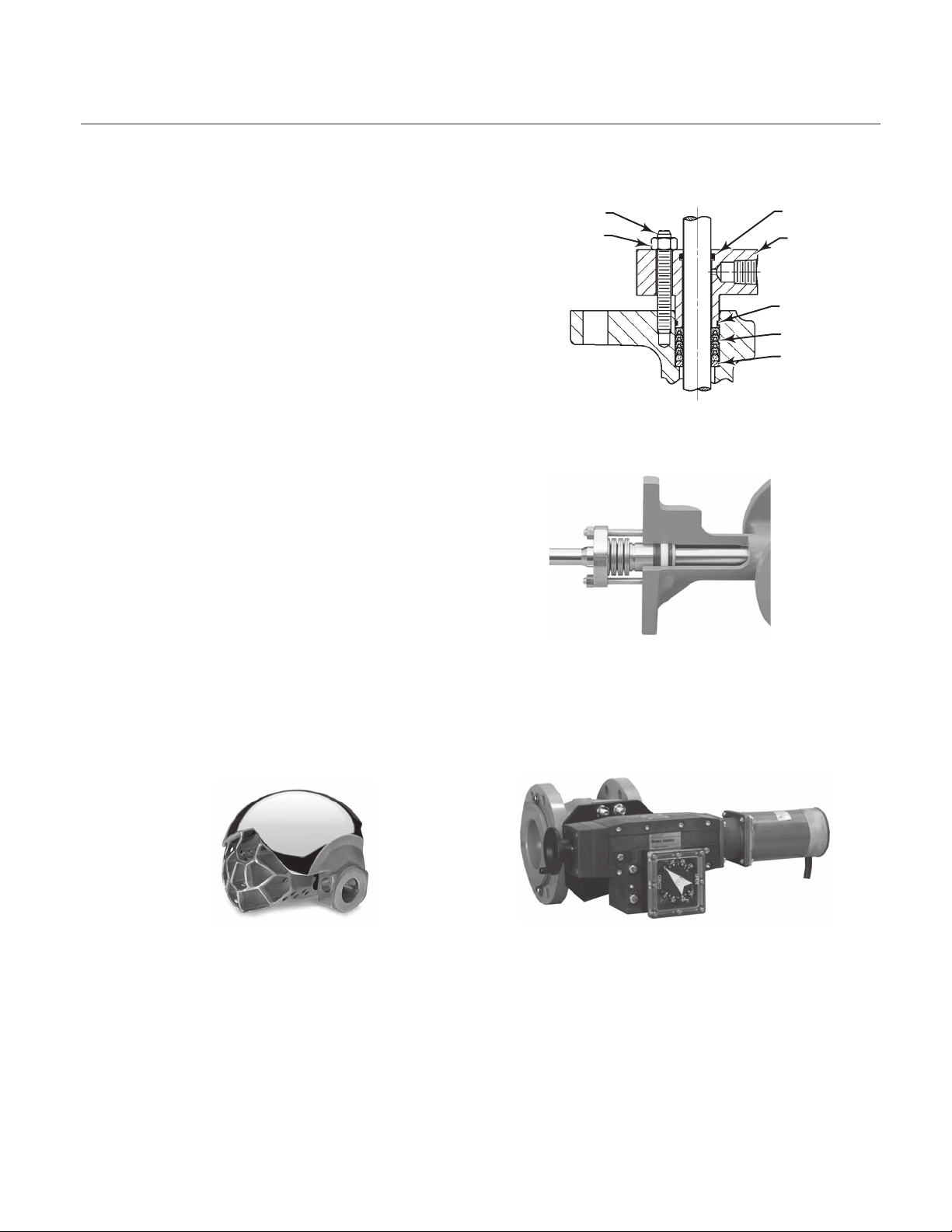

Protection Against Process Fluid Emissions . . .

Optional ENVIRO-SEAL packing systems provide an

excellent shaft seal to prevent the loss of valuable or

hazardous process fluids. These live-loaded

systems provide long packing life and reliability.

Materials for Sour Service . . . Emerson Process

Management offers materials and manufacturing

procedures for compliance with NACE (National

Association of Corrosion Engineers) standard NACE

MR01752002, MR0103, and MR0175 / ISO 15156.

W74351/IL

Figure 2. Fisher V150 or V300 Valves

Easy Seal Inspection . . . Seals can be inspected

without removing the actuator or disassembling the

valve.

Noise Attenuator Ball. . . Depending on service

conditions, up to -10dBA acoustical attenuation and

a K

C

of 1.0 for liquid flow are possible with the noise

attenuator ball (available with DN 100 through DN

300 and NPS 4 through 20 valves).

Basis Weight Control Valve . . . Fisher V150,

V200, and V300 valves are available to meet the

precision control requirements of basis weight

control in the paper-making industry.

Other Rotary Products

Fisher V500 Valve . . . The V500 valve uses rugged

valve components and a choice of erosion-resistant

trim materials for highly erosive and severe

operating conditions at pressures to PN 100 (CL600)

and temperatures to 538C.

Fisher CV500 Valve . . . The CV500 combines the

rangeability of the cammed-segmented V-notched

ball, with the inherent ruggedness found in the V500

heavy duty bearings, seals and body. This

combination provides a balance of high capacity,

erosion resistance, and pressure control for liquid

and gas.

High-Capacity Rotary Valves

Product Flier

PF51.3:Vee-Ball

May 2009

3

The Fisher Vee-Ball Valve Family (Continued)

Other Rotary Products (Continued)

Fisher V250 . . . The V250 valve is a heavy-duty

valve often used in gas transmission lines, gas

distribution, or liquid pipelines. It is available in sizes

to NPS 24 and CL600 or CL900

pressure-temperature ratings.

Fisher V260 . . . The V260 valve has special

energy-dissipating trim to reduce noise effects that

cause pipeline vibrations. It is available in NPS 8,

10, 12, 16, 20, and 24 sizes.

Fisher Control-Disk Valve . . . This rotary valve

with an equal percentage flow characteristic

provides an improved throttling range. This improved

capability allows you to control closer to the target

set point, regardless of process disturbances. This

capability results in a reduction in process variability.

Fisher 8532, 8580, and 8510/8510B . . . This family

of high performance butterfly valves is designed for

optimal control performance, as well as tight shutoff

isolation service. These valves are available in size

range NPS 2 to 24 and a variety of pressure classes

and body styles.

Fisher A11 . . . The POSISEAL A11

high-performance butterfly valves are designed for

optimal control performance as well as tight shutoff

for isolation, automated on/off service. These valves

feature square, keyed, or splined shafts. These

valves are designed for use in highpressure,

hightemperature, or cryogenic applications, and

available in sizes NPS 3 through 72, and pressure

classes up to CL2500.

ENVIRO-SEAL PACKING SYSTEM

(SINGLE PTFE V-RING)

PACKING STUD

PACKING NUT

O-RING

PACKING

FOLLOWER

PACKING

SET

PACKING BOX

RING

O-RING

14B9917-B

E0735 / IL

LEAK-OFF PACKING ASSEMBLY

FOR NPS 1 THROUGH 12 VALVES

W7557-1/IL

Figure 3. Optional Rotary Valve Packing Assemblies

BASIS WEIGHT VALVE AND ACTUATOR

W5393

Vee-Ball VALVE BALL WITH ATTENUATOR

W7555/IL

Figure 4. Attenuator and Basis Weight Valve

High-Capacity Rotary Valves

Product Flier

PF51.3:Vee-Ball

May 2009

4

Selecting Vee-Ball Products

Only a few of the more commonly selected product materials,

sizes, options, and accessories are covered in this flier.

Contact your Emerson Process Management sales office (refer

to the back cover) for assistance in selecting and sizing these

products. More detailed specifications are available on request.

Selecting Valve Components

Valve Type Selection 5...............................

Body Materials, End Connections, and Ratings 7.........

Valve Component Materials and Temperatures 7.........

Selecting an Actuator

Fisher 2052 Diaphragm Actuator 8.....................

Fisher 1051 and 1052 Diaphragm Actuators 9...........

Fisher 1061 Piston Actuator 10........................

Selecting Valve Instrumentation and Accessories

Fisher FIELDVUE Digital Valve Controllers 11...........

Fisher 3610J Valve Positioners 13......................

Other Accessories 14.................................

Reference Information

Maximum Inlet Pressure for CW2M Valve Bodies 15......

Shutoff Pressure Drop Limits for Trim Parts 15...........

Flow Coefficients 16..................................

Actuator-Valve Selection (Shutoff Pressure Drops) 17....

Approximate Weights 21..............................

Dimensions 22.......................................

Emerson Process Management Sales Offices 24........

High-Capacity Rotary Valves

Product Flier

PF51.3:Vee-Ball

May 2009

5

Fisher Vee-Ball Valves

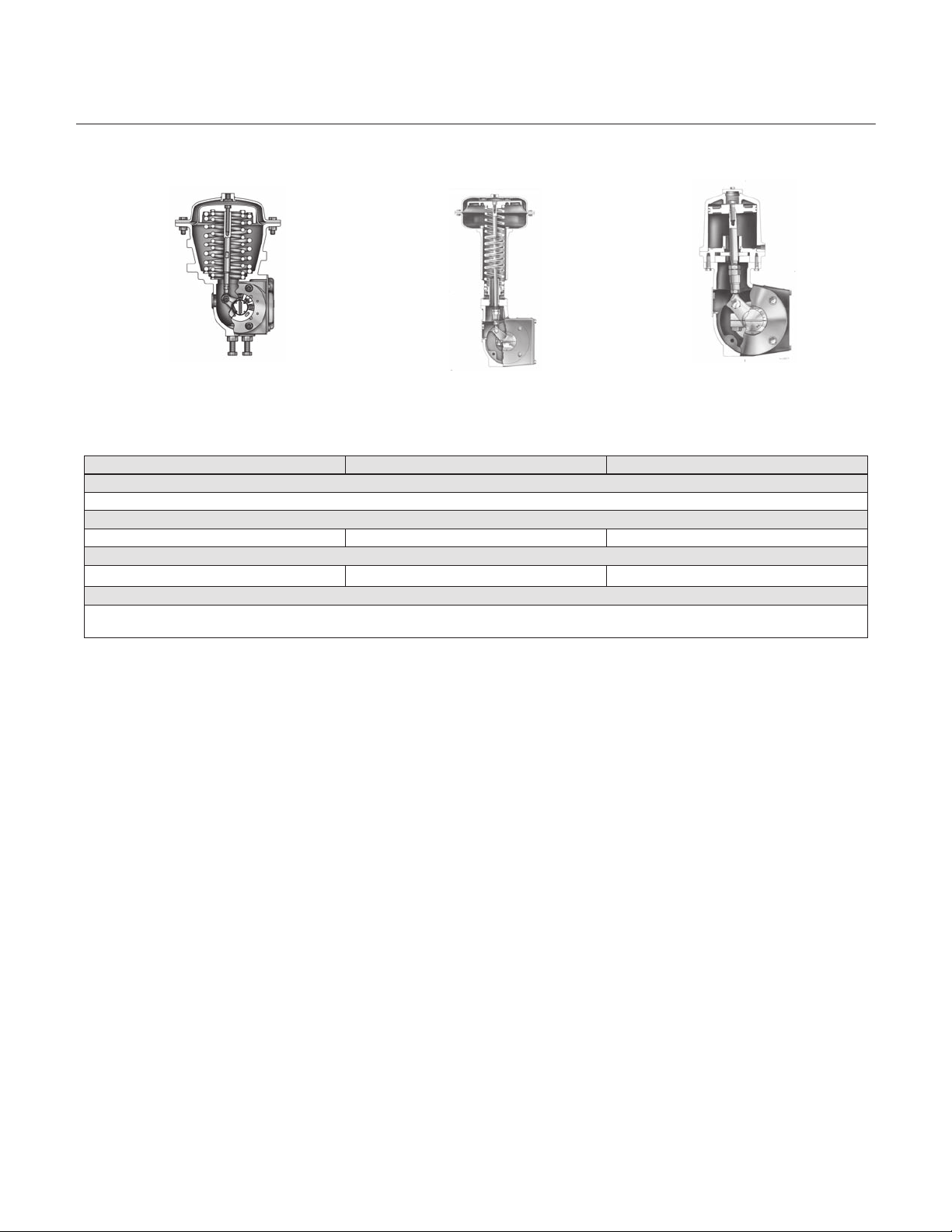

V150 VALVE

W5787/IL

V200 VALVE

W7435/IL

V300 VALVE

W7435/IL

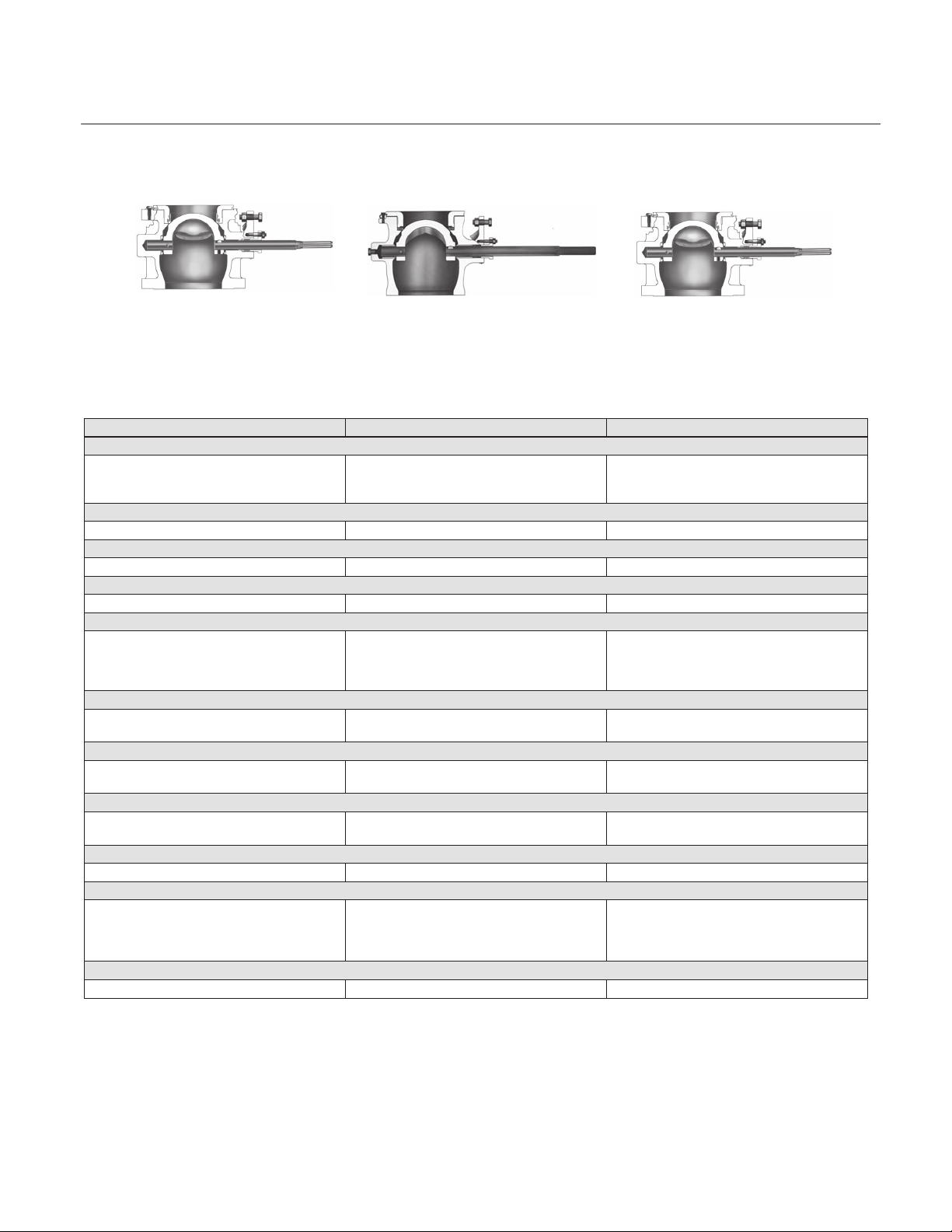

Figure 5. Fisher Vee-Ball Valves

Table 1. Vee-Ball Valves

V150 V200 V300

Applications

Excellent for fibrous slurries as well as liquids,

gas, and steam. Shearing V-notch ball for

smooth, non-clogging action.

Excellent for fibrous slurries as well as liquids,

gas, and steam. Shearing V-notch ball for

smooth, non-clogging action.

Excellent for fibrous slurries as well as liquids,

gas, and steam. Shearing V-notch ball for

smooth, non-clogging action.

Sizes

V150: DN 25 - 500 or NPS 1 - 24 x 20 NPS 1, 1-1/2, 2, 3, 4, 6, 8, 10 DN 25 - 500 or NPS 1 - 20

Ratings

V150: PN 10/16 or CL150 CL150, CL300, or CL600 depending on size. PN 25/40 or CL300

End Connections

Raised-face (RF) flanged Flangeless Raised-face (RF) flanged

Valve Body Materials

EN: 1.0619 steel, 1.4409 stainless steel, M35-1,

or CW2M

ASME: SA216 WCC steel, SA351 CF3M, CF8M

stainless steel, M35-1, or CW2M

EN: 1.0619 steel, 1.4409 stainless steel, M35-1,

or CW2M

ASME: SA216 WCC steel, SA351 CF3M, CF8M

stainless steel, M35-1, or CW2M

EN: 1.0619 steel, 1.4409 stainless steel, M35-1,

or CW2M

ASME: SA216 WCC steel, SA351 CF3M,

CG8M stainless steel M35-1, or CW2M

Ball Material

SA351 CF3M, or CG8M, CG8M stainless steel,

CW2M

SA351 CF3M or CG8M stainless steel, CW2M SA351 CF3M, or CG8M stainless steel, CW2M

Seal Types

TCM Plus, metal (S31600), HD (heavy duty)

metal, or flow ring

TCM Plus, metal (S31600), HD (heavy duty)

metal, or flow ring

TCM Plus, metal (S31600), HD (heavy duty)

metal, or flow ring

Flow Characteristics and Maximum Flow Coefficients

Modified equal percentage

Maximum Cv from 3.64 to 10,300

Modified equal percentage

Maximum Cv from 8.4 to 3000

Modified equal percentage

Maximum Cv from 8.4 to 10,300

Rangeability

300 to 1 300 to 1 300 to 1

Shutoff Class

Composition Seal: Class VI

Metal Seal: Class IV

Flow Ring Construction: 5% of wide-open

capacity

Composition Seal: Class VI

Metal Seal: Class IV

Flow Ring Construction: 5% of wide-open

capacity

Composition Seal: Class VI

Metal Seal: Class IV

Flow Ring Construction: 5% of wide-open

capacity

Available Actuators (refer to page 8)

Fisher 2052, 1051, 1052, 1061, and FieldQ Fisher 2052, 1051, 1052, 1061, and FieldQ

Fisher 2052, 1051, 1052, 1061, and FieldQ

High-Capacity Rotary Valves

Product Flier

PF51.3:Vee-Ball

May 2009

6

Fisher Actuators

2052 ACTUATOR

1051 AND 1052 ACTUATORS

1061 ACTUATOR

W3813/IL

W3827/IL

W9589-1/IL

Figure 6. Fisher Rotary Valve Actuators

Table 2. Fisher Rotary Valve Actuators

2052 1051 AND 1052 1061

Features

Heavy-duty actuator with enclosed linkage and splined actuator-valve connection for minimized lost motion

Style

Spring-return pneumatic diaphragm actuator Spring-return pneumatic diaphragm actuator Double-acting pneumatic piston actuator

Typical Operating Torque Range (Varies with Operating Pressure and Construction)

50.8 to 565 Nm 85 to 1370 Nm 282 to 19,800 Nm

Accessories

Pneumatic or electro-pneumatic valve positioners, FIELDVUE digital valve controllers, limit switches, position transmitters, handwheels, travel stops,

lock-out device to disable actuator during maintenance, supply pressure filter-regulator.

High-Capacity Rotary Valves

Product Flier

PF51.3:Vee-Ball

May 2009

7

Valve Component Materials and Temperatures

Table 3. Valve Component Materials and Temperatures

BODY, SHAFT, AND BALL (TEMPERATURE IS DETERMINED BY OTHER PARTS LISTED BELOW)

Valve Body

CF3M (316L stainless steel), DIN 1.0619 steel, WCC steel, or

CG8M (317 stainless steel)

Valve Shaft

S20910 or S17400 (17-4PH stainless steel)

V-Notch Ball

CF3M (316L stainless steel), chromium-plated CF3M, CG8M (317 stainless steel), or

chromium-plated CG8M

SEAL, BEARING, AND PACKING

SEAL MATERIAL BEARING MATERIAL

MAXIMUM

TEMPERATURE, C

NOTES

PTFE

V-Ring

Packing

Graphite

Packing

Composition (TCM plus)

PEEK (poly-ether-ether-ketone)/PTFE,

R30006 (alloy 6B) or silver-plated

R30006

232 232

Minimum temperature

for DIN valve bodies is

10C

Minimum temperature

for ASME constructions

is 29C for steel

valves and 46C for

stainless steel valves

Contact your

Emerson Process

Management sales

office for

ENVIRO-SEAL packing

temperatures and

pressures

Contact your

Emerson Process

Management sales

office for pressure

drops and temperatures

with TCM-Ultra

composition seal.

Flat metal—(spring-tempered stainless steel)

(available on DN 80 through 300

[NPS 3 through 12] only)

PEEK/PTFE 232 260

R30006, silver-plated R30006, or

S31600L (316L stainless steel) nitride

232 427

HD (heavy-duty) metal

( CF10SMnN or

CD7MCuN [alloy 255 duplex stainless

steel], or R30006

PEEK/PTFE 232 260

R30006, silver-plated R30006, or

S31600L nitride

232 288

Flow ring (steel or stainless to match

body material)

PEEK/PTFE 232 260

R30006, silver-plated R30006, or

S31600L nitride

232 427

OTHER PARTS

PART MATERIAL

MAXIMUM

TEMPERATURE, C

PTFE

V-Ring

Packing

Graphite

Packing

Wave spring and radial seal (HD metal only)

N07750 and PTFE with

N10276

Temperature is

determined by parts listed

above

Micro-notch V-notch ball for DN 25 (NPS 1)

Chromium-plated CG8M or solid alloy 6

Solid VTC ceramic 93 93

Gasket Graphite

Temperature is

determined by parts listed

above

Optional line bolting

B7, B7M, or strain-hardened B8M

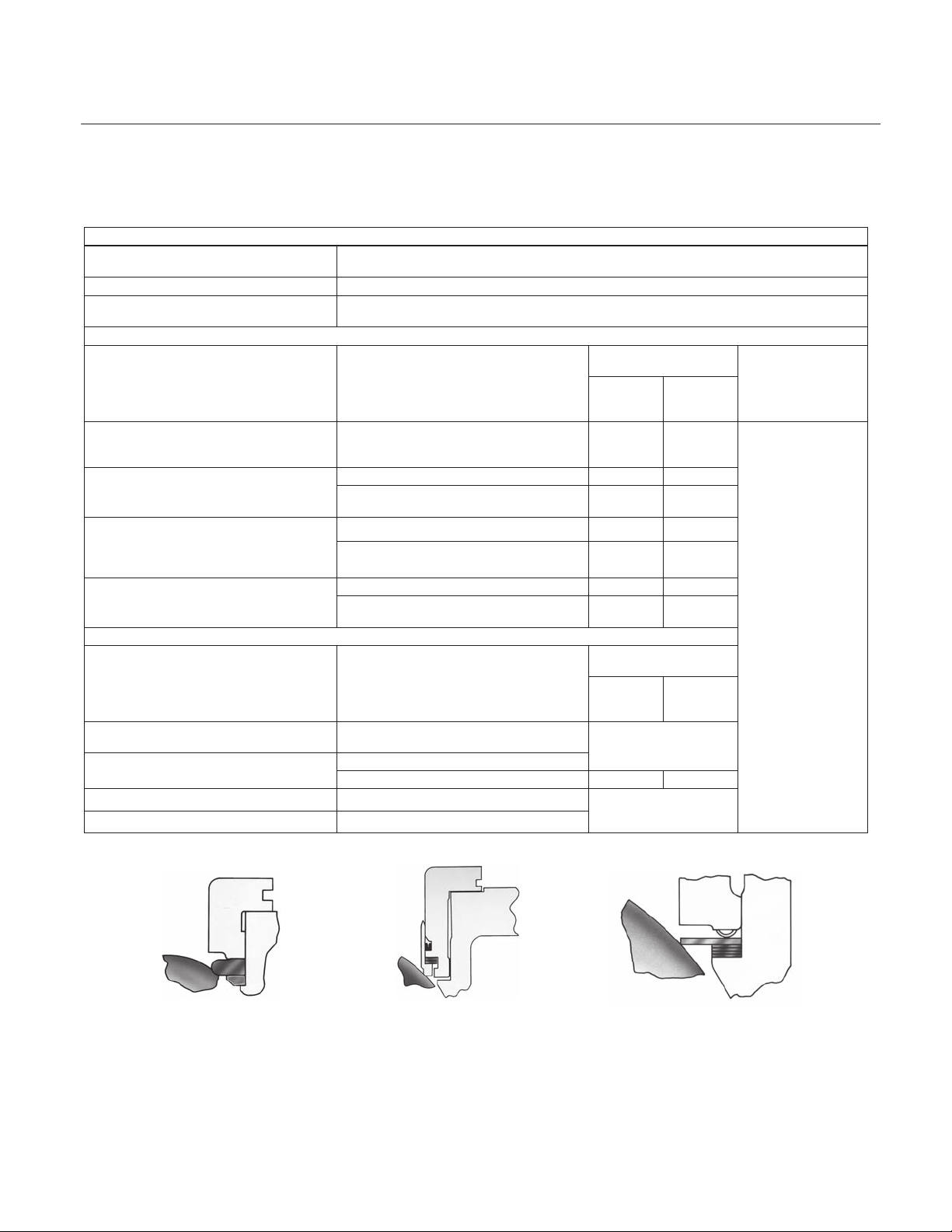

COMPOSITION SEAL

W6197-1*

HD (HEAVY-DUTY) METAL SEAL

W5704-1/IL

FLAT METAL SEAL

W4713-3/IL

Figure 7. Fisher Vee-Ball Seals

High-Capacity Rotary Valves

Product Flier

PF51.3:Vee-Ball

May 2009

8

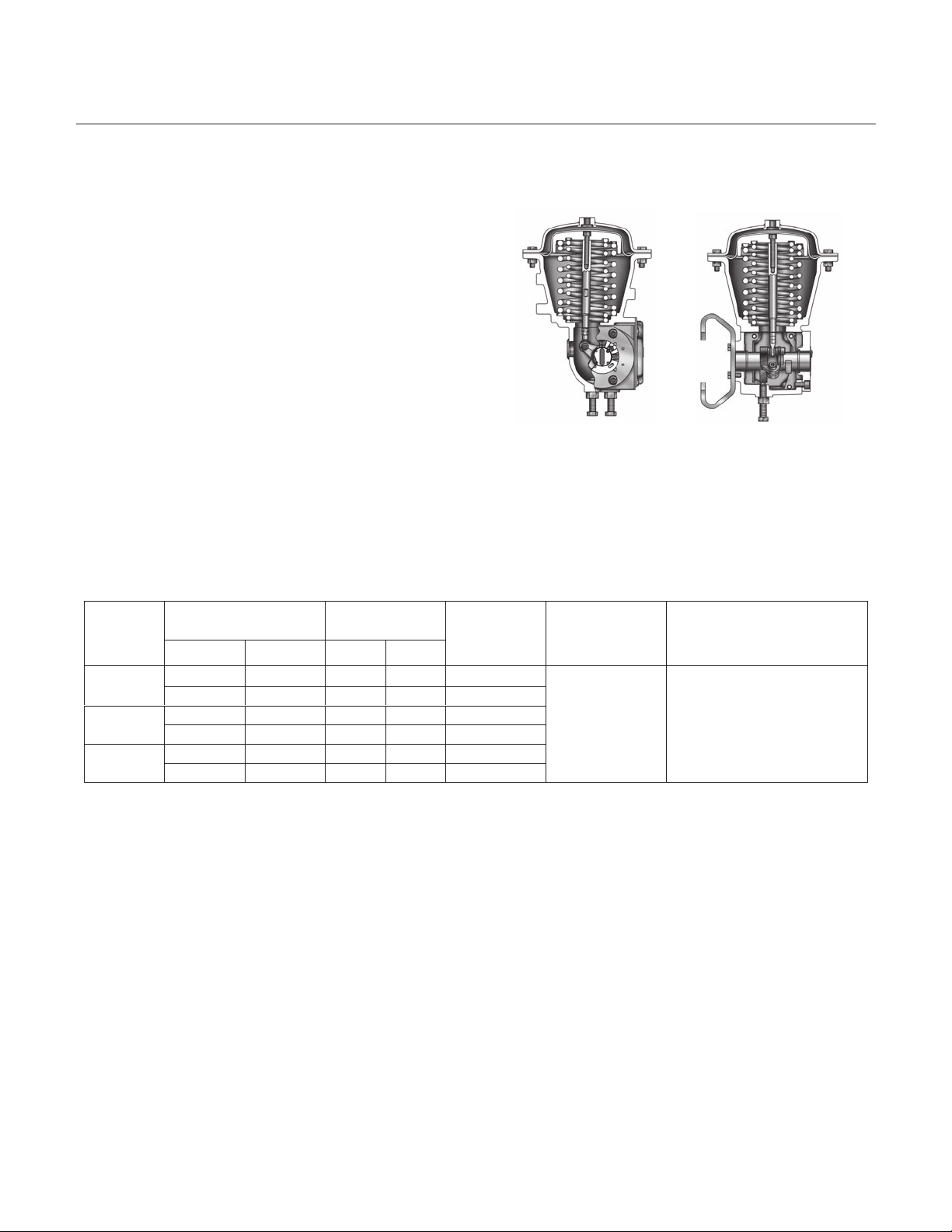

Fisher 2052 Diaphragm Actuators

The 2052 pneumatic diaphragm rotary actuators are

compact, spring-return actuators that provide reliable

operation for the valves in this flier.

The 2052 actuator mountings conform to ISO 5211;

the actuator can be mounted directly to non-spline

shafts, such as square or double-D, allowing the

actuator to be paired with a wider range of valves to

be used for both automated on/off and throttling

applications.

This actuator features single-joint linkage with

splined-and-clamped levers for minimum lost motion

and high control accuracy.

It also features a nested spring design, which

requires no bench set, simplifying the actuator

selection process.

Options . . .

Top-mounted handwheel, Fisher

1078 declutchable handwheel actuator, and

actuator locking mechanism

W9589/IL

W9588-1/IL

Figure 8. Fisher 2052 Actuator

Accessories . . . Pneumatic and

electro-pneumatic positioners,

FIELDVUE digital

valve controllers, and

Limit and proximity

switches.

Table 4 .Fisher 2052 Actuator Specifications

2052

ACTUATOR

SIZE

NOMINAL OPERATING

PRESSURE RATINGS

MAXIMUM CASING

PRESSURE

MAXIMUM

VALV E

BREAKOUT

TORQUE, N

m

AMBIENT

TEMPERATURE, qC

MATERIALS

Bar Psig Bar Psig

1

2-3 30-43 5.0 73 28

40 to 80

Upper Casing: Steel

Housing: Cast Iron

Diaphragm: Nitrile and nylon is

standard; silicone and polyester

low-temperature is optional

Lever: Ductile iron

Diaphragm Plate: Cast iron

4-5 60-72 5.0 73 50.8

2

2-3 30-43 5.0 73 104

4-5 60-72 5.0 73 209

3

2-3 30-43 5.0 73 270

4-5 60-72 5.0 73 565

Loading...

Loading...