Emerson 51-DO-03, 51-DO-04, DO-04, DO-03 User Manual

Instruction Manual

51-DO-03/04/rev.C October 2004

Model DO-03/04

Dissolved Oxygen Measurement System with Air Blast Cleaner

ESSENTIAL INSTRUCTIONS

READ THIS PAGE BEFORE PROCEEDING!

Rosemount Analytical designs, manufactures, and tests its products to meet many national and international standards. Because these instruments are sophisticated technical products, you must properly install, use, and maintain them to ensure they continue to operate within their normal specifications. The following instructions must be adhered to and integrated into your safety program when installing, using, and maintaining Rosemount Analytical products. Failure to follow the proper instructions may cause any one of the following situations to occur: Loss of life; personal injury; property damage; damage to this instrument; and warranty invalidation.

•Read all instructions prior to installing, operating, and servicing the product. If this Instruction Manual is not the correct manual, telephone 1- 800-654-7768 and the requested manual will be provided. Save this Instruction Manual for future reference.

•If you do not understand any of the instructions, contact your Rosemount representative for clarification.

•Follow all warnings, cautions, and instructions marked on and supplied with the product.

•Inform and educate your personnel in the proper installation, operation, and maintenance of the product.

•Install your equipment as specified in the Installation Instructions of the appropriate Instruction Manual and per applicable local and national codes. Connect all products to the proper electrical and pressure sources.

•To ensure proper performance, use qualified personnel to install, operate, update, program, and maintain the product.

•When replacement parts are required, ensure that qualified people use replacement parts specified by Rosemount. Unauthorized parts and procedures can affect the product’s performance and place the safe operation of your process at risk. Look alike substitutions may result in fire, electrical hazards, or improper operation.

•Ensure that all equipment doors are closed and protective covers are in place, except when maintenance is being performed by qualified persons, to prevent electrical shock and personal injury.

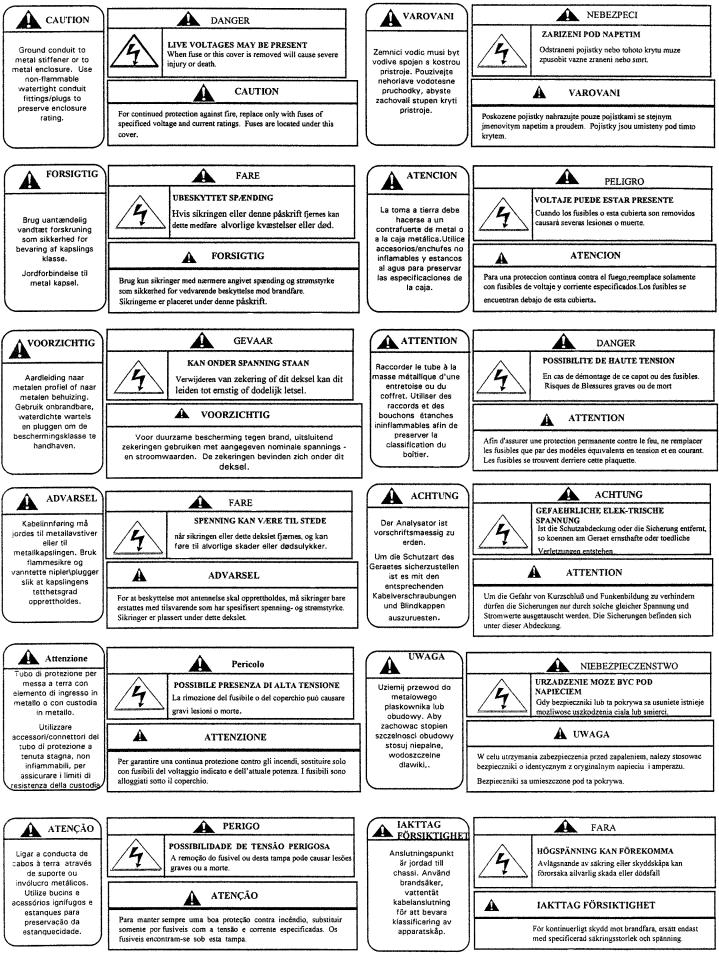

WARNING

ELECTRICAL SHOCK HAZARD

Making cable connections to and servicing this instrument require access to shock hazard level voltages which can cause death or serious injury, therefore, disconnect all hazardous voltage before accessing the electronics.

Relay contacts made to separate power sources must be disconnected before servicing.

Electrical installation must be in accordance with the National Electrical Code (ANSI/NFPA-70) and/or any other applicable national or local codes.

Unused cable conduit entries must be securely sealed by non-flammable closures to provide enclosure integrity in compliance with personal safety and environmental protection requirements. Use NEMA 4X or IP65 conduit plugs supplied with the instrument to maintain the ingress protection rating (IP65).

For safety and proper performance this instrument must be connected to a properly grounded three-wire power source.

Proper relay use and configuration is the responsibility of the user. No external connection to the instrument of more than 60VDC or 43V peak allowed with the exception of power and relay terminals. Any violation will impair the safety protection provided.

Do not operate this instrument without front cover secured. Refer installation, operation and servicing to qualified personnel.

WARNING

This product is not intended for use in the residential, commercial or light industrial environment per  certification to EN61326.

certification to EN61326.

About This Document

This manual contains instructions for installation and operation of the Model DO-03/04. The following list provides notes concerning all revisions of this document.

Rev. Level Date Notes

A1/04 This is the initial release of the product manual. The manual has been reformatted to reflect the

Emerson documentation style and updated to reflect any changes in the product offering.

B5/04 Drawings and part numbers were updated on pages 5, 6, 7, and 51.

C10/04 Updated Specifications, Section 1.0.

Emerson Process Management

Rosemount Analytical Inc.

2400 Barranca Parkway

Irvine, CA 92606 USA

Tel: (949) 757-8500

Fax: (949) 474-7250

http://www.raihome.com

© Rosemount Analytical Inc. 2004

MODEL DO-03/04 |

TABLE OF CONTENTS |

|

MODEL DO-03/04 MEASURING SYSTEM |

|

|

TABLE OF CONTENTS |

|

Section Title |

Page |

|

1.0 |

SPECIFICATIONS................................................................................................... |

1 |

1.1 |

Features and Applications ....................................................................................... |

1 |

1.2 |

Specifications........................................................................................................... |

2 |

1.3 |

Ordering Information................................................................................................ |

6 |

2.0 |

INSTALLATION....................................................................................................... |

7 |

2.1 |

Unpacking and Inspection ....................................................................................... |

7 |

2.2 |

Installation................................................................................................................ |

7 |

3.0 |

WIRING ................................................................................................................... |

12 |

3.1 |

General.................................................................................................................... |

12 |

3.2 |

Power, Alarm, and Output Wiring ............................................................................ |

12 |

3.3 |

Sensor Wiring.......................................................................................................... |

16 |

4.0 |

DISPLAY AND OPERATION................................................................................... |

17 |

4.1 |

Display..................................................................................................................... |

17 |

4.2 |

Key Functions and Control...................................................................................... |

17 |

4.3 |

Alarm Status ............................................................................................................ |

17 |

5.0 |

SOFTWARE CONFIGURATION ............................................................................. |

18 |

5.1 |

Changing Alarm Setpoints....................................................................................... |

24 |

5.2 |

Ranging the Outputs................................................................................................ |

25 |

5.3 |

Testing Outputs and Alarms .................................................................................... |

26 |

5.4 |

Choosing Display Options ....................................................................................... |

27 |

5.5 |

Changing Output Parameters.................................................................................. |

29 |

5.6 |

Changing Alarm Parameters ................................................................................... |

31 |

5.7 |

Temperature Compensation and Temperature Units............................................... |

35 |

5.8 |

Noise Reduction ...................................................................................................... |

36 |

5.9 |

Barometric Pressure................................................................................................ |

37 |

5.10 |

Main Sensor Calibration Parameters ...................................................................... |

38 |

5.11 |

Security.................................................................................................................... |

39 |

5.12 |

Analyzer Mode Priority ............................................................................................ |

40 |

6.0 |

CALIBRATION - TEMPERATURE.......................................................................... |

41 |

6.1 |

Introduction.............................................................................................................. |

41 |

6.2 |

Temperature Calibration .......................................................................................... |

42 |

7.0 |

CALIBRATION - DISSOLVED OXYGEN................................................................ |

43 |

7.1 |

Introduction.............................................................................................................. |

43 |

7.2 |

Zeroing the Sensor.................................................................................................. |

44 |

7.3 |

Calibrating the Sensor in Air.................................................................................... |

45 |

7.4 |

Calibrating the Sensor Against a Standard Instrument ........................................... |

47 |

7.5 |

Calibrating Barometric Pressure.............................................................................. |

48 |

8.0 |

CALIBRATION - CURRENT OUTPUTS................................................................. |

49 |

8.1 |

Introduction.............................................................................................................. |

49 |

8.2 |

Trimming the Outputs .............................................................................................. |

49 |

i

MODEL DO-03/04 |

TABLE OF CONTENTS |

|

TABLE OF CONTENTS (CONTINUED) |

|

Section |

Title |

Page |

9.0 |

MAINTENANCE ...................................................................................................... |

50 |

9.1 |

Analyzer (Model 54eA-01)....................................................................................... |

50 |

9.2 |

Oxygen Sensor (Model 499ADO-54) ...................................................................... |

50 |

9.3 |

Air Compressor........................................................................................................ |

52 |

9.4 |

Air Blast Sensor Washer ......................................................................................... |

53 |

10.0 |

TROUBLESHOOTING ............................................................................................ |

54 |

10.1 |

Overview.................................................................................................................. |

54 |

10.2 |

Troubleshooting When a Fault Message is Showing.............................................. |

54 |

10.3 |

Troubleshooting When No Fault Message is Showing - Temperature.................... |

56 |

10.4 |

Troubleshooting When No Fault Message is Showing - Oxygen............................ |

56 |

10.5 |

Troubleshooting Not Related to Measurement Problems ....................................... |

59 |

10.6 |

Simulating Inputs - Dissolved Oxygen..................................................................... |

59 |

10.7 |

Simulating Temperature........................................................................................... |

60 |

11.0 |

RETURN OF MATERIALS...................................................................................... |

61 |

LIST OF TABLES

Table No. Title ......................................................................................................................... |

Page |

|

5-1 |

Program Settings List .............................................................................................. |

21 |

5-2 |

Controller Mode Priority Chart................................................................................. |

40 |

9-1 |

Replacment Parts .................................................................................................... |

50 |

ii

MODEL DO-03/04 |

TABLE OF CONTENTS |

LIST OF FIGURES

Section |

Title |

Page |

1-1 |

Suggested Arrangement of Handrail Mounting Assembly, Maintenance Clamp,.... |

|

|

Air Compressor Enclosure, and 54eA Analyzer ...................................................... |

4 |

1-2 |

Analyzer Dimensions............................................................................................... |

4 |

1-3 |

Enclosure Dimensions............................................................................................. |

5 |

1-4 |

Standard Sensor with Integral Cable....................................................................... |

5 |

1-5 |

Air Blast Washer Head ............................................................................................ |

5 |

2-1 |

Suggested Arrangement of Handrail Mounting Assembly, Maintenance Clamp,.... |

|

|

Air Compressor Enclosure, and 54eA Analyzer ...................................................... |

8 |

2-2 |

Pipe Mounting.......................................................................................................... |

8 |

2-3 |

Attaching the Air Compressor Enclosure to the Handrail........................................ |

10 |

2-4 |

Assembling and Attaching the Handrail Mounting Assembly .................................. |

10 |

2-5 |

Installing the Sensor in the Washer Head Assembly .............................................. |

11 |

3-1 |

Power Input, Relay, and Output Wiring for 54eA Analyzer...................................... |

13 |

3-2 |

Model DO-03 — Wiring Air Blast Compressor to Model 54eA Analyzer 115 Vac.. |

14 |

3-3 |

Model DO-04 — Wiring Air Blast Compressor to Model 54eA Analyzer 230 Vac.. |

15 |

3-4 |

Wiring Label............................................................................................................. |

16 |

3-5 |

Oxygen Sensor with Standard Cable ...................................................................... |

16 |

3-6 |

Oxygen Sensor with Optimum EMI/RFI Cable or Variopol Cable........................... |

16 |

4-1 |

Main Display Screen................................................................................................ |

17 |

5-1 |

Menu Tree for the 54eA Analyzer............................................................................ |

18 |

5-2 |

Low Alarm................................................................................................................ |

32 |

5-3 |

High Alarm............................................................................................................... |

32 |

5-4 |

Interval Timer .......................................................................................................... |

34 |

7-1 |

Sensor Current as a Function of Dissolved Oxygen Concentration ....................... |

43 |

9-1 |

Sensor Parts............................................................................................................ |

52 |

9-2 |

Replacement Parts .................................................................................................. |

53 |

10-1 |

Simulate Dissolved Oxygen..................................................................................... |

59 |

10-2 |

Three-Wire RTD Configuration................................................................................ |

60 |

10-3 |

Simulating RTD Inputs............................................................................................. |

60 |

iii

MODEL DO-03/04 |

SECTION 1.0 |

|

SPECIFICATIONS |

SECTION 1.0

SPECIFICATIONS

•COMPLETE SYSTEM INCLUDES sensor, analyzer, sensor washer head, mounting hardware, and air compressor.

• AIR BLAST CLEANER system can keep DO sensors funtioning up to 3 months or longer.

•SENSOR MAINTENANCE is quick and easy.

•FEATURE-PACKED ANALYZER: on-board pressure sensor for completely automatic air calibration, large backlit display, dual outputs, three fully programmable alarm relays.

FEATURES AND BENEFITS

The Model DO-03/04 is a complete system for the determination of dissolved oxygen in wastewater aeration basins. It consists of a sensor, an analyzer, a handrail mounting assembly, a sensor washer head, and an air compressor. A timer in the analyzer allows the user to customize the air blast cleaning cycle.

The Model DO-03/04 uses a membrane-covered amperometric sensor. A polarizing voltage applied to a gold cathode behind the membrane destroys oxygen diffusing through the membrane and keeps the concentration of oxygen in the sensor equal to zero. The current generated by the cathode reaction is proportional to the rate of diffusion of oxygen through the membrane. Because the concentration of oxygen in the sensor is zero, the diffusion rate and the current are proportional to the concentration of oxygen in the sample.

Sensor maintenance is fast and easy. Replacing a membrane requires no special tools or fixtures. A screw cap holds the pre-tensioned membrane in place. Replacing the electrolyte solution takes only minutes.

The Model DO-03/04 includes the rugged, easy-to-use Model 54eA analyzer. The analyzer features two fully programmable 4-20 mA outputs, and three fully programmable alarm relays. The backlit three line display allows the user to read oxygen levels at a glance. The analyzer permits both air calibration and calibration against a laboratory instrument. Air calibration is completely automatic. All the user does is expose the sensor to water-saturated air and press a few buttons.

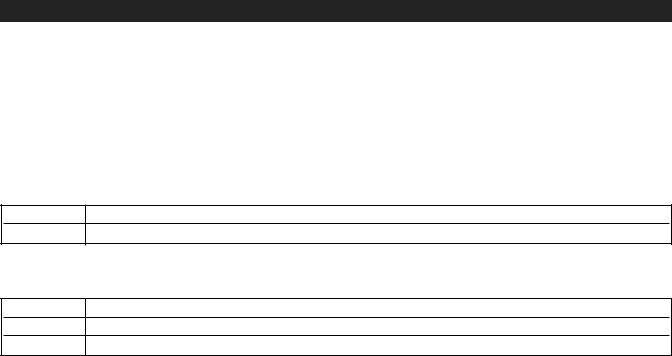

The Air Blast Sensor Cleaner, which includes the washer head and air compressor, keeps the sensor membrane clean, helping ensure reliable, trouble-free oxygen measurements and reducing sensor cleaning maintenance to as little as every three months. At programmed intervals, the air blast cleaner blows a stream of air across the membrane to clear bio-film from on the membrane. The frequency and duration of the air blast is programmable from the 54eA analyzer.

The photograph shows a sensor after nine weeks in an aeration basin. The cathode is clearly visible under the membrane. A 60-second air blast every eight hours is keeping the membrane clean.

Plant service air can be used in place of the air compressor. The 54eA analyzer relay is then used to operate a solenoid valve.

1

MODEL DO-03/04 |

SECTION 1.0 |

|

SPECIFICATIONS |

SPECIFICATIONS - 499ADO-54 SENSOR

Range: 0 to 20 ppm (mg/L)

Wetted parts: Noryl1 Viton2 EPDM, Teflon3, silicone

Cathode: Gold (not normally wetted)

Accuracy: ±0.2 ppm at 25°C

Repeatability: ±0.05 ppm 25°C

Response time: 25 sec to 63% of final reading at 25°C

Pressure: 0 to 65 psig (0 to 549 kPa abs)

Temperature: 32 to 122°F (0 to 50°C)

Process connection: 1 inch MNPT

Electrolyte volume: 25 mL (approx.)

Cable length (standard): 25 ft (7.6 m)

Cable length (maximum): 300 ft (91 m)

SPECIFICATIONS - 54EA-01 ANALYZER

Enclosure: Epoxy-painted (light gray) cast aluminum, NEMA 4X (IP65). 144 x 144 x 132 mm

(5.7 x 5.7 x 5.2 in.), DIN size panel cut-out.

Front Panel: Membrane keypad with tactile feedback. Three green LEDs indicate alarm status. Red LED indicates fault condition.

Display: Three-line, back-lit, dot matrix LCD, 70 x 35 mm. First line is oxygen reading. Second line is temperature and current output. Third line is userselectable. Character heights: 1st line - 16 mm (0.6 in.), 2nd and 3rd lines - 7 mm (0.3 in.).

Power:

115 VAC ± 10%, 50/60 Hz ± 6%, 8 W 230 VAC ± 10%, 50/60 Hz ± 6%, 8 W

RFI/EMI: EN-61326

LVD: EN-61010-1

Outputs: Two 4-20 mA or 0-20 mA isolated outputs. Continuously adjustable. Outputs can be assigned to oxygen or temperature. Output dampening is user-selectable. Maximum load at 100/200 Vac is 550 ohms.

Output Accuracy: ± 0.05 mA

Alarms: Relays 1, 2, and 3 are assignable to oxygen or temperature. One relay can also be used as an interval timer to operate the air blast cleaner.

Relay 4 - Sensor/analyzer fault alarm

Each relay has a dedicated LED on the front panel.

Relay Contacts: Relays 1-3: Epoxy sealed form A contacts, SPST, normally open

Relay 4: Epoxy sealed form C, SPDT

|

Resistive |

Inductive |

115 Vac |

5.0 Amps |

3.0 Amps |

230 Vac |

5.0 Amps |

1.5 Amps |

Ambient Temperature: 0 to 50°C (32 to 122°F). Analyzer can be operated between -20 and 60°C (-4 to 140°F) with some degradation in display quality.

Relative Humidity: 95% (maximum) non-condensing

Temperature correction for membrane permeability: automatic between 0 and 50°C.

Calibration: automatic air calibration or calibration against a standard instrument

Pressure sensor range: 113 to 862 mm Hg (150 to 1150 mbar)

1Noryl is a registered trademark of General Electric

2Viton is a registered trademark of E.I. duPont de Nemours & Co.

3Teflon is a registered trademark of E.I. duPont de Nemours & Co.

2

MODEL DO-03/04 |

SECTION 1.0 |

|

SPECIFICATIONS |

SPECIFICATIONS - COMPRESSOR FOR AIR BLAST CLEANER SYSTEM

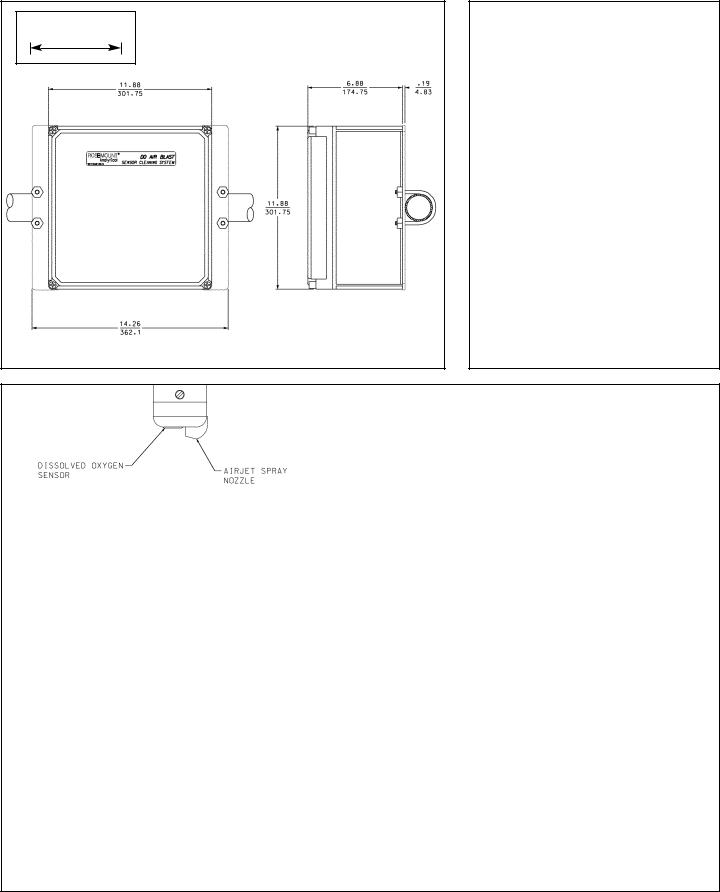

Enclosure: Fiberglass reinforced polyester with polyester cover, NEMA 4x (IP65). 11.9 x 11.9 x 6.9 in (302 x 302 x 175 mm).

Compressor: Oil-less, non-lubricating piston and cylinder. 1/12 HP permanent split capacitor motor with thermal overload protection.

Maximum continuous pressure: 50 psig (446 kPa abs)

Operating pressure: 20 psig (239 kPa abs)

Air hose: 25 ft (7.6 m) included with ABSH

Ambient temperature: 5 to 122°F (-15 to 50°C) assuming intermittent operation

Power:

Code -03: 115 VAC, 60 Hz or 100 VAC, 50/60 Hz, single phase,1.3 to 1.4 A, starting current 3.88 A, insulation class B; UL approved

Code -04: 220 VAC, 50 Hz, single phase, 0.6 A, starting current 1.5 A, insulation class A; CE approved

SPECIFICATIONS - AIR BLAST CLEANER SYSTEM WASHER HEAD

Process connection: 1-1/2 inch PVC pipe socket

Dimensions (diameter x length): 2-1/2 x 10-3/4 inches (64 x 273 mm)

Wetted materials: PVC, Noryl, Viton

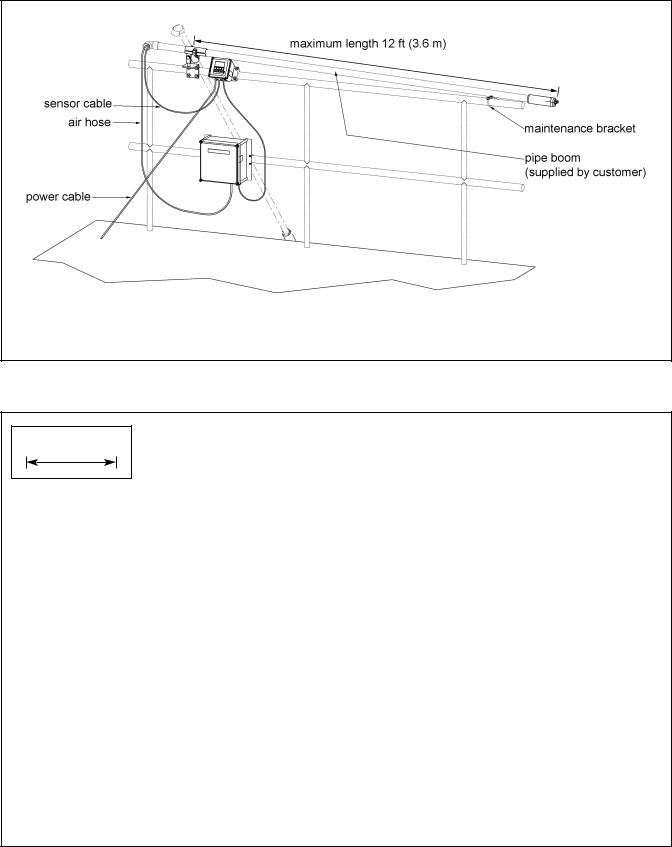

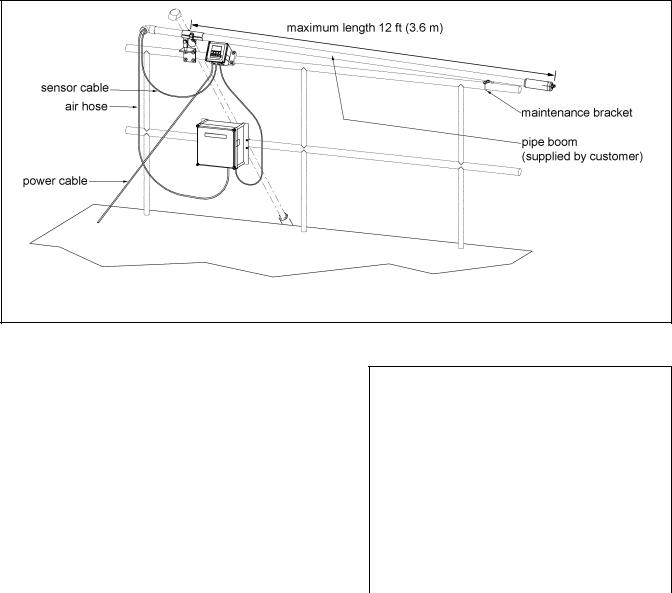

Pipe boom: 1-1/2 inch schedule 80 PVC, maximum length 12 feet (3.6 m) past handrail mounting clamp. Pipe boom is supplied by customer.

Maximum distance between compressor and sensor:

25 ft (7.6 m). ABSH is supplied with 25 ft (7.6 m) of air hose.

SPECIFICATIONS - HANDRAIL MOUNTING ASSEMBLY

Materials of Construction:

Weather cap: Schedule 40 PVC

Pipe clamp and bracket: Aluminum

Clevis: zinc-plated steel

U-bolts, nuts, and bolts: zinc-plated steel

Washers: stainless steel

SHIPPING INFORMATION

The Model DO-03/04 is shipped in a single container. Shipping weight is 38 lbs (17.5 kg).

PLANT AIR SYSTEM REQUIREMENTS

(for customers using plant air in place of air compressor)

Pressure: 20 psig (239 kPa abs)

Flow: 0.50 SCFM (14 L/min at STP)

Air hose: (customer supplied) compatible with ¼ inch barbed fitting for connection at washer head

3

MODEL DO-03/04 |

SECTION 1.0 |

|

SPECIFICATIONS |

FIGURE 1-1. Suggested arrangement of handrail mounting assembly, maintenance clamp, air compressor enclosure, and 54eA analyzer

WHEN INCH AND METRIC DIMS |

ARE GIVEN |

MILLIMETER |

INCH |

FIGURE 1-2. Analyzer dimensions

4

MODEL DO-03/04

WHEN INCH AND METRIC DIMS |

ARE GIVEN |

INCH |

MILLIMETER |

FIGURE 1-3. Enclosure dimensions

SECTION 1.0

SPECIFICATIONS

FIGURE 1-4. Standard sensor with integral cable

FIGURE 1-5. Air blast washer head

5

MODEL DO-03/04 |

SECTION 1.0 |

|

SPECIFICATIONS |

ORDERING INFORMATION

The Model DO -03/04 is a complete system for the determination of oxygen in wastewater aeration basins. It consists of a 54eA analyzer, a 499ADO-54 oxygen sensor, an air blast washer head with air compressor and hose, and a handrail mounting bracket. All hardware necessary to mount the analyzer and the air compressor enclosure on a handrail is provided. Cable gland fittings for the analyzer are also supplied. Three replacement membranes and a bottle of electrolyte solution are shipped with the sensor. Pipe boom is supplied by customer.

MODEL DO DISSOLVED OXYGEN MEASURING SYSTEM WITH AIR BLAST CLEANER

|

MODEL |

|

Description |

|

|

DO |

|

Dissolved Oxygen Measuring System |

|

|

|

|

|

|

|

CODE |

|

Power (required selection) |

|

|

-03 |

|

115 Vac, 60 Hz or 100 Vac, 50/60 Hz |

|

|

-04 |

|

220 Vac, 50 Hz |

|

|

DO -03 |

EXAMPLE |

|

|

|

|

|

|

|

ACCESSORIES FOR 54eA ANALYZER

Part # DESCRIPTION

9240048-00 Tag, stainless steel, specify marking

CONSUMABLES FOR SENSOR

Part # DESCRIPTION

23502-00 Membrane replacement kit with O-ring, qty 3

9210264 Amperometric sensor fill solution #1, 4 oz (120 mL)

Customers using plant compressed air should order the following items in place of Model -03/04:

|

54e-A-01 |

Model 54eA analyzer |

|

|

2002577 |

Mounting bracket for Model 54e, pipe/wall |

|

|

23554-00 |

Cable glands kit for Model 54e, qty 5 |

|

|

499ADO-54 |

Model 499ADO oxygen sensor |

|

|

24057-00 |

Smooth membrane retainer for 499ADO sensor |

|

|

HRMS-02 |

Handrail clamp assembly for washer head (clamp, sensor maintenance kit, and elbow) |

|

|

9320101 |

Elbow, 90° female socket, PVC schedule 40 |

|

|

24049-00 |

Air blast washer head |

|

|

9160549 |

Air hose, 1/4-inch ID x 1/2-inch OD, 25 ft (7.6 m) |

|

|

|

|

|

REPLACMENT PARTS AND ACCESSORIES

|

9380088 |

Air compressor; 115 Vac, 60 Hz or 100 Vac, 50/60 Hz |

|

|

9380089 |

Air compressor; 220 Vac, 50 Hz |

|

|

24051-00 |

Mounting hardware for air compressor enclosure |

|

|

24053-00 |

O-ring kit for sensor washer head (three O-rings and lube) |

|

|

|

|

|

6

MODEL DO-03/04 |

SECTION 2.0 |

|

INSTALLATION |

SECTION 2.0

INSTALLATION

2.1 UNPACKING AND INSPECTION

Inspect the shipping container. If it is damaged, contact the shipper immediately for instructions. If there is no apparent damage, unpack the container. Be sure all items shown on the packing list are present. If items are missing, notify Rosemount Analytical immediately.

The Model DO-03/04 consists of the following items.

|

Model or part number |

Description |

|

|

|

|

|

|

54e-A-01 |

Model 54eA analyzer |

|

|

|

|

|

|

2002577 |

Mounting bracket for Model 54e, pipe/wall |

|

|

|

|

|

|

23544-00 |

Cable glands kit for Model 54e, qty 5 |

|

|

|

|

|

|

499ADO-54 |

Model 499ADO oxygen sensor |

|

|

|

|

|

|

24057-00 |

Smooth membrane retainer for 499ADO sensor |

|

|

|

|

|

|

HRMS-02 |

Handrail clamp assembly (clamp, sensor maintenance kit, and elbow) |

|

|

|

|

|

|

24049-00 |

Air blast washer head |

|

|

|

|

|

|

24050-00 |

Air compressor and enclosure with air hose (115 VAC) option -03 only |

|

|

|

|

|

|

24050-01 |

Air compressor and enclosure with air hose (220 VAC) option -04 only |

|

|

|

|

|

|

24051-00 |

Mounting hardware for air compressor enclosure |

|

|

|

|

|

|

24053-00 |

O-ring kit for sensor washer head (three O-rings and lube) |

|

|

|

|

|

The customer must supply a schedule 80 1-1/2 inch PVC pipe boom to immerse the sensor and cleaning head in the aeration basin.

2.2 INSTALLATION

2.2.1 General information

1.Although the equipment is suitable for outdoor use, do not install it in direct sunlight or in areas of extreme temperatures.

2.Install the equipment in an area where vibrations and electromagnetic and radio frequency interference are minimized or absent.

3.To keep the analyzer watertight, install plugs (provided) in the unused cable openings.

4.Keep the analyzer and sensor wiring at least one foot from high voltage conductors. Be sure there is easy access to the analyzer.

5.Provide room to allow the sensor and attached piping to be removed from the aeration basin for service. A maintenance bracket (part of PN 24048-00) can be used to rest the PVC pipe boom on the handrail.

Figure 2-1 shows the suggested arrangement of the analyzer, air compressor, and maintenance bracket on the handrail.

7

MODEL DO-03/04 |

SECTION 2.0 |

|

INSTALLATION |

FIGURE 2-1. Suggested arrangement of handrail mounting assembly, maintenance clamp, air compressor enclosure, and 54eA analyzer.

2.2.2 Installing the analyzer

When used in Model DO-03/04, the 54eA analyzer is intended to be mounted on the basin handrail. See Figures 2-1 and 2-2.

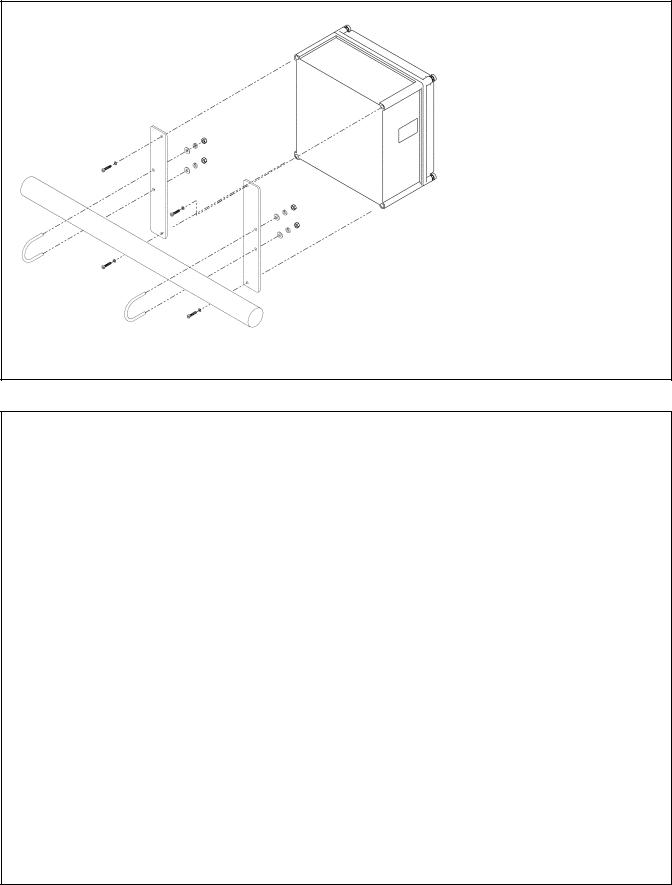

2.2.3 Installing the air compressor enclosure

The air compressor is in a NEMA 4X fiberglass enclosure.

Figure 2-3 shows how to attach the enclosure to a handrail.

1. |

Locate the enclosure within 25 ft (7.6 m) of the sensor. |

|

2. |

Be sure the ambient temperature is between 5 and |

|

|

122°F (-15 to 50°C). Do not expose the enclosure to |

FIGURE 2-2. Pipe Mounting |

|

direct sunlight. The operating temperature for the air |

|

|

|

|

|

compressor might be exceeded. |

|

|

|

2.2.4 Installing the handrail mounting assembly

The handrail mounting assembly (PN 24048-00) is shipped completely disassembled. Assemble and attach the mounting assembly to the handrail. Refer to Figure 2-4. The spring pin shipped with the handrail mounting assembly is not needed. Do not attach the boom clamp to the clevis yet. Attach the maintenance bracket (PN 24044-00) to the handrail. See Figure 2-1.

2.2.5 Assembling the pipe and pipe clamp

Slide the PVC pipe boom through the handrail mounting pipe clamp. Tighten the bolt to keep the clamp from sliding off. Use 1-1/2 inch schedule 80 PVC piping. Distance between the clamp and the end of the pipe should not exceed 12 feet (3.6 m). See Figures 2-1 and 2-4.

8

MODEL DO-03/04 |

SECTION 2.0 |

|

INSTALLATION |

2.2.6 Installing the sensor in the washer head assembly

1.Remove the sensor from its box. Remove the plastic protective cap from the end of the sensor. Save the cap.

2.Replace the knurled cap provided with the sensor with the smooth cap (PN 33521-01). The smooth cap is shipped loose.

a.Hold the sensor with the membrane end pointing up.

b.Unscrew the knurled cap. Leave the membrane in place.

c.Screw the smooth cap in place. Hand tighten.

d.Hold the sensor with the membrane end pointing down. Shake the sensor a few times as though shaking down a clinical thermometer.

e.Slide the protective cap back over the end of the sensor.

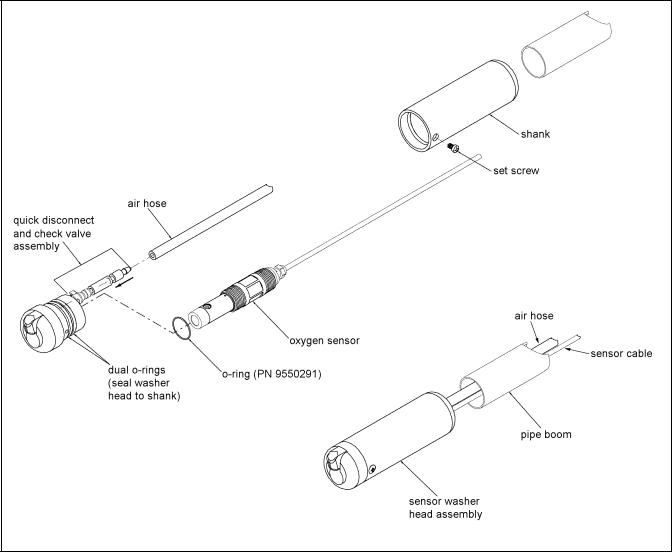

3.Remove the set screw at the bottom of the sensor washer head assembly. See Figure 2-5. Pull the washer head from the shank. You are pulling against a dual O-ring seal.

4.Press the metal tab on the air hose quick connect fitting and remove the fitting and check valve.

5.Wrap the bottom facing threads of the sensor with pipe tape. Remove the protective cap and slide the O-ring (PN 9550291) over the end of the sensor until it rests against the lower edge of the bottom facing thread. The O-ring is in a bag taped to the side of the washer head assembly.

6.Screw the sensor into the bottom of the washer assembly. Hand tighten only. Replace the air hose and check valve assembly.

2.2.7 Assembling the washer head and pipe boom

1.Cement the upper portion of the washer assembly head to the PVC pipe boom. See Figure 2-5. Use 1-1/2 inch schedule 80 PVC pipe. Press (do not cement) the PVC elbow (PN 9320101) to the top of the pipe boom. The elbow keeps water from collecting in the pipe boom.

2.Pass the sensor cable and air hose through the boom and elbow.

3.Connect the end of the air hose to the barbed fitting on the check valve.

4.Push the washer head back onto the shank. Use a small amount of grease to lubricate the O-rings. Replace and tighten the set screw.

2.2.8 Attaching the pipe boom to the handrail mounting assembly

1.Slide the tongue of the pipe clamp into the clevis. Insert the bolt as shown in Figure 2-3.

2.Rest the boom on the maintenance bracket until ready to submerge the sensor in the basin.

9

MODEL DO-03/04 |

SECTION 2.0 |

|

INSTALLATION |

FIGURE 2-3. Attaching the air compressor enclosure to the handrail

FIGURE 2-4. Assembling and attaching the handrail mounting assembly.

The spring pin (not shown) shipped with the handrail mounting assembly is not used.

10

MODEL DO-03/04 |

SECTION 2.0 |

|

INSTALLATION |

FIGURE 2-5. Installing the sensor in the washer head assembly

11

MODEL DO-03/04 |

SECTION 3.0 |

|

WIRING |

SECTION 3.0

WIRING

3.1 GENERAL

WARNING

Electrical installation must conform to the National Electrical Code, all state and local codes, and all plant codes and standards for electrical equipment. Electrical installation and wiring must be done by qualified personnel.

The five holes in the bottom of the Model 54eA enclosure accept 1/2-in. (PG-13.5) strain relief connectors or conduit fittings. The rear openings are for power and alarm relay wiring. The left front opening is for sensor wiring and the right front opening is for analog output wiring. Seal unused openings with conduit plugs.

3.2 POWER, ALARM, AND OUTPUT WIRING

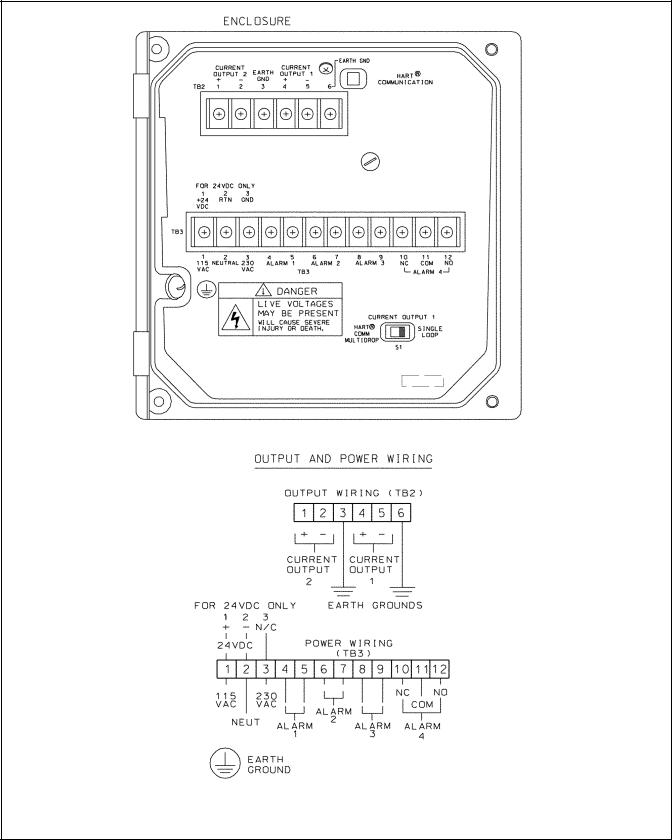

Figure 3-1 shows the power, relay, and current output terminals. For access to the terminals, loosen the screw holding the protective cover in place and remove the cover. Make power and alarm connections on TB3. Make analog output wiring connections on TB2.

DANGER

Live voltages may be present.

Will cause severe injury or death.

Alarm contacts are dry (i.e., not powered) and are normally open. Refer to Section 1.0 for relay specifications.

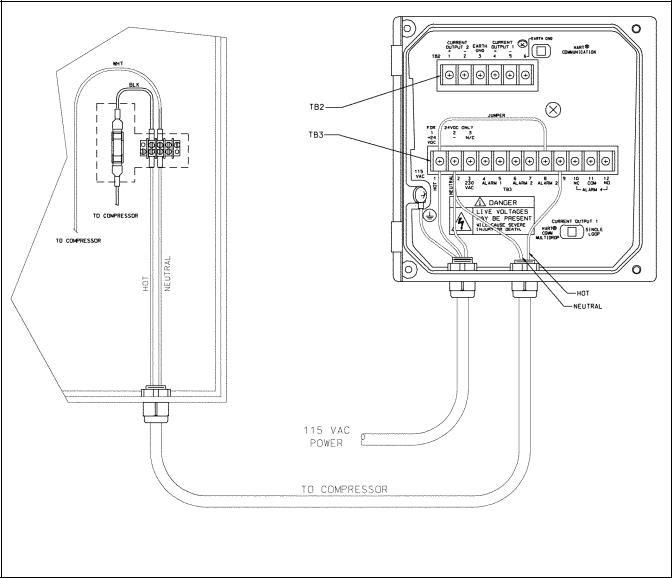

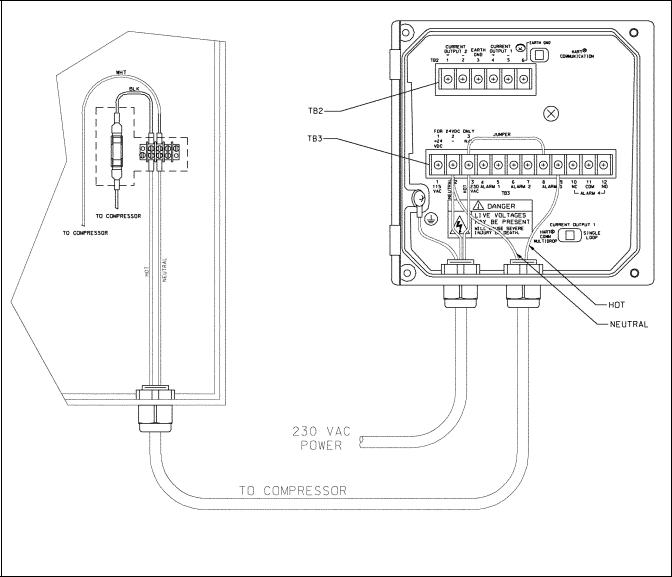

Refer to Figure 3-2 or 3-3 for details on how to wire the Model ABSH (air blast system) to the 54eA analyzer. Figure 3-2 is for Model DO-03 (115 Vac 60 Hz). Figure 3-3 is for Model DO-04 (220 Vac 50 Hz).

NOTE

The 54eA analyzer has four alarm relays. Relays 1, 2, or 3 are normally open (NO) and can be used to operate the air blast cleaner. The wiring diagrams show alarm relay 3 being used. The relay used for the air blast cleaner MUST be configured as an interval timer. See Section 5.6 for programming details.

For best EMI/RFI protection, shield the output cable and enclose it in an earth-grounded, rigid, metal conduit. Connect the outer shield of the output cable to the earth ground connection on TB2 (see Figure 3-1).

Keep sensor and output signal wiring separate from power wiring. Do no run sensor and power cables in the same conduit or close together in a cable tray.

AC wiring must be 14 gauge or greater. Be sure to connect earth ground from the power cable to the nearby ground lug. A good earth ground is necessary for proper operation of the analyzer. Provide a switch or breaker to disconnect the analyzer from the main power supply. Install the switch or breaker near the analyzer and label it as the disconnecting device.

WARNING: RISK OF ELECTRICAL SHOCK

AC connections and grounding must comply with UL 508 or local electrical code. DO NOT apply power to the analyzer until all electrical connections are verified and secure.

12

MODEL DO-03/04 |

SECTION 3.0 |

|

WIRING |

DWG. NO. |

REV. |

454EPH02 |

D |

|

|

FIGURE 3-1. Power Input, Relay, and Output Wiring for 54eA analyzer

13

MODEL DO-03/04 |

SECTION 3.0 |

|

WIRING |

FIGURE 3-2. Model DO-03 — Wiring Air Blast Compressor to Model 54eA Analyzer 115 Vac

14

MODEL DO-03/04 |

SECTION 3.0 |

|

WIRING |

FIGURE 3-3. Model DO-04 — Wiring Air Blast Compressor to Model 54eA Analyzer 230 Vac

15

Loading...

Loading...