Emerson ASCO 7000 User Manual

Operator’s

Manual

7000 Series ATS Automatic Transfer Switches D design, 30 through 230 A

7000 Series ATS Automatic Transfer Switches D design, 30 through 230 A

DANGER is used in this manual to warn of high voltages capable of causing shock, burns, or death.

WARNING is used in this manual to warn of possible personal injury.

Refer to the outline and wiring drawings provided with your 7000 Series ATS for all installation and connection details and accessories.

Refer to Group 5 Controller User’s Guide 381333–126 for ATS status display messages, time delays, pickup & dropout settings, and adjustments.

CAUTION is used in this manual to warn of possible equipment damage.

30---230 amp. size

Rating Label

Each Automatic Transfer Switch contains a rating label to define the loads and fault circuit withstand/closing ratings. Refer to the label on the Transfer Switch for specific values.

Do not exceed the values on the rating label. Exceeding the rating can cause personal injury or serious equipment damage.

Nameplate

The Transfer Switch nameplate includes data for each specific 7000 Series ATS. Use the switch only within the limits shown on this nameplate. A typical Catalog Number is shown on the next page with its elements explained.

An experienced licensed electrician must install the ATS.

TABLE OF CONTENTS section-page

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . 1-1 Mounting and Line Connections . . . . . . . . . 1-1 Auxiliary Circuits and Harness . . . . . . . . . . . 1-2 Engine Starting Contacts . . . . . . . . . . . . . . . 1-2 Functional Test . . . . . . . . . . . . . . . . . 1-2, 1-3, 1-4

TESTING & SERVICE . . . . . . . . . . . . . . . . . . 2-1 Transfer Test . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 Preventive Maintenance . . . . . . . . . . . . . . . . 2-1 Disconnecting the Controller . . . . . . . . . . . . 2-1 Manual Load Transfer . . . . . . . . . . . . . . . . . . 2-2 Trouble-Shooting . . . . . . . . . . . . . . . . . . . . . . 2-2

INDEX . . . . . . . . . . . . . . . . . . . . . . . . . back cover

50 Hanover Road, Florham Park, New Jersey 07932–1591 USA |

381333–229 D |

For sales or service call 1 800 800–2726 (ASCO) www.ascopower.com |

|

ASCO POWER TECHNOLOGIES CANADA PO Box 1238, 17 Airport Road, Brantford, Ontario, Canada N3T 5T3 telephone 519 758–8450, fax 519 758–0876, for service call 1 888 234–2726 (ASCO) www.asco.ca

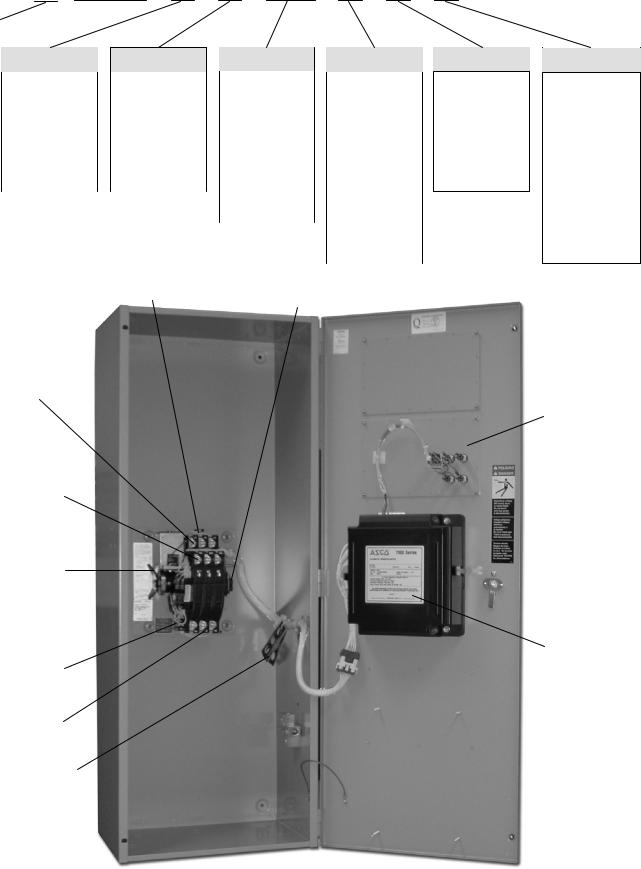

Catalog Number Identification

Typical 7000 Series 7ATS catalog no. for overlapping neutral, 3 pole, 150 amp, 480 V, in Type 1 enclosure:

D |

7ATS |

C |

3 |

150 |

design prefix letter

Neutral |

Phase Poles |

|

Amperes |

|||

|

|

|

|

|

|

|

A – solid |

2 |

– single Ø |

30 |

|

||

B – switched |

3 |

– three Ø |

70 |

|

||

C – overlapping |

|

|

100 |

|

||

blank – none |

|

|

150 |

|

||

|

|

|

|

200 |

** |

|

|

|

|

|

230 ** |

||

|

|

|

|

|

|

|

|

|

|

|

** 200 and 230 amp. |

||

|

|

|

|

limited to 480 volts |

||

N 5 C

Voltage

A 115 |

J 400 |

B 120 |

K 415 |

C 208 |

L 440 |

D 220 |

M 460 |

E 230 |

N 480 |

F 240 |

P 550 |

G 277 |

Q 575 |

H 380 |

R 600 |

|

|

Controller

5 – standard

5X – if accessories ordered

Enclosure

C – type 1

F – type 3R

G – type 4

L – type 12

M –type 3R secure

N –type 4 secure

P –type 4X secure

Q –type 12 secure blank – open type

Transfer Switch |

terminals for switch |

|

position contacts |

||

|

load power connections

emergency power connections

maintenance handle

(see WARNING under Manual Operation)

terminals for engine start contacts

normal power connections

cable spacers

(see INSTALLATION)

transfer control & lights

Controller

150 amp. size in typical enclosure with location of customer connections

SECTION 1 INSTALLATION

The ASCO 7000 Series Automatic Transfer Switch (ATS) is factory wired and tested. Field installation requires mounting, connecting service cables, and connecting engine start and auxiliary control circuits (if required).

Supporting Foundation

The supporting foundation for the enclosure must be level and straight. Refer to the applicable enclosure outline drawing included with the switch for all mounting details including door opening space.

If bottom cable entry is used, the foundation must be prepared so that the conduit stubs are located correctly. Refer to the enclosure outline drawing for specified area and location. Provide cable bending space and ½ inch minimum clearance to live metal parts. When a concrete floor is poured, use interlocking conduit spacer caps or a wood or metal template to maintain proper conduit alignment.

Mounting

Refer to the Outline and Mounting Diagram provided with the ATS; it shows all mounting details and instructions.

Protect the switch from construction grit and metal chips to prevent malfunction or

shortened life of the automatic switch switch.

Mount the ASCO ATS vertically to a rigid supporting structure. Level all mounting points by using flat washers behind the holes to avoid distortion of the switch.

The controller is mounted on the cabinet door. An add-on DIN rail is provided for some optional accessories and is mounted below the controller on the door.

Line Connections

A Wiring Diagram is furnished with the ASCO 7000 Series ATS (separate from this manual). Refer to this drawing. All wiring must be made in accordance with the National Electrical Code and local codes.

often requires considerable force. The pulling of cables can damage insulation and stretch or break the conductor’s strands. For this reason, after the cables are pulled into position, and before they are connected, they should be tested to verify that they are not defective or have been damaged during installation.

Connecting Power Conductors

After the power cables have been tested, connect them to the appropriate terminal lugs on the transfer switch as shown on the wiring diagram provided with the switch. Make sure the lugs provided are suitable for use with the cables being installed. Standard terminal lugs are solderless screw type and will accept the wire sizes listed on the drawings provided with the switch. Be careful when stripping insulation from the cables; avoid nicking or ringing the conductor. Remove surface oxides from cables by cleaning with a wire brush. When aluminum cable is used, apply joint compound to conductors. Tighten cable lugs to the torque specified on rating label.

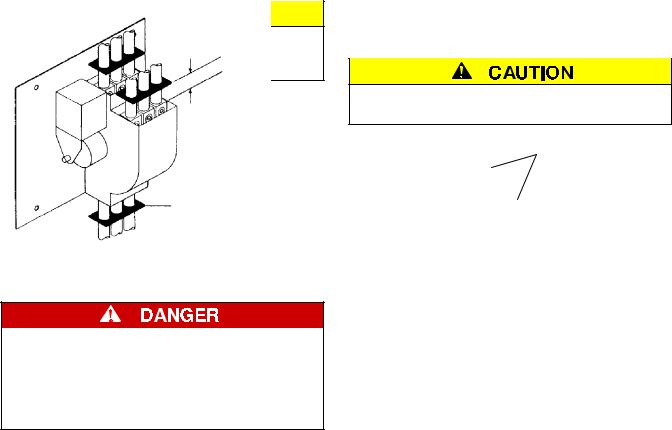

Three cable spacers are included with 150, 200, & 230 A transfer switches. When installing power cables, run the cables through the cable spacers as shown in Figure 1-1.

Position the cable spacers within 1½ inches from the lugs.

The cable spacers must be located as shown for 150, 200, and 230 ampere transfer switches.

cable spacers

1 ½ inch approximate

De–energize the conductors before making any line or auxiliary circuitry connections. Be sure that Normal and Emergency line connections are in proper phase rotation. Place engine generator starting control in the OFF position. Make sure engine generator is not in operation.

Testing Power Conductors

Do not connect the power conductors to the transfer switch until they are tested. Installing power cables in conduit, cable troughs and ceiling-suspended hangers

cable spacer

Figure 1-1. Cable spacer for 150, 200, and 230 amp. transfer switches.

Controller Ground

A grounding wire must be connected to the controller’s lower left mounting stud. Because the controller is mounted on the enclosure door, a conductive strap must be used between the enclosure and the door. This connection provides proper grounding which does not rely upon the door hinges.

1---1

Loading...

Loading...