Emerson 1F97-1277 User Manual

Big Blue Touchscreen Thermostat with

CAUTION

!

Automatic Heat/Cool Changeover Option

Installation and Operating Instructions for Model:

Save these instructions for future use!

FAILURE TO READ AND FOLLOW ALL INSTRUCTIONS

CAREFULLY BEFORE INSTALLING OR OPERATING THIS

CONTROL COULD CAUSE PERSONAL INJURY AND/OR

PROPERTY DAMAGE.

Model Programming Choices

1F97-1277

Non-Programmable 5+1+1 Day 7 Day

APPLICATIONS

THERMOSTAT APPLICATION GUIDE

Description

Heat Pump (No Aux. or Emergency Heat) Yes

Heat Pump (with Aux. or Emergency Heat) Yes

Systems with up to 3 Stages Heat, 2 Stages Cool No

Heat Only Systems Yes

Millivolt Heat Only Systems – Floor or Wall Furnaces Yes

Cool Only Systems Ye s

Gas or Oil Heat Yes

Electric Furnace Yes

Hydronic (Hot Water) Zone Heat – 2 Wires Ye s

Hydronic (Hot Water) Zone Heat – 3 Wires Ye s

Wired Remote Temperature Sensor (Indoor/Outdoor) Yes

Dual Fuel Feature (Heat Pump Mode) Yes

1F97-1277 Touchscreen Thermostat

SPECIFICATIONS

Electrical Rating:

Battery Power.......................... mV to 30 VAC, NEC Class II, 50/60 Hz or DC

Input-Hardwire ......................... 20 to 30 VAC

Terminal Load ............................. 1.5A per terminal, 2.5A maximum all terminals combined

Setpoint Range ............................ 45 to 99°F (7 to 37°C)

Differential (Single Stage) .................... Heat 0.6°F; Cool 1.2°F

Differential (Multi-Stage) ..................... Heat 0.6°F; Cool 1.2°F

Differential (Heat Pump) ..................... Heat 1.2°F; Cool 1.5°F

Operating Ambient.......................... 32°F to +105°F (0 to +41°C)

Operating Humidity ......................... 90% non-condensing max.

Shipping Temperature Range ................. -4 to +150°F (-20 to +65°C)

Dimensions Thermostat...................... 4-9/16"H x 5-13/16"W x 1-3/16"D

To prevent electrical shock and/or equipment damage,

disconnect electric power to system at main fuse or

circuit breaker box until installation is complete.

Index Page

Installation 2

Wiring Connections 2

Thermostat Quick Reference 4

Installer Conguration Menu 5

Operating Your Thermostat 8

Programming 9

Troubleshooting 12

www.white-rodgers.com

www.emersonclimate.com

ATTENTION: MERCURY NOTICE

This product does not contain mercury. However, this

product may replace a product that contains mercury.

Mercury and products containing mercury must not be

discarded in household trash. Do not touch any spilled

mercury. Wearing non-absorbent gloves, clean up any

spilled mercury and place in a sealed container. For proper

disposal of a product containing mercury or a sealed

container of spilled mercury, place it in a suitable shipping

container. Refer to www.thermostat-recycle.org for

location to send the product containing mercury.

PART NO. 37-7388A

1241

2 "AA" Batteries

INSTALLATION

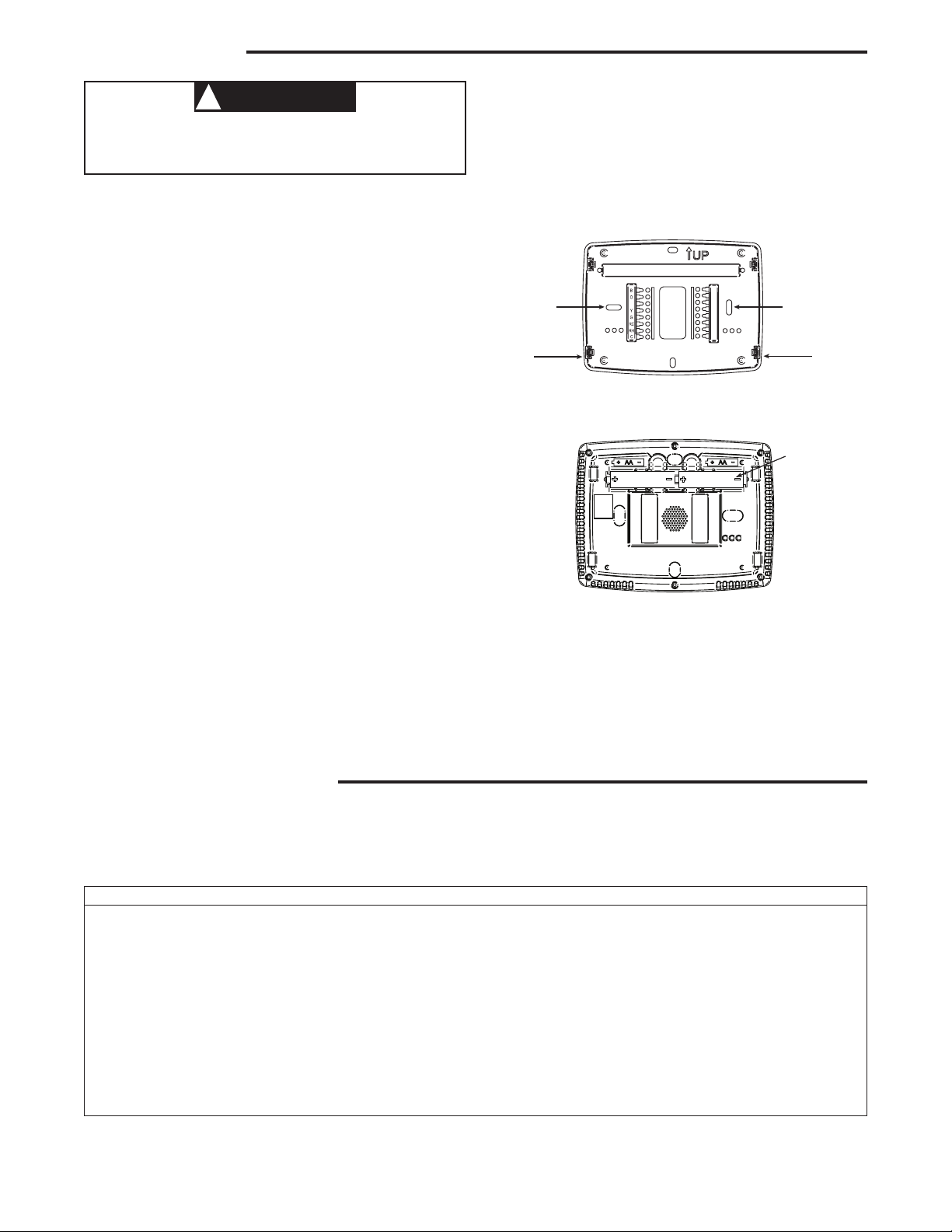

Mounting

Hole

Mounting

Hole

Place Level

across

Mounting Tabs

(for appearance only)

Place Level

across

Mounting Tabs

(for appearance only)

+

S

-

W/E

6

L

WARNING

!

Thermostat installation and all components of the

control system shall conform to Class II circuits per

the NEC code.

Remove Old Thermostat

A standard heat/cool thermostat consists of three basic parts:

1. The cover, which may be either a snap-on or hinge type.

2. The base, which is removed by loosening all captive

screws.

3. The switching subbase, which is removed by unscrewing

the mounting screws that hold it on the wall or adapter

plate. Before removing wires from old thermostat,

label each wire with the terminal designation from

which it was attached. Disconnect the wires from the old

thermostat one at a time. Do not let wires fall back into

the wall.

Battery Location

2 "AA" alkaline batteries are included in the thermostat at

the factory with a battery tag to prevent power drainage.

Remove the battery tag to engage the batteries.

To replace batteries, set system to OFF, remove thermostat

from wall and install the batteries in the rear along the top of

the thermostat (see Figure 1).

Figure 1 – Thermostat Base Multi-Stage 1F97-1277

Installing New Thermostat

1. Pull the thermostat body off the thermostat base. Forcing

or prying on the thermostat will cause damage to the unit.

2. Place base over hole in wall and mark mounting hole

locations on wall using base as a template.

3. Move base out of the way. Drill mounting holes. If you

are using existing mounting holes and the holes drilled

are too large and do not allow you to tighten base snugly,

use plastic screw anchors to secure the base.

4. Fasten base snugly to wall using mounting holes shown

in Figure 1 and two mounting screws. Leveling is for

appearance only and will not affect thermostat operation.

5. Connect wires to terminal block on base using appropriate

wiring schematic (see diagrams on next page).

6. Push excess wire into wall and plug hole with a re resistant material (such as berglass insulation) to prevent

drafts from affecting thermostat operation.

7. Carefully line the thermostat up with the base and snap

into place.

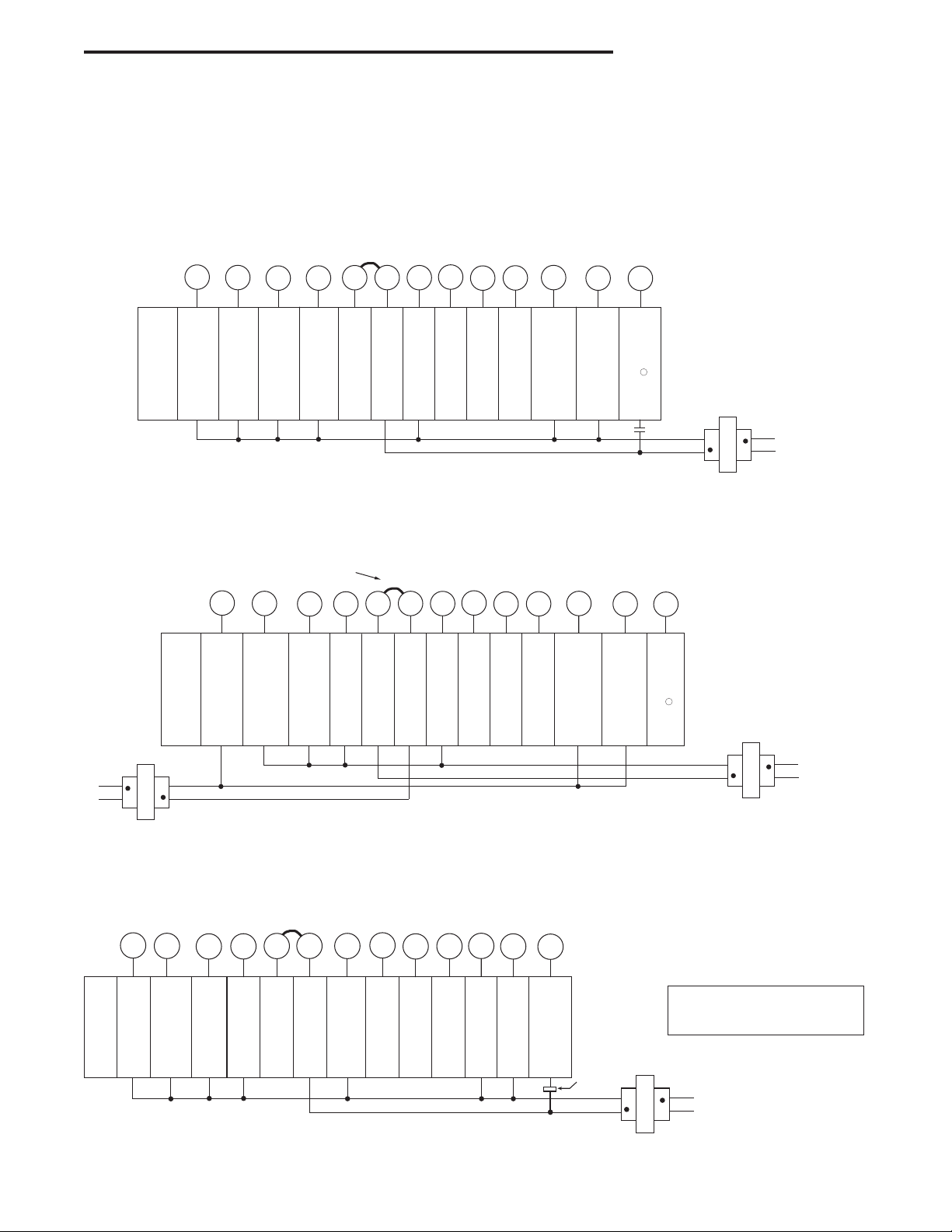

WIRING CONNECTIONS

Refer to equipment manufacturers' instructions for specic

system wiring information. After wiring, see CONFIGURA-

TION section for proper thermostat conguration.

Rear view of thermostat

For wiring diagrams, see next page.

Wiring diagrams shown are for typical systems and describe

the thermostat terminal functions.

TERMINAL DESIGNATION DESCRIPTIONS

Terminal Designation Description

B ...................Changeover valve for heat pump energized constantly in heating

O ...................Changeover valve for heat pump energized constantly in cooling

Y ...................Compressor Relay

G ...................Fan Relay

RC...................Power for Cooling

RH...................Power for Heating

C ...................Common wire from secondary side of cooling

L ...................For Call for Service indicator for systems with diagnostic connection

6 ...................Powered closed connection for 3-wire zone valve

W ...................Heat Relay

-....................Common (DC) for wired remote temperature sensor

S ...................Frequency signal from remote temperature sensor

+ ...................Power (DC) to remote temperature sensor

2

WIRING CONNECTIONS

To Remote Te mperature Sensor

HEATING

To Remote Temperature Sensor

Single Stage Connections

Refer to equipment manufacturers' instructions for specic system

wiring information.

This thermostat is designed to operate a single-transformer or twotransformer system.

You can congure the thermostat for use with the following systems:

Single Stage System with Single Transformer

To Remote Te mperature Sensor

Jumper

B

120VAC

TRANSFORMER

System

Single

Stage

(SS)

CLASS II

Energized

in Heat

or Off

Mode

System

Single

Stage

(SS)

NEUTRAL

24VAC

HOT

Energized in

Cool

Mode

B

Energized

in Heat,

Off Mode

O

Energized

on call

for Cool

(Compressor)

O

Energized

in Cool

Mode

Y

Remove Jumper Wire

between RH & RC

Energized

on call

for Cool

(Compressor)

G

Blower/

Circulator Fan

Energized on

call for

Cool &

for Heat

(if ELE

is selected)

Y

RC

RH

C*

DC

supply

24 Volt

voltage

Com-

24 Volt

24 Volt

(Hot)

Cool

(Hot)

Heat

mon

(optional)

to remote

Temperature

Sensor

*Common connection required for fault or

malfunction indication and remote sensor.

Single Stage with Two Transformers

Jumper

RC

24 Volt

(Hot)

Cool

RH

C*

24 Volt

Com-

24 Volt

mon

(Hot)

(option-

Heat

al)

*Common connection required for fault or

malfunction indication and remote sensor.

G

Blower/

Circulator Fan

Energized on

call for

Heat or

Cool

(if ELE

is selected)

SINGLE STAGE gas, oil or electric.

HEAT PUMP TYPE 1 (HP 1). Single stage compressor system; gas

or electric backup.

After wiring, see INSTALLER CONFIGURATION section for proper

thermostat conguration.

{

+

S

-

Remote

Temperature

Sensor

signal

DC

Return

to

Remote

Temperature

Sensor

W

Energized

on call for

Heat

6

Third

wire for

3-wire

zone

valve

L

Diagnostic

Indicator

(See

1

Note

)

NEUTRAL

24VAC

HOT

CLASS II

TRANSFORMER

120VAC

{

NOTE: If continuous backlight or hardwired

power input are desired but do not function

+

DC

supply

voltage

to remote

Temperature

Sensor

S

Remote

Temperature

Sensor

signal

-

DC

Return

to

Remote

Temperature

Sensor

W

Energized

on call for

Heat

6

Third wire

for 3-wire

zone valve

Diagnostic

Indicator

(See

Note

in both HEAT and COOL modes, cut the

L

heating transformer 24V wires and tape off.

Connect the neutral circuit disconnected

from the heating transformer to the neutral

circuit of the cooling transformer. Disconnect the wire to the RH terminal and install

a jumper between RH and RC. Depending

on the system requirements, replace the

1

)

cooling transformer with a 75VA class II

transformer if needed.

NEUTRAL

24VAC

HOT

CLASS II

TRANSFORMER

120VAC

COOLING

Heat Pump Systems

{

Jumper

B

System

Heat

Pump 1

(HP1)

Energized in

Heat/

Emergency

Mode

O

Energized

in Cool

& Off

Mode

Y

1st

Stage

Heat

& Cool

(Compressor)

**

RC

G

Blower/

Circulator Fan

24 VAC

Energiz-

(Hot)

ed on

Cool

call for

Heat or

Cool

RH

24 VAC

(Hot)

Heat

24 VAC

Common

(optional)

NOTE ➀: Connection for Call for Service diagnostic indicator compatible with mechanical or electronic condenser control with Comfort AlertTM.

+

C*

DC

supply

voltage

to remote

Temperature

Sensor

S

Remote

Temperature

Sensor

signal

-

DC

Return

to

Remote

Temperature

Sensor

W

Auxiliary &

Emergency

Heat

1st

Stage

6

Power

Closed

Connection

for

3-wire

zone

valve

L

Diagnostic

Indicator

(See

Note )

Comfort

Alert II module

or similar

malfunction

module

NEUTRAL

24VAC

HOT

TRANSFORMER

*24 VAC common connection

optional for system operation.

Required for fault or malfunction indi-

cation, remote temperature sensor, or

for continuous backlight operation.

**Dual fuel de-energizes

compressor when auxiliary heat is

energized.

120VAC

CLASS II

3

1

2

3

4

5

6

7

8

9

10

11

12

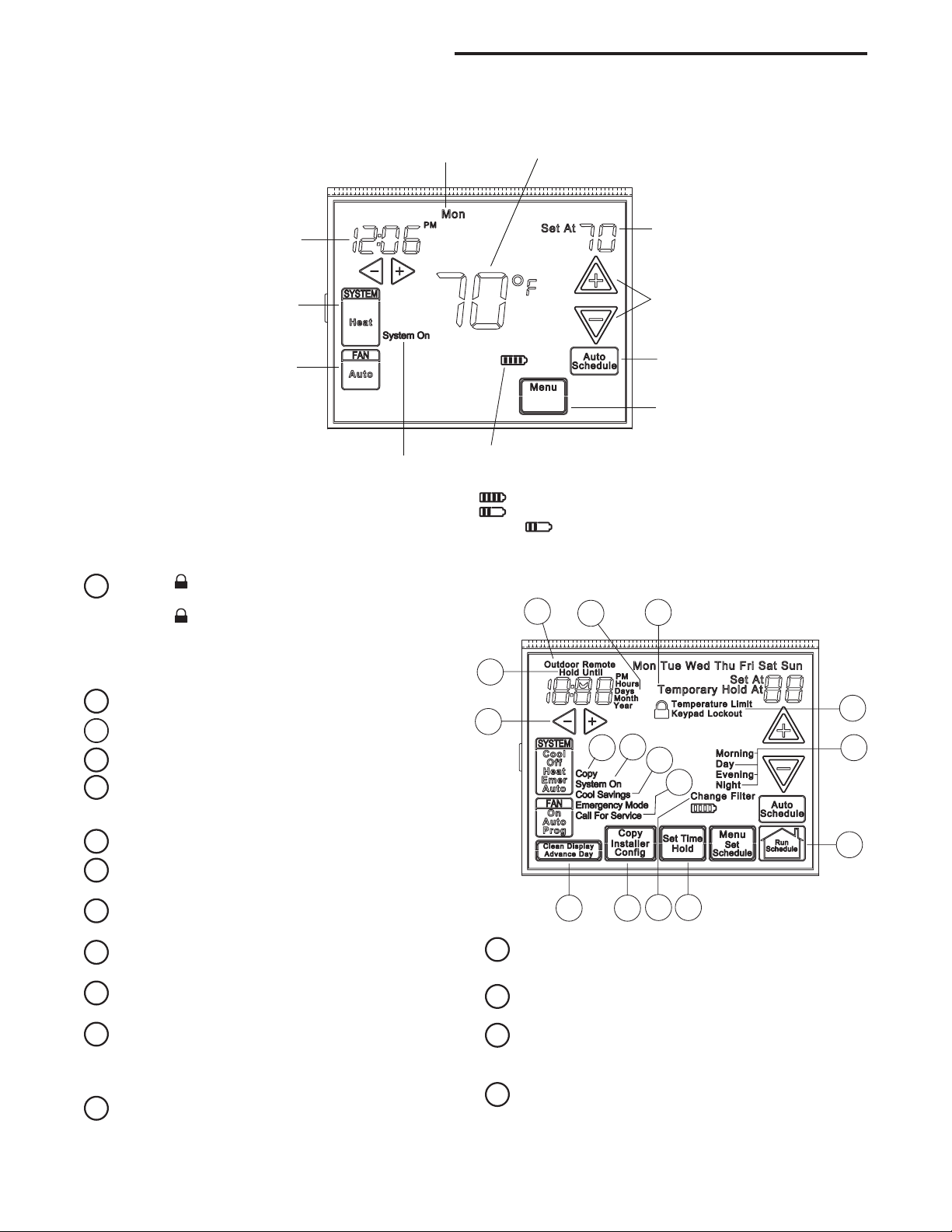

Time of Day

Day of Week

Room

Temperature

System

Switch

Fan

Switch

Indicates when

thermostat is calling

for Heat or Cool

Battery Level Indicator

Indicating the current power level

of the 2 “AA” batteries.

Full power remaining.

Half power remaining.

Change The batteries should be replaced at this time.

Menu key for entering

different modes such as

Configuration, Set Time,

Set Schedule and Cleaning

Enters user-friendly

program into

the schedule

Temperature

UP/Down used for

modifying set point

as well as to

navigating the menus

Set Temperature

THERMOSTAT QUICK REFERENCE

13

14

15

16

16

15

14

13

12

11

10

9

8

76

54

3

2

1

Home Screen Description

Figure 2 – Home Screen Display

Programming and Conguration Items

Displays and "Keypad Lockout" when in keypad

lockout mode.

Displays

Lockout" when limited range is activated and locked.

Displays only "Temperature Limit" when limited range

is activated.

Indicates period of day being programmed.

RUN SCHEDULE (run program) button.

SET TIME button or HOLD temperature button.

Displays "Change Filter" when the system has run

for the programmed lter time period as a reminder to

change or clean your lter.

COPY button or INSTALLER CONFIG button.

CLEAN DISPLAY button allows 30 seconds to wipe off

the display or ADVANCE DAY button for programming.

Used in programming to set time and in conguration

menu to change selections.

"Hold Until" indicates the time when a temporary hold

period will end.

"Hours" and "Days" displays during steps in installer

conguration.

The words "Hold At" are displayed when the thermo-

stat is in the HOLD mode. "Temporary Hold At" is

displayed when the thermostat is in a temporary HOLD

mode.

"Call For Service" indicates a fault in the heating/cool-

ing system. It does not indicate a fault in the thermostat.

4

and "Temperature Limit" and "Keypad

Figure 3 – Programming & Conguration Items

"System On" indicates when heating or cooling stage

is energized.

"Copy" indicates the copy program feature is being

used during programming.

A steady "Cool Savings" display indicates the feature

is enabled in the installer menu. A ashing "Cool Savings" display indicates the feature is active.

"Remote" indicates that the indoor remote temperature

sensor, is being accessed. "Outdoor Remote" indicates the outdoor remote temperature sensor is being

accessed.

Loading...

Loading...