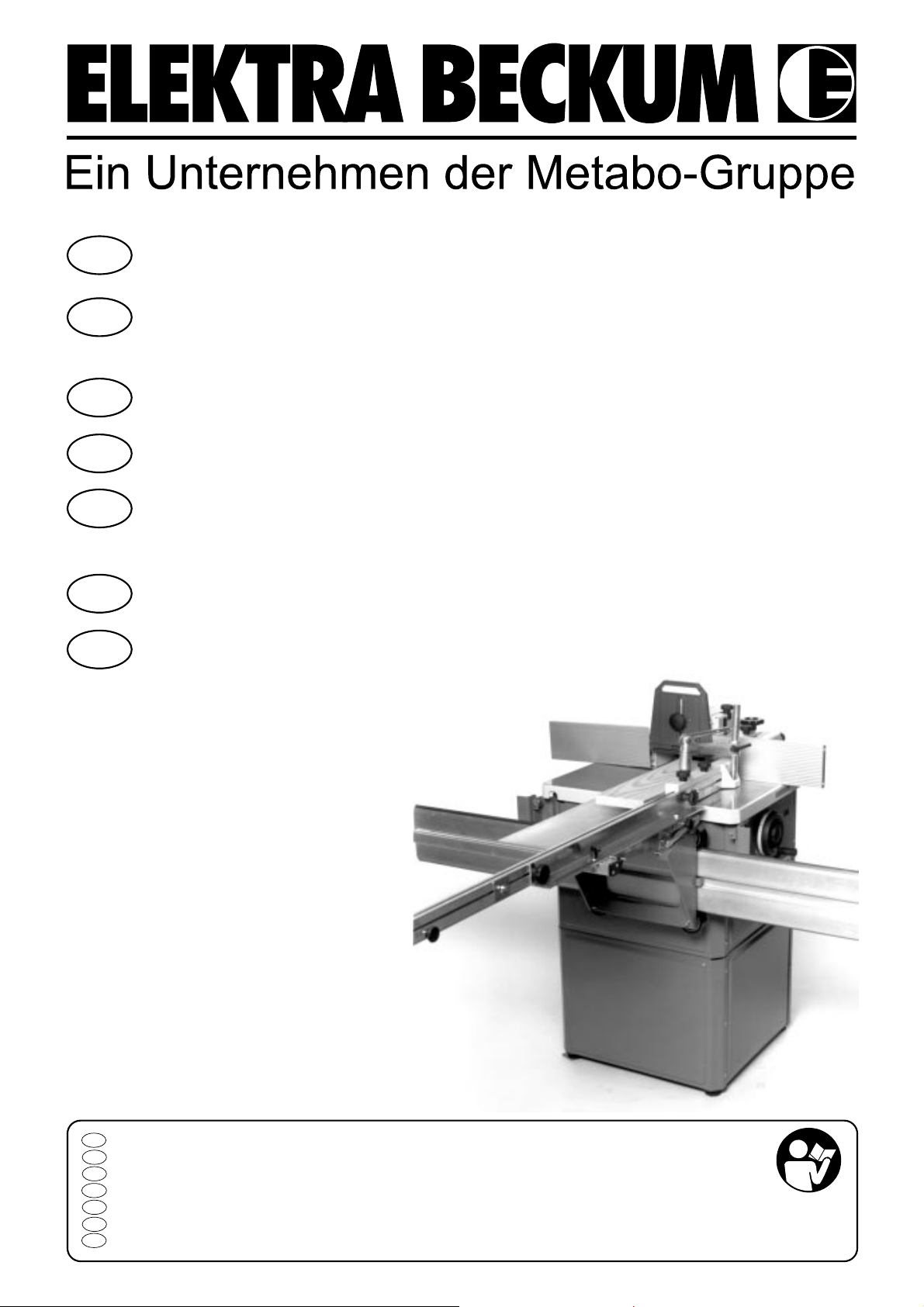

Elektra Beckum TF 900 User Manual

®

115 160 0154 / D/ENG/F/NL/IT/ES/DA / 4000 / 2.0

Montage- und Betriebsanleitung Schiebeschlitten

Assembly and Operation Manual

Sliding Carriage

Instructions de service relatives au chariot coulissant

Montage en gebruiksaanwijzing Afkortgeleider

Istruzioni per l'uso ed il montaggio della slitta di

spinta

Instrucciones de montaje y uso - Carro deslizante

Betjeningsvejledning Tapslæde

TF 900/TF 904

D

ENG

F

NL

IT

ES

DA

Achtung! Lesen Sie diese Anleitung vor der Installation und Inbetriebnahme aufmerksam durch.

Attention! Carefully read through these instructions prior to installation and commissioning.

Attention! Prière de lire attentivement la présente notice avant l'installation et la mise en service.

Attentie! Lees deze instructies voor de installatie en ingebruikname aandachtig door.

Attenzione! Prima dell'installazione e della messa in esercizio, leggete attentamente e completamente queste istruzioni.

Atención! Lea atentamente estas instrucciones antes de la instalación y puesta en marcha.

Bemærk! Læs denne vejledning opmærksomt igennem inden installationen og idrifttagningen.

IT

DA

D

NL

F

ENG

ES

ENG

Contents

1 Scope of Application

2 Specifications

3 Product Liability/Warranty

4 Safety Information

5 Installation

6 Operation

7 Care and Maintenance

8 Spare Parts List

4 Safety Instructions

Feeding the workpiece with a sliding carriage is considered semi-mechanical feed. The cutterheads and moulding

tools used must be approved for mechanical feed. Always perform such moulding operation with the cutterhead

running at counterrotation, i.e. the cutterhead is turning against the direction of feed of the workpiece. Always have

the workpiece firmly secured to the sliding carriage's table with the clamps provided.

1 Scope of Application

This Sliding Carriage is intented for use with the Elekta Beckum Spindle Moulder models TF900/TF904. It is used

for working across the endgrain of timber having a square or rectangular crossection.

- Please observe all relevant safety regulations for the use of spindle moulders applicable in your area.

When in industrial use in the U.K. use of this accessory falls under the 1974 Woodworking Regulations. In the

interest of health & safety of the machine user we recommend you study and follow these regulations.

We would also draw your attention to the booklet "Woodworking Machines Regulations 1974-Guidance on

Regulations" ref. L4 /ISBN 0118855921) published by HSMO.

2 Specifications

Table size: 280 x 525 mm

Carriage travel: 700 mm

Fence: adjustable 45° through 90°

Graduation: 1°

Carriage guides: 4 rollers, on ball bearings

Max. allowable workpiece weight: 20 kg

Mounting: quick-action locks

Workpiece clamping: quick-action clamp

3 Product Liability/Warranty

This product carries a 12 month manufacturer warranty under the prevailing legal provisions, which may vary from

country to country. The warranty period begins with the date of the original purchase by the end user. Proof of

purchase should be retained and must be presented in the event of a warranty claim. This warranty excludes and

does not cover defects, malfunctions and failures caused by natural wear, overload, unreasonable use or failure

to provide reasonable and necessary maintenance.

In case of a defect notify your dealer or Elektra Beckum distributor, who will decide how to handle your claim.

Warranty claims can only be taken care of by your Elektra Beckum dealer or authorized service centre.

This product or any of its parts should not be altered or changed from standard specifications. The user of this

product shall have the sole responsibility for any malfunction which results from improper use or unauthorized

modification from standard specifications, faulty maintenance, damage or improper repair by anyone other than

qualified person approved by Eleketra Beckum or its representatives.

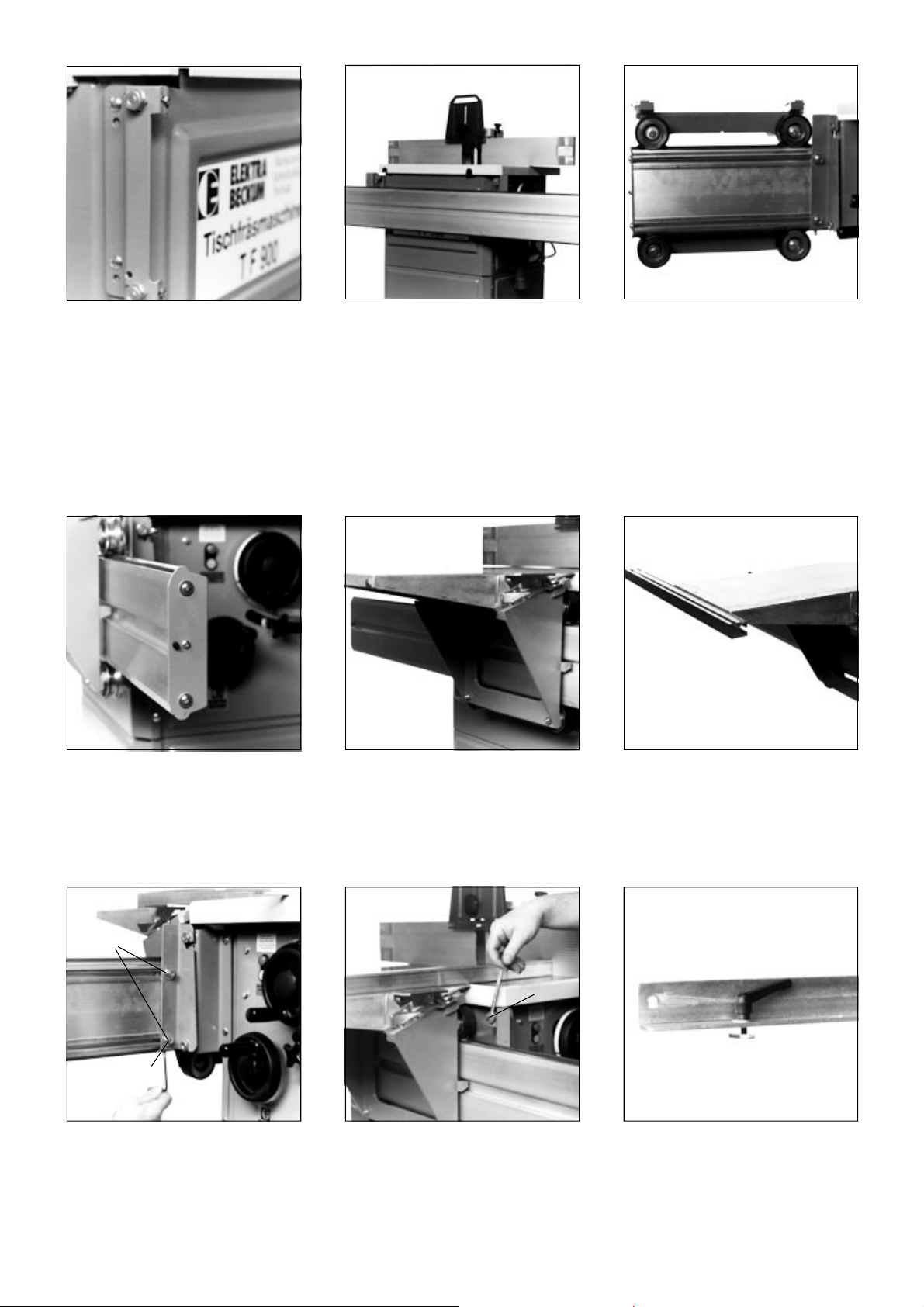

5 Installation

Fit the two crosshead plates (370/371) to

the machine housing.

Use 4 each

cup square neck bolt M 6x20

flange nut M 6

Hook roller carriage extrusion (358) with

both extrusion brackets (319 + 320) onto the

crosshead plates. If it is a tight fit remove

some paint from the slots in the extrusion

brackets.

Secure roller carriage extrusion by fixing the

rear extrusion bracket (319) to the crosshead

plate (371), to prevent unhooking.

Use 1 each

hexagen head bolt M 6x16

hexagon nut M 6

Remove the front backstop plate (360) and

slide traversing saddle onto the roller car-

riage extrusion.

The carriage table should be set approx.

0.5 mm higher than the machine table. Set

with setting screws B. Loosen screw

holding rear extrusion bracket (319/371

and 320/370) to bracket before turning

setting screw B and tighten after setting.

Make trial cut to verify proper setting. After

setting is completed, tighten all 4 nuts

(408) M8 (A).

Alignment:

Set roller carriage extrusion parallel to the

machine table with both front and rear set-

ting screws C. It does not matter if the

carriage table is higher or lower than the

machine table.

After successful parallel alignment tighten

the counter nuts on all 4 setting screws B.

Den Klemmhebel mit Unterlegscheibe durch

den Schlitz der Kulissenschiene führen und

den Stellgleiter aufschrauben.

C

B

A

Reinstall backstop plate. Place sliding carriage table onto traversing

saddle and secure with the lock levers.

Loosely fit two cup square neck screws M

6x20 with washer Ø6.4, spring washer Ø6

and hexagon nut M6 to the two holes in the

front of the carriage table.

Slide link bracket extrusion on the heads of

the just fitted cup square neck screws. At this

stage do not tighten the screws.

Loading...

Loading...