Echo CS-300, CS-340, CS-345 User Manual

Chain Saw

Instruction Manual

MODELS : CS-300

Serial Number 03001001 - 03999999

CS-340

Serial Number 03001001 - 03999999

CS-345

Serial Number 03001001 - 03999999

X7503203102

WARNING

Read rules for safe operation and instructions carefully. ECHO provides an Instruction

Manual and a Safety Manual. Both must be read and understood for proper and safe

operation.

DANGER

X750003241

04/03

RULES FOR SAFE OPERATION

A. Kickback Safety Precaution for Chain Saw Users

WARNING!

KICKBACK may occur when the nose or tip of the

guide bar touches an object, or when the wood

closes in and pinches the saw chain in the cut.

Tip contact in some cases may cause a lightning

fast reverse REACTION, Kicking the guide bar up

and back towards the operator . Pinching the saw

chain along the top of the guide bar may push the

guide bar rapidly back towards the operator. Either of these reactions may cause you to lose control of the saw which could result in serious personal injury .

Do not rely exclusively upon the safety devices built

into your saw. As a chain saw user , you should take

several steps to keep your cutting jobs free from

accident or injury .

1. With a basic understanding of kickback, you

can reduce or eliminate the element of surprise.

Sudden surprise contributes to accidents.

2. Keep a good firm grip on the saw with both

hands, the right hand on the rear handle, and

the left hand on the front handle, when the engine is running. Use a firm grip with thumbs and

fingers encircling the chain saw handles. A firm

grip will help you reduce kickback and maintain control of the saw . Don’t’ let go.

3. Make sure that the area in which you are cutting is free from obstructions. Do not let the

nose of the guide bar contact a log, branch, or

any other obstruction which could be hit while

you are operating the saw.

4. Cut at high engine speeds.

5. Do not overreach or cut above shoulder height.

6. Follow manufacturer’s sharpening and maintenance instructions for the saw chain.

7. Only use replacement bars and chains specified by the manufacturer or the equivalent.

B. Other Safety Precautions

1. Do not operate a chain saw with one hand! Serious injury to the operator, helpers, byst anders, or any combination of these persons may

result from one-handed operation. A chain saw

is intended for two-handed use.

2. Do not operate a chain saw when you are fatigued.

3. Use safety footwear; snug-fitting clothing; protective gloves; and eye, hearing and head protection devices.

Copyright© 2003 By Echo, Incorporated

All Rights Reserved.

4. Use caution when handling fuel. Move the chain

saw at least 3 m (10 feet) from the fueling point

before starting the engine.

5. Do not allow other persons to be near the chain

saw when starting or cutting with the chain saw .

Keep bystanders and animals out of the work

area.

6. Do not start cutting until you have a clear work

area, secure footing, and a planned retreat path

from the falling tree.

2

7. Keep all parts of your body away from the saw

chain when the engine is running.

14.Keep the handles dry, clean, and free of oil or

fuel mixture.

8. Before you start the engine, make sure that

the saw chain is not contacting anything.

9. Carry the chain saw with the engine stopped,

the guide bar and saw chain to the rear , and

the muffler away from your body .

10.Do not operate a chain saw that is damaged,

improperly adjusted, or not completely and

securely assembled. Be sure that the saw

chain stops moving when the throttle control

trigger is released.

11.Shut off the engine before setting the chain saw

down.

12.Use extreme caution when cutting small size

brush and saplings because slender material

may catch the saw chain and be whipped toward you or pull you off balance.

13.When cutting a limb that is under tension, be

alert for spring back so that you will not be

struck when the tension in the wood fibers is

released.

15.Operate the chain saw only in well-ventilated

areas.

16.Do not operate a chain saw in a tree unless

you have been specifically trained to do so.

17.All chain saw service, other than the items listed

in the Instruction Manual maintenance instructions, should be performed by competent chain

saw service personnel. (For example, if improper tools are used to remove the flywheel

or if an improper tool is used to hold the flywheel in order to remove the clutch, structural

damage to the flywheel could occur and could

subsequently cause the flywheel to burst.)

18.When transporting your chain saw, use the

appropriate guide bar scabbard.

19.Spark arrestor mufflers approved to SAE Standard J335b are Standard on ECHO Chain

saws to reduce the possibility of forest fires.

Do not operate the chain saw with a loose or

defective muffler . Do not remove the spark arrestor screen.

CONTENTS

Page

Rules for Safe Operation..................................................................................................2

T echnical Data .................................................................................................................4

Emission Data .................................................................................................................5

Description ...................................................................................................................... 5

Nomenclature of Parts......................................................................................................6

Preparation for Use..........................................................................................................7

Fuel and Lubricant............................................................................................................8

Operation......................................................................................................................... 9

Cutting Instructions ......................................................................................................... 11

Maintenance and Care................................................................................................... 15

Chain and Guide Bar Combinations............................................................................... 18

Setting the Saw Chain....................................................................................................18

Troubleshooting..............................................................................................................20

Storage.......................................................................................................................... 21

Correct Use of Chain Brake ...........................................................................................22

Servicing Information......................................................................................................24

3

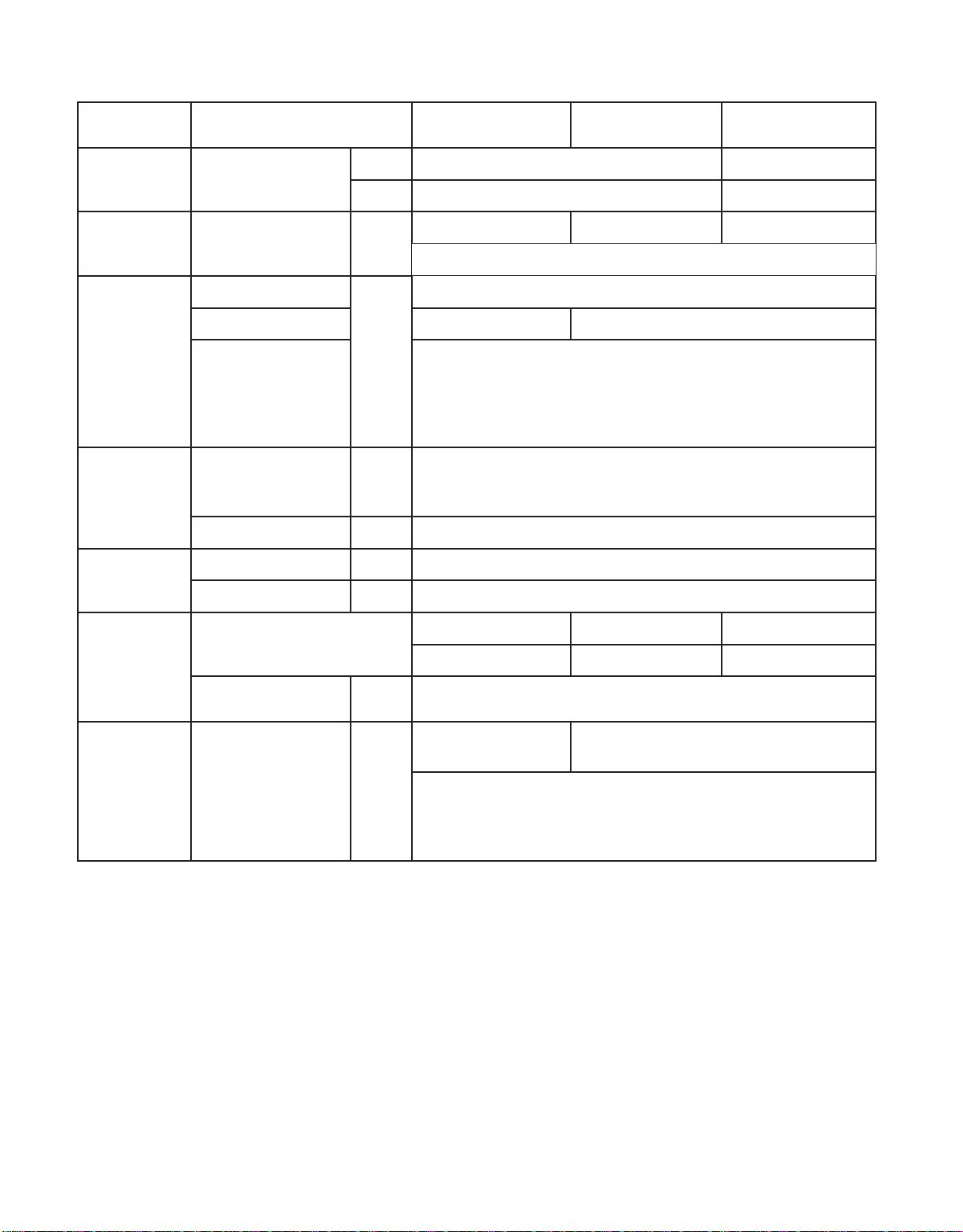

TECHNICAL DATA

ledoM

mm022x532x062542x532x083

noisnemiDHxWxL

hcni7.8x2.9x2.016.9x2.9x0.51

thgieWyrd,daehrewoPgk)bl1.7(2.3)bl3.7(3.3)bl5.7(4.3

enignEepyT

tnemecalpsiD).ni.uc38.1(1.03).ni.uc30.2(4.33

roterubraC

otengaM

gulPkrapS

retratS

leuFoitarerutxiMdnelBrewoPohcEhtiwoitar1:05

yticapaCknaTL ).S.Uzolf6.8(52.0

liOniahcdnaraB)liorotomro(lioniahcdnarabOHCE

lm

noissimsnartrewoP

003-SC043-SC543-SC

rednilycelgnis,ekorts-owt,delooc-riA

epytmgarhpaiD

metsysIDC:otengamleehwylF

Y8-MPBKGN

retratslioceR

hctulclagufirtneccitamotuA

MT

rabediugdnaniahctuohtiW

.lioekorts-2

,lohoclalyhtemgniniatnocleufesutonoD.dedaelnuenatco98

.EBTM%51rolohoclalyhte%01nahterom

yticapaCknaTL ).S.U.zo.lf5(51.0

rabediuG

niahcwaS

noitacirbuLpmupliocitamotuaelbatsujdA

dradnatS

serutaef

* Technical data subject to change without notice.

dradnatS.ni21dradnatS.ni41dradnatS.ni61

lanoitpO.ni61,41lanoitpO.ni61,21lanoitpO.ni41,21

eldnaHpoTeldnahlanoitnevnoC

draugdnahraeR

,draugdnahtnorF

,ecivednoitarbiv-itnA

,ekarbniahC,tuokcollortnocelttorhT

relffumrotserrakrapS,rehctacniahC

4

EMISSION CONTROL

EPA Phase II

EMISSION DATA

The emission control system for these engines are

EM (Engine Modification).

An Emission Control Label is located on the

engine. (This is an EXAMPLE ONLY, information on

ENGINE FAMILY: 2EXHS.0334RA

DISPLACEMENT: 33.4 CC

THIS ENGINE MEETS U.S. EPA PAHSE II EMISSION REGULATIONS FOR S.O.R.E. REFER TO OWNER'S MANUAL FOR

MAINTENANCE SPECIFICATIONS AND ADJUSTMENTS.

EMISSION COMPLIANCE PERIOD : 300 HRS.

IMPORTANT ENGINE INFORMATION

label varies by engine FAMILY).

PRODUCT EMISSION DURABILITY

The 300 hour emission durability compliance period is the time span selected by the manufacturer certifying

the engine emissions output meets applicable California and/or U.S. EPA emissions regulations, provided

that approved maintenance procedures are followed as listed in the Maintenance Section of this manual.

DESCRIPTION

The ECHO product you purchased has been factory pre-assembled for your convenience. Due to packaging

restrictions, guide bar and saw chain installation and other assembly may be necessary.

After opening the carton, check for damage. Immediately notify your retailer or ECHO Dealer of damaged or

missing parts. Use the contents list to check for missing parts.

CONTENTS

1 - Power Head

1 - Guide Bar

1 - Saw Chain

1 - Instruction Manual

1 - Safety Manual

1 - Warranty Registration Card

1 - Limited Warranty Statement

1 - Kick Guard Installation Manual

1 - Scrench

1 - Echo Power Blend TM 2-stroke oil sample

5

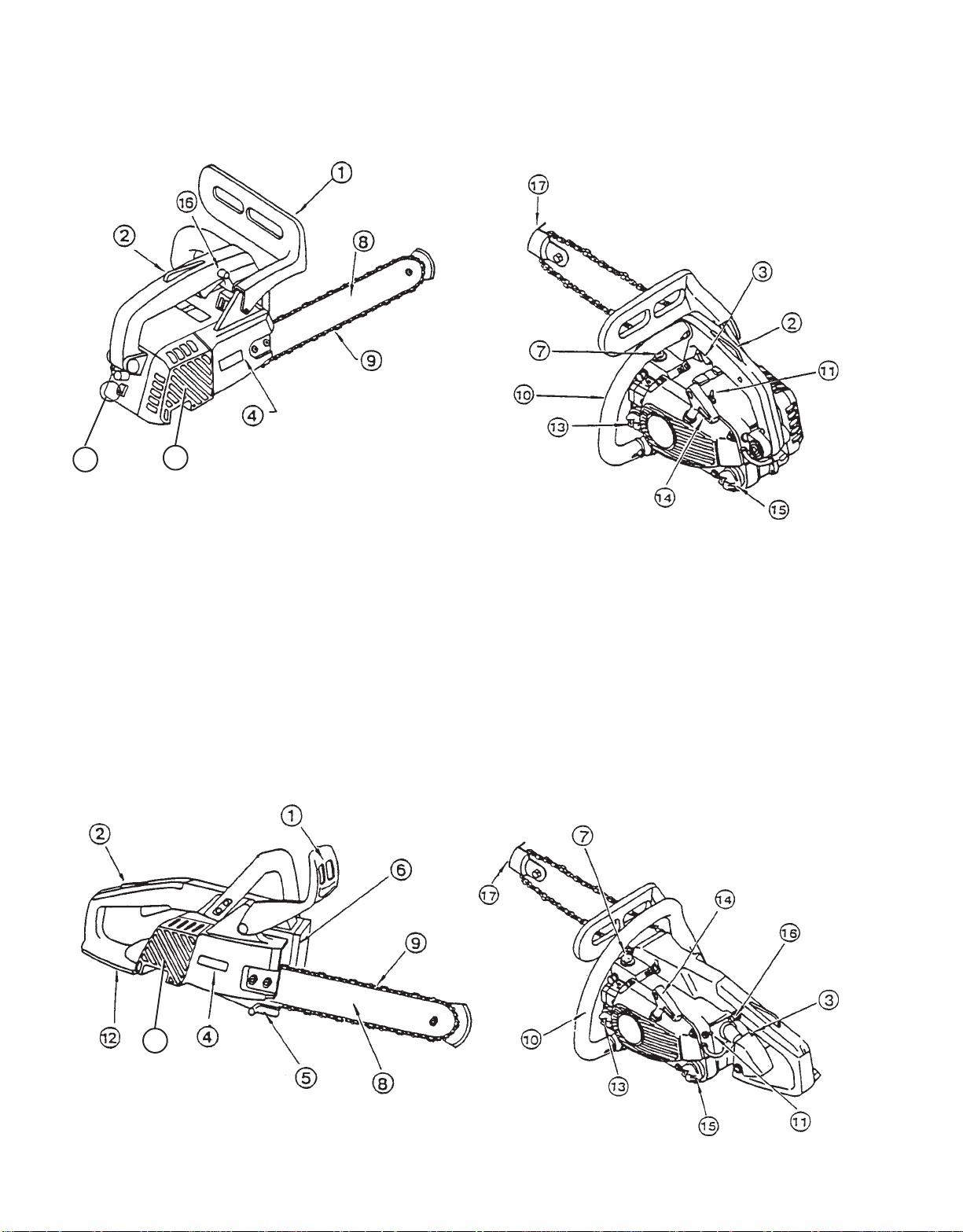

CS-300, CS-340

NOMENCLATURE OF P ARTS

19

1. Hand guard

(Chain brake actuating lever)

2. Throttle control lockout

3. Throttle control trigger

4. Sprocket guard

5. Chain catcher

18

CS-345

6. Air cleaner cover

7. Purge bulb

8. Guide bar

9. Saw chain

10. Front handle

11. On / Off switch

12. Rear hand guard

13. Fuel tank cap

14. Pull starter

15. Oil tank cap

16. Throttle control latch

17. Tip guard

18. Muffler

19. Lanyard ring

18

6

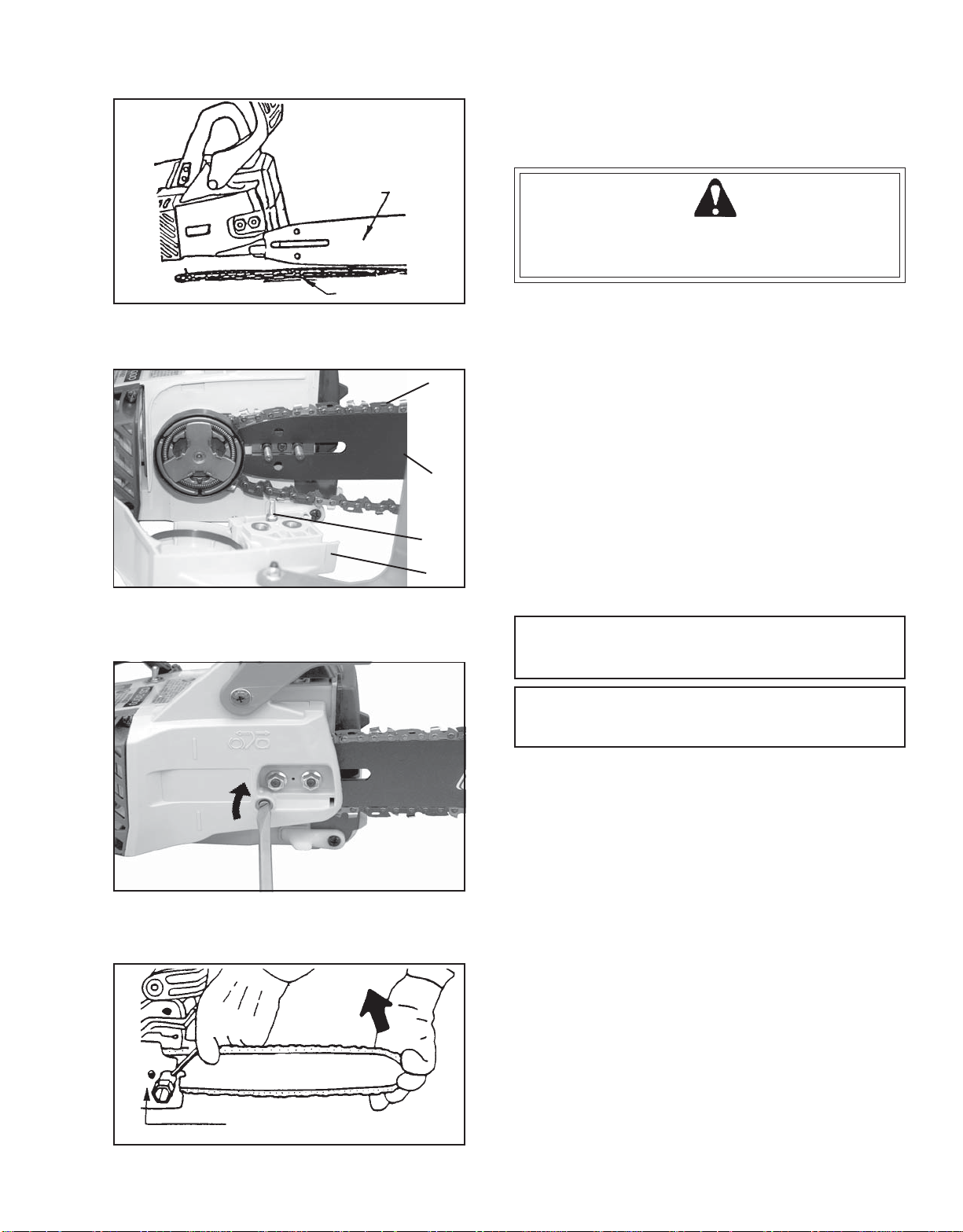

PREPARA TION FOR USE

The machine may be delivered with guide bar (A), tip

guard, and saw chain (B) separated. Install guide bar , tip

guard, and saw chain as follows:

A

W ARNING DANGER

Saw Chain is sharp! Always wear gloves when

handling assembly, otherwise serious personal injury

may result.

B

CAUTION

1. All adjustments should be made cold.

2. Always wear gloves when working on chain.

B

A

C

D

3. Do not operate with a loose chain.

GUIDE BAR AND SAW CHAIN

• Follow the instructions enclosed with tip guard to

install guard to guide bar .

• Remove two guide bar nuts and remove sprocket

guard (D).

• Mount guide bar (A) on studs, and slide toward

sprocket to make saw chain installation easier .

• Install saw chain (B) as shown, with cutters facing

forward.

IMPORTANT

Be certain tensioner (C) fits into lower adjuster hole

before tightening guide bar nuts.

NOTE

Move chain brake lever fully rearward to install

sprocket guard to saw.

• Install sprocket guard (D), and tighten guide bar nuts

finger tight.

• Adjust saw chain tension, as instructed in “Adjustment, Chain T ension.”

ADJUSTMENT, CHAIN TENSION

• Loosen two guide bar nuts.

• Turn the adjuster screw clockwise until the chain

touches the bottom of the bar.

UP

D

• Hold the bar nose up and tighten the chain until there

is no clearance between the bar and chain.

• Tighten both guide bar nuts with bar nose held up, to

eliminate clearance.

• Pull the saw chain around the guide bar by hand.

Loosen the adjustment, if you feel tight spots.

• Start the engine and run at low speed. Stop and

readjust, if necessary .

7

FUEL AND LUBRICANT

FUEL STATEMENT

GASOLINE - Use 89 Octane [R+M/2] (mid grade or higher)

gasoline or gasohol known to be good quality. Gasohol may

contain up to 10% Ethyl (grain) alcohol or 15% MTBE (methyl

tertiary-butyl ether). Gasohol containing methyl (wood) alcohol

is NOT approved.

TWO STROKE OIL - A two-stroke engine oil meeting ISO-LEGD (ISO/CD 13738) and J.A.S.O. FC Standards must be

used. Echo brand premium Power Blend TM Universal 2-Stroke

Oil meets these standards. Engine problems due to inadequate

lubrication caused by failure to use an ISO-L-EGD and J.A.S.O.

FC certified oil, such as Echo premium Power Blend TM, will void

the two-stroke engine warranty. (Emission related parts only

are covered for two years, regardless of two-stroke oil used, per

the statement listed in the Emission Defect Warranty Explanation.)

Mixing Instructions

1. Fill an approved fuel container with half of the required

amount of gasoline.

2. Add the proper amount of 2-stroke oil to gasoline.

3. Close container and shake to mix oil with gasoline.

4. Add remaining gasoline and remix.

5. Install fuel container cap and wipe any spilled fuel from

container and surrounding area.

Oil

50

Gasoline

Fuel Mix Chart

50:1

).S.U()CIRTEM(

SAGLIOSAGLIO

.laG.zo.lFretiL.cc

1

2

5

6.2

1.5

8.21

4

8

02

08

061

004

IMPORTANT

Stored fuel ages. Do not mix more fuel than you expect to

use in thirty (30) days, ninety (90) days when a fuel stabilizer is added.

Stored two-stroke fuel may sep arate. AL WAYS shake fuel

container thoroughly before each use.

IMPORTANT

Spilled fuel is a leading cause of hydrocarbon emissions.

Some states may require the use of automatic fuel shutoff containers to reduce fuel spillage. Contact your ECHO

dealer for ordering information.

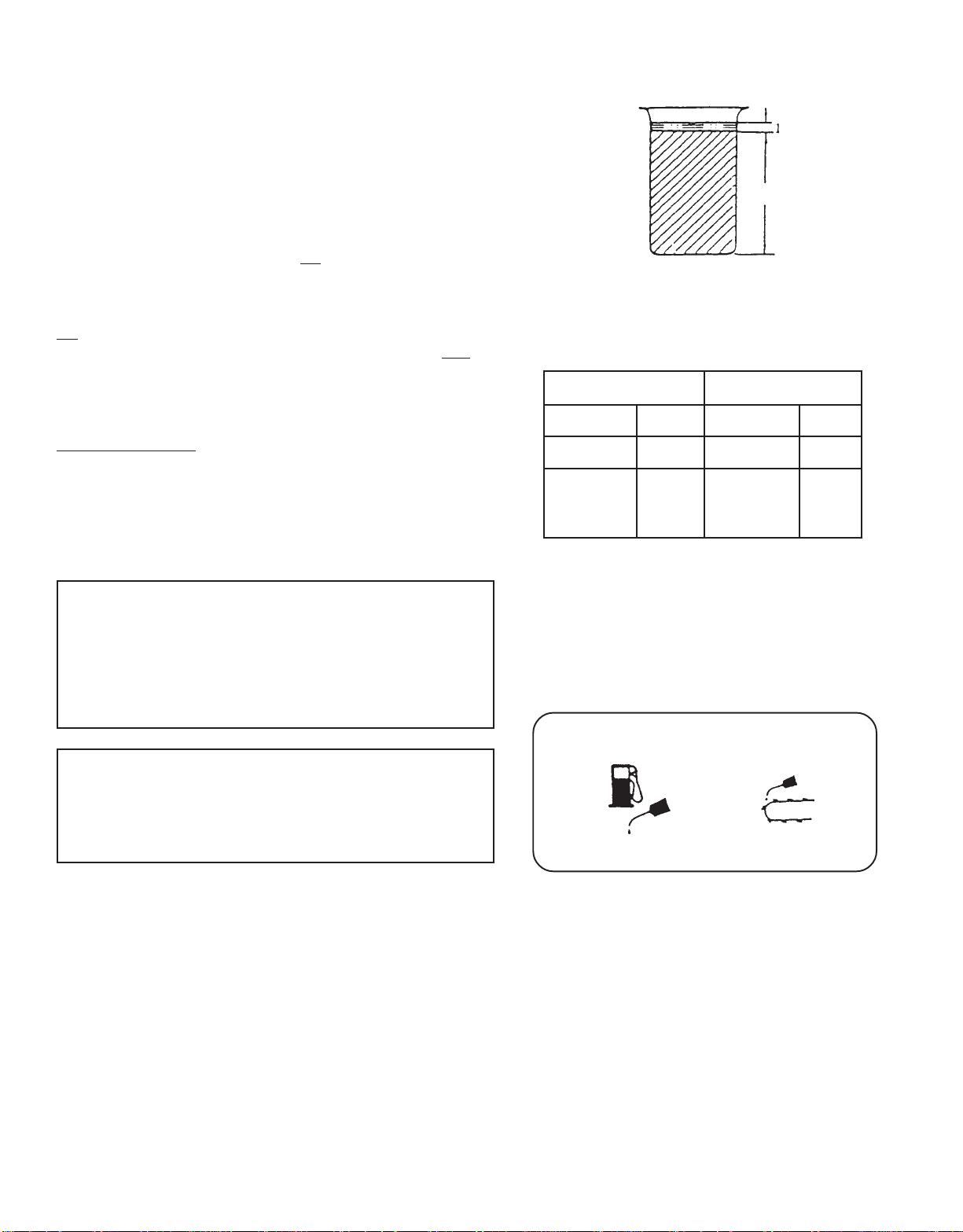

CHAIN LUBRICANT

Proper lubrication of the chain while in operation reduces friction

between the chain and the guide bar to a minimum and assures

a longer service life.

• use bar and chain oil of high quality for this purpose.

• Do not use used or reclaimed oil to avoid various oiler

problems.

• Use ECHO bar and chain oil.

• When ECHO bar and chain oil is not available:

Use motor oil, etc.

• Use bar and chain oil of the following grades:

SAE NO. 30 ..... in summer

SAE NO. 10 ..... in winter or when cutting resinous trees.

• When refueling, also refill chain oil.

T ANK INDICATION

FUEL T ANK OIL T ANK

8

Loading...

Loading...