Druck DPI 530 User Manual

K162 Issue No. 2

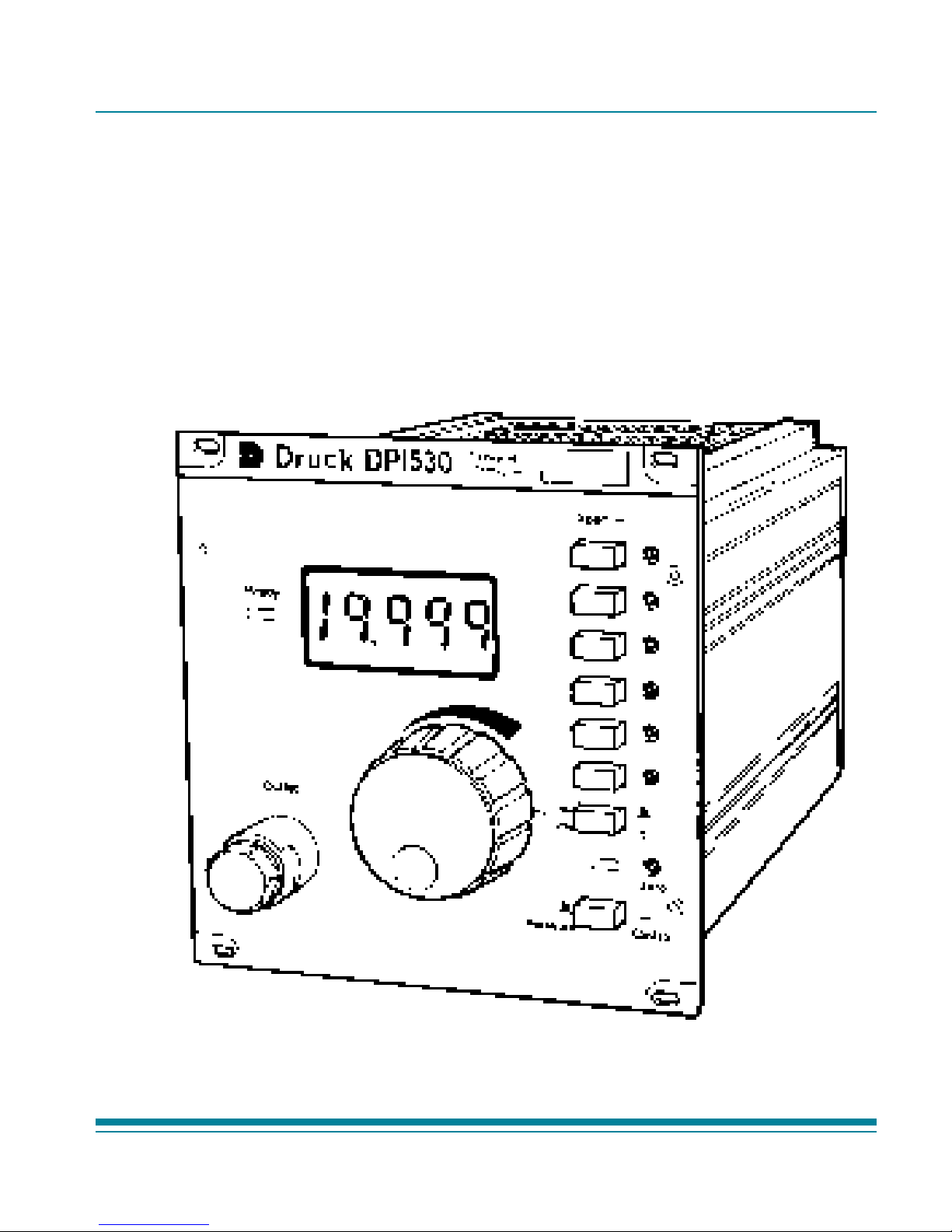

Druck DPI 530 Sub-Rack

Pneumatic Pressure Controller

User Manual

K162

K162 Issue No. 2

DPI 530 User Manual i

Safety

The manufacturer has designed this instrument to be safe when operated

using the procedures detailed in this manual. Do not use this instrument

for any other purpose than that stated. Do not apply values greater than

the maximum value stated.

This manual contains operating and safety instructions that must be

followed for safe operation and to maintain the instrument in a safe

condition. The safety instructions are either warnings or cautions issued

to protect the user and the equipment from injury or damage. Use

qualified* personnel and good engineering practice for all procedures in

this manual.

Pressure

Do not apply pressure greater the maximum safe working pressure to the

instrument.

Electrical Safety

This instrument is designed to be safe when using options and accessories

supplied by the manufacturer.

Toxic Materials

There are no known toxic materials used in this instrument.

Maintenance

The instrument must be maintained using the manufacturer’s procedures

and should be carried out by authorised service agents or the manufacturer’s

service departments.

Technical Advice

For technical advice contact the manufacturer or subsidiary refer to section

5.5.

* A qualified person must have attended a product training course given by

the manufacturer or appointed agent and successfully completed the

training course on this equipment.

K162 Issue No. 2

ii DPI 530 User Manual

Hazard, a warning highlighting a danger that would result

in injury. Also a marking on the instrument referring the

user to this publication.

Protective conductor terminal

Abbreviations and Symbols

The following abbreviations are used in this manual.

Note:

Abbreviations are the same in the singular and plural.

DVM digital voltmeter

FS full-scale

IEC International Electrical Council

inHg inch of mercury

kg/cm

2

kilogram per centimetre squared

kPa kilo Pascal

LCD liquid crystal display

mA milli Ampere

mm milli metre

psi pound per square inch

V Volt

VA Volt amp

Symbols

This product meets the essential protection requirements

of the relevant EEC directives. Further details of applied

standards may be found in the product specification.

K162 Issue No. 2

DPI 530 User Manual iii

Contents

Section page

1 Introduction ............................................................................... 1

1.1 Specification ............................................................................... 2

2 Installation ................................................................................. 5

2.1 Mounting ..................................................................................... 5

2.2 Source/Outlet Connections ........................................................ 5

2.3 Electrical Connections................................................................ 5

2.4 Pressure Connections ................................................................ 11

2.5 Fitting into Euro Rack ................................................................. 12

2.6 Applications ................................................................................. 13

3 Operation ................................................................................... 19

3.1 Description .................................................................................. 19

3.2 Controlling a Pressure ................................................................ 23

4 Calibration ................................................................................. 25

4.1 Accuracy Check.......................................................................... 26

4.2 Pressure Calibration Adjustment ............................................... 28

4.3 Remote Voltage and Current Set-point Calibration Adjustment 32

4.4 Assembly..................................................................................... 34

5 Maintenance .............................................................................. 35

5.1 Fault Finding ............................................................................... 35

5.2 Controller Adjustment ................................................................. 35

5.3 Leak Check ................................................................................. 37

5.4 Cleaning ...................................................................................... 38

5.5 Approved Service Agents........................................................... 39

K162 Issue No. 2

iv DPI 530 User Manual

Illustrations

Figure page

2-1 Rear Panel Connections ............................................................ 6

2-2 Ready Output .............................................................................. 10

2-3 Euro Sub Rack Fitting ................................................................ 12

Applications

2A Measure or Control Mode .......................................................... 14

2B Apply Fixed Set-points ............................................................... 14

2C V to P or I to P Conversion ........................................................ 15

2D Automatic Pressure Cycling ....................................................... 16

2E Pressure Switch Test Cycling .................................................... 17

2F Remote Controller with Ready Signal Interface ........................ 18

3-1 Schematic Diagram .................................................................... 21

3-2 Front Panel ................................................................................. 22

4-1 Access for Adjustments ............................................................. 27

4-2 Printed Circuit Board .................................................................. 29

4-3 Units of Pressure Measurement and Switch Positions ............ 31

4-4 Units of Pressure Measurement Potentiometers ...................... 31

DPI 530 User Manual 1

K162 Issue No.2

1 Introduction

The DPI 530 instrument is a fast response, closed loop, pneumatic

pressure controller. It is contained in a Euro sub-rack module that can be

mounted in a 3U high sub-rack. A push switch on the front panel enables

the instrument to operate in either the pressure measure mode or pressure

control mode.

Pressure is sensed by a transducer containing a silicon strain gauge

diaphragm with electronic thermal compensation and linearization. One of

five units of pressure measurement or percentage of full-scale can be

selected by switches on the rear panel of the instrument. A seven segment

LCD display shows, in the measure mode, the pressure value and, in the

control mode, the set-point value.

In the pressure control mode the set-point can be set by a centrallylocated, ten-turn potentiometer or by six independent preset span divider

keys. The preset value of each span divider is adjusted by individual

potentiometers. Each span divider has full control from the lowest

calibrated pressure to the span value. The controller uses pulse width

modulation to operate solenoid valves in an analogue control loop.

Remote control can be selected by switches on the rear panel. The

instrument can be remotely controlled by an analogue input signal of either

0 to 10 V d.c. or 0 to 20 mA d.c.

A pressure outlet port connection is located on both the front and rear

panels; all other connections are on the rear panel.

K162 Issue No. 2

2 DPI 530 User Manual

1.1 Specification

Range ..................................................................................... -1 to 20 bar

Accuracy ..................................................................................... ±0.1 % FS

Temperature effects.......................... combined zero and span shifts of <0.5%FS

(over 0 - 50°C)

Stability .............................................................. <0.025% rdg per 90 days

Controller stability ..................................................................................<0.01% FS

Maximum Safe Working Pressure ............................................................... 2 x FS

Pneumatic Supply ..................................................... clean, dry non-corrosive gas

source pressure ............................................................... 110 to 140% FS

vent pressure at least 5% FS less than the lowest controlled pressure

Pneumatic Connection

Outlet .................................................. front and rear panel G1/8 female

Reference ..................................................................... rear panel M5 female

Source .................................................................. rear panel G1/8 female

Vent .................................................................. rear panel G1/8 female

Five selectable units of pressure measurement and percentage of fullscale

bar, psi, kg/cm2, kPa, inHg, 0-100%FS

Electrical Safety

.................................................. meets EN61010-1 as applicable

The instrument must be connected to power supply with a protective earth/

ground conductor.

Power supply

Voltage .............................................................. 88 to 130 or 205 to 260 V

(set at manufacture)

Power consumption .......................................................................... 15 VA

Frequency................................................................................. 45 to 65 Hz

DPI 530 User Manual 3

K162 Issue No.2

Remote control

Voltage ............................................ 0 to 10 V, input impedance >500 kΩ

Current ................................................................ 0 to 20 mA, 100Ω sense

Display .............................................................................. 7-segment LCD

read-out .............................................................................................. 19999

resolution ................................................................ Better than ±0.005% FS

Electromagnetic compatibility

This instrument complies with European EMC directive and meets:

................................................................ EN 50081-1 (emissions)

.................................................................. EN 50082-1 (immunity)

Environmental

Temperature

Operating ................................................................................... 0° to 50° C

Storage ................................................................................ -20° to +70° C

Ingress protection ..................................................................... front panel to IP40

Dimensions ........................................................ 130 mm x 120 mm x 190 mm

(3U sub-rack, 24 HP wide)

Weight ................................................................................................. 2 kg

K162 Issue No. 2

4 DPI 530 User Manual

(blank page)

DPI 530 User Manual 5

K162 Issue No. 2

2 Installation

Installation must be carried out by suitably qualified installation personnel.

2.1 Mounting

This instrument is a 3U high, Euro sub-rack unit, designed to be mounted

in a Euro Sub-rack.

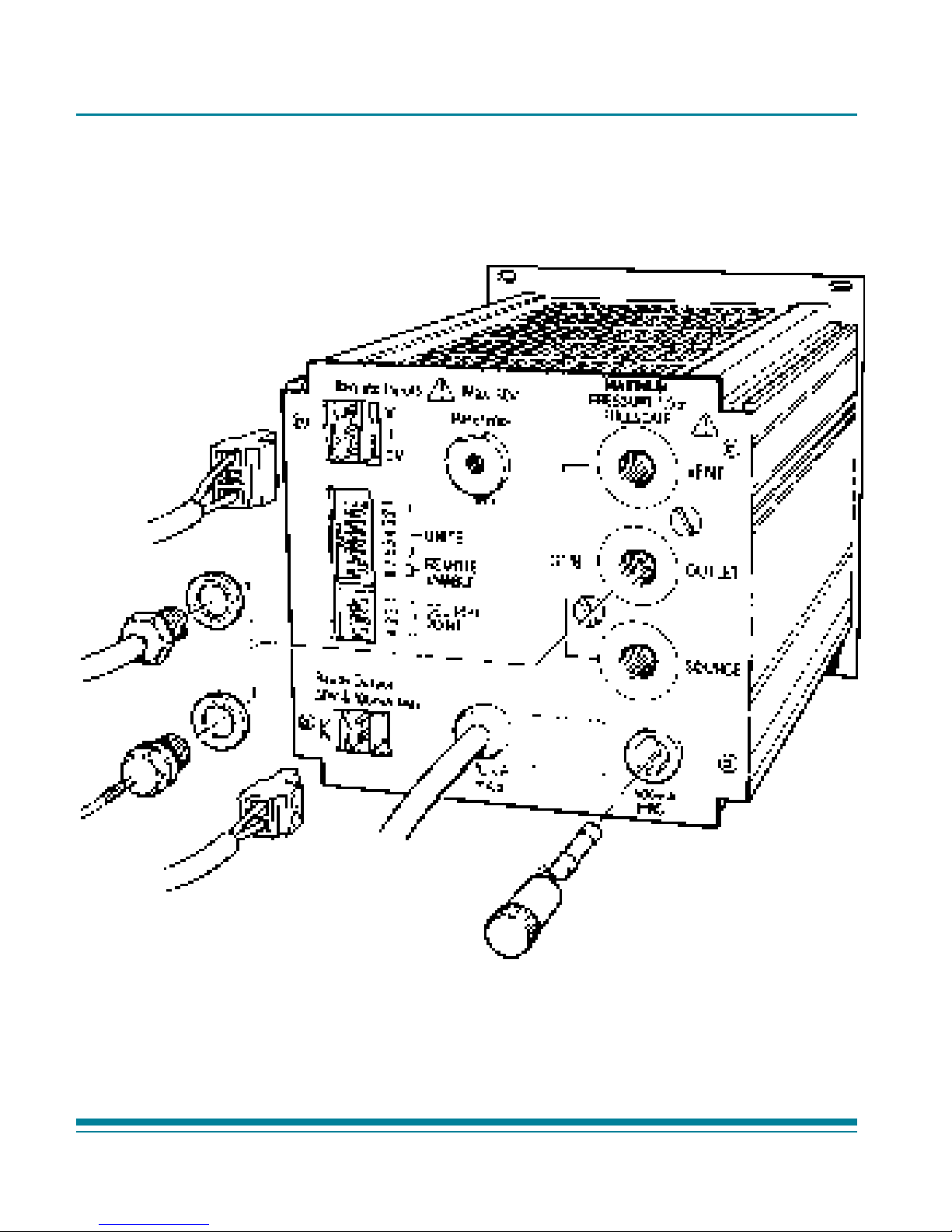

2.2 Source/Outlet Connections (Figure 2-1)

The common front and rear pressure outlet ports should have a blanking

plug fitted when not in use. All other the connections to the instrument are

on the rear panel. Figure 2-1 shows the rear panel pressure and electrical

connections.

Note: Allow enough cabling and piping for the instrument to be pulled out from the

sub-rack for access to the connections.

2.3 Electrical Connections (Figure 2-1)

Before connecting the instrument, make sure the DIP switches are set on

the rear panel for:

Units of measurement

Decimal point position on the display

Local or remote operation

WARNINGS

1 VOLTAGES IN EXCESS OF 30 V (RMS) A.C. OR 50 V D.C. CAN, IN

CERTAIN CIRCUMSTANCES, BE LETHAL. CARE MUST BE TAKEN

WHEN WORKING ON LIVE, EXPOSED CONDUCTORS.

2 ISOLATE THE POWER SUPPLY BEFORE CONNECTING THE

INSTRUMENT.

3 ISOLATE THE POWER SUPPLY BEFORE REMOVING THE

INSTRUMENT COVERS.

K162 Issue No. 2

6 DPI 530 User Manual

Figure 2-1 Rear Panel Connections

DPI 530 User Manual 7

K162 Issue No. 2

CAUTIONS

1USE THE CORRECT POWER SUPPLY SETTINGS. OPERATING VOLTAGE RANGES ARE

MARKED

ON THE REAR PANEL OF THE INSTRUMENT AND DETAILED IN THE

SPECIFICATION

.

2THE EARTH/GROUND CABLE (COLOURED GREEN/YELLOW) MUST BE CONNECTED TO

THE

POWER SUPPLY SAFETY EARTH/GROUND.

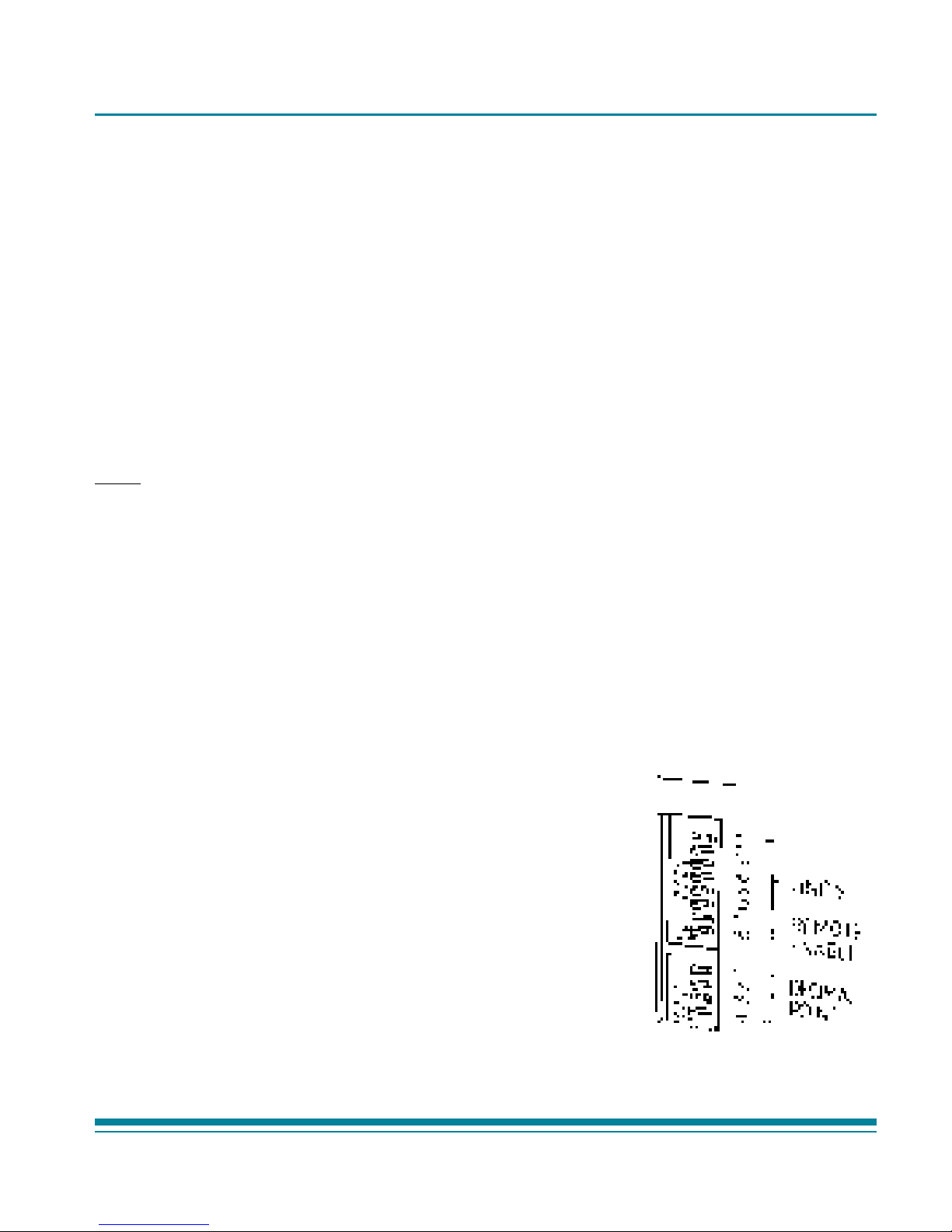

2.3.1 Setting the Pressure Measurement Units

Set the required pressure measurement units by selecting the applicable DIP

switches on the rear panel.

If necessary, change the front panel label to show the new units of pressure

measurement. This illustration shows bar selected.

Note: All other switches in the group (1-6) should be set to OFF (left).

Switch Pressure

Position Unit

1 On bar (for instruments <1bar)

1 On mbar (for instruments >1 bar)

2 On psi

3 On kg/cm

2

4 On kPa

5 On inHg

6 On 0 to 100% F.S.

K162 Issue No. 2

8 DPI 530 User Manual

2.3.2 Set-up Decimal Point Position

Set the decimal point position by selecting the switches on the rear panel

to on as shown below.

Note: All other switches in the (1 to 4) group should be set to OFF.

Switch Position Display

4 On 1.9999

3 On 19.999

2 On 199.99

1 On 1999.9

2.3.3 Enable Remote Control

For local control from the front panel potentiometer or span divider keys,

set switch 7 to ON and switch 8 to OFF.

For remote control from either an external voltage or current source, set

switch 8 to ON and switch 7 to OFF.

2.3.4 Power Supply Connections

A.C. power is supplied to the instrument through a captive power supply

cable. Figure 2-1 shows the cable and the related power supply fuse.

Connect the power supply cable to the power supply as follows.

Brown - Live (L)

Blue - Neutral (N)

Green/Yellow - Ground (Protective Earth)

For U.S. Versions

Black - Live (L)

White - Neutral (N)

Green - Ground(Protective Earth)

It is recommended that a power supply isolator is fitted between

the power supply and the instrument.

Loading...

Loading...