DeWalt D25023, N027959, D25012 User Manual

|

|

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA DE GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES |

|

|

|

|

If you have questions or comments, contact us. Pour toute question ou tout commentaire, nous contacter. Si tiene dudas o comentarios, contáctenos. |

1-800-4-DEWALT • www.dewalt.com |

DE USAR EL PRODUCTO. |

|

|

|

|

INSTRUCTION MANUAL |

GUIDE D'UTILISATION MANUAL DE INSTRUCCIONES |

|

|

|

||

|

|

|

|

|

||

|

|

|

|

|

D25012, D25013, D25023 Heavy-Duty 7/8" (22 mm) Compact SDS Plus® Rotary Hammers |

Marteaux rotatifs industriels compacts SDS Plus®, 22 mm (7/8 po), D25012, D25013, D25023 |

Rotomartillos SDS Plus® compactos D25012, D25013, D25023 de 22 mm (7/8") para trabajos pesados |

DEWALT Industrial Tool Co., 701 Joppa Road, Baltimore, MD 21286

(JUN09) |

Part No. N027959 |

D25012, D25013, D25023 |

|

Copyright © 2008, 2009 DEWALT |

|

The following are trademarks for one or more DEWALT power tools: the yellow and black color scheme; the “D” shaped air intake grill; the array of pyramids on the handgrip; the kit box configuration; and the array of lozenge-shaped humps on the surface of the tool.

Definitions: Safety Guidelines

The definitions below describe the level of severity for each signal word. Please read the manual and pay attention to these symbols.

DANGER: Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

DANGER: Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

WARNING: Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

WARNING: Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

NOTICE: indicates a practice not related to personal injury which, if not avoided, may result in property damage.

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS OR ANY DEWALT TOOL, CALL US TOLL FREE AT: 1-800-4-DEWALT (1-800-433-9258)

WARNING: To reduce the risk of injury, read the instruction manual.

WARNING: To reduce the risk of injury, read the instruction manual.

General Power Tool Safety Warnings

WARNING! Read all safety warnings and all instructions. Failure to follow the warnings and instructions may result in electric shock, fire and/or serious injury.

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE

The term “power tool” in the warnings refers to your mains-operated (corded) power tool or battery-operated (cordless) power tool.

1)WORK AREA SAFETY

a)Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b)Do not operate power tools in explosive atmospheres, such as in the presence of flammable liquids, gases or dust. Power tools create sparks which may ignite the dust or fumes.

c)Keep children and bystanders away while operating a power tool. Distractions can cause you to lose control.

2)ELECTRICAL SAFETY

a)Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any adapter plugs with earthed (grounded) power tools. Unmodified plugs and matching outlets will reduce risk of electric shock.

b)Avoid body contact with earthed or grounded surfaces such as pipes, radiators, ranges and refrigerators. There is an increased risk of electric shock if your body is earthed or grounded.

c)Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the risk of electric shock.

d)Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power tool. Keep cord away from heat, oil, sharp edges or moving parts. Damaged or entangled cords increase the risk of electric shock.

e)When operating a power tool outdoors, use an extension cord suitable for outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

f)If operating a power tool in a damp location is unavoidable, use a ground fault circuit interrupter (GFCI) protected supply. Use of a GFCI reduces the risk of electric shock.

3)PERSONAL SAFETY

a)Stay alert, watch what you are doing and use common sense when operating a power tool. Do not use a power tool while you are tired or under the influence of drugs, alcohol or medication. A moment of inattention while operating power tools may result in serious personal injury.

b)Use personal protective equipment. Always wear eye protection. Protective equipment such as dust mask, non-skid safety shoes, hard hat, or hearing protection used for appropriate conditions will reduce personal injuries.

c)Prevent unintentional starting. Ensure the switch is in the off position before connecting to power source and/or battery pack, picking up or carrying the tool.

Carrying power tools with your finger on the switch or energising power tools that have the switch on invites accidents.

d)Remove any adjusting key or wrench before turning the power tool on. A wrench or a key left attached to a rotating part of the power tool may result in personal injury.

e)Do not overreach. Keep proper footing and balance at all times. This enables better control of the power tool in unexpected situations.

f)Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing and gloves away from moving parts. Loose clothes, jewellery or long hair can be caught in moving parts.

g)If devices are provided for the connection of dust extraction and collection facilities, ensure these are connected and properly used. Use of dust collection can reduce dustrelated hazards.

4)POWER TOOL USE AND CARE

a)Do not force the power tool. Use the correct power tool for your application. The correct power tool will do the job better and safer at the rate for which it was designed.

b)Do not use the power tool if the switch does not turn it on and off. Any power tool that cannot be controlled with the switch is dangerous and must be repaired.

c)Disconnect the plug from the power source and/or the battery pack from the power tool before making any adjustments, changing accessories, or storing power tools.

Such preventive safety measures reduce the risk of starting the power tool accidentally.

d)Store idle power tools out of the reach of children and do not allow persons unfamiliar with the power tool or these instructions to operate the power tool. Power tools are dangerous in the hands of untrained users.

e)Maintain power tools. Check for misalignment or binding of moving parts, breakage of parts and any other condition that may affect the power tool’s operation. If damaged, have the power tool repaired before use. Many accidents are caused by poorly maintained power tools.

f)Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges are less likely to bind and are easier to control.

g)Use the power tool, accessories and tool bits etc., in accordance with these instructions taking into account the working conditions and the work to be performed. Use of the power tool for operations different from those intended could result in a hazardous situation.

5)SERVICE

a)Have your power tool serviced by a qualified repair person using only identical replacement parts. This will ensure that the safety of the power tool is maintained.

Additional Safety Instructions for Rotary Hammers

•Wear ear protectors. Exposure to noise can cause hearing loss.

•Use auxiliary handles supplied with the tool. Loss of control can cause personal injury.

•Hold power tools by insulated gripping surfaces when performing an operation where the cutting tool may contact hidden wiring or its own cord. Contact with a “live” wire will make exposed metal parts of the tool “live” and shock the operator.

•Use clamps or other practical way to secure and support the workpiece to a stable platform. Holding the work by hand or against your body is unstable and may lead to loss of control.

•Wear safety goggles or other eye protection. Hammering operations cause chips to fly. Flying particles can cause permanent eye damage. Wear a dust mask or respirator for applications that generate dust. Ear protection may be required for most applications.

•Keep a firm grip on the tool at all times. Do not attempt to operate this tool without holding it with both hands. It is recommended that the side handle be used at all times. Operating this tool with one hand will result in loss of control. Breaking through or encountering hard materials such as re-bar may be hazardous as well. Tighten the side handle securely before use.

•The hammer is only for light chiselling applications.

•The forward/reverse switch must be in the forward position when chiselling.

•Do not use this tool to mix or pump easily combustible or explosive fluids (benzine, alcohol, etc.).

•Do not mix or stir inflammable liquids labelled accordingly.

•Do not operate this tool for long periods of time. Vibration caused by hammer action may be harmful to your hands and arms. Use gloves to provide extra cushion and limit exposure by taking frequent rest periods.

•Do not recondition bits yourself. Chisel reconditioning should be done by an authorized specialist. Improperly reconditioned chisels could cause injury.

•Wear gloves when operating tool or changing bits. Accessible metal parts on the tool and bits may get extremely hot during operation. Small bits of broken material may damage bare hands.

•Never lay the tool down until the bit has come to a complete stop. Moving bits could cause injury.

•Do not strike jammed bits with a hammer to dislodge them. Fragments of metal or material chips could dislodge and cause injury.

•Slightly worn chisels can be resharpened by grinding.

•Keep the power cord away from the rotating bit. Do not wrap the cord around any part of your body. An electric cord wrapped around a spinning bit may cause personal injury and loss of control.

•Air vents often cover moving parts and should be avoided. Loose clothes, jewellery or long hair can be caught in moving parts.

•An extension cord must have adequate wire size (AWG or American Wire Gauge) for safety. The smaller the gauge number of the wire, the greater the capacity of the cable, that is 16 gauge has more capacity than 18 gauge. An undersized cord will cause a drop in line voltage resulting in loss of power and overheating. When using more than one extension to make up the total length, be sure each individual extension contains at least the minimum wire size. The following table shows the correct size to use depending on cord length and nameplate ampere rating. If in doubt, use the next heavier gauge. The smaller the gauge number, the heavier the cord.

Minimum Gauge for Cord Sets

|

|

Volts |

Total Length of Cord in Feet (meters) |

|||

Ampere Rating |

120V |

25 (7.6) |

50 (15.2) |

100 (30.5) |

150 (45.7) |

|

|

|

240V |

50 (15.2) |

100 (30.5) |

200 (61.0) |

300 (91.4) |

More |

Not More |

|

|

AWG |

|

|

Than |

Than |

|

|

|

|

|

0 |

6 |

|

18 |

16 |

16 |

14 |

6 |

10 |

|

18 |

16 |

14 |

12 |

10 |

12 |

|

16 |

16 |

14 |

12 |

12 |

16 |

|

14 |

12 |

Not Recommended |

|

NOTE: Do not overheat the bit (discoloration) while grinding a new edge. Badly worn chisels require reforging. Do not reharden and temper the chisel.

WARNING: ALWAYS use safety glasses. Everyday eyeglasses are NOT safety glasses. Also use face or dust mask if cutting operation is dusty. ALWAYS WEAR CERTIFIED SAFETY EQUIPMENT:

WARNING: ALWAYS use safety glasses. Everyday eyeglasses are NOT safety glasses. Also use face or dust mask if cutting operation is dusty. ALWAYS WEAR CERTIFIED SAFETY EQUIPMENT:

•ANSI Z87.1 eye protection (CAN/CSA Z94.3),

•ANSI S12.6 (S3.19) hearing protection,

•NIOSH/OSHA/MSHA respiratory protection.

WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains chemicals known to cause cancer, birth defects or other reproductive harm. Some examples of these chemicals are:

WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains chemicals known to cause cancer, birth defects or other reproductive harm. Some examples of these chemicals are:

•lead from lead-based paints,

•crystalline silica from bricks and cement and other masonry products, and

•arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to these chemicals: work in a well ventilated area, and work with approved safety equipment, such as those dust masks that are specially designed to filter out microscopic particles.

•Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling, and other construction activities. Wear protective clothing and wash exposed areas with soap and water. Allowing dust to get into your mouth, eyes, or lay on the skin may promote absorption of harmful chemicals.

WARNING: Use of this tool can generate and/or disburse dust, which may cause serious and permanent respiratory or other injury. Always use NIOSH/OSHA approved respiratory protection appropriate for the dust exposure. Direct particles away from face and body.

WARNING: Use of this tool can generate and/or disburse dust, which may cause serious and permanent respiratory or other injury. Always use NIOSH/OSHA approved respiratory protection appropriate for the dust exposure. Direct particles away from face and body.

WARNING: Always use eye protection. All users and bystanders must wear eye protection that conforms to ANSI Z87.1.

WARNING: Always use eye protection. All users and bystanders must wear eye protection that conforms to ANSI Z87.1.

WARNING: Always wear proper personal hearing protection that conforms to ANSI S12.6 (S3.19) during use. Under some conditions and duration of use, noise from this product may contribute to hearing loss.

WARNING: Always wear proper personal hearing protection that conforms to ANSI S12.6 (S3.19) during use. Under some conditions and duration of use, noise from this product may contribute to hearing loss.

•The label on your tool may include the following symbols. The symbols and their definitions are as follows:

V........................ |

volts |

A....................... |

amperes |

||||||

Hz...................... |

hertz |

W...................... |

watts |

||||||

min .................... |

minutes |

|

|

|

.................... |

alternating current |

|||

|

|

|

|

direct current |

|

|

|

|

alternating or direct current |

|

|

|

................. |

no .................... |

|||||

|

|

|

|

Class I Construction |

no load speed |

||||

|

|

|

|

||||||

|

|

...................... |

|

||||||

|

|

|

|

(grounded) |

|

|

|

|

earthing terminal |

|

|

|

|

|

|

|

|

||

.......................... |

|

|

|

|

|

|

..................... |

||

|

|

...................... |

|

Class II Construction |

|

|

|

..................... |

safety alert symbol |

.......................... |

|

|

|

(double insulated) |

BPM ................. |

beats per minute |

|||

…/min ............... |

per minute |

RPM................. |

revolutions per minute |

||||||

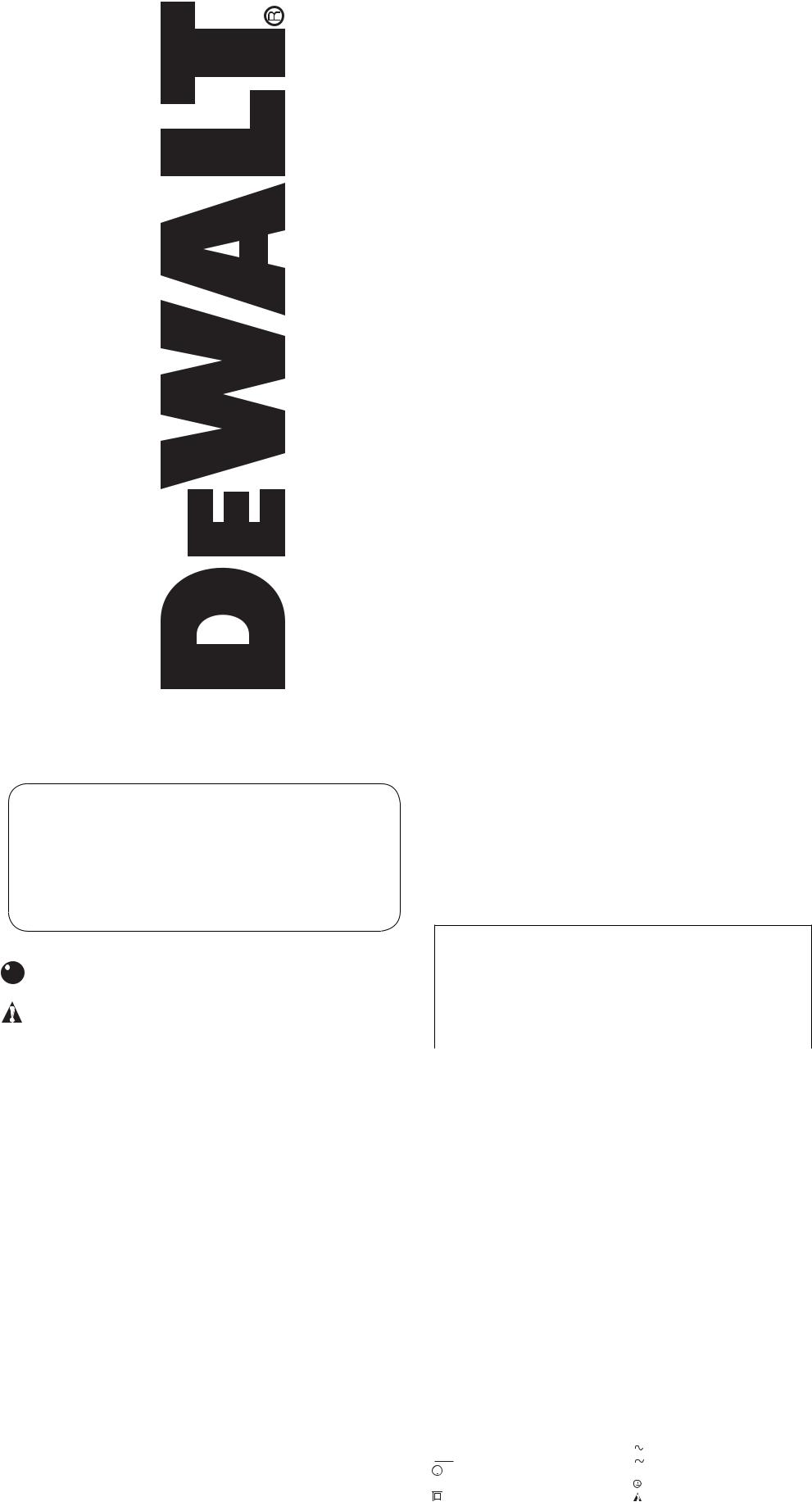

FIG. 1 |

|

|

|

|

|

E |

F |

G |

|

H |

D25012 |

|

|

|

|

|

|

|

|

|

|

|

I |

D |

J |

|

|

|

B |

|

|

|

A |

|

|

|

|

|

|

|

|

C |

|

D25013 |

|

|

|

|

|

|

|

|

|

E |

F |

G |

H |

|

A |

|

|

|

|

|

J |

|

|

|

|

|

B |

D |

J |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

C |

C |

|

D25023 |

|

|

|

|

|

|

|

|

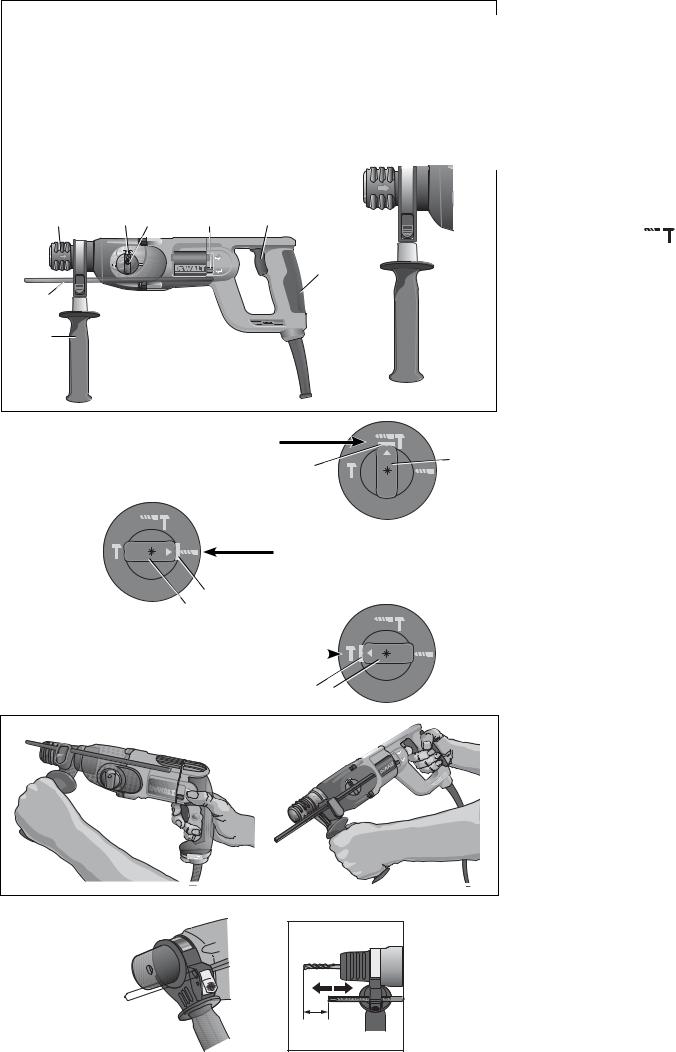

FIG. 2 |

|

|

HAMMERDRILL MODE |

|

|

MODE PERFORATION-PERÇAGE |

G |

|

MODO TALADRO/PERCUTOR |

||

F |

||

|

DRILL-ONLY MODE

MODE PERÇAGE SEULEMENT

MODO SÓLO TALADRO

F

G

HAMMER-ONLY MODE

MODE PERFORATION SEULEMENT

MODO SÓLO MARTILLO

F |

G |

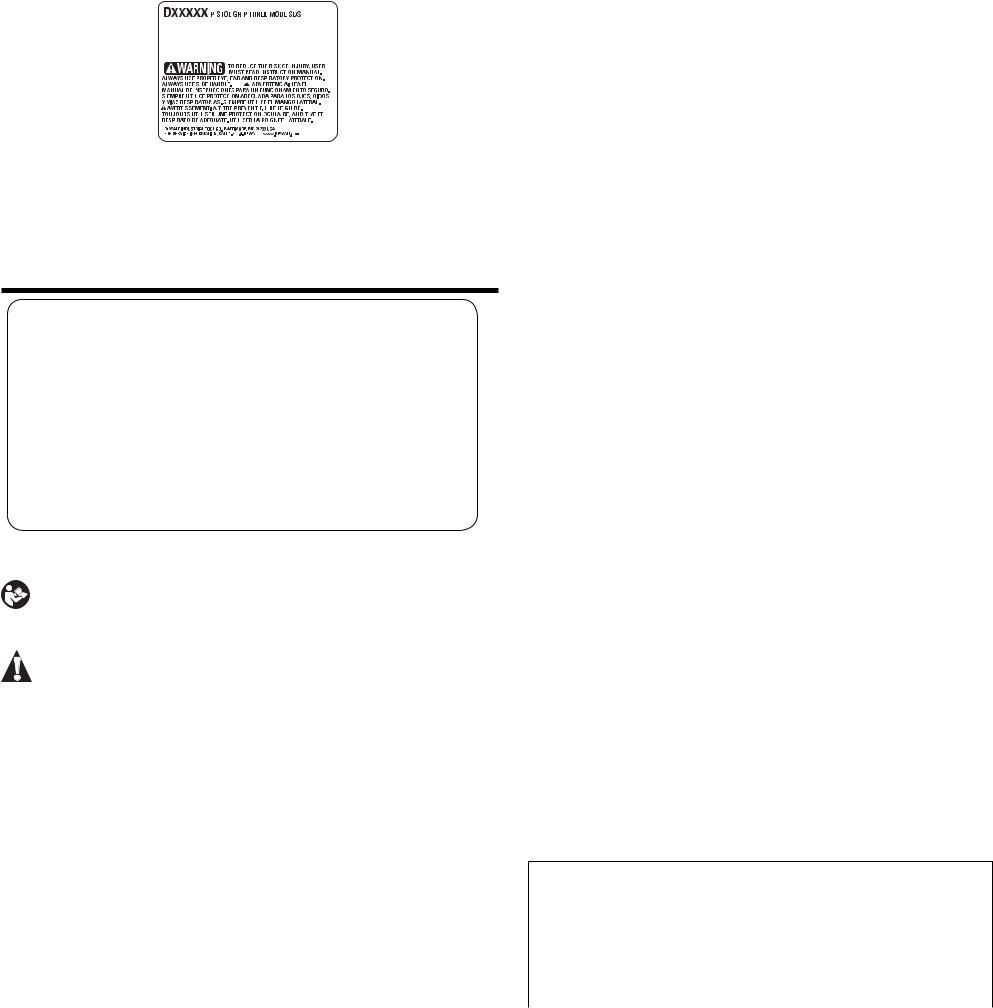

FIG. 3 |

|

FIG. 4

J

D

C

Motor

Your DEWALT tool is powered by a DEWALT-built motor. Be sure your power supply agrees with the nameplate markings. Voltage decrease of more than 10% will cause loss of power and overheating. All DEWALT tools are factory tested.

COMPONENTS (Fig. 1)

WARNING: Never modify the power tool or any part of it. Damage or personal injury could

WARNING: Never modify the power tool or any part of it. Damage or personal injury could

result. |

|

A. Variable speed trigger switch |

G. Mode selector |

B. Main handle |

H. Reversing lever |

C. Side handle |

I. Lock-on button |

D. Depth rod |

(D25012, D25013 only) |

E. SDS Plus® chuck |

J. Depth rod release button |

F. Mode selector button |

|

INTENDED USE

These heavy-duty rotary hammers have been designed for professional drilling and hammerdrilling, screwdriving and light chipping at various work sites (i.e., construction sites). DO NOT use under wet conditions or in presence of flammable liquids or gases.

These heavy-duty rotary hammers are professional power tools. DO NOT let children come into contact with the tool. Supervision is required when inexperienced operators use this tool.

Side Handle (Fig. 1)

WARNING: To reduce the risk of personal injury, ALWAYS operate the tool with the side handle properly installed and securely tightened. Failure to do so may result in the side handle slipping during tool operation and subsequent loss of control. Hold tool with both hands to maximize control.

WARNING: To reduce the risk of personal injury, ALWAYS operate the tool with the side handle properly installed and securely tightened. Failure to do so may result in the side handle slipping during tool operation and subsequent loss of control. Hold tool with both hands to maximize control.

A side handle comes assembled with this rotary hammer. The side handle (C) can be fitted to suit both right-hand and left-hand users.

TO ADJUST THE SIDE HANDLE

1.Loosen the side handle (C) by turning it counterclockwise.

2.Rotate the side handle to the desired position.

3.Tighten the side handle by turning it clockwise.

TO CHANGE SIDES

For right-hand users: slide the side handle clamp over the chuck, handle at the left. For left-hand users: slide the side handle clamp over the chuck, handle at the right.

Trigger Switch (Fig. 1)

To start the rotary hammer, depress the trigger switch (A). To stop rotary hammer, release the switch.

NOTE: Use lower speeds for starting holes without a centerpunch, drilling in metal, plastics or ceramics, or driving screws. Higher speeds are better for drilling in masonry for maximum efficiency.

VARIABLE SPEED

The variable speed trigger switch (A) permits speed control. The farther the trigger switch is depressed, the higher the speed of the drill.

LOCK-ON BUTTON (D25012, D25013 ONLY)

WARNING: Be sure to release the locking mechanism before disconnecting the plug from the power supply. Failure to do so will cause the hammerdrill to start immediately the next time it is plugged in. Damage or personal injury could result.

WARNING: Be sure to release the locking mechanism before disconnecting the plug from the power supply. Failure to do so will cause the hammerdrill to start immediately the next time it is plugged in. Damage or personal injury could result.

The lock-on button (I) is for use only when the rotary hammer is stationary, mounted in a drill press stand or for chipping applications.

Before using the tool each time, be sure that the lock-on button release mechanism is working freely.

For continuous operation, press and hold the trigger switch (A); press the lock-on button (I); release the trigger switch and then release the lock-on button. The tool will continue to run.

To stop the tool in continuous operation, quickly press and release the trigger switch.

Reversing Lever (Fig. 1)

The reversing lever (H) is used to reverse the rotary hammer for backing out fasteners or jammed bits in drill-only mode.

CAUTION: When reversing to clear jammed bits, be ready for strong reactive torque.

CAUTION: When reversing to clear jammed bits, be ready for strong reactive torque.

To reverse the rotary hammer, turn it off and align the reversing lever (H) with the yellow arrow pointing backward (viewed when holding drill in operating position).

To position the lever for forward operation, turn the rotary hammer off and align the reversing lever

(H) with the yellow arrow pointing forward (viewed when holding drill in operating position).

Mode Selector (Fig. 2)

NOTICE: Tool must come to a complete stop before activating the mode selector button or damage to the tool may result.

DRILL-ONLY MODE

To use drill-only mode, press mode selector button (F) and turn the mode selector (G) so the yellow arrow points to the corresponding symbol as shown. Use drill-only mode for wood, metal, and plastics.

HAMMERDRILL MODE

To use hammerdrill mode, press the mode selector button (F) and turn the mode selector (G) so the yellow arrow points to the corresponding symbol as shown. Use this mode for masonry drilling.

HAMMER-ONLY MODE  (D25013, D25023)

(D25013, D25023)

For light chiseling, press the mode selector button (F) and turn the mode selector (G) so the yellow arrow points to the corresponding symbol as shown.

NOTE: The yellow arrow on the mode selector MUST be aligned with one of the symbols at all times. There are no operable positions between the positions.

SDS Plus® Chuck (Fig. 1)

WARNING:To reduce the risk of serious personal injury, turn tool off and disconnect tool from power source before making any adjustments or removing/installing attachments or accessories.

WARNING:To reduce the risk of serious personal injury, turn tool off and disconnect tool from power source before making any adjustments or removing/installing attachments or accessories.

WARNING: Burn Hazard. ALWAYS wear gloves when changing bits. Accessible metal parts on the tool and bits may get extremely hot during operation. Small bits of broken material may damage bare hands.

WARNING: Burn Hazard. ALWAYS wear gloves when changing bits. Accessible metal parts on the tool and bits may get extremely hot during operation. Small bits of broken material may damage bare hands.

WARNING: Do not attempt to tighten or loosen drill bits (or any other accessory) by gripping the front part of the chuck and turning the tool on. Damage to the chuck and personal injury may occur.

WARNING: Do not attempt to tighten or loosen drill bits (or any other accessory) by gripping the front part of the chuck and turning the tool on. Damage to the chuck and personal injury may occur.

To insert bit, insert shank of bit about 3/4" (19 mm), no further than 7/8" (22 mm) into chuck. Push and rotate bit until it locks in place. The bit will be securely held.

To release bit, pull the chuck sleeve (E) back and remove the bit.

OPERATION

WARNING:To reduce the risk of serious personal injury, turn tool off and disconnect tool from power source before making any adjustments or removing/installing attachments or accessories.

WARNING:To reduce the risk of serious personal injury, turn tool off and disconnect tool from power source before making any adjustments or removing/installing attachments or accessories.

WARNING:To reduce the risk of personal injury, ALWAYS ensure workpiece is anchored or clamped firmly. If drilling thin material, use a wood “back-up” block to prevent damage to the material.

WARNING:To reduce the risk of personal injury, ALWAYS ensure workpiece is anchored or clamped firmly. If drilling thin material, use a wood “back-up” block to prevent damage to the material.

WARNING: To reduce the risk of personal injury, ALWAYS operate the tool with the side handle properly installed and securely tightened. Failure to do so may result in the side handle slipping during tool operation and subsequent loss of control. Hold tool with both hands to maximize control.

WARNING: To reduce the risk of personal injury, ALWAYS operate the tool with the side handle properly installed and securely tightened. Failure to do so may result in the side handle slipping during tool operation and subsequent loss of control. Hold tool with both hands to maximize control.

Proper Hand Position (Fig. 3)

WARNING: To reduce the risk of serious personal injury, ALWAYS use proper hand position as shown.

WARNING: To reduce the risk of serious personal injury, ALWAYS use proper hand position as shown.

WARNING: To reduce the risk of serious personal injury, ALWAYS hold securely in anticipation of a sudden reaction.

WARNING: To reduce the risk of serious personal injury, ALWAYS hold securely in anticipation of a sudden reaction.

Proper hand position requires one hand on the side handle (C), with the other hand on the main handle (B).

Overload Clutch

If the drill bit becomes jammed or caught, the drive to the drill spindle is interrupted by the overload clutch. Because of the forces that occur as a result, always hold the machine securely with both hands and take a firm stance.

Drilling Tools

The machine is intended for hammerdrilling in concrete, brick and stone. It is also suitable for drilling without impact in wood, metal, ceramic and plastic.

Drilling (Fig. 1)

WARNING:To reduce the risk of serious personal injury, turn tool off and disconnect tool from power source before making any adjustments or removing/installing attachments or accessories.

WARNING:To reduce the risk of serious personal injury, turn tool off and disconnect tool from power source before making any adjustments or removing/installing attachments or accessories.

WARNING: To reduce the risk of personal injury, ALWAYS ensure workpiece is anchored or clamped firmly. If drilling thin material, use a wood “back-up” block to prevent damage to the material.

WARNING: To reduce the risk of personal injury, ALWAYS ensure workpiece is anchored or clamped firmly. If drilling thin material, use a wood “back-up” block to prevent damage to the material.

Press mode selector button (F) and turn the mode selector (G) to the drill bit symbol for drilling, to the hammer symbol for hammering or to the hammerdrill symbol for hammerdrilling.

DRILLING OPERATION

1.For WOOD, use twist bits, spade bits, power auger bits or hole saws. For METAL, use highspeed steel twist drill bits or hole saws. Use a cutting lubricant when drilling metals. The exceptions are cast iron and brass which should be drilled dry. For MASONRY, use carbidetipped bits or masonry bits. A smooth, even flow of dust indicates the proper drilling rate.

2.Always apply pressure in a straight line with the bit. Use enough pressure to keep the drill bit biting, but do not push hard enough to stall the motor or deflect the bit.

3.Hold tool firmly with both hands to control the twisting action of the drill.

WARNING: Drill may stall if overloaded causing a sudden twist. Always expect the stall. Grip the drill firmly with both hands to control the twisting action and avoid injury.

WARNING: Drill may stall if overloaded causing a sudden twist. Always expect the stall. Grip the drill firmly with both hands to control the twisting action and avoid injury.

4. IF DRILL STALLS, it is usually because it is being overloaded. RELEASE TRIGGER IMMEDIATELY, remove drill bit from work, and determine cause of stalling. DO NOT

CLICK TRIGGER OFF AND ON IN AN ATTEMPT TO START A STALLED DRILL – THIS CAN DAMAGE THE DRILL.

5.To minimize stalling or breaking through the material, reduce pressure on drill and ease the bit through the last fractional part of the hole.

6.Keep the motor running when pulling the bit back out of a drilled hole. This will help prevent jamming.

7.With variable speed drills there is no need to center punch the point to be drilled. Use a slow speed to start the hole and accelerate by squeezing the trigger harder when the hole is deep enough to drill without the bit skipping out.

DRILLING IN METAL

An SDS Plus® to round shank adaptor chuck is required. Ensure that tool is in drill-only mode. Start drilling with slow speed and increase to full power while applying firm pressure on the tool. A smooth even flow of metal chips indicates the proper drilling rate. Use a cutting lubricant when drilling metals. The exceptions are cast iron and brass which should be drilled dry.

NOTE: Large [5/16" to 1/2" (7.9 mm to 12.7 mm)] holes in steel can be made easier if a pilot hole [5/32" to 3/16" (4 mm to 4.8 mm)] is drilled first.

DRILLING IN WOOD

An SDS Plus® to round shank adaptor chuck is required. Ensure that tool is in drill-only mode. Start drilling with slow speed and increase to full power while applying firm pressure on the tool. Holes in wood can be made with the same twist drills used for metal. These bits may overheat unless pulled out frequently to clear chips from the flutes. For larger holes, use spade bits, power auger bits, or hole saws. Work that is apt to splinter should be backed up with a block of wood.

HAMMERDRILL OPERATION

1.When drilling, use just enough force on the hammer to keep it from bouncing excessively or “rising” off the bit. Too much force will cause slower drilling speeds, overheating, and a lower drilling rate.

2.Drill straight, keeping the bit at a right angle to the work. Do not exert side pressure on the bit when drilling as this will cause clogging of the bit flutes and a slower drilling speed.

3.When drilling deep holes, if the hammer speed starts to drop off, pull the bit partially out of the hole with the tool still running to help clear debris from the hole.

4.For masonry, use carbide-tipped bits or masonry bits. A smooth even flow of dust indicates the proper drilling rate.

Chipping and Chiselling (D25013, D25023)

1.To switch from hammer drilling to chiselling, first insert the SDS Plus® chisel and check if it is properly locked.

2.When switching from hammer drilling mode to chiselling mode, turn the chisel to the desired position. If you find resistance during mode change, turn the chisel slightly to engage the spindle lock.

Depth Rod (Fig. 4)

TO ADJUST THE DEPTH ROD

1.Push in and hold the depth rod release button (J) on the side handle.

2.Move the depth rod (D) so the distance between the end of the rod and the end of the bit equals the desired drilling depth.

3.Release the button to lock rod into position. When drilling with the depth rod, stop when end of rod reaches surface of material.

MAINTENANCE

WARNING:To reduce the risk of serious personal injury, turn tool off and disconnect tool from power source before making any adjustments or removing/installing attachments or accessories.

WARNING:To reduce the risk of serious personal injury, turn tool off and disconnect tool from power source before making any adjustments or removing/installing attachments or accessories.

Cleaning

WARNING: Blow dirt and dust out of all air vents with dry air at least once a week. Wear proper ANSI Z87.1 (CAN/CSA Z94.3) eye protection and proper NIOSH/OSHA/MSHA respiratory protection when performing this.

WARNING: Blow dirt and dust out of all air vents with dry air at least once a week. Wear proper ANSI Z87.1 (CAN/CSA Z94.3) eye protection and proper NIOSH/OSHA/MSHA respiratory protection when performing this.

WARNING: Never use solvents or other harsh chemicals for cleaning the non-metallic parts of the tool. These chemicals may weaken the plastic materials used in these parts. Use a cloth dampened only with water and mild soap. Never let any liquid get inside the tool; never immerse any part of the tool into a liquid.

WARNING: Never use solvents or other harsh chemicals for cleaning the non-metallic parts of the tool. These chemicals may weaken the plastic materials used in these parts. Use a cloth dampened only with water and mild soap. Never let any liquid get inside the tool; never immerse any part of the tool into a liquid.

Lubrication

Your tool was properly lubricated before leaving the factory. In from two to six months, depending upon use, take or send your tool to an authorized service center for a complete cleaning, inspection and lubrication. Tools used constantly on production jobs will need relubrication more often. Also, tools “out of service” for long periods should be relubricated before being put back to work.

Accessories

WARNING: Since accessories, other than those offered by DEWALT, have not been tested with this product, use of such accessories with this tool could be hazardous. To reduce the risk of injury, only DEWALT, recommended accessories should be used with this product.

WARNING: Since accessories, other than those offered by DEWALT, have not been tested with this product, use of such accessories with this tool could be hazardous. To reduce the risk of injury, only DEWALT, recommended accessories should be used with this product.

Recommended accessories for use with your tool are available at extra cost from your local dealer or authorized service center. If you need assistance in locating any accessory, please contact DEWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286, call 1-800-4-DEWALT (1-800-433-9258) or visit our website www.dewalt.com.

MAXIMUM RECOMMENDED CAPACITIES

|

D25012, D25013, D25023 |

Masonry |

7/8" (22 mm) |

Steel |

1/2" (13 mm) |

Wood |

1-1/8" (30 mm) |

|

OPTIMUM CAPACITY |

Masonry |

5/32"–1/2" (4 mm–13 mm) |

Repairs

To assure product SAFETY and RELIABILITY, repairs, maintenance and adjustments (including brush inspection and replacement) should be performed by a DEWALT factory service center, a DEWALT authorized service center or other qualified service personnel. Always use identical replacement parts.

Three Year Limited Warranty

DEWALT will repair, without charge, any defects due to faulty materials or workmanship for three years from the date of purchase. This warranty does not cover part failure due to normal wear or tool abuse. For further detail of warranty coverage and warranty repair information, visit www.dewalt.com or call 1-800-4-DEWALT (1-800-433-9258). This warranty does not apply to accessories or damage caused where repairs have been made or attempted by others. This warranty gives you specific legal rights and you may have other rights which vary in certain states or provinces.

In addition to the warranty, DEWALT tools are covered by our:

1 YEAR FREE SERVICE

DEWALT will maintain the tool and replace worn parts caused by normal use, for free, any time during the first year after purchase.

90 DAY MONEY BACK GUARANTEE

If you are not completely satisfied with the performance of your DEWALT Power Tool, Laser, or Nailer for any reason, you can return it within 90 days from the date of purchase with a receipt for a full refund – no questions asked.

LATIN AMERICA: This warranty does not apply to products sold in Latin America. For products sold in Latin America, see country specific warranty information contained either in the packaging, call the local company or see website for warranty information.

FREE WARNING LABEL REPLACEMENT: If your warning labels become illegible or are missing, call 1-800-4-DEWALT for a free replacement.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SPECIFICATIONS |

|

|

|||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

D25012 |

D25013, D25023 |

||||||||||||||

Voltage: |

|

|

|

|

|

|

|

120 V AC~ |

120 V AC~ |

||||||||||||||||||

Ampere rating: |

|

|

|

|

|

|

|

6.0 A |

6.0 A |

||||||||||||||||||

Frequency: |

|

|

|

|

|

|

|

60 Hz |

60 Hz |

||||||||||||||||||

Watts |

650 |

|

|

|

|

|

|

|

|

|

|

650 |

|||||||||||||||

RPM: |

|

|

|

|

|

|

|

0–1,550/min |

0–1,550/min |

||||||||||||||||||

Beats per minute: |

|

|

|

|

|

|

|

0–4,150 |

0–4,550 |

||||||||||||||||||

Définitions : lignes directrices en matière de sécurité

Les définitions ci-dessous décrivent le niveau de danger pour chaque mot-indicateur employé. Veuillez lire le mode d’emploi et porter une attention particulière à ces symboles.

DANGER : indique une situation dangereuse imminente qui, si elle n’est pas évitée, causera la mort ou des blessures graves.

DANGER : indique une situation dangereuse imminente qui, si elle n’est pas évitée, causera la mort ou des blessures graves.

AVERTISSEMENT : indique une situation potentiellement dangereuse qui, si elle n’est pas évitée, pourrait se solder par un décès ou des blessures graves.

AVERTISSEMENT : indique une situation potentiellement dangereuse qui, si elle n’est pas évitée, pourrait se solder par un décès ou des blessures graves.

ATTENTION : indique une situation potentiellement dangereuse

ATTENTION : indique une situation potentiellement dangereuse

qui, si elle n’est pas évitée pourrait se solder par des blessures mineures ou modérées.

AVIS : indique une pratique ne posant aucun risque de dommages corporels mais qui par contre, si rien n’est fait pour l’éviter, pourrait poser des risques de dommages matériels.

POUR TOUTE QUESTION OU TOUT COMMENTAIRE RELATIF À CET OUTIL OU À PROPOS DE TOUT AUTRE OUTIL DEWALT, COMPOSER SANS FRAIS LE : 1-800-4-DEWALT

(1-800-433-9258).

AVERTISSEMENT : afin de réduire le risque de blessures, lire le mode d’emploi de l’outil.

Avertissements de sécurité généraux pour les outils électriques

AVERTISSEMENT! Lire tous les avertissements de sécurité et les directives. Le non-respect des avertissements et des directives pourrait se solder par un choc électrique, un incendie et/ou une blessure grave.

CONSERVER TOUS LES AVERTISSEMENTS ET TOUTES LES DIRECTIVES POUR UN USAGE ULTÉRIEUR

Le terme « outil électrique » cité dans les avertissements se rapporte à votre outil électrique à alimentation sur secteur (avec fil) ou par piles (sans fil).

1)SÉCURITÉ DU LIEU DE TRAVAIL

a)Tenir l’aire de travail propre et bien éclairée. Les lieux encombrés ou sombres sont propices aux accidents.

b)Ne pas faire fonctionner d’outils électriques dans un milieu déflagrant, tel qu’en présence de liquides, de gaz ou de poussières inflammables. Les outils électriques produisent des étincelles qui pourraient enflammer la poussière ou les vapeurs.

c)Éloigner les enfants et les personnes à proximité pendant l’utilisation d’un outil électrique. Une distraction pourrait en faire perdre la maîtrise à l’utilisateur.

2)SÉCURITÉ EN MATIÈRE D’ÉLECTRICITÉ

a)Les fiches des outils électriques doivent correspondre à la prise. Ne jamais modifier la fiche d’aucune façon. Ne jamais utiliser de fiche d’adaptation avec un outil électrique mis à la terre. Le risque de choc électrique sera réduit par l’utilisation de fiches non modifiées correspondant à la prise.

b)Éviter tout contact physique avec des surfaces mises à la terre comme des tuyaux, des radiateurs, des cuisinières et des réfrigérateurs. Le risque de choc électrique est plus élevé si votre corps est mis à la terre.

c)Ne pas exposer les outils électriques à la pluie ou à l’humidité. La pénétration de l’eau dans un outil électrique augmente le risque de choc électrique.

d) Ne pas utiliser le cordon de façon abusive. Ne jamais utiliser le cordon pour transporter, tirer ou débrancher un outil électrique. Tenir le cordon éloigné de la chaleur, de l’huile, des bords tranchants et des pièces mobiles. Les cordons endommagés ou enchevêtrés augmentent les risques de choc électrique.

e)Pour l’utilisation d’un outil électrique à l’extérieur, se servir d’une rallonge convenant

àcette application. L’utilisation d’une rallonge conçue pour l’extérieur réduira les risques de choc électrique.

f)S’il est impossible d’éviter l’utilisation d’un outil électrique dans un endroit humide, brancher l’outil dans une prise ou sur un circuit d’alimentation dotés d’un disjoncteur de fuite à la terre (GFCI). L’utilisation de ce type de disjoncteur réduit les risques de choc électrique.

3)SÉCURITÉ PERSONNELLE

a)Être vigilant, surveiller le travail effectué et faire preuve de jugement lorsqu’un outil électrique est utilisé. Ne pas utiliser d’outil électrique en cas de fatigue ou sous l’influence de drogues, d’alcool ou de médicaments. Un simple moment d’inattention en utilisant un outil électrique peut entraîner des blessures corporelles graves.

b)Utiliser des équipements de protection individuelle. Toujours porter une protection oculaire. L’utilisation d’équipements de protection comme un masque antipoussière, des chaussures antidérapantes, un casque de sécurité ou des protecteurs auditifs lorsque la situation le requiert réduira les risques de blessures corporelles.

c)Empêcher les démarrages intempestifs. S’assurer que l’interrupteur se trouve à la position d’arrêt avant de relier l’outil à une source d’alimentation et/ou d’insérer un bloc-piles, de ramasser ou de transporter l’outil. Transporter un outil électrique alors que le doigt repose sur l’interrupteur ou brancher un outil électrique dont l’interrupteur est

àla position de marche risque de provoquer un accident.

d)Retirer toute clé de réglage ou clé avant de démarrer l’outil. Une clé ou une clé de réglage attachée à une partie pivotante de l’outil électrique peut provoquer des blessures corporelles.

e)Ne pas trop tendre les bras. Conserver son équilibre en tout temps. Cela permet de mieux maîtriser l’outil électrique dans les situations imprévues.

f)S’habiller de manière appropriée. Ne pas porter de vêtements amples ni de bijoux. Garder les cheveux, les vêtements et les gants à l’écart des pièces mobiles. Les vêtements amples, les bijoux ou les cheveux longs risquent de rester coincés dans les pièces mobiles.

g)Si des composants sont fournis pour le raccordement de dispositifs de dépoussiérage et de ramassage, s’assurer que ceux-ci sont bien raccordés et utilisés. L’utilisation d’un dispositif de dépoussiérage peut réduire les dangers engendrés par les poussières.

4)UTILISATION ET ENTRETIEN D’UN OUTIL ÉLECTRIQUE

a)Ne pas forcer un outil électrique. Utiliser l’outil électrique approprié à l’application.

L’outil électrique approprié effectuera un meilleur travail, de façon plus sûre et à la vitesse pour laquelle il a été conçu.

b)Ne pas utiliser un outil électrique dont l’interrupteur est défectueux. Tout outil électrique dont l’interrupteur est défectueux est dangereux et doit être réparé.

c)Débrancher la fiche de la source d’alimentation et/ou du bloc-piles de l’outil électrique avant de faire tout réglage ou changement d’accessoire ou avant de ranger l’outil. Ces mesures préventives réduisent les risques de démarrage accidentel de l’outil électrique.

d)Ranger les outils électriques hors de la portée des enfants et ne permettre à aucune personne n’étant pas familière avec un outil électrique ou son mode d’emploi d’utiliser cet outil. Les outils électriques deviennent dangereux entre les mains d’utilisateurs inexpérimentés.

e)Entretien des outils électriques. Vérifier si les pièces mobiles sont mal alignées ou coincées, si des pièces sont brisées ou présentent toute autre condition susceptible de nuire au bon fonctionnement de l’outil électrique. En cas de dommage, faire réparer l’outil électrique avant toute nouvelle utilisation. Beaucoup d’accidents sont causés par des outils électriques mal entretenus.

f)S’assurer que les outils de coupe sont aiguisés et propres. Les outils de coupe bien entretenus et affûtés sont moins susceptibles de se coincer et sont plus faciles à maîtriser.

g)Utiliser l’outil électrique, les accessoires, les forets, etc. conformément aux présentes directives en tenant compte des conditions de travail et du travail à effectuer. L’utilisation d’un outil électrique pour toute opération autre que celle pour laquelle il a été conçu est dangereuse.

5)RÉPARATION

a)Faire réparer l’outil électrique par un réparateur professionnel en n’utilisant que des pièces de rechange identiques. Cela permettra de maintenir une utilisation sécuritaire de l’outil électrique.

Consignes de sécurité additionnelles propres aux marteaux rotatifs

•Porter un dispositif de protection auditif. Le bruit en résultant pourrait occasionner une perte de l’acuité auditive.

•Utiliser les poignées auxiliaires fournies avec l’outil. Une perte de contrôle de l’outil pourrait occasionner des dommages corporels.

•Tenir l’outil par les surfaces isolées prévues à cet effet pendant toute utilisation où l’organe de coupe pourrait entrer en contact avec des fils électriques cachés ou son propre cordon. Tout contact avec un fil sous tension met les parties métalliques exposées de l’outil sous tension et électrocute l’utilisateur.

•Utiliser des serre-joints, ou tout autre moyen, pour fixer et immobiliser le matériau sur une surface stable. Tenir la pièce à la main ou contre son corps offre une stabilité insuffisante qui pourrait vous en faire perdre le contrôle.

•Porter des lunettes de protection ou toute autre protection oculaire. Le martelage pourrait faire voltiger des éclats. Ces particules volantes pourraient occasionner des dommages oculaires permanents. Porter un masque anti-poussières ou un appareil de protection des voies respiratoires pour toute application productrice de poussières. Une protection auditive peut s’avérer nécessaire pour la plupart des applications.

•Maintenir systématiquement l’outil fermement. Ne pas tenter d’utiliser cet outil sans le maintenir à deux mains. Il est recommandé d’utiliser systématiquement la poignée latérale. Le fait d’utiliser cet outil à une main pourra vous en faire perdre le contrôle. Traverser ou rencontrer des matériaux durs comme les armatures peut aussi s’avérer dangereux. Resserrer soigneusement la poignée latérale avant toute utilisation.

•Utiliser le marteau seulement pour des applications de ciselage léger.

•L’interrupteur avant/arrière doit être en marche avant pour le ciselage.

•Ne pas utiliser l’outil pour mélanger ou pomper tout liquide facilement combustible ou explosif (benzène, alcool, etc.)

•Ne pas mélanger ou remuer des liquides classifiés inflammables.

•Ne pas utiliser cet outil pendant des périodes de temps prolongées. Les vibrations causées par la percussion peuvent poser des risques pour les mains ou les bras. Porter des gants pour amortir les vibrations, et pour limiter les risques, faire des pauses fréquentes.

•Ne pas remettre à neuf les forets soi-même. La remise à neuf de tout burin doit être effectuée par un spécialiste agréé. Tout burin remis à neuf incorrectement pose des risques de dommages corporels.

•Porter des gants lors de l’utilisation de l’outil ou le changement de mèche. Les parties métalliques accessibles de l’outil et des mèches/forets pourraient s’avérer brûlantes lors de l’utilisation. De petits débris de matériau pourraient aussi blesser les mains nues.

•Attendre systématiquement l’arrêt complet de la mèche/foret avant de déposer l’outil où que ce soit. Des forets/mèches en rotation posent des risques de dommages corporels.

•Ne pas donner des coups de marteau sur des forets/mèches coincés pour les déloger.

Des fragments de métal ou de matériau pourraient être éjectés et causer des dommages corporels.

•Les burins légèrement usés peuvent être réaffutés.

•Maintenir le cordon d’alimentation à l’écart d’une mèche en rotation. Ne pas enrouler le cordon autour d’une partie quelconque de votre corps. Un cordon électrique enroulé autour d’une mèche en rotation pose des risques de dommages corporels et de perdre le contrôle de l’outil.

•Prendre des précautions à proximité des évents, car ils cachent des pièces mobiles.

Vêtements amples, bijoux ou cheveux longs risquent de rester coincés dans ces pièces mobiles.

•Pour la sécurité de l’utilisateur, utiliser une rallonge de calibre adéquat (AWG, American Wire Gauge [calibrage américain normalisé des fils électriques]). Plus le calibre est petit, et plus sa capacité est grande. Un calibre 16, par exemple, a plus de capacité qu’un calibre 18. L’usage d’une rallonge de calibre insuffisant causera une chute de tension entraînant perte de puissance et surchauffe. Si plusieurs rallonges sont nécessaires pour obtenir une certaine longueur, s’assurer que chaque rallonge présente au moins le calibre de fil minimum. Le tableau ci-dessous illustre les calibres à utiliser selon la longueur de rallonge et l’intensité nominale indiquée sur la plaque signalétique. En cas de doute, utiliser le calibre suivant. Plus le calibre est petit, plus la rallonge peut supporter de courant.

Calibres minimaux des rallonges

|

|

Volts |

Longueur totale de cordon en mètres (pieds) |

|||

Intensité (en ampères) |

120V |

7,6 (25) |

15,2 (50) |

30,5 (100) |

45,7 (150) |

|

|

|

240V |

15,2 (50) |

30,5 (100) |

61,0 (200) |

91,4 (300) |

|

|

|

|

|

|

|

Plus de |

Pas plus de |

|

|

AWG |

|

|

0 |

6 |

|

18 |

16 |

16 |

14 |

6 |

10 |

|

18 |

16 |

14 |

12 |

10 |

12 |

|

16 |

16 |

14 |

12 |

12 |

16 |

|

14 |

12 |

Non recommandé |

|

Loading...

Loading...