Desa RJ45, RJ70 User Manual

PORTABLE

FORCED

AIR HEATER

OWNER’S MANUAL

IMPORTANT: Read and understand this manual before assembling, starting,

or servicing heater. Improper use of heater can cause serious injury. Keep

this manual for future reference.

Heater Sizes:

RJ45 And RJ70

2

104950

PORTABLE FORCED AIR HEATERS

RJ45 And RJ70

UNPACKING

1. Remove all packing items applied to

heater for shipment.

2. Remove all items from carton.

3. Check items for shipping damage. If

heater is damaged, promptly inform

dealer where you bought heater.

Carbon Monoxide Poisoning: Early

signs of carbon monoxide poisoning re-

semble the flu, with headaches, dizziness,

and/or nausea. If you have these signs, the

heater may not be working properly. Get

fresh air at once! Have heater serviced.

Some people are more affected by carbon

monoxide than others. These include preg-

nant women, persons with heart or lung

disease or anemia, those under the influence

of alcohol, and those at high altitudes.

Make certain you read and understand all

Warnings. Keep this manual for reference.

It is your guide to safe and proper operation

of this heater.

• Use only kerosene or no. 1 fuel oil to

avoid risk of fire or explosion. Never use

gasoline, naphtha, paint thinner, alcohol,

or other highly flammable fuels.

• Fueling

a)Personnel involved with fueling shall

be qualified and thoroughly familiar

with the manufacturer’s instructions

and applicable governing regulations

regarding the safe fueling of heating

units.

b)Only the type of fuel specified on the

heater’s data plate shall be used.

c)All flame shall be extinguished

and the heater allowed to cool,

prior to fueling.

IMPORTANT: Read this Owner’s

Manual carefully and completely

before trying to assemble, oper-

ate, or service this heater. Im-

proper use of this heater can

cause serious injury or death from

burns, fire, explosion, electrical

shock, and carbon monoxide

poisoning.

SAFETY

INFORMATION

DANGER: Carbon monoxide

poisoning may lead to death!

WARNINGS

d)During fueling, all fuel lines and fuel-

line connections shall be inspected for

leaks. Any leaks shall be repaired prior

to returning the heater to service.

e)At no time shall more than one day’s

supply of heater fuel be stored inside

a building in the vicinity of the heater.

Bulk fuel storage shall be outside the

structure.

f) All fuel storage shall be located a

minimum of 8 meters from heaters,

torches, welding equipment, and

similar sources of ignition (excep-

tion: the fuel reservoir integral with

the heater unit).

g)Whenever possible, fuel storage shall

be confined to areas where floor pen-

etrations do not permit fuel to drip

onto or be ignited by a fire at lower

elevation.

h) Fuel storage shall be in accordance

with the authority having jurisdiction.

• Never use heater where gasoline, paint

thinner, or other highly flammable va-

pors are present.

• Follow all local ordinances and codes

when using heater.

• Heaters used in the vicinity of tarpau-

lins, canvas, or similar enclosure ma-

terials shall be located a safe distance

from such materials. The recommended

minimum safe distance is 3 meters. It

is further recommended that these en-

closure materials be of a fire retardant

nature. These enclosure materials shall

be securely fastened to prevent them

from igniting or from upsetting the

heater due to wind action.

• Use only in well-vented areas. Before

using heater, provide at least a 2800

square-centimeter opening of fresh,

outside air for each 25,000 Kcal/Hr of

rating.

• Use only in places free of flammable

vapors or high dust content.

• Use only the electrical voltage and fre-

quency specified on model plate.

• Use only a three-prong, grounded ex-

tension cord.

• Minimum heater clearances from com-

bustibles:

Outlet: 2.5 meters

Sides: 1.25 meters

Top: 1.25 meters

Rear: 1.25 meters

• Locate heater on a stable and level sur-

face if heater is hot or running or a fire

may occur.

• When moving or storing heater, keep

heater in a level position or fuel spill-

age may occur.

• Keep children and animals away from

heater.

• Unplug heater when not in use.

• When used with thermostat, heater may

start anytime.

• Never use heater in living or sleeping

areas.

• Never block air inlet (rear) or air outlet

(front) of heater.

• Never move, handle, refuel, or service

a hot, operating, or plugged-in heater.

• Never attach duct work to front or rear

of heater.

3

104950

OWNER’S MANUAL

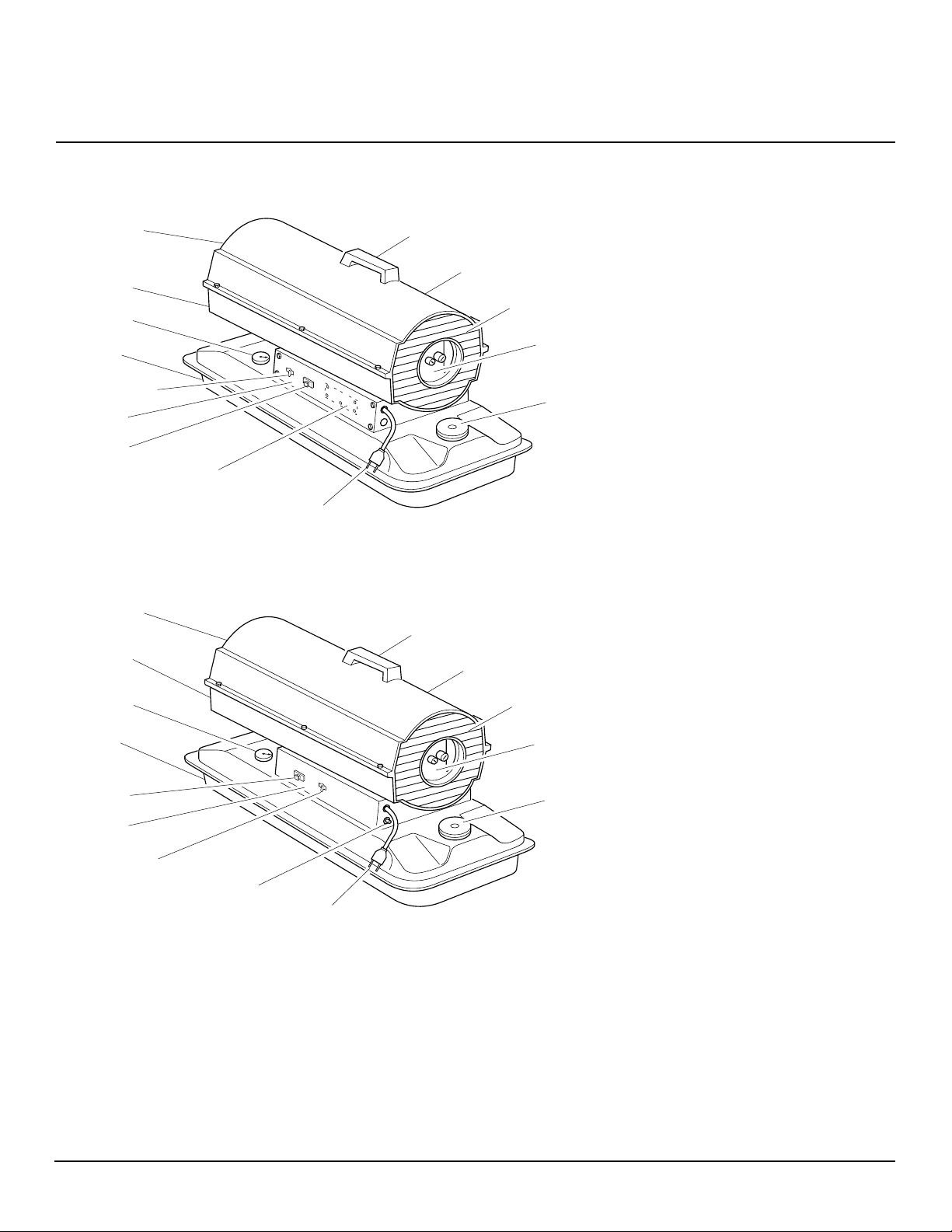

PRODUCT IDENTIFICATION

Figure 1 - RJ45

Handle

Fuel Cap

Lower Shell

Power Cord

Fuel Tank

Hot Air Outlet

Air Filter

End Cover

Fan Guard

Upper Shell

Side Cover

Ignition Control Assembly

(assembly on inside of side cover)

Handle

Fuel Cap

Lower Shell

Power Cord

Fuel Tank

Hot Air Outlet

Air Filter

End Cover

Fan Guard

Upper Shell

Side Cover

Flame-Out Control Reset Button

Fuel Gauge

Receptacle

ON/OFF Switch

Fuel Gauge

Receptacle

ON/OFF Switch

Figure 2 - RJ70

4

104950

PORTABLE FORCED AIR HEATERS

RJ45 And RJ70

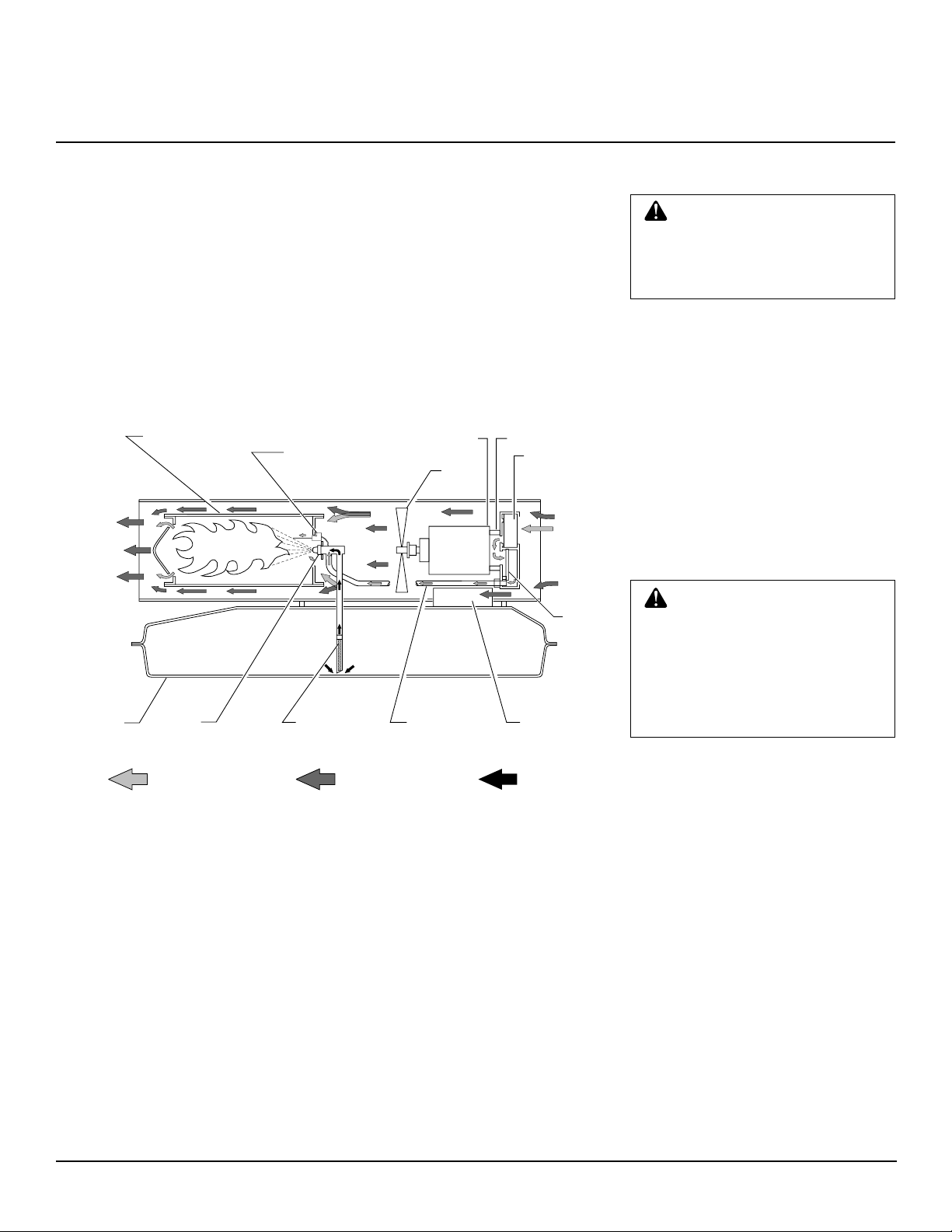

Figure 3 - Cross Section Operational View

Fuel

Filter

Air Line

To Burner

Air

Output

Filter

Air Pump

Air Intake

Filter

Cool

Air In

Fan

Combustion Chamber

Ignitor or

Spark Plug

Motor

Clean

Heated

Air Out

Ignition

Control

Assembly or

Electronic

Ignitor

Air For Fuel

System

Air For Combustion

And Heating

Fuel

Nozzle

The Fuel System: The air pump forces air

through the air line. The air is then pushed

through the nozzle. This air causes fuel to

lift from the tank. A fine mist of fuel is

sprayed into the combustion chamber.

The Air System: The motor turns the fan.

The fan pushes air into and around the

combustion chamber. This air is heated and

provides a stream of clean, hot air.

Fuel

Tank

The Ignition System (RJ45): The igni-

tion control assembly provides power to the

ignitor. This ignites the fuel/air mixture in

the combustion chamber.

The Ignition System (RJ70): The elec-

tronic ignitor sends voltage to the spark

plug. The spark plug ignites the fuel and air

mixture.

The Flame-Out Control System: This

system causes the heater to shut down if the

flame goes out.

THEORY OF OPERATION

WARNING: Use only kerosene

or no. 1 fuel oil to avoid risk of fire

or explosion. Never use gasoline,

naphtha, paint thinners, alcohol,

or other highly flammable fuels.

FUELS

Do not use heavy fuels such as diesel. Using

heavy fuels will result in:

• clogged fuel filter and nozzle

• the need of nontoxic anti-icer in fuel dur-

ing very cold weather

IMPORTANT:

Use a KEROSENE ONLY

storage container. Be sure storage container is

clean. Foreign matter such as rust, dirt, or

water will cause the control to shut down the

heater. Foreign matter may also require you to

clean fuel system often.

WARNING: Follow the mini-

mum fresh, outside air ventila-

tion requirements. If proper fresh,

outside air ventilation is not pro-

vided, carbon monoxide poison-

ing can occur. Provide proper

fresh, outside air ventilation be-

fore running heater.

VENTILATION

Provide at least a 2800 square-centimeter

opening of fresh, outside air for each 25,000

Kcal/Hr rating. Provide extra fresh air if

more heaters are being used.

Example:

The RJ45 (11,900 Kcal/Hr) heater requires

a 1400 square-centimeter opening of fresh

outside air.

The RJ70 (17,600 Kcal/Hr) heater requires

a 2000 square-centimeter opening of fresh

outside air.

5

104950

OWNER’S MANUAL

Item

Fuel tank

Air output and lint filters

Air intake filter

Fuel filter

RJ45: Ignitor

RJ70: Spark Plug

Fan blades

Motor

WARNING: Never service heater while it is plugged in, operating, or

hot. Severe burns and electrical shock can occur.

STORING,

TRANSPORTING,

OR SHIPPING

Note:

If shipping, transport companies re-

quire fuel tanks to be empty.

1. Drain fuel tank. Drain fuel through

drain-plug under tank. Be sure all fuel

is removed.

2. If any debris is noted in old fuel, add 1

or 2 liters of clean kerosene to tank, stir,

and drain again. This will prevent ex-

cess debris from clogging filters dur-

ing future use.

3. Replace fuel cap. Properly dispose of old

and dirty fuel. Check with local auto-

motive service stations that recycle oil.

4. If storing, store heater in dry place.

Make sure storage place is free of dust

and corrosive fumes.

IMPORTANT:

Do not store kerosene over

summer months for use during next heating

season. Using old fuel could damage heater.

WARNING: Review and un-

derstand the warnings in the

Safety Information

section, page

2. They are needed to safely op-

erate this heater. Follow all local

codes when using this heater.

TO START HEATER

1. Follow all ventilation and safety in-

formation.

2. Fill fuel tank with kerosene or no. 1

fuel oil.

3. Attach fuel cap.

4. Plug power cord of heater into

grounded extension cord. Extension

cord must be at least 2 meters long.

Extension Cord Wire Size

Requirements

• 2 to 3 meters long, use 1 mm

2

cord

• 3 to 30 meters long, use 1.5 mm

2

cord

• 30 to 60 meters long, use 2 mm

2

cord

OPERA TION

5. Plug extension cord into standard 100

volt/50 or 60 hertz grounded outlet.

6. Switch heater ON.

RJ45 Note:

Ignitor will preheat for

five seconds, then heater will start.

RJ70 Note:

If heater will not start,

push in flame-out control reset button

(see Figure 2, page 3).

TO STOP HEATER

1. Switch heater OFF.

2. Unplug extension cord from outlet.

TO RESTART HEATER

1. Switch heater OFF. Wait 10 seconds

(two minutes if heater has been running).

2. Switch heater ON.

RJ45 Note:

Ignitor will preheat for

five seconds then heater will start.

RJ70 Note:

If heater will not start,

push in flame-out control reset button

(see Figure 2, page 3).

PREVENTATIVE

MAINTENANCE

SCHEDULE

How To

See Storing, Transporting, or Shipping,

above

See Air Output, Air Intake, and Lint Filters,

page 8

See Air Output, Air Intake, and Lint Filters,

page 8

See Fuel Filter, page 9

See Spark Plug, page 10

See Fan, page 8

How Often

Flush every 150-200 hours of operation or

as needed

Replace every 500 hours of operation or

once a year

Wash and dry with soap and water every

500 hours of operation or replace as needed

Clean twice a heating season or replace as

needed

No maintenance required

Clean and regap every 600 hours of opera-

tion or replace as needed

Clean each season or as needed

Not required/permanently lubricated

6

104950

PORTABLE FORCED AIR HEATERS

RJ45 And RJ70

TROUBLESHOOTING

RJ45

WARNING: Never service heater while it is plugged in, operating, or

hot. Severe burns and electrical shock can occur.

REMEDY

1. Check circuit breaker in electrical panel

2. Check all electrical connections. See

Wiring Diagrams, page 12

3. If fan does not turn freely, see Pump Ro-

tor, page 11

4. Replace ignition control assembly

5. Replace motor

6. Replace ON/OFF switch

1. Fill tank with kerosene

2. See Pump Pressure Adjustment, page 8

3. See Fuel Filter, page 9

4. See Nozzle, page 10

5. Drain and flush fuel tank with clean

kerosene. See Storing, T ransporting, or

Shipping, page 5

6. Check electrical connections. See Wir-

ing Diagrams, page 12

7. Replace ignitor, see page 9

8. Replace ignition control assembly

1. See Pump Pressure Adjustment, page 8

2. See Air Output, Air Intake, and Lint F il-

ters, page 8

3. See Fuel Filter, page 9

4. See Nozzle, page 10

5. Make sure photocell boot is properly

seated in bracket

6. Clean photocell lens

7. Check electrical connections. See Wir-

ing Diagrams, page 12

8. Replace photocell

9. Replace ignition control assembly

OBSERVED FAULT

Motor does not start five seconds after heater

is plugged in and switched ON

Motor starts and runs but heater does not

ignite

Heater ignites but ignition control assembly

shuts heater off after a short period of time

POSSIBLE CAUSE

1. No power to heater

2. Bad electrical connection between mo-

tor and ignition control assembly or ig-

nition assembly and power cord

3. Binding pump rotor

4. Defective ignition control assembly

5. Defective motor

6. Defective ON/OFF switch

1. No fuel in tank

2. Pump pressure incorrect

3. Dirty fuel filter

4. Obstruction in nozzle

5. Water in fuel tank

6. Bad electrical connection between igni-

tor and ignition control assembly

7. Defective ignitor

8. Defective ignition control assembly

1. Pump pressure incorrect

2. Dirty air intake, air output, and/or lint

filter

3. Dirty fuel filter

4. Obstruction in nozzle

5. Photocell assembly not properly in-

stalled (not seeing the flame)

6. Dirty photocell lens

7. Bad electrical connection between pho-

tocell and ignition control assembly

8. Defective photocell

9. Defective ignition control assembly

WARNING: High voltage!

WARNING: High voltage!

WARNING: High voltage!

Loading...

Loading...