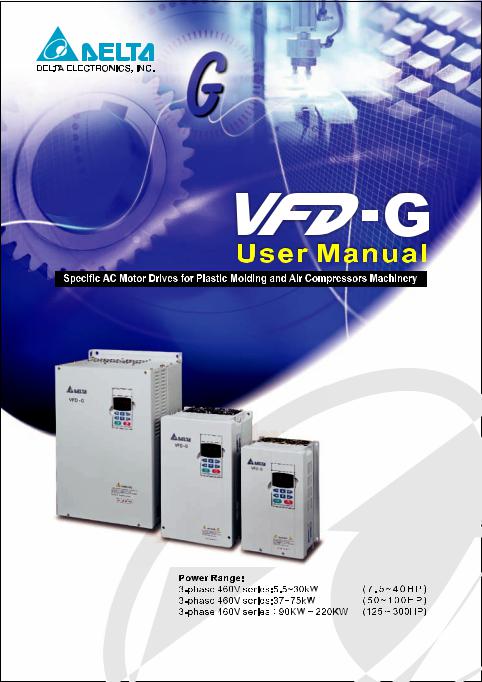

Delta Electronics VFD-G User Manual

Preface

Thank you for choosing DELTA’s VFD-G Series for plastic molding and air compressors machinery. The VFD-G Series is manufactured with high-quality components and materials and incorporates the latest microprocessor technology available.

This manual is to be used for the installation, parameter setting, troubleshooting, and daily maintenance of the AC motor drive. To guarantee safe operation of the equipment, read the following safety guidelines before connecting power to the AC motor drive. Keep this operating manual at hand and distribute to all users for reference.

To ensure the safety of operators and equipment, only qualified personnel familiar with AC motor drive are to do installation, start-up and maintenance. Always read this manual thoroughly before using VFD-G series AC Motor Drive, especially the WARNING, DANGER and CAUTION notes.

Failure to comply may result in personal injury and equipment damage. If you have any questions, please contact your dealer.

PLEASE READ PRIOR TO INSTALLATION FOR SAFETY.

DANGER!

DANGER!

1.AC input power must be disconnected before any wiring to the AC motor drive is made.

2.A charge may still remain in the DC-link capacitors with hazardous voltages, even if the power has been turned off. To prevent personal injury, please ensure that power has been turned off before opening the AC motor drive and wait ten minutes for the capacitors to discharge to safe voltage levels.

3.Never reassemble internal components or wiring.

4.The AC motor drive may be destroyed beyond repair if incorrect cables are connected to the input/output terminals. Never connect the AC motor drive output terminals U/T1, V/T2, and W/T3 directly to the AC mains circuit power supply.

5.Ground the VFD-G using the ground terminal. The grounding method must comply with the laws of the country where the AC motor drive is to be installed. Refer to the Basic Wiring Diagram.

6.VFD-G series is used only to control variable speed of 3-phase induction motors, NOT for 1- phase motors or other purpose.

7.VFD-G series shall NOT be used for life support equipment or any life safety situation.

WARNING!

WARNING!

1.DO NOT use Hi-pot test for internal components. The semi-conductor used in the AC motor drive is easily damaged by high-pressure.

2.There are highly sensitive MOS components on the printed circuit boards. These components are especially sensitive to static electricity. To prevent damage to these components, do not touch these components or the circuit boards with metal objects or your bare hands.

3.Only qualified persons are allowed to install, wire and maintain AC motor drives.

CAUTION!

CAUTION!

1.Some parameter settings will cause the motor to run immediately after applying power.

2.DO NOT install the AC motor drive in a place subjected to high temperature, direct sunlight, high humidity, excessive vibration, corrosive gases or liquids, or airborne dust or metallic particles.

3.Only use AC motor drives within specification. Failure to comply may result in fire, explosion or electric shock.

4.To prevent personal injury, please keep children and unqualified people away from the equipment.

5.When the motor cable between the AC motor drive and motor is too long, the layer insulation of the motor may be damaged. Please use a frequency inverter duty motor or add an AC output reactor to prevent damage to the motor. Refer to appendix B Reactor for details.

6.The rated voltage for the AC motor drive must be ≤ 480V for 460V models and the mains supply current capacity must be ≤ 5000A RMS (≤10000A RMS for the ≥ 40hp (30kW) models).

Table of Contents

Preface ............................................................................................................. |

i |

|

Table of Contents .......................................................................................... |

iii |

|

Chapter 1 Introduction................................................................................ |

1-3 |

|

1.1 |

Receiving and Inspection ................................................................... |

1-3 |

1.1.1 Nameplate Information................................................................ |

1-3 |

|

1.1.2 Model Explanation ...................................................................... |

1-3 |

|

1.1.3 Series Number Explanation ........................................................ |

1-3 |

|

1.1.4 Drive Frames .............................................................................. |

1-3 |

|

1.2 |

Appearances ...................................................................................... |

1-3 |

1.3 |

Remove Instructions........................................................................... |

1-3 |

1.3.1 Remove Keypad ......................................................................... |

1-3 |

|

1.3.2 Remove Front Cover................................................................... |

1-3 |

|

1.4 |

Lifting.................................................................................................. |

1-3 |

1.5 |

Preparation for Installation and Wiring ............................................... |

1-3 |

1.5.1 Ambient Conditions..................................................................... |

1-3 |

|

1.5.2 Minimum Mounting Clearances................................................... |

1-3 |

|

1.6 |

Dimensions......................................................................................... |

1-3 |

Chapter 2 Installation and Wiring .............................................................. |

2-3 |

|

2.1 |

Wiring ................................................................................................. |

2-3 |

2.2 |

External Wiring ................................................................................... |

2-3 |

2.3 |

Main Circuit Connection...................................................................... |

2-3 |

2.4 |

Control Terminals ............................................................................... |

2-3 |

2.5 |

Specification for main circuit terminals and control terminals.............. |

2-3 |

2.6 |

Wiring Explanation for Analog Input Terminal..................................... |

2-3 |

Chapter 3 Keypad and Start Up .................................................................. |

3-3 |

|

3.1 |

Digital Keypad VFD-PU01 .................................................................. |

3-3 |

3.1.1 Description of the Digital Keypad ................................................ |

3-3 |

|

3.1.2 How to Operate the Digital Keypad VFD-PU01........................... |

3-3 |

|

3.1.3 VFD-PU01 Dimensions ............................................................... |

3-3 |

|

3.1.4 Reference Table for the LED Display of the Digital Keypad ........ |

3-3 |

|

3.2 |

Operation Method ............................................................................... |

3-3 |

3.3 |

Trial Run ............................................................................................. |

3-3 |

Chapter 4 Parameters.................................................................................. |

4-3 |

|

4.1 |

Summary of Parameter Settings......................................................... |

4-3 |

4.2 |

Parameter Settings for Applications.................................................... |

4-3 |

4.3 |

Description of Parameter Settings ...................................................... |

4-3 |

Chapter 5 Troubleshooting ......................................................................... |

5-3 |

|

5.1 |

Over Current (OC) .............................................................................. |

5-3 |

5.2 |

Ground Fault....................................................................................... |

5-3 |

5.3 |

Over Voltage (OV) .............................................................................. |

5-3 |

5.4 |

Low Voltage (Lv)................................................................................. |

5-3 |

5.5 |

Over Heat (OH)................................................................................... |

5-3 |

5.6 |

Overload ............................................................................................. |

5-3 |

5.7 |

Keypad Display is Abnormal ............................................................... |

5-3 |

5.8 |

Phase Loss (PHL)............................................................................... |

5-3 |

5.9 Motor cannot Run............................................................................... |

5-3 |

||

5.10 |

Motor Speed cannot be Changed..................................................... |

5-3 |

|

5.11 |

Motor Stalls during Acceleration....................................................... |

5-3 |

|

5.12 |

The Motor does not Run as Expected .............................................. |

5-3 |

|

5.13 |

Electromagnetic/Induction Noise ...................................................... |

5-3 |

|

5.14 |

Environmental Condition .................................................................. |

5-3 |

|

5.15 |

Affecting Other Machines ................................................................. |

5-3 |

|

Chapter 6 Fault Code Information and Maintenance................................ |

6-3 |

||

6.1 Fault Code Information....................................................................... |

6-3 |

||

6.1.1 Common Problems and Solutions............................................... |

6-3 |

||

6.1.2 Reset .......................................................................................... |

6-3 |

||

6.2 Maintenance and Inspections............................................................. |

6-3 |

||

Appendix A Specifications ........................................................................ |

A-3 |

||

Appendix B Accessories ........................................................................... |

B-3 |

||

B.1 |

All Brake Resistors & Brake Units Used in AC Motor Drives.............. |

B-3 |

|

B.2 |

Non-fuse Circuit Breaker Chart .......................................................... |

B-3 |

|

B.3 |

Fuse Specification Chart .................................................................... |

B-3 |

|

B.4 |

AC Reactor ........................................................................................ |

B-3 |

|

B.4.1 AC Input Reactor Recommended Value..................................... |

B-3 |

||

B.4.2 AC Output Reactor Recommended Value.................................. |

B-3 |

||

B.4.3 Applications ................................................................................ |

B-3 |

||

B.5 |

Zero Phase Reactor (RF220X00A) .................................................... |

B-3 |

|

B.6 |

PU06.................................................................................................. |

B-3 |

|

B.6.1 Description of the Digital Keypad VFD-PU06 ............................. |

B-3 |

||

B.6.2 Explanation of Display Message................................................. |

B-3 |

|

B.6.3 PU06 Operation Flow Chart........................................................ |

B-3 |

|

Appendix C How to Select the Right AC Motor Drive.............................. |

C-3 |

|

C.1 |

Capacity Formulas ............................................................................ |

C-3 |

C.2 |

General Precaution ........................................................................... |

C-3 |

C.3 |

How to Choose a Suitable Motor....................................................... |

C-3 |

Chapter 1 Introduction

1.1 Receiving and Inspection

This VFD-G AC motor drive has gone through rigorous quality control tests at the factory before shipment. After receiving the AC motor drive, please check for the following:

Check to make sure that the package includes an AC motor drive, the User Manual/Quick Start and CD, dust covers and rubber bushings.

Inspect the unit to assure it was not damaged during shipment.

Make sure that the part number indicated on the nameplate corresponds with the part number of your order.

1.1.1 Nameplate Information

Example for 10HP/7.5kW 3-phase 460V AC drive

AC Drive Model |

|

|

|

|

|

|

|

MODE |

|

|

|

|

: VFD075F43A-G |

|||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||

Input Spec. |

|

|

|

|

|

INPUT |

|

|

|

|

: 3PH 380-480V 50/60Hz 19.0A |

|||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||

Output Spec. |

|

|

|

|

|

OUTPUT |

|

|

|

|

: 3PH 0-480V 18A 14kVA 10HP |

|||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||

Output Frequency Range |

|

|

|

|

Freq. Range : 0.1~120.00Hz |

|||||||||||||||||||||||||||||||||||||||||||

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||

Enclosure type |

|

|

|

ENCLOSURE: TYPE 1 |

||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||

Bar Code |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

Serial Number |

|

|

|

|

|

|

|

|

075F43AG4T5010001 |

|

||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.1.2 Model Explanation

VFD 075 F 43 A-G

|

|

|

|

|

|

VFD-G series |

|

|

|

|

|

|

Version Type |

|

|

|

|

|

|

|

|

|

|

|

|

|

Input Voltage |

|

|

|

|

|

|

|

|

|

|

|

|

|

43:Three phase 460V |

|

|

|

|

|

|

|

Series |

|

|

|

|

|

|

Name |

|

|

|

Applicable motor capacity |

||

|

|

|

|

|

|

|

055:7.5HP(5.5kW) 075:10HP(7.5kW) 110:15HP(11kW) 150:20HP(15kW) 185:25HP(18.5kW) 220:30HP(22kW) 300:40HP(30kW) 370:50HP(37kW) 450:60HP(45kW)

550:75HP(55kW) 750:100HP(75kW) 900:125HP(90kW) 1100:150HP(110kW) 1320:175HP(132kW) 1600:215HP(160kW) 1850:250HP(185kW) 2200:300HP(220kW)

Revision July 2008, EG03, SW V1.06 |

1-1 |

Chapter 1 Introduction|

1.1.3 Series Number Explanation

075F43AG4 T 7 01 0001

Production number

460V 3-PHASE 10HP(7.5kW) |

Production model |

|

If the nameplate information does not correspond to your purchase order or if there are any problems, please contact your distributor.

1.1.4 Drive Frames

Frame |

Power Range |

Models |

|

|

|

|

|

C |

7.5-20HP (5.5-15kW) |

VFD055F43B-G, VFD075F43B-G, VFD110F43A-G, |

|

VFD150F43A-G |

|||

|

|

||

D |

25-40HP (18.5-30kW) |

VFD185F43A-G, VFD220F43A-G, VFD300F43A-G |

|

|

|

|

|

E |

50-75HP (37-55kW) |

VFD370F43A-G,VFD450F43A-G,VFD550F43A-G |

|

|

|

|

|

E1 |

100-125HP (75-90kW) |

VFD750F43A-G,VFD900F43C-G |

|

|

|

|

|

G |

150-215HP (110-160kW) |

VFD1100F43C-G,VFD1320F43A-G,VFD1600F43A-G |

|

|

|

|

|

H |

250-300HP (185-220kW) |

VFD1850F43A-G, VFD2200F43A-G |

|

|

|

|

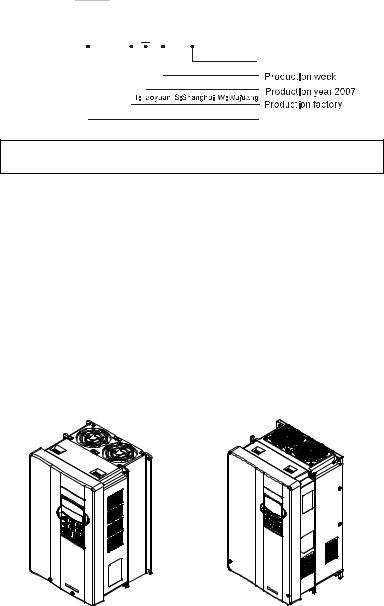

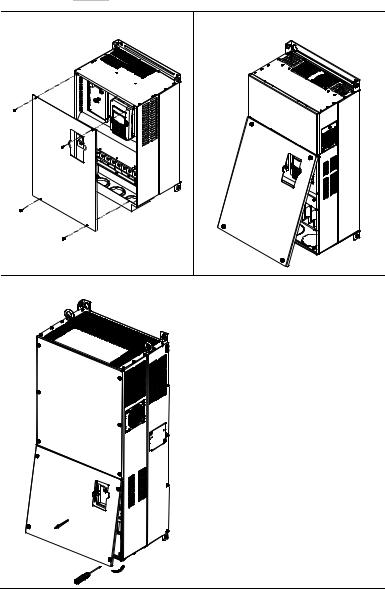

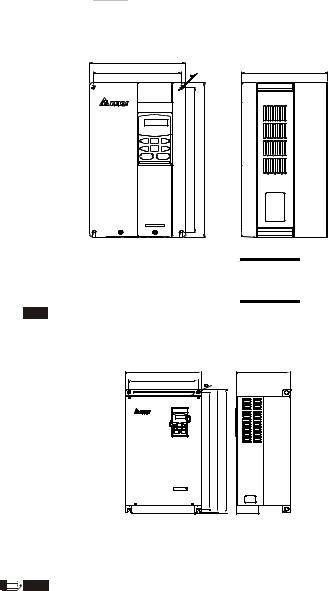

1.2 Appearances

(Refer to chapter 2.3 for exact dimensions)

7.5-20HP/5.5-15kW(Frame C) |

25-40HP/18.5-30kW(Frame D) |

|

|

1-2 |

Revision July 2008, EG03, SW V1.06 |

Chapter 1 Introduction|

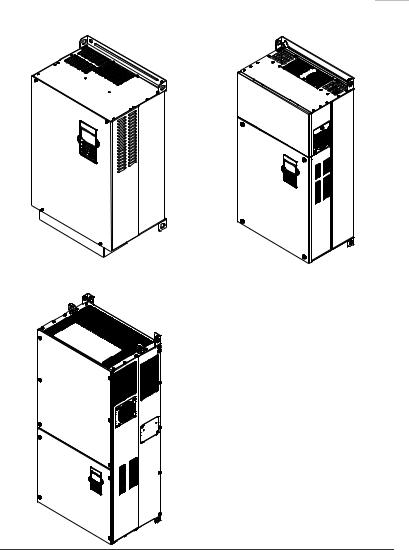

50-125HP/37-90kW(Frame E, E1) |

150-215HP/110-160kW(Frame G) |

|

|

250-300HP/185-220kW(Frame H)

Revision July 2008, EG03, SW V1.06 |

1-3 |

Chapter 1 Introduction|

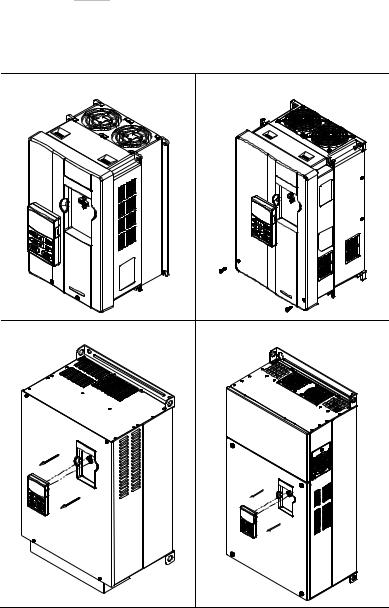

1.3Remove Instructions 1.3.1 Remove Keypad

7.5-20HP/5.5-15kW(Frame |

C) |

25-40HP/18.5-30kW(Frame D) |

50-125HP/37-90kW(Frame |

E, E1) |

150-215HP/110-160kW(Frame G) |

1-4 |

Revision July 2008, EG03, SW V1.06 |

Chapter 1 Introduction|

250-300HP/185-220kW(Frame H)

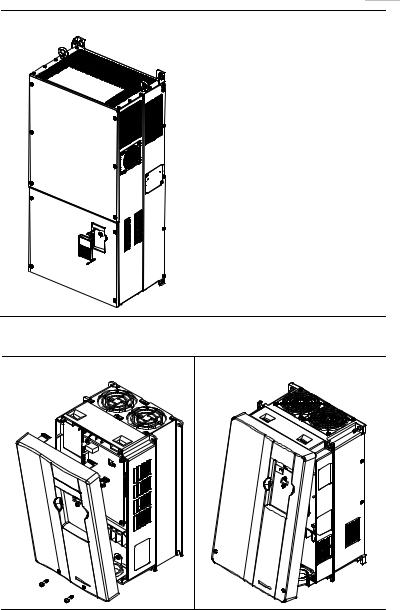

1.3.2 Remove Front Cover

7.5-20HP/5.5-15kW(Frame C) |

25-40HP/18.5-30kW(Frame D) |

Revision July 2008, EG03, SW V1.06 |

1-5 |

Chapter 1 Introduction|

50-125HP/37-90kW(Frame E, E1) |

150-215HP/110-160kW(Frame G) |

250-300HP/185-220kW(Frame H) |

|

1-6 |

Revision July 2008, EG03, SW V1.06 |

Chapter 1 Introduction|

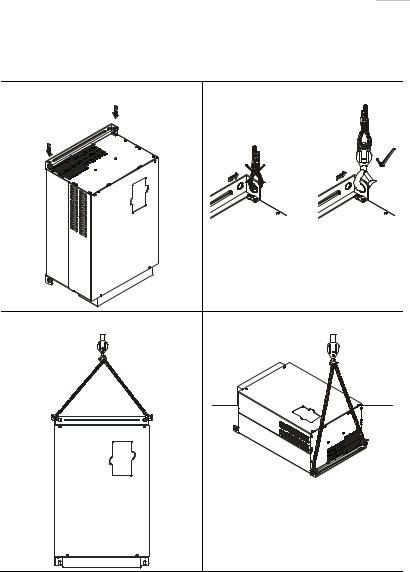

1.4 Lifting

Please carry only fully assembled AC motor drives as shown in the following.

For 50-125HP (Frame E, E1)

Step 1 |

Step 2 |

Step 3 |

Step 4 |

Revision July 2008, EG03, SW V1.06 |

1-7 |

Chapter 1 Introduction|

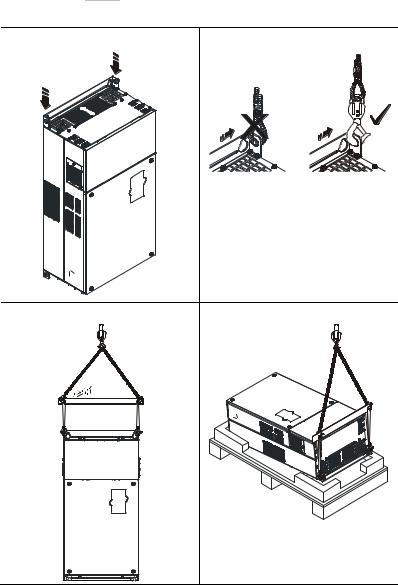

For 150-215HP (Frame G)

Step 1 |

Step 2 |

Step 3 |

Step 4 |

1-8 |

Revision July 2008, EG03, SW V1.06 |

Chapter 1 Introduction|

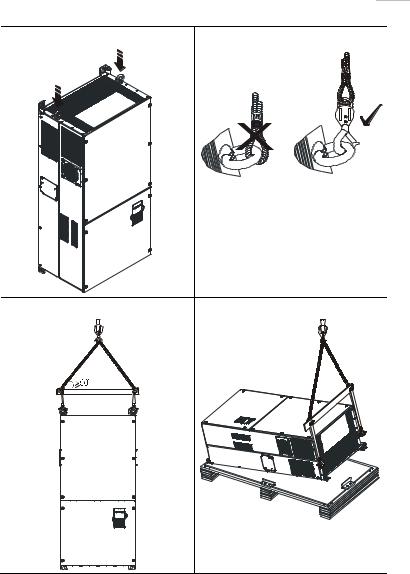

For 250-300HP (Frame H)

Step 1 |

Step 2 |

Step 3 |

Step 4 |

Revision July 2008, EG03, SW V1.06 |

1-9 |

Chapter 1 Introduction|

1.5 Preparation for Installation and Wiring

1.5.1 Ambient Conditions

Install the AC motor drive in an environment with the following conditions:

|

|

Air Temperature: |

|

-10 ~ +40°C (14 ~ 104°F) |

|

|

|

Relative Humidity: |

<90%, no condensation allowed |

||

|

|

|

|

|

|

|

Operation |

Atmosphere |

|

86 ~ 106 kPa |

|

|

pressure: |

|

|

||

|

|

|

|||

|

|

Installation Site |

<1000m |

||

|

|

Altitude: |

|||

|

|

|

|

||

|

|

Vibration: |

|

<20Hz: 9.80 m/s2 (1G) max |

|

|

|

|

20 ~ 50Hz: 5.88 m/s2 (0.6G) max |

|

|

|

|

|

|||

|

|

Temperature: |

-20°C ~ +60°C (-4°F ~ 140°F) |

||

|

|

|

|

||

|

Storage |

Relative Humidity: |

|

<90%, no condensation allowed |

|

|

Transportation |

Atmosphere |

86 ~ 106 kPa |

||

|

|

pressure: |

|||

|

|

|

|

||

|

|

Vibration: |

|

<20Hz: 9.80 m/s2 (1G) max |

|

|

|

|

20 ~ 50Hz: 5.88 m/s2 (0.6G) max |

||

|

|

|

|||

|

Pollution Degree |

2: good for a factory type environment. |

|||

|

|

|

|

|

|

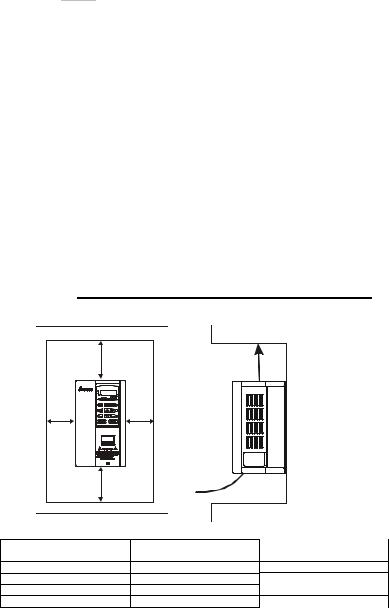

1.5.2 Minimum Mounting Clearances

H |

Air Flow |

|

|

|

FWD |

|

REV |

W |

W |

|

|

H |

|

|

|

HP |

W |

H |

|

mm (inch) |

mm (inch) |

||

|

|||

1-5HP |

50 (2) |

150 (6) |

|

7.5-20HP |

75 (3) |

175 (7) |

|

25-75HP |

75 (3) |

200 (8) |

|

100HP and above |

75 (3) |

250 (10) |

1-10 |

Revision July 2008, EG03, SW V1.06 |

Chapter 1 Introduction|

CAUTION!

CAUTION!

1.Operating, storing or transporting the AC motor drive outside these conditions may cause damage to the AC motor drive.

2.Failure to observe these precautions may void the warranty!

3.Mount the AC motor drive vertically on a flat vertical surface object by screws. Other directions are not allowed.

4.The AC motor drive will generate heat during operation. Allow sufficient space around the unit for heat dissipation.

5.The heat sink temperature may rise to 90°C when running. The material on which the AC motor drive is mounted must be noncombustible and be able to withstand this high temperature.

6.When AC motor drive is installed in a confined space (e.g. cabinet), the surrounding temperature must be within 10 ~ 40°C with good ventilation. DO NOT install the AC motor drive in a space with bad ventilation.

7.Prevent fiber particles, scraps of paper, saw dust, metal particles, etc. from adhering to the heatsink.

8.When installing multiple AC more drives in the same cabinet, they should be adjacent in a row with enough space in-between. When installing one AC motor drive below another one, use a metal separation between the AC motor drives to prevent mutual heating.

Revision July 2008, EG03, SW V1.06 |

1-11 |

Chapter 1 Introduction|

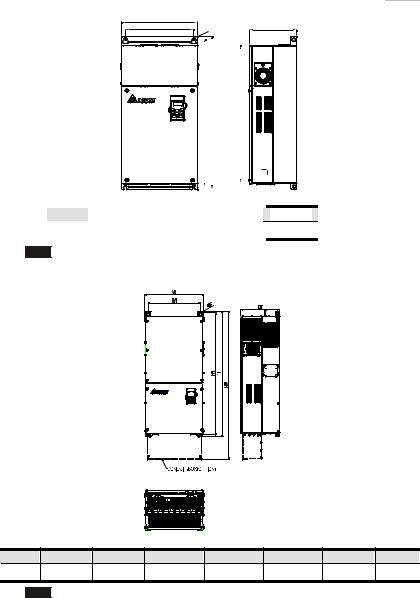

1.6 Dimensions

W |

|

W1 |

D |

|

F |

H

H1

|

|

|

|

|

|

|

Unit: mm [inch] |

|

Frame |

W |

W1 |

H |

|

H1 |

D |

|

F |

C |

200.0 [7.88] |

185.6 [7.31] |

323.0 [12.72] |

303.0 [11.93] |

183.2 [7.22] |

|

7.0 [0.28] |

|

D |

250.0 [9.84] |

226.0 [8.90] |

403.8 [15.90] |

|

384.0 [15.12] |

205.4 [8.08] |

|

10.0 [0.39] |

NOTE

NOTE

Frame C: VFD055F43B-G, VFD075F43B-G, VFD110F43A-G, VFD150F43A-G

Frame D: VFD185F43A-G, VFD220F43A-G, VFD300F43A-G

W D

W1

F

F

H2

H

H1

Unit: mm [inch]

Frame |

W |

W1 |

H |

H1 |

H2 |

D |

F |

E |

370.0[14.57] |

335.0[13.19] |

589.0[23.19] |

560.0[22.05] |

- |

260.0[10.24] |

13.0[0.51] |

E1 |

370.0[14.57] |

335.0[13.19] |

589.0[23.19] |

560.0[22.05] |

595.0[23.43] |

260.0[10.24] |

13.0[0.51] |

NOTE |

|

Frame E: VFD370F43A-G, VFD450F43A-G, VFD550F43A-G |

|

Frame E1: VFD750F43A-G, VFD900F43C-G |

|

1-12 |

Revision July 2008, EG03, SW V1.06 |

W

W1

RF

|

|

|

|

|

|

|

H1 |

H |

H2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Chapter 1 Introduction|

D

|

|

|

|

|

|

|

|

|

Unit: mm [inch] |

|

Frame |

W |

W1 |

H |

H1 |

|

|

H2 |

|

D |

F |

G |

425.0[16.73] |

381.0[15.00] |

850.0[33.46] |

819.5[32.26] |

764.0[30.08] |

|

264.0[10.39] |

6.5[0.26] |

||

|

|

|

|

|

|

|

|

|

|

|

NOTE

NOTE

Frame G: VFD1100F43C-G, VFD1320F43A-G, VFD1600F43A-G

|

|

|

|

|

|

Unit: mm [inch] |

|

Frame |

W |

W1 |

H |

H1 |

H2 |

D1 |

F |

H |

547.0[21.54] |

480.0[18.90] |

1150.0[45.28] |

1119.0[44.06] |

1357.6[53.45] |

360.0[14.17] |

13.0[0.51] |

NOTE

NOTE

Frame H: VFD1850F43A-G, VFD2200F43A-G

Revision July 2008, EG03, SW V1.06 |

1-13 |

Chapter 1 Introduction|

This page intentionally left blank.

1-14 |

Revision July 2008, EG03, SW V1.06 |

Chapter 2 Installation and Wiring

After removing the front cover, check if the power and control terminals are clear. Be sure to observe the following precautions when wiring.

General Wiring Information Applicable Codes

All VFD-G series are Underwriters Laboratories, Inc. (UL) and Canadian Underwriters Laboratories (cUL) listed, and therefore comply with the requirements of the National Electrical Code (NEC) and the Canadian Electrical Code (CEC).

Installation intended to meet the UL and cUL requirements must follow the instructions provided in “Wiring Notes” as a minimum standard. Follow all local codes that exceed UL and cUL requirements. Refer to the technical data label affixed to the AC motor drive and the motor nameplate for electrical data.

The "Line Fuse Specification" in Appendix B, lists the recommended fuse part number for each VFD-G Series part number. These fuses (or equivalent) must be used on all installations where compliance with U.L. standards is a required.

CAUTION!

CAUTION!

1.Make sure that power is only applied to the R/L1, S/L2, T/L3 terminals. Failure to comply may result in damage to the equipment. The voltage and current should lie within the range as indicated on the nameplate.

2.All the units must be grounded directly to a common ground terminal to prevent lightning strike or electric shock.

3.Please make sure to fasten the screw of the main circuit terminals to prevent sparks which is made by the loose screws due to vibration.

4.Check following items after finishing the wiring:

A.Are all connections correct?

B.No loose wires?

C.No short-circuits between terminals or to ground?

Revision July 2008, EG03, SW V1.06 |

2-1 |

Chapter 2 Installation and Wiring|

DANGER!

DANGER!

1.A charge may still remain in the DC bus capacitors with hazardous voltages even if the power has been turned off. To prevent personal injury, please ensure that the power is turned off and wait ten minutes for the capacitors to discharge to safe voltage levels before opening the AC motor drive.

2.Only qualified personnel familiar with AC motor drives is allowed to perform installation, wiring and commissioning.

3.Make sure that the power is off before doing any wiring to prevent electric shock.

2.1 Wiring

Users must connect wires according to the circuit diagrams on the following pages. Do not plug a modem or telephone line to the RS-485 communication port or permanent damage may result. Pins 1 & 2 are the power supply for the optional copy keypad only and should not be used for RS-485 communication.

2-2 |

Revision July 2008, EG03, SW V1.06 |

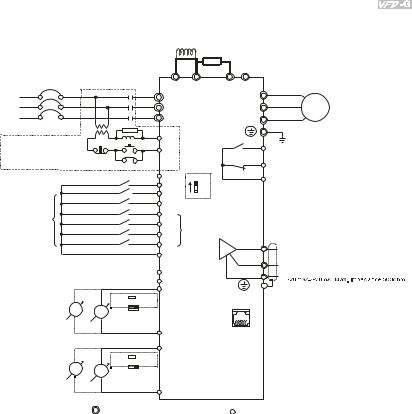

For 460V series, 20hp and below |

|

|

|

|

|

Chapter 2 Installation and Wiring| |

||||

|

|

|

|

|

|

|

||||

|

|

|

|

DC Reactor |

|

|

|

|||

|

|

|

|

(Opti onal) |

Brak e Resistor |

|

||||

|

|

|

|

|

|

|

(Opti onal) |

|

||

|

|

|

|

Jumper |

|

BR |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

NFB |

MC |

|

+1 |

+2/B1 |

B2 |

- |

Motor |

||

R/L1 |

|

|

|

R/L1 |

|

|

|

U/T1 |

||

|

|

|

|

|

|

IM |

||||

|

|

|

|

|

VFD-G |

|||||

S/L2 |

|

|

|

|

S/L2 |

|

V/T2 |

|||

T/L3 |

NFB |

|

|

T/L3 |

|

|

|

W/T3 |

3~ |

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

||

|

|

|

SA |

|

|

|

|

|

|

|

Recommended Circui t |

ON |

|

RB1 |

|

|

|

RA1 |

Multi-function indication |

||

when power s upply |

|

RC1 |

|

|

|

|||||

OFF |

|

|

|

|

|

output contacts |

||||

is turned OFF by a |

MC |

|

|

|

|

RB1 |

240VAC 2.5A |

|||

fault output |

|

|

|

|

|

|

|

|

120VAC 5A |

|

|

|

|

|

|

+24V |

|

Sink |

|

RC1 |

28VDC 5A |

|

|

E.F. |

|

|

|

|

Fac tory setting: dis able |

|||

|

|

|

|

EF |

|

Sw1 |

|

|

||

|

|

FWD/STOP |

|

|

|

|

|

|||

|

|

|

FWD |

|

Source |

|

|

|

||

|

|

REV/STOP |

|

|

|

|

|

|||

|

|

|

REV |

|

|

|

|

|

||

|

|

Multi-s tep1 |

|

|

|

|

|

|

||

|

Fac tory |

|

MI1 |

|

|

|

|

|

||

|

Multi-s tep2 |

|

|

|

|

|

|

|||

|

|

MI2 |

Multi-function |

|

|

|||||

|

Setting |

Multi-s tep3 |

|

|

|

|||||

|

|

|

MI3 |

input |

|

|

|

|||

|

|

Multi-s tep4 |

|

|

|

|

||||

|

|

|

MI4 |

terminals |

|

|

Multi-function Analog |

|||

|

|

Digital Si gnal Common |

|

AFM1 |

||||||

|

|

DCM |

|

|

|

output terminal |

||||

|

|

*Don't apply the mains voltage |

|

|

|

|||||

|

|

|

|

|

|

AFM2 |

Factory setting: output frequency |

|||

|

|

directly to abov e terminals. |

+12V |

|

|

|

AOM |

0~10VDC/2mA |

||

|

|

|

|

|

|

|

|

Factory setting: output current |

||

|

|

|

|

|

ACM |

|

|

|

E |

Analog Signal Common |

|

|

|

|

|

AI1 |

|

|

|

||

|

|

|

0-10V 0-1A |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

||

|

|

V |

SW2 |

|

|

|

|

|

6←1 |

RS-485 |

|

|

A |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

Seri al communic ation interfac e |

||

|

0~10V |

0~1A |

|

|

|

|

|

|

||

|

|

AC1 |

|

|

|

|

1: Reserv ed |

|||

|

|

Analog Signal Common |

|

|

|

|

2: GND |

|||

|

|

|

|

|

|

|

3: SG - |

|||

|

|

|

|

|

AI2 |

|

|

|

|

4: SG+ |

|

|

|

0-10V 0-1A |

|

|

|

|

|

5: Reserv ed |

|

|

|

V |

SW3 |

|

|

|

|

|

|

6: Reserv ed |

|

|

A |

|

|

|

|

|

|

|

|

|

0~10V |

0~1A |

|

AC2 |

|

|

|

|

|

|

|

|

Analog Signal Common |

|

|

|

|

NOTE:*1-3 are optional. |

|||

|

|

|

|

|

|

|

||||

|

|

|

Main c irc ui t (power) terminals |

|

Control c ircuit terminals |

|||||

Revision July 2008, EG03, SW V1.06 |

2-3 |

Chapter 2 Installation and Wiring| |

|

|

|

|

Brak e |

|

|||

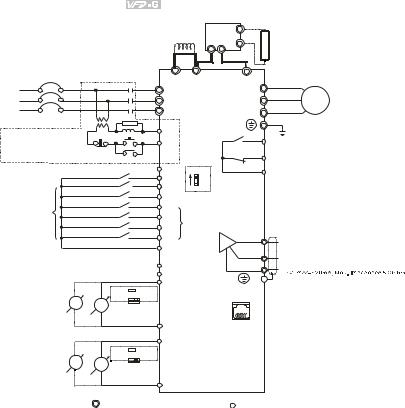

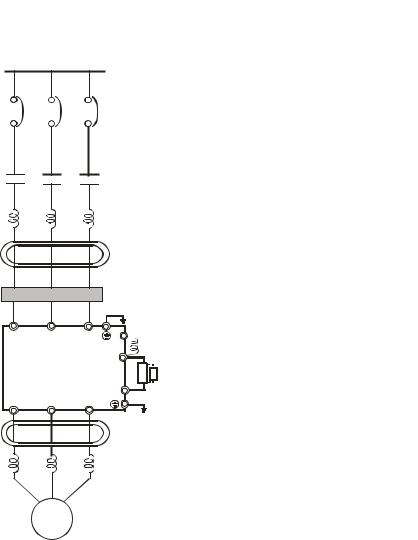

For 460V series, 25hp and above |

|

|

|

|

|||||

|

|

|

|

|

DC Reactor VFDB B1 |

Unit (O ptional ) |

|||

|

|

|

|

|

|

|

|||

|

|

|

|

|

(Opti onal) |

P N B2 |

|

Brak e |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

Resistor |

|

|

|

|

Jumper |

|

|

|

(Opti onal) |

|

|

|

|

|

|

|

|

|

||

|

NFB |

MC |

|

+1 |

+2 |

|

- |

Motor |

|

R/L1 |

|

|

|

R/L1 |

|

|

U/T1 |

||

|

|

|

|

|

IM |

||||

|

|

|

|

VFD-G |

|||||

S/L2 |

|

|

|

|

S/L2 |

V/T2 |

|||

T/L3 |

NFB |

|

|

T/L3 |

|

|

W/T3 |

3~ |

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

||

|

|

|

SA |

|

|

|

|

|

|

Recommended Circui t |

ON |

|

RB1 |

|

|

RA1 |

Multi-function indication |

||

|

|

|

|

||||||

when power s upply |

|

RC1 |

|

|

|||||

OFF |

|

|

|

|

output contacts |

||||

is turned OFF by a |

MC |

|

|

|

RB1 |

240VAC 2.5A |

|||

fault output |

|

|

|

|

|

|

|

120VAC 5A |

|

|

|

|

|

|

+24V |

Sink |

|

RC1 |

28VDC 5A |

|

|

E.F. |

|

|

|

Fac tory setting: dis able |

|||

|

|

|

|

EF |

Sw1 |

|

|||

|

|

FWD/STOP |

|

|

|

||||

|

|

|

FWD |

Source |

|

|

|||

|

|

REV/STOP |

|

|

|

||||

|

|

|

REV |

|

|

|

|

||

|

|

Multi-s tep1 |

|

|

|

|

|

||

|

Fac tory |

|

MI1 |

|

|

|

|

||

|

Multi-s tep2 |

|

|

|

|

|

|||

|

|

MI2 |

Multi-function |

|

|

||||

|

Setting |

Multi-s tep3 |

|

|

|

||||

|

|

|

MI3 |

input |

|

|

|

||

|

|

Multi-s tep4 |

|

|

|

|

|||

|

|

|

MI4 |

terminals |

|

Multi-function Analog |

|||

|

|

Digital Si gnal Common |

DCM |

|

|

AFM1 |

|||

|

|

|

|

output terminal |

|||||

|

|

*Don't apply the mains voltage |

|

|

|

AFM2 |

Factory setting: output frequency |

||

|

|

directly to abov e terminals. |

+12V |

|

|

AOM |

0~10VDC/2mA |

||

|

|

|

|

|

|

|

Factory setting: output current |

||

|

|

|

|

|

ACM |

|

|

E |

Analog Signal Common |

|

|

|

|

|

AI1 |

|

|

||

|

|

|

0-10V 0-1A |

|

|

|

|

||

|

|

|

|

|

|

|

|

||

|

|

V |

SW2 |

|

|

|

|

6←1 |

RS-485 |

|

|

A |

|

|

|

|

|||

|

|

|

|

|

|

|

Seri al communic ation interfac e |

||

|

0~10V |

0~1A |

|

|

|

|

|

||

|

|

|

|

|

|

1: Reserv ed |

|||

|

|

Analog Signal Common |

AC1 |

|

|

|

2: GND |

||

|

|

|

|

|

|

3: SG - |

|||

|

|

|

|

|

AI2 |

|

|

|

4: SG+ |

|

|

|

0-10V 0-1A |

|

|

|

|

5: Reserv ed |

|

|

|

V |

SW3 |

|

|

|

|

|

6: Reserv ed |

|

|

A |

|

|

|

|

|

|

|

|

0~10V |

0~1A |

|

|

|

|

|

|

|

|

|

Analog Signal Common |

AC2 |

|

|

|

NOTE:*1-3 are optional. |

||

|

|

|

|

|

|

||||

|

|

|

Main c irc ui t (power) terminals |

|

Control c ircuit terminals |

||||

2-4 |

Revision July 2008, EG03, SW V1.06 |

Chapter 2 Installation and Wiring|

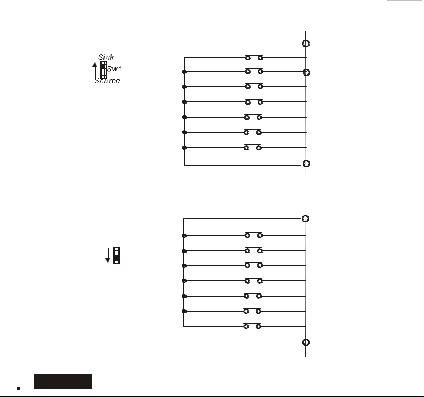

Wiring for SINK mode and SOURCE mode

SINK Mode |

E.F. |

|

|

|

FWD/STOP |

|

REV/STOP |

|

Multi-step1 |

|

Multi-step2 |

|

Multi-step3 |

|

Multi-step4 |

|

Digital Signal Common |

*Don't apply the mains voltage directly to above terminals

SOURCE Mode |

E.F. |

|

Sink |

FWD/STOP |

|

Sw1 |

||

REV/STOP |

||

Source |

||

Multi-step1 |

||

|

||

|

Multi-step2 |

|

|

Multi-step3 |

|

|

Multi-step4 |

*Don't apply the mains voltage directly to above terminals

CAUTION!

CAUTION!

+24V

+24V

EF

EF

FWD

FWD

REV

REV

MI1

MI1

MI2

MI2

MI3

MI3

MI4

MI4  DCM

DCM

+24V

+24V

EF

EF

FWD

FWD

REV

REV

MI1

MI1

MI2

MI2

MI3

MI3

MI4

MI4  DCM

DCM

1.The wiring of main circuit and control circuit should be separated to prevent erroneous actions.

2.Please use shield wire for the control wiring and not to expose the peeled-off net in front of the terminal.

3.Please use the shield wire or tube for the power wiring and ground the two ends of the shield wire or tube.

4.Damaged insulation of wiring may cause personal injury or damage to circuits/equipment if it comes in contact with high voltage.

5.The AC motor drive, motor and wiring may cause interference. To prevent the equipment damage, please take care of the erroneous actions of the surrounding sensors and the equipment.

6.When the AC drive output terminals U/T1, V/T2, and W/T3 are connected to the motor terminals U/T1, V/T2, and W/T3, respectively. To permanently reverse the direction of motor rotation, switch over any of the two motor leads.

Revision July 2008, EG03, SW V1.06 |

2-5 |

Chapter 2 Installation and Wiring|

7.With long motor cables, high capacitive switching current peaks can cause over-current, high leakage current or lower current readout accuracy. To prevent this, the motor cable should be less than 20m for 3.7kW models and below. And the cable should be less than 50m for 5.5kW models and above. For longer motor cables use an AC output reactor.

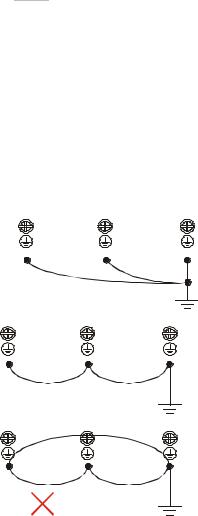

8.The AC motor drive, electric welding machine and the greater horsepower motor should be grounded separately.

9.Use ground leads that comply with local regulations and keep them as short as possible.

10.No brake resistor is built in the VFD-G series, it can install brake resistor for those occasions that use higher load inertia or frequent start/stop. Refer to Appendix B for details.

11.Multiple VFD-G units can be installed in one location. All the units should be grounded directly to a common ground terminal, as shown in the figure below. Ensure there are no ground loops.

Excellent

Good

Not allowed

2-6 |

Revision July 2008, EG03, SW V1.06 |

2.2 External Wiring

Power Supply

|

|

|

FUSE/NFB |

|

|

|

|

Magnetic |

|

|

|

|

contactor |

|

|

|

|

Input AC |

|

|

|

|

Line Reactor |

|

|

|

|

Zero-phase |

|

|

|

|

Reactor |

|

|

EMI Filter |

|

|

|

R/L1 |

S/L2 |

T/L3 |

+1 |

|

|

|

|

DC |

|

|

|

|

Choke |

|

|

|

|

+2 |

BR Brake resistor |

|

|

|

VF DB |

|

U/T1 |

V/T2 |

|

- |

Brake unit |

W/T3 |

|

|||

|

|

|

Zero-phase |

|

|

|

|

Reactor |

|

|

|

|

Output AC |

|

|

|

|

Line Reactor |

|

|

Motor |

|

|

|

|

Chapter 2 Installation and Wiring| |

|

|

|

|

|

|

|

|

||

|

|

|

|

||

Items |

Explanations |

|

|||

Power |

Please follow the specific power |

||||

supply requirements shown in |

|||||

supply |

|||||

Appendix A. |

|

||||

|

|||||

|

There may be an inrush current during |

||||

Fuse/NFB |

power up. Please check the chart of |

||||

Appendix B and select the correct fuse |

|||||

(Optional) |

|||||

with rated current. Use of an NFB is |

|||||

|

optional. |

|

|||

Magnetic |

Please do not use a Magnetic |

||||

contactor as the I/O switch of the AC |

|||||

contactor |

|||||

motor drive, as it will reduce the |

|||||

(Optional) |

|||||

operating life cycle of the AC drive. |

|||||

|

|||||

|

|

|

|

||

|

Used to improve the input power |

||||

|

factor, to reduce harmonics and |

||||

|

provide protection from AC line |

||||

|

disturbances (surges, switching |

||||

Input AC |

spikes, short interruptions, etc.). AC |

||||

Line Reactor |

line reactor should be installed when |

||||

(Optional) |

the power supply capacity is 500kVA |

||||

|

or phase lead reactor will be switched. |

||||

|

And the mains wiring distance ≤10m. |

||||

|

Please refer to Appendix B for more |

||||

|

details. |

|

|||

|

Zero phase reactors are used to |

||||

Zero-phase |

reduce radio noise especially when |

||||

audio equipment is installed near the |

|||||

Reactor |

|||||

inverter. Effective for noise reduction |

|||||

(Ferrite Core |

|||||

Common |

on both the input and output sides. |

||||

Attenuation quality is good for a wide |

|||||

Choke) |

|||||

range from AM band to 10MHz. |

|||||

(Optional) |

|||||

Appendix B specifies the zero phase |

|||||

|

|||||

|

reactor. (RF220X00A) |

|

|||

EMI filter |

To reduce electromagnetic |

||||

interference, please refer to Appendix |

|||||

(Optional) |

|||||

B for more details. |

|||||

|

|||||

|

|

|

|

||

Brake |

Used to reduce the deceleration time |

||||

of the motor. Please refer to the chart |

|||||

Resistor |

|||||

in Appendix B for specific Brake |

|||||

(Optional) |

|||||

Resistors. |

|||||

|

|||||

|

|

|

|

||

Output AC |

Motor surge voltage amplitude |

||||

depends on motor cable length. For |

|||||

Line Reactor |

applications with long motor cable |

||||

(Optional) |

(>20m), it is necessary to install a |

||||

|

reactor at the inverter output side. |

||||

|

|

|

|

|

|

Revision July 2008, EG03, SW V1.06 |

2-7 |

Loading...

Loading...