Page 1

SEMICONDUCTOR TECHNICAL DATA

1

REV 3

Motorola, Inc. 1997

1/97

The MPC930/931 is a 3.3V compatible, PLL based clock driver device

targeted for high performance clock applications. With output frequencies

of up to 150MHz and output skews of 300ps the MPC930/931 is ideal for

the most demanding clock distribution designs. The device employs a

fully differential PLL design to minimize cycle to cycle and long term jitter.

This parameter is of significant importance when the clock driver is

providing the reference clock for PLL’ s on board todays microprocessors

and ASiC’s. The device offers 6 low skew outputs, and a choice between

internal or external feedback. The feedback option adds to the flexibility of

the device, providing numerous input to output frequency relationships.

• On–Board Crystal Oscillator (MPC930)

• Differential LVPECL Reference Input (MPC931)

• Fully Integrated PLL

• Output Shut Down Mode

• Output Frequency up to 150MHz

• Compatible with PowerPC and Intel Microprocessors

• 32–Lead TQFP Packaging

• Power Down Mode

• ±100ps Typical Cycle–to–Cycle Jitter

The MPC930 and MPC931 are very similar in basic functionality, but

there are some minor differences. The MPC931 has been optimized for

use as a zero delay buffer . In addition to tighter specification limits on the

phase offset of the device, a higher speed VCO has been used on the

MPC931. The MPC930, on the other hand, is more optimized for use as a

clock generator. When choosing between the 930 and 931, pay special

attention to the differences in the AC parameters of each device.

The MPC930/931 offers two power saving features for power conscious portable or “green” designs. The power down pin will

seemlessly reduce all of the clock rates by one half so that the system will run at half the potential clock rate to extend battery life.

The POWER_DN pin is synchronized internally to the slowest output clock rate. This allows the transition in and out of the

power–down mode to be output glitch free. In addition, the shut down control pins will turn off various combinations of clock

outputs while leaving a subset active to allow for total processor shut down while maintaining system monitors to “wake up” the

system when signaled. During shut down, the PLL will remain locked, if internal feedback is used, so that wake up time will be

minimized. The shut down and power down pins can be combined for the ultimate in power savings. The Shut_Dn pins are

synchronized to the clock internal to the chip to eliminate the possibility of generating runt pulses.

The MPC930/931 devices offer a great deal of flexibility in what is used as the PLL reference. The MPC930 offers an

integrated crystal oscillator that allows for an inexpensive crystal to be used as the frequency reference. For more information on

the crystal oscillator please refer to the applications section of this data sheet. In those applications where the 930/931 will be

used to regenerate clocks from an existing source or as a zero delay buffer , alternative reference clock inputs are provided. Both

devices offer an LVCMOS input that can be used as the PLL reference. In addition the MPC931 replaces the crystal oscillator

inputs with a differential PECL reference clock input that allows the device to be used in mixed technology clock distribution trees.

An internal feedback divide by 8 of the VCO frequency is compared with the input reference provided by the on–board crystal

oscillator when the internal feedback is selected. The on–board crystal oscillator requires no external components other than a

series resonant crystal (see Applications Information section for more on crystals). The internal VCO is running at 8x the input

reference clock. The outputs can be configured to run at 4x, 2x, 1.25x or 0.66x the input reference frequency. If the external

feedback is selected, one of the MPC931’s outputs must be connected to the Ext_FB pin. Using the external feedback, numerous

input/output frequency relationships can be developed.

The MPC930/931 is fully 3.3V compatible and requires no external loop filter components. All control inputs accept LVCMOS

or LVTTL compatible levels while the outputs provide LVCMOS levels with the capability to drive terminated 50Ω transmission

lines. For series terminated applications, each output can drive two 50Ω transmission lines, effectively increasing the fanout to

1:12. The device is packaged in a 32–lead TQFP package to provide the optimum combination of board density and cost.

PowerPC is a trademark of International Business Machines Corporation. Pentium is a trademark of Intel Corporation.

LOW VOLTAGE

PLL CLOCK DRIVER

FA SUFFIX

32–LEAD TQFP PACKAGE

CASE 873A–02

Page 2

MPC930 MPC931

MOTOROLA TIMING SOLUTIONS

BR1333 — Rev 6

2

÷2÷4÷2÷4÷4

÷6

FUNCTION TABLES

TCLK_Sel Reference

0

1

xtal (PECL_CLK)

TCLK

PLL_En PLL Status

0

1

Test Mode

PLL Enabled

ExtFB_Sel Reference

0

1

Int. ÷8

Ext_FB

GNDO

Qa1

Qa0

VCCO

Div_Sela

Div_Selb

Div_Selc

NC

GNDO

Qc1

Qc0

VCCO

Ext_FB

Shut_Dn1

Shut_Dn0

NC

GNDO

Qb0

Qb1

VCCO

ExtFB_Sel

TCLK_Sel

PLL_En

NC

NC

PLL_VCC

Power_Dn

TCLK

MR/Tristate

xtal1 (930)

xtal2 (930)

GNDI

25

26

27

28

29

30

31

32

15

14

13

12

11

10

9

12345678

24 23 22 21 20 19 18 17

16

MPC930/

MPC931

Power_Dn PLL Status

0

1

VCO/1

VCO/2

Div_Sela,b,c

0

1

Qa Qb Qc

Shut_Dn1

0

0

1

1

Div_Seln

Qb & Qc Low, Qa Toggle

Qa & Qb Low, Qc Toggle

Qb Low, Qa & Qc Toggle

All Toggle

Shut_Dn0

0

1

0

1

Figure 1. 32–Lead Pinout (Top View)

PECL_CLK (931)

PECL_CLK (931)

Figure 2. Logic Diagram

POWER–ON RESET

VCO

PHASE

DETECTOR

LPF

÷

8

MR/Tristate

xtal

OSC

Shut_Dn1

Shut_Dn0

xtal2

xtal1

PLL_En

Qa0

Qb0

Qb1

Power_Dn

÷2/÷

4

÷2/÷

4

÷4/÷

6

Qc0

Qc1

DISABLE

LOGIC

Div_Selb

Div_Sela

Qa1

TCLK

TCLK_Sel

Ext_FB

ExtFB_Sel

Div_Selc

MPC930

PECL_CLK

PECL_CLK

MPC931

MR/Tristate PLL Status

0

1

Disabled

Enabled

(Pullup)

(Pullup)

(Pulldown)

(Pullup)

(Pullup)

(Pulldown)

(Pulldown)

(Pulldown)

(Pullup)

(Pullup)

(Pulldown)

(Pullup)

(Pullup)

(None)

÷

2

Page 3

MPC930 MPC931

TIMING SOLUTIONS

BR1333 — Rev 6

3 MOTOROLA

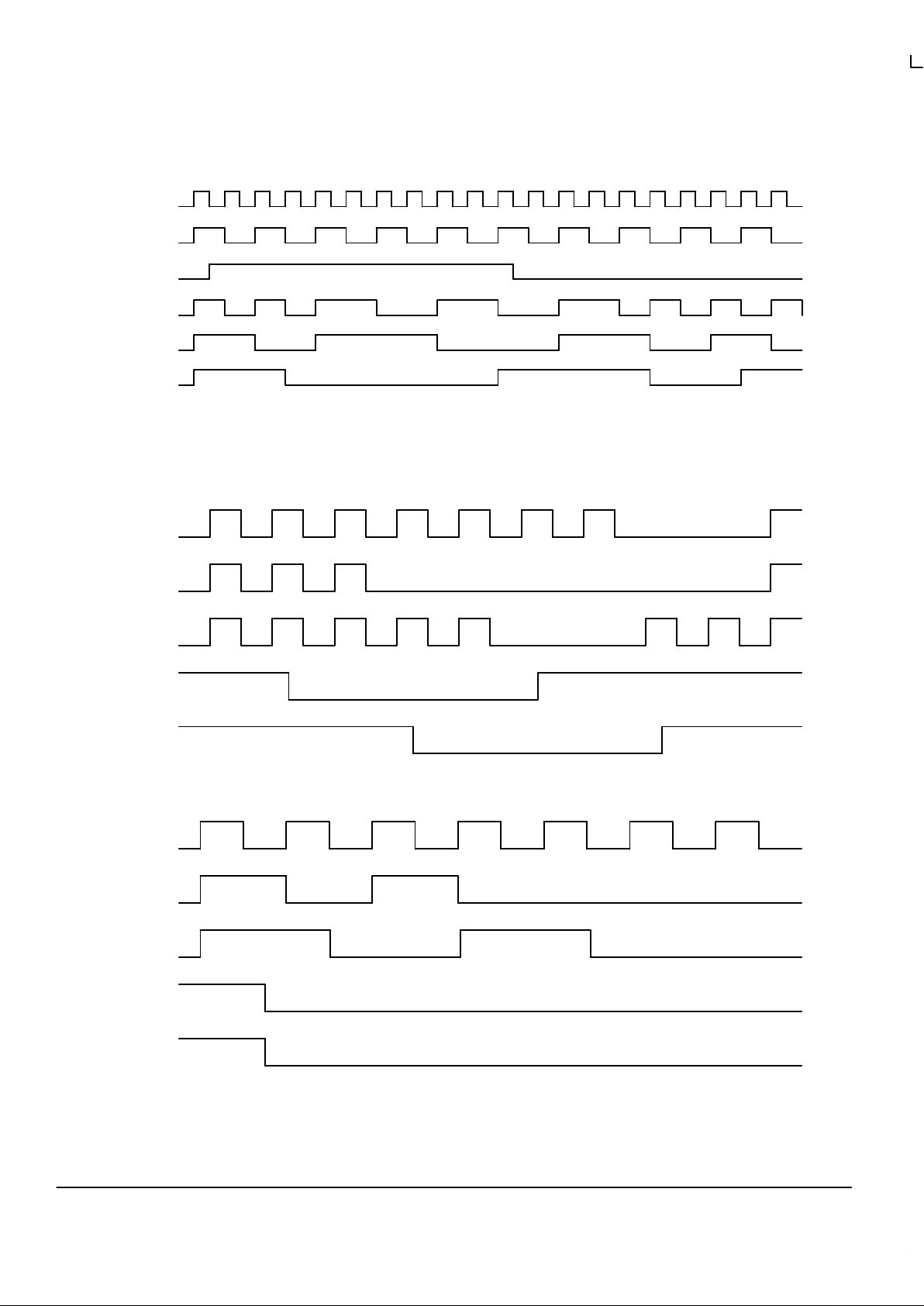

Figure 3. Power_Dn Timing Diagram

VCO

Figure 4. Shut_Dn Timing Diagram

Qa

Qb

Qc

SHUT_DN0

SHUT_DN1

Qa (÷2)

Qb (÷4)

Qc (

÷

6)

SHUT_DN0

SHUT_DN1

VCO/2

Power_Dn

Qa (÷2)

Qb (÷4)

Qc (÷6)

Page 4

MPC930 MPC931

MOTOROLA TIMING SOLUTIONS

BR1333 — Rev 6

4

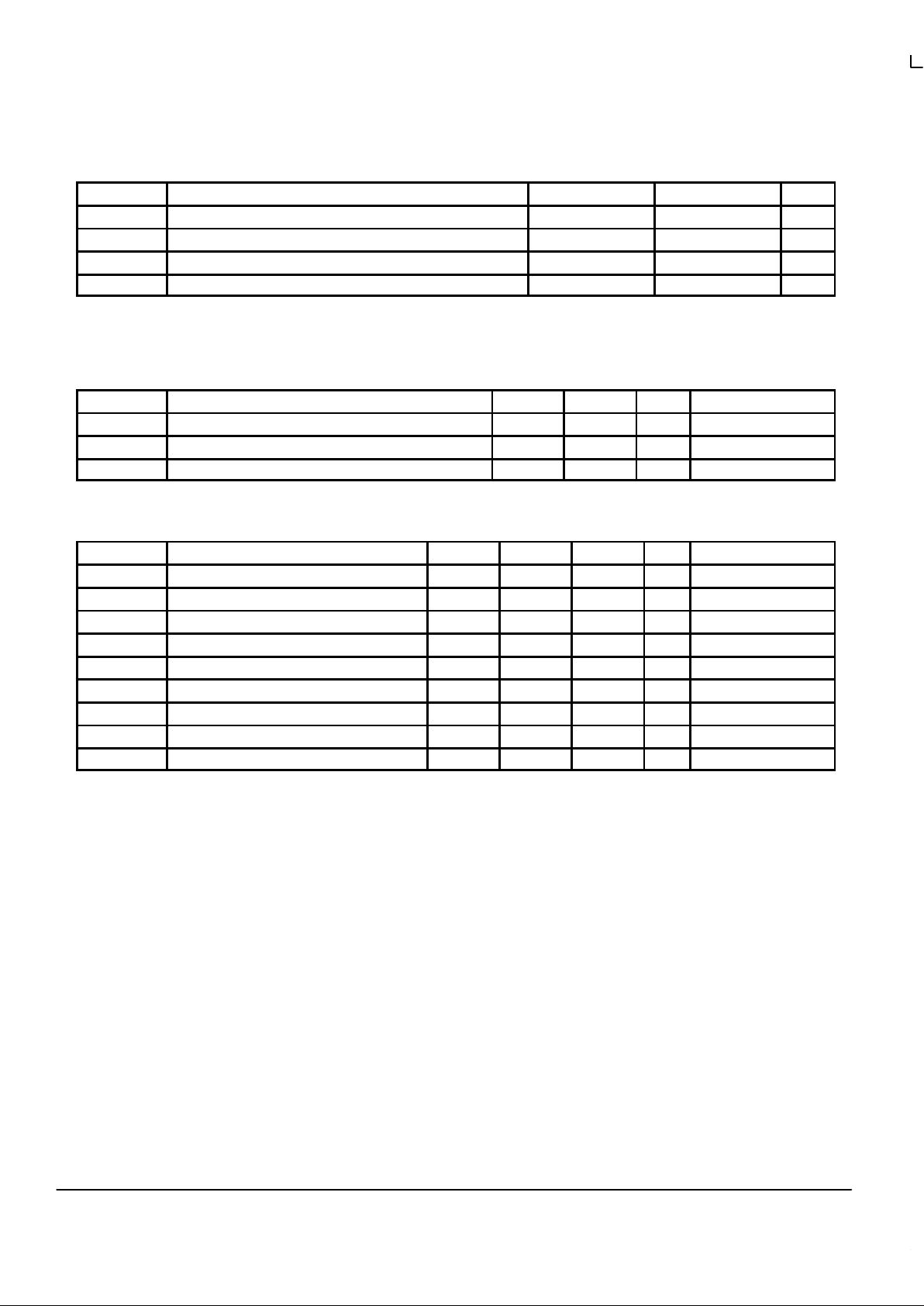

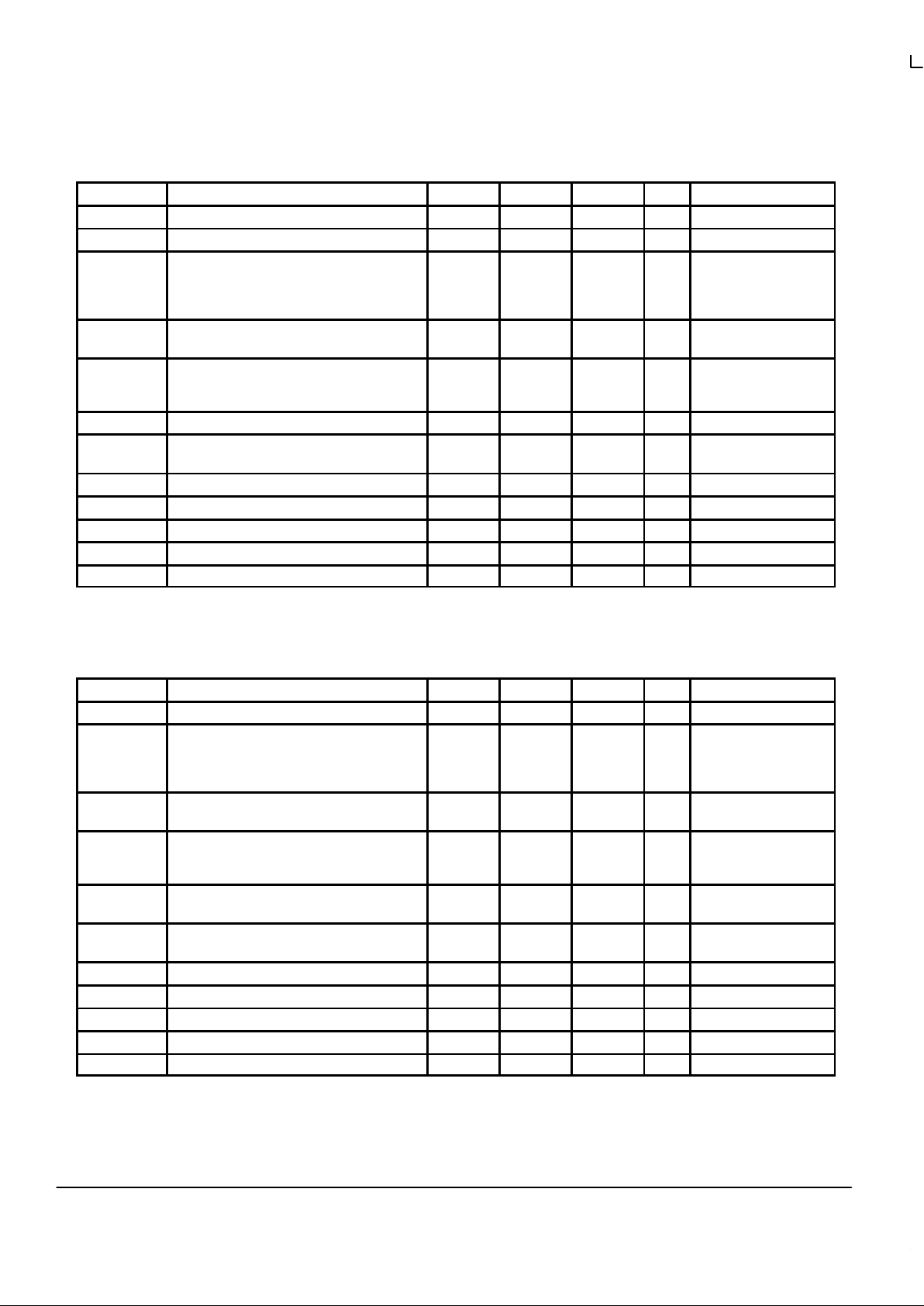

ABSOLUTE MAXIMUM RATINGS*

Symbol Parameter Min Max Unit

V

CC

Supply Voltage –0.3 4.6 V

V

I

Input Voltage –0.3 VDD + 0.3 V

I

IN

Input Current ±20 mA

T

Stor

Storage Temperature Range –40 125 °C

* Absolute maximum continuous ratings are those values beyond which damage to the device may occur. Exposure to these conditions or

conditions beyond those indicated may adversely affect device reliability. Functional operation under absolute–maximum–rated conditions is

not implied.

PLL INPUT REFERENCE CHARACTERISTICS (TA = 0 to 70°C)

Symbol Characteristic Min Max Unit Condition

tr, t

f

TCLK Input Rise/Falls 3.0 ns

f

ref

Reference Input Frequency 10 Note 1. MHz

f

refDC

Reference Input Duty Cycle 25 75 %

1. Maximum input reference frequency is limited by the VCO lock range and the feedback divider.

DC CHARACTERISTICS (TA = 0° to 70°C, VCC = 3.3V ±5%)

Symbol Characteristic Min Typ Max Unit Condition

V

IH

Input HIGH Voltage 2.0 3.6 V

V

IL

Input LOW Voltage 0.8 V

V

OH

Output HIGH Voltage 2.4 V IOH = –20mA (Note 2.)

V

OL

Output LOW Voltage 0.5 V IOL = 20mA (Note 2.)

I

IN

Input Current ±120 µA Note 3.

I

CC

Maximum Core Supply Current 65 85 mA

I

CCPLL

Maximum PLL Supply Current 15 20 mA

C

IN

4 pF

C

pd

25 pF Per Output

2. The MPC930/931 outputs can drive series or parallel terminated 50Ω (or 50Ω to VCC/2) transmission lines on the incident edge (see Applications

Info section).

3. Inputs have pull–up/pull–down resistors which affect input current.

Page 5

MPC930 MPC931

TIMING SOLUTIONS

BR1333 — Rev 6

5 MOTOROLA

MPC930 AC CHARACTERISTICS (TA = 0° to 70°C, VCC = 3.3V ±5%)

Symbol Characteristic Min Typ Max Unit Condition

f

xtal

Crystal Oscillator Frequency Range 10 20 MHz Note 5., Note 7.

f

ref

Input Reference Frequency Note 7. Note 7. MHz Ref = TCLK

t

os

Output–to–Output Skew Same Frequency

(Note 4.) Diff Frequency

Same Frequency

Diff Frequency

200

300

300

450

300

400

400

600

ps f

max

≤ 100MHz

f

max

≤ 100MHz

f

max

> 100MHz

f

max

> 100MHz

f

VCO

VCO Lock Range Power_Dn = 0

Power_Dn = 1

100

50

280

140

MHz

f

max

Maximum Output Frequency Qa, Qb (÷2)

Qa, Qb, Qc (÷4)

Qc (÷6)

140

80

47

MHz Note 4.

t

pd

TCLK to EXT_FB Delay –600 –100 400 ps f

ref

= 50MHz, FB = ÷4

t

pw

Output Duty Cycle (Note 4.) t

CYCLE

/2

–750

t

CYCLE

/2

±500

t

CYCLE

/2

+750

ps

tr, t

f

Output Rise/Fall Time (Note 4.) 0.1 1.0 ns 0.8 to 2.0V

t

PLZ

, t

PHZ

Output Disable Time 2.0 8.0 ns 50Ω to VCC/2

t

PZL

Output Enable Time 2.0 10 ns 50Ω to VCC/2

t

jitter

Cycle–to–Cycle Jitter (Peak–to–Peak) ±100 ps Note 6.

t

lock

Maximum PLL Lock Time 10 ms

4. Measured with 50Ω to VCC/2 termination.

5. See Applications Info section for more Crystal specifications.

6. See Applications Info section for more jitter information.

7. Input reference frequency is bounded by VCO lock range and feedback divide selection.

MPC931 AC CHARACTERISTICS (TA = 0° to 70°C, VCC = 3.3V ±5%)

Symbol Characteristic Min Typ Max Unit Condition

f

ref

Input Reference Frequency Note 11. Note 11. MHz

t

os

Output–to–Output Skew Same Frequency

(Note 8.) Diff Frequency

Same Frequency

Diff Frequency

200

300

300

450

300

400

400

600

ps f

max

≤ 100MHz

f

max

≤ 100MHz

f

max

> 100MHz

f

max

> 100MHz

f

VCO

VCO Lock Range Power_Dn = 0

Power_Dn = 1

200

100

480

240

MHz

f

max

Maximum Output Frequency Qa, Qb (÷2)

Qa, Qb, Qc (÷4)

Qc (÷6)

150

120

80

MHz Note 9.

t

pd

Reference to EXT_FB Average Delay TCLK

PECL_CLK

–150

–400

0

–250

+150

–100

ps f

ref

= 50MHz; FB = ÷8;

Note 12.

t

pw

Output Duty Cycle (Note 8.) t

CYCLE

/2

–750

t

CYCLE

/2

±500

t

CYCLE

/2

+750

ps

tr, t

f

Output Rise/Fall Time (Note 8.) 0.1 1.0 ns 0.8 to 2.0V

t

PLZ

, t

PHZ

Output Disable Time 2.0 8.0 ns 50Ω to VCC/2

t

PZL

Output Enable Time 2.0 10 ns 50Ω to VCC/2

t

jitter

Cycle–to–Cycle Jitter (Peak–to–Peak) ±100 ps Note 10.

t

lock

Maximum PLL Lock Time 10 ms

8. Measured with 50Ω to VCC/2 termination.

9. f

max

limited by skew spec. Outputs will generate valid CMOS signals up to 180MHz.

10.See Applications Info section for more jitter information.

11.Input reference frequency is bounded by VCO lock range and feedback divide selection.

12.tpd is specified for 50MHz input reference, the window will shrink/grow proportionally from the minimum limit with shorter/linger reference

periods. The tpd does not include jitter.

Page 6

MPC930 MPC931

MOTOROLA TIMING SOLUTIONS

BR1333 — Rev 6

6

APPLICATIONS INFORMATION

Programming the MPC930/931

The MPC930/931 clock driver outputs can be configured

into several frequency relationships, in addition the external

feedback option allows for a great deal of flexibility in

establishing unique input to output frequency relationships.

The output dividers for the three output groups allows the

user to configure the outputs into 1:1, 2:1, 3:1, 3:2 and 3:2:1

frequency ratios. The use of even dividers ensures that the

output duty cycle is always 50%. Table 1 illustrates the

various output configurations, the table describes the outputs

using the VCO frequency as a reference. As an example for a

3:2:1 relationship the Qa outputs would be set at VCO/2, the

Qb’s at VCO/4 and the Qc’s at VCO/6. These settings will

provide output frequencies with a 3:2:1 relationship.

The division settings establish the output relationship, but

one must still ensure that the VCO will be stable given the

frequency of the outputs desired. The VCO lock range can be

found in the specification tables. The feedback frequency

and the Power_Dn pin can be used to situate the VCO into a

frequency range in which the PLL will be stable. The design

of the PLL is such that for output frequencies between 25 and

180MHz the MPC930/931 can generally be configured into a

stable region.

The relationship between the input reference and the

output frequency is also very flexible. Table 2 shows the

multiplication factors between the inputs and outputs when

the internal feedback option is used. For external feedback

Table 1 can be used to determine the multiplication factor,

there are too many potential combinations to tabularize the

external feedback condition. Figure 5 through Figure 10

illustrates several programming possibilities, although not

exhaustive it is representative of the potential applications.

Table 1. Programmable Output Frequency Relationships

(Power_Dn = ‘0’)

INPUTS OUTPUTS

Div_Sela Div_Selb Div_Selc Qa Qb Qc

0 0 0 VCO/2 VCO/2 VCO/4

0 0 1 VCO/2 VCO/2 VCO/6

0 1 0 VCO/2 VCO/4 VCO/4

0 1 1 VCO/2 VCO/4 VCO/6

1 0 0 VCO/4 VCO/2 VCO/4

1 0 1 VCO/4 VCO/2 VCO/6

1 1 0 VCO/4 VCO/4 VCO/4

1 1 1 VCO/4 VCO/4 VCO/6

Table 2. Input Reference/Output Frequency Relationships (Internal Feedback Only)

INPUTS OUTPUTS

Qa Qb Qc

Div_Sela Div_Selb Div_Selc Power_Dn=0 Power_Dn=1 Power_Dn=0 Power_Dn=1 Power_Dn=0 Power_Dn=1

0 0 0 4x 2x 4x 2x 2x x

0 0 1 4x 2x 4x 2x 4/3x 2/3x

0 1 0 4x 2x 2x x 2x x

0 1 1 4x 2x 2x x 4/3x 2/3x

1 0 0 2x x 4x 2x 2x x

1 0 1 2x x 4x 2x 4/3x 2/3x

1 1 0 2x x 2x x 2x x

1 1 1 2x x 2x x 4/3x 2/3x

Page 7

MPC930 MPC931

TIMING SOLUTIONS

BR1333 — Rev 6

7 MOTOROLA

MPC930

Figure 5. Dual Frequency Configuration

Div_Sela‘0’

Div_Selb‘1’

Div_Selc‘0’

ExtFB_Sel‘0’

Input Ref16.66MHz

66.66MHz (Processor)Qa

33.33MHz (PCI)Qb

33.33MHz (PCI)Qc

2

2

2

MPC930

Figure 6. Single Frequency Configuration

Div_Sela‘1’

Div_Selb‘1’

Div_Selc‘0’

ExtFB_Sel‘0’

Input Ref16.66MHz

33.33MHzQa

33.33MHzQb

33.33MHzQc

2

2

2

MPC931

Figure 7. “Zero” Delay Fractional Multiplier

Div_Sela‘1’

Div_Selb‘1’

Div_Selc‘1’

ExtFB_Sel‘1’

Input Ref33.33MHz

50MHzQa

50MHzQb

33.33MHzQc

2

2

2

Figure 8. “Zero” Delay Fractional Divider

Ext_FB

1

MPC931

Div_Sela‘0’

Div_Selb‘1’

Div_Selc‘1’

ExtFB_Sel‘1’

Input Ref50MHz

100MHzQa

50MHzQb

33.33MHzQc

2

2

2

Ext_FB

1

MPC931

Figure 9. “Zero” Delay Multiply by 3 (50% Duty Cycle)

Div_Sela‘0’

Div_Selb‘0’

Div_Selc‘1’

ExtFB_Sel‘1’

Input Ref33.33MHz

100MHzQa

100MHzQb

33.33MHzQc

2

2

2

Figure 10. “Zero” Delay Divide by 3 (50% Duty Cycle)

Ext_FB

1

MPC931

Div_Sela‘0’

Div_Selb‘0’

Div_Selc‘1’

ExtFB_Sel‘1’

Input Ref100MHz

100MHzQa

100MHzQb

33.33MHzQc

2

2

2

Ext_FB

1

Using the MPC930/931 as a Zero Delay Buffer

The external feedback option of the MPC930/931 clock

driver allows for its use as a zero delay buffer . By using one of

the outputs as a feedback to the PLL the propagation delay

through the device is eliminated. The PLL works to align the

output edge with the input reference edge thus producing a

near zero delay. The Tpd of the device is specified in the

specification tables. For zero delay buffer applications, the

MPC931 is recommended over the MPC930. The MPC931

has been optimized and specified specifically for use as a

zero delay buffer.

When used as a zero delay buffer the MPC930/931 will

likely be in a nested clock tree application. For these

applications the MPC931 offers a LVPECL clock input as a

PLL reference. This allows the user to use LVPECL as the

primary clock distribution device to take advantage of its far

superior skew performance. The MPC931 then can lock onto

the LVPECL reference and translate with near zero delay to

low skew LVCMOS outputs. Clock trees implemented in this

fashion will show significantly tighter skews than trees

developed from CMOS fanout buffers.

To minimize part–to–part skew the external feedback

option again should be used. The PLL in the MPC931

decouples the delay of the device from the propagation delay

variations of the internal gates. From the specification table

one sees a Tpd variation of only ±150ps, thus for multiple

devices under identical configurations the part–to–part skew

will be around 850ps (300ps for Tpd variation plus 300ps

Page 8

MPC930 MPC931

MOTOROLA TIMING SOLUTIONS

BR1333 — Rev 6

8

output–to–output skew plus 250ps jitter). For devices that are

configured differently the differences between the nominal

delays must also be accounted for.

When using the MPC931 as a zero delay buffer there is

more information which can help minimize the overall timing

uncertainty. To fully minimize the specified uncertainty, it is

crucial that the relative position of the outputs be known. It is

recommended that if all of the outputs are going to be used

that the Qc0 output be used as the feedback reference. The

Qc0 output lies in the middle of the other outputs with respect

to output skew. Therefore it can be assumed that the output

to output skew of the device is ±150ps with respect to output

Qc0.

There will be some cases where only a subset of the

outputs of the MPC931 are required. There is significantly

tighter skew performance between outputs on a common

bank (i.e., Qa0 to Qa1). The skews between these common

bank outputs are outlined in the table below. In general the

skews between outputs on a given bank is about a third of the

skew between all banks, reducing the skew to a value of

100ps.

Table 3. Within–Bank Skews

Outputs Relative Skews

Qa0 → Qa1 +35ps, ±50ps

Qb0 → Qb1 –30ps, ±50ps

Qc0 → Qc1 20ps, ±50ps

Jitter Performance of the MPC930/931

With the clock rates of today’s digital systems continuing

to increase more emphasis is being placed on clock

distribution design and management. Among the issues

being addressed is system clock jitter and how that affects

the overall system timing budget. The MPC930/931 was

designed to minimize clock jitter by employing a differential

bipolar PLL as well as incorporating numerous power and

ground pins in the design. The following few paragraphs will

outline the jitter performance of the MPC930/931, illustrate

the measurement limitations and provide guidelines to

minimize the jitter of the device.

The most commonly specified jitter parameter is

cycle–to–cycle jitter. Unfortunately with today’s high

performance measurement equipment there is no way to

measure this parameter for jitter performance in the class

demonstrated by the MPC930/931. As a result different

methods are used which approximate cycle–to–cycle jitter.

The typical method of measuring the jitter is to accumulate a

large number of cycles, create a histogram of the edge

placements and record peak–to–peak as well as standard

deviations of the jitter. Care must be taken that the measured

edge is the edge immediately following the trigger edge. If

this is not the case the measurement inaccuracy will add

significantly to the measured jitter. The oscilloscope cannot

collect adjacent pulses, rather it collects data from a very

large sample of pulses. It is safe to assume that collecting

pulse information in this mode will produce jitter values

somewhat larger than if consecutive cycles were measured,

therefore, this measurement will represent an upper bound of

cycle–to–cycle jitter. Most likely, this is a conservative

estimate of the cycle–to–cycle jitter.

1212

12

Peak–to–Peak PLL Jitter

Peak–to–Peak Period Jitter

Figure 11. PLL Jitter and Edge Displacement

1232

12

123

3

Peak–to–Peak PLL Jitter

Peak–to–Peak Period Jitter

There are two sources of jitter in a PLL based clock driver,

the commonly known random jitter of the PLL and the less

intuitive jitter caused by synchronous, different frequency

outputs switching. For the case where all of the outputs are

switching at the same frequency the total jitter is exactly

equal to the PLL jitter. In a device, like the MPC930/931,

where a number of the outputs can be switching

synchronously but at different frequencies a “multi–modal”

jitter distribution can be seen on the highest frequency

outputs. Because the output being monitored is affected by

the activity on the other outputs it is important to consider

what is happening on those other outputs. From Figure 11,

one can see for each rising edge on the higher frequency

signal the activity on the lower frequency signal is not

constant. The activity on the other outputs tends to alter the

internal thresholds of the device such that the placement of

the edge being monitored is displaced in time. Because the

signals are synchronous the relationship is periodic and the

resulting jitter is a compilation of the PLL jitter superimposed

on the displaced edges. When histograms are plotted the

jitter looks like a “multi–modal” distribution as pictured in

Figure 11 on page 8. Depending on the size of the PLL jitter

and the relative displacement of the edges the “multi–modal”

distribution will appear truly “multi–modal” or simply like a

“fat” Gaussian distribution. Again note that in the case where

Page 9

MPC930 MPC931

TIMING SOLUTIONS

BR1333 — Rev 6

9 MOTOROLA

all the outputs are switching at the same frequency there is

no edge displacement and the jitter is reduced to that of

the PLL.

Figure 12 graphically represents the PLL jitter of the

MPC930/931. The data was taken for several different output

configurations. Because of the relatively few outputs on the

MPC930/931, the multimodal distribution is of a second order

affect on the 930/931 and can be ignored. As one can see in

the figure the PLL jitter is much less dependent on output

configuration than on internal VCO frequency . However , for a

given VCO frequency, a lower output frequency produces

more jitter.

Figure 12. RMS Jitter versus VCO Frequency

(Qa0 Output)

10

15

20

25

30

35

40

45

80 120 160 200 240 280

Conf 1

Conf 2

Conf 1 = Qa=÷2, Qb=Qc=÷4

Conf 2 = Qa=

÷

2, Qb=Qc=Shut Down

Conf 3 = Qa=

÷

4, Qb=Qc=Shut Down

VCO Frequency (MHz)

RMS Jitter (ps)

Figure 13. RMS Jitter versus Output Frequency

(Qa0 Output)

10

15

20

25

30

35

20 40 60 80 100 120 140

Frequency Output (MHz)

RMS Jitter (ps)

Conf 2 = Qa=÷2, Qb=Qc=Shut Down

Conf 3 = Qa=

÷

4, Qb=Qc=Shut Down

Conf 3

Conf 2

Conf 3

Finally from the data there are some general guidelines

that, if followed, will minimize the output jitter of the device.

First and foremost always configure the device such that the

VCO runs as fast as possible. This is by far the most critical

parameter in minimizing jitter. Second keep the reference

frequency as high as possible. More frequent updates at the

phase detector will help to reduce jitter. Note that if there is a

tradeoff between higher reference frequencies and higher

VCO frequency always chose the higher VCO frequency to

minimize jitter. The third guideline is to try to shut down

outputs that are unused. Minimizing the number of switching

outputs will minimize output jitter.

Power Supply Filtering

The MPC930/931 is a mixed analog/digital product and as

such it exhibits some sensitivities that would not necessarily

be seen on a fully digital product. Analog circuitry is naturally

susceptible to random noise, especially if this noise is seen

on the power supply pins. The MPC930/931 provides

separate power supplies for the output buffers (V

CCO

) and

the internal PLL (PLL_VCC) of the device. The purpose of

this design technique is to try and isolate the high switching

noise digital outputs from the relatively sensitive internal

analog phase–locked loop. In a controlled environment such

as an evaluation board this level of isolation is sufficient.

However, in a digital system environment where it is more

difficult to minimize noise on the power supplies a second

level of isolation may be required. The simplest form of

isolation is a power supply filter on the PLL_VCC pin for the

MPC930/931.

Figure 14. Power Supply Filter

PLL_VCC

VCC

MPC930/931

0.01µF

22

µ

F

0.01

µ

F

3.3V

RS=10–15

Ω

Figure 14 illustrates a typical power supply filter scheme.

The MPC930/931 is most susceptible to noise with spectral

content in the 1KHz to 1MHz range. Therefore the filter

should be designed to target this range. The key parameter

that needs to be met in the final filter design is the DC voltage

drop that will be seen between the VCC supply and the

PLL_VCC pin of the MPC930/931. From the data sheet the

I

PLL_VCC

current (the current sourced through the PLL_VCC

pin) is typically 15mA (20mA maximum), assuming that a

minimum of 3.0V must be maintained on the PLL_VCC pin

very little DC voltage drop can be tolerated when a 3.3V V

CC

supply is used. The resistor shown in Figure 14 must have a

resistance of 10–15Ω to meet the voltage drop criteria. The

RC filter pictured will provide a broadband filter with

approximately 100:1 attenuation for noise whose spectral

content is above 20KHz. As the noise frequency crosses the

series resonant point of an individual capacitor it’s overall

impedance begins to look inductive and thus increases with

increasing frequency. The parallel capacitor combination

shown ensures that a low impedance path to ground exists

for frequencies well above the bandwidth of the PLL.

Page 10

MPC930 MPC931

MOTOROLA TIMING SOLUTIONS

BR1333 — Rev 6

10

Although the MPC930/931 has several design features to

minimize the susceptibility to power supply noise (isolated

power and grounds and fully differential PLL) there still may

be applications in which overall performance is being

degraded due to system power supply noise. The power

supply filter schemes discussed in this section should be

adequate to eliminate power supply noise related problems

in most designs.

Using the Power Management Features of the

MPC930/931

The MPC930/931 clock driver offers two different features

that designers can take advantage of for managing power

dissipation in their designs. The first feature allows the user

to turn off outputs which drive portions of the system which

may go idle in a sleep mode. The Shut_Dn pins allow for

three different combinations of output shut down schemes.

The schemes are summarized in the function tables in the

data sheet. The MPC930/931 synchronizes the shut down

signals internal to the chip and applies them in a manner

which eliminates the possibility of creating runt pulse on the

outputs. The device waits for the output to go into the “LOW”

state prior to disabling. When the outputs are re–enabled the

device waits and re–enables the output such that the

transition is synchronous and in the proper phase

relationship to the outputs which remained active.

The Power_Dn pin offers another means of implementing

power management schemes into a design. To use this

feature the device must be set up in its normal operating

mode with the Power_Dn pin “LOW”, in addition the user

must use the internal feedback option. If the external

feedback option were used the output frequency reduction

would change the feedback frequency and the PLL will lose

lock. When the Power_Dn pin is driven “HIGH” the

MPC930/931 synchronizes the signal to the internal clock

and then seemlessly reduces the frequency of the outputs by

one half. The Power_Dn signal is synchronized to the

slowest internal VCO clock. It waits until both VCO clocks are

in the “LOW” state and then switches from the nominal speed

VCO clock to the half speed VCO clock. This will in turn

cause the current output pulse to stretch to reflect the

reduction in output frequency. When the Power_Dn pin is

brought back “LOW” the device will again wait until both of

the VCO clocks are “LOW” and then switch to the nominal

VCO clock. This will cause the current output pulses, and all

successive pulses, to shrink to match the higher output

frequency. Both the power up and power down features are

illustrated in the timing diagrams of in this data sheet.

Timing diagrams for both of the power management

features are shown in Figure 3 and Figure 4 on page 3.

Using the On–Board Crystal Oscillator

The MPC930 features an on–board crystal oscillator to

allow for seed clock generation as well as final distribution.

The on–board oscillator is completely self contained so that

the only external component required is the crystal. As the

oscillator is somewhat sensitive to loading on its inputs the

user is advised to mount the crystal as close to the

MPC930/931 as possible to avoid any board level parasitics.

To facilitate co–location surface mount crystals are

recommended, but not required.

The oscillator circuit is a series resonant circuit as

opposed to the more common parallel resonant circuit, this

eliminates the need for large on–board capacitors. Because

the design is a series resonant design for the optimum

frequency accuracy a series resonant crystal should be used

(see specification table below). Unfortunately most off the

shelf crystals are characterized in a parallel resonant mode.

However a parallel resonant crystal is physically no different

than a series resonant crystal, a parallel resonant crystal is

simply a crystal which has been characterized in its parallel

resonant mode. Therefore in the majority of cases a parallel

specified crystal can be used with the MPC930 with just a

minor frequency error due to the actual series resonant

frequency of the parallel resonant specified crystal. Typically

a parallel specified crystal used in a series resonant mode

will exhibit an oscillatory frequency a few hundred ppm lower

than the specified value. For most processor implement–

ations a few hundred ppm translates into kHz inaccuracies, a

level which does not represent a major issue.

Table 4. Crystal Specifications

Parameter Value

Crystal Cut Fundamental AT Cut

Resonance Series Resonance*

Frequency Tolerance ±75ppm at 25°C

Frequency/Temperature Stability ±150pm 0 to 70°C

Operating Range 0 to 70°C

Shunt Capacitance 5–7pF

Equivalent Series Resistance (ESR) 50 to 80Ω Max

Correlation Drive Level 100µW

Aging 5ppm/Yr (First 3 Y ears)

* See accompanying text for series versus parallel resonant

discussion.

The MPC930 is a clock driver which was designed to

generate outputs with programmable frequency relationships

and not a synthesizer with a fixed input frequency. As a result

the crystal input frequency is a function of the desired output

frequency. For a design which utilizes the external feedback

to the PLL the selection of the crystal frequency is straight

forward; simply chose a crystal which is equal in frequency to

the fed back signal. To determine the crystal required to

produce the desired output frequency for an application

which utilizes internal feedback the block diagram of

Figure 15 should be used. The P and the M values for the

MPC930/931 are also included in Figure 15. The M values

can be found in the configuration tables included in this

applications section.

Page 11

MPC930 MPC931

TIMING SOLUTIONS

BR1333 — Rev 6

11 MOTOROLA

Figure 15. PLL Block Diagram

f

ref

Phase

Detector

QnVCO

LPF

÷

P

÷

N

÷

m

N

f

ref

+

fQn · N · P

m

f

ref

+

f

VCO

m

,f

VCO

+

fQn·N·P

m = 8

P = 1 (Power_Dn=‘0’), 2 (Power_Dn=‘1’)

For the MPC930 clock driver, the following will provide an

example of how to determine the crystal frequency required

for a given design.

Given:

Qa = 66.6MHz

Qb = 33.3MHz

Qc = 22.2MHz

Power_Dn = ‘0’

f

ref

+

fQn · N · P

m

From Table 4

fQc = VCO/6 then N = 6

From Figure 15

m = 8 and P = 1

f

ref

+

22.22 · 6 · 1

8

+

16.66MHz

Driving Transmission Lines

The MPC930/931 clock driver was designed to drive high

speed signals in a terminated transmission line environment.

To provide the optimum flexibility to the user the output

drivers were designed to exhibit the lowest impedance

possible. With an output impedance of less than 10Ω the

drivers can drive either parallel or series terminated

transmission lines. For more information on transmission

lines the reader is referred to application note AN1091 in the

Timing Solutions brochure (BR1333/D).

In most high performance clock networks point–to–point

distribution of signals is the method of choice. In a

point–to–point scheme either series terminated or parallel

terminated transmission lines can be used. The parallel

technique terminates the signal at the end of the line with a

50Ω resistance to VCC/2. This technique draws a fairly high

level of DC current and thus only a single terminated line can

be driven by each output of the MPC930/931 clock driver. For

the series terminated case however there is no DC current

draw, thus the outputs can drive multiple series terminated

lines. Figure 16 illustrates an output driving a single series

terminated line vs two series terminated lines in parallel.

When taken to its extreme the fanout of the MPC930/931

clock driver is effectively doubled due to its capability to drive

multiple lines.

Figure 16. Single versus Dual Transmission Lines

7

Ω

IN

MPC930/931

OUTPUT

BUFFER

RS = 43

Ω

ZO = 50

Ω

OutA

7

Ω

IN

MPC930/931

OUTPUT

BUFFER

RS = 43

Ω

ZO = 50

Ω

OutB0

RS = 43

Ω

ZO = 50

Ω

OutB1

The waveform plots of Figure 17 show the simulation

results of an output driving a single line vs two lines. In both

cases the drive capability of the MPC930/931 output buffers

is more than sufficient to drive 50Ω transmission lines on the

incident edge. Note from the delay measurements in the

simulations a delta of only 43ps exists between the two

differently loaded outputs. This suggests that the dual line

driving need not be used exclusively to maintain the tight

output–to–output skew of the MPC930/931. The output

waveform in Figure 17 shows a step in the waveform, this

step is caused by the impedance mismatch seen looking into

the driver. The parallel combination of the 43Ω series resistor

plus the output impedance does not match the parallel

combination of the line impedances. The voltage wave

launched down the two lines will equal:

VL = VS ( Zo / (Rs + Ro +Zo))

Zo = 50Ω || 50Ω

Rs = 43Ω || 43Ω

Ro = 7Ω

VL = 3.0 (25 / (21.5 + 7 + 25) = 3.0 (25 / 53.5)

= 1.40V

At the load end the voltage will double, due to the near

unity reflection coefficient, to 2.8V. It will then increment

towards the quiescent 3.0V in steps separated by one round

trip delay (in this case 4.0ns).

Page 12

MPC930 MPC931

MOTOROLA TIMING SOLUTIONS

BR1333 — Rev 6

12

Figure 17. Single versus Dual Waveforms

TIME (nS)

VOLTAGE (V)

3.0

2.5

2.0

1.5

1.0

0.5

0

2 4 6 8 10 12 14

OutB

tD = 3.9386

OutA

tD = 3.8956

In

Since this step is well above the threshold region it will not

cause any false clock triggering, however designers may be

uncomfortable with unwanted reflections on the line. To

better match the impedances when driving multiple lines the

situation in Figure 18 should be used. In this case the series

terminating resistors are reduced such that when the parallel

combination is added to the output buffer impedance the line

impedance is perfectly matched.

Figure 18. Optimized Dual Line Termination

7

Ω

MPC930/931

OUTPUT

BUFFER

RS = 36

Ω

ZO = 50

Ω

RS = 36

Ω

ZO = 50

Ω

7Ω + 36Ω k 36Ω = 50Ω k 50Ω

25Ω = 25Ω

SPICE level output buffer models are available for

engineers who want to simulate their specific interconnect

schemes. In addition IV characteristics are in the process of

being generated to support the other board level simulators in

general use.

Page 13

MPC930 MPC931

TIMING SOLUTIONS

BR1333 — Rev 6

13 MOTOROLA

OUTLINE DIMENSIONS

FA SUFFIX

TQFP PACKAGE

CASE 873A–02

ISSUE A

DETAIL Y

A

S1

VB

1

8

9

17

25

32

AE

AE

P

DETAIL Y

BASE

N

J

DF

METAL

SECTION AE–AE

G

SEATING

PLANE

R

Q

_

W

K

X

0.250 (0.010)

GAUGE PLANE

E

C

H

DETAIL AD

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DATUM PLANE –AB– IS LOCATED AT BOTTOM OF

LEAD AND IS COINCIDENT WITH THE LEAD

WHERE THE LEAD EXITS THE PLASTIC BODY AT

THE BOTTOM OF THE PARTING LINE.

4. DATUMS –T–, –U–, AND –Z– TO BE DETERMINED

AT DATUM PLANE –AB–.

5. DIMENSIONS S AND V TO BE DETERMINED AT

SEATING PLANE –AC–.

6. DIMENSIONS A AND B DO NOT INCLUDE MOLD

PROTRUSION. ALLOWABLE PROTRUSION IS

0.250 (0.010) PER SIDE. DIMENSIONS A AND B

DO INCLUDE MOLD MISMATCH AND ARE

DETERMINED AT DATUM PLANE –AB–.

7. DIMENSION D DOES NOT INCLUDE DAMBAR

PROTRUSION. DAMBAR PROTRUSION SHALL

NOT CAUSE THE D DIMENSION TO EXCEED

0.520 (0.020).

8. MINIMUM SOLDER PLATE THICKNESS SHALL BE

0.0076 (0.0003).

9. EXACT SHAPE OF EACH CORNER MAY VARY

FROM DEPICTION.

DIMAMIN MAX MIN MAX

INCHES

7.000 BSC 0.276 BSC

MILLIMETERS

B 7.000 BSC 0.276 BSC

C 1.400 1.600 0.055 0.063

D 0.300 0.450 0.012 0.018

E 1.350 1.450 0.053 0.057

F 0.300 0.400 0.012 0.016

G 0.800 BSC 0.031 BSC

H 0.050 0.150 0.002 0.006

J 0.090 0.200 0.004 0.008

K 0.500 0.700 0.020 0.028

M 12 REF 12 REF

N 0.090 0.160 0.004 0.006

P 0.400 BSC 0.016 BSC

Q 1 5 1 5

R 0.150 0.250 0.006 0.010

V 9.000 BSC 0.354 BSC

V1 4.500 BSC 0.177 BSC

__

____

DETAIL AD

A1

B1

V1

4X

S

4X

B1 3.500 BSC 0.138 BSC

A1 3.500 BSC 0.138 BSC

S 9.000 BSC 0.354 BSC

S1 4.500 BSC 0.177 BSC

W 0.200 REF 0.008 REF

X 1.000 REF 0.039 REF

9

–T–

–Z–

–U–

T–U0.20 (0.008) ZAC

T–U0.20 (0.008) ZAB

0.10 (0.004) AC

–AC–

–AB–

M

_

8X

–T–, –U–, –Z–

T–U

M

0.20 (0.008) ZAC

Page 14

MPC930 MPC931

MOTOROLA TIMING SOLUTIONS

BR1333 — Rev 6

14

Motorola reserves the right to make changes without further notice to any products herein. Motorola makes no warranty , representation or guarantee regarding

the suitability of its products for any particular purpose, nor does Motorola assume any liability arising out of the application or use of any product or circuit, and

specifically disclaims any and all liability, including without limitation consequential or incidental damages. “T ypical” parameters which may be provided in Motorola

data sheets and/or specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals”

must be validated for each customer application by customer’s technical experts. Motorola does not convey any license under its patent rights nor the rights of

others. Motorola products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other

applications intended to support or sustain life, or for any other application in which the failure of the Motorola product could create a situation where personal injury

or death may occur. Should Buyer purchase or use Motorola products for any such unintended or unauthorized application, Buyer shall indemnify and hold Motorola

and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees

arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim alleges that

Motorola was negligent regarding the design or manufacture of the part. Motorola and are registered trademarks of Motorola, Inc. Motorola, Inc. is an Equal

Opportunity/Affirmative Action Employer.

How to reach us:

USA/EUROPE/ Locations Not Listed: Motorola Literature Distribution; JAPAN: Nippon Motorola Ltd.; Tatsumi–SPD–JLDC, 6F Seibu–Butsuryu–Center,

P.O. Box 5405; Denver, Colorado 80217. 303–675–2140 or 1–800–441–2447 3–14–2 Tatsumi Koto–Ku, Tokyo 135, Japan. 81–3–3521–8315

Mfax: RMFAX0@email.sps.mot.com – TOUCHTONE 602–244–6609 ASIA/PACIFIC: Motorola Semiconductors H.K. Ltd.; 8B Tai Ping Industrial Park,

INTERNET: http://www.mot.com/sps/ 51 Ting Ko k Road, Tai Po, N.T., Hong Kong. 852–26629298

MPC930/D

*MPC930/D*

◊

Loading...

Loading...