Page 1

®

ICM7555, ICM7556

Data Sheet August 24, 2006

General Purpose Timers

The ICM7555 and ICM7556 are CMOS RC timers providing

significantly improved performance over the standard

SE/NE 555/6 and 355 timers, while at the same time being

direct replacements for those devices in most applications.

Improved parameters include low supply current, wide

operating supply voltage range, low THRESHOLD,

TRIGGER

supply current during output transitions, higher frequency

performance and no requirement to decouple CONTROL

VOLTAGE for stable operation.

Specifically, the ICM7555 and ICM7556 are stable

controllers capable of producing accurate time delays or

frequencies. The ICM7556 is a dual ICM7555, with the two

timers operating independently of each other, sharing only

V+ and GND. In the one shot mode, the pulse width of each

circuit is precisely controlled by one external resistor and

capacitor. For astable operation as an oscillator, the free

running frequency and the duty cycle are both accurately

controlled by two external resistors and one capacitor. Unlike

the regular bipolar SE/NE 555/6 devices, the CONTROL

VOLTAGE terminal ne ed not be decouple d with a cap acitor.

The circuits are triggered and rese t on fa lling (negative)

waveforms, and the output inverter can source or sink

currents large enough to drive TTL loads, or provide minimal

offsets to drive CMOS loads.

and RESET currents, no crowbarring of the

FN2867.9

Features

• Exact Equivalent in Most Cases for SE/NE555/556 or

TLC555/556

• Low Supply Current

- ICM7555. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60μA

- ICM7556. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120μA

• Extremely Low Input Currents . . . . . . . . . . . . . . . . . 20pA

• High Speed Operation . . . . . . . . . . . . . . . . . . . . . . . 1MHz

• Guaranteed Supply Voltage Range . . . . . . . . . 2V to 18V

• Temperature Stability . . . . . . . . . . . . 0.005%/°C at +25°C

• Normal Reset Function - No Crowbarring of Supply During

Output Transition

• Can be Used with Higher Impedance Timing Elements

than Regular 555/6 for Longer RC Time Constants

• Timing from Microseconds through Hours

• Operates in Both Astable and Monostable Modes

• Adjustable Duty Cycle

• High Output Source/Sink Driver can Drive TTL/CMOS

• Outputs have Very Low Offsets, HI and LO

• Pb-Free Plus Anneal Available (RoHS Compliant)

Applications

• Precision Timing

• Pulse Generation

• Sequential Timing

Pinouts

ICM7555 (8 LD PDIP, SOIC)

TOP VIEW

1

GND

RESET

2

3

4

TRIGGER

OUTPUT

1

8

V

DD

7

DISCHARGE

6

THRESHOLD

CONTROL

5

VOLTAGE

• Time Delay Generation

• Pulse Width Modulation

• Pulse Position Modulation

• Missing Pulse Detector

ICM7556 (14 LD PDIP, CERDIP)

TOP VIEW

DISCHARGE

THRESH-

CONTROL

VOLTAGE

OUTPUT

TRIGGER

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 1-888-468-3774

Copyright © Intersil Americas Inc. 2002, 2004, 2005, 2006. All Rights Reserved

1

2

OLD

3

RESET

4

5

6

GND

7

| Intersil (and design) is a registered trademark of Intersil Americas Inc.

All other trademarks mentioned are the property of their respective owners.

14

V

DD

DISCHARGE

13

12

THRESHOLD

CONTROL

11

VOLTAGE

RESET

10

OUTPUT

9

TRIGGER

8

Page 2

ICM7555, ICM7556

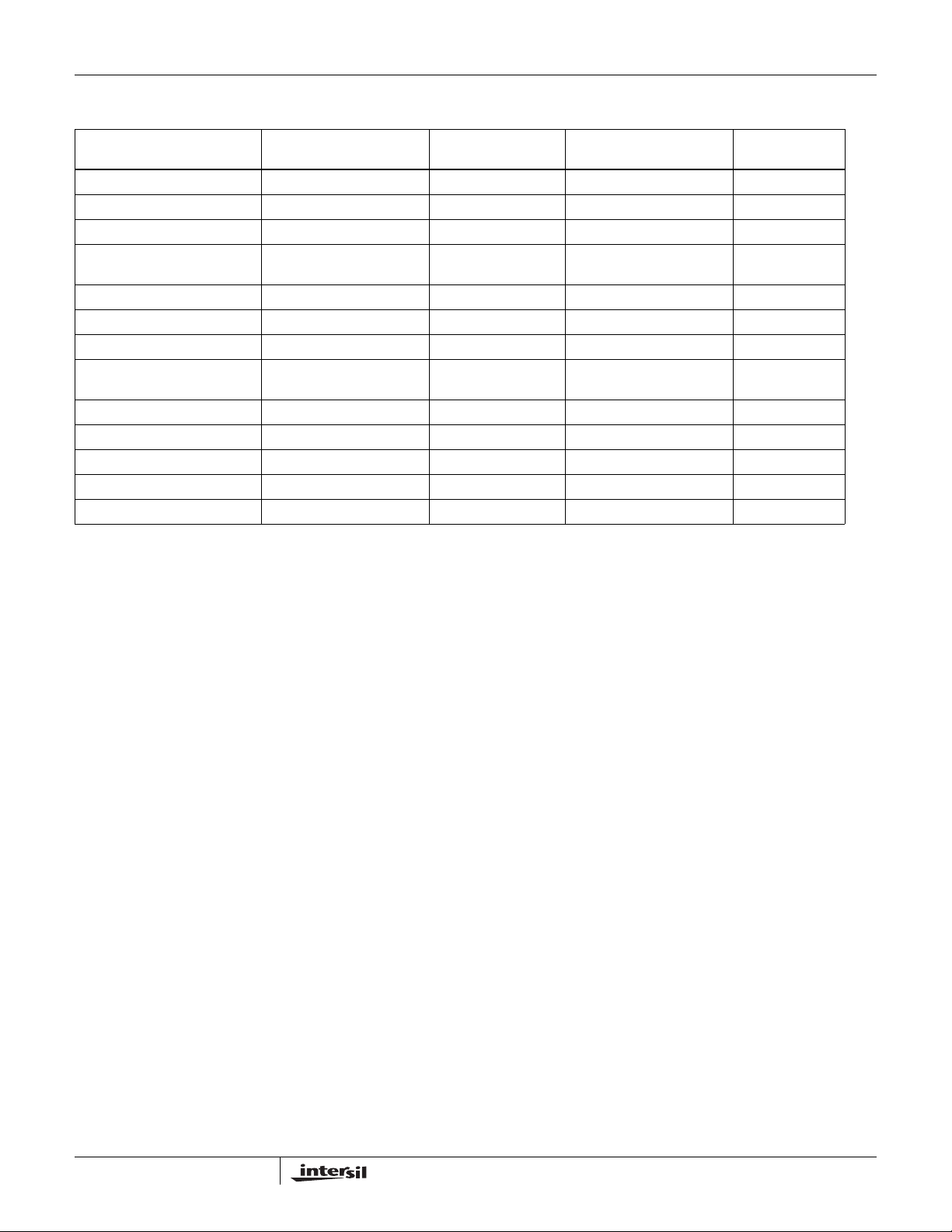

Ordering Information

TEMP. RANGE

PART NUMBER PART MARKING

ICM7555CBA 7555 CBA 0 to +70 8 Ld SOIC M8.15

ICM7555CBA-T 7555 CBA 0 to +70 8 Ld SOIC Tape and Reel M8.15

ICM7555CBAZ (Note) 7555 CBAZ 0 to +70 8 Ld SOIC (Pb-free) M8.15

ICM7555CBAZ-T (Note) 7555 CBAZ 0 to +70 8 Ld SOIC (Pb-free)

ICM7555IBA 7555 IBA -25 to +85 8 Ld SOIC M8.15

ICM7555IBAT 7555 IBA -25 to +85 8 Ld SOIC Tape and Reel M8.15

ICM7555IBAZ (Note) 7555 IBAZ -25 to +85 8 Ld SOIC (Pb-free) M8.15

ICM7555IBAZ-T (Note) 7555 IBAZ -25 to +85 8 Ld SOIC (Pb-free)

ICM7555IPA 7555 IPA -25 to +85 8 Ld PDIP E8.3

ICM7555IPAZ (Note) 7555 IPAZ -25 to +85 8 Ld PDIP** (Pb-free) E8.3

ICM7556IPD ICM7556IPD -25 to +85 14 Ld PDIP E14.3

ICM7556IPDZ (Note) ICM7556IPDZ -25 to +85 14 Ld PDIP** (Pb-free) E14.3

ICM7556MJD ICM7556MJD -55 to +125 14 Ld Cerdip F14.3

**Pb-free PDIPs can be used for through hole wave solder processing only. They are not intended for use in Reflow solder processing

applications.

(°C) PACKAGE PKG. DWG. #

M8.15

Tape and Reel

M8.15

Tape and Reel

NOTE: Intersil Pb-free products employ special Pb-free material sets; molding compounds/die attach materials and 100% matte tin plate

termination finish, which are RoHS compliant and compatible with both SnPb and Pb-free soldering operations. Intersil Pb-free products are

MSL classified at Pb-free peak reflow te mperatures that meet or exceed the Pb-free re q uire men ts of IPC/JEDEC J STD-020.

2

FN2867.9

August 24, 2006

Page 3

ICM7555, ICM7556

Absolute Maximum Ratings Thermal Information

Supply Voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .+18V

Input Voltage

Trigger

, Control Voltage, Threshold,

Reset

(Note 1) . . . . . . . . . . . . . . . . . . . . . V+ +0.3V to GND -0.3V

Output Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100mA

Operating Conditions

Temperature Range

ICM7555C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0°C to +70°C

ICM7555I, ICM7556I . . . . . . . . . . . . . . . . . . . . . . -25°C to +85°C

ICM7556M . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -55°C to +125°C

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation of the

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTES:

1. Due to the SCR structure inherent in the CMOS process used to fabricate these devices, connecting any terminal to a voltage greater than

V+ +0.3V or less than V- -0.3V may cause destructive latchup. For this reason it is recommended that no inputs from external sources not

operating from the same power supply be applied to the device before its power supply is established. In multiple supply systems, the supply

of the ICM7555 and ICM7556 must be turned on first.

2. θ

is measured with the component mounted on a low effective thermal conductivity test board in free air. See Tech Brief 379 for details.

JA

Thermal Resistance (Typical, Note 2) θ

14 Lead CERDIP Package. . . . . . . . . . 80 24

(°C/W) θJC (°C/W)

JA

14 Lead PDIP Package* . . . . . . . . . . . 115 N/A

8 Lead PDIP Package* . . . . . . . . . . . . 130 N/A

8 Lead SOIC Package . . . . . . . . . . . . . 170 N/A

Maximum Junction Temperature (Hermetic Package) . . . . . . . +175°C

Maximum Junction Temperature (Plastic Package) . . . . . . .+150°C

Maximum Storage Temperature Range . . . . . . . . -65°C to +150°C

Maximum Lead Temperature (Soldering 10s) . . . . . . . . . . . +300°C

(SOIC - Lead Tips Only)

* Pb-free PDIPs can be used for through hole wave solder

processing only. They are not intended for use in Reflow solder

processing applications.

Electrical Specifications Applies to ICM7555 and ICM7556, unless otherwise specified

T

A

PARAMETER SYMBOL TEST CONDITIONS

Static Supply Current I

Monostable Timing Accuracy R

Drift with Temperature

(Note 3)

Drift with Supply (Note 3) V

Astable Timing Accuracy R

Drift with Temperature

(Note 3)

Drift with Supply (Note 3) V

Threshold Voltage V

Trigger Voltage V

Trigger Current I

TRIGVDD

TRIG

Threshold Current I

Control Voltage V

ICM7555 VDD = 5V 40 200 300 μA

DD

V

= 15V 60 300 300 μA

DD

ICM7556 VDD = 5V 80 400 600 μA

V

= 15V 120 600 600 μA

DD

= 10K, C = 0.1μF, VDD = 5V 2 %

A

V

= 5V 150 ppm/°C

DD

V

= 10V 200 ppm/°C

DD

= 15V 250 ppm/°C

V

DD

= 5V to 15V 0.5 0.5 %/V

DD

= RB = 10K, C = 0.1μF, VDD = 5V 2 %

A

V

= 5V 150 ppm/°C

DD

V

= 10V 200 ppm/°C

DD

= 15V 250 ppm/°C

V

DD

= 5V to 15V 0.5 0.5 %/V

DD

VDD = 15V 62677161 72% V

TH

= 15V 28323627 37% V

VDD = 15V 10 50 nA

VDD = 15V 10 50 nA

TH

VDD = 15V 62677161 72% V

CV

= +25°C

(NOTE 4)

-55°C TO +125°C

UNITSMIN TYP MAX MIN TYP MAX

858 1161 μs

1717 2323 μs

DD

DD

DD

3

FN2867.9

August 24, 2006

Page 4

ICM7555, ICM7556

Electrical Specifications Applies to ICM7555 and ICM7556, unless otherwise specified (Continued)

= +25°C

T

A

PARAMETER SYMBOL TEST CONDITIONS

Reset Voltage V

Reset Current I

RST

Discharge Leakage I

Output Voltage V

V

Discharge Output Voltage V

Supply Voltage (Note 3) V

Output Rise Time (Note 3) t

Output Fall Time (Note 3) t

Oscillator Frequency

(Note 3)

f

MAX

NOTES:

3. These parameters are based upon characterization data and are not tested.

4. Applies only to military temperature range product (M suffix).

VDD = 2V to 15V 0.4 1.0 0.2 1.2 V

RST

VDD = 15V 10 50 nA

VDD = 15V 10 50 nA

DIS

VDD = 15V, I

OL

V

= 5V, I

DD

VDD = 15V, I

OH

VDD = 5V, I

VDD = 5V, I

DIS

V

= 15V, I

DD

Functional Operation 2.0 18.0 3.0 16.0 V

DD

RL = 10M, CL = 10pF, VDD = 5V 75 ns

R

RL = 10M, CL = 10pF, VDD = 5V 75 ns

F

VDD = 5V, RA = 470Ω, RB = 270Ω,

= 20mA 0.4 1.0 1.25 V

SINK

= 3.2mA 0.2 0.4 0.5 V

SINK

SOURCE

SOURCE

SINK

SINK

= 0.8mA 14.3 14.6 14.2 V

= 0.8mA 4.0 4.3 3.8 V

= 15mA 0.2 0.4 0.6 V

= 15mA 0.4 V

1MHz

C = 200pF

(NOTE 4)

-55°C TO +125°C

UNITSMIN TYP MAX MIN TYP MAX

Functional Diagram

V

DD

8

R

COMPARATOR

THRESHOLD

6

5

CONTROL

VOLTAGE

TRIGGER

2

R

R

GND

A

+

-

+

-

COMPARATOR

B

1

NOTE: This functional diagram reduces the circuitry down to its simplest equivalent components. Tie down unused inputs.

THRESHOLD VOLTAGE TRIGGER

VOLTAGE RESET OUTPUT DISCHARGE SWITCH

Don’t Care Don’t Care Low Low On

2

>

/3(V+) >1/3(V+) High Low On

2

<

/3(V+) >1/3(V+) High Stable Stable

Don’t Care <

1

/3(V+) High High Off

FLIP-FLOP

4

RESET

TRUTH TABLE

OUTPUT

DRIVERS

3

7

DISCHARGE

n

1

OUTPUT

NOTE: RESET

will dominate all other inputs: TRIGGER will dominate over THRESHOLD.

4

FN2867.9

August 24, 2006

Page 5

Schematic Diagram

ICM7555, ICM7556

PP P

R

V

P

DD

THRESHOLD

CONTROL

VOLTAGE

TRIGGER

R = 100kΩ ±20% (TYP)

NN

R

PP

R

Application Information

General

The ICM7555 and ICM7556 devices are, in most instances,

direct replacements for the NE/SE 555/6 devices. However,

it is possible to effect economies in the external component

count using the ICM7555 and ICM7556. Because the bipolar

NE/SE 555/6 devices produce large crowbar currents in the

output driver, it is necessary to decouple the power supply

lines with a good capacitor close to the device. The ICM7555

and ICM7556 devices produce no such transients. See

Figure 1.

500

400

300

200

100

SUPPLY CURRENT (mA)

FIGURE 1. SUPPLY CURRENT TRANSIENT COMPARED WITH

TA = 25°C

SE/NE555

0

ICM7555/56

400 8006002000

TIME (ns)

A STANDARD BIPOLAR 555 DURING AN OUTPUT

TRANSITION

NPN

NNNNN

RESET DISCHARGE

NN

The ICM7555 and ICM7556 produce supply current spikes

of only 2mA - 3mA instead of 300mA - 400mA and supply

decoupling is normally not necessary. Also, in most

instances, the CONTROL VOLTAGE decoupling capacitors

are not required since the input impedance of the CMOS

comparators on chip are very high. Thus, for many

applications, two capacitors can be saved using an ICM7555

and three capacitors with an ICM7556.

POWER SUPPLY CONSIDERATIONS

Although the supply current consumed by the ICM7555 and

ICM7556 devices is very low, the total system supply current

can be high unless the timing components are high

impedance. Therefore, use high values for R and low values

for C in Figures 2A, 2B, and 3.

GND

TRIGGER

OUTPUT

R

1

2

3

V

DD

4

RESET

FIGURE 2A. ASTABLE OPERATION

V

DD

8

DISCHARGE

7

THRESHOLD

6

5

C

OUTPUT

GND

V

CONTROL

VOLTAGE

OPTIONAL

CAPACITOR

DD

10K

ALTERNATE OUTPUT

5

FN2867.9

August 24, 2006

Page 6

ICM7555, ICM7556

V

DD

R

A

1

2

OUTPUT

V

DD

FIGURE 2B. ALTERNATE ASTABLE CONFIGURATION

3

4

C

8

7

6

R

5

B

OPTIONAL

CAPACITOR

OUTPUT DRIVE CAPABILITY

The output driver consists of a CMOS inverter capable of

driving most logic families including CMOS and TTL. As

such, if driving CMOS, the output swing at all supply

voltages will equal the supply voltage. At a supply voltage of

4.5V or more, the ICM7555 and ICM7556 will drive at least

two standard TTL loads.

ASTABLE OPERATION

The circuit can be connected to trigger itself and free run as

a multivibrator, see Figure 2A. The output swings from rail to

rail, and is a true 50% duty cycle square wave. (Trip points

and output swings are symmetrical.) Less than a 1%

frequency variation is observed over a voltage range of +5V

to +15V.

1

------------------

f

=

1.4 RC

(EQ. 1)

The timer can also be connected as shown in Figure 2B. In this

circuit, the frequency is:

f1.44RA2RB+()⁄ C=

The duty cycle is controlled by the values of R

and RB, by the

A

(EQ. 2)

equation:

DRARB+()RA2RB+()⁄=

(EQ. 3)

= -ln

(1/3) R

1

2

3

4

C = 1.1RAC

A

ICM7555

OPTIONAL

CAPACITOR

V

DD

8

DISCHARGE

7

THRESHOLD

6

CONTROL

VOLTAGE

5

R

A

C

t

OUTPUT

TRIGGER

OUTPUT

RESET

≤18V

V

DD

FIGURE 3. MONOSTABLE OPERATION

CONTROL VOLT AGE

The CONTROL VOLTAGE terminal permits the two trip

voltages for the THRESHOLD and TRIGGER

internal

comparators to be controlled. This provides the possibility of

oscillation frequency modulation in the astable mode or even

inhibition of oscillation, depending on the applied voltage. In

the monostable mode, delay times can be changed by

varying the applied voltage to the CONTROL VOLTAGE pin.

RESET

The RESET terminal is designed to have essentially the

same trip voltage as the standard bipolar 555/6, i.e., 0.6V to

0.7V. At all supply voltages it represents an extremely high

input impedance. The mode of operation of the RESET

function is, however, much improved over the standard

bipolar NE/SE 555/6 in that it controls only the internal flipflop, which in turn controls simultaneously the state of the

OUTPUT and DISCHARGE pins. This avoids the multiple

threshold problems sometimes encountered with slow falling

edges in the bipolar devices.

MONOSTABLE OPERATION

In this mode of operation, the timer functions as a one-shot.

See Figure 3. Initially the external capacitor (C) is held

discharged by a transistor inside the timer. Upon application of

a negative TRIGGER

pulse to pin 2, the internal flip-flop is set

which releases the short circuit across the external capacitor

and drives the OUTPUT high. The voltage across the capacitor

now increases exponentially with a time constant t = R

When the voltage across the capacitor equals

2

/3 V+, the

C.

A

comparator resets the flip-flop, which in turn discharges the

capacitor rapidly and also drives the OUTPUT to its low state.

TRIGGER

must return to a high state before the OUTPUT can

return to a low state.

6

FN2867.9

August 24, 2006

Page 7

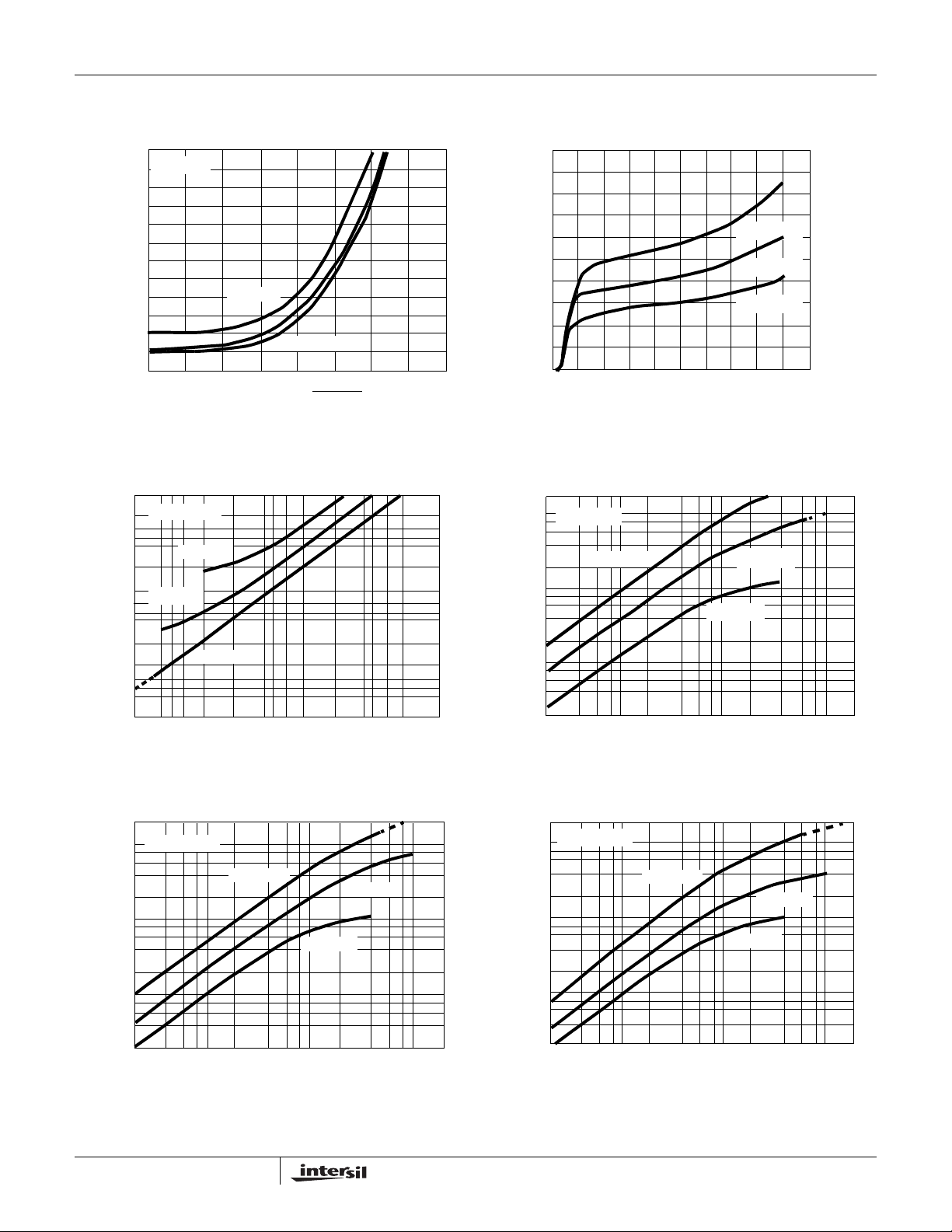

Typical Performance Curves

ICM7555, ICM7556

1200

TA = 25°C

1100

1000

900

800

700

600

500

400

300

MINIMUM PULSE WIDTH (ns)

200

VDD = 5V

100

0

010203040

LOWEST VOLTAGE LEVEL OF TRIGGER

VDD = 2V

VDD = 18V

PULSE (%VDD)

FIGURE 4. MINIMUM PULSE WIDTH REQUIRED FOR

TRIGGERING

-0.1

TA = 25°C

-1.0

VDD = 2V

VDD = 5V

200

180

160

140

120

100

80

60

40

SUPPLY CURRENT (ICM7555) (μA)

20

0

0 2 4 6 8 10121416 18 20

SUPPLY VOLTAGE (V)

TA = -20°C

TA = 25°C

TA = 70°C

FIGURE 5. SUPPLY CURRENT vs SUPPLY VOLTAGE

100

TA = -20°C

10.0

VDD = 18V

VDD = 5V

VDD = 2V

400

360

320

280

240

200

160

120

80

40

0

SUPPLY CURRENT (ICM7556) (μA)

1.0

OUTPUT SINK CURRENT (mA)

0.1

0.01 0.1 1.0 10.0

OUTPUT LOW VOLTAGE (V)

OUTPUT SOURCE CURRENT (mA)

-10.0

-100

VDD = 18V

OUTPUT VOLTAGE REFERENCED TO V

DD

-0.01-0.1-1.0-10

(V)

FIGURE 6. OUTPUT SOURCE CURRENT vs OUTPUT VOLTAGE FIGURE 7. OUTPUT SINK CURRENT vs OUTPUT VOLTAGE

100

TA = 25°C

VDD = 18V

10.0

1.0

OUTPUT SINK CURRENT (mA)

0.1

0.01 0.1 1.0 10.0

OUTPUT LOW VOLTAGE (V)

VDD = 5V

VDD = 2V

100

TA = 70°C

VDD = 18V

10.0

1.0

OUTPUT SINK CURRENT (mA)

0.1

0.01 0.1 1.0 10.0

OUTPUT LOW VOLTAGE (V)

VDD = 5V

VDD = 2V

FIGURE 8. OUTPUT SINK CURRENT vs OUTPUT VOLTAGE FIGURE 9. OUTPUT SINK CURRENT vs OUTPUT VOLTAGE

7

FN2867.9

August 24, 2006

Page 8

Typical Performance Curves (Continued)

8

TA = 25°C

6

4

2

0

RA = RB = 10MΩ

C = 100pF

ICM7555, ICM7556

100

10.0

TA = 25°C

VDD = 18V

VDD = 5V

VDD = 2V

2

4

6

NORMALIZED FREQUENCY DEVIATION (%)

8

0.1 1.0 10.0 100.0

RA = RB = 10kΩ

C = 0.1μF

SUPPLY VOLTAGE (V)

FIGURE 10. NORMALIZED FREQUENCY STABILITY IN THE

ASTABLE MODE vs SUPPLY VOLTAGE

600

VDD = 5V

500

400

300

200

PROPAGATION DELAY (ns)

100

0

TA = 70°C

TA = 25°C

TA = -20°C

010203040

LOWEST VOLTAGE LEVEL OF TRIGGER

PULSE (%VDD)

FIGURE 12. PROPAGATION DELAY vs VOLTAGE LEVEL OF

TRIGGER PULSE

1.0

DISCHARGE SINK CURRENT (mA)

0.1

0.01 0.1 1.0 10.0

DISCHARGE LOW VOLTAGE (V)

FIGURE 11. DISCHARGE OUTPUT CURRENT vs DISCHARGE

OUTPUT VOLTAGE

+1.0

+0.9

+0.8

+0.7

+0.6

+0.5

+0.4

+0.3

+0.2

+0.1

NORMALIZED FREQUENCY DEVIATION (%)

-0.1

RA = RB = 10kΩ

C = 0.1μF

VDD = 2V

0

VDD = 5V

VDD = 18V

VDD = 2V

06080

TEMPERATURE (°C)

4020-20

FIGURE 13. NORMALIZED FREQUENCY STABILITY IN THE

ASTABLE MODE vs TEM PER ATURE

1.0

TA = 25°C

(RA + 2RB)

100.1 1 100 1k 10k 100k 1M 10M

FREQUENCY (Hz)

CAPACITANCE (F)

100m

10m

1m

100μ

10μ

1μ

100n

10n

1n

100p

10p

1p

FIGURE 14. FREE RUNNING FREQUENCY vs R

8

1kΩ

10kΩ

100kΩ

1MΩ

10MΩ

100MΩ

, RB AND C

A

1.0

1m

1μ

1n

1p

TA = 25°C

1kΩ

10kΩ

100kΩ

1MΩ

10MΩ

100MΩ

10μ100n 1μ 100μ 1m 10m 100m 1 10

TIME DELAY (s)

R

A

CAPACITANCE (F)

100m

10m

100μ

10μ

100n

10n

100p

10p

FIGURE 15. TIME DELAY IN THE MONOSTABLE MODE vs

AND C

R

A

August 24, 2006

FN2867.9

Page 9

ICM7555, ICM7556

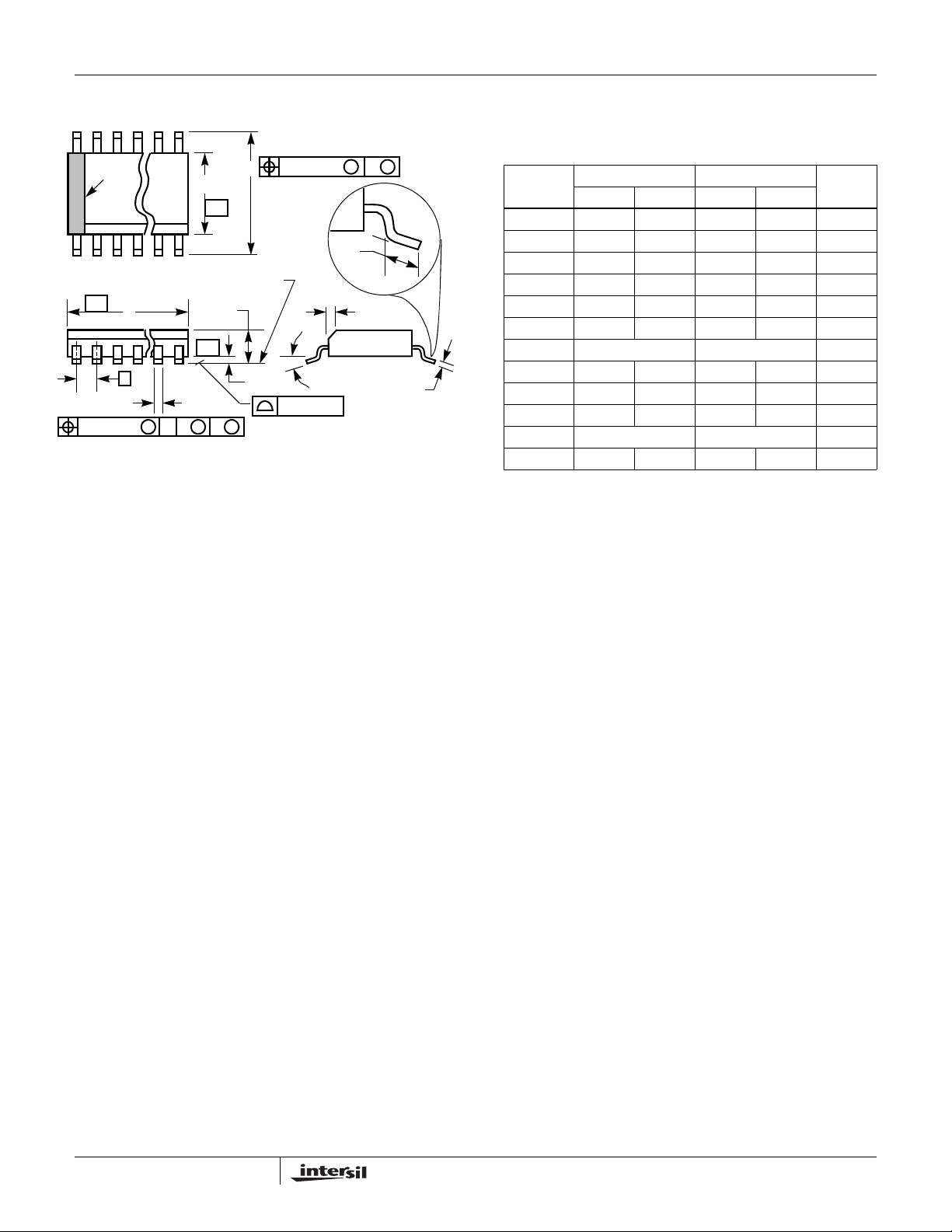

Small Outline Plastic Packages (SOIC)

N

INDEX

AREA

123

-A-

E

-B-

SEATING PLANE

D

A

-C-

0.25(0.010) BM M

H

L

h x 45°

α

e

B

0.25(0.010) C AM BS

M

NOTES:

1. Symbols are defined in the “MO Series Symbol List” in Section 2.2 of

Publication Number 95.

2. Dimensioning and tolerancing per ANSI Y14.5M-1982.

3. Dimension “D” does not include mold flash, protrusions or gate burrs.

Mold flash, protrusion and gate burrs shall not exceed 0.15mm (0.006

inch) per side.

4. Dimension “E” does not include interlead flash or protrusions. Interlead flash and protrusions shall not exceed 0.25mm (0.010 inch) per

side.

5. The chamfer on the body is optional. If it is not present, a visual index

feature must be located within the crosshatched area.

6. “L” is the length of terminal for soldering to a substrate.

7. “N” is the number of terminal positions.

8. Terminal numbers are shown for reference only.

9. The lead width “B”, as measured 0.36mm (0.014 inch) or greater

above the seating plane, shall not exceed a maximum value of

0.61mm (0.024 inch).

10. Controlling dimension: MILLIMETER. Converted inch dimensions

are not necessarily exact.

A1

C

0.10(0.004)

M8.15 (JEDEC MS-012-AA ISSUE C)

8 LEAD NARROW BODY SMALL OUTLINE PLASTIC PACKAGE

INCHES MILLIMETERS

SYMBOL

A 0.0532 0.0688 1.35 1.75 -

A1 0.0040 0.0098 0.10 0.25 -

B 0.013 0.020 0.33 0.51 9

C 0.0075 0.0098 0.19 0.25 -

D 0.1890 0.1968 4.80 5.00 3

E 0.1497 0.1574 3.80 4.00 4

e 0.050 BSC 1.27 BSC -

H 0.2284 0.2440 5.80 6.20 -

h 0.0099 0.0196 0.25 0.50 5

L 0.016 0.050 0.40 1.27 6

N8 87

α

0° 8° 0° 8° -

NOTESMIN MAX MIN MAX

Rev. 1 6/05

9

FN2867.9

August 24, 2006

Page 10

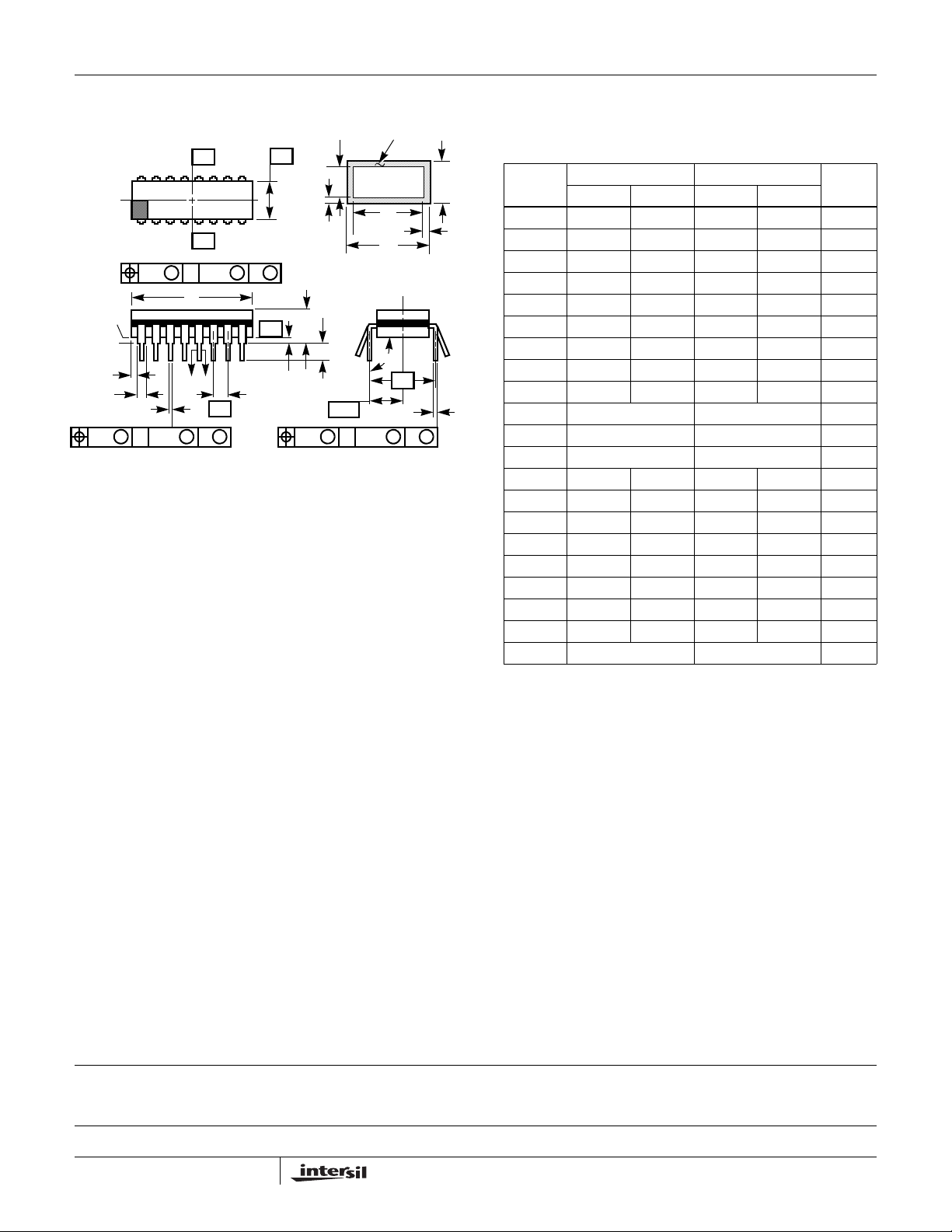

Dual-In-Line Plastic Packages (PDIP)

ICM7555, ICM7556

N

D1

-C-

E1

-B-

A2

A

L

A

1

e

C

e

e

INDEX

AREA

BASE

PLANE

SEATING

PLANE

D1

B1

12 3 N/2

-AD

e

B

0.010 (0.25) C AM BS

NOTES:

1. Controlling Dimensions: INCH. In case of conflict between

English and Metric dimensions, the inch dimensions control.

2. Dimensioning and tolerancing per ANSI Y14.5M-1982.

3. Symbols are defined in the “MO Series Symbol List” in Section

2.2 of Publication No. 95.

4. Dimensions A, A1 and L are measured with the package seated

in JEDEC seating plane gauge GS-3.

5. D, D1, and E1 dimensions do not include mold flash or protrusions. Mold flash or protrusions shall not exceed 0.010 inch

(0.25mm).

6. E and are measured with the leads constrained to be per-

7. e

e

pendicular to datum .

A

and eC are measured at the lead tips with the leads uncon-

B

strained. e

must be zero or greater.

C

-C-

8. B1 maximum dimensions do not include dambar protrusions.

Dambar protrusions shall not exceed 0.010 inch (0.25mm).

9. N is the maximum number of terminal positions.

10. Corner leads (1, N, N/2 and N/2 + 1) for E8.3, E16.3, E18.3,

E28.3, E42.6 will have a B1 dimension of 0.030 - 0.045 inch

(0.76 - 1.14mm).

E8.3 (JEDEC MS-001-BA ISSUE D)

8 LEAD DUAL-IN-LINE PLASTIC PACKAGE

INCHES MILLIMETERS

SYMBOL

A-0.210 - 5.33 4

E

A1 0.015 - 0.39 -4

A2 0.115 0.195 2.93 4.95 -

B 0.014 0.022 0.356 0.558 -

C

L

A

C

B

B1 0.045 0.070 1.15 1.77 8, 10

C 0.008 0.014 0.204 0.355 D 0.355 0.400 9.01 10.16 5

D1 0.005 - 0.13 -5

E 0.300 0.325 7.62 8.25 6

E1 0.240 0.280 6.10 7.11 5

e 0.100 BSC 2.54 BSC -

e

A

e

B

0.300 BSC 7.62 BSC 6

- 0.430 - 10.92 7

L 0.115 0.150 2.93 3.81 4

N8 89

NOTESMIN MAX MIN MAX

Rev. 0 12/93

10

FN2867.9

August 24, 2006

Page 11

Dual-In-Line Plastic Packages (PDIP)

ICM7555, ICM7556

N

D1

-C-

E1

-B-

A1

A2

E

A

L

e

C

C

L

e

A

C

e

B

INDEX

AREA

BASE

PLANE

SEATING

PLANE

D1

B1

12 3 N/2

-AD

e

B

0.010 (0.25) C AM BS

NOTES:

1. Controlling Dimensions: INCH. In case of conflict between English

and Metric dimensions, the inch dimensions control.

2. Dimensioning and tolerancing per ANSI Y14.5M-1982.

3. Symbols are defined in the “MO Series Symbol List” in Section 2.2 of

Publication No. 95.

4. Dimensions A, A1 and L are measured with the package seated in

JEDEC seating plane gauge GS-3.

5. D, D1, and E1 dimensions do not include mold flash or protrusions.

Mold flash or protrusions shall not exceed 0.010 inch (0.25mm).

6. E and are measured with the leads constrained to be perpen-

7. e

e

dicular to datum .

A

and eC are measured at the lead tips with the leads uncon-

B

strained. e

-C-

must be zero or greater.

C

8. B1 maximum dimensions do not include dambar protrusions. Dambar

protrusions shall not exceed 0.010 inch (0.25mm).

9. N is the maximum number of terminal positions.

10. Corner leads (1, N, N/2 and N/2 + 1) for E8.3, E16.3, E18.3, E28.3,

E42.6 will have a B1 dimension of 0.030 - 0.045 inch (0.76 -

1.14mm).

E14.3 (JEDEC MS-001-AA ISSUE D)

14 LEAD DUAL-IN-LINE PLASTIC PACKAGE

INCHES MILLIMETERS

SYMBOL

A-0.210 - 5.33 4

A1 0.015 - 0.39 -4

A2 0.115 0.195 2.93 4.95 -

B 0.014 0.022 0.356 0.558 B1 0.045 0.070 1.15 1.77 8

C 0.008 0.014 0.204 0.355 -

D 0.735 0.775 18.66 19.68 5

D1 0.005 - 0.13 -5

E 0.300 0.325 7.62 8.25 6

E1 0.240 0.280 6.10 7.11 5

e 0.100 BSC 2.54 BSC -

e

A

e

B

0.300 BSC 7.62 BSC 6

- 0.430 - 10.92 7

L 0.115 0.150 2.93 3.81 4

N14 149

NOTESMIN MAX MIN MAX

Rev. 0 12/93

11

FN2867.9

August 24, 2006

Page 12

ICM7555, ICM7556

Ceramic Dual-In-Line Frit Seal Packages (CERDIP)

LEAD FINISH

c1

-A-

-B-

bbb C A - B

S

BASE

PLANE

SEATING

PLANE

S1

b2

b

ccc C A - BMD

D

A

A

e

S

S

NOTES:

1. Index area: A notch or a pin one identification mark shall be located adjacent to pin one and shall be located within the shaded

area shown. The manufacturer’s identification shall not be used

as a pin one identification mark.

2. The maximum limits of lead dimensions b and c or M shall be

measured at the centroid of the finished lead surfaces, when

solder dip or tin plate lead finish is applied.

3. Dimensions b1 and c1 apply to lead base metal only. Dimension

M applies to lead plating and finish thickness.

4. Corner leads (1, N, N/2, and N/2+1) may be configured with a

partial lead paddle. For this configuration dimension b3 replaces

dimension b2.

5. This dimension allows for off-center lid, meniscus, and glass

overrun.

6. Dimension Q shall be measured from the seating plane to the

base plane.

7. Measure dimension S1 at all four corners.

8. N is the maximum number of terminal positions.

9. Dimensioning and tolerancing per ANSI Y14.5M - 1982.

10. Controlling dimension: INCH.

-DBASE

E

D

S

S

Q

A

-CL

METAL

b1

M

(b)

SECTION A-A

α

(c)

M

eA

eA/2

aaa CA - B

M

c

D

S

S

F14.3 MIL-STD-1835 GDIP1-T14 (D-1, CONFIGURATION A)

14 LEAD CERAMIC DUAL-IN-LINE FRIT SEAL PACKAGE

INCHES MILLIMETERS

SYMBOL

A-0.200 - 5.08 -

b 0.014 0.026 0.36 0.66 2

b1 0.014 0.023 0.36 0.58 3

b2 0.045 0.065 1.14 1.65 b3 0.023 0.045 0.58 1.14 4

c 0.008 0.018 0.20 0.46 2

c1 0.008 0.015 0.20 0.38 3

D-0.785 - 19.94 5

E 0.220 0.310 5.59 7.87 5

e 0.100 BSC 2.54 BSC eA 0.300 BSC 7.62 BSC -

eA/2 0.150 BSC 3.81 BSC -

L 0.125 0.200 3.18 5.08 -

Q 0.015 0.060 0.38 1.52 6

S1 0.005 - 0.13 -7

α

90° 105° 90° 105° aaa - 0.015 - 0.38 bbb - 0.030 - 0.76 ccc - 0.010 - 0.25 -

M-0.0015 - 0.038 2, 3

N14 148

NOTESMIN MAX MIN MAX

Rev. 0 4/94

All Intersil U.S. products are manufactured, assembled and tested utilizing ISO9000 quality systems.

Intersil Corporation’s quality certifications can be viewed at www.intersil.com/design/quality

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design, software and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate and

reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result

from its use. No license is granted by implicat ion or oth erwise u nde r any p a tent or p at ent r ights of Intersil or its subsidiari es.

For information regarding Intersil Corporation and its products, see www.intersil.com

12

FN2867.9

August 24, 2006

Loading...

Loading...