Page 1

Isolated 15-bit A/D Converter

Technical Data

Features

• 12-bit Linearity

• 700 ns Conversion Time

(Pre-Trigger Mode 2)

• 5 Conversion Modes for

Resolution/Speed Trade-Off;

12-bit Effective Resolution

with 18 µs Signal Delay

(14-bit with 94 µs)

• Fast 3 µs Over-Range

Detection

• Serial I/O (SPI®, QSPI® and

Microwire® Compatible)

• ±200 mV Input Range with

Single 5 V Supply

• 1% Internal Reference

Voltage Matching

H

HCPL-7860

HCPL-0870, -7870

• Offset Calibration

• -40°C to +85°C Operating

Temperature Range

• 15 kV/µs Isolation Transient

Immunity

• Regulatory Approvals; UL,

CSA, VDE

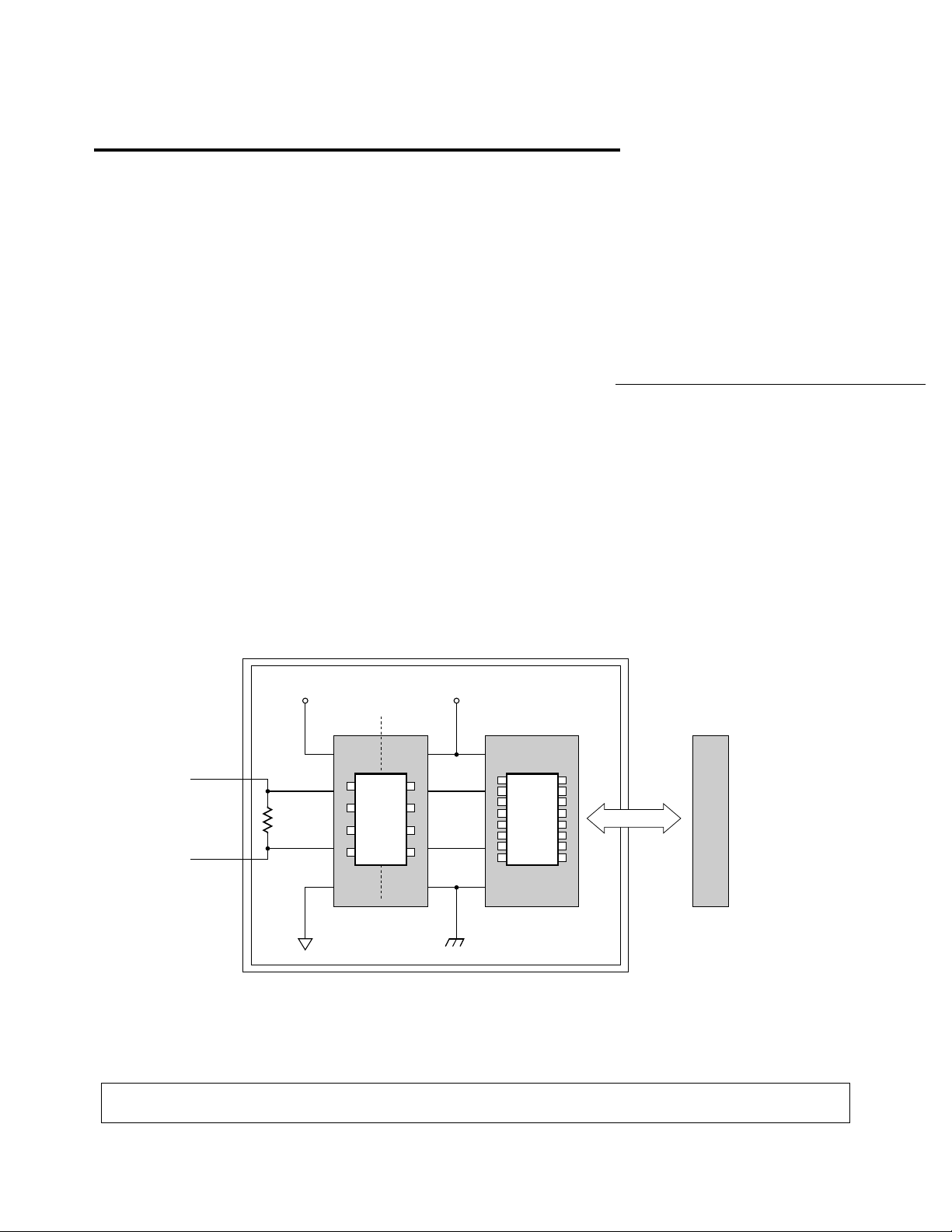

DIGITAL CURRENT SENSOR

++

YYWW

HPx870

DIGITAL

INTERFACE IC

OUTPUT

DATA

MICRO-CONTROLLER

INPUT

CURRENT

ISOLATION

BOUNDARY

YYWW

HP7860

ISOLATED

MODULATOR

Hewlett-Packard’s Isolated A/D Converter delivers the reliability, small size, superior

isolation and over-temperature performance motor drive designers need to accurately

measure current at half the price of traditional solutions.

CAUTION: It is advised that normal static precautions be taken in handling and assembly of this component to

prevent damage and/or degradation which may be induced by ESD.

SPI and QSPI are trademarks of Motorola Corp.

Microwire is a trademark of National Semiconductor Inc.

1-260

5965-5255E

Page 2

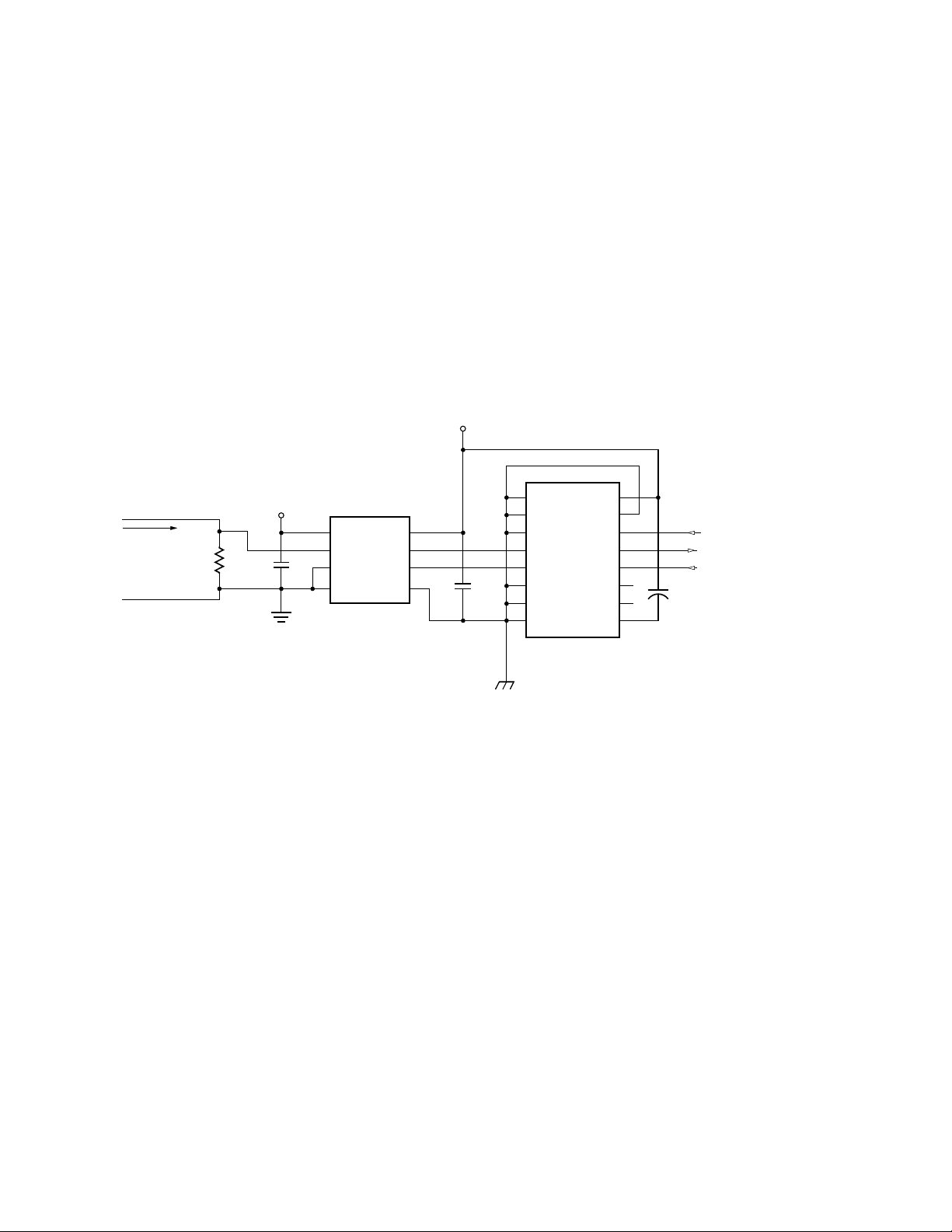

Digital Current Sensing Circuit

As shown in Figure 1, using the

Isolated 2-chip A/D converter to

sense current can be as simple as

connecting a current-sensing

resistor, or shunt, to the input

and reading output data through

the 3-wire serial output interface.

By choosing the appropriate

shunt resistance, any range of

current can be monitored, from

less than 1 A to more than 100 A.

Even better performance can be

achieved by fully utilizing the

more advanced features of the

Isolated A/D converter, such as

the pre-trigger circuit which can

reduce conversion time to less

NON-ISOLATED

+ 5 V

than 1 µs, the fast over-range

detector for quickly detecting

short circuits, different conversion

modes giving various resolution/

speed trade-offs, offset calibration mode to eliminate initial

offset from measurements, and

an adjustable threshold detector

for detecting non-short circuit

overload conditions.

ISOLATED

+ 5 V

R

SHUNT

0.02

+

C1

0.1 µF

INPUT

CURRENT

Figure 1: Typical Application Circuit.

Product Overview

Description

The HCPL-7860 Isolated Modulator and the HCPL-x870 Digital

Interface IC together form an

isolated programmable two-chip

analog-to-digital converter. The

isolated modulator allows direct

measurement of motor phase

currents in power inverters while

the digital interface IC can be

programmed to optimize the

conversion speed and resolution

trade-off.

In operation, the HCPL-7860

Isolated Modulator (optocoupler

with 3750 V

stand voltage rating) converts a

dielectric with-

RMS

V

V

DD1

MCLK

IN+

MDAT

IN-

GND2

HCPL-7860

DD2

C2

0.1 µF

V

V

GND1

low-bandwidth analog input into

a high-speed one-bit data stream

by means of a sigma-delta (∑∆)

oversampling modulator. This

modulation provides for high

noise margins and excellent

immunity against isolation-mode

transients. The modulator data

and on-chip sampling clock are

encoded and transmitted across

the isolation boundary where they

are recovered and decoded into

separate high-speed clock and

data channels.

The Digital Interface IC converts

the single-bit data stream from

the Isolated Modulator into

fifteen-bit output words and

provides a serial output interface

CCLK V

CLAT CHAN

CDAT SCLK

MCLK1 SDAT

MDAT1 CS

MCLK2 THR1

MDAT2 OVR1

GND RESET

HCPL-x870

DD

3-WIRE

SERIAL

INTERFACE

+

C3

10 µF

that is compatible with SPI®,

QSPI®, and Microwire® protocols, allowing direct connection

to a microcontroller. The Digital

Interface IC is available in two

package styles: the HCPL-7870 is

in a 16-pin DIP package and the

HCPL-0870 is in a 300-mil wide

SO-16 surface-mount package.

Features of the Digital Interface

IC include five different conversion modes, three different pretrigger modes, offset calibration,

fast over-range detection, and

adjustable threshold detection.

Programmable features are configured via the Serial Configuration port. A second multiplexed

input is available to allow

measurements with a second

1-261

Page 3

isolated modulator without

additional hardware. Because the

two inputs are multiplexed, only

one conversion at a time can be

made and not all features are

available for the second channel.

The available features for both

channels are shown in the table

at right.

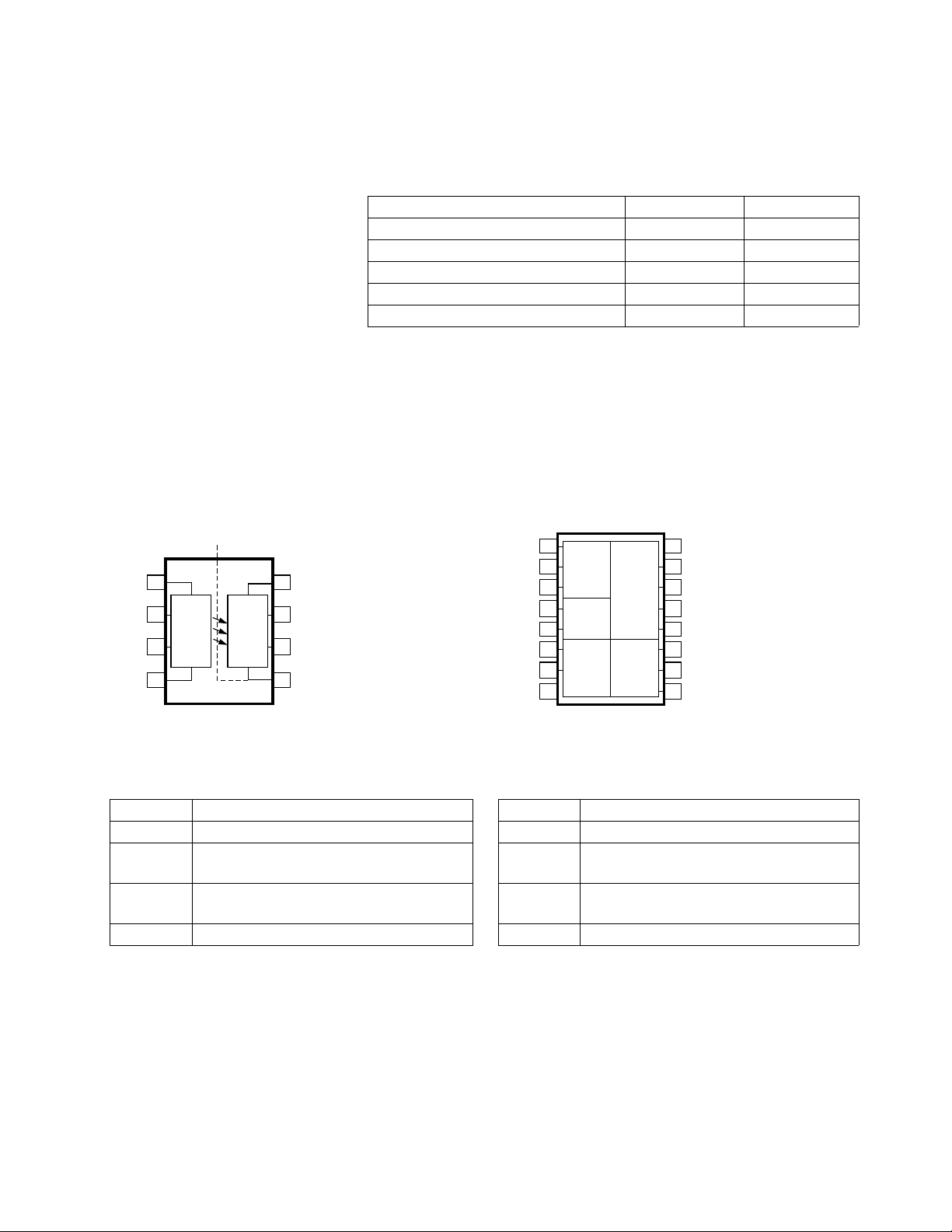

Functional Diagrams

ISOLATION

BOUNDARY

V

DD1

V

IN+

V

IN–

GND1

1

2

3

4

SIGMA-

DELTA

MOD./

ENCODE

DECODE

SHIELD

V

8

DD2

7

MCLK

6

MDAT

GND2

5

HCPL-x870 Digital Interface IC

Feature Channel #1 Channel #2

Conversion Mode ✓✓

Offset Calibration ✓✓

Pre-Trigger Mode ✓

Over-Range Detection ✓

Adjustable Threshold Detection ✓

CCLK

1

2

3

4

5

6

7

8

CONFIG.

INTER-

FACE

CH1

CH2

CON-

VERSION

INTER-

FACE

THRES-

HOLD

DETECT

&

RESET

CLAT

CDAT SCLK

MCLK1 SDAT

MDAT1

MCLK2

MDAT2 OVR1

GND RESET

V

16

DD

15

CHAN

14

13

CS

12

11

THR1

10

9

HCPL-7860 Isolated Modulator

HCPL-x870 Digital Interface IC

Pin Description, Isolated Modulator

Symbol Description Symbol Description

V

DD1

V

IN+

V

IN–

GND1 Input ground GND2 Output ground

Supply voltage input (4.5 V to 5.5 V) V

DD2

Supply voltage input (4.5 V to 5.5 V)

Positive input (± 200 mV MCLK Clock output (10 MHz typical)

recommended)

Negative input MDAT Serial data output

(normally connected to GND1)

1-262

Page 4

Pin Description, Digital Interface IC

Symbol Description

CCLK Clock input for the Serial Configuration

Interface (SCI). Serial Configuration

data is clocked in on the rising edge

of CCLK.

CLAT Latch input for the Serial Configuration

Interface (SCI). The last 8 data bits

clocked in on CDAT by CCLK are

latched into the appropriate

configuration register on the rising

edge of CLAT.

CDAT Data input for the Serial Configuration

Interface (SCI). Serial configuration

data is clocked in MSB first.

MCLK1 Channel 1 Isolated Modulator clock

input. Input Data on MDAT1 is clocked

in on the rising edge of MCLK1.

MDAT1 Channel 1 Isolated Modulator data

input.

MCLK2 Channel 2 Isolated Modulator clock

input. Input Data on MDAT2 is clocked

in on the rising edge of MCLK2.

MDAT2 Channel 2 Isolated Modulator data

input.

GND Digital ground.

Symbol Description

V

Supply voltage (4.5 V to 5.5 V).

DD

CHAN Channel select input. The input level on

CHAN determines which channel of

data is used during the next conversion

cycle. An input low selects channel 1,

a high selects channel 2.

SCLK Serial clock input. Serial data is clocked

out of SDAT on the falling edge of SCLK.

SDAT Serial data output. SDAT changes from

high impedance to a logic low output

at the start of a conversion cycle.

SDAT then goes high to indicate that

data is ready to be clocked out. SDAT

returns to a high-impedance state after

all data has been clocked out and CS

has been brought high.

CS Conversion start input. Conversion

begins on the falling edge of CS. CS

should remain low during the entire

conversion cycle and then be brought

high to conclude the cycle.

THR1 Continuous, programmable-threshold

detection for channel 1 input data. A

high level output on THR1 indicates

that the magnitude of the channel 1

input signal is beyond a user

programmable threshold level between

160 mV and 310 mV. This signal

continuously monitors channel 1

independent of the channel select

(CHAN) signal.

OVR1 High speed continuous over-range

detection for channel 1 input data. A

high level output on OVR1 indicates

that the magnitude of the channel 1

input is beyond full-scale. This signal

continuously monitors channel 1

independent of the CHAN signal.

RESET Master reset input. A logic high input

for at least 100 ns asynchronously

resets all configuration registers to

their default values and zeroes the

Offset Calibration registers.

1-263

Page 5

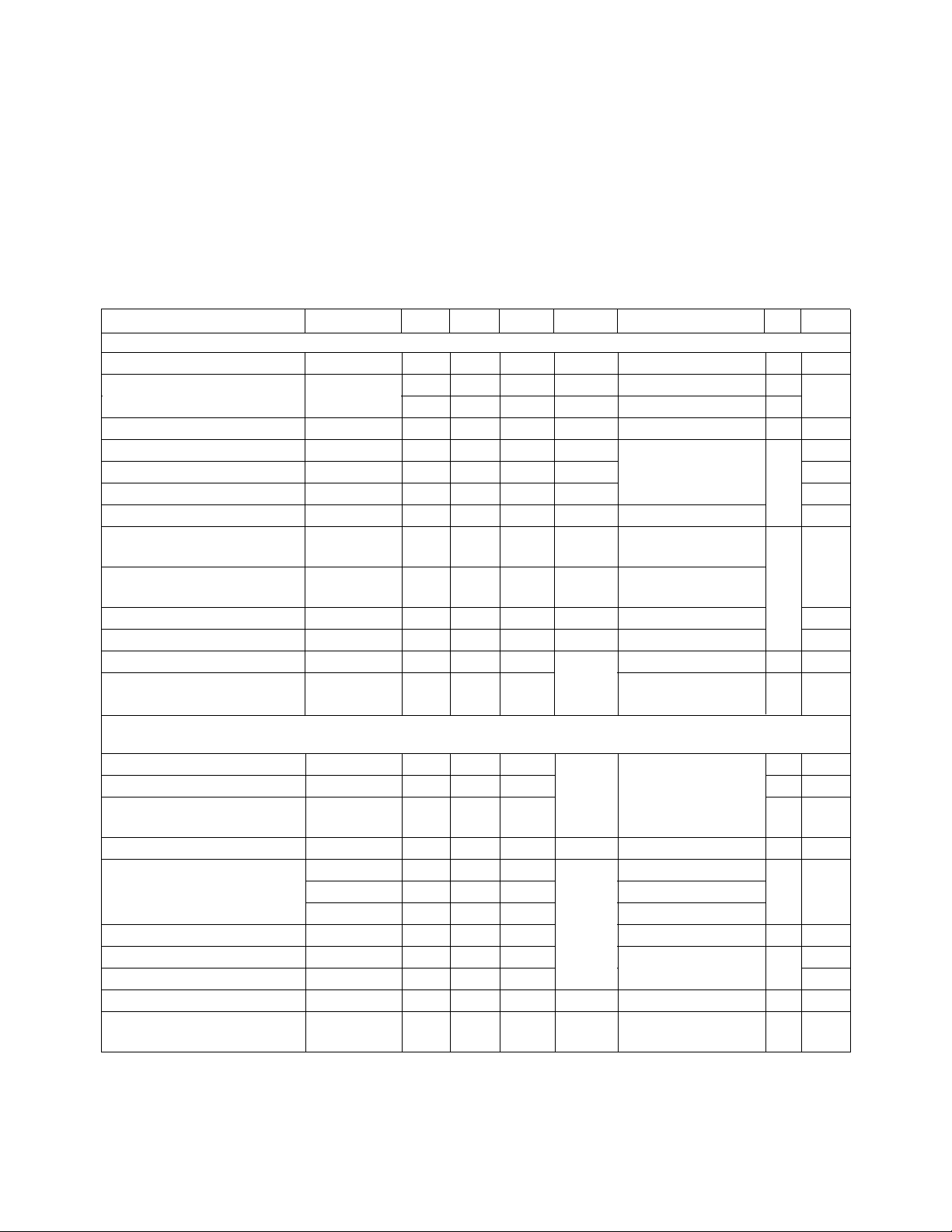

Isolated A/D Converter Performance

Electrical Specifications

Unless otherwise noted, all specifications are at V

specifications are at TA = 25°C and V

TA = -40°C to +85°C, V

DD1

= V

DD2

= V

DD1

DD2

= VDD = 4.5 to 5.5 V.

Parameter Symbol Min. Typ. Max. Units Test Conditions Fig. Note

STATIC CONVERTER CHARACTERISTICS

Resolution 15 bits 1

Integral Nonlinearity INL 6 30 LSB 3 2

Differential Nonlinearity DNL 1 LSB 3

Uncalibrated Input Offset V

OS

Offset Drift vs. Temperature dVOS/dT

Offset drift vs. V

DD1

Internal Reference Voltage V

dVOS/dV

REF

DD1

-1 1 2.5 mV V

A

Absolute Reference Voltage -4 4 % 6 5

Tolerance

Reference Voltage -1 1 % TA = 25°C.

Matching See Note 5

V

Drift vs. Temperature dV

REF

V

Drift vs. V

REF

DD1

dV

Full Scale Input Range -V

REF

REF

/dT

/dV

A

DD1

REF

Recommended Input -200 +200

Voltage Range

DYNAMIC CONVERTER CHARACTERISTICS

(Digital Interface IC is set to Conversion Mode 3.)

Signal-to-Noise Ratio SNR 62 73 dB V

Total Harmonic Distortion THD -67

Signal-to-(Noise SND 66

+ Distortion)

Effective Number of Bits ENOB 10 12 bits 8 7

Conversion Time t

Signal Delay t

Over-Range Detect Time t

Threshold Detect Time t

Signal Bandwidth BW 18 22 kHz 11 12

Isolation Transient CMR 15 20 kV/µsV

Immunity

C2

t

C1

t

C0

DSIG

OVR1

THR1

2.0 2.7 4.2 V

= -200 mV to +200 mV and V

IN+

= 0 V; all Typical

IN-

= VDD = 5 V; all Minimum/Maximum specifications are at

0.025 0.14 % 4

= 0 V 5

IN+

4 µV/°C4

0.7 mV/V

326 mV

190 ppm/°C

0.9 %

+V

REF

mV 6

= 35 Hz, 2,9

IN+

400 mV

(141 mV

pk-pk

rms

) sine

wave.

0.7 1.0 µs Pre-Trigger Mode 2 7, 8

18 22 Pre-Trigger Mode 1

14

37 44 Pre-Trigger Mode 0

18 22 10 9

= 0 to 400 mV 12 10

IN+

10 11

step waveform

= 1 kV 13

ISO

1-264

Page 6

Notes:

1. Resolution is defined as the total

number of output bits. The useable

accuracy of any A/D converter is a

function of its linearity and signal-tonoise ratio, rather than how many

total bits it has.

2. Integral nonlinearity is defined as

one-half the peak-to-peak deviation

of the best-fit line through the

transfer curve for V

+200 mV, expressed either as the

= -200 mV to

IN+

number of LSBs or as a percent of

measured input range (400 mV).

3. Differential nonlinearity is defined as

the deviation of the actual difference

from the ideal difference between

midpoints of successive output

codes, expressed in LSBs.

4. Data sheet value is the average

magnitude of the difference in offset

voltage from TA=25°C to

TA= -40°C, expressed in microvolts

per °C.

5. All units within each HCPL-7860

standard packaging increment (either

50 per tube or 1000 per reel) have an

Absolute Reference Voltage tolerance

of ±1%. An Absolute Reference

Voltage tolerance of ± 4% is

guaranteed between standard

packaging increments.

6. Beyond the full-scale input range the

output is either all zeroes or all ones.

7. The effective number of bits (or

effective resolution) is defined by the

equation ENOB = (SNR-1.76)/6.02

and represents the resolution of an

ideal, quantization-noise limited A/D

converter with the same SNR.

8. Conversion time is defined as the

time from when the convert start

signal CS is brought low to when

SDAT goes high, indicating that

output data is ready to be clocked

out. This can be as small as a few

cycles of the isolated modulator clock

and is determined by the frequency of

the isolated modulator clock and the

selected Conversion and Pre-Trigger

modes. For determining the true

signal delay characteristics of the A/D

converter for closed-loop phase

margin calculations, the signal delay

specification should be used.

9. Signal delay is defined as the effective delay of the input signal through

the Isolated A/D converter. It can be

measured by applying a -200 mV to

± 200 mV step at the input of modulator and adjusting the relative delay

of the convert start signal CS so that

the output of the converter is at midscale. The signal delay is the elapsed

time from when the step signal is

applied at the input to when output

data is ready at the end of the conversion cycle. The signal delay is the

most important specification for

determining the true signal delay

characteristics of the A/D converter

and should be used for determining

phase margins in closed-loop applications. The signal delay is determined

by the frequency of the modulator

clock and which Conversion Mode is

selected, and is independent of the

selected Pre-Trigger Mode and,

therefore, conversion time.

10. The minimum and maximum overrange detection time is determined by

the frequency of the channel 1 isolated modulator clock.

11. The minimum and maximum threshold detection time is determined by

the user-defined configuration of the

adjustable threshold detection circuit

and the frequency of the channel 1

isolated modulator clock. See the

Applications Information section for

further detail. The specified times

apply for the default configuration.

12. The signal bandwidth is the frequency

at which the magnitude of the output

signal has decreased 3 dB below its

low-frequency value. The signal

bandwidth is determined by the frequency of the modulator clock and

the selected Conversion Mode.

13. The isolation transient immunity (also

known as Common-Mode Rejection)

specifies the minimum rate-of-rise of

an isolation-mode signal applied

across the isolation boundary beyond

which the modulator clock or data

signals are corrupted.

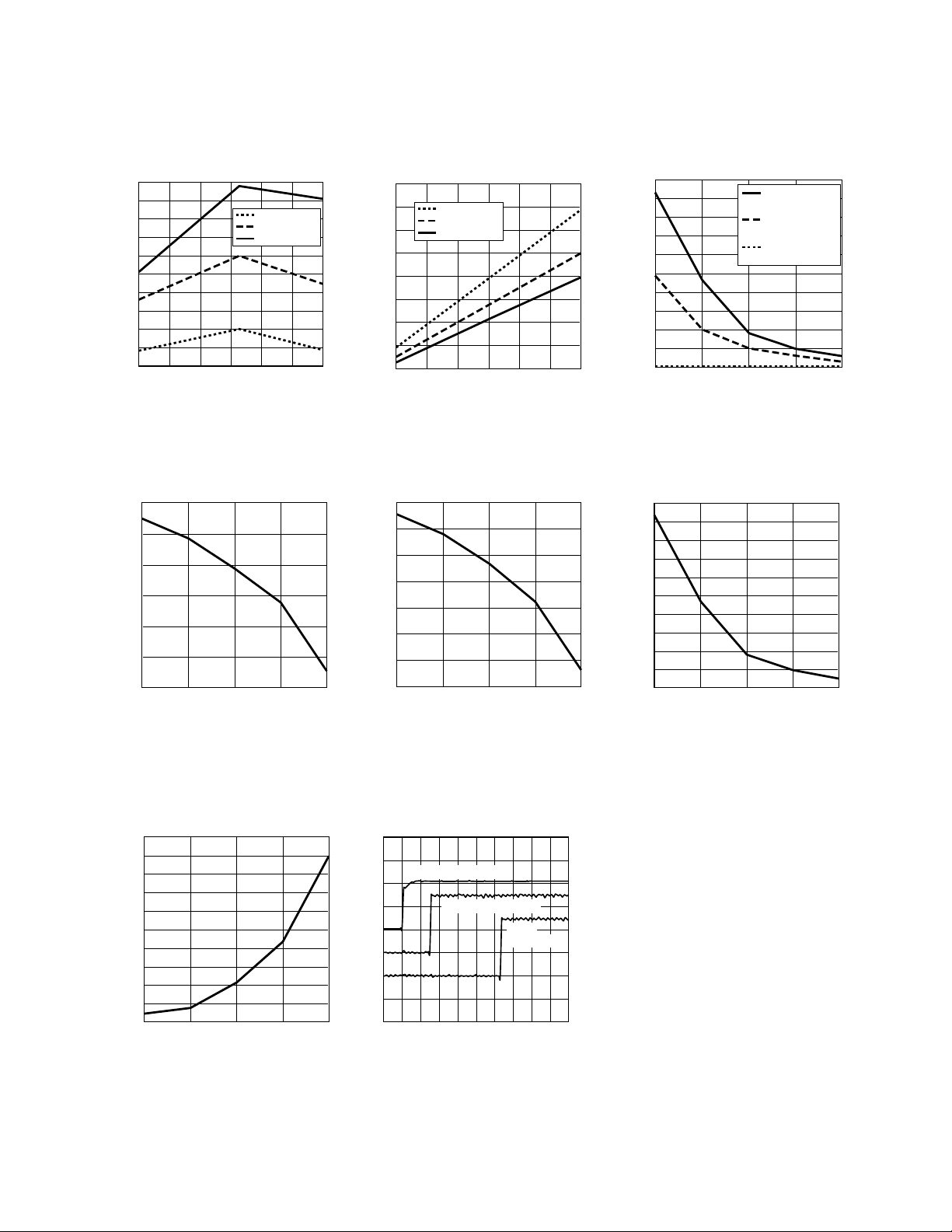

75.0

V

= 4.5 V

DD1

= 5.0 V

74.5

74.0

SNR

73.5

73.0

72.5

-40 85040

V

DD1

V

= 5.5 V

DD1

-20

20 60

TEMPERATURE – °C

Figure 2. SNR vs. Temperature.

16

14

12

10

8

6

INL – LSB

4

2

0

-40 85040

V

= 4.5 V

DD1

= 5.0 V

V

DD1

V

= 5.5 V

DD1

-20

20 60

TEMPERATURE – °C

Figure 3. INL (Bits) vs. Temperature.

0.08

0.07

0.06

0.05

0.04

INL – %

0.03

0.02

0.01

0

-40 85040

V

= 4.5 V

DD1

= 5.0 V

V

DD1

V

= 5.5 V

DD1

-20

20 60

TEMPERATURE – °C

Figure 4. INL (%) vs. Temperature.

1-265

Page 7

400

300

200

100

0

-100

-200

-300

OFFSET CHANGE – µV

-400

-500

-600

-40 85

040

-20

TEMPERATURE – °C

V

DD1

V

DD1

V

DD1

20 60

= 4.5 V

= 5.0 V

= 5.5 V

2.5

2.0

1.5

1.0

0.5

CHANGE – %

0

REF

V

-0.5

-1.0

-1.5

-40 85040

V

= 4.5 V

DD1

= 5.0 V

V

DD1

V

= 5.5 V

DD1

-20

20 60

TEMPERATURE – °C

200

180

160

140

120

100

80

60

40

CONVERSION TIME – µs

20

0

15

2

CONVERSION MODE #

PRE-TRIGGER

MODE 0

PRE-TRIGGER

MODE 1

PRE-TRIGGER

MODE 2

34

Figure 5. Offset Change vs.

Temperature.

14

13

12

11

10

9

EFFECTIVE RESOLUTION (# BITS)

8

15

2

34

CONVERSION MODE #

Figure 8. Effective Resolution vs.

Conversion Mode.

100

90

80

70

60

50

40

30

20

SIGNAL BANDWIDTH – kHz

10

0

2

15

CONVERSION MODE #

34

Figure 6. V

Temperature.

85

80

75

70

SNR

65

60

55

50

15

Figure 9. SNR vs. Conversion Mode.

V

IN+

Change vs.

REF

2

34

CONVERSION MODE #

(200 mV/DIV.)

OVR1 (200 mV/DIV.)

THR1

(2 V/DIV.)

2

s/DIV.

Figure 7. Conversion Time vs.

Conversion Mode.

100

90

80

70

60

50

40

30

SIGNAL DELAY – µs

20

10

0

2

15

CONVERSION MODE #

34

Figure 10. Signal Delay vs.

Conversion Mode.

Figure 11. Signal Bandwidth vs.

Conversion Mode.

1-266

Figure 12. Over-Range and Threshold

Detect Times.

Page 8

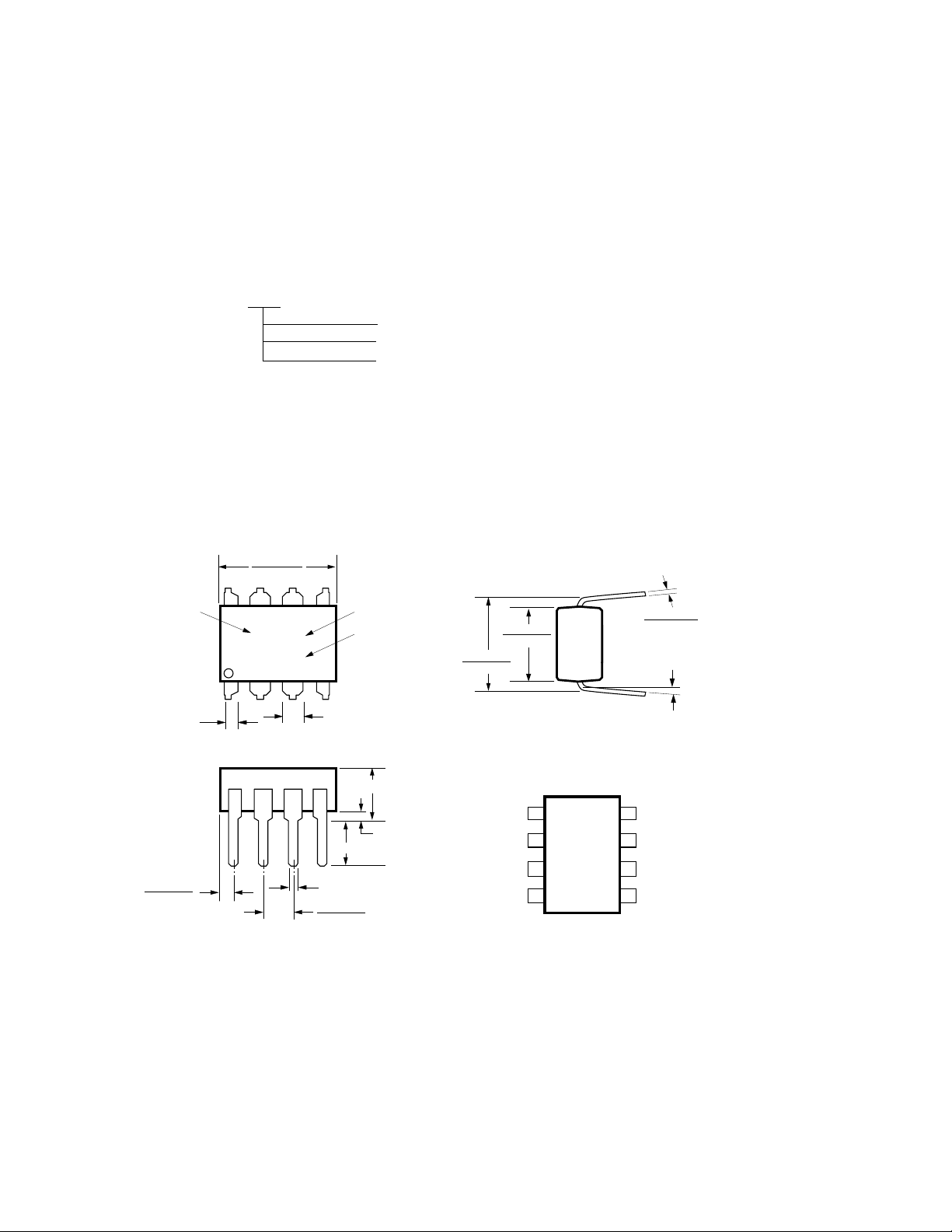

Isolated Modulator

Ordering Information

Specify Part Number followed by Option Number (if desired).

Example:

HCPL-7860#XXX

No Option = Standard DIP package, 50 per tube.

300 = Gull Wing Surface Mount Option, 50 per tube.

500 = Tape and Reel Packaging Option, 1000 per reel.

Option data sheets available. Contact Hewlett-Packard sales representative or authorized distributor.

Package Outline Drawings

8-pin DIP Package

9.40 (0.370)

9.90 (0.390)

5678

TYPE NUMBER

PIN ONE

HP 7860X

YYWW

REFERENCE VOLTAGE

MATCHING SUFFIX*

DATE CODE

4321

6.10 (0.240)

6.60 (0.260)

7.36 (0.290)

7.88 (0.310)

0.18 (0.007)

0.33 (0.013)

5° TYP.

1.19 (0.047) MAX.

PIN ONE

0.76 (0.030)

1.24 (0.049)

DIMENSIONS IN MILLIMETERS AND (INCHES).

*ALL UNITS WITHIN EACH HCPL-7860 STANDARD PACKAGING INCREMENT (EITHER 50 PER TUBE OR 1000 PER REEL)

HAVE A COMMON MARKING SUFFIX TO REPRESENT AN ABSOLUTE REFERENCE VOLTAGE TOLERANCE OF ± 1%.

AN ABSOLUTE REFERENCE VOLTAGE TOLERANCE OF ± 4% IS GUARANTEED BETWEEN STANDARD PACKAGING

INCREMENTS.

1.78 (0.070) MAX.

4.70 (0.185) MAX.

0.51 (0.020) MIN.

2.92 (0.115) MIN.

0.65 (0.025) MAX.

2.28 (0.090)

2.80 (0.110)

PIN DIAGRAM

1

V

DD1

2

V

IN+

V

3

IN–

4

GND1

V

DD2

MCLK

MDAT

GND2

8

7

6

5

1-267

Page 9

8-pin DIP Gull Wing Surface Mount Option 300

PIN LOCATION (FOR REFERENCE ONLY)

9.65 ± 0.25

(0.380 ± 0.010)

6

5

6.350 ± 0.25

(0.250 ± 0.010)

3

4

1.780

(0.070)

MAX.

4.19

MAX.

(0.165)

MOLDED

1.19

(0.047)

MAX.

7

8

1

2

1.02 (0.040)

1.19 (0.047)

1.19 (0.047)

1.78 (0.070)

9.65 ± 0.25

(0.380 ± 0.010)

7.62 ± 0.25

(0.300 ± 0.010)

4.83

(0.190)

0.255 (0.075)

0.010 (0.003)

TYP.

9.65 ± 0.25

(0.380 ± 0.010)

0.380 (0.015)

0.635 (0.025)

1.080 ± 0.320

(0.043 ± 0.013)

2.540

(0.100)

BSC

DIMENSIONS IN MILLIMETERS (INCHES).

TOLERANCES (UNLESS OTHERWISE SPECIFIED):xx.xx = 0.01

0.51 ± 0.130

(0.020 ± 0.005)

xx.xxx = 0.005

0.635 ± 0.25

(0.025 ± 0.010)

12° NOM.

LEAD COPLANARITY

MAXIMUM: 0.102 (0.004)

Package Characteristics

Unless otherwise noted, all specifications are at TA = +25°C.

Parameter Symbol Min. Typ. Max. Units Test Conditions Note

Input-Output Momentary V

ISO

Withstand Voltage

(See note ** below)

Resistance (Input - Output) R

Capacitance C

(Input - Output)

Input IC Junction-to-Case θ

Thermal Resistance center underside of

Output IC Junction-to-Case θ

jco

Thermal Resistance

3750 V

I-O

I-O

jci

10

10

10

11

0.7 pF f = 1 MHz

96 °C/W Thermocouple located at

12

114 °C/W

13

RH ≤ 50%, t = 1 min. 14,15

rms

Ω V

= 500 Vdc 15

I-O

TA = 100°C

package

** The Input-Output Momentary Withstand Voltage is a dielectric voltage rating that should not be interpreted as an input-output

continuous voltage rating. For the continuous voltage rating refer to your equipment level safety specification or HP Application Note

1074, Optocoupler Input-Output Endurance Voltage.

1-268

Page 10

Maximum Solder Reflow Thermal Profile

260

240

220

200

180

160

140

120

100

80

60

TEMPERATURE – °C

40

20

0

∆T = 115°C, 0.3°C/SEC

0

123 456789101112

(NOTE: USE OF NON-CHLORINE ACTIVATED FLUXES IS RECOMMENDED.)

∆T = 100°C, 1.5°C/SEC

TIME – MINUTES

∆T = 145°C, 1°C/SEC

Regulatory Information

The HCPL-7860 (isolated modulator) has been approved by the following organizations:

UL

Recognized under UL 1577,

Component Recognition

Program, File E55361.

VDE (Pending)

Approved under VDE 0884/06.92

with V

IORM

= 848 V

PEAK

.

CSA

Approved under CSA Component

Acceptance Notice #5, File CA

88324.

VDE 0884 Insulation Characteristics

Description Symbol Characteristic Unit

Installation classification per DIN VDE 0110/1.89, Table 1

for rated mains voltage ≤ 300 V

for rated mains voltage ≤ 600 V

rms

rms

Climatic Classification 40/85/21

Pollution Degree (DIN VDE 0110/1.89) 2

Maximum Working Insulation Voltage V

IORM

Input to Output Test Voltage, Method b*

V

x 1.875 = VPR, 100% Production Test with tm = 1 V

IORM

PR

sec, Partial Discharge < 5 pC

Input to Output Test Voltage, Method a*

V

x 1.5 = VPR, Type and Sample Test, tm = 60 sec, V

IORM

PR

Partial Discharge < 5 pC

Highest Allowable Overvoltage

(Transient Overvoltage t

= 10 sec) V

ini

IOTM

Safety-Limiting Values–Maximum Values Allowed in the

Event of a Failure, also see Figure 13.

Case Temperature T

Input Power I

Output Power P

Insulation Resistance at TSI, VIO = 500 V R

*Refer to the optocoupler section of the Optoelectronics Designer's Catalog, under Product Safety Regulations section, (VDE 0884)

for a detailed description of Method a and Method b partial discharge test profiles.

Note: Isolation characteristics are guaranteed only within the safety maximum ratings which must be ensured by protective circuits in

application.

S

S, INPUT

S, OUTPUT

S

I - IV

I - III

848 V

PEAK

1590 V

1273 V

6000 V

175 °C

80 mW

250 mW

9

≥ 10

PEAK

PEAK

PEAK

Ω

1-269

Page 11

300

250

200

150

– POWER – mW

100

Si

P

Figure 13. Dependence of SafetyLimiting Values on Temperature.

PSi, OUTPUT

P

, INPUT

Si

MAX. OPERATING

TEMP. IS 100 °C

50

0

0 200

50

100 150

TA – TEMPERATURE – °C

Insulation and Safety Related Specifications

Parameter Symbol Value Units Conditions

Minimum External Air Gap L(I01) 7.4 mm Measured from input terminals to output

(Clearance) terminals, shortest distance through air.

Minimum External Tracking L(I02) 8.0 mm Measured from input terminals to output

(Creepage) terminals, shortest distance path along body

Minimum Internal Plastic Gap 0.5 mm Insulation thickness between emitter and

(Internal Clearance) detector; also known as distance through

insulation.

Tracking Resistance CTI 175 Volts DIN IEC 112/VDE 0303 Part 1

(Comparative Tracking Index)

Isolation Group IIIa Material Group (DIN VDE 0110, 1/89, Table 1)

Option 300 - surface mount classification is Class A in accordance with CECC 00802.

Absolute Maximum Ratings

Parameter Symbol Min. Max. Units Note

Storage Temperature T

Ambient Operating Temperature T

Supply Voltages V

Steady-State Input Voltage V

DD1

IN+

S

A

, V

, V

DD2

IN-

-55 125 °C

-40 +85 °C

0 5.5 Volts

-2.0 V

+ 0.5 Volts 16

DD1

Two Second Transient Input Voltage -6.0

Output Voltages MCLK, MDAT -0.5 V

+0.5 Volts

DD2

Lead Solder Temperature 260°C for 10 sec., 1.6 mm below seating plane 17

Solder Reflow Temperature Profile See Maximum Solder Reflow Thermal Profile section

Recommended Operating Conditions

Parameter Symbol Min. Max. Units Note

Ambient Operating Temperature T

Supply Voltages V

Input Voltage V

DD1

IN+

A

, V

, V

DD2

IN-

-40 +85 °C

4.5 5.5 V

-200 +200 mV 16

1-270

Page 12

Electrical Specifications, Isolated Modulator

Unless otherwise noted, all specifications are at V

TA = 25°C and V

ranges: TA = -40°C to +85°C, V

DD1

= V

= 5 V, and all Minimum and Maximum specifications apply over the following

DD2

= 4.5 to 5.5 V and V

DD1

Parameter Symbol Min. Typ. Max. Units Test Conditions Fig. Note

Average Input Bias Current I

Average Input Resistance R

Input DC Common-Mode CMRR

IN

IN

IN

Rejection Ratio

Output Logic High Voltage V

Output Logic Low Voltage V

Output Short Circuit Current |I

Input Supply Current I

Output Supply Current I

Output Clock Frequency f

Data Hold Time t

Notes:

14. In accordance with UL1577, for devices with minimum V

proof-tested by applying an insulation test voltage greater than 4500 Vrms for one second (leakage current detection limit

II-O<5µa). This test is performed before the Method b, 100% production test for partial discharge shown in VDE 0884

Insulation Characteristics Table.

15. This is a two-terminal measurement: pins 1-4 are shorted together and pins 5-8 are shorted together.

16. If V

17. HP recommends the use of non-chlorinated solder fluxes.

18. Because of the switched-capacitor nature of the isolated modulator, time averaged values are shown.

19. CMRRIN is defined as the ratio of the gain for differential inputs applied between V

20. Short-circuit current is the amount of output current generated when either output is shorted to V

21. Data hold time is amount of time that the data output MDAT will stay stable following the rising edge of output clock MCLK.

(pin 3) is brought above V

IN-

mode is not intended for customer use.

inputs applied to both V

conditions is not recommended.

IN+

DD1

and V

OH

OL

OSC

DD1

DD2

CLK

HDDAT

- 2 V with respect to GND1 an internal optical-coupling test mode may be activated. This test

with respect to input ground GND1.

IN-

3.9 4.9 V I

|10 mAV

9 11 14 MHz 17

= 0 V and V

IN+

DD2

= 4.5 to 5.5 V.

= 0 V, all Typical specifications are at

IN-

-1.0 µA1418

270 kΩ

55 dB 19

= -100 µA

OUT

0.3 0.6 V I

9.5 15 mA V

8.8 15 mA 16

= 1.6 mA

OUT

= V

OUT

= -350 mV 15

IN+

or GND2 20

DD2

to +350 mV

15 ns 21

specified at 3750 V

ISO

, each isolated modulator (optocoupler) is

rms

IN+

and V

to the gain for common-mode

IN-

or GND2. Use under these

DD2

1-271

Page 13

1

0

-1

-2

-3

-4

– mA

IN

-5

I

-6

-7

-8

-9

-4

-6 6-2 2

04

VIN – V

10.5

10.0

9.5

– mA

9.0

DD1

I

8.5

8.0

-400 4000

-200

-40 °C

25 °C

85 °C

200

VIN – mV

Figure 14. IIN vs. VIN. Figure 15. I

9.4

9.2

9.0

8.8

– mA

8.6

DD2

I

8.4

8.2

8.0

-400 4000

Figure 16. I

-200

DD2

VIN – mV

vs. VIN.

-40 °C

25 °C

85 °C

200

11.05

11.00

10.95

10.90

10.85

CLOCK FREQUENCY – MHz

10.80

-40 85040

Figure 17. Clock Frequency vs. Temperature.

vs. VIN.

DD1

-20

20 60

TEMPERATURE – °C

V

= 4.5 V

DD1

V

= 5.0 V

DD1

V

= 5.5 V

DD1

1-272

Page 14

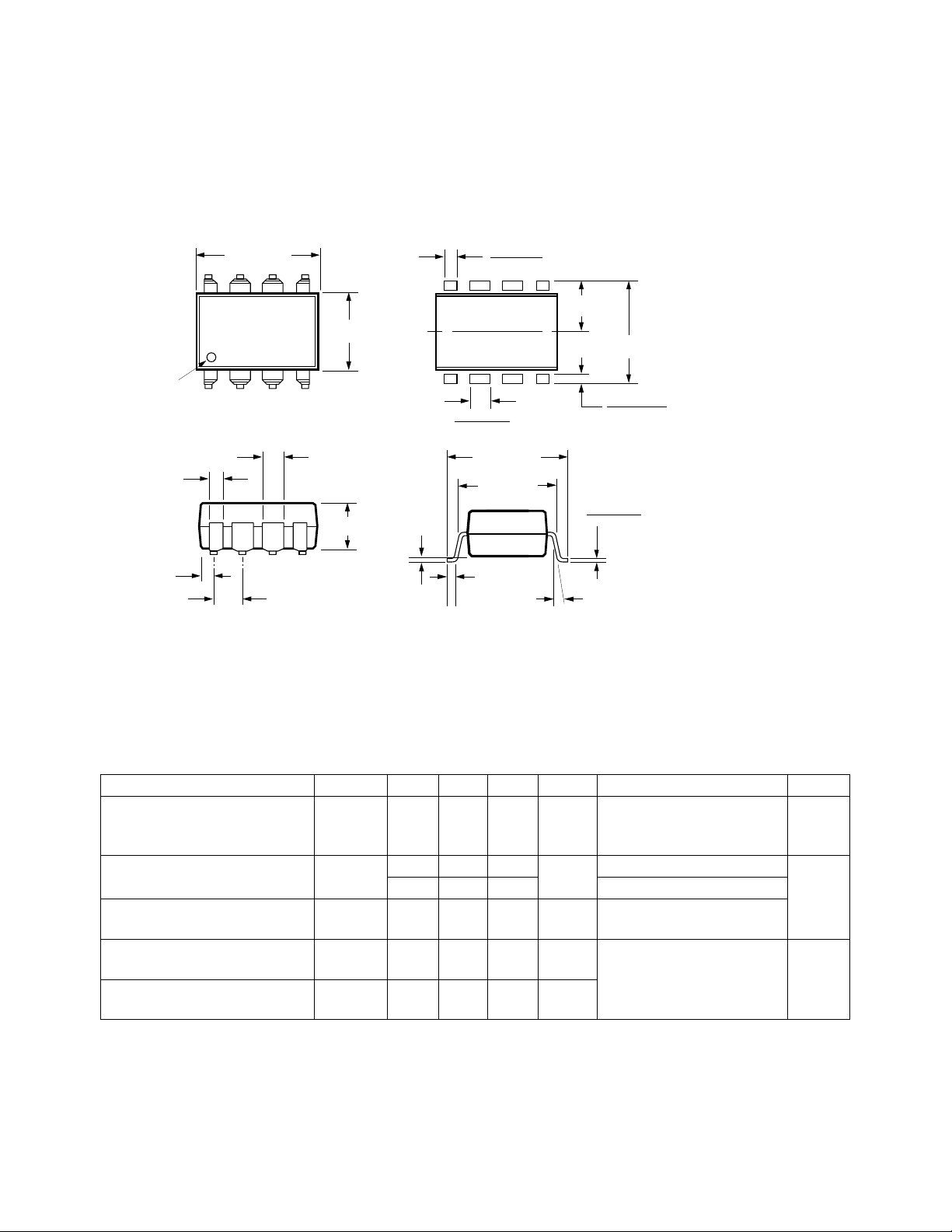

Digital Interface IC

Ordering Information

Specify Part Number followed by Option Number (if desired).

Example

HCPL-7870 Standard 16-pin DIP package, 25 per tube.

HCPL-0870#XXX

No Option = Standard 16-pin SO package, 47 per tube.

500 = Tape and Reel Packaging Option, 1000 per reel.

Option data sheets available. Contact Hewlett-Packard sales representative or authorized distributor.

Package Outline Drawings

Standard 16-pin DIP Package

15 14 13 12 11 10 9

16

R 0.030 x 0.030 DP

HP 7870

YYWW

12345678

0.754

7°

0.018 ± 0.003

0.100 ± 0.010

DIMENSIONS IN INCHES.

TOLERANCES (UNLESS OTHERWISE SPECIFIED): xx.xx = ± 0.01

0.060

TYPE NUMBER

DATE CODE

0.130

0.130 ± 0.010

xx.xxx = ± 0.002

0.150 ± 0.010

0.060

0.060

0.310 ± 0.010

(OUTER TO OUTER)

0.258

7°

0.260

0.310/0.380

(CENTER TO CENTER)

0.010 ± 0.002

1-273

Page 15

Standard 16-pin SO Package

TOP VIEW BOTTOM VIEW

0.33 x 45°

(0.013 x 45°)

PIN NO. 1 IDENTIFIER

∅ 1.27 (0.050) x 0.075 (0.003) DEPTH

SHINY SURFACE

9

10111213141516

1.90

(0.075)

1.90

(0.075)

∅ 1.27 (0.050)

x 0.075 (0.003)

DEPTH

(2x) EJECTOR PIN

SHINY SURFACE

7.544 ± 0.05

(0.297 ± 0.002)

1.27

(0.050)

1.016 ± 0.025

(0.040 ± 0.001)

7°

2.286

(0.090)

DIMENSIONS IN MILLIMETERS (INCHES).

TOLERANCES

(UNLESS OTHERWISE SPECIFIED): xx.xx = ± 0.010

HP 0870

YYWW

1.27 (0.050)

SIDE VIEW END VIEW

1.27 BSC

(0.050 BSC)

10.21 ± 0.10

(0.402 ± 0.002)

0.33–0.51

(0.013–0.020)

xx.xxx = ± 0.002

87654321

10.00–10.65

(0.394–0.419)

(TIP TO TIP)

R 0.18 (R 0.007)

ALL CORNERS

AND EDGES

0.10–0.30

(0.004–0.0118)

2.386–2.586

(0.094–0.1018)

0.01 (0.004)

SEATING PLANE

0° – 8°

0.40 – 1.27

(0.016 – 0.050)

TH

A

DETAIL A

XX

PARTING

LINE

0.23–0.32

(0.0091–0.0125)

1.016 REF.

(0.040)

1-274

Page 16

Maximum Solder Reflow Thermal Profile

260

240

220

200

180

160

140

120

100

80

60

TEMPERATURE – °C

40

20

0

∆T = 115°C, 0.3°C/SEC

0

123 456789101112

(NOTE: USE OF NON-CHLORINE ACTIVATED FLUXES IS RECOMMENDED.)

∆T = 100°C, 1.5°C/SEC

TIME – MINUTES

∆T = 145°C, 1°C/SEC

Absolute Maximum Ratings

Parameter Symbol Min. Max. Units Note

Storage Temperature T

Ambient Operating Temperature T

Supply Voltage V

S

A

DD

Input Voltage All Inputs -0.5 VDD + 0.5 V

Output Voltage All Outputs -0.5 VDD + 0.5 V

Lead Solder Temperature 260°C for 10 seconds, 1.6 mm below seating plane 17

Solder Reflow Temperature Profile See Reflow Thermal Profile

-55 +125 °C

-40 +85 °C

0 5.5 V

Note:

17. HP recommends the use of non-chlorinated solder fluxes.

Recommended Operating Conditions

Parameter Symbol Min. Max. Units Note

Ambient Operating Temperature T

Supply Voltage V

A

DD

Input Voltage All Inputs 0 V

-40 +85 °C

4.5 5.5 V

DD

V

1-275

Page 17

Electrical Specifications, Digital Interface IC

Unless otherwise noted, all Typical specifications are at TA = 25°C and VDD = 5 V, and all Minimum and

Maximum specifications apply over the following ranges: TA = -40°C to +85°C and VDD = 4.5 to 5.5 V.

Parameter Symbol Min. Typ. Max. Units Test Conditions Fig. Note

Supply Current I

DC Input Current I

Input Logic Low Voltage V

Input Logic High Voltage V

Output Logic Low Voltage V

Output Logic High Voltage V

Clock Frequency (CCLK, f

DD

IN

IL

IH

OL

OH

CLK

2.0 V

4.3 5.0 V I

MCLK and SCLK)

Clock Period (CCLK, t

PER

50 ns 18,

MCLK and SCLK) 19

Clock High Level Pulse t

PWH

20 ns

Width (CCLK, MCLK

and SCLK)

Clock Low Level Pulse t

PWL

20

Width (CCLK, MCLK

and SCLK)

Setup Time from DAT to t

SUCLK

10 18

Rising Edge of CLK

(CDAT, CCLK, MDAT

and MCLK)

DAT Hold Time after t

HDCLK

10

Rising Edge of CLK

(CDAT, CCLK, MDAT

and MCLK)

Setup Time from Falling t

SUCL1

20

Edge of CLAT to First

Rising Edge of CCLK

Setup Time from Last t

SUCL2

20

Rising Edge of CCLK

to Rising Edge of CLAT

Delay Time from Falling t

DSDAT

Edge of SCLK to SDAT

Setup Time from Data t

SUS

200

Ready to First Falling

Edge of SCLK

Setup Time from CHAN t

SUCHS

20

to falling edge of CS

Reset High Level Pulse t

PWR

100

Width

20 35 mA f

0.001 10 µA

0.8 V

0.15 0.4 V I

20 MHz

15 19

= 10 MHz

CLK

= 4 mA

OUT

= -400 µA

OUT

1-276

Page 18

CLAT

t

SUCL1

t

SUCL2

CDAT

B7 B6 B5 B4 B3 B2 B1 B0

t

t

SUCLK

HDCLK

t

PWH

CCLK

t

t

PWL

PER

Figure 18. Serial Configuration Interface Timing.

CHAN

t

SUCHS

CS

SDAT

SCLK

t

C

Figure 19. Conversion Timing.

B14 B13 B12 B11 B10 B1 B0

t

DSDAT

t

PWH

123456

t

PER

t

SUS

t

PWL

15 16

1-277

Page 19

Applications Information

Product Description

The HCPL-7860 Isolated Modulator (optocoupler) uses sigmadelta modulation to convert an

analog input signal into a highspeed (10 MHz) single-bit digital

data stream; the time average of

the modulator’s single-bit data is

directly proportional to the input

signal. The isolated modulator’s

other main function is to provide

galvanic isolation between the

analog input and the digital

output. An internal voltage

reference determines the fullscale analog input range of the

modulator (approximately

± 320 mV); an input range of

± 200 mV is recommended to

achieve optimal performance.

The primary functions of the

HCPL-x870 Digital Interface IC

are to derive a multi-bit output

signal by averaging the single-bit

modulator data, as well as to

provide a direct microcontroller

interface. The effective resolution

of the multi-bit output signal is a

function of the length of time

(measured in modulator clock

cycles) over which the average is

taken; averaging over longer

periods of time results in higher

resolution. The Digital Interface

IC can be configured for five

conversion modes which have

different combinations of speed

and resolution to achieve the

desired level of performance.

Other functions of the HCPLx870 Digital Interface IC include

a Phase Locked Loop based pretrigger circuit that can either give

more precise control of the

Table 1. Input Full-Scale Range and Code Assignment.

Analog Input Voltage Input Digital Output

Full Scale Range 640 mV 32768 LSBs

Minimum Step Size 20 µV 1 LSB

+Full Scale +320 mV 111111111111111

Zero 0 mV 100000000000000

-Full Scale -320 mV 000000000000000

effective sampling time or reduce

conversion time to less than 1 µs,

a fast over-range detection circuit

that rapidly indicates when the

magnitude of the input signal is

beyond full-scale, an adjustable

threshold detection circuit that

indicates when the magnitude of

the input signal is above a useradjustable threshold level, an

offset calibration circuit, and a

second multiplexed input that

allows a second Isolated

Modulator to be used with a

single Digital Interface IC.

The digital output format of the

Isolated A/D Converter is 15 bits

of unsigned binary data. The

input full-scale range and code

assignment is shown in Table 1

below. Although the output contains 15 bits of data, the effective

resolution is lower and is determined by selected conversion

mode as shown in Table 2 below.

Table 2. Isolated A/D Converter Typical Performance Characteristics.

Signal-to-

Noise Ratio

Mode (dB) (bits) 0 12(µs) (kHz)

1 83 13.5 188 94 94 3.4

2 79 12.8 95 47 47 6.9

3 73 11.9 37 18 0.7 18 22

4 66 10.7 19 10 10 45

5 53 8.5 10 5 5 90

Note: Bold italic type indicates Default values.

1-278

Effective

Resolution

Conversion Time (µs)

Pre-Trigger Mode

Signal

Delay

Signal

BandwidthConversion

Page 20

Digital Interface Timing

Power Up/Reset

At power up, the digital interface

IC should be reset either

manually, by bringing the RESET

pin (pin 9) high for at least

100 ns, or automatically by

connecting a 10 µF capacitor

between the RESET pin and V

(pin 16). The RESET pin operates

asynchronously and places the IC

in its default configuration, as

specified in the Digital Interface

Configuration section.

Conversion Timing

Figure 19 illustrates the timing

for one complete conversion

cycle. A conversion cycle is

initiated on the falling edge of the

convert start signal (CS); CS

should be held low during the

entire conversion cycle. When CS

is brought low, the serial output

data line (SDAT) changes from a

high-impedance to the low state,

indicating that the converter is

busy. A rising edge on SDAT

indicates that data is ready to be

clocked out. The output data is

clocked out on the negative edges

of the serial clock pulses (SCLK),

MSB first. A total of 16 pulses is

needed to clock out all of the data.

After the last clock pulse, CS

should be brought high again,

causing SDAT to return to a highimpedance state, completing the

conversion cycle. If the external

circuit uses the positive edges of

SCLK to clock in the data, then a

total of sixteen bits is clocked in,

the first bit is always high

(indicating that data is ready)

followed by 15 data bits. If fewer

than 16 cycles of SCLK are input

before CS is brought high, the

conversion cycle will terminate

and SDAT will go to the high-

DD

impedance state after a few

cycles of the Isolated Modulator’s

clock.

The amount of time between the

falling edge of CS and the rising

edge of SDAT depends on which

conversion and pre-trigger modes

are selected; it can be as low as

0.7 µs when using pre-trigger

mode 2, as explained in the

Digital Interface Configuration

section.

Serial Configuration Timing

The HCPL-x870 Digital Interface

IC is programmed using the

Serial Configuration Interface

(SCI) which consists of the clock

(CCLK), data (CDAT), and

enable/latch (CLAT) signals.

Figure 18 illustrates the timing

for the serial configuration interface. To send a byte of configuration data to the HCPL-x870, first

bring CLAT low. Then clock in

the eight bits of the configuration

byte (MSB first) using CDAT and

the rising edge of CCLK. After the

last bit has been clocked in,

bringing CLAT high again will

latch the data into the appropriate configuration register inside

the interface IC. If more than

eight bits are clocked in before

CLAT is brought high, only the

last eight bits will be used. Refer

to the Digital Interface Configuration section to determine appropriate configuration data. If the

default configuration of the

digital interface IC is acceptable,

then CCLK, CDIN and CLAT may

be connected to either VDD or

GND.

Channel Select Timing

The channel select signal (CHAN)

determines which input channel

will be used for the next conver-

sion cycle. A logic low level

selects channel one, a high level

selects channel 2. CHAN should

not be changed during a conversion cycle. The state of the CHAN

signal has no effect on the

behavior of either the over-range

detection circuit (OVR1) or the

adjustable threshold detection

circuit (THR1). Both OVR1 and

THR1 continuously monitor

channel 1 independent of the

CHAN signal. CHAN also does not

affect the behavior of the pretrigger circuit, which is tied to

the conversion timing of channel

1, as explained in the Digital

Interface Configuration section.

Digital Interface Configuration

Configuration Registers

The Digital Interface IC contains

four 6-bit configuration registers

that control its behavior. The two

LSBs of any byte clocked into the

serial configuration port (CDAT,

CCLK, CLAT) are used as address

bits to determine which register

the data will be loaded into.

Registers 0 and 1 (with address

bits 00 and 01) specify the

conversion and offset calibration

modes of channels 1 and 2,

register 2 (address bits 10)

specifies the behavior of the

adjustable threshold circuit, and

register 3 (address bits 11)

specifies which pre-trigger mode

to use for channel 1. These

registers are illustrated in Table 3

below, with default values

indicated in bold italic type. Note

that there are several reserved

bits which should always be set

low and that the configuration

registers should not be changed

during a conversion cycle.

1-279

Page 21

Table 3. Register Configuration.

Configuration Data Bits Address Bits

Register Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Channel 1 Conversion Mode Channel 1 Reserved

0

High High Low Low Low Low Low Low

Channel 2 Conversion Mode Channel 2 Reserved

1

High High Low Low Low Low Low High

Threshold Threshold Level

2

Detection Time

High Low Low Low Low Low High Low

Pre-Trigger Mode Reserved

3

Low Low Low Low Low Low High High

Note: Bold italic type indicates default values. Reserved bits should be set low.

Offset Cal

Offset Cal

Conversion Mode

The conversion mode determines

the speed/resolution trade-off for

the Isolated A/D converter. The

four MSBs of registers 0 and 1

determine the conversion mode

for the appropriate channel. The

bit settings for choosing a particular conversion mode are shown

in Table 4 below. See Table 2 for

Table 4. Conversion Mode Configuration.

Conversion

Mode Bit 7 Bit 6 Bit 5 Bit 4

1 Low High Low High

2 Low Low High High

3 High High High Low

4 High High Low Low

5 High Low High Low

Note: Bold italic type indicates default values.

Configuration Data Bits

a summary of how performance

changes as a function of conversion mode setting. Combinations

of data bits not specified in Table

4 below are not recommended.

1-280

Page 22

Pre-Trigger Mode

The pre-trigger mode refers to

the operation of a PLL-based

circuit that affects the sampling

behavior and conversion time of

the A/D converter when channel 1

is selected. The PLL pre-trigger

circuit has two modes of operation; the first mode allows more

precise control of the time at

which the analog input voltage is

effectively sampled, while the

second mode essentially

eliminates the time between when

the external convert start

command is given and when output data is available (reducing it

to less than 1 µs). A brief

description of how the A/D converter works with the pre-trigger

circuit disabled will help explain

how the pre-trigger circuit affects

operation when it is enabled.

With the pre-trigger circuit is

disabled (pre-trigger mode 0),

Figure 20 illustrates the relationship between the convert start

command, the weighting function

used to average the modulator

data, and the data ready signal.

The weighted averaging of the

modulator data begins immedi-

ately following the convert start

command. The weighting function increases for half of the conversion cycle and then decreases

back to zero, at which time the

data ready signal is given,

completing the conversion cycle.

The analog signal is effectively

sampled at the peak of the

weighting function, half-way

through the conversion cycle.

This is the default mode.

If the convert start signal is

periodic (i.e., at a fixed frequency) and the PLL pre-trigger

circuit is enabled (pre-trigger

modes 1 or 2), either the peak of

the weighting function or the end

of the conversion cycle can be

aligned to the external convert

start command, as shown in

Figure 20. The Digital Interface

IC can therefore synchronize the

conversion cycle so that either

the beginning, the middle, or the

end of the conversion is aligned

with the external convert start

command, depending on whether

pre-trigger mode 0, 1, or 2 is

selected, respectively. The only

requirement is that the convert

start signal for channel 1 be

periodic. If the signal is not

periodic and pre-trigger mode 1

or 2 is selected, then the pretrigger circuit will not function

properly.

An important distinction should

be made concerning the difference between conversion time

and signal delay. As can be seen

in Figure 20, the amount of time

from the peak of the weighting

function (when the input signal is

being sampled) to when output

data is ready is the same for all

three modes. This is the actual

delay of the analog signal through

the A/D converter and is independent of the “conversion time,”

which is simply the time between

the convert start signal and the

data ready signal. Because signal

delay is the true measure of how

much phase shift the A/D

converter adds to the signal, it

should be used when making

calculations of phase margin and

loop stability in feedback

systems.

There are different reasons for

using each of the pre-trigger

modes. If the signal is not

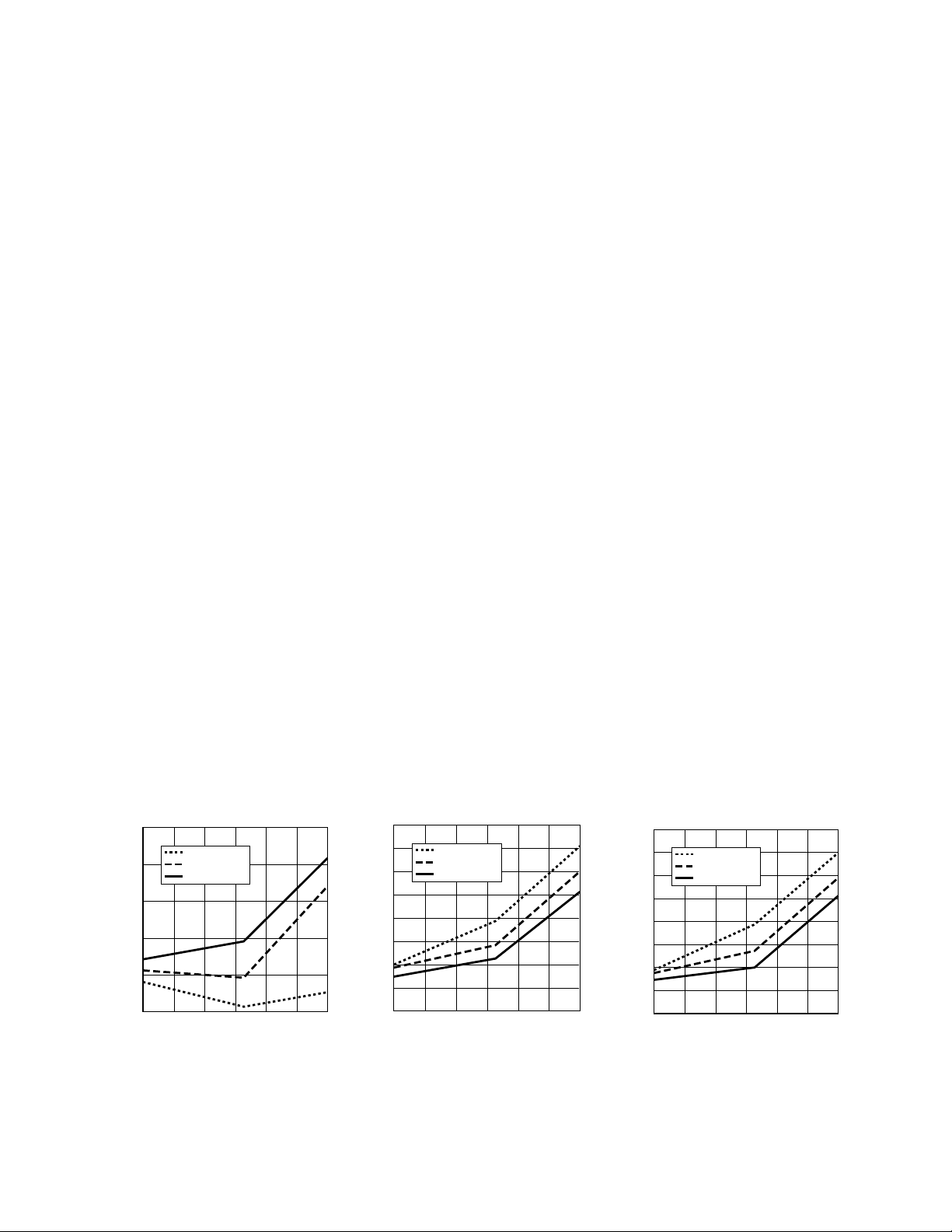

WEIGHTING

FUNCTION

CONVERT START – CS

DATA READY – SDAT

A) PRE-TRIGGER MODE 0 B) PRE-TRIGGER MODE 1 C) PRE-TRIGGER MODE 2

Figure 20. Pre-Trigger Modes 0, 1, and 2.

1-281

Page 23

periodic, then the pre-trigger

circuit should be disabled by

selecting pre-trigger mode 0. If

the most time-accurate sampling

of the input signal is desired,

then mode 1 should be selected.

If the shortest possible conversion time is desired, then mode 2

should be selected.

The pre-trigger circuit functions

only with channel 1; the circuit

ignores any convert start signals

while channel 2 is selected with

the CHAN input. This allows

conversions on channel 2 to be

performed between conversions

on channel 1 without affecting

the operation of the pre-trigger

circuit. As long as the convert

Table 5. Pre-Trigger Mode Configuration.

Configuration Data Bits

Pre-Trigger Mode Bit 7 Bit 6

0 Low Low

1 Low High

2 High Don’t Care

Note: Bold italic type indicates default values.

start signals are periodic while

channel 1 is selected, then the

pre-trigger circuit will function

properly.

The three different pre-trigger

modes are selected using bits 6

and 7 of register 3, as shown in

Table 5 below.

Offset Calibration

The offset calibration circuit can

be used to separately calibrate

the offsets of both channels 1 and

2. The offset calibration circuit

contains a separate offset register

for each channel. After an offset

calibration sequence, the offset

registers will contain a value

equal to the measured offset,

which will then be subtracted

from all subsequent conversions.

A hardware reset (bringing the

RESET pin high for at least

100 ns) is required to reset the

offset calibration registers to

zero.

The following sequence is

recommended for performing an

offset calibration:

1. Select the appropriate channel

using the CHAN pin (low =

channel 1, high = channel 2).

2. Force zero volts at the input of

the selected isolated

modulator.

3. Send a configuration data byte

to the appropriate register for

the selected channel (register

0 for channel 1, register 1 for

channel 2). Bit 3 of the

configuration byte should be

set high to enable offset

calibration mode and bits 4

through 7 should be set to

select conversion mode 1 to

achieve the highest resolution

measurement of the offset.

4. Perform one complete conversion cycle by bringing CS low

until SDAT goes high, indicating completion of the conversion cycle. Because bit 3 of the

configuration has been set

high, the uncalibrated output

data from the conversion will

be stored in the appropriate

offset calibration register and

will be subtracted from all

subsequent conversions on

that channel. If multiple

conversion cycles are

performed while the offset

calibration mode is enabled,

the uncalibrated data from the

last conversion cycle will be

stored in the offset calibration

register.

5. Send another configuration

byte to the appropriate register for the selected channel,

setting bit 3 low to disable

calibration mode and setting

bits 4 through 7 to select the

desired conversion mode for

subsequent conversions on

that channel.

To calibrate both channels,

perform the above sequence for

each channel. The offset

calibration sequence can be

performed as often as needed.

The table below summarizes how

to turn the offset calibration

mode on or off using bit 3 of

configuration registers 0 and 1.

Table 6. Offset Calibration

Configuration.

Offset

Calibration

Mode Bit 3

Off Low

On High

Note: Bold italic type indicates default

values.

Configuration

Data Bits

1-282

Page 24

Over-Range Detection

The over-range detection circuit

allows fast detection of when the

magnitude of the input signal on

channel 1 is near or beyond full

scale, causing the OVR1 output to

go high. This circuit can be very

useful in current-sensing applications for quickly detecting when a

short-circuit occurs. The overrange detection circuit works by

detecting when the modulator

output data has not changed state

for at least 25 clock cycles in a

row, indicating that the input

signal is near or beyond fullscale, positive or negative.

Typical response time to overrange signals is less than 3 µs.

The over-range circuit actually

begins to indicate an over-range

condition when the magnitude of

the input signal exceeds approximately 250 mV; it starts to

generate periodic short pulses on

OVR1 which get longer and more

frequent as the input signal

approaches full scale. The OVR1

output stays high continuously

when the input is beyond full

scale.

The over-range detection circuit

continuously monitors channel 1

independent of which channel is

selected with the CHAN signal.

This allows continuous monitoring of channel 1 for faults while

converting an input signal on

channel 2.

Adjustable Threshold Detection

The adjustable threshold detector

causes the THR1 output to go

high when the magnitude of the

input signal on channel 1 exceeds

a user-defined threshold level.

The threshold level can be set to

one of 16 different values

between approximately 160 mV

and 310 mV. The adjustable

threshold detector uses a smaller

version of the main conversion

circuit in combination with a

digital comparator to detect when

the magnitude of the input signal

on channel 1 is beyond the

defined threshold level. As with

the main conversion circuit, there

is a trade-off between speed and

resolution with the threshold

detector; selecting faster detection times exhibit more noise as

the signal passes through the

threshold, while slower detection

times offer lower noise. Both the

detection time and threshold level

are programmable using bits 2

through 7 of configuration

register 2, as shown in Tables 7

and 8 below.

As with the over-range detector,

the adjustable threshold detector

continuously monitors channel 1

independent of which channel is

selected with the CHAN signal.

This allows continuous monitoring of channel 1 for faults while

converting Channel 2.

Table 7. Threshold

Detection Configuration.

Threshold

Detection

Time Bit 7 Bit 6

2 - 6 µs Low Low

3 - 10 µs Low High

5 - 20 µs High Low

10 - 35 µs High High

Note: Bold italic type indicates default

values.

Configuration

Data Bits

Table 8. Threshold Level Configuration.

Configuration Data Bits

Threshold Level Bit 5 Bit 4 Bit 3 Bit 2

±

160 mV Low Low Low Low

± 170 mV Low Low Low High

± 180 mV High Low

± 190 mV High

± 200 mV High Low Low

± 210 mV High

± 220 mV High Low

± 230 mV High

± 240 mV High Low Low Low

± 250 mV High

± 260 mV High Low

± 270 mV High

± 280 mV High Low Low

± 290 mV High

± 300 mV High Low

± 310 mV High

Note: Bold italic type indicates default values.

1-283

Page 25

Analog Interfacing

Power Supplies and Bypassing

The recommended application

circuit is shown in Figure 21. A

floating power supply (which in

many applications could be the

same supply that is used to drive

the high-side power transistor) is

regulated to 5 V using a simple

zener diode (D1); the value of

resistor R1 should be chosen to

supply sufficient current from the

existing floating supply. The

voltage from the current sensing

resistor or shunt (Rsense) is

applied to the input of the HCPL7860 (U2) through an RC antialiasing filter (R2 and C2). And

finally, the output clock and data

of the isolated modulator are

connected to the digital interface

IC. Although the application

circuit is relatively simple, a few

recommendations should be

followed to ensure optimal

performance.

The power supply for the isolated

modulator is most often obtained

from the same supply used to

power the power transistor gate

FLOATING

POSITIVE

SUPPLY

HV+

GATE DRIVE

CIRCUIT

drive circuit. If a dedicated

supply is required, in many cases

it is possible to add an additional

winding on an existing transformer. Otherwise, some sort of

simple isolated supply can be

used, such as a line powered

transformer or a high-frequency

DC-DC converter.

An inexpensive 78L05 threeterminal regulator can also be

used to reduce the floating supply

voltage to 5 V. To help attenuate

high-frequency power supply

noise or ripple, a resistor or

inductor can be used in series

with the input of the regulator to

form a low-pass filter with the

regulator’s input bypass

capacitor.

As shown in Figure 21, 0.1 µF

bypass capacitors (C1 and C3)

should be located as close as

possible to the input and output

power-supply pins of the isolated

modulator (U2). The bypass

capacitors are required because

of the high-speed digital nature of

the signals inside the isolated

modulator. A 0.01 µF bypass

+ 5 V

capacitor (C2) is also recommended at the input due to the

switched-capacitor nature of the

input circuit. The input bypass

capacitor also forms part of the

anti-aliasing filter, which is

recommended to prevent highfrequency noise from aliasing

down to lower frequencies and

interfering with the input signal.

PC Board Layout

The design of the printed circuit

board (PCB) should follow good

layout practices, such as keeping

bypass capacitors close to the

supply pins, keeping output

signals away from input signals,

the use of ground and power

planes, etc. In addition, the layout

of the PCB can also affect the

isolation transient immunity

(CMR) of the isolated modulator,

due primarily to stray capacitive

coupling between the input and

the output circuits. To obtain

optimal CMR performance, the

layout of the PC board should

minimize any stray coupling by

maintaining the maximum

possible distance between the

input and output sides of the

circuit and ensuring

R1

D1

5.1 V

R2 39 Ω

MOTOR

Figure 21. Recommended Application Circuit.

+

R

SENSE

-

HV-

1-284

C1

0.1 µF

C2

0.01 µF

V

DD1

V

IN+

V

IN-

GND1

HCPL-7860

V

DD2

MCLK

MDAT

GND2

C3

0.1 µF

CCLK V

CLAT CHAN

CDAT SCLK

MCLK1 SDAT

MDAT1 CS

MCLK2 THR1

MDAT2 OVR1

GND RESET

HCPL-X870

DD

TO

CONTROL

CIRCUIT

Page 26

that any ground or power plane

on the PC board does not pass

directly below or extend much

wider than the body of the

isolated modulator.

Shunt Resistors

The current-sensing shunt

resistor should have low

resistance (to minimize power

dissipation), low inductance (to

minimize di/dt induced voltage

spikes which could adversely

affect operation), and reasonable

tolerance (to maintain overall

circuit accuracy). Choosing a

particular value for the shunt is

usually a compromise between

minimizing power dissipation and

maximizing accuracy. Smaller

shunt resistances decrease power

dissipation, while larger shunt

resistances can improve circuit

accuracy by utilizing the full

input range of the isolated

modulator.

The first step in selecting a shunt

is determining how much current

the shunt will be sensing. The

graph in Figure 22 shows the

RMS current in each phase of a

three-phase induction motor as a

function of average motor output

power (in horsepower, hp) and

motor drive supply voltage. The

40

35

30

25

20

15

10

5

0

MOTOR OUTPUT POWER – HORSEPOWER

Figure 22. Motor Output Horsepower

vs. Motor Phase Current and Supply

Voltage.

440

380

220

120

5350

MOTOR PHASE CURRENT – A (rms)

15 20 25 30

10

maximum value of the shunt is

determined by the current being

measured and the maximum

recommended input voltage of

the isolated modulator. The

maximum shunt resistance can be

calculated by taking the maximum recommended input voltage

and dividing by the peak current

that the shunt should see during

normal operation. For example, if

a motor will have a maximum

RMS current of 10 A and can

experience up to 50% overloads

during normal operation, then the

peak current is 21.1 A

(=10x1.414x1.5). Assuming a

maximum input voltage of

200 mV, the maximum value of

shunt resistance in this case

would be about 10 mΩ.

The maximum average power

dissipation in the shunt can also

be easily calculated by multiplying the shunt resistance times the

square of the maximum RMS

current, which is about 1 W in

the previous example.

If the power dissipation in the

shunt is too high, the resistance

of the shunt can be decreased

below the maximum value to

decrease power dissipation. The

minimum value of the shunt is

limited by precision and accuracy

requirements of the design. As

the shunt value is reduced, the

output voltage across the shunt is

also reduced, which means that

the offset and noise, which are

fixed, become a larger percentage

of the signal amplitude. The

selected value of the shunt will

fall somewhere between the

minimum and maximum values,

depending on the particular

requirements of a specific design.

When sensing currents large

enough to cause significant

heating of the shunt, the

temperature coefficient (tempco)

of the shunt can introduce

nonlinearity due to the signal

dependent temperature rise of the

shunt. The effect increases as the

shunt-to-ambient thermal

resistance increases. This effect

can be minimized either by

reducing the thermal resistance

of the shunt or by using a shunt

with a lower tempco. Lowering

the thermal resistance can be

accomplished by repositioning

the shunt on the PC board, by

using larger PC board traces to

carry away more heat, or by

using a heat sink.

For a two-terminal shunt, as the

value of shunt resistance

decreases, the resistance of the

leads becomes a significant

percentage of the total shunt

resistance. This has two primary

effects on shunt accuracy. First,

the effective resistance of the

shunt can become dependent on

factors such as how long the

leads are, how they are bent, how

far they are inserted into the

board, and how far solder wicks

up the lead during assembly

(these issues will be discussed in

more detail shortly). Second, the

leads are typically made from a

material such as copper, which

has a much higher tempco than

the material from which the

resistive element itself is made,

resulting in a higher tempco for

the shunt overall.

Both of these effects are eliminated when a four-terminal shunt

is used. A four-terminal shunt has

two additional terminals that are

Kelvin-connected directly across

the resistive element itself; these

two terminals are used to monitor

the voltage across the resistive

element while the other two

terminals are used to carry the

load current. Because of the

Kelvin connection, any voltage

1-285

Page 27

drops across the leads carrying

the load current should have no

impact on the measured voltage.

Several four-terminal shunts from

Isotek (Isabellenhütte) suitable

for sensing currents in motor

drives up to 71 A

(71 hp or

rms

53 kW) are shown in Table 9; the

maximum current and motor

power range for each of the PBVseries shunts are indicated. For

shunt resistances from 50 mΩ

down to 10 mΩ, the maximum

current is limited by the input

voltage range of the isolated

modulator. For the 5 mΩ and

2mΩ shunts, a heat sink may be

required due to the increased

power dissipation at higher

currents.

When laying out a PC board for

the shunts, a couple of points

should be kept in mind. The

Kelvin connections to the shunt

should be brought together under

the body of the shunt and then

run very close to each other to

the input of the isolated modulator; this minimizes the loop area

of the connection and reduces the

possibility of stray magnetic

fields from interfering with the

measured signal. If the shunt is

not located on the same PC board

as the isolated modulator circuit,

a tightly twisted pair of wires can

accomplish the same thing.

Also, multiple layers of the PC

board can be used to increase

current carrying capacity.

Numerous plated-through vias

should surround each non-Kelvin

terminal of the shunt to help

distribute the current between the

layers of the PC board. The PC

board should use 2 or 4 oz.

copper for the layers, resulting in

a current carrying capacity in

excess of 20 A. Making the

current carrying traces on the PC

board fairly large can also

improve the shunt’s power

dissipation capability by acting as

a heat sink. Liberal use of vias

where the load current enters and

exits the PC board is also

recommended.

Shunt Connections

The recommended method for

connecting the isolated modulator to the shunt resistor is shown

in Figure 21. V

(pin 2 of the

IN+

HPCL-7860) is connected to the

positive terminal of the shunt

resistor, while V

(pin 3) is

IN-

shorted to GND1 (pin 4), with the

power-supply return path functioning as the sense line to the

negative terminal of the current

shunt. This allows a single pair of

wires or PC board traces to

connect the isolated modulator

circuit to the shunt resistor. By

referencing the input circuit to

the negative side of the sense

resistor, any load current induced

noise transients on the shunt are

seen as a common-mode signal

and will not interfere with the

current-sense signal. This is

important because the large load

currents flowing through the

motor drive, along with the

parasitic inductances inherent in

the wiring of the circuit, can

generate both noise spikes and

offsets that are relatively large

compared to the small voltages

that are being measured across

the current shunt.

If the same power supply is used

both for the gate drive circuit and

for the current sensing circuit, it

is very important that the connection from GND1 of the isolated

modulator to the sense resistor

be the only return path for

supply current to the gate drive

power supply in order to

eliminate potential ground loop

problems. The only direct connection between the isolated

modulator circuit and the gate

drive circuit should be the

positive power supply line.

Table 9. Isotek (Isabellenhütte) Four-Terminal Shunt Summary.

Shunt Maximum Motor Power Range

Shunt Resistor

Resistance Tol. RMS Current 120 Vac-440 V

Part Number mΩ %A hp kW

PBV-R050-0.5 50 0.5 3 0.8-3 0.6-2

PBV-R020-0.5 20 0.5 7 2-7 1.4-5

PBV-R010-0.5 10 0.5 14 4-14 3-10

PBV-R005-0.5 5 0.5 25 [28] 7-25 [8-28] 5-19 [6-21]

PBV-R002-0.5 2 0.5 39 [71] 11-39 [19-71] 8-29 [14-53]

Note: Values in brackets are with a heatsink for the shunt.

1-286

ac

Page 28

In some applications, however,

supply currents flowing through

the power-supply return path may

cause offset or noise problems. In

this case, better performance

may be obtained by connecting

V

IN+

and V

directly across the

IN-

shunt resistor with two conductors, and connecting GND1 to the

shunt resistor with a third

conductor for the power-supply

return path, as shown in Figure

23. When connected this way,

both input pins should be

bypassed. To minimize electromagnetic interference of the

sense signal, all of the conductors

(whether two or three are used)

connecting the isolated modulator to the sense resistor should be

either twisted pair wire or closely

spaced traces on a PC board.

FLOATING

POSITIVE

HV+

SUPPLY

GATE DRIVE

CIRCUIT

The 39 Ω resistor in series with

the input lead (R2) forms a lowpass anti-aliasing filter with the

0.01 µF input bypass capacitor

(C2) with a 400 kHz bandwidth.

The resistor performs another

important function as well; it

dampens any ringing which might

be present in the circuit formed

by the shunt, the input bypass

capacitor, and the inductance of

wires or traces connecting the

two. Undamped ringing of the

input circuit near the input

sampling frequency can alias into

the baseband producing what

might appear to be noise at the

output of the device.

Voltage Sensing

The HCPL-7860 Isolated Modulator can also be used to isolate

signals with amplitudes larger

than its recommended input

range with the use of a resistive

voltage divider at its input. The

only restrictions are that the

impedance of the divider be

relatively small (less than 1 kΩ)

so that the input resistance

(280 kΩ) and input bias current

(1 µA) do not affect the accuracy

of the measurement. An input

bypass capacitor is still required,

although the 39 Ω series damping

resistor is not (the resistance of

the voltage divider provides the

same function). The low-pass

filter formed by the divider

resistance and the input bypass

capacitor may limit the achievable

bandwidth. To obtain higher

bandwidth, the input bypass

capacitor (C2) can be reduced,

but it should not be reduced

much below 1000 pF to maintain

adequate input bypassing of the

isolated modulator.

R1

D1

5.1 V

R2a 39 Ω

R2b 39 Ω

MOTOR

Figure 23. Schematic for Three Conductor Shunt Connection.

+

R

SENSE

-

HV-

C1

0.1 µF

C2a

0.01 µF

C2b

0.01 µF

V

DD1

V

IN+

V

IN-

GND1

HCPL-7860

V

DD2

MCLK

MDAT

GND2

1-287

Loading...

Loading...