DATASENSOR US30 Instruction Manual

r

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 Web: www.ctiautomation.net - E-mail: info@ctiautomation.net

US30 SERIES

- analogue output -

Programming push-button (ANALOG)

This push-button allows to program the reading points of the sensor.

Response time selection push-button (MODE)

This push-button allows to select the response time (Fast or Slow).

POWER LED indicator Indication

OFF Power is OFF.

ON Red Target is weak or outside sensing range.

ON Green Sensor is operating in normal conditions.

OUT LED indicator Indication

OFF Target is outside operating field (NO operating mode)

ON Yellow Target is inside operating field (NO operating mode)

SIGNAL LED indicator Indication

OFF Target is outside operating field

Blinking Red Target is inside operating field

MODE LED indicator Indication

ON Amber Indicates response time selected (Fast or Slow)

BROWN

BLUE 3

WHITE 2

BLACK

4-POLE M12 CONNECTOR

Ultrasonic sensors emit a series of ultrasonic energy pulses, which travel through the air at the speed of

sound. A portion of this energy is reflected by the target and travels back to the sensor. The sensor

measures the total time required for the energy to reach the target and return to the sensor.

The distance to the object is then calculated using the following formula:

To improve accuracy, an ultrasonic sensor elaborates the average results of several pulses before

activating the output.

Temperature effects

The speed of sound depends on the composition, pressure and temperature of the gas in which it is

travelling. For most ultrasonic applications, the composition and pressure of the gas a re rela tively f ixed,

while the temperature may vary.

In air, the speed of sound varies according to the following approximate formulas:

Temperature Compensation

Changes in air temperature affect the speed of sound, which in turn affects the distance reading

measured by the sensor. An increase in air temperature shifts both sensing window limits closer to the

sensor. Viceversa, a decrease in air temperature shifts both limits farther away from the sensor.

This shift is approximately 3.5% of the limit distance for a 20° C change in temperature.

The US30 ultrasonic sensors are temperature compensated. This reduces the error due to temperature

by about 90%. The sensor will maintain its window limits to within 2.2% over the -40° to +70°C range.

Notes:

- Exposure to direct sunlight can affect the sensor’s ability to accurately compensate for changes in

temperature.

- If the sensor is measuring across a temperature gradient, the compensation will be less effective.

ultrasonic sensors

INSTRUCTION MANUAL

CONTROLS

CONNECTIONS

1

4

2

10 … 30 VDC

+

0 V

REMOTE

ANALOGU E OUTPUT

(4…20 mA / 0…10 V)

1

3

PRINCIPLES OF OPERATION

D = Distance from the sensor to the target

C = Speed of sound in the air

T = Transit time for the signal

4

Cm/s = Speed of sound in meters per second

Tc = Temperature in °C

TECHNICAL DATA

Power supply:

Ripple:

Consumption

(load current excluded):

Analogue output configuration:

Outputs:

Response time:

Switching frequency:

Indicators:

Setting:

Remote input levels:

Delay at Power On:

Temperature effect:

Temperature drift:

Linearity:

Resolution:

Minimum reading window size:

Ultrasonic emission frequency:

Operating temperature:

Storage temperature:

Maximum relative humidity:

Operating distance (typical values):

Vibrations:

Shock resistance:

Reference standard:

Housing material:

Push-button material:

Mechanical protection:

Connections:

Weight:

US30-XX-

N13-IH

Voltage

output:

4…20 mA

Voltage output: 2.5 K minimum load resistance.

Minimum supply for a full 10V output is 12Vdc

(for supply voltages between 10 and 12V, out max is at

least V supply – 2V)

Current output:

Max load resistance = (Vcc-4)/0.02 .

Example, at Vin = 24V, R 1K (1watt)

For Vdc = 24V, R 1K (1 watt).

45 ms (fast), 105 ms (slow)

11 Hz (fast), 4.7 Hz (slow) 5.4 Hz (fast), 2.2 Hz (slow)

Power On LED (GREEN), Out LED (YELLOW), Signal

LED (RED), Time Response Mode LEDs (YELLOW)

(remote teach). Minimum and maximum detection limits

can be programmed using the ANALOG push-button or

0,1 % of distance (0.5 mm

0.5 mm amplitude, 10…55 Hz frequency, for every axis

11 ms (30 G) shock for every axis (EN60068-2-27)

US30-XX-

N13-VH

reverse polarity protection

Voltage

output

0…10 V

Short-circuit protection

Selectable:

ANALOG push-button, remote command input

Active: V

Disabled: V

HIGH

0.02% of distance /°C

< 1 % of reading distance

min.)

224 KHz 174 KHz

95% a 50°C (without condensation)

100…1000 mm 200…2000 mm

M12 4-pol connector

US30-XX-

N23-IH

10 … 30 Vdc

2 Vpp

40mA max.

Voltage

output:

4…20 mA

Selectable:

92 ms (fast), 222 ms (slow)

remote input.

≤ 2 V @ 1mA

LOW

≥ 5V @ 50uA (leakage current)

500 ms

0.25% of distance

0,1 % of distance (1 mm

10 mm

-40 … 70 °C

-40 … 70 °C

(EN60068-2-6)

EN60947-5-2

PBT polyester

Polyester

IP67

68 g

min.)

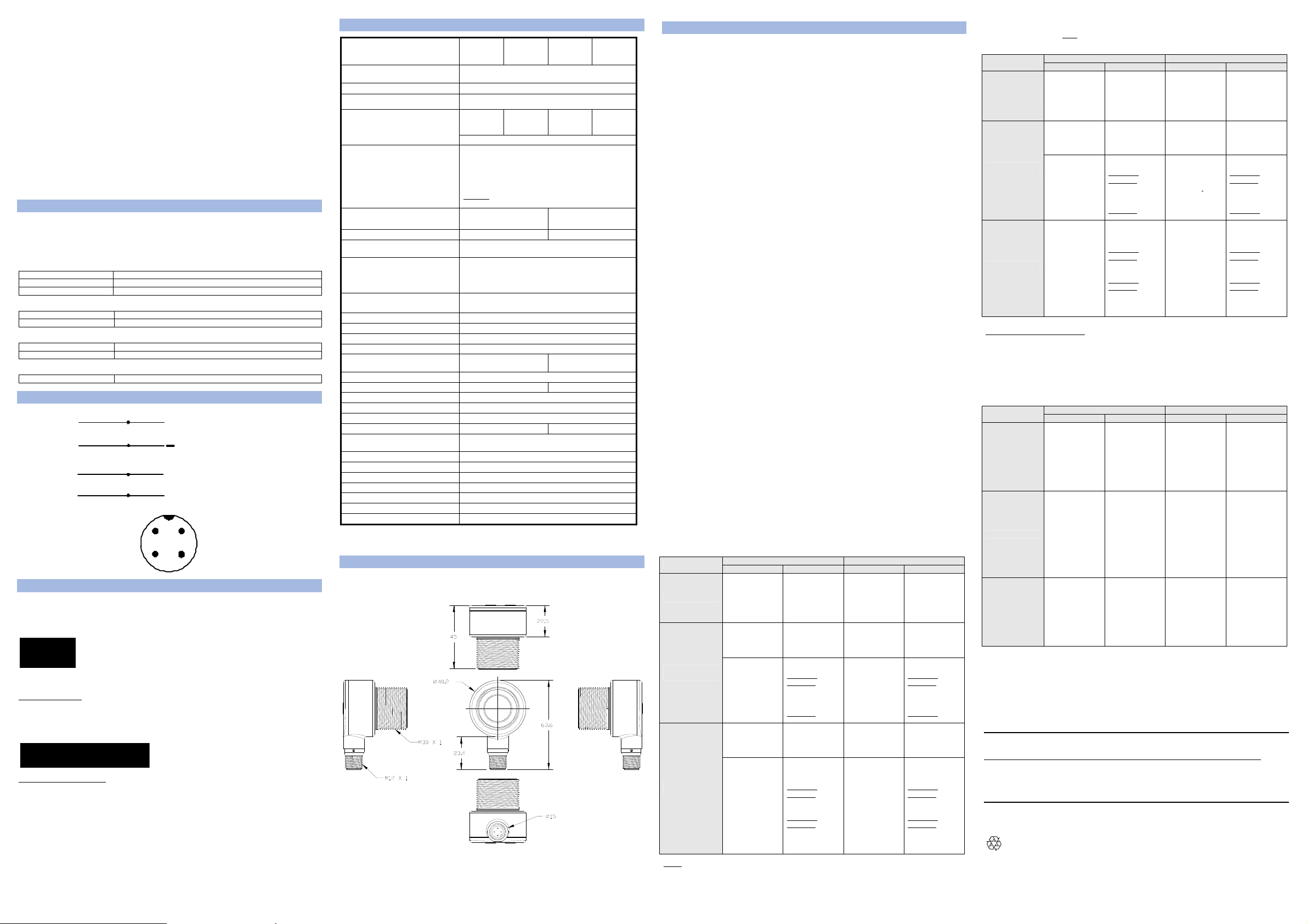

DIMENSIONS

mm

US30-XX-

N23-VH

Voltage

output

0…10 V

SENSOR PROGRAMMING

Two TEACH methods may be used to program the sensor:

Detect minimum and maximum limits, or

Use Auto-Window feature to centre a sensing window

The sensor may be programmed either via ANALOG push-button, or

via a remote command (remote teach).

Remote programming may be used to disable the push-button,

preventing unauthorized personnel from adjusting the programming

settings. To access this feature, connect the Remote Teach wire of

the sensor to 0 Vdc, with a remote configuration switch between the

sensor and the voltage.

Programming is accomplished by following the sequence of input pulses. The duration of each pulse

(corresponding to a push-button “click”), and the period between multiple pulses, are defined as “T”:

around the taught position.

0.04 seconds < T < 0.8 seconds

Indication of sensor status and relative signals

Positive or negative output slope programming

The sensor may be programmed for either a positive or a negative output slope, based on which limit is

taught first (see pictures).

If the Minimum limit is taught first, the slope will be positive.

If the Maximum limit is taught first, the slope will be negative.

The analogue output signal, is automatically distributed over the width of programmed sensing window.

In the event of signal loss for more than 2 sec., the analogue output goes to 3.6mA or 0Vdc, which may

be used to trigger an alarm.

TEACH Mode

TEACH

First Limit

TEACH

Second Limit

ANALOG push-button REMOTE Line

Procedure LED indicators Procedure LED indicators

Push and hold

ANALOG push-

button for >2sec.

Position the

target for the first

limit

Press ANALOG

push-button for

the first limit

Position the

target for the

second limit

Press ANALOG

push-button for

the second limit

LED OUT: ON

LED PWR: OFF

LED SIGNAL:

must be on or

blinking

Teach accepted:

LED PWR: OFF

LED OUT:

Blinking

Teach not

accepted:

LED OUT: ON

LED SIGNAL:

must be on or

blinking

Teach accepted:

LED PWR: ON

LED OUT: ON

Teach not

accepted:

: OFF

LED PWR

LED OUT

:

Blinking.

No action

required. Sensor

is ready for 1st

limit teach

Position target for

the first limit

Single-pulse the

remote line (0.04

s < T < 0.8 s).

Position target for

the second limit

Single-pulse the

remote line (0.04

s < T < 0.8 s).

None.

LED SIGNAL:

must be on or

blinking

Teach accepted:

LED PWR: OFF

LED OUT:

Blinking

Teach not

accepted:

LED PWR: ON

LED SIGNAL:

must be on or

blinking

Teach accepted

LED PWR: ON

LED OUT: ON

Teach not

accepted:

LED PWR

LED OUT

Blinking.

NOTE: the duration of each pulse (remote teach) and the period between multiple pulses are

defined as "T" and must be included between 0.04 s and 0.8 s (0.04 s < T < 0.8 s).

: OFF

:

Teaching limits using the Auto-Window feature

Teaching the same limit twice for the same output automatically centres a 100mm window on the

taught position ( 50 mm).

TEACH Mode

TEACH

First Limit

TEACH

Second Limit

DISCRETE push-button REMOTE Line

Procedure LED indicators Procedure LED indicators

Push and hold

ANALOG pushbutton for >2sec

Position the

target for the first

limit

Press ANALOG

push-button

Press ANALOG

push-button again

without moving

target

LED OUT: ON

LED PWR: OFF

LED SIGNAL:

must be on or

blinking

Teach accepted:

LED PWR: OFF

LED OUT:

Blinking

Teach not

accepted:

LED OUT: ON

Teach accepted:

LED PWR: ON

LED OUT: ON

Teach not

accepted:

LED PWR: OFF

LED OUT:

Blinking

No action

required. Sensor

is ready for 1st

limit teach

Position target for

the first limit

Single-pulse the

remote line (0.04

s < T < 0.8 s).

Pulse again the

remote line

without moving

the target (0.04 s

< T < 0.8 s).

None

LED SIGNAL:

must be on or

blinking

Teach accepted:

LED PWR: OFF

LED OUT:

Blinking

Teach not

accepted:

LED PWR: ON

Teach accepted:

LED PWR: ON

LED OUT: ON

Teach not

accepted:

LED PWR: OFF

LED OUT:

Blinking

General Notes on Programming

The sensor will return to RUN mode if the first TEACH condition is not registered within 120 seconds.

After the first limit is taught, the sensor will remain in PROGRAM mode until the TEACH sequence is

finished.

To exit PROGRAM mode without saving any changes, press and hold the programming push button >

2 seconds (before teaching the second limit). The sensor will revert to the last saved program.

Response time selection (Fast or Slow)

Two different response times can be selected using the MODE push-button or remote line.

TEACH Mode

Output selection

Save and

activate new

mode

DECLARATION OF CONFORMITY

We DATASENSOR S.p.A. declare under our sole responsibility that these products are conform to the

2004/108/CE, 2006/95/CE Directives and successive amendments.

WARRANTY

DATASENSOR S.p.A. warrants its products to be free from defects.

DATASENSOR S.p.A. will repair or replace, free of charge, any product found to be defective during

the warranty period of 36 months from the manufacturing date. This warranty does not cover damage

or liability deriving from the improper application of DATASENS OR products.

DATASENSOR S.p.A. Via Lavino 265

40050 Monte S. Pietro - Bologna - Italy

Tel: +39 051 6765611 Fax: +39 051 6759324

http://www.datasensor.com e-mail: info@datasensor.com

DATASENSOR S.p.A. cares for the environment: 100% recycled paper.

DATASENSOR S.p.A. reserves the right to make modifications and improvements without prio

notification.

MODE push-button REMOTE Line

Procedure LED indicators Procedure LED indicators

Push and hold

MODE pushbutton for >2sec

Press MODE to

choose between

FAST or SLOW

Push and hold

MODE pushbutton for >2sec

LED PWR: OFF

LED MODE:

Blinking amber

LED shows

previously

selected mode

LED PWR: OFF

LED MODE:

Blinking amber

LED shows

currently selected

mode.

LED PWR: ON

LED MODE:

Blinking amber

LED shows

currently selected

mode.

Double-pulse the

remote line

Single pulse:

SLOW

Double pulse:

FAST

None. Sensor

exits

programming

procedure.

LED PWR: OFF

LED MODE:

Blinking amber

LED shows

previously

selected mode

LED PWR: ON

LED MODE:

Blinking amber

LED shows

currently selected

mode.

None.

826003980 Rev.A

r

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 Web: www.ctiautomation.net - E-mail: info@ctiautomation.net

US30 SERIES

- digital output -

Programming push-button (DISCRETE)

This push-button allows to program the reading points of the sensor.

Output configuration push-button (MODE)

This push-button allows to select the output configuration.

POWER LED indicator Indication

OFF Power is OFF.

ON Green Sensor is operating in normal conditions.

OUT LED indicator Indication

OFF Target is outside operating field (NO operating mode)

ON Yellow Target is inside operating field (NO operating mode)

SIGNAL LED indicator Indication

OFF Target is outside operating field

Blinking Red Target is inside operating field

MODE LED indicator Indication

ON Amber Indicates selected output configuration (PNP/NPN and NO/NC)

BROWN

BLUE 3

WHITE 2

BLACK

M12 4-POLE CONNECTOR

Ultrasonic sensors emit a series of ultrasonic energy pulses, which travel through the air at the speed of

sound. A portion of this energy is reflected by the target and travels back to the sensor. The sensor

measures the total time required for the energy to reach the target and return to the sensor.

The distance to the object is then calculated using the following formula:

To improve accuracy, an ultrasonic sensor elaborates the average results of several pulses before

activating the output.

Temperature effects

The speed of sound depends on the composition, pressure and temperature of the gas in which it is

travelling. For most ultrasonic applications, the composition and pressure of the gas a re rela tively f ixed,

while the temperature may vary.

In air, the speed of sound varies according to the following approximate formulas:

Temperature Compensation

Changes in air temperature affect the speed of sound, which in turn affects the distance reading

measured by the sensor. An increase in air temperature shifts both sensing window limits closer to the

sensor. Viceversa, a decrease in air temperature shifts both limits farther away from the sensor.

This shift is approximately 3.5% of the limit distance for a 20° C change in temperature.

The US30 ultrasonic sensors are temperature compensated. This reduces the error due to temperature

by about 90%. The sensor will maintain its window limits to within 2.2% over the -40° to +70°C range.

Notes:

- Exposure to direct sunlight can affect the sensor’s ability to accurately compensate for changes in

temperature.

- If the sensor is measuring across a temperature gradient, the compensation will be less effective.

ultrasonic sensors

INSTRUCTION MANUAL

CONTROLS

CONNECTIONS

1

4

2

10 … 30 VDC

+

0 V

REMOTE

NPN/P NP OUT PUT

1

3

PRINCIPLES OF OPERATION

D = Distance from the sensor to the target

C = Speed of sound in the air

T = Transit time for the signal

4

Cm/s = Speed of sound in meters per second

Tc = Temperature in °C

TECHNICAL DATA

US30-XX-N13 US30-XX-N23

Power supply: 10 … 30 VDC

Ripple:

Consumption

(load current excluded):

Outputs: PNP/NPN and N.O./N.C. selectable

Output current: 100 mA max., short-circuit protection

Output saturation voltage:

Response time: 45 ms 92 ms

Switching frequency: 11 Hz 5.4 Hz

Indicators: Power on LED (GREEN), Out LED (YELLOW), Signal LED

Setting:

Remote input levels: Active: V

Delay at Power On:: 500 ms

Temperature effect: 0.02% of distance / °C

Temperature drift: < 1 % of reading distance

Repeatability: 0.1 % of distance

Minimum reading window size: 10 mm

Hysteresis: 2 mm 3 mm

Ultrasonic emission frequency: 224 kHz 174 kHz

Operating temperature: -40 … 70 °C

Storage temperature: -40 … 70 °C

Maximum relative humidity: 95% a 50 °C (without condensation)

Operating distance (typical values): 100…1000 mm 200…2000 mm

Vibrations: 0.5 mm amplitude, 10…55 Hz frequency, for every axis

Shock resistance: 11 ms (30 G) 6 shock for every axis (EN60068-2-27)

Reference standard: EN60947-5-2

Housing material: PBT polyester

Push-button material: Polyester

Mechanical protection: IP67

Connections: M12 4-pole connector

Weight: 68 g

(remote teach). Minimum and maximum detection limits can

be programmed using the DISCRETE push-button or remote

reverse polarity protection

2 Vpp

40 mA max.

PNP: 3 V a 100 mA,

NPN: 1.6 V a 100 mA

(RED), Output Mode LEDs (YELLOW)

DISCRETE push-button, remote command input

input.

≤ 1 V @ 1 mA

Disabled: V

(0.5 mm min.)

LOW

≥ 5V @ 50 uA (leakage current)

HIGH

0.1 % of distance

(1 mm min.)

(EN60068-2-6)

Programmazione dei punti di lettura, minimo e massimo, del sensore

TEACH Mode

TEACH

First Limit

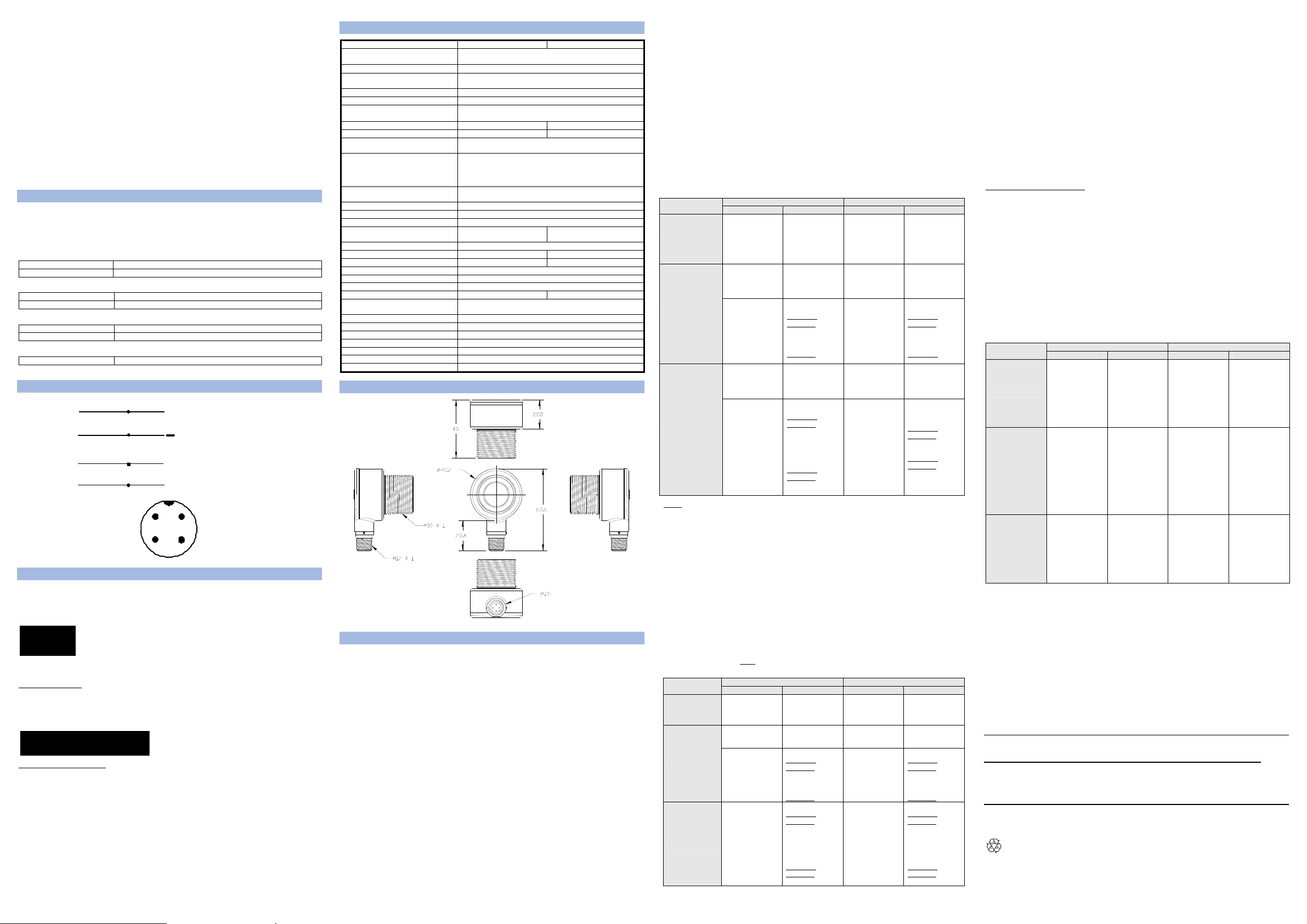

DIMENSIONS

TEACH

Second Limit

NOTE: the duration of each pulse (remote teach) and the period between multiple pulses are

defined as "T" and must be included between 0.04 s and 0.8 s (0.04 s < T < 0.8 s).

Mm

SENSOR PROGRAMMING

Two TEACH methods may be used to program the sensor:

Detect minimum and maximum limits, or

Use Auto-Window feature to centre a sensing window around the taught position.

This mode is particularly suitable if the sensor is used as background suppression (refer to drawing).

The sensor may be programmed either via DISCRETE push-button, or via a remote command (remote

teach).

Remote programming may be used to disable the push-button, preventing unauthorized personnel from

adjusting the programming settings. To access this feature, connect the Remote Teach wire of the

sensor to 0 VDC, with a remote configuration switch between the sensor and the voltage.

Programming is accomplished by following the sequence of input pulses.

The duration of each pulse (corresponding to a push-button “click”), and the period between multiple

pulses, are defined as “T”:

Teaching limits using the Auto-Window feature

Teaching the same limit twice for the same output automatically centres a 100mm window on the

taught position ( 50 mm).

TEACH Mode

TEACH

First Limit

TEACH

Second Limit

Indication of sensor status and relative signals

DISCRETE push-button REMOTE Line

Procedure LED indicators Procedure LED indicators

Push and hold

DISCRETE push-

button for >2sec.

Position the

target for the first

limit

Press DISCRETE

push-button for

the first limit

Position the

target for the

second limit

Press DISCRETE

push-button for

the second limit

LED OUT: ON

LED PWR: OFF

LED SIGNAL:

must be on or

blinking

Teach accepted:

LED PWR: OFF

LED OUT:

Blinking

Teach not

accepted:

LED OUT: ON

LED SIGNAL:

must be on or

blinking

Teach accepted:

LED PWR: ON

LED OUT: ON

(depends on the

NO or SC mode

selected)

Teach not

accepted:

LED PWR: OFF

LED OUT:

Blinking

No action

required. Sensor

is ready for 1st

limit teach

Position target for

the first limit

Single-pulse the

remote line (0.04

s < T < 0.8 s)

Position target for

the second limit

Single-pulse the

remote line (0.04

s < T < 0.8 s)

None.

LED SIGNAL:

must be on or

blinking

Teach accepted:

LED PWR: OFF

LED OUT:

Blinking

Teach not

accepted:

LED PWR: ON

LED SIGNAL:

must be on or

blinking

Teach accepted

LED PWR: ON

LED OUT: ON

Teach not

accepted:

LED PWR: OFF

LED OUT:

Blinking.

Refer to “NO and NC function selection” chapter

DISCRETE push-button REMOTE Line

Procedure LED indicators Procedure LED indicators

Push and hold

DISCRETE pushbutton for >2sec.

Position the

target for the first

limit

Press DISCRETE

push-button

Press DISCRETE

push-button again

without moving

target

LED OUT: ON

LED PWR: OFF

LED SIGNAL:

must be on or

blinking

Teach accepted

LED PWR: OFF

LED OUT:

Blinking

Teach not

accepted:

LED OUT: ON

Teach accepted

LED PWR

LED OUT

: ON o

OFF (depends on

the NO or SC

mode selected)

Teach not

accepted:

LED PWR: OFF

LED OUT:

Blinking

: ON

No action

required. Sensor

is ready for 1st

limit teach

Position target for

the first limit

Single-pulse the

remote line (0.04

s < T < 0.8 s)

Pulse again the

remote line

without moving

the target (0.04 s

< T < 0.8 s)

None

LED SIGNAL:

must be on or

blinking

Teach accepted

LED PWR: OFF

LED OUT:

Blinking

Teach not

accepted:

LED OUT: ON

Teach accepted

LED PWR

LED OUT

OFF (depends on

the NO or SC

mode selected)

Teach not

accepted:

LED PWR: OFF

LED OUT:

Blinking

: ON

: ON o

General Notes on Programming

The sensor will return to RUN mode if the first TEACH condition is

not registered within 120 s econds.

After the first limit is taught, the sensor will remain in PROGRAM

mode until the TEACH sequence is finished.

To exit PROGRAM mode without saving any changes, press and

hold the programming push button > 2 seconds (before teaching

the second limit). The sensor will revert to the last saved program.

N.O. (normally open) or N.C. (normally closed) mode selection

The sensor can be configured as NPN or PNP, by choosing between the N.O. and N.C. modes or

remote line. A pulse series along this line switches the sensor between N.O. / N.C and PNP / NPN.

N.O. configuration: sensor output is activated in presence of the target to detect.

N.C. configuration: sensor output is activated when there is no target to detect.

TEACH Mode

Output selection

Save and

activate new

mode

Refer to “NO and NC function selection” chapter

MODE push-button REMOTE Line

Procedure LED indicators Procedure LED indicators

Push and hold

MODE pushbutton for >2sec

Press and hold

MODE push-

button to select

mode in the

following

sequence:

NPN – N.O.

NPN – N.C.

PNP – N.O.

PNP – N.C.

Push and hold

MODE pushbutton for >2sec

LED PWR: OFF

LED MODE:

Blinking amber

LED shows

previously

selected mode

LED PWR: OFF

LED MODE:

Blinking amber

LED shows

currently selected

mode.

LED PWR: ON

LED MODE:

Blinking amber

LED shows

currently selected

mode.

Double-pulse the

remote line

Single pulse:

NPN – N.O.

Double pulse:

NPN – N.C.

Triple pulse: PNP

– N.O. Four

pulses: PNP –

N.C.

None. Sensor

exits

programming

procedure.

LED PWR: OFF

LED MODE:

Blinking amber

LED shows

previously

selected mode

LED PWR: ON

LED MODE:

Blinking amber

LED shows

currently selected

mode.

None

DECLARATION OF CONFORMITY

We DATASENSOR S.p.A. declare under our sole responsibility that these products are conform to the

2004/108/CE, 2006/95/CE Directives and successive amendments.

WARRANTY

DATASENSOR S.p.A. warrants its products to be free from defects.

DATASENSOR S.p.A. will repair or replace, free of charge, any product found to be defective during

the warranty period of 36 months from the manufacturing date. This warranty does not cover damage

or liability deriving from the improper application of DATASENSOR products.

DATASENSOR S.p.A. Via Lavino 265

40050 Monte S. Pietro - Bologna - Italy

Tel: +39 051 6765611 Fax: +39 051 6759324

http://www.datasensor.com e-mail: info@datasensor.com

DATASENSOR S.p.A. cares for the environment: 100% recycled paper.

DATASENSOR S.p.A. reserves the right to make modifications and improvements without prio

notification.

826003990 Rev.A

Loading...

Loading...