DATASENSOR S10 Instruction Manual

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

S10 SERIES

INSTRUCTION MANUAL

CONTROLS

OUTPUT LED (S10-…A01/B01/C01/C11/C21/D01/F01/T01)

The yellow LED indicates the output status.

STABILITY LED (S10-…A01/B01/C01/C11/C21/D01/F01)

green LED ON indicates that the received signal has a safety margin

greater than 30% compared to the output switching value.

POWER ON LED (S10-…G00)

The green LED indicates that the sensor is operating.

TRIMMER (S10-…A01/B01/C01/C11/C21/D01/F01/T01)

The trimmer can be used to adjust sensitivity; the operating distance

increases turning the trimmer clockwise.

WARNING: The trimmer rotation is limited to 270° by a mechanical stop.

Do not apply excessive torque when adjusting (max 40 Nmm).

CONNECTIONS

NPN OUTPUT PNP OUTPUT

BROWN

BLACK

BLUE

1

10 … 30 Vdc

+

NPN

150mA

4

3

0 V

BROWN

BLACK

BLUE

S10-…G00-XE S10-…G00-XF

BROWN

BLACK

BLUE

1

10 … 30 Vdc

+

4

TEST +

3

0 V

BROWN

BLACK

BLUE

M12 CONNECTOR

2

3

1

10 … 30 Vdc

+

4

PNP

150mA

3

0 V

1

10 … 30 Vdc

+

4

TEST -

3

0 V

1

4

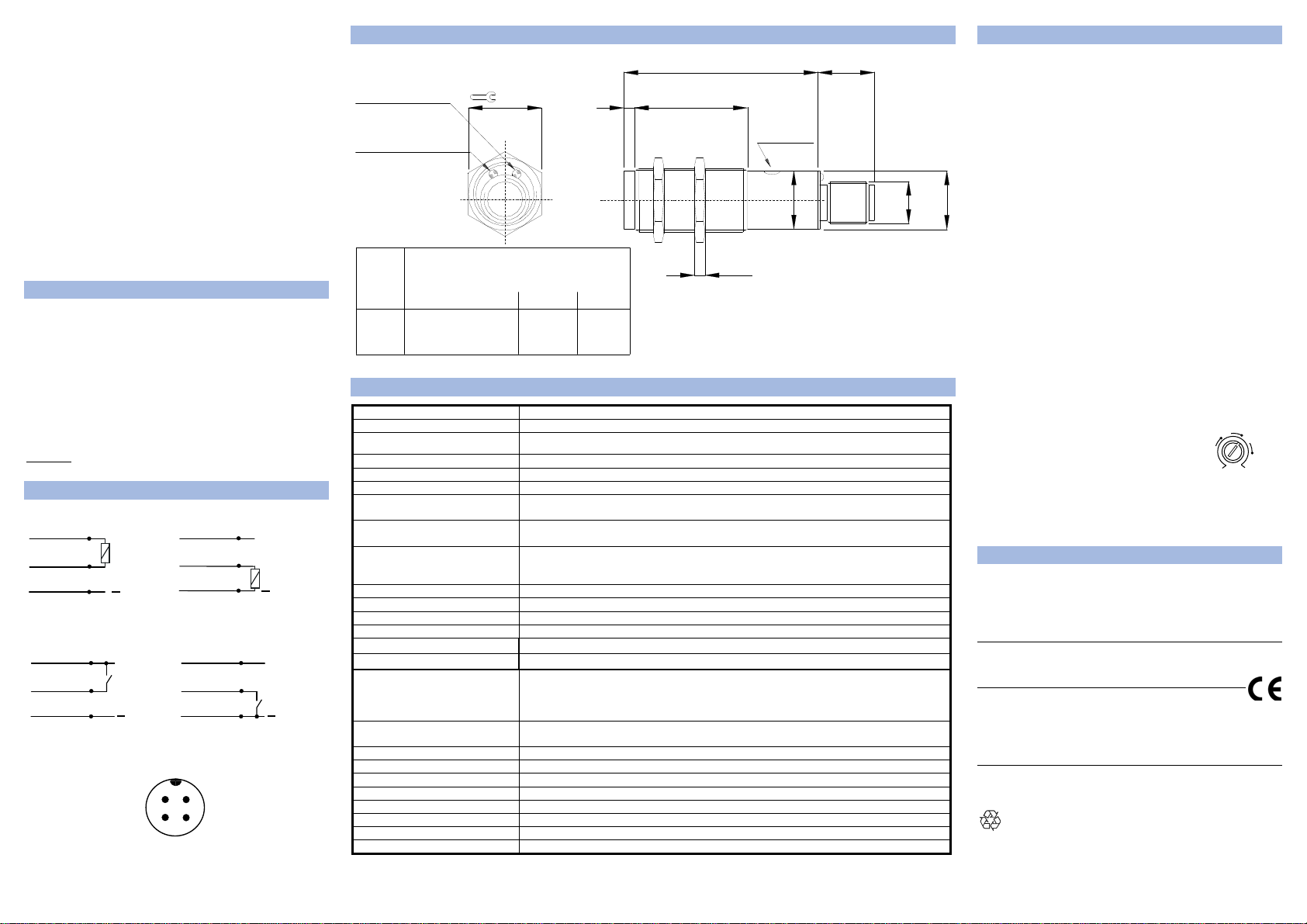

DIMENSIONS

16

OUTPUT LED

POWER ON LED

STABILITY LED

24

L

3

X1

TRIMMER

M18x1

M O D E L S

A01/C01/C11/C21/

D01/F01/T01

L

X1

Power supply: 10 … 30 VDc limit values

Ripple: 2 Vpp max.

Current consumption

(output current excluded):

Outputs: NPN or PNP; 30 Vdc max. (short-circuit protection at 200 mA)

Output current: 150 mA max.

Output saturation voltage: 1 V max.

Response time:

Switching frequency:

Indicators:

Setting: sensitivity trimmer (G00 mod. excluded)

Selection Dark/Light: selection light (L) selection dark (D)..

Operating temperature: -25 … 55 °C

Storage temperature: -25 … 70 °C

Dielectric strength: 500 Vac 1 min., between electronics and housing

Insulating resistance:

Operating distance (minimum

values):

Emission type:

Ambient light rejection: according to EN 60947-5-2

Vibrations: 0.5 mm amplitude, 10 … 55 Hz frequency, for every axis (EN60068-2-6)

Shock resistance: 11 ms (30 G) 6 shock for every axis (EN60068-2-27)

Housing/connector material: Nichel-plated brass (S10-MA vers.) / AISI 316L stainless steel (S10-NA vers.)

Lens material: PMMA plastic

Mechanical protection: IP69K

Connections: metal M12 4-pole connector

Weight: 50 g. max.

65.1

41.3

B01

67.4

43.6

G00

55.1

31.3

mm

TECHNICAL DATA

2 ms max. mod. F01/G00

250 Hz max. mod. F01/G00

STABILITY LED (GREEN) A01/B01/C01/C11/C21/D01/F01 mod.

A01: 0.1…4 m on R2 / B01: 0.1…3 m on R2 / T01: 0.1…0.8 m on R2

OUTPUT LED (YELLOW) G00 mod. excluded

POWER ON LED (GREEN) G00 mod.

>20 MΩ 500 Vdc, between electronics and housing

C01: 1…10 cm / C11: 1…35 cm / C21: 1…60 cm

D01: 14 mm with 1.5 mm spot

F01/G00: 0…18 m

infrared (880 nm) mod.A01/C01/C11/C21/G00

red (660 nm) mod.B01/D01/T01

4

30 mA max.

1 ms max.

500 Hz max.

M12

SETTING

The following procedures are valid for the LIGHT mode. The yellow

Output LED (OUT) works in the opposite manner in the DARK mode

models.

Alignment S10-…A01/B01

Position the sensor and reflector on opposite sides.

Turn the sensitivity trimmer to maximum. Find the points where the

yellow LED (OUT) is switched ON and OFF in both vertical and

horizontal positions and fix the sensor in the centre between these

points.

Optimum operation is obtained when both LEDs are switched ON.

If necessary, reduce sensitivity in order to detect very small targets.

In order to improve alignment, repeat the procedure detailed above

whilst progressively reducing the sensitivity.

Alignment S10-…T01

16.6

Position the sensor and reflector on opposite sides.

Turn the sensitivity trimmer to maximum. Find the points where the

yellow LED (OUT) is switched ON and OFF in both vertical and

horizontal positions and fix the sensor in the centre between these

points.

If necessary, reduce sensitivity in order to detect transparent objects. In

order to improve alignment, repeat the procedure detailed above whilst

progressively reducing the sensitivity.

Alignment S10-…F01/G00

Turn the sensitivity trimmer to maximum. Find the points where the

yellow LED (OUT) is switched ON and OFF in both vertical and

horizontal positions and fix the sensor in the centre between these

points. Optimum operation is obtained when both LEDs are switched

ON.

If necessary, reduce sensitivity using the trimmer, in order to detect very

small targets. In order to improve alignment, repeat the procedure

detailed above whilst progressively reducing the sensitivity.

Alignment S10-…C01/C11/C21/D01

Position the sensor and turn the sensitivity trimmer at minimum:

The green LED is ON and the yellow LED is OFF.

Place the target opposite the sensor. Turn the

sensitivity trimmer clockwise until the yellow LED

turns ON (Target detected state, pos.A).

Remove the target, the yellow LED turns OFF. Turn the trimmer

clockwise until the yellow LED turns ON (Background detected state,

pos.B).

The trimmer reaches maximum if the background is not detected.

Turn the trimmer to the intermediate position C, between the two

positions A and B. The green LED must be ON.

TEST FUNCTION (S10-…G00)

The TEST input can be used to inhibit the emitter and verify that the

system is correctly operating.

The receiver output should switch when the test is activated while the

beam is uninterrupted.

The inputs activating voltage range is 10 … 30 Vdc, whilst respecting the

polarity.

DECLARATION OF CONFORMITY

We DATASENSOR S.p.A. declare under our sole responsibility that

these products are conform to the 2004/108/CE, 2006/95/CE Directives

and successive amendments.

WARRANTY

DATASENSOR S.p.A. warrants its products to be free from defects.

DATASENSOR S.p.A. will repair or replace, free of charge, any product

found to be defective during the warranty period of 36 months from the

manufacturing date.

This warranty does not cover damage or liability deriving from the

improper application of DATASENSOR products.

DATASENSOR S.p.A. Via Lavino 265

40050 Monte S. Pietro - Bologna - Italy

Tel: +39 051 6765611 Fax: +39 051 6759324

http://www.datasensor.com e-mail: info@datasensor.co m

DATASENSOR S.p.A. cares for the environment: 100% recycled

paper.

DATASENSOR S.p.A. reserves the right to make modifications

and improvements without prior notification.

826003170 Rev.A

A

C

B

MAX

MIN

Loading...

Loading...