DAEWOO DWD-F1011, DWD-F1012, DWD-F1013, DWD-F1021, DWD-F1031 Service manual

...

S/M No. : WDF1011002(r)

Service Manual

Washing Machine

Model: DWD-F1011/F1012/F1013/F1211/F1212/F1213 DWD-F1021/F1022/F1023/F1221/F1222/F1223 DWD-F1031/F1032/F1033/F1231/F1232/F1233 DWD-F1041/F1042/F1043/F1241/F1242/F1243 NFL-1065/NFL-1265

Caution

:In this Manual, some parts can be changed for improving, their performance without notice in the parts list. So, if you need the latest parts information, please refer to PPL(Parts Price List) in Service Information Center (http://svc.dwe.co.kr).

DAEWOO ELECTRONICS CORP.

http : //svc.dwe.co.kr |

Apr. 2008 |

SHER |

AUTO WASHER |

AUTO WASHER |

AUTO WASHER |

AUTO WASHER |

AUTO WASHER |

AUTO WASHER |

AUTO WASHER |

AUTO |

WASH |

||||||||||

TO |

WASHER |

AUTO |

WASHER |

AUTO |

WASHER |

AUTO |

WASHER |

AUTO |

WASHER |

AUTO |

WASHER |

AUTO |

WASHER |

AUTO |

WASHER |

AU |

|||

SHER |

AUTO WASHER |

AUTO WASHER |

AUTO WASHER |

AUTO WASHER |

AUTO WASHER |

AUTO WASHER |

AUTO WASHER |

AUTO |

WASH |

||||||||||

TO |

WASHER |

AUTO |

WASHER |

AUTO |

WASHER |

AUTO |

WASHER |

AUTO |

WASHER |

AUTO |

WASHER |

AUTO |

WASHER |

AUTO |

WASHER |

AU |

|||

SHER |

AUTO WASHER |

AUTO WASHER |

AUTO WASHER |

AUTO WASHER |

AUTO WASHER |

AUTO WASHER |

AUTO WASHER |

AUTO |

WASH |

||||||||||

TO |

WASHER |

AUTO |

WASHER |

AUTO |

WASHER |

AUTO |

WASHER |

AUTO |

WASHER |

AUTO |

WASHER |

AUTO |

WASHER |

AUTO |

WASHER |

AU |

|||

SHER |

AUTO WASHER |

AUTO WASHER |

AUTO WASHER |

AUTO WASHER |

AUTO WASHER |

AUTO WASHER |

AUTO WASHER |

AUTO |

WASH |

||||||||||

WASHING MACHINE

Contents

1. SPECIFICATIONS.................................................................................................................... |

2 |

2. INSTALLATION ........................................................................................................................ |

5 |

Removing transit bolts ...................................................................................................... |

5 |

Installation place requirement........................................................................................... |

6 |

BS Plug Safety Details (For U.K. User)............................................................................ |

6 |

Connecting inlet hose ....................................................................................................... |

7 |

Installation of drain hose................................................................................................... |

8 |

Level adjustment............................................................................................................... |

9 |

3. MAINTENANCE ..................................................................................................................... |

10 |

Cleaning your washer..................................................................................................... |

10 |

Cold condition ................................................................................................................. |

10 |

Cleaning the water inlet filter .......................................................................................... |

11 |

Cleaning the drain pump filter......................................................................................... |

11 |

Cleaning the detergent case........................................................................................... |

12 |

Cleaning the washing drum............................................................................................ |

12 |

4. DIRECTION FOR DISASSEMBLY ........................................................................................ |

13 |

5. EXPLODE VIEW AND PARTS LIST ..................................................................................... |

16 |

6. FUNCTIONS OF THE CONTROL PANEL ............................................................................ |

29 |

7. FUNCTIONS OF THE CONTROLLER.................................................................................. |

37 |

8. FUNCTION OF THE CONVENIENT SERVICE..................................................................... |

39 |

9. TROUBLESHOOTING GUIDE .............................................................................................. |

41 |

10. WIRING DIAGRAM .............................................................................................................. |

45 |

1.SPECIFICATIONS

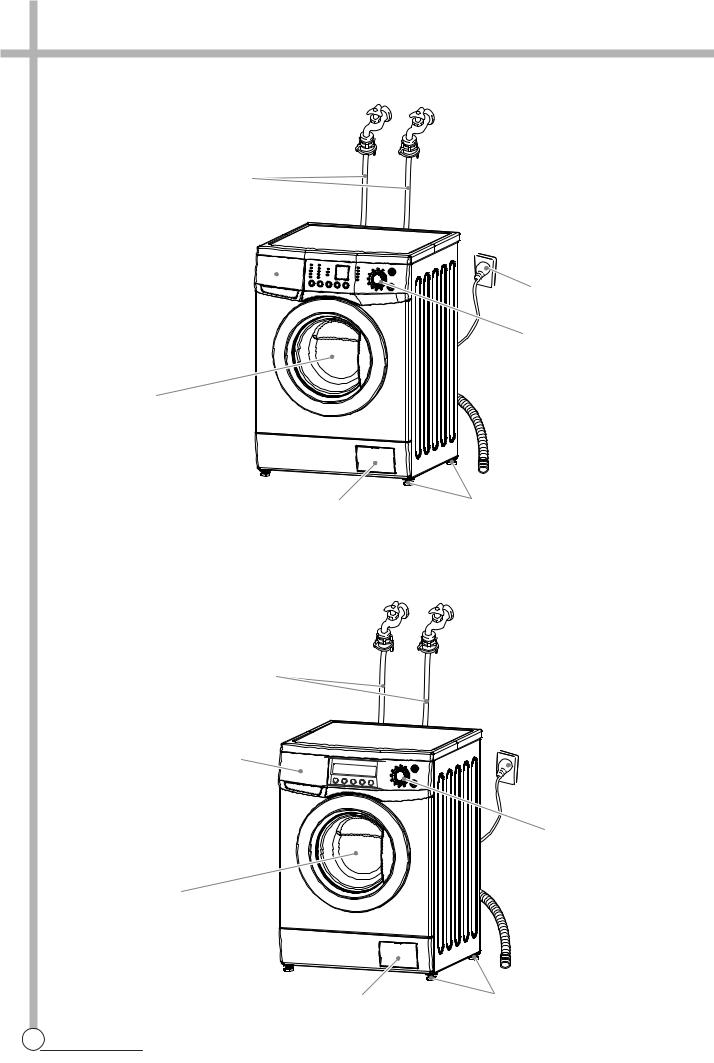

■DWD-F1X1X SERIES

HOT |

COLD |

(OPTION) |

|

INLET HOSE

DETERGENT CASE

POWER CORD

CONTROL PANEL

DOOR

HOSE DRAIN

HOSE DRAIN

LOWER COVER |

ADJUSTABLE LEG |

■ DWD-F1X2X SERIES

HOT |

COLD |

(OPTION)

INLET HOSE

DETERGENT CASE

POWER CORD

POWER CORD

CONTROL PANEL

DOOR

HOSE DRAIN

HOSE DRAIN

LOWER COVER |

|

ADJUSTABLE LEG |

|

|

|

2 SPECIFICATIONS

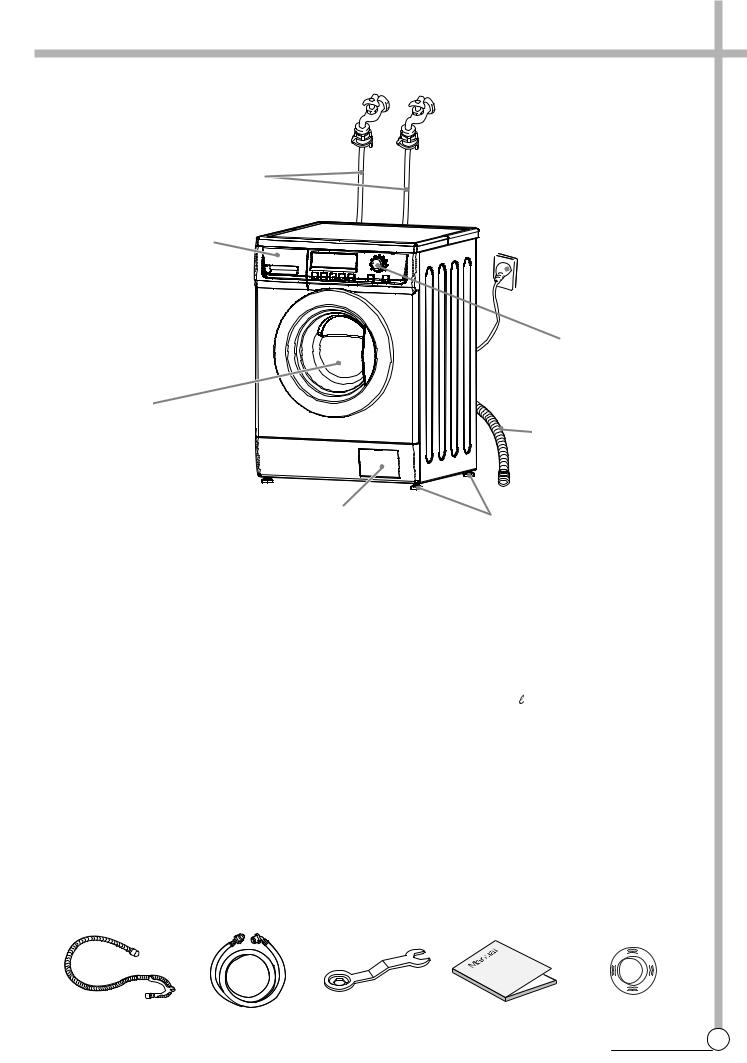

■ DWD-F1X3X SERIES

HOT |

COLD |

(OPTION)

INLET HOSE

DETERGENT CASE

POWER CORD

POWER CORD

CONTROL PANEL

DOOR

HOSE DRAIN

|

|

LOWER COVER |

|

|

|

|

|

ADJUSTABLE LEG |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DWD-F1011/F1012/F1013/F1211/F1212/F1213 |

||

MODEL |

|

|

|

DWD-F1021/F1022/F1023/F1221/F1222/F1223 |

||

|

|

|

DWD-F1031/F1032/F1033/F1231/F1232/F1233 |

|||

|

|

|

|

|||

|

|

|

|

NFL-1065/NFL-1265 |

||

|

|

|

|

|

|

|

POWER SOURCE |

|

|

|

220-240V, 50Hz |

||

|

|

|

|

|

|

|

DiMENSION (WXDXH) |

|

|

|

595mm x 540mm x 850mm |

||

|

|

|

|

|

|

|

WEIGHT |

|

|

|

|

64kg |

|

|

|

|

|

|

|

|

WATER CONSUMPTION |

|

|

47~59 |

|

||

|

|

|

|

|

|

|

POWER CONSUMPTION |

|

|

|

2200W |

||

|

|

|

|

|

|

|

MAXIMUM MASS |

|

WASH |

|

6 / 6.5 / 7 kg |

||

|

|

|

|

|

|

|

OF TEXTILE |

|

SPIN |

|

6 / 6.5 / 7 kg |

||

|

|

|

|

|

|

|

WASHER TYPE |

|

|

DRUM TYPE (FRONT LOADING WASHING MACHINE) |

|||

|

|

|

|

|

|

|

OPERATING WATER PRESSURE |

|

0.3 ~ 8kgf/cm2 (29.4 ~ 784kPa) |

||||

|

|

|

|

|

|

|

■ Accessories

Hose drain |

Inlet hose |

Spanner (Option) |

Manual |

Cap holder(3EA) |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SPECIFICATIONS 3

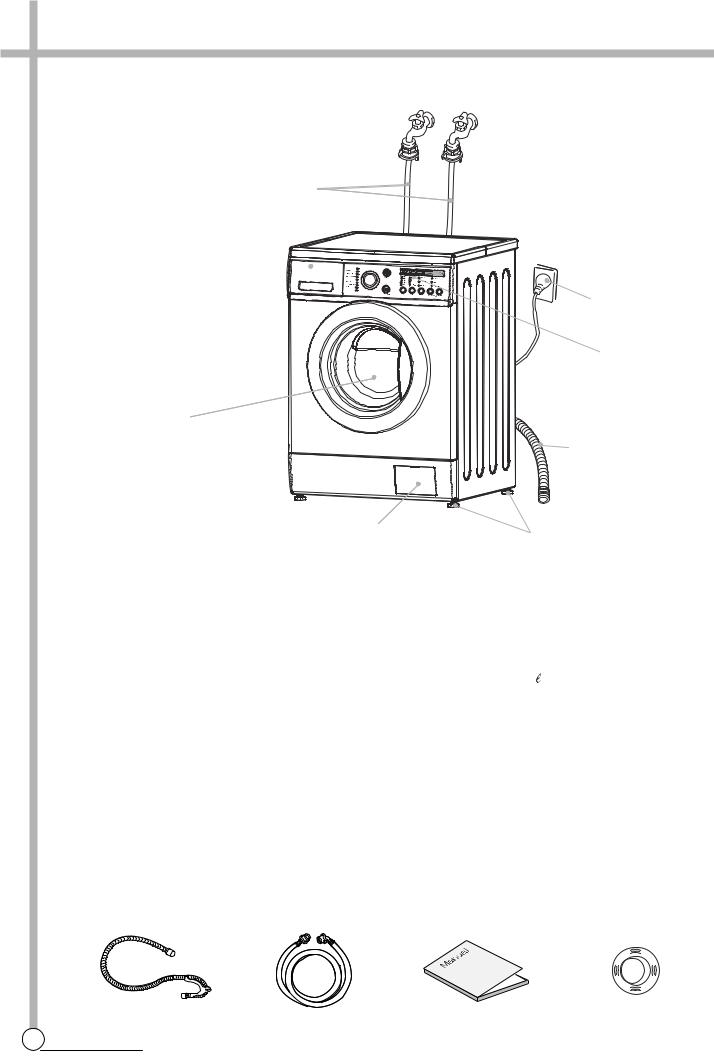

■ DWD-FU1X4X SERIES

HOT |

COLD |

(OPTION) |

|

INLET HOSE

DETERGENT CASE

POWER CORD

CONTROL PANEL

DOOR

HOSE DRAIN

|

|

|

LOWER COVER |

|

|

|

|

|

|

|

ADJUSTABLE LEG |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MODEL |

|

|

|

|

DWD-FU1041/1042/1043/1241/1242/1243 |

||

|

|

|

|

|

|

|

|

POWER SOURCE |

|

|

|

|

220-240V, 50/60Hz |

||

|

|

|

|

|

|

|

|

DiMENSION (WXDXH) |

|

|

|

|

595mm x 540mm x 850mm |

||

|

|

|

|

|

|

|

|

WEIGHT |

|

|

|

|

64 kg |

||

|

|

|

|

|

|

|

|

WATER CONSUMPTION |

|

|

|

47~59 |

|

||

|

|

|

|

|

|

|

|

POWER CONSUMPTION |

|

|

|

|

2200W |

||

|

|

|

|

|

|

|

|

MAXIMUM MASS |

WASH |

|

|

6 / 6.5 / 7 kg |

|||

|

|

|

|

|

|

|

|

OF TEXTILE |

SPIN |

|

|

6 / 6.5 / 7 kg |

|||

|

|

|

|

|

|

|

|

WASHER TYPE |

|

|

|

DRUM TYPE (FRONT LOADING WASHING MACHINE) |

|||

|

|

|

|

|

|

|

|

OPERATING WATER PRESSURE |

|

|

0.3 ~ 8kgf/cm2 (29.4 ~ 784kPa) |

||||

|

|

|

|

|

|

|

|

■ Accessories

Hose drain |

Inlet hose |

Manual |

Cap holder(3EA) |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 SPECIFICATIONS

2. INSTALLATION

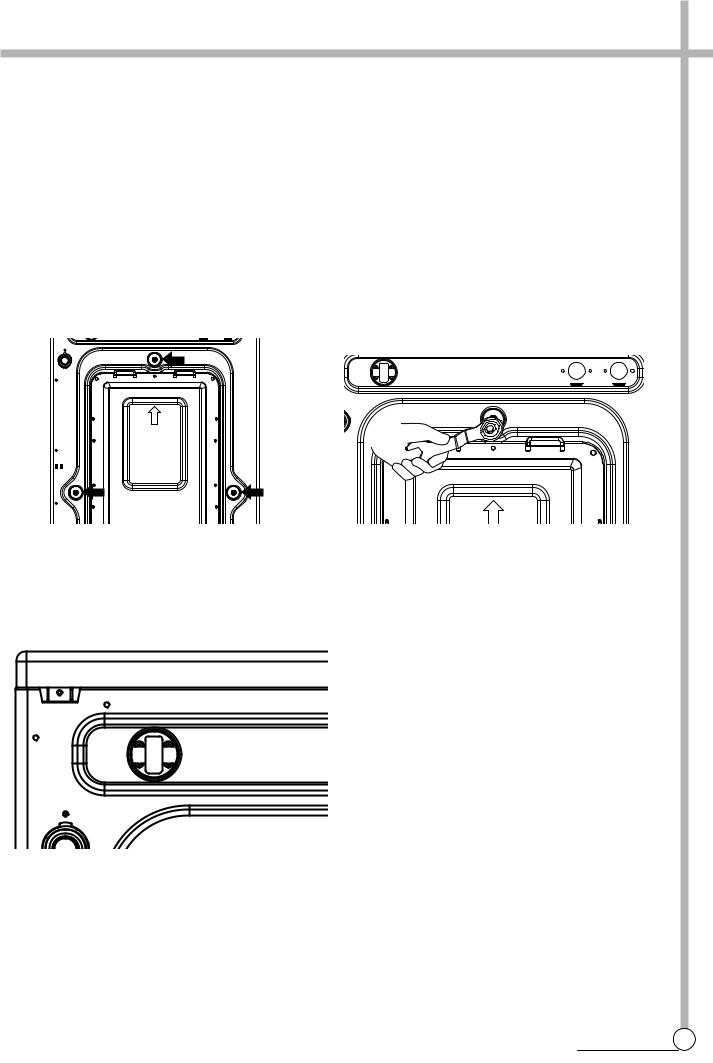

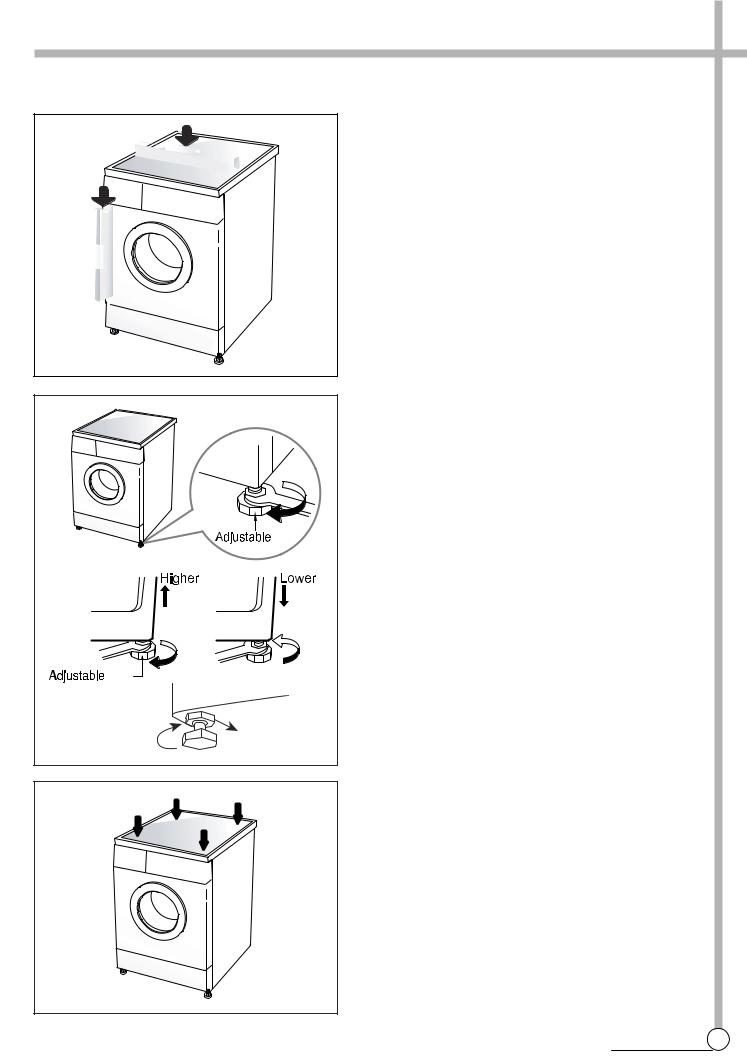

■ Transit bolts

The appliance is fitted with transit bolts to prevent internal damage during transport.

■ Removing transit bolts

1.To prevent internal damage during transport, the special 3 bolts are locked. Before operating the washer, remove the bolts along with the rubber bungs.

•If they are not removed, it may cause heavy vibration, noise and malfunction.

2.Unscrew the 3 bolts with the spanner supplied, and take out the 3 bolts with the rubber bungs. Keep the 3 bolts and the spanner for future use.

•Whenever the appliance is transported, the transit bolts must be refitted.

3. Close the holes with the caps supplied.

INSTALLATION 5

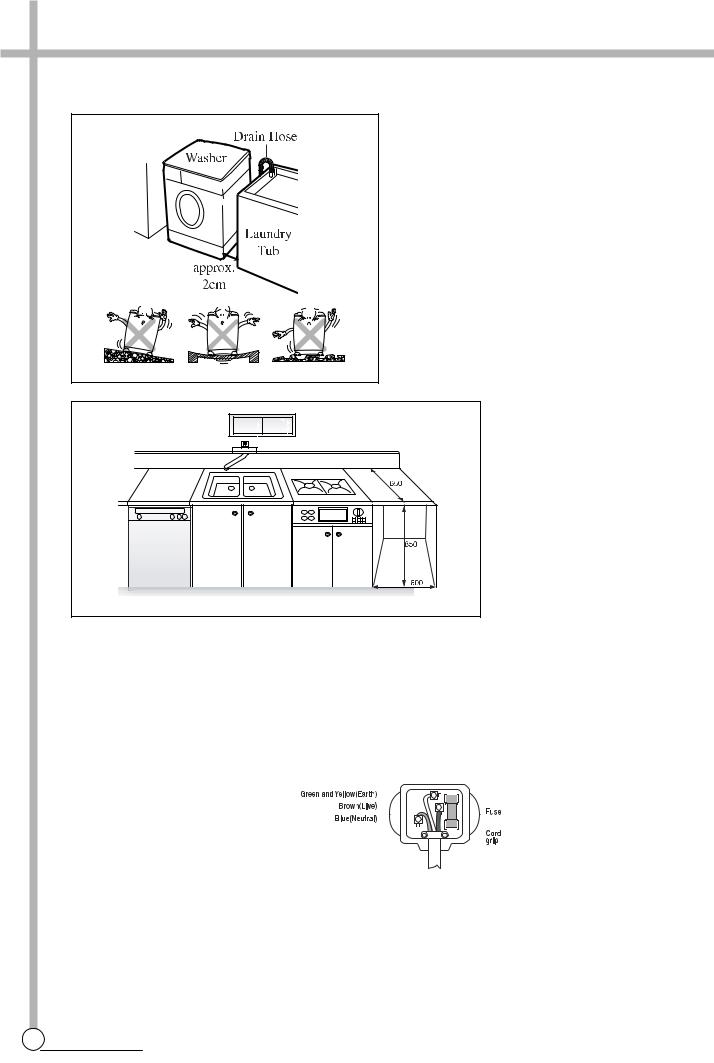

■ Installation place requirement

Level floor :

Allowable slope under entire washer is 1°

Power outlet :

Must be with 1.5 meters of entire side of location of washer. Do not overload the outlet with more than one appliance.

Additional Clearance :

For wall, door and floor modeling is required. (10cm : rear / 2cm : right & left side)

Do not place or store laundry products on top of washer at any times.

They can damage the finish or controls.

■ BS Plug Safety Details (For U.K. User)

IMPORTANT

THE WIRES IN THIS MAINS LEAD ARE COLOURED IN ACCORDANCE WITH THE FOLLOWING CODE:

GREEN AND YELLOW : EARTH

BLUE : NEUTRAL

BROWN : LIVE

This appliance must be earthed

As the colours of the wires in the mains lead of this apparatus may not correspond with the coloured markings identifying the terminals in your plug, proceed as follows:

The wire which is coloured Green and Yellow must be connected to the terminal in the plug which is marked with the letter E or by the earth symbol  or coloured Green or Green and Yellow.

or coloured Green or Green and Yellow.

The wire which is coloured Blue must be connected to the terminal which is marked with the letter N or coloured Black. The wire which is coloured Brown must be connected to the terminal which is marked with the letter L or

coloured Red.

If a 13 amp (BS 1363) plug is used, fit a 13amp BS 1362 fuse.

6 INSTALLATION

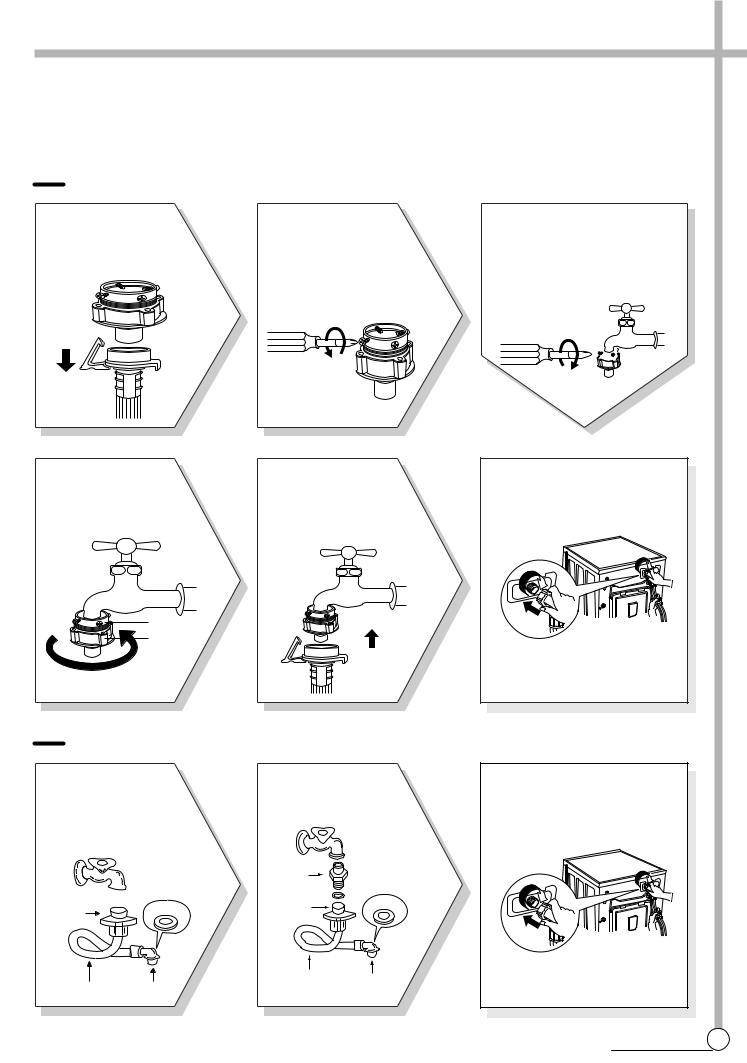

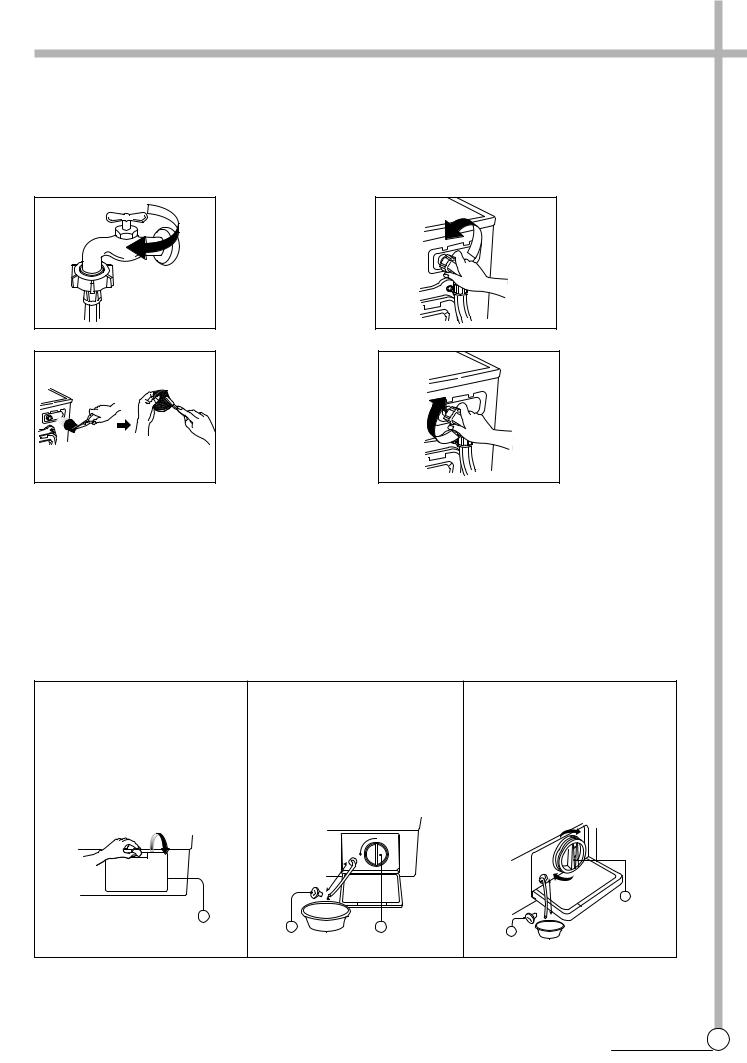

■ Connecting inlet hose

In using only one water tap or in case of only one water inlet valve, connect the inlet hose to the cold water inlet valve. Option : Be careful not to confuse hot water inlet and cold water inlet.

FOR ORDINARY TAP

1Pull down the collar of the inlet hose to separate it from the water tap adapter.

4Remove the tape, and screw connector B into connect A tightly.

Connector A

Connector B

2Loosen the four screws properly in order to fit into water tap.

5Conect the inlet hose to the water tap adapter by pulling down the collar of the hose end.

FOR SCREW-SHAPED TAP

1Conect the inlet hose to the water tap adapter by pulling down the collar of the hose end.

|

Rubber |

Connector D |

Packing |

Inlet Hose |

Connector C |

2Conect the connectorinlet supplied if necessary.

Connector

Inlet

|

Rubber |

Connector D |

Packing |

|

Hose

Connector C

3Fit the water tap adapter into the water tap and tighten the four screws evenly while pushing up the adapter so that the rubber packing can stick to the water tap tightly.

TAPE

TAPE

6Connect the inlet hose adapter of the hose to the water inlet of the washer by turning it clockwise to be fixed tightly.

•Please check the rubber packing present inside the inlet hose adapter of the hose.

3Connect the inlet hose adapter to the water inlet of the washer and turn it to be fixed.

• Check the packing in the inlet.

INSTALLATION 7

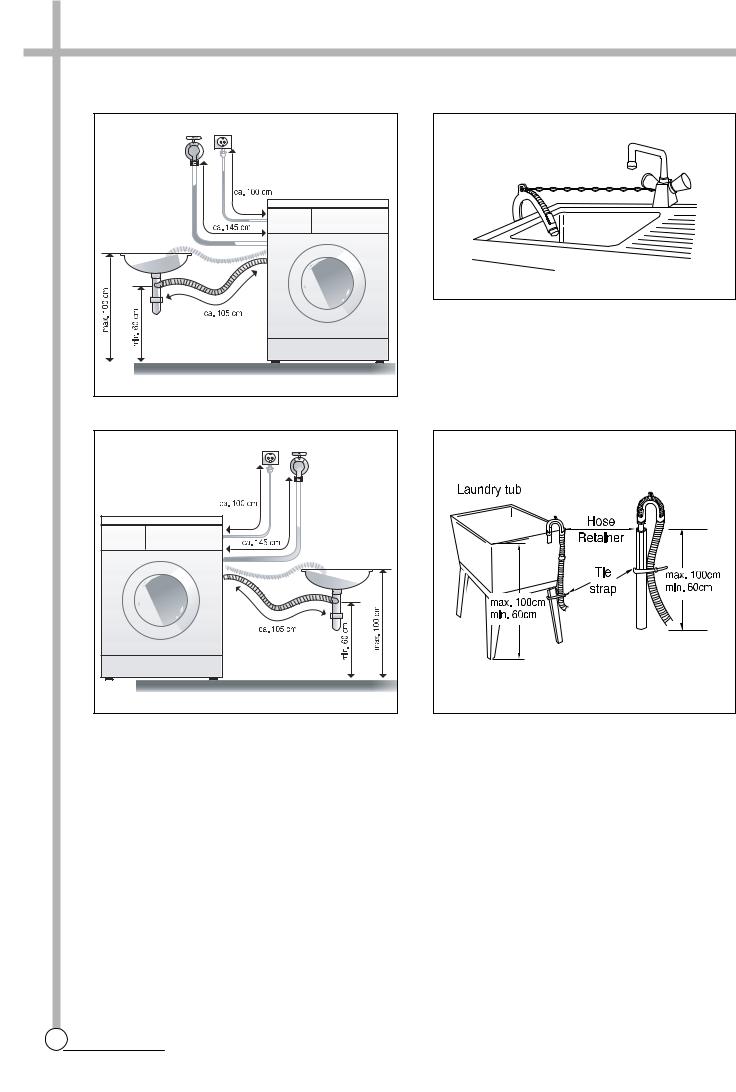

■ Installation of drain hose

• When installing the drain hose in sink, secure it tightly with a string.

• Proper securing of the drain hose will protect the floor from damage due to water leakage.

•The drain hose should not be placed higher than

100cm above the floor.

•Proper securing of the drain hose will protect the floor from damage due to water leakage.

•When the drain hose is too long, do not force back in to the washer. This will cause abnormal noise.

8 INSTALLATION

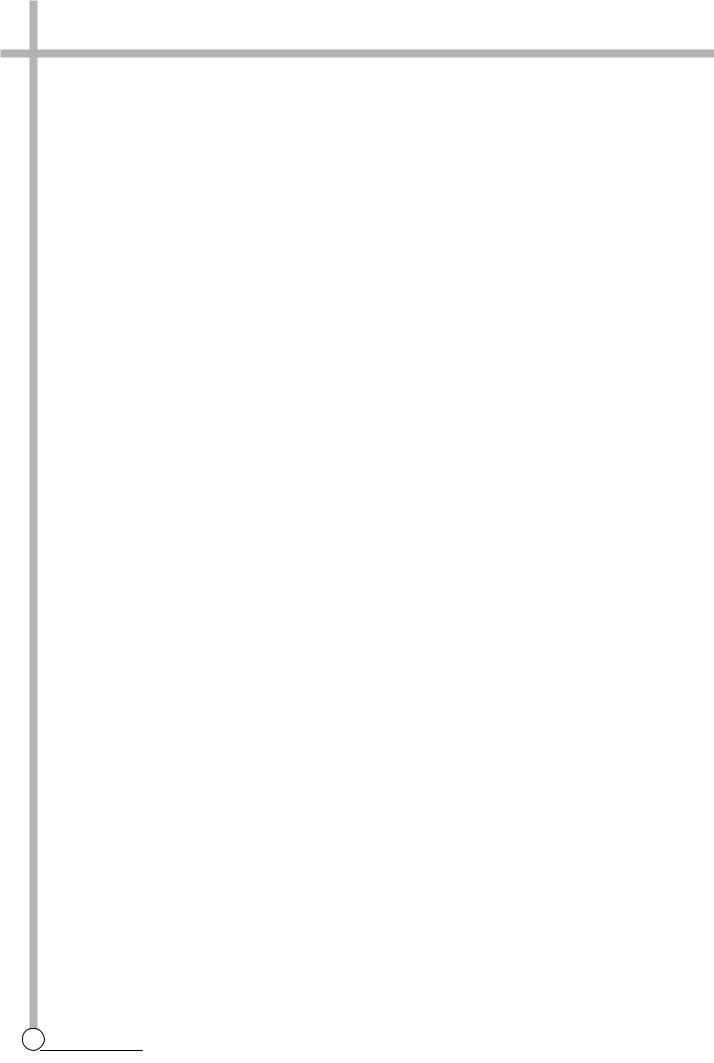

■ Level adjustment

1. The level adjustment of the washing machine prevents excessive noise and vibration.

Install the washing machine on a solid and even floor surface, if possible, in a corner of the room.

Note: the wooden floor may cause excessive vibration.

leg |

leg |

Fixing Nut |

2.If the floor is uneven, adjust the adjustable leg as the following.

(Do not insert pieces of wood etc. under legs.)

•Please check whether there is any gap between four adjustable legs and the floor.

•Turn adjustable legs by the enclosed spanner in order to adjust the level of the washing machine.

•Make it sure that there is no swaying of the washing machine and check that the washing machine is even completely. (use a spirit level)

•After the level adjustment is finished, turn fixing nuts up tightly so that the washing machine maintains the adjustment.

Diagonal Check

When pushing down the edges of the washing machine top plate diagonally, the machine should not move up and down at all.

(Please, check both of two directions)

If machine rocks when pushing the machine top plate diagonally, adjust legs again.

INSTALLATION 9

3.MAINTENANCE

Before cleaning the washer interior, unplug the electrical power cord avoid electrical shock hazards.

■ Cleaning your washer

1. Exterior

Proper care of your washer can extend its life.

The outside of the machine can be cleaned with warm water and a neutral non abrasive household detergent. Immediately wipe off any spills. Wipe with damp cloth.

Try not to hit surface with sharp objects.

• Do not use methylated spirits, diluents or similar products.

2. Interior

Dry around the washer door opening, flexible gasket and door glass.

Run washer through a complete cycle using hot water.

Repeat process if necessary.

•Remove hard water deposits using only cleaners labeled as washer safe.

■Cold condition

If the washer is stored in an area where freezing may occur or moved in freezing temperature, follow these instructions to prevent damage to the washer.

1.Turn off water supply tap.

2.Disconnect hoses from water supply and drain water from hoses.

3.Plug electrical cord into a properly grounded electrical outlet.

4.Add 1gallon(3.8L) of nontoxic recreational vehicle(RV) antifreeze into empty wash drum. Close the door.

5.Set spin cycle and let washer spin for 1minute to drain out all water.

6.Unplug eletrical power cord, dry the drum interior, and close the door.

7.Remove detergent case and dry excessive water from the compartments.

8.Store washer in an upright position.

9.To remove antifreeze from washer after storage, run empty washer through a complete cycle using detergent. Do not add wash load.

10 MAINTENANCE

■Cleaning the water inlet filter

•"IE" error message will blink on the control panel when water does not enter the detergent drawer.

•If your water is very hard or contains traces of lime deposit, the water inlet filter may become clogged.

•It is therefore a good idea to clean it from time to time.

1. Turn off the |

2. Unscrew the |

water tap. |

water inlet |

|

hose. |

3. Clean the filter |

4. Tighten up the |

using a had |

inlet hose. |

bristle brush. |

|

■Cleaning the drain pump filter

•The drain filter collects threads and small objects left in the laundry.

•Check regularly that the filter is clean to ensure smooth running of your machine.

CAUTION Be careful when draining if the water is hot.

1.Open the lower cover(1) by

using a coin. Turn the cap hose(2) to pull out the hose.

Pull out the hose maximally. (About 13~14cm.)

1

2.Unplug the cap hose(2), allowing

the water to flow out. At this time use a vessel to prevent water flowing on to the floor. When water does not flow any more, turn the pump filter(3) open to the left.

|

about |

|

13~14cm |

2 |

3 |

3.Remove any foreign material from the pump filter(3). After

cleaning, turn the pump filter clockwise and insert the cap hose(2) to the original place.

Close the lower cover.

about

13~14cm 3

2

MAINTENANCE 11

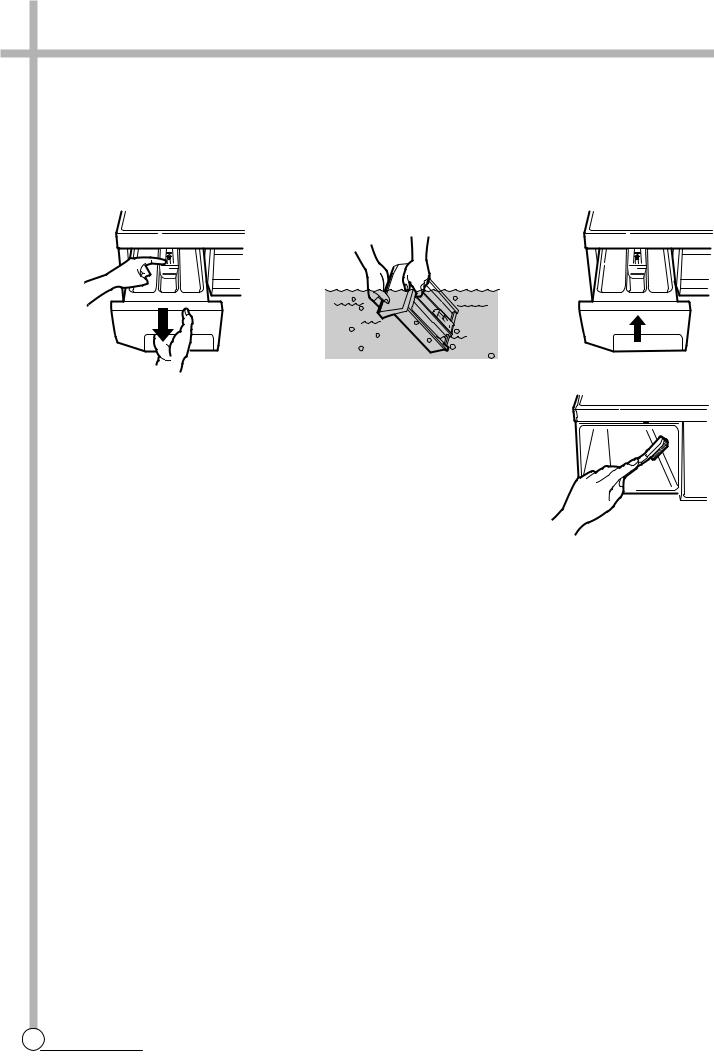

■Cleaning the detergent case

After a while detergents and fabric softeners leave a deposit in the detergent case.

•It should be cleaned from time to time with a jet of running water.

•If necessary it can be removed completely from the machine by pressing the catch downwards and by pulling it out.

•To facilitate cleanling, the upper part of the fabric softener compartment can be removed.

max

Inlet box recess

Detergent can also accumulate inside the recess which should be cleaned occasionally with an old toothbrush.

•Once you have finished cleaning, replace the detergent case and run a rinse cycle without laundry.

■Cleaning the washing drum

•If you live in a hard water area, limescale may continuously build up in places where it cannot be seen and thus not easily removed.

•Over time the build up of scale clogs appliances, and if it is not kept in check these may have to be replaced.

•Although the washing drum is made of stainless steel, specks of rust can be caused by small metal articles (paper clips, safety pins) which have been left in the drum.

•The washing drum should be cleaned from time to time.

•If you use descaling agents, dyes or bleaches, make sure they are suitable for washing machine use.

Descaler may contain chemicals that may damage part of your washing machine.

Remove any spots with a stainless steel cleaning agent.

Never use steel wool.

12 MAINTENANCE

4. DIRECTION FOR DISASSEMBLY

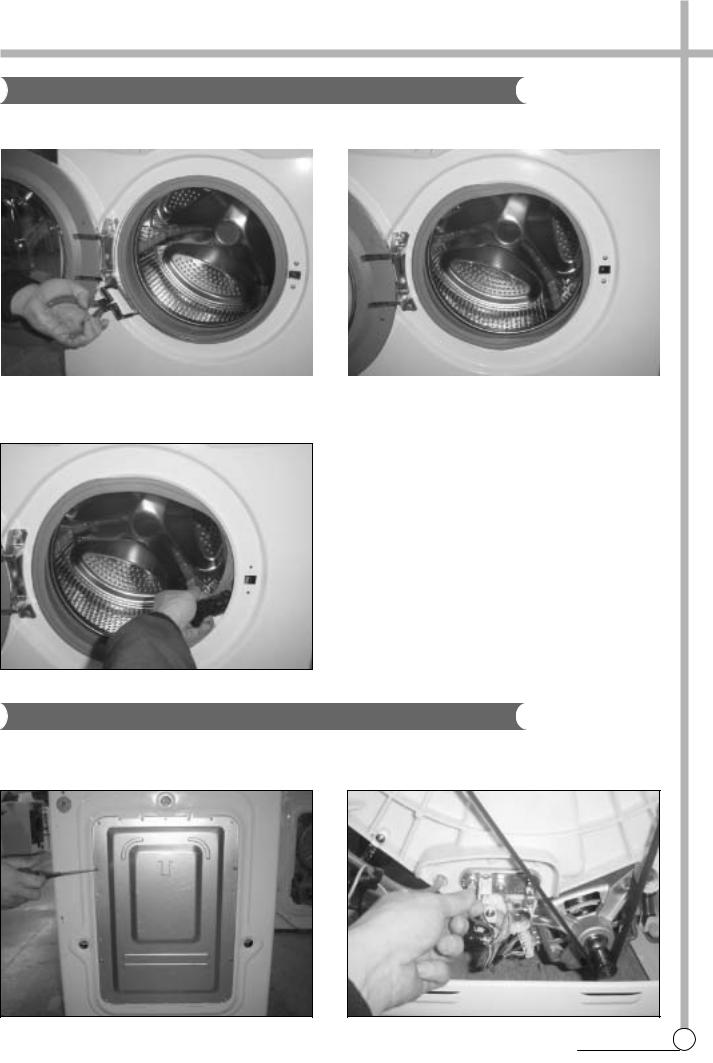

DOOR LOCK SWITCH

1) Open the door and remove the gasket clamp. |

|

2) Remove the gasket from the front cabinet. |

|

|

|

|

|

|

3)Remove two screws, and remove the door lock switch.

HEATER AND THERMISTOR

1)Remove four screws on the back cover, and remove the back cover.

2) Remove connectors and the earth terminal.

DIRECTION FOR DISASSEMBLY 13

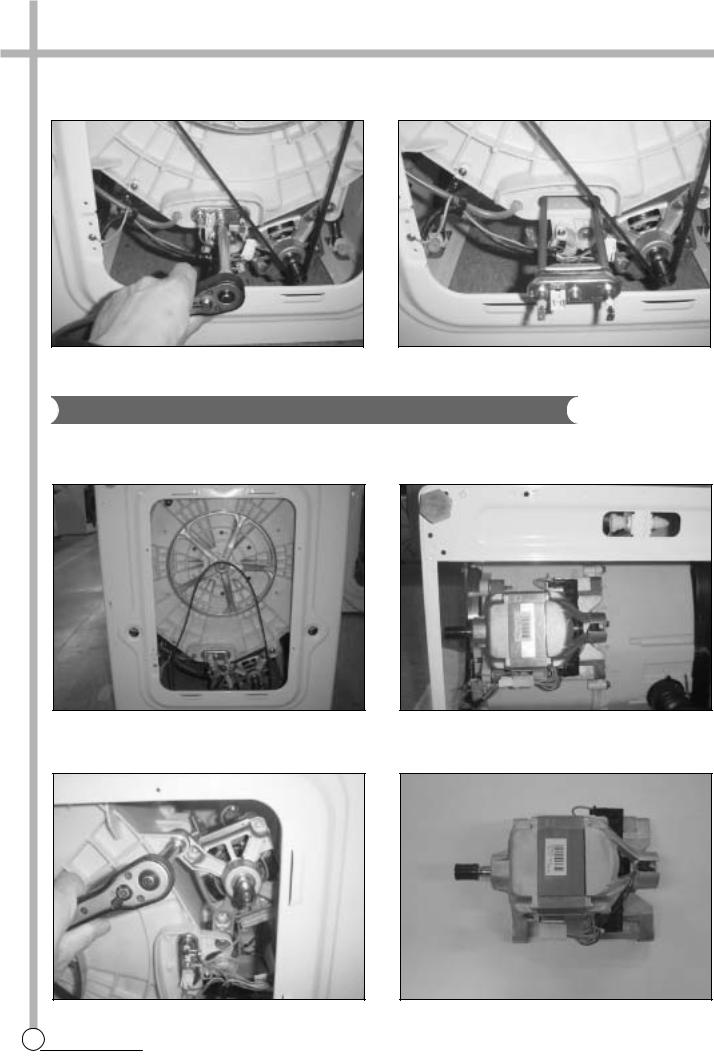

3)Remove the nut by using a box wrench, and remove the earth terminal.

4)Loosen the nut by using a box wrench, and pull out the heater.

UNIVERSAL MOTOR

1) remove the belt from the pulley.

3)Remove two bolts and two nuts mounting the motor by using a box wrench.

2)Lay the right side of the washer on the floor, and remove the connector.

4) Remove the motor from the tub.

14 DIRECTION FOR DISASSEMBLY

Loading...

Loading...