CLA-VAL eFlowMeter X144D-AF, X144D e-FlowMeter Quick Start Installation & Removal Instructions

Page 1

X144D-AF e-FlowMeter

CLA-VAL

Quick Start Installation & Removal Instructions

X144D-AF e-FlowMeter Included Hardware

1

2

1

flow

Sensing Probe

Flow

Display

Sensing

3

Cable

Complete

4

Installation Kit

Parts List

1) Sensing Probe

2) Flow Display

3) Sensing Cable

a) Insertion Tool

4) Installation Kit containing:

a) Insertion Tool

b) Locking Collar with

(a and b come assembled)

Score

Marks

b)

Thumb Set

Screw

Step-By-Step X144D-AF e-FlowMeter Installation Instructions

Isolation Valves

Step 1: Take necessary safety precautions

• Isolate the control valve using main line

isolation valves

• Bleed pressure from valve before removing

body plug

• Remove an inlet body plug

NOTE: If both inlet body tappings are used for

the pilot system, consult factory for correct

modification instructions.

Thumb Set Screw

Locking

Collar

2

Step 2A:

Loosen Knurled Lock Nut on e-FlowMeter Assembly

3

Step 3A: Screw Locking Collar on straight threads. Insert

angled end of provided tool as shown, until it stops

Thumb Set Screw

Locking Collar

tape not supplied

4

Sensor/Head Assembly

sensor

tip

Threaded Swivel Insert

Step 2B: Pull apart. Straighten Measurement Cylinder by

hand. Set aside Sensor/Head in safe location,

protecting sensor tip

Thumb Set Screw

Step 3B: Tighten Thumb Set Screw

Step 4: Apply Teflon® tape to NPT Threads

• Check threads on valve

• Use thread chasing tool (not supplied), if

necessary

Measurement

Cylinder

Page 2

X144 e-FlowMeter

Quick Start Installation & Removal Instructions

Step-By-Step X144D-AF e-FlowMeter Installation Instructions (continued)

flow

inside view

top view

Step 5: Insert straightened Swivel Insert/Measurement

Cylinder Assembly into valve, orient arrow on

wrench flat to point downstream

7

65

Verify score mark is

flush with flat face

of straight thread

to ensure full

engagement

Step 6: Loosen Thumb Set Screw. Remove Locking Collar

from tool. Remove tool and re-insert opposite end into

Swivel Assembly. Engage the tool and push firmly to orient

Measurement Cylinder 90˚ into flow path

8

Step 7: Remove tool from Threaded Swivel Insert

9

Step 9: Line-Up Centering Groove on straight threads

with Centering Pin; push to seat o-ring

Centering

Pin

Centering

Groove

Step 8: Insert tip of e-FlowMeter Sensor/Head Assembly

into Threaded Swivel Insert

10

Knurled

Lock

Please see display

programming manual for

display configuration.

Step 10: HAND TIGHTEN Knurled Lock onto straight

threads. Attach Sensing Cable to Sensing Probe

and Flow Display.

Proceed in accordance with Wiring Diagram

Page 3

X144D-AF e-FlowMeter

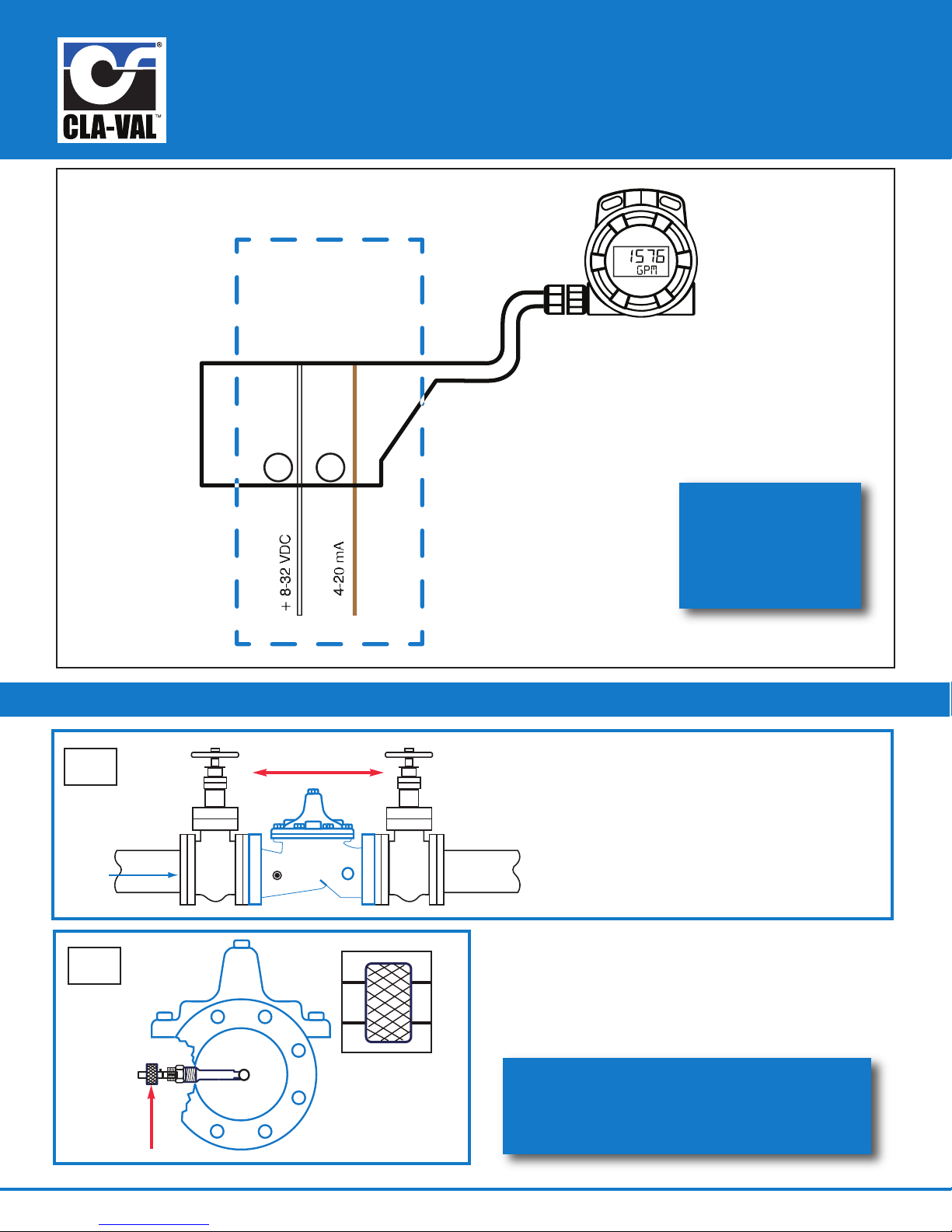

X144D-AF

Flow Display

7

8

4-20mA Loop

Power

Circuit Wiring

CLA-VAL

flow

Quick Start Installation & Removal Instructions

Standard Wiring

for additional

wiring diagrams,

download N-144

IOM Manual at

www.cla-val.com

Step-By-Step X144D-AF e-FlowMeter Removal Instructions

1

2

Isolation Valves

Knurled

Lock

Step 1: Take necessary safety precautions

a) Isolate the control valve

using main line isolation valves

b) Bleed pressure from valve before

removing the e-FlowMeter

c) Disconnect power to all electronic

devices on valve, including e-FlowMeter

Step 2: After isolating the valve, bleeding pressure and

disconnecting electronic devices, hand loosen the

Knurled Lock from straight threads

call 800.942.6326 for assistance

or log-on to

www.cla-val.com for more information

Page 4

X144D-AF e-FlowMeter

Quick Start Installation & Removal Instructions

Step-By-Step X144D-AF e-FlowMeter Removal Instructions (continued)

3

Step 3:

• Remove the e-FlowMeter Sensor/Head Assembly by

pulling straight outward, being careful not to hit the

sensor tip on the Threaded Swivel Insert tube

• Set Sensor/Head Assembly aside, taking care to

protect the sensor tip

5

flow

Before

flow

After

4

Step 4:

• Orient the Installation Tool so that the bevel is

facing downstream, away from the centering

groove as shown in detail drawing, and insert into

the Threaded Swivel Insert

6

entering groove

c

top view

Step 5:

• Once inserted into the Threaded Swivel Insert tube,

the Installation Tool will engage the top face of the

Measurement Cylinder and force it to the 45° position,

as shown above

top view

7

Step 7:

• Once engaged, use light force to straighten the

measurement cylinder, and then secure the Installation

Tool in place with Locking Collar in locked position

N-X144D-AF Quick Start, Removal & Wiring (R-07-2017)

Installation Tool lip

Step 6:

• Slide Installation Tool straight out, then rotate 180° so that

the bevel is facing upstream of the valve, which is now

facing the same direction of the centering groove, see above

• The lip of the Installation Tool will engage the inside of the

Measurement Cylinder as shown in photo

8

Step 8:

• Remove Threaded Swivel Insert from the valve tapping with

the Measurement Cylinder straightened

• Insert body plug into tapping while servicing the e-FlowMeter

Loading...

Loading...