Page 1

60-31/660-31

Page 2

0

LO

......

......

I

I

O'I

N

N

......

I

I

......

......

0

0

~

a_

<

0::

IO

"

co

v

N

0

(.)

,....,.

~

N

~

co

N

0::

<

0

_J

(.)

(.)

w

0::

'-'

0

a_

LL

w

<

z

0::

(.)

~

0::

<

~

w

LL

Ul

_J

_J

<

0

z

CD

0

~

F

a_

Ul

0

Cl

0

~

w

0

0

:::!!

0

w

<

0::

z

a_

5

I=!

I

v

<

N

0

I

"

>-

~

CD

<

>-

:::l

<

:::::>

:e

:::I!

LL.I

(/]

5'

LL.I

a::

I-

0

:z:

0

0

I

is

~

i!5

!i:

~

co

a::

~

......

i5

0

ti5

(.)

5'

w

LL.I I..._..

a::

0

w

Ul

cs

_J

w

Li:

0::

w

z

Ul

0

0

Vi

0

5

ID

w

0

0::

w

w

0

w

0

Ul

<

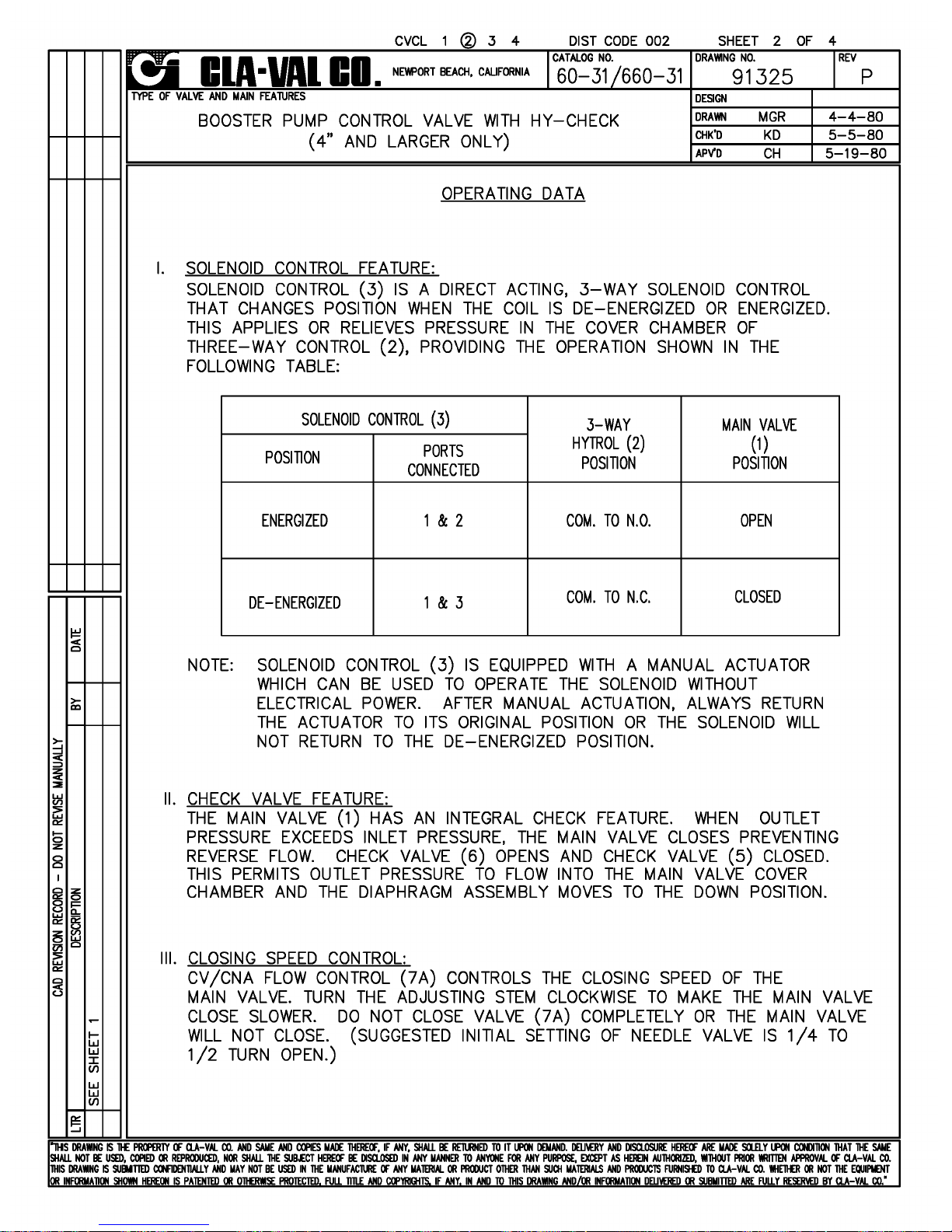

CVCL

1 @ 3 4

DIST

CODE

002

SHEET

1

DRAWING

NO.

91325

BOOSTER PUMP CONTROL VALVE

WITH

HY-CHECK

(4"

AND LARGER ONLY)

DESIGN

DRAWN

CHK'D

APV'D

- - - -

NOT

FURNISHED

BY

CLA-VAL

CO.

~~~3

- - - - -

OPTIONAL

FEAlURES

~

I

/I\

2

~E6

N.C. r

~

COM.

N.O.

~7A

4

/6

/

~

(

------00--------

(

'\7..,

L_

+--

\.

I

P3_/

-/

f-j /

MGR

KD

CH

-------

n

~

n.

-·~~

INLET

~

~

OUTLET

B

........

•USE

CV

FLOW

CONTROLS

ON

6" & SMALLERlQ(60-3}

1

*USE

CV

FLOW

CONTROLS

ON

8" & SMALLER

VALVES

(660-31)

1

1:1

BASIC

COMPONENTS

QTY

L

1

100-04

HY-CHECK

(60-31)

MAIN

VALVE

1

100-23

HY-CHECK

(660-31)

MAIN

VALVE

8 CK2

COCK

(ISOLATION VALVE)

2

102C-3H

3-WAY

HYTROL

W/PIPE

PLUG

3

CS3SM

SOLENOID

CONTROL

4 X105LCW LIMIT

SWITCH

ASSEMBLY 1

5

CDC

CHECK

VALVE 1

6 CDC/CSC

CHECK

VALVE 1

7 *CV

FLOW

CONTROL/CNA

NEEDLE

VALVE 2

OPTIONAL

FEATURE

SUFFIX

ADDED

TO

CATALOG

NUMBER

A X46A

FLOW

CLEAN

STRAINER

1

B CK2

COCK

(ISOLATION VALVE) 3

P

X141

PRESSURE

GAUGE

ASSEMBLY 3

Y X43

"y"

STRAINER

1

OF

4

IREV

p

4-4-80

5-5-80

5-19-80

--7B

"lllS

DRAWING

IS

11£

PRa'ERlY

Cl'

a..A-VAl

CO.

AND

SAME

AND

COPIES

MADE

lHERECI',

IF

ANY,

SHAl.l

BE

REMNED

TO

IT~

DEMAND.

DELMRY

AND

DISQ.OSURE

HERE<I'

ARE

MADE

sa.n.Y ~ C<NllllOO

lHAT

lHE

SAME

SHAl.l

NOT

BE

USED,

COPIED

OR

REPROOUCED,

NOR

SHAl.l

lHE

SUB.ECT

HERE<I'

BE

DISQ.OSED

IN

ANY

MANNER

TO

ANYl*E

FOR

ANY

PURPOSE,

EXCEPT

AS

HEREIN

AUlHORIZED,

WllHOUT

PRIOR

WlllTTEN

APPROVAl

Cl'

a.A-VAL

CO.

lHIS

DRAWNG

IS

SUBllTIED

CMIDENllAl.lY

AND

llAY

NOT

BE

USED

IN

lHE

llANUFACME

Cl'

ANY

llA1ERIAL

OR

PROOIJCT

OlHER

lHAN

SUQl

llA1ERIAl.S

AND

PRODUClS

FURNISHED

TO

a..A-VAl

CO.

WllE11£R

OR

NOT

lHE

EQUIPMENT

OR

INFORllAllOO

SHO\ltl

HEREOO

IS

PAlENTED

OR

OlHERWISE

PROlECTED

FUil

1Tn.E

AND

C<l'YRIGilS.

IF

AN't'.

IN

AND

TO

lHIS

DRAWING

AND/OR

INFORllAllOO

DEU\fRED

OR

SUBlllTIED

ARE

FULlY

RESER\fll

BY

a..A-VAl

CO.'

Page 3

>-

CD

1-

w

w

I

Ul

w

w

Ul

CVCL

1 @ 3 4

DIST

CODE

002

SHEET

2

OF

4

DRAWING

NO.

IREV

p

91325

DESIGN

BOOSTER

PUMP

CONTROL

VALVE

WITH

HY-CHECK

(4"

AND

LARGER

ONLY)

DRAWN

MGR

4-4-80

CHK'D

KD

5-5-80

APV'D

CH

5-19-80

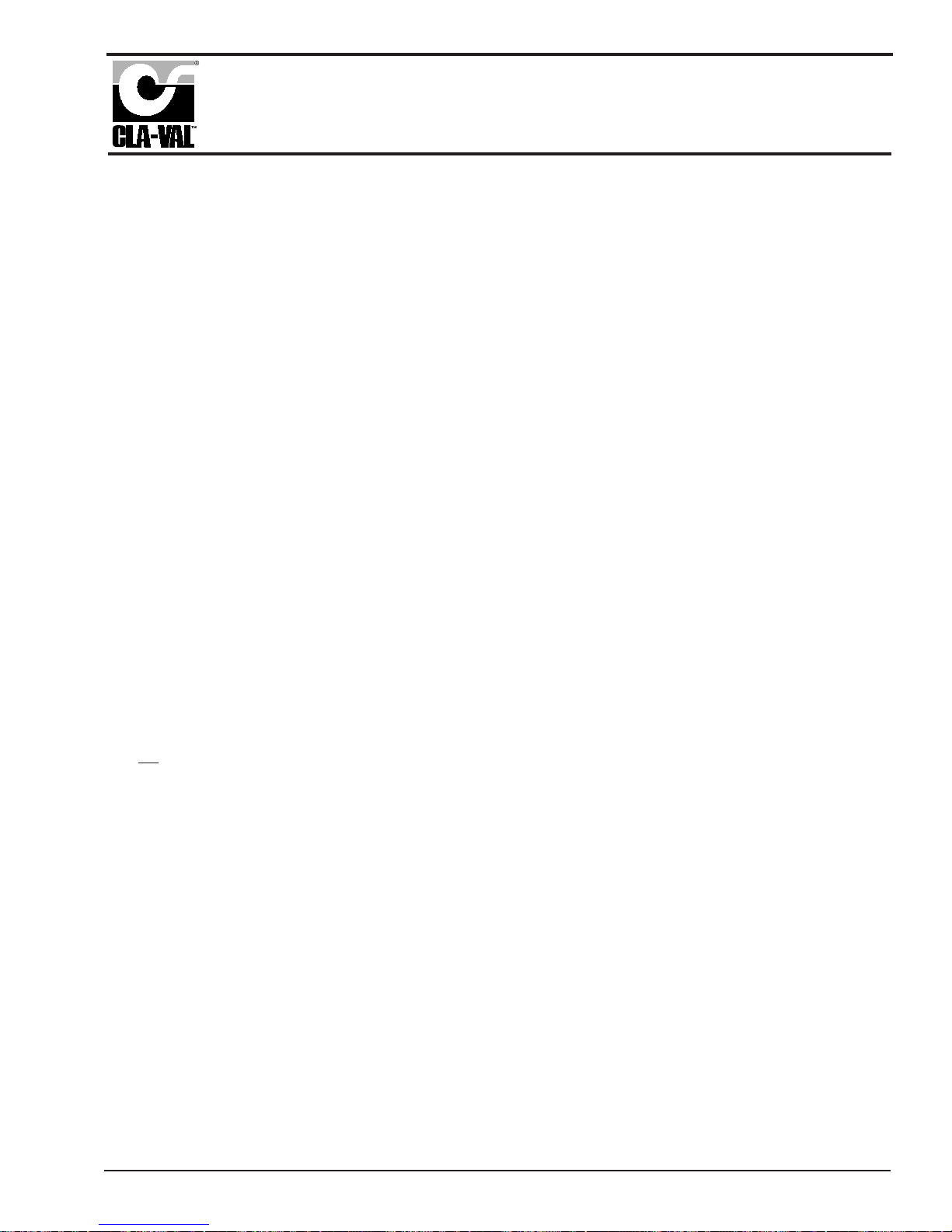

OPERATING

DATA

I.

SOLENOID

CONTROL

FEATURE:

SOLENOID

CONTROL

(3)

IS A DIRECT

ACTING,

3-WAY

SOLENOID

CONTROL

THAT

CHANGES

POSITION

WHEN

THE

COIL

IS

DE-ENERGIZED

OR

ENERGIZED.

THIS

APPLIES

OR

RELIEVES

PRESSURE

IN

THE

COVER

CHAMBER

OF

THREE-WAY

CONTROL

(2),

PROVIDING

THE

OPERATION

SHOWN

IN

THE

FOLLOWING

TABLE:

SOLENOID

CONTROL

(3)

POSITION

ENERGIZED

DE-ENERGIZED

PORTS

CONNECTED

1 & 2

1

& 3

3-WAY

HYTROL

(2)

POSITION

COM.

TO

N.O.

COM.

TO

N.C.

MAIN

VALVE

(1)

POSITION

OPEN

CLOSED

NOTE:

SOLENOID

CONTROL

(3)

IS

EQUIPPED

WITH

A MANUAL

ACTUATOR

WHICH

CAN

BE

USED

TO

OPERATE

THE

SOLENOID

WITHOUT

ELECTRICAL

POWER.

AFTER

MANUAL

ACTUATION,

ALWAYS

RETURN

THE

ACTUATOR

TO

ITS

ORIGINAL

POSITION

OR

THE

SOLENOID

WILL

NOT

RETURN

TO

THE

DE-ENERGIZED

POSITION.

II.

CHECK

VALVE

FEATURE:

THE

MAIN

VALVE

(1)

HAS

AN

INTEGRAL

CHECK

FEATURE.

WHEN

OUTLET

PRESSURE

EXCEEDS

INLET

PRESSURE,

THE

MAIN

VALVE

CLOSES

PREVENTING

REVERSE

FLOW.

CHECK

VALVE

(6)

OPENS

AND

CHECK

VALVE

(5)

CLOSED.

THIS

PERMITS

OUTLET

PRESSURE

TO

FLOW

INTO

THE

MAIN

VALVE

COVER

CHAMBER

AND

THE

DIAPHRAGM

ASSEMBLY

MOVES

TO

THE

DOWN

POSITION.

Ill.

CLOSING

SPEED

CONTROL:

CV

/CNA

FLOW

CONTROL

(7

A)

CONTROLS

THE

CLOSING

SPEED

OF

THE

MAIN

VALVE.

TURN

THE

ADJUSTING

STEM

CLOCKWISE

TO

MAKE

THE

MAIN

VALVE

CLOSE

SLOWER.

DO

NOT

CLOSE

VALVE

(7A)

COMPLETELY

OR

THE

MAIN

VALVE

WILL

NOT

CLOSE.

(SUGGESTED

INITIAL

SETTING

OF

NEEDLE

VALVE

IS

1/4

TO

1

/2

TURN

OPEN.)

"lllS

DRAWING

IS

11£

PRa'ERlY

Cl'

a..A-VAl

CO.

AND

SAME

AND

COPIES

MADE

lHERECI',

IF

ANY,

SHAl.l

BE

REMNED

TO

IT~

DEMAND.

DELMRY

AND

DISQ.OSURE

HERE<I'

ARE

MADE

sa.n.Y ~ C<NllllOO

lHAT

lHE

SAME

SHAl.l

NOT

BE

USED,

COPIED

OR

REPROOUCED,

NOR

SHAl.l

lHE

SUB.ECT

HERE<I'

BE

DISQ.OSED

IN

ANY

MANNER

TO

ANYl*E

FOR

ANY

PURPOSE,

EXCEPT

AS

HEREIN

AUlHORIZED,

WllHOUT

PRIOR

WlllTTEN

APPROVAl

Cl'

a.A-VAL

CO.

lHIS

DRAWNG

IS

SUBllTIED

CXN'IDENllAl.lY

AND

llAY

NOT

BE

USED

IN

lHE

llANUFACME

Cl'

ANY

llAlERIAl

OR

PROOIJCT

OlHER

lHAN

SUQl

llAlERIAl.S

AND

PRODIJClS

FURNISHED

TO

a..A-VAl

CO.

WllE11£R

OR

NOT

lHE

EQUIPMENT

OR

INFORllAllOO

SHO\ltl

HEREOO

IS

PAlENTED

OR

OlHERWISE

PROlECTED

FUil

1Tn.E

AND

C<l'YRIGilS.

IF

AN't'.

IN

AND

TO

lHIS

DRAWING

AND/OR

INFORllAllOO

DEU\fRED

OR

SUBlllTIED

ARE

FULlY

RESER\fll

BY

a..A-VAl

CO.'

Page 4

CVCL

1 @ 3 4

DIST

CODE

002

BOOSTER

PUMP

CONTROL

VALVE

WITH

HY-CHECK

(4"

AND

LARGER

ONLY)

OPERATING

DATA-CONTINUED

IV.

OPENING

SPEED

CONTROL:

SHEET

3

DRAWING

NO.

91325

DESIGN

DRAWN

MGR

CHK'D

KD

APV'D

CH

CV

/CNA

FLOW

CONTROL

(7B)

CONTROLS

THE

OPENING

SPEED

OF

THE

OF

4

IREV

p

4-4-80

5-5-80

5-19-80

MAIN

VALVE

TURN

THE

ADJUSTING

STEM

CLOCKWISE

TO

MAKE

THE

MAIN

VALVE

OPEN

SLOWER.

DO

NOT

CLOSE

VALVE

(7B)

COMPLETELY

OR

THE

MAIN

VALVE

WILL

NOT

OPEN.

(SUGGESTED

INITIAL

SETTING

OF

NEEDLE

VALVE

IS 1 /4

TO

1

/2

TURN

OPEN).

V.

SWITCH

ASSEMBLY

FEATURE:

SWITCH

ASSEMBLY

(4)

IS

ACTUATED

BY A STEM

EXTENSION

ATTACHED

TO

THE

MAIN

VALVE

STEM.

THE

SWITCH

ASSEMBLY

IS

FACTORY

ADJUSTED

TO

ACTUATE

A SINGLE-POLE DOUBLE-THROW

SWITCH

WHEN

THE

MAIN

VALVE

IS

ALMOST

CLOSED.

WHEN

THE

MAIN

VALVE

STARTS

TO

OPEN,

THE

SPRING

LOADED

SWITCH

ACTUATING

LEVER

IS

RELEASED

AND

RETURNS

THE

SWITCH

TO

ITS

NORMAL

POSITION.

VI.

OPTIONAL

FEATURE

OPERATING

DATA:

I=!

SUFFIX A (FLOW

CLEAN

STRAINER):

~

A SELF-CLEANING

STRAINER

IS

INSTALLED

IN

THE

MAIN

VALVE

INLET

BODY

BOSS

WHICH

PROTECTS

THE

PILOT

SYSTEM

FROM

FOREIGN

PARTICLES.

>-

CD

1-

w

w

I

Ul

w

w

Ul

SUFFIX B (ISOLATION

VALVES):

CK2

COCKS

(B)

ARE

USED

TO

ISOLATE

THE

PILOT

SYSTEM

FROM

MAIN

LINE

PRESSURE.

THESE

VALVES

MUST

BE

OPEN

DURING

NORMAL

OPERATION.

SUFFIX P (PRESSURE

GAUGE):

PRESSURE

GAUGES

(P1

), (P2),

AND

(P3)

PROVIDE

PRESSURE

READING

IN

THE

INLET,

OUTLET,

AND

COVER

CONNECTIONS.

SUFFIX

y CY-STRAINER):

A Y-PATTERN

STRAINER

IS

INSTALLED

IN

THE

PILOT

SUPPLY

LINE

TO

PROTECT

THE

PILOT

SYSTEM

FROM

FOREIGN

PARTICLES.

THE

STRAINER

SCREEN

MUST

BE

CLEANED

PERIODICALLY.

"lllS

DRAWING

IS

11£

PRa'ERlY

Cl'

CLA-VAl

CO.

AND

SAME

AND

COPIES

MADE

lHERECI',

IF

ANY,

SHAl.l

BE

REMNED

TO

IT~

DEMAND.

DELMRY

AND

DISQ.OSURE

HERE<I'

ARE

MADE

sa.n.Y ~ COOTION

lHAT

lHE

SAME

SHAl.l

NOT

BE

USED,

COPIED

OR

REPROOUCED,

NOR

SHAl.l

lHE

SUB.ECT

HERE<I'

BE

DISQ.OSED

IN

ANY

MANNER

TO

ANYl*E

FOR

ANY

PURPOSE,

EXCEPT

AS

HEREIN

AUlHORIZED,

WllHOUT

PRIOR

WlllTTEN

APPROVAl

Cl'

a.A-VAL

CO.

lHIS

DRAWNG

IS

SUBllTIED

CMIDENllAl.lY

AND

llAY

NOT

BE

USED

IN

lHE

llANUFACME

Cl'

ANY

llAlERIAl

OR

PROOIJCT

OlHER

lHAN

SUQl

llAlERIAl.S

AND

PRODUClS

FURNISHED

TO

CLA-VAl

CO.

WllE11£R

OR

NOT

lHE

EQUIPMENT

OR

INFORMATION

SHO\ltl

HEREON

IS

PAlENTED

OR

011£RWISE

PROlECTED

FUil

1Tn.E

AND

C<l'YRIGilS.

IF

AN't'.

IN

AND

TO

lHIS

DRAWING

AND/OR

INFORMATION

DEU\fRED

OR

SUBlllTIED

ARE

FULlY

RESER\fll

BY

CLA-VAl

CO.'

Page 5

>-

CD

1-

w

w

I

Ul

w

w

Ul

CVCL

1 @ 3 4

DIST

CODE

002

BOOSTER

PUMP

CONTROL

VALVE

WITH

HY-CHECK

(4"

AND

LARGER

ONLY)

OPERATING

DATA-CONTINUED

VII.

CHECK

LIST

FOR

PROPER

OPERATION:

( )

SYSTEM

VALVES

OPEN

UPSTREAM

AND

DOWNSTREAM.

SHEET

4

OF

4

DRAWING

NO.

IREV

p

91325

DESIGN

DRAWN

MGR

4-4-80

CHK'D

KD

5-5-80

APV'D

CH

5-19-80

( )

AIR

REMOVED

FROM

THE

MAIN

VALVE

COVER

AND

PILOT

SYSTEM

AT

ALL

HIGH

POINTS.

( )

PERIODIC

CLEANING

OF

STRAINER

(Y)

IS

RECOMMENDED

(OPTIONAL

FEATURE).

( )

CV

FLOW

CONTROLS

(7

A)

AND

(7B)

OPEN

AT

LEAST 4 TURNS

(OPTIONAL

FEATURE).

( )

NEEDLE

VALVES

(7A)

AND

(7B)

OPEN

AT

LEAST

1/4

TURN.

( )

CORRECT

VOLTAGE

TO

SOLENOID

CONTROL

(3).

( ) MANUAL

OPERATOR

OF

SOLENOID

CONTROL

(3)

DISENGAGED.

( )

LIMIT

SWITCH

ASSEMBLY

(4)

PROPERLY

WIRED.

( )

CK2

COCK

(8)

OPEN

DURING

NORMAL

OPERATION.

( )

CK2

COCKS

(B)

OPEN

(OPTIONAL

FEATURE).

"lllS

DRAWING

IS

11£

PRa'ERlY

Cl'

a..A-VAl

CO.

AND

SAME

AND

COPIES

MADE

lHERECI',

IF

ANY,

SHAl.l

BE

REMNED

TO

IT~

DEMAND.

DELMRY

AND

DISQ.OSURE

HERE<I'

ARE

MADE

sa.n.Y ~ C<NllllOO

lHAT

lHE

SAME

SHAl.l

NOT

BE

USED,

COPIED

OR

REPROOUCED,

NOR

SHAl.l

lHE

SUB.ECT

HERE<I'

BE

DISQ.OSED

IN

ANY

MANNER

TO

ANYl*E

FOR

ANY

PURPOSE,

EXCEPT

AS

HEREIN

AUlHORIZED,

WllHOUT

PRIOR

WlllTTEN

APPROVAl

Cl'

a.A-VAL

CO.

lHIS

DRAWNG

IS

SUBllTIED

CXN'IDENllAl.lY

AND

llAY

NOT

BE

USED

IN

lHE

llANUFACME

Cl'

ANY

llAlERIAl

OR

PROOIJCT

OlHER

lHAN

SUQl

llAlERIAl.S

AND

PRODIJClS

FURNISHED

TO

a..A-VAl

CO.

WllE11£R

OR

NOT

lHE

EQUIPMENT

OR

INFORllAllOO

SHO\ltl

HEREOO

IS

PAlENTED

OR

OlHERWISE

PROlECTED

FUil

1Tn.E

AND

C<l'YRIGilS.

IF

AN't'.

IN

AND

TO

lHIS

DRAWING

AND/OR

INFORllAllOO

DEU\fRED

OR

SUBlllTIED

ARE

FULlY

RESER\fll

BY

a..A-VAl

CO.'

Page 6

• Built-in Automatic Check Valve

• Drip Tight, Positive Seating

• Globe or Angle Pattern

• Service Without Removal From Line

• Every valve factory-tested

The C la- Val M ode l 100 -04 Hy-C hec k Val ve is a

hydraulically operated diaphragm valve with a built-in check

feature to prevent return flow. Available in globe or angle

pa ttern, it con si st s of a body, co ve r and diaphragm

assembly. The diaphragm assembly which is guided top

and botto m by a precisi on machined stem is the only

moving part.

A synthetic rubber disc retained on three and one half sides

forms a drip-tight seal wi th the renewable seat when

operating pressure is applied a bove the no n-wicking

di aphragm . W hen pressu re above th e d iaphragm i s

relieved, the valve opens wide. The rate of closing or

opening can be controlled by modulating the flow into or out

of the cover chamber. When a pressure reversal occurs the

split stem will immediately allow the disc retainer assembly

to check cl osed reg ar dless of the posi ti on of t he

diaphragm.

The Model 100-04 is used on system applications such as

remote control, pressure regulation, solenoid control, etc.;

wherever a positive check feature is necessary to prevent

reverse flow. Its packless construction and simplicity of

desig n mini miz es mai ntena nce an d as su res a long

dependable service life.

100-04

Hy-Check Valve

Full Open Operation

When pre ssure in th e cov er

chamber is relieved to a zone of

lower pressure, the line pressure at

th e valve inl et opens the v alve,

allowing full flow.

Check Action

When a static condition or pressure

reversal occurs, the split stem design

allows the valve to instantly check

closed. Re turn flo w is preven te d

regar dle ss of

the d ia phr agm's

position.

Tight Closing Operation

When pressure from the valve inlet

is applied to the cover chamber, the

valve closes drip-tight.

On-Off Control

On-Off Control

Modulating

Control

Principle of Operation

Note: For optimum operation of built-in check feature, installation with stem vertically up is recommended.

MODEL

see page 2 for

approvals

Page 7

Epoxy Coating - suffix KC

This opti on N SF 6 1 Li st ed and F DA

approved, fusion bonded epoxy coating is

for use with cast iron, ductile iron or steel

valves. This coating is resistant to various

water conditions, certain acids, chemicals,

solvents and alkalies.

Epoxy coatings are

applied in accordance with AWWA coating

specifications C116-03.

Do not use with temperatures above

175° F

/80

°C.

Viton

®

Rubber Parts- suffix KB

Op tional diaphrag m, disc and o-ring

fabricated with Viton®synthetic rubber. Viton

®

is well suited for use with mineral acids, salt

solutions, chlorinated hydrocarbons, and

petroleum oils; and is primarily used in high

temperature applications up to 250°F/120°C.

Do not use with epoxy co ating ab ov e

175°F/80° C.

For assistance in selecting appropriate

valve options or valves manufactured

with spe cial des ign requ ire ments ,

pleas e co nta ct o ur R egion al S ale s

Office or Factory.

Options

S

pecifications

M

odel 100-04

O

perating Temp. Range

Available Sizes

Pattern Flanged

Globe

2" - 16"

50 - 400 mm

Angle

3" - 16"

80 - 400 mm

Fluids

-40° to 180° F

-40° to 82° C

Component Standard Material Combinations

Body & Cover Ductile Iron Cast Steel Bronze

Available Sizes (inches) 2" - 16" 2" - 16" 2" - 16"

Available Sizes (mm) 50 - 400 mm 50 - 400 mm 50 - 400 mm

Disc Retainer &

Diaphragm Washer

Cast Iron Cast Steel Bronze

Trim: Disc Guide,

Seat & Cover Bearing

Bronze is Standard

Stainless Steel is optional

Disc Buna-N®Rubber

Diaphragm Nylon Reinforced Buna-N®Rubber

Stem, Nut & Spring Stainless Steel

For material options not listed, consult factory.

Cla-Val manufactures valves in more than 50 different alloys.

Materials

B

OLT/HEX NUT (TYP)

C

OVER BEARING

UPPER DIAPHRAGM WASHER

S

EAT

STUD/BOLT (TYP)

BODY

INLET

PIPE PLUG (TYP)

OUTLET

SEAT-O-RING

DISC GUIDE

DIAPHRAGM

UPPER STEM NUT

COVER

PIPE PLUG (TYP)

UPPER STEM

DISC GUIDE SCREW (TYP)

L

OCK WASHER

LOWER STEM NUT

SPRING

LOWER STEM

S

PRING

LOWER DIAPHRAGM WASHER

DISC

DISC RETAINER

Valve Body & Cover

Pressure Class

Flanged Threaded

Grade Material

ANSI

Standards*

150

Class

300

Class

End‡

Details

ASTM A536 Ductile Iron B16.42 250 400 400

ASTM A216-WCB Cast Steel B16.5 285 400 400

UNS 87850 Bronze B16.24 225 400 400

Note: * ANSI standards are for flange dimensions only.

Flanged valves are available faced but not drilled.

‡ End Details machined to ANSI B2.1 specifications.

Valves for higher pressure are available; consult factory for details

Pressure Ratings

(Recommended Maximum Pressure - psi)

NSF International

recognizes Cla-Val

as complying with

NSF/ANSI 61 and all

applicable

requirements.

NSF/ANSI 372:

National Lead Free

Mandate “Reduction

of Lead in Drinking

Water Act”

Approvals

Page 8

V

alve Size

Inches 2 3 4 6 8 10 12 14 16

m

m.

50 80 100 150 200 250 300 350 400

C

V

Factor

Globe

Pattern

Gal./Min. (gpm.)

54 115 200 440 770 1245 1725 2300 3130

L

itres/Sec. (l/s.)

13 27.6 48 105.6 184.8 299 414 552 706

Angle

P

attern

G

al./Min. (gpm.)

61 139 240 541 990 1575 2500* 3060* 4200*

Litres/Sec. (l/s.)

14.6 33.4 58 130 238 378 600 734.4 1008

Equivalent

Length

of

Pipe

G

lobe

P

attern

F

eet (ft.)

51 85 116 211 291 347 467 422 503

M

eters (m.)

15.5 25.9 35.3 64.2 88.6 105.8 142.4 128.6 153.6

A

ngle

Pattern

Feet (ft.)

40 58 80 139 176 217 222* 238* 247*

M

eters (m.)

12.1 17.8 24.5 42.5 53.6 66.1 67.8 72.7 75.2

K

Factor

Globe Pattern

5.6 6.0 5.9 6.2 6.1 5.8 6.1 5.0 4.6

Angle Pattern

4.4 4.1 4.1 4.1 3.7 3.6 2.9 2.8 2.6

Liquid Displaced from

C

over Chamber When

V

alve Opens

F

l. Oz

— — — — — — — — —

U.S. Gal.

0.3 .08 .17 .53 1.26 2.51 4.0 6.5 9.6

m

l

121 303 643 — — — — — —

Litres

— — — 2.0 4.8 9.5 15.1 24.6 36.2

10 20 30 40 60 80 100 200 500 1000 2000 5000 10,000 20,000 50,000

1

2

3

4

6

8

10

20

30

40

60

80

100

53

Angle Valve Sizes (Inches)

Globe Valve Sizes (Inches)

4

6

810

12

12

46810

14

16

16

Pr

essure Drop — psi

14

Flow Rate gpm (water)

3

3

2

2

Model 100-04 Flow Chart (Based on normal flow through a wide open valve)

K =

894d

4

C

2

v

L =

K

12 f

K Factor (Resistance Coefficient)

The Value of K is calculated from the formula:

(U.S. system units)

Equivalent Length of Pipe

Equivalent lengths of pipe (L) are determined from the formula:

(U.S. system units)

Fluid Velocity

Fluid velocity can be calculated from the following formula:

(U.S. system units)

d

V =

.4085 Q

2

d

C

V

Factor

Formulas for computing C Factor, Flow (Q) and Pressure Drop

V

( P):

C

V

=

Q

P

C

V

=

Q

P

C

V

=

Q

P

2

V

Where:

U.S. (gpm) @ 1 psi differential at 60 F water

(l/s) @ 1 bar (14.5 PSIG) differential

or

at 15 C water

inside pipe diameter of Schedule 40 Steel Pipe (inches)

friction factor for clean, new Schedule 40 pipe

(dimensionless) (from Cameron Hydraulic Data,

18th Edition, P 3-119)

Resistance Coefficient (calculated)

Equivalent Length of Pipe (feet)

Flow Rate in U.S. (gpm) or (l/s)

Fluid Velocity (feet per second) or (meters per second)

Pressure Drop in (psi) or (bar)

=

=

=

=

=

=

=

=

=

P

V

Q

L

K

f

d

C

Functional Data

Model 100-04

*Estimated

Page 9

CLA-VAL

1701 Placentia Ave • Costa Mesa CA 92627 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: info@cla-val.com • www.cla-val.com

Copyright Cla-Val 2018

•

Printed in USA • Specifications subject to change without notice.

©

C

la-Val 100-04 Hy-Check Main Valve Dimensions

Service

Cla-Val Control Valves operate with maximum efficiency when mounted in horizontal piping with the main valve cover UP, however, other

positions are acceptable. Due to component size and weight of 8 inch and larger valves, installation with cover UP is advisable. We recommend

isolation valves be installed on inlet and outlet for maintenance. Adequate space above and around the valve for service personnel should be

considered essential. A regular maintenance program should be established based on the specific application data. However, we recommend a

thorough inspection be done at least once a year. Consult factory for specific recommendations.

E-100-04 (R-02/2018)

G

GG

D

Inlet

DD

F

100-04

Flanged

A

E

C

(MAX)

K

J

H

Inlet

Outlet

AA

B

(Diameter)

V

alve Size (Inches)

A 150 ANSI

AA 300 ANSI

B Diameter

C Maximum

D 150 ANSI

DD 300 ANSI

E

F 150 ANSI

FF 300 ANSI

G 150 ANSI

GG 300 ANSI

H NPT Body Tapping

J NPT Cover Center Plug

K NPT Cover Tapping

Stem Travel

Approx. Ship Weight (lbs)

15.00

1

5.62

11. 50

10.62

7.50

7.81

3.19

4.50

5.00

5.00

5.31

0.75

0.75

0.75

1.10

140

4

9.38

1

0.00

6.62

6.50

4.75

5.00

1.50

2.50

3.25

3.25

3.25

0.38

0.50

0.38

0.60

35

2

1

2.00

1

3.25

9

.12

8.19

6.00

6.38

2.56

3.75

4.13

4.00

4.38

0.50

0.50

0.50

.080

70

3

2

0.00

21.00

15.75

13.38

10.00

10.50

4.31

5.50

6.25

6.00

6.50

0.75

0.75

0.75

1.70

285

6

8

2

5.38

26.38

2

0.00

16.00

12.69

13.19

5.31

6.75

7.50

8.00

8.50

1.00

1.00

1.00

2.30

500

1

0

29.75

3

1.12

23.62

17.12

14.88

15.56

9.25

8.00

8.75

8.62

9.31

1.00

1.00

1.00

2.80

780

12

34.00

3

5.50

28.00

20.88

17.00

17.75

10.75

9.50

10.25

13.75

14.50

1.00

1.25

1.00

3.40

116 5

14

39.00

4

0.50

3

2.75

24.19

19.50

20.25

12.62

10.50

11. 50

14.88

15.62

1.00

1.50

1.00

4.00

1500

16

4

1.38

43.50

3

5.50

25.00

20.69

21.75

15.50

11. 75

12.75

15.69

16.50

1.00

2.00

1.00

4.50

2265

Valve Size (mm)

A 150 ANSI

AA 300 ANSI

B Diameter

C Maximum

D 150 ANSI

DD 300 ANSI

E

F 150 ANSI

FF 300 ANSI

G 150 ANSI

GG 300 ANSI

H NPT Body Tapping

J NPT Cover Center Plug

K NPT Cover Tapping

Stem Travel

Approx. Ship Weight (kgs)

100

381

397

292

270

191

200

81

114

127

127

135

0.75

0.75

0.75

28

64

50

238

254

168

165

121

127

38

76

83

83

89

0.38

0.50

0.38

15

16

80

305

337

232

208

152

162

65

95

105

102

111

0.50

0.50

0.50

20

32

150

508

533

400

340

254

267

109

140

159

152

165

0.75

0.75

0.75

43

129

200

645

670

508

406

322

335

135

171

191

203

216

1.00

1.00

1.00

58

227

250

756

790

600

435

378

395

235

203

222

219

236

1.00

1.00

1.00

71

354

300

864

902

711

530

432

451

273

241

260

349

368

1.00

1.25

1.00

86

528

350

991

1029

832

614

495

514

321

267

292

378

397

1.00

1.50

1.00

102

726

400

1051

110 5

902

635

526

552

394

298

324

399

419

1.00

2.00

1.00

114

1027

Page 10

600 Series

Hy-Check Valve

• Built-in Automatic Check Valve

• Improved Flow Characteristics

• Drip Tight, Positive Seating

• Globe or Angle Pattern

• Packless Construction

The Cla-Val Model 100-23 Hy-Check Valve is a hydraulically

operated diaphragm valve with a built-in check feature to

prevent return flow. Available in a globe or angle pattern, it

consi st s of th ree pa rts: b ody, c over a nd dia ph ragm

assembly.

The only moving

part

is the diaphragm assembly

which is guided top and bottom by a precision machined stem

.

When operating pressure is applied above the non-wicking

diaphragm, a synthetic rubber disc retained on three and

one-half sides forms a drip-tight seal with the renewable

seat. When pressure above the diaphragm is relieved the

valve opens wide. The rate of closing or opening can be

contr olled by m od ula ting t he flo w in to or o ut of t he

diaphragm chamber. When a pressure reversal occurs the

split valve stem will allow the disc retainer assembly to

check c los ed rega rdl es s of th e posit ion o f the

diaphragm.

The Model 100-23 is used on system applications requiring

remote control, pressure regulation, solenoid control, rate of

flow control, liquid level control, or wherever a positive

check feature is necessary to prevent reverse flow.

Principle of Operation

Full Open Operation

When pressure in the

cover chamber

is relie ved to a zo ne of lo wer

pressure, the line pressure at the

valve inlet opens the valve, allowing

full flow.

Check Action

When a static condition or pressure

rever sal occ urs, the spli t st em

design allows the valve to instantly

check clo sed . Re turn fl ow i s

preve nte d reg ardle ss of t he

diaphragm's position.

Tight Closing Operation

When pressure from the valve inlet

is applied to the cover chamber, the

valve closes drip-tight.

On-Off Control

On-Off Control

Modulating

Control

Note: For optimum operation of built-in check feature, installation with stem vertically up is recommended.

MODEL

100-23

see page 2 for

approvals

Page 11

Epoxy Coating - suffix KC

This optio n NSF 61 Lis te d and FDA

approved, fusion bonded epoxy coating is

for use with cast iron, ductile iron or steel

valves. This coating is resistant to various

water con ditio ns, certa in a cids,

chemicals, solvents and alkalies.

Epoxy

coatings are applied in accordance with

AWWA coating specifications C116-03.

Do not use with temperatures above

175° F.

Viton® Rubber Parts

-

suffix KB

Optio nal di aph ragm, disc and o -r ing

fabricated with Viton®synthetic rubber.

Viton®is well suited for use with mineral

acids , salt solut ions, c hlori nat ed

hydrocarbons, and petroleum oils; and is

prima ril y used in high t emp eratu re

applications up to 250° F. Do not use with

epoxy coating above 175°F.

For assistance in selecting appropriate

valve options or valves manufactured

with s pec ia l de sign r equ ir eme nts,

please c on ta ct our Re gional S al es

Office or Factory.

Options

6" Angle, Flanged

12" Globe, Flanged

20" Globe, Flanged

6" Globe, Flanged

C

la-Val 100-23 Hy-Check Main Valve Specifications

Available Sizes

Component Standard Material Combinations

Body & Cover Ductile Iron Cast Steel Bronze

Available Sizes (inches) 3" - 24" 3" - 16" 3" - 16"

Available Sizes (mm) 80 - 600 mm 80 - 400 mm 80 - 400 mm

Disc Retainer &

Diaphragm Washer

Cast Iron Cast Steel Bronze

Trim: Disc Guide,

Seat & Cover Bearing

Bronze is Standard

Stainless Steel is optional

Disc Buna-N®Rubber

Diaphragm Nylon Reinforced Buna-N®Rubber

Stem, Nut & Spring Stainless Steel

For material options not listed, consult factory.

Cla-Val manufactures valves in more than 50 different alloys.

Materials

Pressure Ratings

(Recommended Maximum Pressure - psi)

Valve Body & Cover

Pressure Class

Flanged

Grade Material

ANSI

Standards*

150

Class

300

Class

ASTM A536 Ductile Iron B16.42 250 400

ASTM A216-WCB Cast Steel B16.5 285 400

UNS 87850 Bronze B16.24 225 400

Note: * ANSI standards are for flange dimensions only.

Flanged valves are available faced but not drilled.

Valves for higher pressure are available; consult factory for details

Operating Temp. Range

Fluids

-40° to 180° F

-40° to 82° C

Pattern Flanged

G

lobe (inches)

3

" - 24"

Globe (mm) 80 - 600 mm

Angle (inches) 6", 8"

Angle (mm) 150 and 200 mm

NSF International

recognizes Cla-Val

as complying with

NSF/ANSI 61 and all

applicable

requirements.

NSF/ANSI 372:

National Lead Free

Mandate “Reduction

of Lead in Drinking

Water Act”

Approvals

Page 12

Model 100-23 Flow Chart (Based on normal flow through a wide open valve)

12

10 20 30 40 60 80 100 200 500 1000 2000 5000 10,000 20,000 50,000

1

2

3

4

6

8

10

20

30

40

60

80

100

53

Angle Valve Sizes (Inches)

Globe Valve Sizes (Inches)

6

8

10

24

68

16

20

Pressure Drop — psi

18

14

4

4

Flow Rate gpm (water)

K =

894d

4

C

2

v

L =

K

12 f

K Factor (Resistance Coefficient)

The Value of K is calculated from the formula:

(U.S. system units)

Equivalent Length of Pipe

Equivalent lengths of pipe (L) are determined from the formula:

(U.S. system units)

Fluid Velocity

Fluid velocity can be calculated from the following formula:

(U.S. system units)

d

V =

.4085 Q

2

d

C

V

Factor

Formulas for computing C Factor, Flow (Q) and Pressure Drop

V

( P):

C

V

=

Q

P

C

V

=

Q

P

C

V

=

Q

P

2

V

Where:

U.S. (gpm) @ 1 psi differential at 60 F water

(l/s) @ 1 bar (14.5 PSIG) differential

or

at 15 C water

inside pipe diameter of Schedule 40 Steel Pipe (inches)

friction factor for clean, new Schedule 40 pipe

(dimensionless) (from Cameron Hydraulic Data,

18th Edition, P 3-119)

Resistance Coefficient (calculated)

Equivalent Length of Pipe (feet)

Flow Rate in U.S. (gpm) or (l/s)

Fluid Velocity (feet per second) or (meters per second)

Pressure Drop in (psi) or (bar)

=

=

=

=

=

=

=

=

=

P

V

Q

L

K

f

d

C

Cla-Val 100-23 Hy-Check Main Valve Functional Data

*Estimated

Valve Size

I

nches

3 4 6 8 1

0

1

2

1

4

1

6

1

8

2

0

2

4

m

m.

80 100 150 200 250 300 350 400 460 500 600

C

V

Factor

G

lobe

P

attern

Gal./Min. (gpm.)

62 136 229 480 930 1458 1725 2110 3250* 3400* 4020

L

itres/Sec. (l/s.)

15 32.5 55 115 223 350 414 506 705 816 965

Angle

Pattern

Gal./Min. (gpm.)

— 135 233 545 — — — — — — —

L

itres/Sec. (l/s.)

— 32 56 132 — — — — — — —

Equivalent

Length

of

Pipe

G

lobe

Pattern

F

eet (ft.)

293 251 777 748 621 654 750 977 983 1125 3005

M

eters (m.)

89.3 76.4 237.1 228.1 189.5 199.4 228.7 298.1 299.9 343.2 916.6

A

ngle

P

attern

Feet (ft.)

— 254 751 580 — — — — — — —

M

eters (m.)

— 77.6 229 176.9 — — — — — — —

K

Factor

Globe Pattern

20.6 12.7 23.1 15.7 10.4 8.5 8.9 10.2 6.9 9.7 14.5

A

ngle Pattern

— 12.9 22.3 12.2 — — — — — — —

L

iquid Displaced from

C

over Chamber When

Valve Opens

F

l. Oz

— — — — — — — — — — —

U.S. Gal.

0.32 .08 .17 .53 1.26 2.51 4.0 4.0 9.6 9.6 9.6

m

l

— — — — — — — — — — —

Litres

.12 .30 .64 2.0 4.8 9.5 15.1 15.1 36.2 36.2 36.2

Page 13

CLA-VAL

1701 Placentia Ave • Costa Mesa CA 92627 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: info@cla-val.com • www.cla-val.com

Copyright Cla-Val 2018 • Printed in USA • Specifications subject to change without notice.

©

Cla-Val Control Valves operate with maximum efficiency when mounted in horizontal piping with the main valve cover UP, however, other

positions are acceptable. Due to component size and weight of 10 inch and larger valves, installation with cover UP is advisable. We recommend

isolation valves be installed on inlet and outlet for maintenance. Adequate space above and around the valve for service personnel should be

considered essential. A regular maintenance program should be established based on the specific application data. However, we recommend a

thorough inspection be done at least once a year. Consult factory for specific recommendations.

EE

D

E

Inlet

DD

AA

100-23

F

langed

F

A

C

(MAX)

K

J

H

Inlet

Outlet

FF

B

(Diameter)

C

la-Val 100-23 Hy-Check Main Valve Dimensions

E-100-23 (R-02/2018)

Service and Installation

For assistance in selecting appropriate valve options or valves manufactured with special design requirements, please contact our Regional Sales Office or Factory.

Valve Size (Inches)

A 150 ANSI

A

A 300 ANSI

B Diameter

C Maximum

D

150 ANSI

D

D 300 ANSI

E

E

E

F

150 ANSI

FF 300 ANSI

150 ANSI

300 ANSI

H NPT Body Tapping

J NPT Cover Center Plug

K NPT Cover Tapping

Stem Travel

Approx. Ship Weight (lbs)

Approx. X Pilot System

Approx. Y Pilot System

Approx. Z Pilot System

1

3.88

14.50

9.12

8

.62

6

.94

7.25

5.50

5

.81

4

.50

5.00

0.50

0.50

0.50

0.80

85

4

15.00

11.00

11.00

10.25

1

1.00

6.62

7.00

—

—

—

—

3

.75

4.12

.375

0.50

.375

0.60

45

3

13.00

10.00

10.00

17.75

1

8.62

11.50

11.62

8.88

9

.38

6.75

7

.25

5.50

6.25

0.75

0.75

0.75

1.10

195

6

27.00

18.00

18.00

8

2

1.38

22.38

15.75

15.00

1

0.69

1

1.19

7.25

7.75

6.75

7.50

0.75

0.75

0.75

1.70

330

30.00

20.00

20.00

10

2

6.00

27.38

20.00

17.88

8.00

8.75

1.00

1.00

1.00

2.30

625

—

—

—

—

33.00

22.00

22.00

12

3

0.00

31.50

2

3.62

21.00

9.50

10.25

1.00

1.00

1.00

2.80

900

—

—

—

—

36.00

24.00

24.00

14

3

4.25

35.75

2

7.47

20.88

11.00

1.00

1.25

1.00

3.40

1250

—

—

—

—

—

36.00

26.00

26.00

16

3

5.00

36.62

28.00

2

5.75

11. 75

12.75

1.00

1.25

1.00

3.40

1380

—

—

—

—

41.00

26.00

26.00

18

4

2.12

43.63

35.44

2

5.00

15.88

15.88

1.00

2.00

1.00

4.50

2365

—

—

—

—

40.00

30.00

30.00

20

4

8.00

49.62

35.44

3

1.50

14.56

16.06

1.00

2.00

1.00

4.50

2551

—

—

—

—

46.00

30.00

30.00

24

4

8.00

49.75

35.44

3

1.50

17.00

19.00

1.00

2.00

1.00

4.50

2733

—

—

—

—

55.00

30.00

30.00

Valve Size (Inches)

A 150 ANSI

A

A 300 ANSI

B Diameter

C Maximum

D

150 ANSI

D

D 300 ANSI

E

E

E

F

150 ANSI

FF 300 ANSI

150 ANSI

300 ANSI

H NPT Body Tapping

J NPT Cover Center Plug

K NPT Cover Tapping

Stem Travel

Approx. Ship Weight (lbs)

Approx. X Pilot System

Approx. Y Pilot System

Approx. Z Pilot System

1

3.88

14.50

9.12

8

.62

6

.94

7.25

5.50

5

.81

4

.50

5.00

0.50

0.50

0.50

0.80

85

4

15.00

11.00

11.00

10.25

1

1.00

6.62

7.00

—

—

—

—

3

.75

4.12

.375

0.50

.375

0.60

45

3

13.00

10.00

10.00

17.75

1

8.62

11.50

11.62

8.88

9

.38

6.75

7

.25

5.50

6.25

0.75

0.75

0.75

1.10

195

6

27.00

18.00

18.00

8

2

1.38

22.38

15.75

15.00

1

0.69

1

1.19

7.25

7.75

6.75

7.50

0.75

0.75

0.75

1.70

330

30.00

20.00

20.00

10

2

6.00

27.38

20.00

17.88

8.00

8.75

1.00

1.00

1.00

2.30

625

—

—

—

—

33.00

22.00

22.00

12

3

0.00

31.50

2

3.62

21.00

9.50

10.25

1.00

1.00

1.00

2.80

900

—

—

—

—

36.00

24.00

24.00

14

3

4.25

35.75

2

7.47

20.88

11.00

1.00

1.25

1.00

3.40

1250

—

—

—

—

—

36.00

26.00

26.00

16

3

5.00

36.62

28.00

2

5.75

11. 75

12.75

1.00

1.25

1.00

3.40

1380

—

—

—

—

41.00

26.00

26.00

18

4

2.12

43.63

35.44

2

5.00

15.88

15.88

1.00

2.00

1.00

4.50

2365

—

—

—

—

40.00

30.00

30.00

20

4

8.00

49.62

35.44

3

1.50

14.56

16.06

1.00

2.00

1.00

4.50

2551

—

—

—

—

46.00

30.00

30.00

24

4

8.00

49.75

35.44

3

1.50

17.00

19.00

1.00

2.00

1.00

4.50

2733

—

—

—

—

55.00

30.00

30.00

Valve Size (Inches)

A 150 ANSI

AA 300 ANSI

B Diameter

C Maximum

D 150 ANSI

DD 300 ANSI

E

EE

F 150 ANSI

FF 300 ANSI

150 ANSI

300 ANSI

H NPT Body Tapping

J NPT Cover Center Plug

K NPT Cover Tapping

Stem Travel

Approx. Ship Weight (lbs)

Approx. X Pilot System

Approx. Y Pilot System

Approx. Z Pilot System

13.88

14.50

9.12

8.62

6.94

7.25

5.50

5.81

4.50

5.00

0.50

0.50

0.50

0.80

85

4

15.00

11.00

11.00

10.25

11.00

6.62

7.00

—

—

—

—

3.75

4.12

.375

0.50

.375

0.60

45

3

13.00

10.00

10.00

17.75

18.62

11.50

11.62

8.88

9.38

6.75

7.25

5.50

6.25

0.75

0.75

0.75

1.10

195

6

27.00

18.00

18.00

8

21.38

22.38

15.75

15.00

10.69

11.19

7.25

7.75

6.75

7.50

0.75

0.75

0.75

1.70

330

30.00

20.00

20.00

10

26.00

27.38

20.00

17.88

8.00

8.75

1.00

1.00

1.00

2.30

625

—

—

—

—

33.00

22.00

22.00

12

30.00

31.50

23.62

21.00

9.50

10.25

1.00

1.00

1.00

2.80

900

—

—

—

—

36.00

24.00

24.00

14

34.25

35.75

27.47

20.88

11.00

1.00

1.25

1.00

3.40

1250

—

—

—

—

—

36.00

26.00

26.00

16

35.00

36.62

28.00

25.75

11. 75

12.75

1.00

1.25

1.00

3.40

1380

—

—

—

—

41.00

26.00

26.00

18

42.12

43.63

35.44

25.00

15.88

15.88

1.00

2.00

1.00

4.50

2365

—

—

—

—

40.00

30.00

30.00

20

48.00

49.62

35.44

31.50

14.56

16.06

1.00

2.00

1.00

4.50

2551

—

—

—

—

46.00

30.00

30.00

24

48.00

49.75

35.44

31.50

17.00

19.00

1.00

2.00

1.00

4.50

2733

—

—

—

—

55.00

30.00

30.00

Valve Size (mm)

A 150 ANSI

AA 300 ANSI

B Diameter

C Maximum

D 150 ANSI

DD 300 ANSI

E

EE

F 150 ANSI

FF 300 ANSI

150 ANSI

300 ANSI

H NPT Body Tapping

J NPT Cover Center Plug

K NPT Cover Tapping

Stem Travel

Approx. Ship Weight (kgs)

Approx. X Pilot System

Approx. Y Pilot System

Approx. Z Pilot System

100

353

368

232

219

176

184

140

148

114

127

0.50

0.50

0.50

20

39

381

279

279

80

260

279

168

178

—

—

—

—

95

105

0.38

0.50

0.38

15

20

330

254

254

150

451

473

292

295

226

238

171

184

140

159

0.75

0.75

0.75

28

89

686

457

457

200

543

568

400

381

272

284

184

197

171

191

0.75

0.75

0.75

43

150

762

508

508

250

660

695

508

454

CF*

CF*

CF*

CF*

203

222

1.00

1.00

1.00

58

284

838

559

559

CF*

CF*

CF*

CF*

300

762

800

600

533

241

260

1.00

1.00

1.00

71

409

914

610

610

CF*

CF*

CF*

CF*

350

870

908

698

530

279

1.00

1.25

1.00

86

568

—

914

660

660

CF*

CF*

CF*

CF*

400

889

930

711

654

298

324

1.00

1.25

1.00

86

627

1041

660

660

CF*

CF*

CF*

CF*

450

1070

1108

900

635

403

403

1.00

2.00

1.00

86

681

1016

762

762

CF*

CF*

CF*

CF*

500

1219

1260

900

800

370

408

1.00

2.00

1.00

114

1157

1168

762

762

CF*

CF*

CF*

CF*

600

1219

1263

900

800

432

483

1.00

2.00

1.00

114

1249

1397

762

762

Page 14

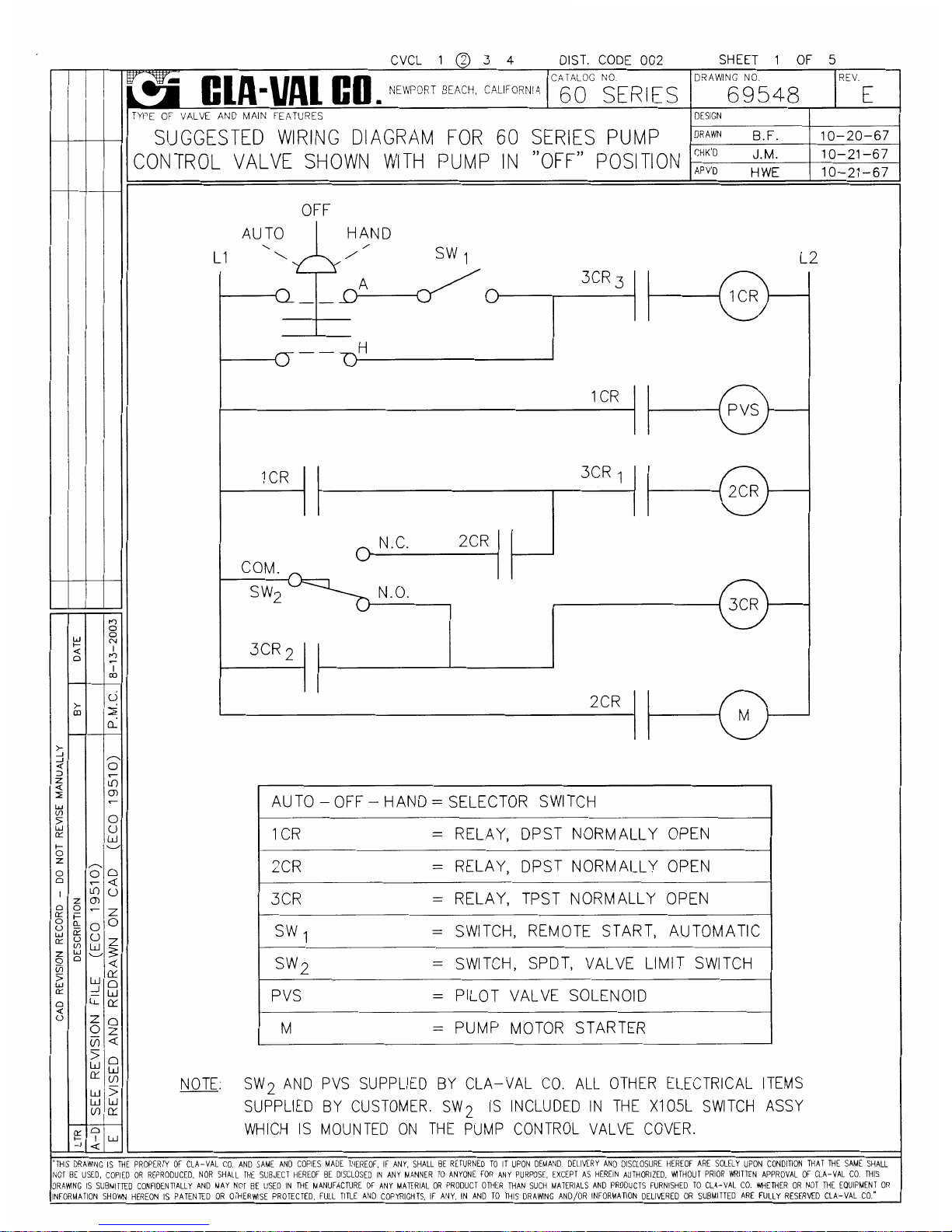

Start Up Procedure

The limit switch (SW2) on the valve should be adjusted

before the pump control valve is placed in service. The

stop collar on the limit switch stem should be adjusted to

strike the switch arm roller as the valve travels closed to

the 95% (approx.) closed position. The N.O. contacts on

the SW2 limit switch will close when the adjustable collar

strikes the limit switch roller and moves the switch arm.

Please read the operating instructions carefully. Make

all adjustments (opening speed control, closing speed

control and limit switch) before starting the booster pump

or turning on the electrical control power.

After the above adjustments have been made the

H-O-A switch should be placed in the “off” position and

the electrical control power should be turned on. The 60

Series control valve should then be permitted to close

(please see manual) and allow the limit switch (SW2) stop

collar to contact the SW2 switch roller. This action closes

the N.O. contacts on SW2 and energizes the coil on relay

3CR.

The H-O-A switch can now be placed in the “automatic”

position and the following operation should result:

Pump Starting - Pump Running Cycle

There are two ways in which the pump motor (M) start-

ing cycle may be “called” on:

1 - The pump motor may be “called” on by manually

placing the H-O-A switch in the hand position. This action

bypasses the automatic remote switch (SW1) and calls the

pump on.

2 - The pump motor may be “called” on by manually

placing the H-O-A switch in the “automatic” position provided that the automatic switch (SW1) contacts close. This

action places the pump motor under the command of SW1

and the associated safety controls. The pump motor (M)

can not

be called on, under any conditions,

if the H-O-A

switch is manually placed in the “off” position.

When SW1 contacts close (assuming that 3CR coil is

energized—see start up procedure above) coil 1CR is

energized, both contacts 1CR close to energize pilot

valve solenoid (PVS) and relay coil 2CR. Both contacts

2CR close and the pump motor (M) starts immediately as

the valve begins to open. As the limit switch SW2 stem

collar lifts off the roller, SW2 contacts N.C., close. The

pump is now locked on the line by SW2 and the valve

slowly continues to go completely open, directing all liquid flow to the pipeline.

Power Failure (While Pump Is Running) Conditions

If a momentary power failure should occur while the

pump is running, relay coil 3CR would be de-energized

and contacts 3CR1, 3CR2, and 3CR3 would open. This

action would completely lock the pump motor out from

restarting and keep the valve solenoid PVS de-energized

until the diaphragm assembly lowers to the setpoint of

SW2 limit switch. The Cla-Val 60 Series valve is equipped

with an integral “drop” check that will close immediately

when the pump motor stops and prevent backflow.

However, a time period of several seconds is required for

the diaphragm assembly to travel to the down position to

hold the valve closed when the pump restarts. Thus, even

though the power is restored immediately following the

power failure the pump cannot restart until the system

is “ready”, hydraulically, for a new start up.

Pump Stopping - Pump Off Conditions

When SW1 contacts are opened, or the H-O-A switch is

manually placed in the off position, coil 1CR contacts open

and the PVS coil is de-energized. Since the SW2 contacts

are in the normally closed position the pump motor (M)

continues to run as the pump control valve slowly closes.

When the SW2 stop collar reaches the roller arm, the SW2

N.C. contacts will open, 2CR coil will be de-energized,

both 2CR contacts will open and the pump motor (M) will

stop.

The pump motor will remain off under these conditions. Coil 3 CR will remain energized and contacts 3CR1,

3CR2, and 3CR3 will remain closed. The Cla-Val 60 Series

will remain closed under these conditions.

Note:

Please refer to Cla-Val. drawing #69548, the Product Data Catalog and the Installation, Operation, & Maintenance

Manual shipped with the Control Valve.

60 Series

Booster Pump Control Valves - Electrical Controls

N-C60E (R-3/2011)

Page 15

Page 16

NORMALLY OPEN

PRESS AT 3 (C)

NORMALLY CLOSED

PRESS AT 3 (C)

UNIVERSAL-PRESS

AT ANY ORIFICE.

FORM

SOLENOID

DE-

ENERGIZED

SOLENOID

ENERGIZED

3

I

(C)

2

(B)(A)

3

I

(C)

2

(B)(A)

3

I

(C)

2

(B)(A)

3

I

(C)

2

(B)(A)

3

I

(C)

2

(B)(A)

3

I

(C)

2

(B)(A)

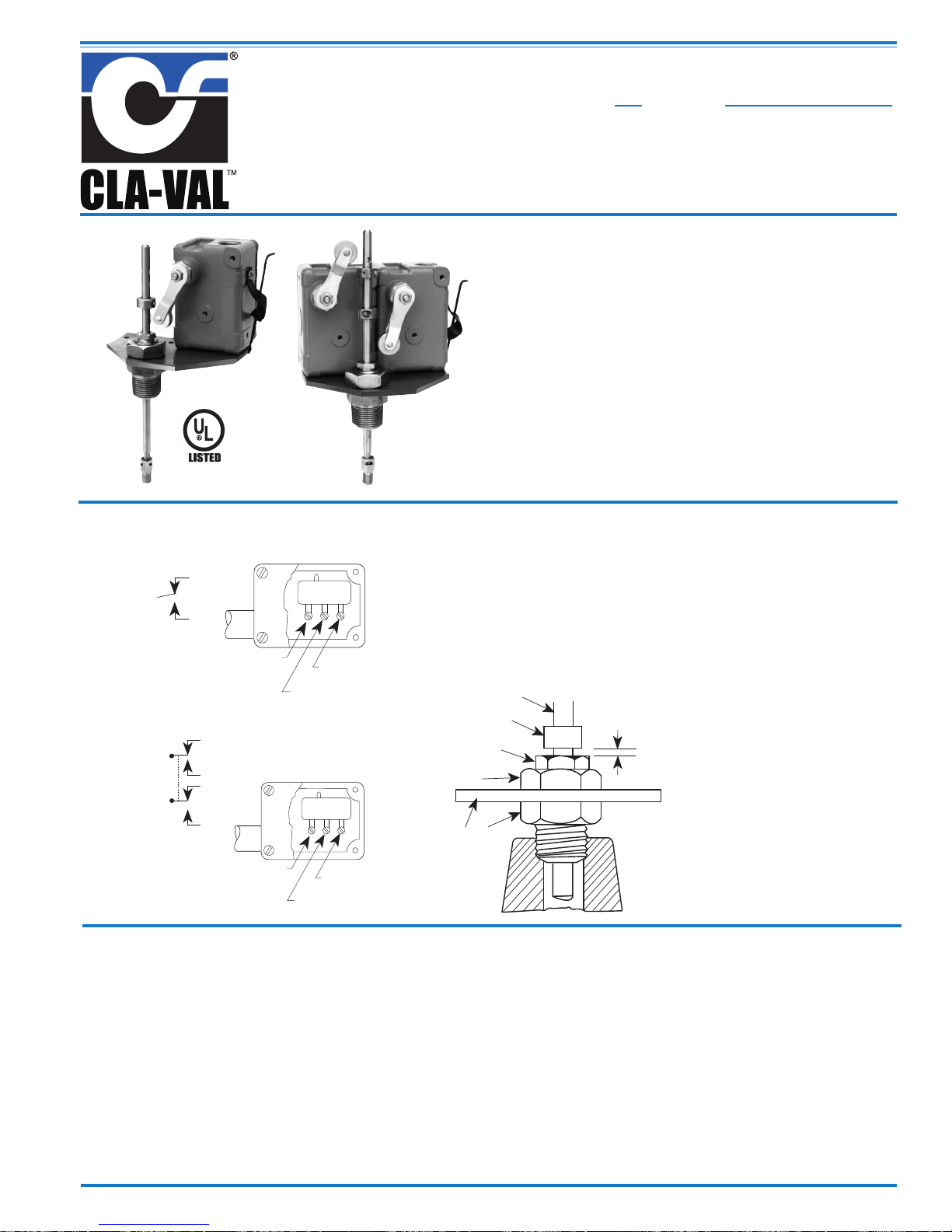

DESCRIPTION

MANUAL OPERATORS (OPTIONAL)

NOTE: Port Markings 1, 2, and 3 correspond directly to A, B

and C.

Bulletin 8320 is a small 3-way solenoid operated valve with all three

pipe connections located in the body. The bodies are of brass or stainless steel construction. Standard valves have General Purpose, Nema

Type 1 Solenoid Enclosures. Valves that are equipped with a solenoid

enclosure which is designed to meet Nema Type 4-Water tight, Nema

Type 7 (C or D) Hazardous Locations - Class I, Group C or D, and

Nema Type 9 (E, F or G) Hazardous Locations - Class II, Group E, F or

G are shown on separate sheets of Installation and Maintenance

Instructions, Form Numbers V-5391 and V-5381.

Check Nameplate for correct Catalog Number, pressure, voltage and

service.

Valves with suffix "MO" or "MS" in catalog number are provided with a

Manual Operator which allows manual operation when desired or during an interruption of electrical power.

INSTALLATION

Valve may be mounted in any position

POSITIONING

Connect piping to valve according to markings on valve body. Refer to

Flow Diagram provided. Apply pipe compound sparingly to male pipe

threads only; if applied to valve threads, it may enter valve and cause

operational difficulty. Pipe strain should be avoided by proper support

and alignment of piping. When tightening pipe, do not use valve as

lever.

PIPING

Wiring must comply with local and National Electrical Codes. For valves

equipped with an explosion-proof, watertight solenoid enclosure, the

electrical fittings must be approved for use in the approved hazardous

locations. Housings for all solenoids are made with connections for 1/2

inch conduit. The general purpose enclosure may be rotated to facilitate

wiring by removing the retaining cap.

WIRING

OPERATION

Normally Closed: Applies pressure when solenoid is energized:

exhausts pressure when solenoid is de-energized

Normally Open: Applies pressure when solenoid is de-energized;

exhausts pressure when solenoid is energized.

Universal: For normally closed or normally open operation, selection

or diversion of pressure can be applied at port 1 (A), 2 (B), or 3 (C).

NOTE

SOLENOID TEMPERATURE

MAINTENANCE

COIL REPLACEMENT

(REF. FIG. 2)

Alternating Current (A-C) and Direct Current (D-C) solenoids are built

differently. To convert from one to other, it is necessary to change the

complete solenoid, including the core assembly.

Turn off electrical power, disconnect coil lead wires and proceed as

follows:

Spare Parts Kits and Coils are available for ASCO valves. Parts

marked with

Standard catalog valves are supplied with coils designed for continuous duty service. When the solenoid is energized for a long period,

the solenoid enclosure becomes hot and can be touched with the

bare hand for only an instant. This safe operating temperature. Any

excessive heating will be indicated by the smoke and odor of burning coil insulation.

CLEANING

A periodic cleaning of all valves is desirable. The time between

cleanings will vary, depending on the media and service conditions.

In general, if the voltage to the coils is correct, sluggish valve operation or excessive leakage will indicate that cleaning is required.

IMPROPER OPERATION

Faulty Control Circuit: Check the electrical system by energiz-

ing the solenoid. A metallic click signifies the solenoid is operating. Absence of the click indicate loss of power supply. Check for

loose or blown-out fuses, open-circuited or grounded coil, broken

lead wires or splice.

Burned-out Coil: Check for open-circuited coil. Replace coil, if

necessary.

Low Voltage: Check voltage across coil leads. Voltage must be at

least 85% of nameplate ratings.

Incorrect Pressure: Check valve pressure. Pressure to valve

must be within the range specified on nameplate.

Excessive Leakage: Disassemble valve and clean all parts.

Replace parts that are worn or damaged with a complete Spare

Parts Kit for best results.

Turn off electrical power supply and de-pressurize valve.

VALVE DISASSEMBLY AND REASSEMBLY (REF. FIG. 2)

WARNING: Turn off electrical power and line pressure to valve

before making repairs. It is not necessary to remove valve from

pipe line for repairs.

1.

2.

3.

4.

5.

Remove retaining cap, nameplate and cover.

Slip yoke containing coil, sleeves and insulating washers off the

solenoid base sub-assembly. Insulating washers are omitted

when molded coil is used. In some D.C. Constructions, a single

flux plate over the coil replaces yoke, sleeves and insulating

washers.

Reassemble in reverse order of disassembly.

1.

2.

3.

Remove retaining cap and slip entire solenoid off solenoid base

subassembly or plugnut/core tube sub-assembly.

Unscrew bonnet or solenoid base sub-assembly. Remove core

assembly, core spring and body gasket.

Remove end cap, body gasket, disc spring, disc holder, disc or

disc holder assembly.

All parts are now accessible for cleaning or replacement. Replace

worn or damaged parts with a complete Spare Parts Kit for best

results.

Reassemble in reverse order of disassembly paying careful

attention to exploded view provided.

1.

2.

3.

4.

5.

ORDERING INFORMATION FOR SPARE

PARTS KITS

When Ordering Spare Parts Kits or Coils

Specify Valve Catalog Number,

Serial Number and Voltage

INSTALLATION AND

MAINTENANCE INSTRUCTIONS

3-WAY SOLENOID VALVES, NORMALLY OPEN

NORMALLY CLOSED AND UNIVERSAL CONSTRUCTION

IMPORTANT: For protection of the solenoid valve, install a strainer

or filter suitable for the service involved in the inlet side as close to the

valve as possible. Periodic cleaning is required depending on the service conditions.

BULLETIN

8320

ASCO

FORM NO. V5291R2

Page 17

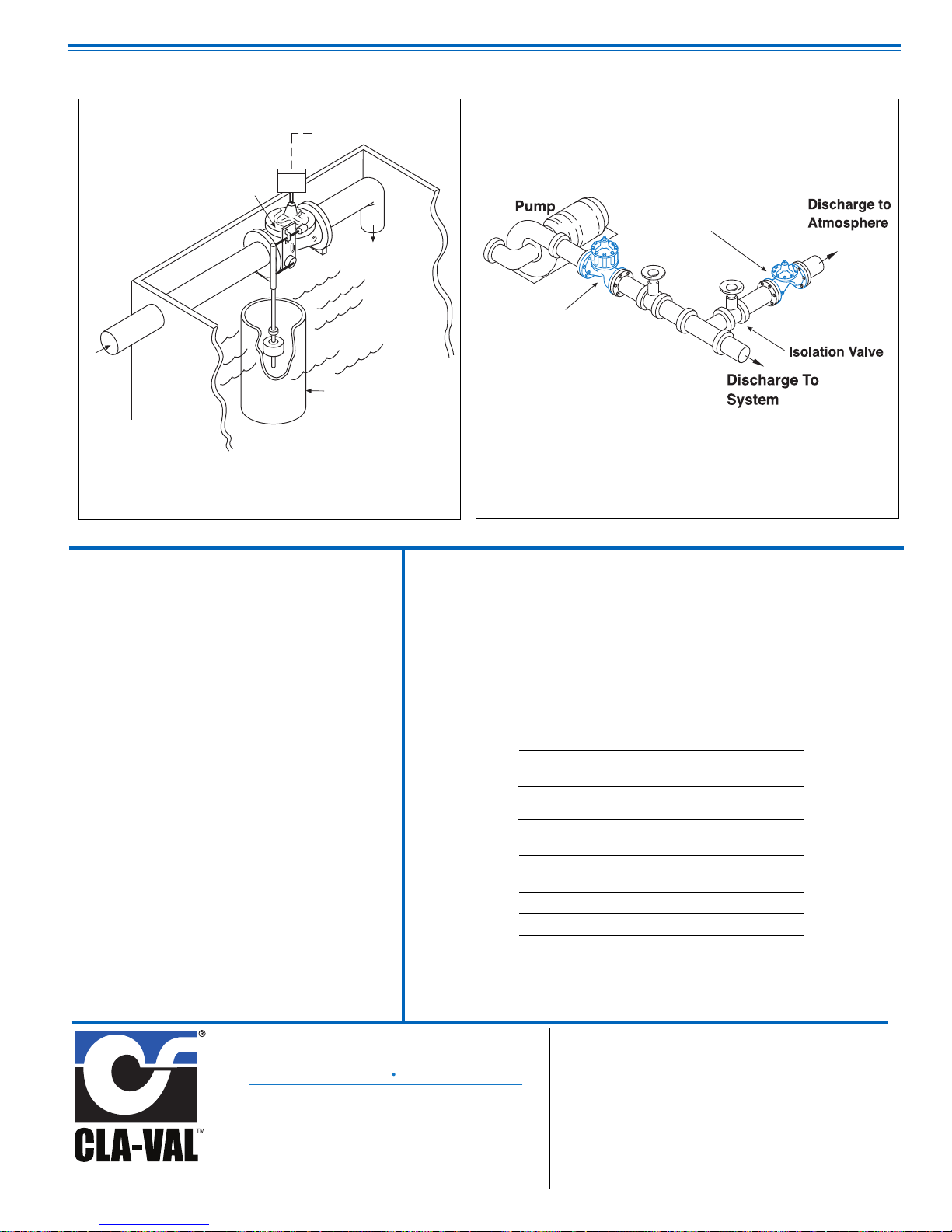

NOTE:

1. FOR MOUNTING, A FLAT SURFACE MUST BE PROVIDED ACROSS THE

ENTIRE LENGTH OF THE BRACKET. THE VALVE BODY BECOMES SECURE

TO BRACKET, WHEN BRACKET IS TIGHTENED IN TO POSITION.

IF THE VALVE HAS A MANUAL OPERATOR, A HOLE MUST BE MADE

THROUGH THE MOUNTING SURFACE FOR THE OPERATOR STEM.

RETAINING CAP

NAMEPLATE

COVER

YOKE

HOUSING

FLUX PLATE

(NOT PRESENT IN

ALL CONSTRUCTIONS)

SOLENOID BASE

SUB ASSEMBLY

(OPTIONAL)

MOUNTING BRACKET

(FOUR POSITIONS)

TWO SELF-TAPPING

SCREWS PROVIDED

CORE SPRING

(WIDE END IN CORE FIRST, CLOSED END

PROTRUDES FROM TOP OF CORE)

CORE ASSEMBLY

BODY GASKET

BODY

(BRASS)

DISC HOLDER

ASSEMBLY

DISC SPRING

BODY GASKET

END CAP

END CAP

BODY GASKET

DISC SPRING

DISC

DISC HOLDER

BODY

(ST. ST.)

BODY GASKET

CORE ASSEMEBLY

CORE SPRING

(WIDE END IN CORE FIRST, CLOSED END

PROTUDES FROM TOP OF CORE)

PLUGNUT/CORE TUBE

SUB-ASSEMBLY

BONNET GASKET

BONNET

SOLENOID ENCLOSURE

RETAINING CAP

PARTS INCLUDED IN

SPARE PARTS KITS

MANUAL OPERATOR

SCREW TYPE

(MS)

MANUAL OPERATOR

PUSH TYPE

(MO)

*

SLEEVE

INSULATING WASHER

(OMITTED WHEN MOLDED

COIL IS USED)

COIL

INSULATING WASHER

(OMITTED WHEN MOLDED

COIL IS USED)

SLEEVE

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

(OPTIONAL)

MOUNTING BRACKET

(SEE NOTE

CLA-VAL

Copyright Cla-Val 2011 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 • Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: claval@cla-val.com • Website cla-val.com

©

N-V5291 (R-3/2011)

Page 18

INSTALLATION AND

MAINTENANCE INSTRUCTIONS

OPEN-FLAME, GENERAL PURPOSE,

WATERTIGHT/EXPLOSIONPROOF SOLENOIDS

BULLETIN

8016G

ASCO

FORM NO. V6583R5

-SERVICE NOTICE-

ASCO®solenoid valves with design change letter "G" in the catalog

number (example: 8210G 1) have an epoxy encapsulated ASCO®Red

Hat II. solenoid. This solenoid replaces some of the solenoids with metal

enclosures and open-frame constructions. Follow these installation and

maintenance instructions if your valve or operator uses this solenoid.

DESCRIPTION

Catalog numbers 8016G1 and 8016G2 are epoxy encapsulated pull-type

solenoids. The green solenoid with lead wires and 1/2 " conduit connection is designed to meet Enclosure Type 1 -General Purpose,Type 2Dripproof,Types 3 and 3S-Raintight, and Types 4 and 4X-Watertight. The

black solenoid on catalog numbers prefixed "EF" is designed to meet

Enclosure Types 3 and 3S-Raintight, Types 4 and 4X-Watertight, Types 6

and 6P-Submersible, type 7 (A, B, C, & D) Explosionproof Class 1,

Division 1, Groups A, B, C, & D and Type 9 (E, F, & G)-Dust-lgnitionproof

Class 11, Division 1, Groups E, F, & G. The Class 11, Groups F & G Dust

Locations designation is not applicable for solenoids or solenoid valves

used for steam service or when a class "H" solenoid is used. See

Temperature Limitations section for solenoid identification and nameplate/retainer for service. When installed just as a solenoid and not

attached to an ASCO valve, the core has a 0.250-28 UNF-2B tapped hole,

0.38 minimum full thread.

Series 8016G solenoids are available in:

• Open-Frame Construction

The green solenoid may be supplied with 1/4 spade, screw, or

DIN terminals (Refer to Figure 4).

• Panel Mounted Construction

These solenoids are specifically designed to be panel mounted by the

customer through a panel having a .062 to .093 maximum wall thickness.

(Refer to Figure 3 and section on Installation of Panel Mounted Solenoid).

Optional Features For Type 1—General Purpose

Construction Only

• Junction Box

This junction box construction meets Enclosure Types 2,3,3S,4, and

4X. Only solenoids with 1/4" spade or screw terminals may have a

junction box. The junction box provides a 1/2 conduit connection,

grounding and spade or screw terminal Connections within the junction

box (See Figure 5).

• DIN Plug Connector Kit No. K236 - 034

Use this kit only for solenoids with DIN terminals. The DIN plug c onnector kit

provides a two pole with grounding contact DIN Type 43650 construction

(See Figure 6).

OPERATION

When the solenoid is energized, the core is drawn into the solenoid base subassembly. IMPORTANT: When the solenoid is de-energized, the initial

return force for the core, Whether developed by spring, pressure, or

weight, must exert a minimum force to overcome residual magnetism created by the solenoid. Minimum return force for AC construction is 11 ounces,

and 4 ounces for DC construction.

INSTALLATION

Check nameplate for correct catalog number, service, and wattage. Check front

of solenoid for voltage and frequency.

WARNING: To prevent the possibility of electrical shock from

the accessibility of live parts, install the open-frame solenoid

in an enclosure.

FOR BLACK ENCLOSURE TYPES 7 AND 9 ONLY

CAUTION: To prevent fire or explosion, do not install solenoid and/or valve

where ignition temperature is less than 165˚ C. On valves used for steam

service or when a class "H" solenoid is used, do not install in hazardous atmosphere where ignition temperature is less than 180˚ C. See nameplate/retainer for service.

NOTE: These solenoids have an internal non-resetable thermal fuse to limit

solenoid temperature in the event that extraordinary conditions occur which could

cause excessive temperatures. These conditions include high input voltage, a

jammed core, excessive ambient temperature or shorted solenoid, etc.

This unique feature is a standard feature is a standard feature only in

solenoids with black explosionproof/dust-ignitionproof enclosures

(types 7&9).

IMPORTANT: To protect the solenoid valve or operator, install a strainer or filter, suitable for the service involved in the inlet side as close to the

valve or operator as possible. Clean periodically depending on service condition & See ASCO Series 8600, 8601, and 8602 for strainers.

Temperature Limitations

For maximum valve ambient temperatures, refer to chart. The temperature limitations listed, only indicate maximum application temperatures for field wiring rated

at 90°C. Check catalog number prefix and watt rating on nameplate to determine maximum ambient temperature. See valve installation and maintenance

instructions for maximum fluid temperature. NOTE: For steam service, refer to

Wiring section, Junction Box for temperature rating of supply wires.

Minimum ambient temperature -40° F (-40° C). Positioning

Positioning

This solenoid is designed to perform properly when mounted in any position.

However, for optimum life and performance, the solenoid should be mounted vertically and upright to reduce the possibility of foreign matter accumulating in the

solenoid base sub-assembly area.

Wiring

Wiring must comply with local codes and the National Electrical Code. All solenoids supplied with lead wires are provided with a grounding wire which is green

or green with yellow stripes and a 1/2" conduit connection. To facilitate wiring, the

solenoid may be rotated 360˚. For the watertight and explosionproof solenoid,

electrical fittings must be approved for use in the approved hazardous locations.

Additional Wiring Instructions For Optional Features:

• Open-Frame solenoid with 1/4" spade terminals

For solenoids supplied with screw terminal connections use #12-18 AWG stranded copper wire rated at 90°C or greater. Torque terminal block screws to 10 ± 2

in-lbs (1,0 + 1,2 Nm). A tapped hole is provided in the solenoid for grounding, use

a #Y10-32 machine screw. Torque grounding screw to 15 -20

Temperature Limitations For Series 8016G Solenoids for use

Valves Rated at 6.1, 8.1,9.1,10.6 or 11.1 Watts

Watts

Rating

Catalog

Number Coil

prefix

Class of

Insulation

Maximum

ambient Temp.

˚F

6.1, 8.1, 9.1,

& 11.1

None, FB, KF, KP,

SF, SP, SC, & SD

F 125

6.1, 8.1, 9.1,

& 11.1

HB, HT, KB, KH,

SS, ST, SU, & ST

H 140

10.6

None, KF,

SF, & SC

F 104

10.6

HT, KH,

SU, & ST

H 104

Page 19

in-lbs (1,7 - 2,3 Nm). On solenoids with screw terminals, the socket head

screw holding the terminal block to the solenoid is the grounding screw.

Torque the screw to 15 - 20 in-lbs (1,7 - 2,3 Nm). with a 5/32" hex key wrench.

• Junction Box

The junction box is used with spade or screw terminal solenoids only

and is provided with a grounding screw and a 1/2" conduit connection.

Connect #12-18AWG standard copper wire only to the screw terminals.

Within the junction box use field wire that is rated 90°C or greater for

connections. For steam service use 105°C rated wire up to 50 psi or

use 125°C rated wire above 50 psi. After electrical hookup, replace

cover gasket, cover, and screws. Tighten screws evenly in a crisscross manner.

• DIN Plug Connector Kit No. KC236-034

1. The open—frame solenoid is provided with DIN terminals to accommodate

the DIN plug connector kit.

2. Remove center screw from plug connector. Using a small screwdriver,

pry terminal block from connector cover.

3. Use #12-18 AWG stranded copper wire rated at 90°C or greater for

connections. Strip wire leads back approximately 1/4" for installation in

socket terminals. The use of wire-end sleeves is also recommended for

these socket terminals. Maximum length of wire-end sleeves to be

approximately 1/4". Tinning of the ends of the lead wires is not recommended.

4. Thread wire through gland nut, gland gasket, washer, and connector

cover.

NOTE: Connector cover may be rotated in 90° increments from position

shown for alternate positioning of cable entry.

5. Check DIN connector terminal block for electrical markings. Then make

electrical hookup to terminal block according to markings on it. Snap

terminal block into connector cover and install center screw.

6. Position connector gasket on solenoid and install plug connector.

Torque center screw to 5 ± 1 in-lbs (0,6 ± 1,1 Nm).

NOTE: Alternating current (AC) and direct current (DC) solenoids are built

differently. To convert from one to the other, it may be necessary to

change the complete solenoid including the core and solenoid base subassembly, not just the solenoid. Consult ASCO.

Installation of Solenoid

Solenoids may be assembled as a complete unit. Tightening is accomplished

by means of a hex flange at the base of the solenoid. The 3/4" bonnet construction (Figure 1) must be disassembled for installation and installed

with a special wrench adapter.

Installation of Panel Mounted Solenoid (See Figure 3)