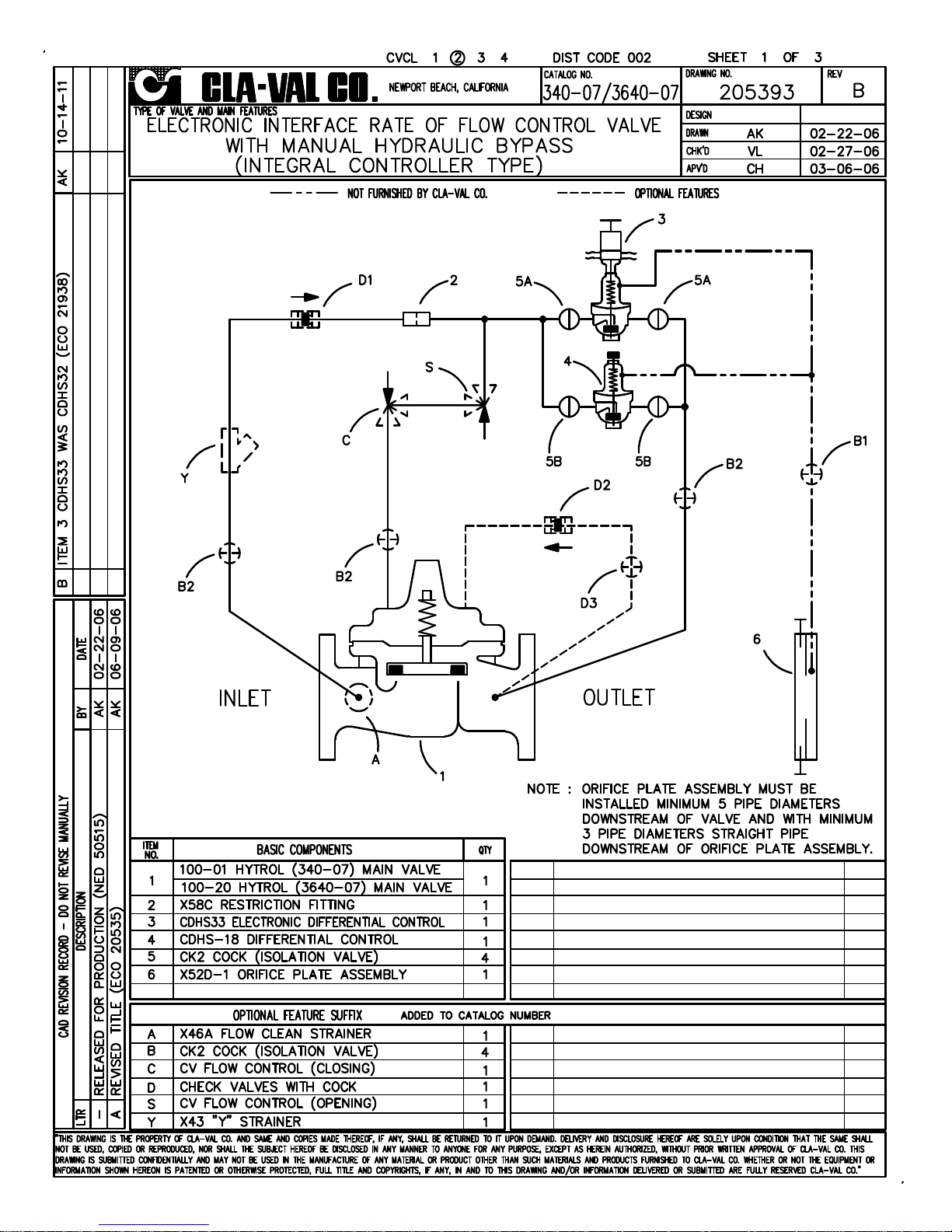

Page 1

340-07/3640-07

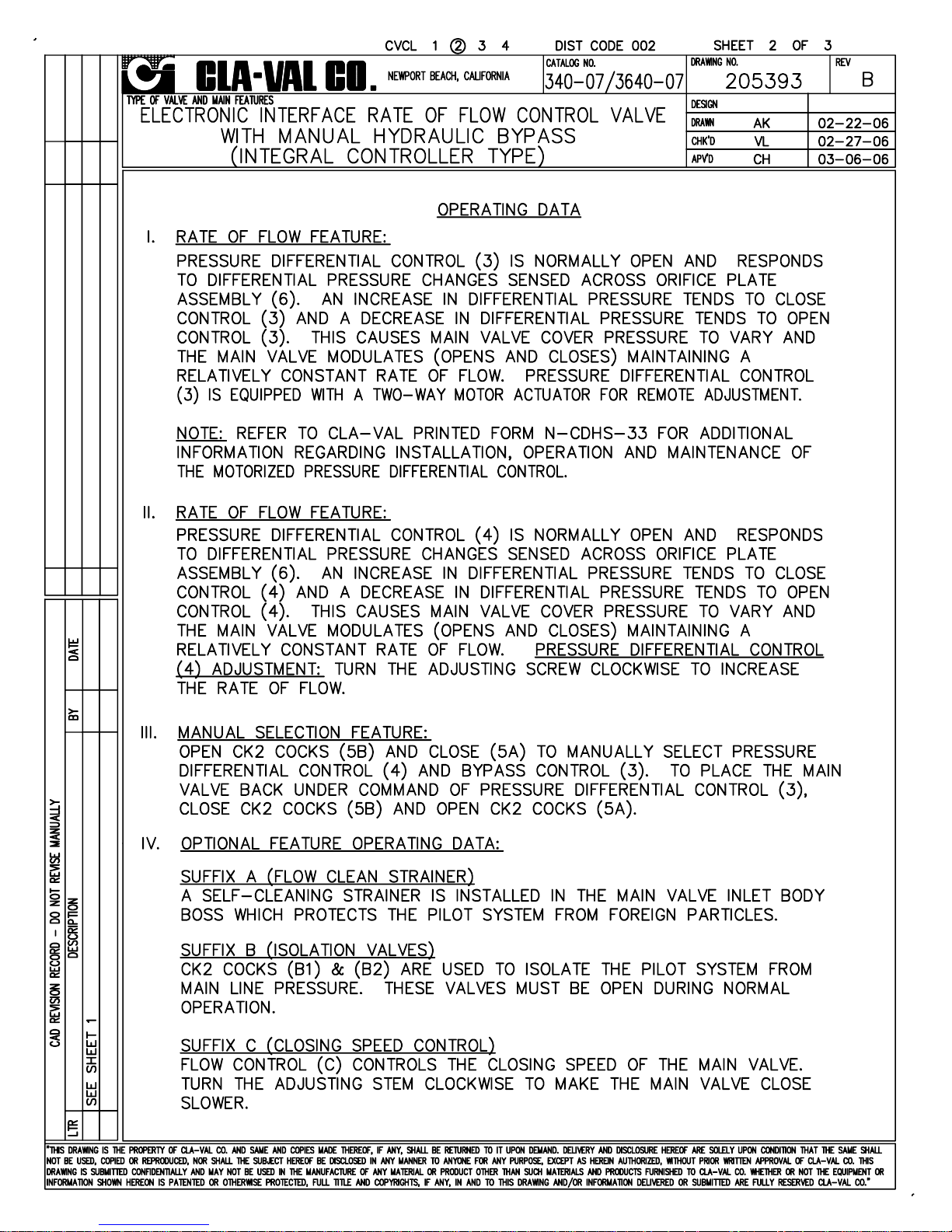

Page 2

Page 3

Page 4

Page 5

Description

The CIa-VaI Model 100-01 Hytrol Valve is a main valve for CIa-VaI

Automatic Control Valves. It is a hydraulically operated, diaphragm-actuated, globe or angle pattern valve.

This valve consists of three major components; body, diaphragm assembly, and cover. The diaphragm assembly is the only moving part. The

diaphragm assembly uses a diaphragm of nylon fabric bonded with synthetic rubber. A synthetic rubber disc, contained on three and one half

sides by a disc retainer and disc guide, forms a seal with the valve seat

when pressure is applied above the diaphragm. The diaphragm assembly forms a sealed chamber in the upper portion of the valve, separating

operating pressure from line pressure.

Installation

1. Before valve is installed, pipe lines should be flushed of all chips,

scale and foreign matter.

2. It is recommended that either gate or block valves be installed on

both ends of the 100-01 Hytrol Valve to facilitate isoIating the valve for

preventive maintenance and repairs.

3. Place the valve in the line with flow through the valve in the direction indicated on the inlet nameplate. (See “Flow Direction” Section)

Note: Valve can be installed in the vertical or horizontal position.

4. Allow sufficient room around valve to make adjustments and for disassembly.

5. CIa-VaI 100-01 Hytrol Valves operate with maximum effic iency when

mounted in horizontal piping with the cover UP, however, other positions are acceptable. Due to size and weight of the cover and internal

components of 8 inch and larger valves, installation with the cover UP

is advisable. This makes internal parts readily accessible for periodic

inspection.

6. Caution must be taken in the installation of this valve to

insure that galvanic and/or electrolytic action does not take

place. The proper use of dielectric fittings and gaskets are

required in all systems using dissimilar metals.

7. If a pilot control system is installed on the 100-01 Hytrol

Valve, use care to prevent damage. If it is necessary to

remove fittings or components, be sure they are kept clean

and replaced exactly as they were.

8. After the valve is installed and the system is first pressurized, vent air from the cover chamber and pilot system tubing by loosening fittings at all high points.

Tight Closing Operation

When pressure from the valve inlet (or

an equivalent independent operating

pressure) is applied to the diaphragm

chamber the valve closes drip-tight.

Full Open Operation

When pressure in diaphragm chamber

is relieved to a zone of lower pressure

(usually atmosphere) the line pressure

(5 psi Min.) at the valve inlet opens the

valve.

Modulating Action

Valve modulates when diaphragm pressure is held at an intermediate point

between inlet and discharge pressure.

With the use of a Cla-Val. "modulating

control," which reacts to line pressure

changes, the pressure above the

diaphragm is varied, allowing the valve

to throttle and compensate for the

change.

Principles of Operation

Three Way

Pilot Control

Three Way

Pilot Control

Restriction

Modulating

Control

100-01

Hytrol Valve

MODEL

INSTALLATION / OPERATION / MAINTENANCE

Page 6

2

Flow Direction

The flow through the 100-01 Hytrol Valve can be in one of two

directions. When flow is “up-and-over the seat,” it is in “normal”

flow and the valve will fail in the open position. When flow is “overthe seat-and down,” it is in “reverse” flow and the valve will fail in

the closed position. There are no permanent flow arrow markings.

The valve must be installed according to nameplate data.

BRIDGEWALL INDlCATOR

Normal Flow Reverse Flow

Troubleshooting

The following troubleshooting information deals strictly with the

Model 100-01 Hytrol Valve. This assumes that all other components of the pilot control system have been checked out and are

in proper working condition. (See appropriate sections in

Technical Manual for complete valve).

Three Checks

The 100-01 Hytrol Valve has only one moving part (the diaphragm

and disc assembly). So, there are only three major types of problems to be considered.

First: Valve is stuck - that is, the diaphragm assembly is not free

to move through a full stroke either from open to close or vice

versa.

Second: Valve is free to move and can’t close because of a worn

out diaphragm.

Third: Valve leaks even though it is free to move and the

diaphragm isn’t leaking.

Closed isolation valves in control system, or in main line.

Lack of cover chamber pressure.

Diaphragm damaged. (See Diaphragm Check.)

Diaphragm assembly inoperative.

Corrosion or excessive scale build up on valve stem.

(See Freedom of Movement Check)

Mechanical obstruction. Object lodged in valve.

(See Freedom of Movement Check)

Worn disc. (See Tight Sealing Check)

Badly scored seat. (See Tight Sealing Check)

Closed upstream and/or downstream isolation

valves in main line.

Insufficient line pressure.

Diaphragm assembly inoperative. Corrosion or excessive

buildup on valve stem. (See Freedom of Movement Check)

Diaphragm damaged. (For valves in "reverse flow" only)

After checking out probable causes and remedies, the following three checks can be used to diagnose the nature of the

problem before maintenance is started. They must be done in the order shown.

Open Isolation valves.

Check upstream pressure, pilot system, strainer, tubing, valves, or needle

valves for obstruction.

Replace diaphragm.

Clean and polish stem. Inspect and replace any damaged or badly eroded

part.

Remove obstruction.

Replace disc.

Replace seat.

Open isolation valves.

Check upstream pressure. (Minimum 5 psi flowing line pressure differential.)

Clean and polish stem. Inspect and replace any

damaged or badly eroded part.

Replace diaphragm.

Fails to Close

Fails to Open

CAUTION:

Care should be taken when doing the troubleshooting checks on

the 100-01 Hytrol Valve. These checks do require the valve to

open fully. This will either allow a high flow rate through the

valve, or the downstream pressure will quickly increase to the

inlet pressure. In some cases, this can be very harmful. Where

this is the case, and there are no block valves in the system to

protect the downstream piping, it should be realized that the

valve cannot be serviced under pressure. Steps should be

taken to remedy this situation before proceeding any further.

(cast into side of valve body)

SYMPTOM PROBABLE CAUSE REMEDY

Recommended Tools

1. Three pressure gauges with ranges suitable to the installation to be put at Hytrol inlet, outlet and cover connections.

2. Cla-Val Model X101 Valve Position Indicator. This provides visual indication of valve position without disassembly

of valve.

3. Other items are: suitable hand tools such as screwdrivers, wrenches, etc. soft jawed (brass or aluminum) vise,

400 grit wet or dry sandpaper and water for cleaning.

All trouble shooting is possible without removing the valve from the

line or removing the cover. It is highly recommended to permanently

install a Model X101 Valve Position Indicator and three gauges in

unused Hytrol inlet, outlet and cover connections.

Page 7

Diaphragm Check (#1 )

1. Shut off pressure to the Hytrol Valve by slowly closing upstream

and downstream isolation valves. SEE CAUTION.

2. Disconnect or close all pilot control lines to the valve cover and

leave only one fitting in highest point of cover open to atmosphere.

3.With the cover vented to atmosphere, slowly open upstream

isolation valve to allow some pressure into the Hytrol Valve body.

Observe the open cover tapping for signs of continuous flow. It is

not necessary to fully open isolating valve. Volume in cover chamber capacity chart will be displaced as valve moves to open position. Allow sufficient time for diaphragm assembly to shift positions. If there is no continuous flow, you can be quite certain the

diaphragm is sound and the diaphragm assembly is tight. If the

fluid appears to flow continuously this is a good reason to believe

the diaphragm is either damaged or it is loose on the stem. In

either case, this is sufficient cause to remove the valve cover and

investigate the leakage. (See “Maintenance” Section for procedure.)

Freedom of Movement Check (#2)

4. Determining the Hytrol Valve’s freedom of movement can be

done by one of two methods.

5. For most valves it can be done after completing Diaphragm

Check (Steps 1, 2, and 3). SEE CAUTION. At the end of step 3

the valve should be fully open.

6. If the valve has a Cla-Val X101 Position Indicator, observe the

indicator to see that the valve opens wide. Mark the point of maximum opening.

7. Re-connect enough of the control system to permit the application of inlet pressure to the cover. Open pilot system cock so

pressure flows from the inlet into the cover.

8. While pressure is building up in the cover, the valve should

close smoothly. There is a hesitation in every Hytrol Valve closure,

which can be mistaken for a mechanical bind. The stem will

appear to stop moving very briefly before going to the closed position. This slight pause is caused by the diaphragm flexing at a

particular point in the valve’s travel and is not caused by a

mechanical bind.

9. When closed, a mark should be made on the X101 Valve position indicator corresponding to the “closed” position. The distance

between the two marks should be approximately the stem travel

shown in chart.

10. If the stroke is different than that shown in stem travel chart

this is a good reason to believe something is mechanically restricting the stroke of the valve at one end of its travel. If the flow does

not stop through the valve when in the indicated “closed” position,

the obstruction probably is between the disc and the seat. If the

flow does stop, then the obstruction is more likely in the cover. In

either case, the cover must be removed, and the obstruction located and removed. The stem should also be checked for scale buildup. (See “Maintenance, section for procedure.)

11. For valves 6” and smaller, the Hytrol Valve’s freedom of movement check can also be done after all pressure is removed from

the valve. SEE CAUTION. After closing inlet and outlet isolation

valves and bleeding pressure from the valve, check that the cover

chamber and the body are temporarily vented to atmosphere.

Insert fabricated tool into threaded hole in top of valve stem, and

lift the diaphragm assembly manually. Note any roughness. The

diaphragm assembly should move smoothly throughout entire

valve stroke. The tool is fabricated from rod that is threaded on

one end to fit valve stem and has a “T” bar handle of some kind

on the other end for easy gripping. (See chart in Step 4 of

“Disassembly” Section.)

12. Place marks on this diaphragm assembly lifting tool when the

valve is closed and when manually positioned open. The distance

between the two marks should be approximately the stem travel

shown in stem travel chart. If the stroke is different than that

shown, there is a good reason to believe something is mechanically restricting the stroke of the valve. The cover must be

removed, and the obstruction located and removed. The stem

should also be checked for scale build-up. (See “Maintenance”

Section for procedure.)

Tight Sealing Check (#3)

13. Test for seat leakage after completing checks #1 & #2 (Steps

1 to 12). SEE CAUTION. Close the isolation valve downstream of

the Hytrol Valve. Apply inlet pressure to the cover of the valve, wait

until it closes. Install a pressure gauge between the two closed

valves using one of the two ports in the outlet side of the Hytrol.

Watch the pressure gauge. If the pressure begins to climb, then

either the downstream isolation valve is permitting pressure to

creep back, or the Hytrol is allowing pressure to go through it.

Usually the pressure at the Hytrol inlet will be higher than on the

isolation valve discharge, so if the pressure goes up to the inlet

pressure, you can be sure the Hytrol is leaking. Install another

gauge downstream of isolating valve. If the pressure between the

valves only goes up to the pressure on the isolation valve

discharge, the Hytrol Valve is holding tight, and it was just the isolation valve leaking.

STEM TRAVEL

(Fully Open to Fully Closed)

Valve Size (inches) Travel (inches)

Inches MM Inches MM

1 1/4 32 0.4 10

1 1/2 40 0.4 10

250 0.615

2 1/2 65 0.7 18

380 0.820

4 100 1.1 28

6 150 1.7 43

8 200 2.3 58

10 250 2.8 71

12 300 3.4 86

14 350 4.0 100

16 400 4.5 114

20 500 5.6 143

24 600 6.7 165

30 800 7.5 190

36 900 8.5 216

COVER CHAMBER CAPACITY

(Liquid Volume displaced when valve opens)

Valve size (inches) Displacement

Gallons Liters

1 1/4 .020 .07

1 1/2 .020 .07

2 .032 .12

2 1/2 .043 .16

3 .080 .30

4 .169 .64

6 .531 2.0

8 1.26 4.8

10 2.51 9.5

12 4.00 15.1

14 6.50 24.6

16 9.57 36.2

20 12.00 45.4

24 29.00 109.8

30 42.00 197.0

36 90.00 340.0

3

Page 8

Maintenance

Preventative Maintenance

The Cla-Val Co. Model 100-01 Hytrol Valve requires no lubrication or

packing and a minimum of maintenance. However, a periodic inspection schedule should be established to determine how the operating

conditions of the system are affecting the valve. The effect of these

actions must be determined by inspection.

Disassembly

Inspection or maintenance can be accomplished without removing

the valve from the line. Repair kits with new diaphragm and disc are

recommended to be on hand before work begins.

WARNING: Maintenance personnel can be injured and equipment

damaged if disassembly is attempted with pressure in the valve. SEE

CAUTION.

1. Close upstream and downstream isolation valves and independ-

ent operating pressure when used to shut off all pressure to the

valve.

2. Loosen tube fittings in the pilot system to remove pressure from

valve body and cover chamber. After pressure has been released

from the valve, use care to remove the controls and tubing. Note and

sketch position of tubing and controls for re-assembly. The schematic in front of the Technical Manual can be used as a guide when

reassembling pilot system.

3. Remove cover nuts and remove cover. If the valve has been in

service for any length of time, chances are the cover will have to be

loosened by driving upward along the edge of the cover with a dull

cold chisel.

On 6” and smaller valves block and tackle or a power hoist can be

used to lift valve cover by inserting proper size eye bolt in place of

the center cover plug. on 8” and larger valves there are 4 holes (5/8”

— 11 size) where jacking screws and/or eye bolts may be inserted

for lifting purposes. Pull cover straight up to keep from damaging

the integral seat bearing and stem.

4. Remove the diaphragm and disc assembly from the valve body.

With smaller valves this can be accomplished by hand by pulling

straight up on the stem so as not to damage the seat bearing.

On large valves, an eye bolt of proper size can be installed in the

stem and the diaphragm assembly can be then lifted with a block and

tackle or power hoist. Take care not to damage the stem or bearings.

The valve won't work if these are damaged.

5. The next item to remove is the stem nut. Examine the stem

threads above the nut for signs of mineral deposits or corrosion.

If the threads are not clean, use a wire brush to remove as much

of the residue as possible. Attach a good fitting wrench to the nut

and give it a sharp “rap” rather than a steady pull. Usually

several blows are sufficient to loosen the nut for further removal.

On the smaller valves, the entire diaphragm assembly can be held

by the stem in a vise equipped with soft brass jaws before

removing the stem nut.

The use of a pipe wrench or a vise without soft brass jaws scars

the fine finish on the stem. No amount of careful dressing can

restore the stem to its original condition. Damage to the finish of

the stem can cause the stem to bind in the bearings and the valve

will not open or close.

6. After the stem nut has been removed, the diaphragm assembly

breaks down into its component parts. Removal of the disc from

the disc retainer can be a problem if the valve has been in service for a long time. Using two screwdrivers inserted along the outside edge of the disc usually will accomplish its removal. Care

should be taken to preserve the spacer washers in water, particularly if no new ones are available for re-assembly.

7. The only part left in the valve body is the seat which ordinarily

does not require removal. Careful cleaning and polishing of inside

and outside surfaces with 400 wet/dry sandpaper will usually

restore the seat’s sharp edge. If, however, it is badly worn and

replacement is necessary, it can be easily removed.

Seats in valve sizes 1 1/4” through 6” are threaded into the valve

body. They can be removed with accessory X109 Seat Removing

Tool available from the factory. On 8” and larger valves, the seat

is held in place by flat head machine screws. Use a tight-fitting,

long shank screwdriver to prevent damage to seat screws. If upon

removal of the screws the seat cannot be lifted out, it will be necessary to use a piece of angle or channel iron with a hole drilled

in the center. Place it across the body so a long stud can be inserted through the center hole in the seat and the hole in the angle

iron. By tightening the nut a uniform upward force is exerted on

the seat for removal.

NOTE: Do not lift up on the end of the angle iron as this may force

the integral bearing out of alignment, causing the stem to bind.

VALVE STEM THREAD SIZE

Valve Size Thread Size (UNF Internal)

1 1/4"

—2 1/2" 10—32

3"—4" 1/4—28

6"—14" 3/8—24

16" 1/2—20

20 3/4-16

24" 3/4-16

30” 3/4-16

36” 3/4-16

COVER CENTER PLUG SIZE

Valve Size Thread Size (NPT)

1 1/4"

—1 1/2" 1/4"

2"—3" 1/2"

4"—6" 3/4"

8"—10" 1"

12" 1 1/4"

14" 1 1/2"

16" 2"

20” & 24" 2"

30” & 36” 2”

NUT

ANGLE OR CHANNEL IRON

LONG STUD OR BOLT

NUT OR BOLT HEAD

DO NOT

LIFT

VALVE SEAT

VALVE BODY

4

Page 9

Lime Deposits

One of the easiest ways to remove lime deposits from the valve

stem or other metal parts is to dip them in a 5-percent muriatic

acid solution just long enough for the deposit to dissolve. This

will remove most of the common types of deposits. CAUTlON:

USE EXTREME CARE WHEN HANDLING ACID. Rinse parts in

water before handling. If the deposit is not removed by acid, then

a fine grit (400) wet or dry sandpaper can be used with water.

Reassembly

1. Reassembly is the reverse of the disassembly procedure. If a

new disc has been installed, it may require a different number of

spacer washers to obtain the right amount of “grip” on the disc.

When the diaphragm assembly has been tightened to a point

where the diaphragm cannot be twisted, the disc should be compressed very slightly by the disc guide. Excessive compression

should be avoided. Use just enough spacer washers to hold the

disc firmly without noticeable compression.

2. MAKE SURE THE STEM NUT IS VERY TIGHT. Attach a good

fitting wrench to the nut and give it a sharp “rap” rather than a

steady pull. Usually several blows are sufficient to tighten the

stem nut for final tightening. Failure to do so could allow the

diaphragm to pull loose and tear when subjected to pressure.

Test Procedure After Valve Assembly

There are a few simple tests which can be made in the field to

make sure the Hytrol Valve has been assembled properly. Do

these before installing pilot system and returning valve to

service. These are similar to the three troubleshooting tests.

1. Check the diaphragm assembly for freedom of movement

after all pressure is removed from the valve. SEE CAUTlON.

Insert fabricated tool into threaded hole in top of valve stem, and

lift the diaphragm assembly manually. Note any roughness,

sticking or grabbing. The diaphragm assembly should move

smoothly throughout entire valve stroke. The tool is fabricated

from rod that is threaded on one end to fit valve stem (See chart

in Step 4 of “Disassembly” section.) and has a “T” Bar handle of

some kind on the other end for easy gripping.

Place marks on this diaphragm assembly lifting tool when the

valve is closed and when manually positioned open. The distance between the two marks should be approximately the stem

travel shown in stem travel chart. (See “Freedom of Movement

Check” section.) If the stroke is different than that shown, there

is a good reason to believe something is mechanically restricting

the stroke of the valve. The cover must be removed, the obstruction located and removed. (See “Maintenance” Section for

procedure.)

Inspection of Parts

After the valve has been disassembled, each part should be

examined carefully for signs of wear, corrosion, or any other

abnormal condition. Usually, it is a good idea to replace the rubber parts (diaphragm and disc) unless they are free of signs of

wear. These are available in a repair kit. Any other parts which

appear doubtful should be replaced. WHEN ORDERlNG

PARTS, BE SURE TO GIVE COMPLETE NAMEPLATE DATA,

ITEM NUMBER AND DESCRlPTlON.

NOTE: If a new disc isn’t available, the existing disc can be

turned over, exposing the unused surface for contact with the

seat. The disc should be replaced as soon as practical.

3. Carefully install the diaphragm assembly by lowering the stem

through the seat bearing. Take care not to damage the stem or

bearing. Line up the diaphragm holes with the stud or bolt holes

on the body. on larger valves with studs, it may be necessary to

hold the diaphragm assembly up part way while putting the

diaphragm over the studs.

4. Put spring in place and replace cover. Make sure diaphragm

is Iying smooth under the cover.

5. Tighten cover nuts firmly using a cross-over pattern until all

nuts are tight.

6. Test Hytrol Valve before re-installing pilot valve system.

Due to the weight of the diaphragm assembly this procedure is

not possible on valves 8” and larger. on these valves, the same

determination can be made by carefully introducing a low

pressure-less than five psi) into the valve body with the cover

vented. SEE CAUTION. Looking in cover center hole see the

diaphragm assembly lift easily without hesitation, and then

settle back easily when the pressure is removed.

2. To check the valve for drip-tight closure, a line should be

connected from the inlet to the cover, and pressure applied at the

inlet of the valve. If properly assembled, the valve should hold

tight with as low as ten PSI at the inlet. See “Tight Sealing

Check” section.)

3. With the line connected from the inlet to the cover, apply full

working pressure to the inlet. Check all around the cover for any

leaks. Re-tighten cover nuts if necessary to stop leaks past the

diaphragm.

4. Remove pressure, then re-install the pilot system and tubing

exactly as it was prior to removal. Bleed air from all high

points.

5. Follow steps under “Start-Up and Adjustment” Section in

Technical Manual for returning complete valve back to service

.

5

Page 10

1

5

8

10

14

16

6

17

7

9

OUTLE

T

INLET

GLOBE PATTERN

9

26

27

12

15

14

16

INLET

OUTLET

ANGLE PATTERN

22

23

13

12

14

10

11

15

23

TOP VIEW

8" - 24" SEAT DETAIL

1 1/4" - 6" SEAT DETAIL

16" COVER DETAIL

4

24

2

25

13

31

28

30

29

5

14

3

Item Description

1. Pipe Plug

2. Drive Screws (for nameplate)

3. Hex Nut (8” and larger)

4. Stud (8” and larger)

5. Cover Bearing

6. Cover

7. Stem Nut

8. Diaphragm Washer

9. Diaphragm

10. Spacer Washers

11. Disc Guide

12. Disc Retainer

13. Disc

14. Stem

15. Seat

16. Body

17. Spring

22. Flat Head Screws (8” and larger)

23. Seat O-Ring

24. Hex head Bolt (1 1/4” thru 4”)

25. Nameplate

26. Upper Spring Washer (Epoxy coated valves only)

27. Lower Spring Washer (Epoxy coated valves only)

28. Cover Bearing Housing (16” only)

29. Cover O-Ring (16’” only)

30. Hex Bolt (16” only)

31. Pipe Cap (16” only)

PARTS LIST

6

Page 11

100-01

Hytrol Valve Service Data

MODEL

INSTALLATION / OPERATION / MAINTENANCE

Description 100-01 Hytrol Valve

The CIa-VaI Model 100-01 Hytrol Valve is a main valve for

CIa-VaI Automatic Control Valves. It is a hydraulically operated,

diaphragm-actuated, globe or angle pattern valve.

This valve consists of three major components; body, diaphragm

assembly, and cover. The diaphragm assembly is the only

moving part. The diaphragm assembly uses a diaphragm of nylon

fabric bonded with synthetic rubber. A synthetic rubber disc,

contained on three and one half sides by a disc retainer and disc

guide, forms a seal with the valve seat when pressure is applied

above the diaphragm. The diaphragm assembly forms a sealed

chamber in the upper portion of the valve, separating operating

pressure from line pressure.

Description 100-20 600 Series Hytrol Valve

The CIa-VaI Model 100-20 Hytrol Valve (600 Series main valve)

have only one part -the body- that is different from standard 100

Series Cla-Val main valve parts. The remaining parts of the 600

series main valve are standard Cla-Val main valve parts. All serv-

ice and maintenance information for the standard 100 Series

main valves also apply to the 600 series main valves.

The most important thing to remember when ordering main

valve repair kits and replacement parts, except for the body, all

other parts are going to be for a smaller size main valve. Cla-

Val identifies main valve parts with the flange size of the stan-

dard 100 Series main valve. Refer to the "Main Valve Sizes”

chart below.

HYTROL Service Data

HYTROL SIZE

Stem

Travel

Cover Capacity

Displacement

Valve Stem

Thread

UNF-Internal

Cover

Center

Plug

NPT

Cover Nut or Bolt

Cover

Lifting

Holes

UNC

Cover Plug Cover Torque Stem Nut**

Stem Nut Torque

(ft. Lbs.)

100-01 100-20

Thread

(Bolt)

Socket

Qty Thread

Socket ft. Lbs.

in. Lbs.

Thread

Socket

(Long)

inches mm inches mm inches mm

Gallons

Liters Lubed DRY

1"

25 0.3 8 1/4" 1/4" - 20 (B) 7/16" 8 4 48 3/8" - 24

4

6

1 1/4"

32

0.4

10

0.020

0.07 10 - 32

1/4"

5/16" - 18 (B)

1/2"

8

8

96 7/16" -20 6 10

1 1/2"

40 0.4 10

0.020 0.07 10 - 32

1/4" 5/16" - 18 (B) 1/2"

8

8

96 7/16" -20 6 10

2"

50 0.6 15

0.032

0.12

10 - 32

1/2"

3/8" - 16 (B)

9/16" 8 3/8"

7/16" 12 1/2" - 20

3/4"

10

15

2 1/2"

65 0.7 18

0.043 0.16

10 - 32 1/2"

7/16" - 14 (B)

5/8" 8 1/2"

9/16" 20 5/8" - 18 15/16" 21

30

3"

80 4" 100 0.8

20

0.080 0.30

1/4 - 28 1/2"

1/2" - 13 (B)

3/4" 8 1/2"

9/16" 30

5/8" - 18

15/16"

21 30

4"

100

6"

150

1.1 23

0.169 0.64

1/4 - 28

3/4"

3/4" - 10 (B)

1 1/8" 8 3/4" 5/8" 110

3/4" - 16

1 1/16"

40

60

6"

150 8" 200 1.7 43

0.531 2.00

3/8 - 24 3/4"

3/4" - 10 (B) 1 1/8"

12 3/4"

5/8"

110 7/8" - 14

1 5/16"

85 125

8"

200 10" 250 2.3 58

1.26 4.80

3/8 - 24 1" 3/4" - 10 1 1/4" 16

5/8" - 11

1"

13/16" 110 1 1/8" -12 1 13/16"

125

185

10"

250 12" 300 2.8 71

2.51 9.50 3/8 - 24

1"

7/8" - 9

1 7/16"

20

3/4" - 10

1"

13/16" 160

1 1/2" -12 1 7/8" 252 375

12"

300 16" 400

3.4 86 4.0 15.10 3/8 - 24 1 1/4" 1 1/8" - 7 1 13/16"

20

3/4" - 10 1" 13/16" 390

1 1/2" -12 2 1/2"

270 400

14"

350 3.9

99

6.5

24.60

3/8 - 24

1 1/2" 1 1/4" - 7 2" 20

1" - 8

1" 13/16" 545 1 1/2" -12

2 1/2"

280 420

16"

400

20", 24"

600 4.5

114

9.6 36.20

1/2 - 20 2"

1 1/4" - 7

2" 20 1" - 8 1"

13/16"

545

2" - 16 3" 500

750

20"

500 5.63

143

12 45.40

3/4 - 16 1 1/2"

1 3/8" - 6

2 1/8" 24 1" - 8 1"

13/16" 670

2 1/4" - 16

3 1/2"

930 N/R

24" 600 30"

800

6.75 165

29.0

108.80

3/4 - 16*

3/4"

1 1/2" - 12 2 3/8" 24 1 1/8"- 7 1" 13/16"

800 3" - 12

Special

1350

N/R

* Adapter

p/n 2594101E

inside 1/4" - 28"

Grade 5 Bolts

"Heavy" Grade Nuts

Tighten cover nuts in a "star" cross-over pattern

** Must Use ONLY

Cla-Val Supplied part

Page 12

CLA-VAL

Copyright Cla-Val 2014 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 • Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: claval@cla-val.com • Website cla-val.com

©

COVER

PIPE PLUG

COVER BEARING

SPRING

STEM NUT

DIAPHRAGM WASHER

DISC RETAINER

BODY

*

SPACER WASHERS

DISC GUIDE

SEAT

PIPE PLUG

STEM

SEAT O-RING

STUD

8" and Larger

*

DIAPHRAGM

*

DISC

*

Repair Parts

Seat Screw

8" and Larger

(Globe

or

Angle)

PIPE PLUG

HEX NUT

8" and Larger

Cover Bolt

6" and Smaller

KO

DISC GUIDE

KO

SEAT

KO Anti-Cavitation

Trim Option

N-100-01 (R-08/2014)

BOLT/NUT TORQUING PROCEDURES ON VALVE COVERS

4

BOLTS

6

BOLTS

8

BOLTS

12

BOLTS

16

BOLTS

20

BOLTS

4

3

2

1

65

4

3

2

1

8

7

6

5

4

3

2

1

0

9

8

7

6

5

3

2

1

12

11

10

9

8

7

6

5

4

3

2

1

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

20

19

18

17

16

15

14

13

12

11

Follow this procedure when reassembling MAIN Valve:

1. Tightens bolts/nuts in a “Star” or “Cross-Over” pattern following the

numbers shown above to insure that cover seats evenly on the diaphragm

material and body.

2. Torque the bolt/nuts in three stages with a "Star" or "Cross-Over" pattern

for each stage:

A. To approximately 10% of final torque.

B. To approximately 75% of final torque.

C. To final required torque.

3. Valves that are to be tested to 375 PSI or higher should be retorqued

after 24 hours.

100-01 Hytrol Main Valve Assembly

Page 13

UNDERSTANDING THE 600 SERIES VALVES

In 1987, Cla-Val introduced the Model 100-20 Hytrol as the basic

main valve for the 600 Series of automatic control valves. To

identify all new valves using the 100-20 Hytrol, an existing catalog number is modified. Making a 600 Series catalog number is

simply done by using a "6" in front of the two digit catalog numbers or replacing the "2" with a "6" in three digit catalog numbers. Current schematics reflect both catalog numbers together

separated by a slash ( i.e. - 90-01/690-01, 58-02/658-02, 21001/610-01, etc). Since these two valves 'share' the same catalog

number and schematic, they provide the same function in a system. The only difference between the two valves is the relative

capacity of the two main valve series.

The 100-01 Hytrol is the basic main valve for Cla-Val automatic

control valves. This valve is the current version of the Clayton

Hytrol valve design originated in 1936. The 100-01 Hytrol is

designed as a full flow area valve. This means that the inlet,

seat and outlet openings are the same size. Thus, the pressure

drop is kept to a minimum for this globe style design.

The 100-20 Hytrol valve has all of the basic features and advantages of the original 100-01 Hytrol. Only one part has been

changed - the body. It is designed with different size inlet, seat

and outlet openings. The 100-20 Hytrol has inlet and outlet

flanges one valve size larger than the seat opening size. This

results in what is sometimes called a ''reduced port' main valve.

For example, a 4" 100-20 valve has a 3" seat. Note: valve size

is always determined by the flange size. The following chart

compares the 100-01 and the 100-20 main valves.

600 Series Hytrol Valve

100-20

MODEL

INSTALLATION / OPERATION / MAINTENANCE

SERVICE AND MAINTENANCE OF 600 SERIES

VALVES

The 600 series main valves have only one part -the body- that is

different from standard 100 Series Cla-Val main valve parts. The

remaining parts of the 600 series main valve are standard ClaVal main valve parts. All service and maintenance information

for the standard 100 Series main valves in this manual also

apply to the 600 series main valves.

The most important thing to remember when ordering main valve

repair kits and replacement parts, except for the body, all other

parts are going to be for a smaller size main valve. Cla-Val identifies main valve parts with the flange size of the standard 100

Series main valve. Refer to the "Main Valve Sizes Comparison"

chart. For example, if you are servicing a 6" 100-20 Hytrol and

needed a repair kit, you would order a repair kit for a 4" 100-01

Hytrol. This kit is also suitable for a 6" 100-20 Hytrol. Complete

Technical Manuals include a repair kit data sheet N-RK that

shows this relationship.

When you order repair parts, it is a good idea to include valve

nameplate data (size, catalog number, and part number) and

description of the parts desired. Do this to be sure parts will fit

the valve you are working on and not be too big for it. Pilot controls and repair kits maintenance information remain the same

for 100 or 600 Series valves.

Cla-Val Main Valves

Catalog Number

The 100-20 Hytrol is available only in ductile iron, 150 and 300

pressure class, and Bronze trim standard. Available extra cost

main valve options include stainless steel trim, epoxy coating,

Dura-Kleen stem, Delrin sleeved stem, and high temperature rubber parts. All four basic main valves have a 600 Series version

available with all of the same benefits and size relationships.

The following chart shows the relationship of Cla-Val main valve

catalog numbers.

Catalog Name

Hytrol

Powertrol

Powercheck

Hycheck

Circa 1936

100 (Angle =2100)

100P & 100PA

100PC & 100PCA

181

100-Series

100-01

100-02

100-03

100-04

600 Series

100-20

100-21

100-22

100-23

(Reduced Internal Port)

Basic Main Valve Size Comparison

Globe Pattern Valves

Flange Size (inch)

Seat Size

100-01 (100 Series) 100-20 (600 Series)

3 3 2

4 4 3

6 6 4

8 8 6

10 10 8

12 12 10

14 14 ---16 16 12

18 ---- 16

20 20 16

24 24 16

30 30 24

36 36 30

42 ---- 36

48 ---- 36

Angle Pattern Valves

Flange Size (inch)

Seat Size

100-01 (100 Series) 100-20 (600 Series)

4 4 3

6 6 4

8 8 6

Page 14

CLA-VAL

Copyright Cla-Val 2011 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 • Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: claval@cla-val.com • Website cla-val.com

©

N-100-20 (R-3/2011)

100-20

PARTS LIST

NO. DESCRIPTION

1 Pipe Plug

2 Drive Screws (for nameplate)

3 Hex Nut (8" and larger)

4 Stud (8" and larger)

5 Cover Bearing

6 Cover

7 Stem Nut

8 Diaphragm Washer

9 Diaphragm

10 Spacer Washers

11 Disc Guide

12 Disc Retainer

13 Disc

14 Stem

15 Seat

16 Body

17 Spring

22 Flat Head Screws (10" and larger)

23 Seat O-Ring

24 Hex Bolt (3 " Thru 6")

25 Nameplate (Mounted on inlet flange)

26 Upper Spring Washer (Epoxy coated valves only)

27 Lower Spring Washer (Epoxy coated valves only)

28 Cover Bearing Housing (20" & 24" & 30")

29 Cover Bearing Housing O-Ring (20"& 24" & 30")

30 Hex Bolt (20" & 24")

31 Pipe Cap (20" & 24 & 30"")

11

14

12434

5

17

16

26

14

7

8

9

27

14

13

22

12

15

31

28

5

30

29

10" — 24" SEAT DETAIL

20" — 24" COVER DETAIL

TOP VIEW

12

13

15

OUTLET

GLOBE

INLET

ANGLE

INLET

6

8

9

2

25

3" — 6" COVER DETAIL

23

11

WHEN ORDERING PARTS, BE SURE TO GIVE COMPLETE

NAMEPLATE DATA, ITEM NUMBER AND DESCRIPTION.

10

Page 15

RDH051228,TB_300-SingleModeControls32.doc,6/16/2006

Technical Bulletin

300 Series (Single-Mode) Electronic Actuated Pilot Controls

Introduction

CDB-32, CDHS-32, CRA-32, CRD-32, and CRL-32 are pilot controls for Cla-Val 300 Series Electronic Actuated

Control Valves. These controls offer the same hydraulic control of the valve as existing manually-set controls, along

with additional remote electronic setpoint adjustment capabilities. The new pilot controls consist of a modified pilot

control sub-assembly, and the 130VC-2 Electronic Actuator with mounting components. Complete controls are valve

mounted with an accessory X56 Mounting Assembly.

I. O. M. Information

A. The 130VC-2 wiring diagram is included with this technical bulletin. The 5-wire cable is permanently attached to

actuator and should be terminated in suitable junction box. Care should be used when attaching to wires to avoid

damage. There are no user serviceable parts inside the actuator and tampering or opening it will void the warranty.

B. For Installation, Operation and Maintenance information only on the pilot sub-assembly use instructions in the

appropriate N-sheet for the manually adjusted pilot control. Since the 130VC-2 Electronic Actuator changes the

setpoint adjustment of the control, all other service and maintenance information remains the same for both. See

table below.

C. Additional service notes:

1. Before disassembly of pilot subassembly from 130VC-2 actuator, adjust pilot control to full minimum range setting

with laptop computer and 130VC-2 software to ensure full adjustment range when reassembled.

2. Note orientation of sub-assembly ports and bracket. Coupler and blue Aluminum bracket will remain attached to

actuator. Loosen and remove jam nut and washer from sub-assembly cover as sub-assembly is removed from

130VC-2 bracket. Count number of turns counterclockwise of pilot adjustment shaft from minimum range set position

to full out stop position. See pilot drawing.

3. After servicing the pilot sub-assembly, re-establish minimum spring setting by manually turning adjusting screw

counterclockwise until it stops (full out stop position). Then, turn in same number of turns found in step 2 to minimum

range set position.

4. Do not lubricate coupler slots. A small amount of waterproof anti-seize grease is used only on sub-assembly

adjusting screw threads and contact point with spring guide inside cover.

5. Reinstall sub-assembly to bracket with jam nut and washer. Check coupler slots and adjusting screw pin are lined

up while installing actuator to bracket. Be sure to retain original alignment of sub-assembly with bracket when

tightening jam nut and washer. A slight manual adjustment of adjusting screw may help align the coupler to adjusting

screw. See pilot assembly drawing.

6. After reinstalling onto valve, use laptop computer and 130VC-2 software to reset range values.

Pilot Control Pilot Assembly

Drawing

Sub-Assembly

IOM (ref. only)

Sub-Assembly

Drawing

Sub-Assembly

Repair Kit

CDB-32 205580 N-CDB-7 201935 9170023H

CDHS-32 205137 N-CDHS-11A 76832 20287401E

CDHS-32A 205333 N-CDHS-11B 205332 9170028G

CRA-32 N-CRA 82528 9170001D

CRD-32 205129 N-CRD 70899 9170002B

CRL-32 205130 N-CRL-5A 90846 20666E

Page 16

•

Simplified Remote Valve Set-Point Control

•

12-24VDC Input Power

•

Easy Interfacing to SCADA Systems

•

Accurate Flow Rate Control

•

Reliable Hydraulic Operation

•

Submersible (IP-68)

The Cla-Val Model CDHS-32 Electronic Actuated Differential Pressure Pilot

Control provides remote set-point adjustment and accurate differential pressure control for rate of flow control on Cla-Val 340 Series Control Valves.

Remote set-point command signals can be from any SCADA-type control

system that uses analog 4-20 mA signals. A precision orifice plate installed

with the valve creates differential pressure used for rate of flow control by

the CDHS-32. Operating on 12 to 24 VDC and consuming very little power,

it is an ideal control system for remote valve sites that may even be solar

powered. Existing manually-set Cla-Val 40 Series Rate-of-Flow control

valves can be retrofitted with CDHS-32 to add remote set-point control.

Verification of differential pressure and corresponding flow rate may be sent

to SCADA system from customer supplied differential pressure sensor

attached to orifice plate.

The CDHS-32 consists of a hydraulic pilot and integral controller that

accepts a 4-20 mA remote set-point and positions the pilot to maintain a

maximum pressure differential at orifice plate and corresponding flow rate

within preset limits. Pressure differential settings are linear between these

settings. Special USB connector cable and free downloadable software is

required to change built-in electronic range limits for differential pressure

and corresponding flow rate. Continuous internal monitoring of actuator

position results in smooth transitions between pilot set-points with no backlash or dithering. When power or control input fail, the CDHS-32 pilot

remains in automatic hydraulic control assuring system stability under all

conditions.

Electronic Actuated

Rate of Flow Pilot Control

Remote

Set-Point

SCADA

Computer

Remote Telemetry Unit

(Customer Supplied)

Standard Flow Sensing

Orifice Plate Assembly

and Optional

Customer Supplied

Transmitter

CLA-VAL

340 Series

Electronic Actuated

Rate of Flow Valve

with CDHS-32 Pilot Control

Flow

CLA-VAL

CDHS-32

Control

Typical Applications

The CDHS-32 Is installed on Cla-Val 340 Series valves that maintain

flow rate and require this flow to be changed from a remote location. It

is also an effective solution for lowering costs associated with "confined

space" requirements by eliminating the need for entry in valve structure

for set-point adjustment. Additional pilot controls, hydraulic and/or electronic, are also available to perform multiple functions to fit exact system

requirements.

CDHS-32

MODELS

CLA-VAL

Page 17

When Ordering, Please Specify

1. Catalog No. CDHS-32 (Orifice Downstream)

CDHS-32A (Orifice Upstream)

2. Adjustment Range

3. Materials - Pilot Control

4. X56 Mounting Kit (Specify Valve Size)

Adjustment Range

30 to 480 inches H2O Differential

End Connection

3/8" NPT

Temperature Range

Water: to 180°F

Materials

Pilot Control: Bronze ASTM B62

Trim:Stainless Steel Type 303

Rubber:Buna-N

®

Synthetic Rubber

Available with optional Stainless Steel or Monel

materials at additional cost. Consult factory for details

Note: Available with Remote Sensing for orifice upstream,

specify CDHS-32A

Note: Shipping Weight: 8 Lbs.

Pilot Control Subassembly Specifications

130VC-2 Electronic Actuator Specifications

PO Box 1325 Newport Beach CA 92659-0325

Phone: 949-722-4800 Fax: 949-548-5441

C

LA-VAL

CLA-VAL CANADA CLA-VAL EUROPE

4687 Christie Drive

Beamsville, Ontario

Canada LOR 1B4

Phone: 905-563-4963

Fax: 905-563-4040

Chemin dés Mesanges 1

CH-1032 Romanel/

Lausanne, Switzerland

Phone: 41-21-643-15-55

Fax: 41-21-643-15-50

©COPYRIGHT CLA-VAL 2007 Printed in USA

Specifications subject to change without notice.

www.cla-val.com

E-CDHS-32 (R-12-07)

Represented By:

CDHS-32 Purchase Specifications

The Electronic Actuated Rate of Flow Control Pilot shall have an integral hydraulic pilot and electronic controller contained in a IP-68 rated

submersible enclosure to provide interface between remote telemetry and valve set-point control. It will compare a remote analog command

signal with an internal position sensor signal and adjust the hydraulic pilot control spring mechanism to a new set-point position. 4-20 mA

actuator position feedback output shall be supplied standard.

If power fails the valve shall continue to control to the last set-point command. If the Remote Set-Point signal is lost the actuator is

programmable to go to either the 4mA, Last, or 20mA command set-point. No mechanical adjustments shall be necessary to the

actuator. The low and high position range adjustment shall be accomplished only with valve manufacturer's components and

instructions to be supplied in a separate kit.

The Electronic Actuated Rate of Flow Pilot Control shall be Cla-Val Model CDHS-32 as manufactured by Cla-Val, Newport Beach, CA.

Ranging software makes it easy to set low (4mA) and

high (20mA) set-point limits.

Supply Power Input: 12V to 24V DC

No Load draw: 50 mA

Max. Load draw: 250 mA

Remote Command Input: 4-20 mA analog signal

Position Feedback Signal: 4-20 mA

Speed of Rotation: Adjustable On/Off time, max 6 rpm

Diagnostic: LED Indicator

Loss of Power: Actuator will remain in last commanded

position.

Loss of Signal Programmable - 4mA, Last, or 20mA

Electrical Connections: Single, permanently attached cable with

color-coded power supply and signal wires

Mechanical Specifications:

Environmental

Protection Class: IP-68 (Temporary submersible)

Ambient Temperature: 15

° to 150° F (-10° to 65° C)

Materials

Enclosure and Bracket: Anodized Aluminum

Coupling Assembly: Stainless Steel

Gear Train: Stainless Steel, permanently lubricated

Options:

Re-ranging software - free download from www.cla-val.com.

USB connection cable required when changing range

parameters or restoring range parameters after servicing

pilot control subassembly.

Page 18

Page 19

Page 20

DESCRIPTION

The Cla-Val CDHS-18 Differential Control Valve is a normally open,

spring loaded, diaphragm type valve that operates hydraulically and is

designed to close on a rising differential pressure. When used as a pilot

control with Cla-Val Valves, it acts as a flow limiting control.

INSTALLATION

The Differential Control may be installed in any position. There is one

inlet port and two outlet ports in the body for either straight or angle

installation. The outlet port senses the high pressure or inlet to the differential

producing device. One of the outlet ports can be used for a gauge

connection. The port above the diaphragm (located in the control cover)

is used to sense the low pressure or outlet side of the differential producing

device. A flow arrow is marked on the body casting.

OPERATION

The Differential Control is normally held open by the compression spring

and the sensing pressure above the diaphragm. When the rate of flow

through the main valve increases, the sensing pressure above the

diaphragm of the control decreases and the higher pressure at the outlet

port closes the control; which, in turn, closes the main valve. When the

rate of flow through the main valve decreases, the sensing pressure

above the diaphragm increases. This opens the control and in turn

opens the main valve. This action causes the main valve to modulate,

limiting the flow rate to the setting of the control.

ADJUSTMENT

The Differential Control Valve can be adjusted to limit the rate of flow as

specified on the data plate. Rate of flow adjustment is made by turning

the adjustment screw to vary the spring pressure on the diaphragm. The

greater the compression on the spring the higher the flow rate.

1. Turn the adjustment screw in (clockwise) to increase flow rate.

2. Turn the adjustment screw out (counterclockwise) to decrease flow

rate.

DISASSEMBLY

The Differential Control Valve should be removed from the Hytrol Valve

assembly. Make sure that pressure shutdown is accomplished prior to

disconnecting assembly. During disassembly inspect all threads for damage or evidence of cross-threading.

NOTE: A bench vice equipped with soft brass jaws should be used to

hold the valve body during disassembly and reassembly. DO NOT tighten

vice jaws more than enough to hold unit firmly. Excessive pressure may

spring or crack casting

1. Remove adjusting screw cap (16).

2. Loosen lock nut on adjusting stem assembly (9) and turn

adjusting screw counterclockwise to relieve tension on spring.

3. Remove bottom plug (8) and gasket (6).

4. Remove disc retainer assembly (5) and inspect sealing surface for

damage or wear. Replace if necessary.

5 Remove 8 screws (12) and carefully Iift off cover (2) spring guide

(10) and spring (13) can now be removed.

6. Remove diaphragm assembly.

7. Remove diaphragm nut (7) and diaphragm washer (4).

8. Remove diaphragm (3), inspect for damage and replace if neces-

sary.

9. Inspect all parts for damage, corrosion, wear, foreign particles, and

cleanliness.

10. Repair minor nicks and scratches, these may be polished out

using a fine grade of emery or crocus cloth.

REASSEMBLY

Prior to reassembly replace all parts which are damaged or worn. When

ordering replacement parts be sure to specify item, part number, and all

nameplate data.

1. Place diaphragm (3) on top of yoke (11) place diaphragm

washer (4) over diaphragm with rounded edges down or next

to diaphragm. Screw on diaphragm nut (7) with the spring

guide shoulder in up position. The nut is not tightened at this time.

2. Align diaphragm flange holes with and folding diaphragm as

shown. Tighten diaphragm nut, retaining alignment shown.

3. Place yoke assembly in body (1) and screw the disc retainer

assembly (5) in until it bottoms.

4. Screw in plug (8).

NOTE: The yoke arms can be viewed through the 3/8" NPT

high pressure sensing outlet. There should be even spacing

between the yoke arms and the 3/8' NPT inlet boss seat

assembly. There must be no drag or friction between these

parts. If there is drag, repeat step 2.

5. Align diaphragm flange holes with the body holes and position

spring and spring guide (13) (10).

6. Replace cover (2) and secure with 8 screws (12).

7. Remove plug (8) and turn adjusting screw clockwise until the

disc retainer assembly moves down.

8. Replace gasket (6) and plug (8).

9. Replace cap (16).

3/8" Differential Control

CDHS-18

DIAPHRAGM

HOLES

DIAPHRAGM

YOKE

DIAPHRAGM HOLE ALIGNMENT

FAILS TO OPEN

CONTROLLING DIFFERENTIAL

NOT CHANGING

CHECK WITH GAUGE OR

MANOMETERS

DIAPHRAGM ASSEMBLY STUCK

CLOSED

DISASSEMBLE AND FREE

FOREIGN OBJECT UNDER

DISC RETAINER

DISASSEMBLE AND REMOVE

FAILS TO CLOSE

INSUFFICIENT CONTROLLING

DIFFERENTIAL

INCREASE DIFFERENTIAL

FOREIGN OBJECT UNDER

DISC

DISASSEMBLE AND REMOVE

DIAPHRAGM ASSEMBLY STUCK

OPEN

DISASSEMBLE AND FREE

DAMAGED DIAPHRAGM DISASSEMBLE AND REPLACE

SPRING COMPRESSED SOLID BACK OFF ADJUSTING STEM

SYMPTOM PROBABLE CAUSE REMEDY

NO SPRING COMPRESSION SCREW IN ADJUSTING STEM

SERVICE SUGGESTIONS

MODEL

INSTALLATION / OPERATION / MAINTENANCE

CLA-VAL

Copyright Cla-Val 2012 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 • Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: claval@cla-val.com • Website cla-val.com

©

N-CDHS18 (R-10/2012)

Page 21

CDHS-18

3/8" Differential Control

ITEM DESCRIPTION MATERIALS PART NUMBER

1 Body & Seat Assembly BFR/SS 83397-02G

2 Cover BRZ C6657F

3 Diaphragm Buna N® C6936JD

4 Diaphragm Washer BRS C1803A

5 Disc Retainer Assembly BRS/RB C5256H

6 Gasket FIB 40174F

7 Diaphragm Nut BRS V5911C

8 Plug, Body BRZ V5653A

9 Adj. Stem Assembly BZ/SS C2002J

10 Spring Guide 303 C1510B

11 Yok e BRZ V6951H

12 Mach. Screw Fil. Hd. (8) SS 67578-21B

13 Spring 316SS 36773A

14 Nameplate BRS C002201G

15 Nameplate Screw — —

16 Cap, Adj. Screw PLS 12576-01D

Adjusting screw

turn clockwise

to increase

setting

3/8 NPT

Inlet

1 3/4 max.

3

16

9

2

10

13

1/8 NPT LOW

PRESSURE

CONNECTION

7

4

3

11

5

1

6

8

3/8 NPT OUTLET

AND HIGH PRESSURE

SENSING

CONNECTION

6 MAX.

14

15

12

3

1

8

MATERIAL: BRONZE BODY

BODY

SIZE

SEAT

SIZE

STOCK

NUMBER

3/8" 1/4 68017D

STAINLESS TRIM

*

*

*

*

Repair Parts Kits*

Standard

High Temp.

Viton

®

9170003K

9170009G

Part Number

Buna"N"

®

CLA-VAL

Copyright Cla-Val 2012 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 • Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: claval@cla-val.com • Website cla-val.com

©

PL-CDHS18 (R-10/2012)

PARTS LIST

Page 22

CLA-VAL

Copyright Cla-Val 2011 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 • Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: claval@cla-val.com • Website cla-val.com

©

PL-CK2 (R-3/2011)

Page 23

D

c

B

A

8

"This drawing

is

the property

of

CLA-VAL

CO.

and some and

copies made thereof,

if

any,

shall

be

returned to it

upon

demand.

Delivery and disclosure hereof ore mode solely upon condition

that the same

shall

not

be

used,

copied

or reproduced, nor

shall

the subject hereof

be

disclosed

in

any manner to

anyone

for any

purpose,

except

as

herein

authorized,

without

prior

written

approval of CLA-VAL

CO.

This

drawing

Is

submrtted conftdentlally

and

may not

be

used

In

the manufacture of any material

or

product

other

than

such

materials

and

products

furnished

to

CLA-VAL

CO.

Whether or not the equipment

or

information

shown

hereon

is

patented

or otherwise

protected,

full

title

and

copyrights, If any,

In

and

to

this drawing

and/or

Information

delivered

or

submitted

are fully reserved by

CLA-VAL

CO."

/

--

,'

1/2-14

NPT

TO

GAGE

SECTION

F

- F

7

NOMINAL

PIPE

SIZE

(INCHES)

DIAMETER

OF

FLANGE

125

LB

BOLT

CIRCLE

DIAMETER

&

NUMBER

OF

BOLTS

150

LB

DIAMETER

OF

BOLT

HOLES

ANGLE

"A"

ANGLE

"D"

DIAMETER

OF

FLANGE

250

LB

BOLT

CIRCLE

DIAMETER

&

NUMBER

OF

BOLTS

300

LB

DIAMETER

OF

BOLT

HOLES

ANGLE

,,

A"

ANGLE

"D"

8 7

I

D

Fl_L-

1

1/2

2

5.00

6.00

3.875

4.750

4 4

.625

.750

30'

24'

ON

¢..

ON

¢..

6.13

6.50

4.500

5.000

4 8

.875

.750

30"

45·

ON

¢..

22.5"

--

--

...

"'I'-

,

,

--

,

(

/

I

I

--

--

I ..---

\ I ..---

\--\--

I

\

---

J,---

""

,

,

'v-'/

B

2

1/2

3

7.00

7.50

5.500

6.000

4 4

.750

.750

30'

45'

ON

¢..

ON

¢..

7.50

8.25

5.875

6.625

8 8

.875

.875

45·

45'

22.5' 22.5'

4

9.00

7.500

8

.

750

45'

22.5'

10.00

7.875

8

.875

45·

22.5"

6

6 8 10

11.00

13.50 16.00

9.500

11.

750

14.250

8 8 12

.875

.875

1.000

45·

45'

14"

22.5" 22.5'

ON

¢..

12.50 15.00 17.50

10.625

13.000 15.250

12 12 16

.875

1.000

1.125

30" 30"

45·

15"

15"

ON

¢..

6

--

\

'

I

\-.

........

........

'

'

5

LP

--~B

A

STAMP

LETTERS

AS

SHOWN

-

....

.....

................

.....

.....

I

...........

...

....

.....

12

19.00

17.000

12

1.000

30"

15"

20.50

17.750

16

1.250

45·

ON

¢..

-

....................................

.....

.....

...

__

,...

....

14

21.00

18.

750

12

1.125

14"

ON

¢..

23.00

20.250

20

1.250

36"

ON

¢..

..............

--.....,

....

,..

-

'J...

...

HP

..........__

j

..........

_

..........

__

c

NOTE:

BOLT

SIZE & NUMBER

OF

BOLT

HOLES

VARY

WITH

PIPE SIZE &

PRESSURE

CLASS

(SEE TABLE

BELOW).

16 18

20

24

23.50

25.00 27.50

32.00

21.250

22.

750

25.000

29.500

16 16

20

20

1.125

1.250

1.250 1.375

45'

36'

35·

36'

ON

¢..

ON

¢..

ON

¢..

ON

¢..

25.50

36.00

22.500

32.000

20

24

1.375 1.625

36'

30"

ON

¢..

ON

t

5

4

LP

I

-$-

1

I

$-

1

HP

4

3

1

/8-27

NPT

TO

GAGE

(FOR

16"

& SMALLER)

3/8-18

NPT

TO

GAGE

(FOR

18"

& LARGER)

DWG

NO.

43831

SH 1 REVF

REVISIONS

REV DESCRIPTION

A-C

SEE

REVISION

FILE

D

REDRAWN

ON

CAD

(ECO

19618)

E

ADDED

24"

DIMS

FOR

250/300

LB

SIZES

(NED

49843)

F

ADDED

18"

DIMS

FOR

125/150

LB

SIZES

(ECO

25532)

LP

1

/8-27

NPT

TO

GAGE

(FOR

16"

& SMALLER)

3/8-18

NPT

TO

GAGE

(FOR

18"

& LARGER)

,

,

,,,......

SECTION

1

DATE APPROVED

12-16-03

AK

6-29-05

PC

12-15-15

RP

HP

---

c-c

SECTION

B - B

UNLESS

OTHERWISE

SPECIFIED

DIMENSIONS

ARE

IN

INCHES

TOLERANCES

ARE:

FRACTIONS

DECIMALS

ANGULAR

±

1/32

.XX± .03 ± .5"

.XXX± .010

MAX = +.00

-.09

MIN = +.09

-.00

SURFACE

FINISH

12

\/

BREAK

CORNERS

.010

MAX

FILLET

RADIUS

.031

--DO

NOT

SCALE

DRAWING--

3

*

QTY 6 FOR

SIZE

10"

AND

LARGER

VALVES

5

DRIVE

SCREW

2

4 NAMEPLATE 1

3 MACHINE

SCREW,

RD.

HD.-8" & SMALLER

4*

2

ORIFICE

PLATE 1

1

ORIFICE

PLATE

HOLDER

1

ITEM

NO. DESCRIPTION

QUANTITY

PARTS LIST

CONTRACT

NO.

-

GlA·VAl

GO.

-----

NE'M'ORT

BEACH,

CALIFORNIA

APPROVALS

DATE

TITLE

DRAWN

C.C.

6-8-62

X52D-1

ORIFICE

FLANGE

ASSEMBLY

CHECKED

M.F.

8-19-68

THREE

SENSING

PORTS

APPROVED

J.M.

8-19-68

SIZE

CAGE

CODE

DWG

NO.

REV

ENGR

D

86184

43831

F

SCALE

NONE

UNITS/PC

SHEET

1

OF

1

2

EK

12-16-15

1

D

c

B

A

r--

0

0

w

0

0

u

I-

(/)

0

Page 24

The strainer is designed for use in conjunction with a Cla-Val

Main Valve, but can be installed in any piping system where

there is a moving fluid stream to keep it clean. When it is used

with the Cla-Val Valve, it is threaded into the upstream body port

provided for it on the side of the valve. It projects through the

side of the Main Valve into the flow stream. All liquid shunted to

the pilot control system and to the cover chamber of the Main

Valve passes through the X46 Flow Clean Strainer.

C

Male

Pipe

SAE

H

D

E

B

I

G

Male

Pipe

B

I

Width Across Flats

Female

Pipe

A

D

E

F

• Self Scrubbing Cleaning Action

• Straight Type or Angle Type

The Cla-Val Model X46 Strainer is designed to prevent passage of

foreign particles larger than .015". It is especially effective against

such contaminant as algae, mud, scale, wood pulp, moss, and root

fibers. There is a model for every Cla-Val. valve.

The X46 Flow Clean strainer operates on a velocity principle utilizing

the circular "air foil" section to make it self cleaning. Impingement of

particles is on the "leading edge" only. The low pressure area on the

downstream side of the screen prevents foreign particles from clogging the screen. There is also a scouring action, due to eddy currents, which keeps most of the screen area clean.

Dimensions

(In Inches)

INSTALLATION

X46 Angle Type B (In Inches)

B

(NPT)C(SAE)

DEH I

1/8 1/4 1-3/8 5/8 7/8 1/4

1/4 1/4 1-3/4 3/4 1 3/8

3/8 1/4 2 7/8 1 1/2

3/8 3/8 1-7/8 7/8 1 1/2

1/2 3/8 2-3/8 1 1-1/4 5/8

X46A Straight

X46B Angle

X46A Straight Type A (In Inches)

A B D E F G I

1/8 1/8 1-3/4 3/4 1/2 1/2 1/4

1/4 1/4 2-1/4 1 3/4 3/4 3/8

3/8 3/8 2-1/2 1 7/8 7/8 1/2

3/8 1/2 2-1/2 1-1/4 1/2 7/8 3/4

1/2 1/2 3 1-1/4 1 1-1/8 3/4

3/8 3/4 3-3/8 2 1/2 1 7/8

3/4 3/4 4 2 1 1-1/2 7/8

3/8 1 4-1/4 2-3/4 1/2 1-3/8 7/8

1 1 4-1/2 2-3/4 1-1/4 1-3/4 7/8

1/2 1 4-1/4 2-3/4 1/2 1-3/8 7/8

Flow Clean Strainer

X46

INSPECTION

Inspect internal and external threads for damage or evidence

of cross-threading. Check inner and outer screens for clogging,

embedded foreign particles, breaks, cracks, corrosion, fatigue,

and other signs of damage.

CLEANING

After inspection, cleaning of the X46 can begin. Water service usually will produce

mineral or lime deposits on metal parts in contact with water. These deposits can

be cleaned by dipping X46 in a 5-percent muriatic acid solution just long enough

for deposit to dissolve. This will remove most of the common types of deposits.

Caution: use extreme care when handling acid. If the deposit is not removed

by acid, then a fine grit (400) wet or dry sandpaper can be used with water.

Rinse parts in water before handling. An appropriate solvent can clean parts used

in fueling service. Dry with compressed air or a clean, lint-free cloth.

Protect from damage and dust until reassembled.

REPLACEMENT

If there is any sign of damage, or if there is the slightest doubt that the Model X46

Flow Clean Strainer may not afford completely satisfactory operation, replace it. Use

Inspection steps as a guide. Neither inner screen, outer screen, nor housing is furnished as a replacement part. Replace Model X46 Flow Clean Strainer as a complete unit.

When ordering replacement Flow-Clean Strainers, it is important to determine pipe

size of the tapped hole into which the strainer will be inserted (refer to column A or

F), and the size of the external connection (refer to column B or G).

When Ordering,

Please Specify:

• Catalog Number X46

• Straight Type or Angle Type

• Size Inserted Into and Size Connection

• Materials

DISASSEMBLY

Do not attempt to remove the screens from the strainer housing.

MODEL

INSTALLATION / OPERATION / MAINTENANCE

CLA-VAL

Copyright Cla-Val 2011 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 • Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: claval@cla-val.com • Website cla-val.com

©

N-X46 (R-3/2011)

(NPT) (NPT)

X46B

X46A

Page 25

CLA-VAL

Copyright Cla-Val 2018 Printed in USA Specifications subject to change without notice.

1701 Placentia Ave • Costa Mesa CA 92627 Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: info@cla-val.com • www.cla-val.com

©

INSTALLATION / OPERATION / MAINTENANCE

Flow Control

CV

MODEL

N-CV (R-06/2018)

DESCRIPTION

The CV Control is an adjustable restriction which acts as a

needle valve when flow is in the direction of the stem. When

flow is in the reverse direction, the port area opens fully to

allow unrestricted flow. When installed in the control system of

a Cla-Val automatic valve, it can be arranged to function as

either an opening or closing speed control.

OPERATION

The CV Flow Control permits full flow from port A to B, and

restricted flow in the reverse direction. Flow from port A to B

lifts the disc from seat, permitting full flow. Flow in the reverse

direction seats the disc, causing fluid to pass through the clearance between the stem and the disc. This clearance can be

increased, thereby increasing the restricted flow, by screwing

the stem out, or counter-clockwise. Turning the stem in, or

clockwise reduces the clearance between the stem and the

disc, thereby reducing the restricted flow.’

INSTALLATION

Install the CV Flow Control as shown in the valve schematic

All connections must be tight to prevent leakage.

DISASSEMBLY

Follow the sequence of the item numbers assigned to the

parts in the cross sectional illustration for recommended

o

rder of disassembly.

Use a scriber, or similar sharp-pointed tool to remove O-ring

from the stem.

INSPECTION

Inspect all threads for damage or evidence of crossthreading. Check mating surface of seat and valve disc for

excessive scoring or embedded foreign particles. Check

spring for visible distortion, cracks and breaks. Inspect all

parts for damage, corrosion and cleanliness.

CLEANING

After disassembly and inspection, cleaning of the parts can

begin. Water service usually will produce mineral or lime

deposits on metal parts in contact with water. These

deposits can be cleaned by dipping the parts in a 5-percent

muriatic acid solution just long enough for deposits to dissolve. This will remove most of the common types of

deposits. Caution: use extreme care when handling

acid. If the deposit is not removed by acid, then a fine grit

(400) wet or dry sandpaper can be used with water. Rinse

parts in water before handling. An appropriate solvent can

clean parts used in fueling service. Dry with compressed air

or a clean, lint-free cloth. Protect from damage and dust

until reassembled.

REPAIR AND REPLACEMENT

Minor nicks and scratches may be polished out using a fine

grade of emery or crocus cloth; replace parts if scratches

cannot be removed.

Replace O-ring packing and gasket each time CV Flow

Control is overhauled.

Replace all parts which are defective. Replace any parts

which create the slightest doubt that they will not afford completely satisfactory operation. Use Inspection steps as a

guide.

REASSEMBLY

Reassembly is the reverse of disassembly; no special tools

are required.

TEST PROCEDURE

No testing of the flow Control is required prior to reassembly

to the pilot control system on Cla-Val Main Valve.

Page 26

3/8" Flow Control

CV

2.12

MAX

STAMP PART NO. ON

SMOOTH SURFACE

RESTRICTED

FLOW

3/8 - 18 NPT

1.84

ADJUSTING STEM

(TURN CLOCKWISE TO

INCREASE RESTRICTION)

1

7

2

10

9

8

6

5

4

3

.85

FREE FLOW

BAR STOCK

CONFIGURATION

When ordering parts,

please specify:

• Number Stamped on Side

• Description (CV Flow Control)

• Part Description

• Material

CLA-VAL

Copyright Cla-Val 2018 Printed in USA Specifications subject to change without notice.

1701 Placentia Ave • Costa Mesa CA 92627 Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: info@cla-val.com • www.cla-val.com

©

PL-CV (R-03/2011)

PARTS LIST

ITEM DESCRIPTION QTY

1

Cap (SS only)

1

2

Nut, Jam

1

3

Seat

1

4

Gasket

1

5

Disc

1

6

Spring

1

7

Ring, Retaining

1

8

Stem

1

9

O-Ring

1

10

Housing

1

Page 27

CLA-VAL

Copyright Cla-Val 2011 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 • Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: claval@cla-val.com • Website cla-val.com

©

Dimensions

Available only in replacement assembly.

PL-CDC-1 (R-6/2011)

NPT

5

3

4

2

1

I

Full Open Operation

NPT

5

3

4

2

1

I

Tight Closing Operation

B

C

A

NSF 61

Approved

Item Description Material

1 Body Brass

2

End

Connection

Brass

3 Disc Polytherimide

4 Seat NBR

5 Spring Stainless Steel

Size

(NPT)

Stock

Number

A B C I C

V

psi Wt.

3/8" 9834501A 1.73 0.79 1.06 0.40 4.55 400 0.37

1/2" 9834502J 2.32 0.98 1.35 0.53 6.00 400 0.32

• NSF 61 Approved

• Meets low lead requirements

• Soft Seat for Bubble Tight Shutoff, Spring Loaded for

Fast Seating Action

• Compact Design

• Low Cracking Pressure 1/2 psi

• Flow Profile Designed to Minimize Head Loss

• Perfect Seating both at High and Low Pressure, Wide

Temperature Range: +10

° to 210°F

•

Polyethermide Disc to ensure the Best Resistance for

Corrosion and Abrasion

•

Patented Disc Guide to Prevent Any Side Loading

CDC-1

PARTS LIST

Check Valve (Sizes 3/8” and 1/2”)

MODEL

Page 28

1

2

3

4

5

3/8 NPT

Strainer

X43

Standard 60 mesh pilot system strainer for fluid service.

CLA-VAL

Copyright Cla-Val 2012 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 • Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: claval@cla-val.com • Website cla-val.com

©

PL- X43 (R-9/2012)

PARTS LIST

ITEM DESCRIPTION MATERIAL

1

Pipe Plug Steel

2

Strainer Plug Brass

3

Gasket Copper

4

Screen SST

5

Body Brass

No parts available. Rreplacement assembly only.

Size Stock Number

3/8 x 3/8 33450J

Page 29

REPAIR KITS

MODEL

INSTALLATION / OPERATION / MAINTENANCE

BUNA-N MATERIAL

RUBBER KIT REPAIR KIT REBUILD KIT STUD & NUT KIT

STOCK NO. STOCK NO. STOCK NO. STOCK NO.

3/8” 9169801K 21176614B 21176633J

1/2” 9169802H 21176602F 21176615A 21176634H

3/4” 9169802H 21176602F 21176615A 21176634H

1” Non-Guided 9169803F 21176601G 21176616K 21176636F