Central Machinery 67414 Set Up, Operating, And Servicing Instructions

GASOLINE AUGER DRILL

67414

SET UP, OPERATING, AND SERVICING

INSTRUCTIONS

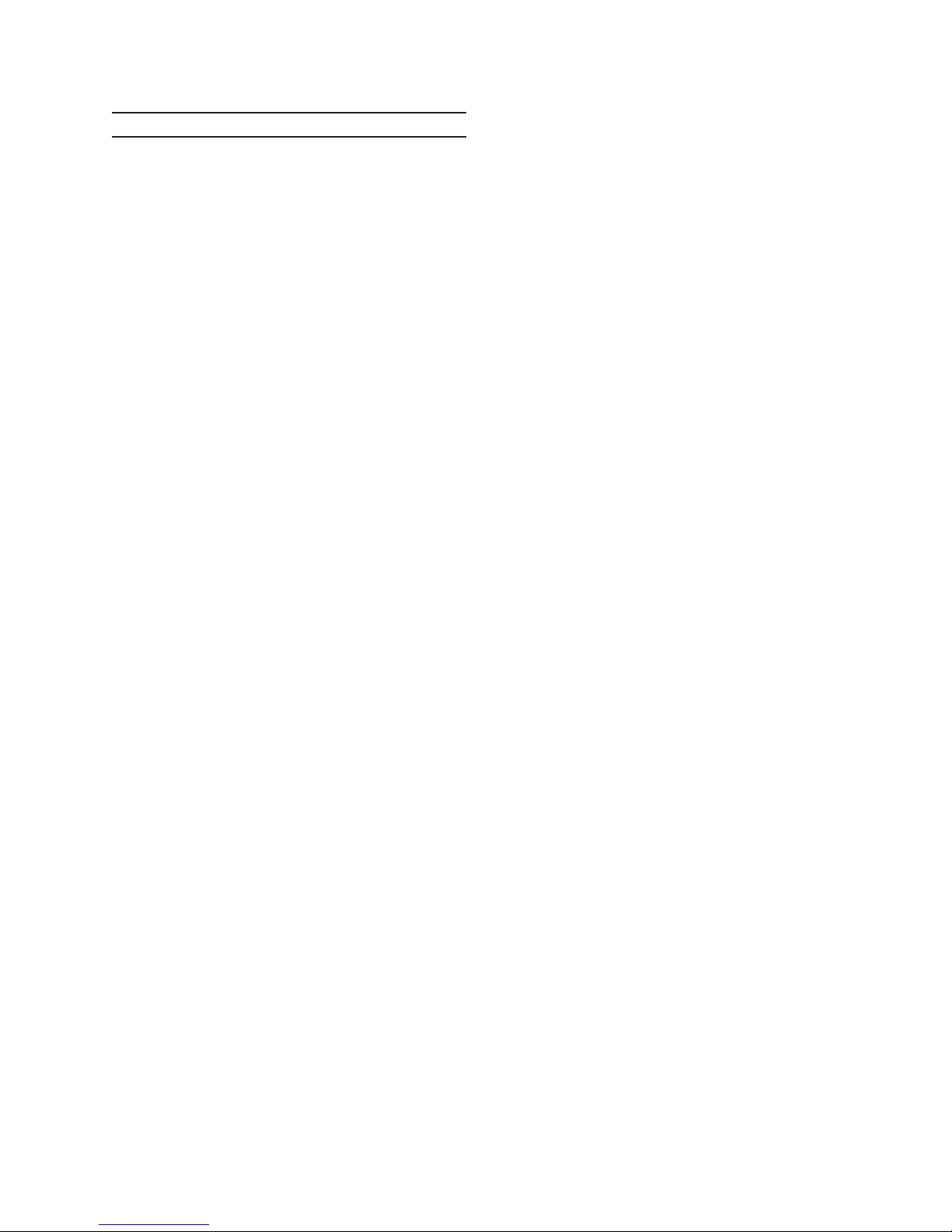

Using an engine indoors CAN KILL YOU IN

MINUTES.

Engine exhaust contains carbon monoxide.

This is a poison you cannot see or smell.

NEVER use inside

a home or garage,

EVEN IF doors and

windows are open.

Distributed exclusively by Harbor Freight Tools®.

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our website at: http://www.harborfreight.com

Only use OUTSIDE

and far away from

windows, doors, and

vents.

Read this material before using this product.

Failure to do so can result in serious injury.

SAVE THIS MANUAL.

Copyright© 2009 by Harbor Freight Tools®. All rights reserved. No portion of this manual or any artwork

contained herein may be reproduced in any shape or form without the express written consent of

Harbor Freight Tools. Diagrams within this manual may not be drawn proportionally. Due to continuing

improvements, actual product may differ slightly from the product described herein. Tools required for

assembly and service may not be included.

For technical questions or replacement parts, please call 1-800-444-3353.

CONTENTS

ENGINE PARTS LIST .................. 20

IMPORTANT SAFETY

INFORMATION ............................3

VIBRATION HAZARD: ..................6

BASIC SPECIFICATIONS .............8

UNPACKING .................................. 8

COMPONENTS AND CONTROLS 8

ASSEMBLY ....................................9

FUEL & OIL INSTRUCTIONS ......10

CHECKING AND FILLING FUEL .....10

FILL THE GEARBOX .......................10

OPERATING INSTRUCTIONS .... 11

TECHNICAL SPECIFICATIONS ..14

SERVICING ..................................14

ENGINE ASSEMBLY DIAGRAM . 21

AUGER PARTS LIST &

ASSEMBLY DIAGRAM ............. 22

FRAME PARTS LIST &

ASSEMBLY DIAGRAM ............. 23

EMISSION CONTROL SYSTEM

WARRANTY ..............................24

LIMITED 1 YEAR / 90 DAY

WARRANTY ..............................26

MAINTENANCE PROCEDURES .....14

DAILY MAINTENANCE ...............14

AIR FILTER ELEMENT

MAINTENANCE .......................15

SPARK PLUG MAINTENANCE ..15

FUEL FILTER MAINTENANCE ..15

CLEANING, MAINTENANCE, AND

LUBRICATION SCHEDULE ..........16

EVERY MONTH (IN DIRTY

ENVIRONMENTS): ...................16

EVERY 3 MONTHS OR 50

OPERATION HOURS: ..............16

EVERY 6 MONTHS OR 100

OPERATION HOURS: ..............16

EVERY 300 OPERATION

HOURS: ....................................16

EVERY 3 YEARS: .......................16

STORAGE ........................................16

TROUBLESHOOTING ......................17

Page 2 For technical questions, please call 1-800-444-3353. SKU 67414

SAVE THIS MANUAL

Keep this manual for the safety

warnings and precautions, assembly,

operating, inspection, maintenance and

cleaning procedures. Write the product’s

serial number in the back of the manual

near the assembly diagram (or month

and year of purchase if product has no

number). Keep this manual and the

receipt in a safe and dry place for future

reference.

IMPORTANT SAFETY

INFORMATION

In this manual, on the labeling,

and all other information

provided with this product:

This is the safety alert

symbol. It is used to alert

you to potential personal

injury hazards. Obey all

safety messages that

follow this symbol to avoid

possible injury or death.

not avoided, could result in

minor or moderate injury.

NOTICE is used to

address practices

not related to personal injury.

CAUTION, without

the safety alert

symbol, is used to address

practices not related to

personal injury.

WARNING! Read all instructions.

Failure to follow all instructions

listed below may result in re,

serious injury and/or DEATH.

The warnings and precautions

discussed in this manual cannot

cover all possible conditions and

situations that may occur. It must

be understood by the operator that

common sense and caution are

factors which cannot be built into

this product, but must be supplied

by the operator.

SAVE THESE INSTRUCTIONS

DANGER indicates

a hazardous

situation which, if not

avoided, will result in death or

serious injury.

WARNING

indicates a

hazardous situation which, if

not avoided, could result in

death or serious injury.

CAUTION, used

with the safety

alert symbol, indicates a

hazardous situation which, if

SET UP PRECAUTIONS

Gasoline fuel and fumes are 1.

ammable, and potentially explosive.

Use proper fuel storage and handling

procedures. Do not store fuel or

other ammable materials nearby.

Have multiple ABC class re 2.

extinguishers nearby.

Operation of this equipment may 3.

create sparks that can start res

around dry vegetation.

A spark arrestor may be required.

The operator should contact

local re agencies for laws or

Page 3For technical questions, please call 1-800-444-3353.SKU 67414

regulations relating to re prevention

requirements.

Wear ANSI-approved safety goggles, 4.

heavy-duty work gloves, and dust

mask/respirator during set up.

Use only oil and fuel recommended 5.

in the “Specications” section of this

manual.

To prevent severe personal injury 4.

or dismemberment from rotating bit:

Stand on at, level, solid surface

and brace against torque during

use. Keep hands and feet away from

auger bit and hole when engine is

running.

Disconnect and insulate spark plug 5.

wire before maintenance and/or

changing bits.

OPERATING PRECAUTIONS

1. CARBON MONOXIDE

HAZARD

Using an engine indoors

CAN KILL YOU IN

MINUTES.

Engine exhaust contains carbon

monoxide. This is a poison you

cannot see or smell.

NEVER use inside a home or garage,

EVEN IF doors and windows are

open.

Only use OUTSIDE and far away

from windows, doors, and vents.

Do not lock trigger on. Always use 2.

with both hands on handles.

Buried utility lines may be unmarked; 3.

contact utility companies before

drilling. Striking utility lines may cause

severe personal injury or death.

Never disable safety switches or 6.

components.

Do not carry between holes with 7.

engine running.

Carry by handle only; not by bit.8.

Gasoline fumes are explosive. Never 9.

smoke or rell with engine running.

Keep bystanders away during use.10.

Keep children away from the 11.

equipment, especially while it is

operating.

IMPORTANT! 12. Your Warranty is

voided if:

You do not operate the Auger Drill a.

with the proper 25:1 fuel mix in

its fuel tank. Do not run the Engine

with an improper fuel mix, low or no

fuel mix. Running the Engine with an

improper fuel mix, low or no fuel mix,

will permanently damage the unit.

You do not operate the Auger b.

Drill with the proper amount of

SAE 80-90 gear oil in its Gearbox.

Do not run the Auger Drill with low

or no gear oil. Running the Auger

Drill with low or no gear oil will

permanently damage the unit.

Do not leave the equipment 13.

unattended when it is running. Turn

Page 4 For technical questions, please call 1-800-444-3353. SKU 67414

off the equipment (and remove safety

keys, if available) before leaving the

work area.

Wear ANSI-approved safety goggles, 14.

heavy duty work gloves, and steeltoed heavy-duty work boots during

setup and use.

Maintain a rm grip on the Auger 15.

Drill with both hands and be aware

of the strong start-up torque of the

tool.

Keep your thumb near the Kill 16.

Switch in the event the Auger Drill

must be turned off immediately.

Do not use the Auger Drill if the 17.

Auger is dull, bent, or damaged.

Drill with the Engine running at 18.

full speed. Fully squeeze the Speed

Control Lever to maintain a steady

drilling speed.

Keep the Auger clean and 19.

undamaged.

Keep all guards and safety devices 20.

in proper working order and

properly adjusted.

Before starting the Engine, make 21.

sure the Auger is not contacting

any object.

should be off during distributor

adjustment.

Use only accessories that are 24.

recommended by Harbor Freight

Tools for your model. Accessories

that may be suitable for one piece of

equipment may become hazardous

when used on another piece of

equipment.

Do not operate in explosive 25.

atmospheres, such as in the

presence of ammable liquids, gases,

or dust. Gasoline-powered engines

may ignite the dust or fumes.

Stay alert, watch what you are 26.

doing and use common sense when

operating this piece of equipment.

Do not use this piece of equipment

while tired or under the inuence of

drugs, alcohol or medication.

Do not overreach. Keep proper 27.

footing and balance at all times.

This enables better control of the

equipment in unexpected situations.

Dress properly. Do not wear loose 28.

clothing or jewelry. Keep hair,

clothing and gloves away from

moving parts. Loose clothes, jewelry

or long hair can be caught in moving

parts.

When shutting off the Engine, 22.

make sure the Auger has stopped

before setting the tool down.

People with pacemakers should 23.

consult their physician(s) before

use. Electromagnetic elds in close

proximity to a heart pacemaker

could cause pacemaker interference

or pacemaker failure. Caution is

necessary when near the engine’s

magneto or recoil starter. Engine

Parts, especially exhaust system 29.

components, get very hot during use.

Stay clear of hot parts.

Do not cover the engine or equipment 30.

during operation.

Keep the equipment, engine, and 31.

surrounding area clean at all times.

Use the equipment, accessories, etc., 32.

in accordance with these instructions

Page 5For technical questions, please call 1-800-444-3353.SKU 67414

and in the manner intended for the

particular type of equipment, taking

into account the working conditions

and the work to be performed. Use

of the equipment for operations

different from those intended could

result in a hazardous situation.

Do not operate the equipment with 33.

known leaks in the engine’s fuel

system.

This product contains or, when 34.

used, produces a chemical known

to the State of California to cause

cancer and birth defects or other

reproductive harm. (California Health

& Safety Code § 25249.5, et seq.)

When spills of fuel or oil occur, they 35.

must be cleaned up immediately.

Dispose of uids and cleaning

materials as per any local, state,

or federal codes and regulations.

Store oil rags in a bottom-ventilated,

covered, metal container.

permanent physical injury, particularly

to the hands, arms and shoulders. To

reduce the risk of vibration-related

injury:

Anyone using vibrating tools regularly 1.

or for an extended period should

rst be examined by a doctor and

then have regular medical checkups to ensure medical problems are

not being caused or worsened from

use. Pregnant women or people

who have impaired blood circulation

to the hand, past hand injuries,

nervous system disorders, diabetes,

or Raynaud’s Disease should not use

this tool. If you feel any symptoms

related to vibration (such as tingling,

numbness, and white or blue ngers),

seek medical advice as soon as

possible.

Do not smoke during use. Nicotine 2.

reduces the blood supply to the

hands and ngers, increasing the risk

of vibration-related injury.

Before use, check for misalignment 36.

or binding of moving parts, breakage

of parts, and any other condition

that may affect the equipment’s

operation. If damaged, have the

equipment serviced before using.

Many accidents are caused by poorly

maintained equipment.

Use the correct equipment for the 37.

application. Do not modify the

equipment and do not use the

equipment for a purpose for which it

is not intended.

Vibration Hazard:

This tool vibrates during use.

Repeated or long-term exposure to

vibration may cause temporary or

Wear suitable gloves to reduce the 3.

vibration effects on the user.

Use tools with the lowest vibration 4.

when there is a choice between

different processes.

Include vibration-free periods each 5.

day of work.

Grip tool as lightly as possible (while 6.

still keeping safe control of it). Let

the tool do the work.

To reduce vibration, maintain the tool 7.

as explained in this manual. If any

abnormal vibration occurs, stop use

immediately.

Page 6 For technical questions, please call 1-800-444-3353. SKU 67414

SERVICE PRECAUTIONS

Before service, maintenance, or 1.

cleaning:

Turn the engine switch to its a.

“OFF” position.

Store equipment out of the reach of 7.

children.

Follow scheduled engine and 8.

equipment maintenance.

Refueling Precautions:9.

Allow the engine to completely b.

cool.

Then, remove the spark plug c.

wire(s) from the spark plug(s).

Keep all safety guards in place and 2.

in proper working order. Safety

guards include mufer, air cleaner,

mechanical guards, and heat shields,

among other guards.

Do not alter or adjust any part of 3.

the equipment or its engine that

is sealed by the manufacturer

or distributor. Only a qualied

service technician may adjust

parts that may increase or

decrease governed engine speed.

Wear ANSI-approved safety goggles, 4.

heavy-duty work gloves, and dust

mask/respirator during service.

Do not smoke, or allow sparks, a.

ames, or other sources of ignition

around the equipment, especially

when refuelling.

Do not rell the fuel tank while the b.

engine is running or hot.

Do not ll fuel tank to the top. Leave c.

a little room for the fuel to expand as

needed.

Refuel in a well-ventilated area only.d.

SAVE THESE

INSTRUCTIONS.

Maintain labels and nameplates 5.

on the equipment. These carry

important information. If unreadable

or missing, contact Harbor Freight

Tools for a replacement.

Have the equipment serviced by a 6.

qualied repair person using only

identical replacement parts. This

will ensure that the safety of the

equipment is maintained. Do not

attempt any service or maintenance

procedures not explained in this

manual or any procedures that you

are uncertain about your ability to

perform safely or correctly.

Page 7For technical questions, please call 1-800-444-3353.SKU 67414

BASIC SPECIFICATIONS

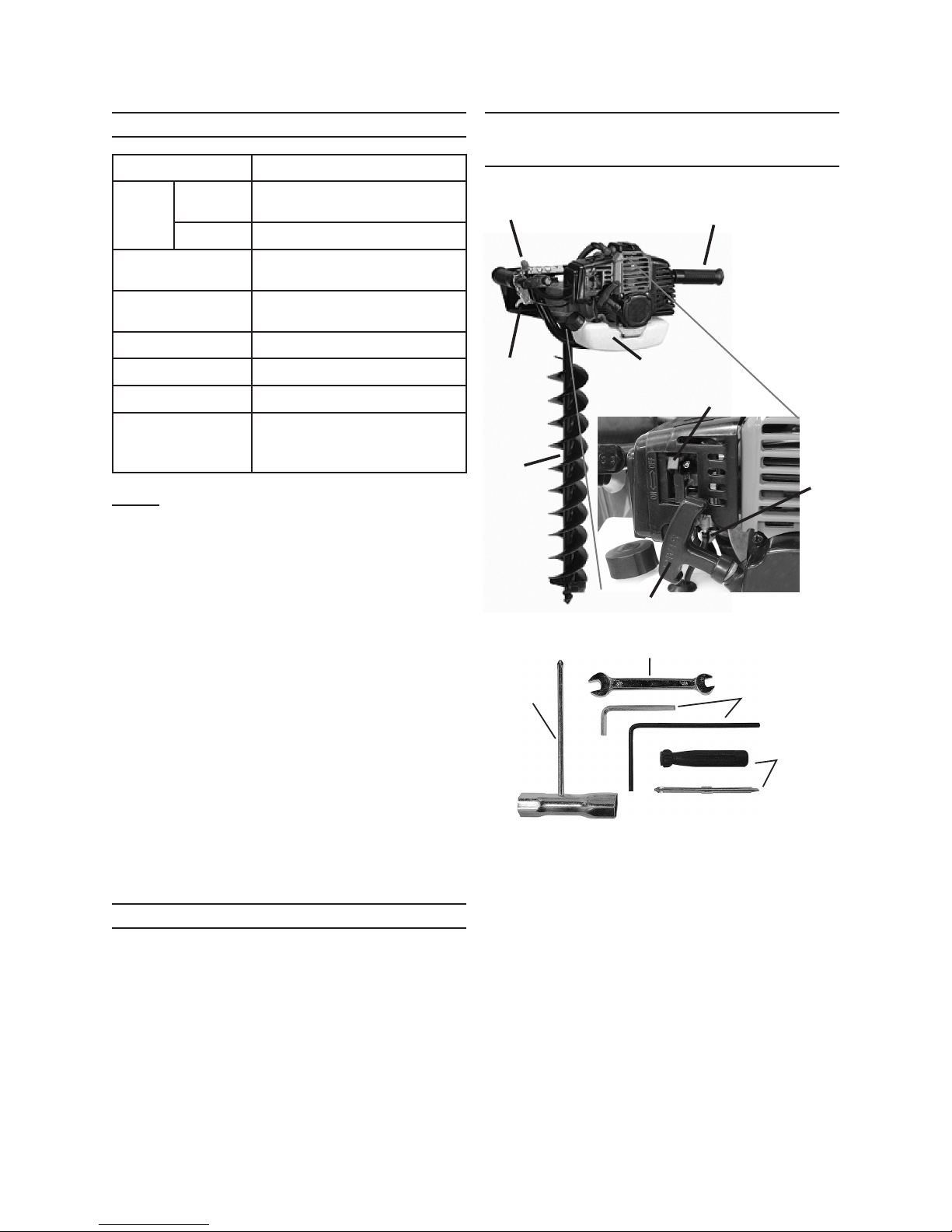

COMPONENTS AND

Engine Rating 1.5 Horsepower

Fuel

Type

Capacity .26 Gallons

Recommended

Gear Oil

Maximum Drilling

Depth

Auger Diameter 4”

Overall Bit Length 30” Long

Drive Shaft 7/8” Diameter x 1-1/2” Long

Accessories

25:1 - 89+ octane unleaded

gasoline to 2 cycle oil mix

SAE 80 - 90 Weight Gear Oil

1’ 10”

Auger Bit, Spark Plug

Wrench, Flat-Head

Screwdriver, Hex Keys

Note: Additional specications found in

the TECHNICAL SPECIFICATIONS

chart in this manual.

The emission control system for this

engine is warranted for standards set by

the U.S. Environmental Protection Agency.

For warranty information, refer to the last

pages of this manual.

At high altitudes, the engine’s

carburetor, governor (if so equipped), and

any other parts that control the fuel-air

ratio will need to be adjusted by a qualied

mechanic to allow efcient high-altitude

use and to prevent damage to the engine

and any other devices used with this

product.

Kill

Switch

(5b)

Speed

Control

(10b)

Auger

(33a)

Spark

Plug

Wrench

(39a)

Figure 1

CONTROLS

Handle (2b)

Fuel Tank (89)

Choke (76)

Starter Handle (7)

Wrench (38a)

Primer

(95)

Hex

Wrenches

(37a)

Screwdriver

(40a)

UNPACKING

When unpacking, make sure that the

item is intact and undamaged. If any parts

are missing or broken, please call Harbor

Freight Tools at 1-800-444-3353 as soon

as possible.

Page 8 For technical questions, please call 1-800-444-3353. SKU 67414

Loading...

Loading...