Carver Magnified current A-500 Series Owner's Manual

Ji3!!!l

dw

VJaMOd

Oi3JalS

®XHl

lAJlluaJJn:)

pa!l!

u6E

lAJ

xOOS-v

XOOS-V'

XOOS:V··

~"O·

"·."'-'·0

C

""

Aj;/.,

'.

:J

-

'*-'

V

xOOS-V

XOOS-\t

o

A-500x

1. Safety

Instructions

9.

Power Cord Protection - Power-supply cords should

be

~

rou

ted

so

that they are not likeIy to

be

waI

ked

upon

or pinc

hed

1.

Read Instructions - All the safety and operation

by items placed upon or against them, paying particular

instructions should

be

read

before

the

Carver

Component

attention to

cords

at

plugs,

convenience

receptacles, and the

·"··'·

..

'.'·"·.I'.:•.'··

~.-.)

•.

"·.".:.

;:

is operated.

2.

Retain Instructions -

The safety and operating

instnlctions should be kept

for

future reference.

3.

Heed Warnings -

All

warnings

on

the

Compo

..

nent and

in

these operating

instnlctions should

be

followed.

4.

Follow

Instructions-

All

operating

and

other

instructions should be

followed.

5.

Water and

Moisture-

The

Component should

not

be used near water

...

for example, near a

bathtub, washbowl,

kitchen sink, laundry tub

t

in

a wet basement, or near

a s\vimming pool, etc.

6.

Ventilation - The

Component

should

be

situated so that its

location or position does

not interfere with its

proper ventilation. For

examplef the

Component

should not be situated

on

a bed,

sofat rug,

or

similar

surface that

may

block

any ventilation openings;

or placed

in

a built-in

installati0 n such

as

a

bookcase or cabinet that

may

impede

the

flow

of

air through ventilation

openings.

7.

Heat - The Compo-

'.~::,,:

point

where

they exit

the

Component.

~

10,

Cleaning -

The

Component should

be

cleaned only as

recommended in this

manual.

I~'-'--

..

f:.{"

I~··il;l

..

:

,.:.!~

..

~

11.

Non-use

Periods-The

power cord ·of the

Conlpo~

(Li'

nent

should be unplugged

~

from the outlet when

unused

for

a long period

of time.

12.

Object and Liquid

Entry - Care should

be

taken so that objects

do

not

fall

into

and

liquids

are

not

spilled into

the

inside

of

the Component.

~:,7i

';·v.~:

~;'4)'~~i

I

13.

Damage Requiring

~

Service - The Compo-

nent should

be

serviced

only

by

qualified service

perS0I111e

I w

he

n:

A.

The

power-supply

cord

or

the

plug

has

been

damaged;

or

B. Objects have fallen, or

liquid has spilled into the

Component;

or

C.

The

Component

has

been exposed

to

rain; or

D.

The Component does

not appear to operate

normally or exhibits

a marked change

in

performance;

or

E.

The Component

has

been dropped, or

its

cabinet

damaged~

CAUTION

RISK OF ELECTRIC

SHOCK

DO NOT OPEN

CAUTION:

TO

REDUCE THE RISK OF ELECTRIC SHOCK

DO NOT REMOVE COVER (OR BACK)

NO

USER..SERVIC'EABLE

PARTS

INSIDE

REFER SERVICING

TO

QUALIFIED SERVICE PERSONNEL

The lightning flash

with

arrowhead

symbol

within an equilateral triangle is intended to

arert

the user

to

the

presence of uninsulated

Udangerous

voltage" within the

product1s

encJosure~

that may

be

of

sufficient magnitude

to constitute a risk of electric shock to

persons~

The exclamation

point

withjn

an

equilateral

tri

angle

is

intended

to

alert the user

of

the

presence

of

important operating

and

main

...

tenance (servicing) instructions

in

the literature

accompanying

the

appliance.

PORTABLE CART WARNING

Carts

and

stands

..

The

Component should

be

used

only with a cart

or

stand

that

is

recommended by

the

manufacturer.

A Component and cart

combination should

be

moved with care. Quick

stopSt

excessive force, and

uneven

surfaces

may

cause

the Component and cart

combination to overturn.

nent should be situated away from heat sources such

as

14.

Servicing - The user should not attempt

to

service the

radiators} or

other

devices which produce heat.

Component beyond those means described

in

this

operating

8. Power Sources -

The

Component

should

be

connected

manual. All other servicing should

be

referred

to

qualified

to a po

wer supply only

of

the

type described

in

these

service personneL

operation instructions or as

marked

on

the

Component

It

15.

To

prevent electric shock

t

do

not use this polarized plug

with

an

extension

cord,

receptacle

or

other

outlet

unless the

blades can be

fully

inserted to prevent blade exposure.

Pour preevenir les chocs electriques ne pas utiliser cette

fiche polarisee avec

un

pro}ongateur, un prise de courant

ou une autre sortie

de

courant,

sauf si

Ies

1ames

peu

ven

t

etre inserees afond sans laisser aucune pariie adecouvert.

16. Grounding

or

Polarization

-..

Precautions should

be

taken

so

that the grounding or polarization means of the

Component is not defeated.

17.

Intern

a1lExternal

Voltage

Selectors - Internal or

external line voltage selector switches, if

any,

should only

be

reset and re-equipped

with

a proper plug

for

alternate

vol

tage

by

a qualified service technician.

See

an

Author

..

ized Carver Dealer for

more

information.

<.

.'.'

_..

oX

~,::.::;:

.

~'.."

~.

~:.':

I..

. .

18.

Attachment Plugs for Alternate

Line

Voltage (Dual

voltage models only) -

See

your Authorized Carver

• I

~.:

••

••••

•••

"

. '"

'A';o

-"5""0"0':

:',

",",~'o:;~

Dealer for

information on the attachlnent plug for alternate

voltage use.

This

pertains

to

dual-voltage units

only.

This apparatus does not exceed the Class A/Class B

(whichever

is

applicable) limits for radio

noise

emissions

from digital apparatus as set

out

in the radio interference

regulations of

the

Canadian Department of

Communica-

tions.

ATTENTION - Le

present appareil numerique

n1emet

pas

de bruits radioelectriques depassant las limites applicables

aux

appareils nunleriques

de

class

Aide class B (selon

Ie

cas) prescrites dans

Ie

reglement sur

Ie

brouillage

radio61ectrique edicte par les

ministere des communications

du Canada.

WARNING -TO

REDUCE

THE

RISK

OF

FIRE

OR

ELECTRIC

SHOCK,

DO NOT EXPOSE THIS APPLIANCE TO RAIN OR MOISTURE.

CAUTION:

TO

PREVENT

ELECTRIC

SHOCK,

MATCH

WIDE

BLADE

OF PLUG

TO

WIDE

SLOT,

FULLY

INSERT.

ATTENTION:

POUR

EVITER

LES CHOCS

ELECTRIQUES,

INTRO-

DUIRE LA

LAME

LA PLVS LARGE

DE

LA FICHE

DANS

LA BORNE

CORRESPONDANTE

DE

LA

PRISE

ET

POUSSER

JUSQU'

AU

FOND.

Contents

1. Safety Instructions

~

+.It

••••••••••

t t

•••••••• ~ •••••••••••.•••••••••••

2

2.

Prelude , 4

3.

Fea,tures

and

Specifications 61' , , ,

••

4.

Unpacking

and

Paperwork 7

5.

Installation , 8

l

..

ocation

and

General Precautions 8

Handle Removal

""

..

~

8

AC

Power Considerations , 9

Connection

Tips

~

9

Rear Panel

Connections

and

Controls

9n

6.

Operation

~ ~

, 10

Front

Panel Features 10

System

Configurations

12

A qUick

note

on

input/output

levels " 17

Amp-to.Preamp

Connections

17

Amp-to-Speaker

Connections

,

17

Wiring

.,

,

"'

17

Hook-up

~

17

Stereo Operation

~

18

Mono

Operation

~

"

18

Amplifier

Protection

19t

Speaker

Protection

19

7..

In

Case

of

Difficulty 21t

8. Care

and

Service Assistance , ,

~

23t

e

..

·:'···;'·/;A"·'"

':~.:',

'.s'"

0'"

0·' . '.

'<.~.:.:;",.'

".~'~~"'-:.

"..

'.

x .

I

•• -:••••

: I •

~:

;

•••

_ I ' - •

~",

_

-.,

2. Prelude

Your

new

Carver

Magnified

Current™

THX

Power

Amplifier carries

with

it a

heritage of over 15 years

of

audio

research,

development

and

design

refinements.

Carver engineers

make

use

of

the

latest

advances

in

electronics

ma·nufacturing

techniques

to

provide

state

..

of-the-art

high-value audio

products

which

empha-

size

innovative

technologies

and

features

at

an

affordable price.

An

American

electronics

innovator

based

in

the

Pacific Northwest,

Carver

began

in

the

early 80s

with

a series

of

product

successes

such

as

the

C-4000

preamplifier

with

Auto-Correlator™

and

Sonic

Holography'11vi,

the

TX-l1

tuner

with

ACCDTM

(Asymmetrical

Charge-Coupled

Detector)

and

the

M-l.S

stereo

power

amplifier,

one

of

the

most

powerful ampli-

fiers available

at

tile

time

for

home

hi

..

fi

uset

.As

technology

has

evolvedt so have

Carver's products.

In

fact, a

number

of

audio technologies an·d features consid-

ered

standard

today-

including

surround-

sound

and

advanced

signal

processing-

had

their

first successful

consumer

appli

w

cations

in

a Carver component! Many

Carver

products

are

now

considered

"clas-

sics",

and

most

are still

in

use

with

their

original

owners

who

routinely upgrade

their Carver-based systems

rather

than

replace

them.

As

it

has

since

our

company!s

beginning,

the

Carver

name

remains

synonymous

with

leading

edge

technology

expressed

in

audio

compo-

nents

that

never

become

obsolete.

At

Carvers

technology

is

regarded

as

a

tool

used for

one

purpose:

to

advance

the

science

of

reproducing

sound

in

the

home. Every

Carver

employee

has

this

common

goal,

from

our

CEO

and

Board

of

Directors,

our

Engineering,

Sales

and

Marketing,

Accounting

and

Finance,

Customer

Service

and

Technical

SUPJ?ort

Staff

to

the

Manufacturing

and

QualIty

Control

people

who

actually

put

the

products

together

here

in

Lynnwood,

Washington.

We love

home

entertain-

ment.

The

vigilant

pursuit

of

I?roviding

0,

quality

and

reliable

products

aImed

at

reproducing

audio

with

absolute

accuracy

-

whether

it

be

from

a treasured

I.,P

vinyl

recording

or

the

digital

formats

of

tomor-

row -is

our

corporate

vision.

To

this end,

the

A-SOOx

was developed

with a number

of

important design

fea

..

tures

and

goals

in

mind.

A power

ampli-

fier

has

only

one

job,

but

a

very

important

one:

amplifying

the

audio

signal

without

being

disturbed by

the

loudspeaker

load.

Ideally,

the

signal

coming

out of an ampli-

fier

should

be

iderttical

in

every

way

ex-

cept

magnitude

to

the

signal

that

went

into

itt

In

realitr'

there

are subtle ways

in

which

the

signa

can

be

changed

by

an

amplifier,

which

are

described by

measure-

ments

such

as

THD, noise,

DC

offset,

crosstalk

and

phase

shift. All

these

techni

..

cal

terms

boil

dow.n

to

one

thing -the

signal

has

been

changed

(distorted)

in

some

way

from

its original

form

by

the

amplifier. I

There

are a

number

of

ways

to

mini-

mize

this

distortion.

One

of

the

most

effective

and

efficient is

to

minimize

the

signal

path~

While

that

may

sound

simple

J

it

is

actually

very

difficult

to

achieve.

OUf

engineers

went

to

great

lengths

to

shorten

the

signal

path

(pun

intended!)

as

much

as

technology

and

physics allow. A

short

signal

path

pre-

vents

corruption

of

the

signal from

the

effects

of

EMI, strayfield

magnetic

radia-

tion

and

cumulative

reactance

in

the

critical signal

conductors.

l~he

result

is

a

much

cleaner

(and

very

nearly

perfect)

reproduction

of

the

signal

at

the

amplifier's

output.

The

A-SOOx

is

rated

conservatively at

250

watts

per

channel

into 8 ohms

and

delivers

over

400

watts

per

channel

into

4

ohms.

It

also

has

the

flexibility

and

power

®

(-

r:':,'·'

L._

L

I.

L

1,."

1'.:

....

:.

L

I·:·:::··

J

I'·

L

k

L

--

reserves

to

become

an

800

watt+

bridged

mono amplifier

when

even

higher

power

levels are needed. This is

an

enormous

am'ount

of

power,

made

possible through

the

development

of a new

multi·state

hybrid power amRlifier design

we

call

Magnifled

Current

. It uses

two

160

amp

peak current

power

MOSFETs

per

channel,

with nanosecond sWitching speed

to

assign twice

the

continuous

voltage

to

the

·

output

stage

when

high

voltages are re-

quired}

or

more

than

twice

the

continuous

Ctlrrent

when

higher

current is needed.

This maximizes

both

the

voltage

and

current

capability (peak

or

continuous)

available for any

loudspeaker

load;

even

thos.e

that

have a substantial

reactive

component

that is difficult for conven-

tional

amplifiers

to

drive.

As

a result

of

this

difficulty

in

driving

demanding

loudspeaker loads,

conven-

tional

amp1ifiers

use

stabilizing

inductors

on

the

output

of

the

amplifier

to

keep

the

amplifier from oscillating

and

even

self-

destructing.

Unfortunately,

these

in·due-

tors also cause low

damping

at

high

fre-

quencies

which

can

create

high

frequency

coloration.

Carver

has

developed

Total

Direct

Coupling™

(TDC)

to

combat

this

problem.

TDC

means

that

the

output

circuitry is

directly

connected

to.

the

loudspeaker

without

the

usual

stabilizin~

inductor

networks

between

the

amplIfier

output

and the loudspeaker termInals. Due

to

the

wide

open

loop

bandwidth,

ideal stability

and

load

immunity

of

the

new

Carver

amplifier module, the traditional sound

altering Ustability

bandaids"

of

conven-

tional

amplifiers are

no

longer

necessary.

This

not

only

cre'ates

a totally stable power

amplifier

into

all speaker loads,

it

also

provides

high

damping

factor

at

all

frequencies-

not

just

i.n

the

bass region.

lUCASFllM

.

.'

··A-500x·:

That

means

full

control

in

th'e bass,

midrange and

high

frequencies.

No

more

harsh

or

rolled

off

highs, just

pure

and

natural clarity from top to bottom.

In

addition

to

new

audio

technologyj

Carver engineers also designed the

A-500x

to

set

new

stand~rds

in

reliability

and

value. The

A-SOOx

makes full

use

of

their

modular

d'esign

philosophy

and

open-

frame

architecture

for efficient

and

cost

...

effective

assembly_

This

has

the

added

benefit

of

providIng

superior

channel

isolation, eliminating the

detrimental

effects

of

interchannel

crosstalk.

The

amplifier's

enclosure

is·

designed

to

pro-

vide

open air access

to

the

heatsinks. This

affords

more

efficient dissipation of

heat

away from

the

triple-diffused

planar

high-

current

output

devices,

which

results

in

greater reliability

and

longevity

of

the

amplifier.

The

THX logo

on

the

front

panel

of

the

Carver

A-SOOx

is

another

important

fea-

ture

of

the

amplifier. THX certification

means

that

the

A-SOOx

meets

a set of strict

performance

standards

which

ensure

that

the

soundtrack's

reproduction

is

faithful

to

the

director's

intent~

The

Carver

A..500x

can

be

used

with

other

THX

certi-

fied

audio

equipment

to

create a

true

Home

TH.X

Audio System.

Other

features are

included

to

provide

convenience

and

flexibility

such

as

vari

...

able

input

sensitivity controls, removable

handles

and

front

panel

analog

meters

with

two

sensitivity settings.

The Carver

A-SOOx

was designed

and

manufactured

by

people

with

a lifetime

commitment

to

providing

the

world's

finest

components

for

sound

reproduction

and

home

entertainment.

Thanks

for

placing

your

confidence

in

Carver. We

know

your

new

amplifier will provide

many

years

of

listening

enjoyment.

If you have

access

to

the

Internet,

you

can

check

out

the

full line

of

Carver

products

and

company

an

..

nouncements

·on

our

World Wide·

Web page (http://www.carver.com).

o.:':'·A··"':··"S:···:'·O'O·

'.-.:

....

I I

•. ~ :.

, .

".~: . ~.

I".

.

~-

,"

.: .., .. > .....

;., ..' :

·X':

'.

~

.,.'.,.,

::

~

\.'

, . . . ,'

r

~;

tr

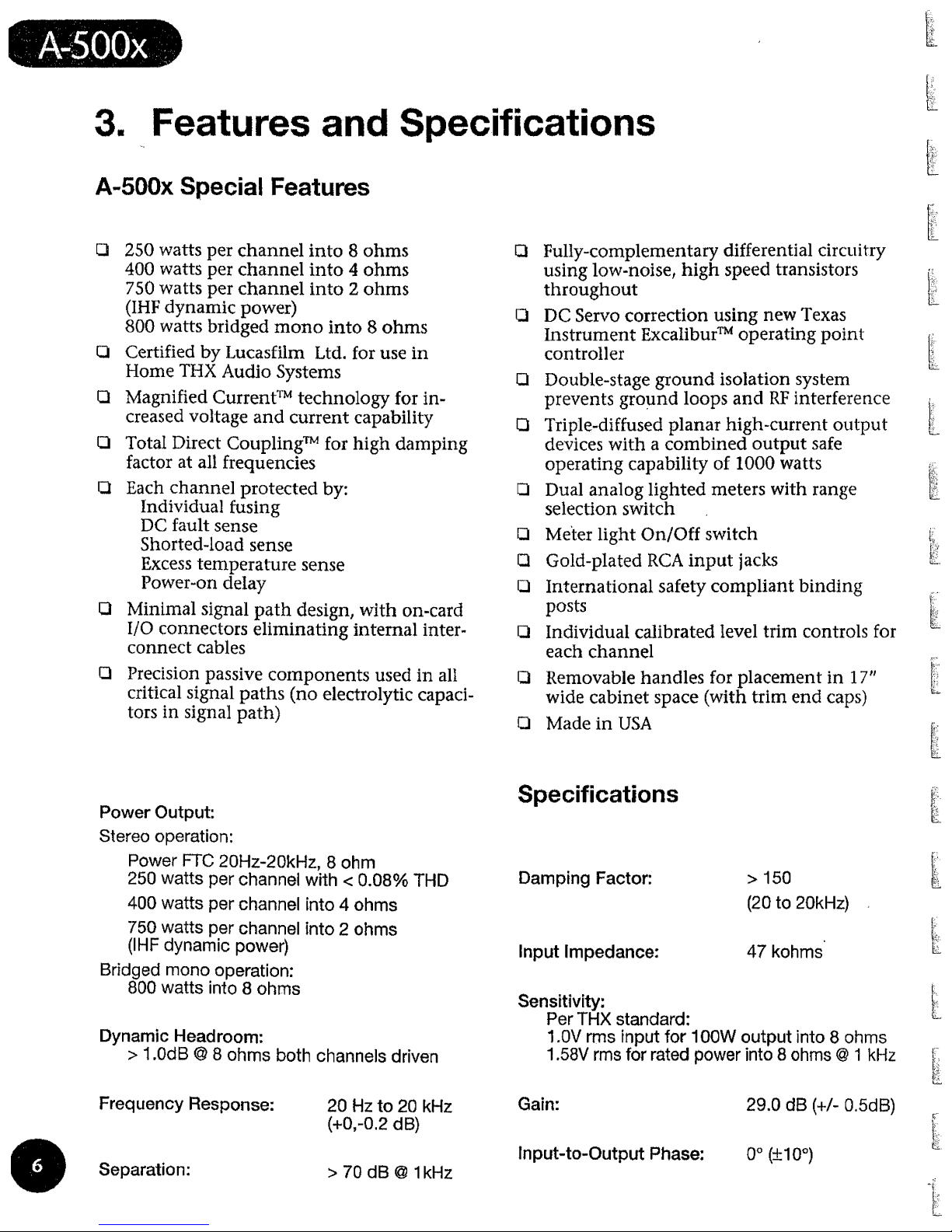

3. Features and Specifications

~

A-500x Special Features

[

0

250 watts

per

channel

into 8 ohms

o Fully-complementary

differential

cirCllitry

400 watts

per

channel

into

4

ohms

using low-noise,

high

speed transistors

t~;~::'

750

watts

per

channel

into

2

ohms

throughout

lL

(IHF

dynamic

power)

o DC Servo correction using new Texas

800

watts

bridged

mono

into 8

ohms

Instrument

Excalibur™

operating

point

":,".','

a Certified

by

Lucasfilm Ltd. for use

in

controller

1

;~.

Home

THX Audio Systems

~

a Double-stage

ground

isolation system

o Magnified

Current™

technology

for in-

prevents

gro~nd

loops and

RF

inte-rference

creased voltage

and

current

capability

o Triple-diffused

planar

high-current

otttput

l~

L..

o Total Direct Coupling™ for

high

damping

devices

with a cOlnbined

output

safe

factor

at

all frequencies

operating

capability

of

1000

watts

o Each channel

protected

by:

o Dual

analog

lighted

meters

with

range

l

Individual

fusing

selection

switch

DC fault sense

o

Meter

light

On/Off

switch

t:.

Shofted-load sense

Excess

temperature

sense

o

Gold-plated

RCA

input

jacks

~:"

Powerwon delay

o

International

safety

compliant

binding

o Minimal signal

path

design,

with

on-card

posts

k,·

t

I/O

connectors

eliminating

internal

inter-

o Individual calibrated level trim controls for

connect

cables

each

channel

'i-:;::."

0

Precision

passive

components used

in

all

o Removable

handles

for

placement

in

17"

rf~

'if...

critical

signal

paths

(no

electrolytic

capaci

w

wide

cabinet

space (with

trim

end

caps)

tors

in

signal

path)

o Made

in

USA

l

Sp'ecifications

!~""

fe',

Power

Output:

E,

L

Stereo operation:

f~,',

,

Power

FTC

20Hz-20kHz, 8 ohm

250

watts per channel with < 0.08%

THD

Damping Factor:

> 150

l

400 watts per channel into 4 ohms

(20

to 20kHz)

v

750 watts per channel into 2 ohms

t~;~,.

(IHF

dynamic power)

8.

Input Impedance:

47 kohms

Bridged mono operation:

r:

800

watts into 8 ohms

Sensitivity:

~:::.

Per

THX

standard:

L

}';"

Dynamic Headroom:

1.0V rms input for 1

DOW

output into 8 ohms

> 1.0dB @ 8 ohms both channels

drive'n

1.58V

rms

for rated power into 8

ohms

@ 1

kHz

t:::,

I

Frequency Response:

20

Hz

to

20

kHz

Gain:

29.0 dB (+/-

O.5dB)

(+0,-0.2 dB)

F'

k

Input-to-Output

Phase:

0°

(±100)

__

Separation:

> 70

dB

@ 1kHz

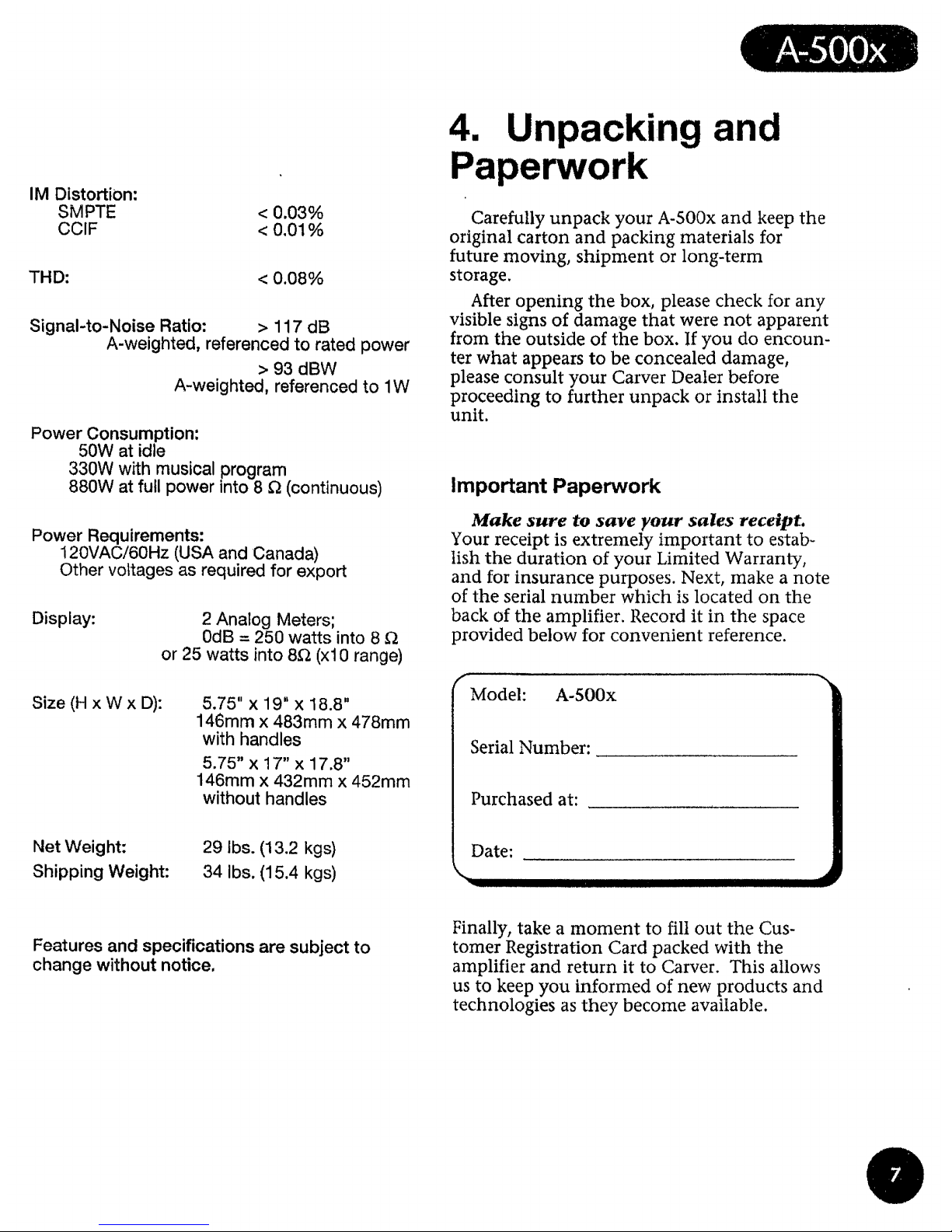

1M

Distortion:

SMPTE

<

0.03%

CCIF

<

O~01

%

THO:

< 0.08%

Signal-to-Noise

Ratio: > 117

dB

A-weighted, referenced to rated power

> 93

dBW

A-weighted, referenced

to

1W

Power Consumption:

50W

at

idle

330W

with

musical

program

880W at full

power

into

8 Q (continuous)

Power

Requirements:

120VAC/60Hz

(USA

and

·Canada)

Other voltages as required

for

export

Display:

2 Analog Meters;

OdS

= 250

watts

into 8 n

or

25

watts

into

an

(x10 range)

Size

(H

x W x

D):

5.75'1

x 19·· X

18.8

11

146mm

x 483mm x

478mm

with

handles

5.75" x17

1f

x 17.8"

146mm x 432mm x 452mm

without

handles

Net Weight:

29

Ibs. (13.2 kgs)

Shipping

Weight:

34

Ib·s.

(15.4

kgs)

Features

and

specifications

are

subject

to

change

without

notice.

..

<

A~5()Ox·<'

, .

I.":

,'-

4. Unpacking and

Paperwork

Carefully

unpack

your

A-SOOx

and

keep

the

original carton

and

packin'g materials

for

future

moving,

shipment

or

long-term

storage~

After

opening

the

box, please check for

any

visible signs

of

damage

that

were

not

apparent

from

the

outside

of

the

box.

If you do encoun-

ter what appears

to

be concealed

damage,

please

consult

your

Carver Dealer before

proceeding

to

further

unpack

or

install

the

unit.

Important

Paperwork

Make

sure

to

save

your

sales

receipt.

Your receipt is

extremely

important

to

estab

w

lish

the

duration

of

your

Limited Warranty}

and

for insurance purposes. Next,

make

a

note

of

the

serial

number

which

is located

on

the

back

of

the

amplifier. Record

it

in

the

space

provided below for convenient reference

..

Model: A-500x

Serial

Number:

_

Purchased at:

----0-..----

Date: _

Finally,

take a moment

to

fill

out

the

Cus-

tomer

Registration

Card

packed

with

the

amplifier

and

return

it

to

Carver

..

This allows

us

to

keep you

informed

of

new

products

and

technologies

as

they

become

available.

e

--

L

1"-

~

• • L

'.;

,<

"0"0'

".'

\<::,!A7$

.

••.....•~ •.....

l::~;:,,

t-

L...;.,;,

5.

Installation

Location and General

Precautions

Observe

the

following

precautions

when

choosing a

location

for

the

A-SOOx:

o Do

not

expose

the

unit

to

rain

or

moisture.

o Protect

from

prolonged

exposure

to

direct

sunlight.

o Avoid excessive

exposure

to

extreme

cold

or

dust.

o Do

not

place heavy

objects

on

the

unit.

000

not

place

magnetic

storage

media

suel1 as

audio

or

video

tapes

near

the

amplifier. All

power

amplifiers

con-

tain

transformers

that

are

surrounded

by

a

fluctuating

magnetic

field

which

can

erase

magnetic

tapes

(or

floppy disks).

a Protect

from

heat

and

allow

adequate

ventilation.

Place

away

from

direct

sources

of

heat,

such

as

heating

vents

and

radiators. All

compo-

nents

produce

some

heat

during

operation!

so

make

sure

that

the

ventilation

holes

are

not

covered

and

that

air is

allowed

to

circulate

freely

behind,

beside

and

above

the

unit.

Excessive

heat

is

the

single greatest

source

of

both

short-term

and

long-term

component

failure.

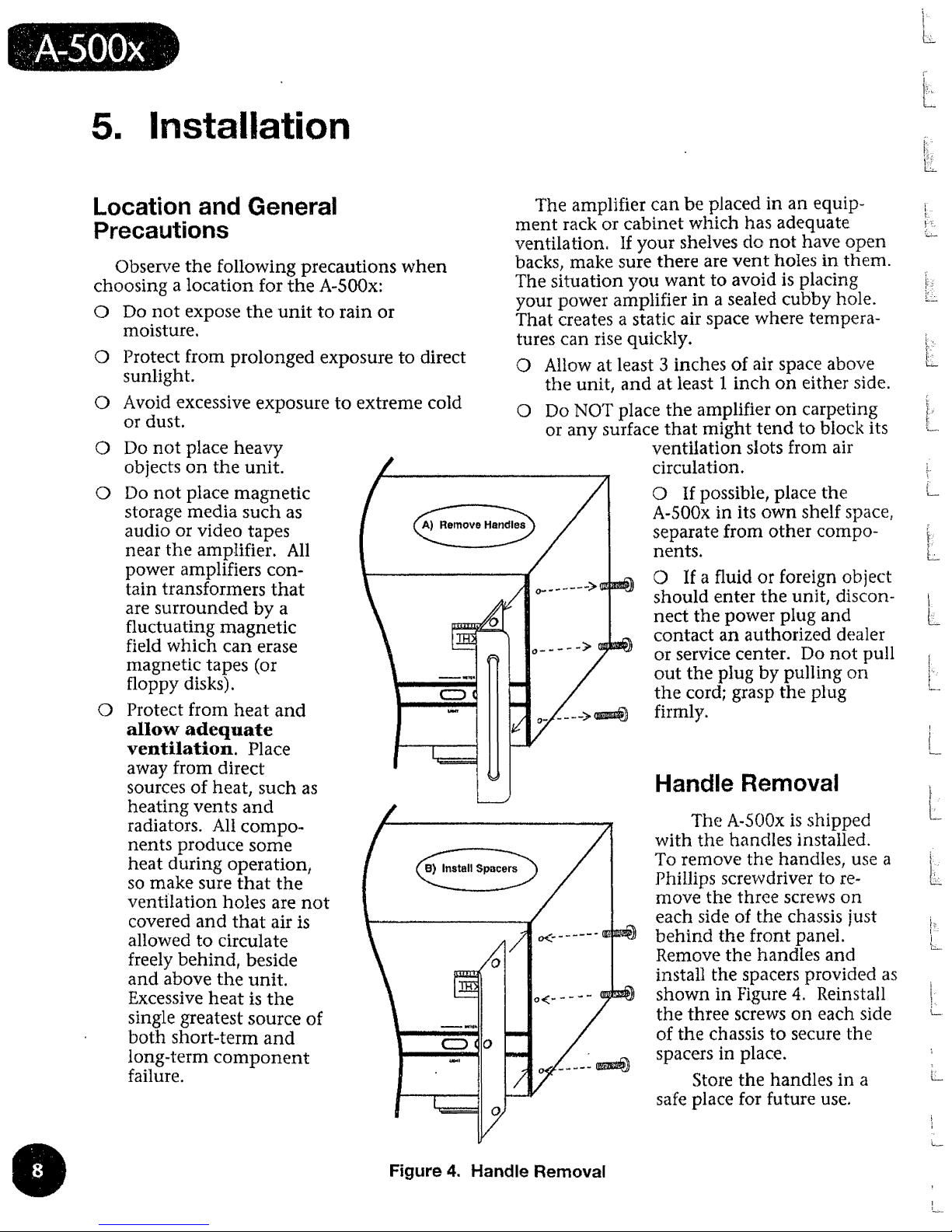

A)

Remove Handles

-----~

B) Install Spacers

The

amplifier

can

be

placed

in

an

equip-

ment

rack

or

cabinet

Wllicll

has

adequate

ventilationQ

If

your shelves

do

not

have

open

backs,

make

sure

there

are

vent

holes

in

them.

The

situation

)'0U

want

to

avoid is

placing

your

power

amplifier

in

a sealed cubby hole.

That

creates a static air space

where

tempera-

tures

can

rise quickly.

o Allow

at

least 3

inches

of

air space above

the

unit}

and

at

least

linch

on

either

side.

o

Do

NOT

place

the

amplifier

on

carpeting

or

any surface

that

might

tend

to

block its

ventilation

slots

from

air

circulation.

o If possible,

place

the

A-SOOx

in

its

own

shelf space,

i

separate

from

other

compo-

l-:-:

5,-_,

nents.

L-

o If a fluid or foreign object

i

should

enter

the

unit

l

discon-

1.

nect

the

power

plllg

and

l

contact

an

authorized

dealer

or

service center.

Do

not

pull

out

the

plug

by

pulling

on

the

cord; grasp

the

pllig

firmly.

-;

1L--

Handle Removal

l-

t

The A..SOOx

is

shipped

with

tIle

h.anciles

installed.

t-

To

remove

the

handles, use a

!'._:

t:

..

>

Phillips screvvdriver to

re~

L::.::..

move

the

three

screws

on

each side of

the

chassis just

1-;-,-

j

behind

the

front

panel.

Remove

the

handles

and

L-

install

the

spacers

provided

as

1--

shown

in

Figure

4.

Reinstall

i

L

the

three

screws

on

each

side

I~

of

the

chassis

to

secure

the

spacers

in

place.

L

Store

the

handles

in

a

safe place for future use.

L-..--

Figure

4.

Handle Removal

1-;.-

Loading...

Loading...