Carver GVC Series, GVT Series Installation, Operation And Maintenance Manual

(GVC) I-460 Rev. 02

(GVT) I-470 Rev. 02

SERVICE RECORD PAGE

Service No. ________________ Size and Type ______________ Make _____ ___________________

Cust. Order No. ________________________ Date Installed ___________ _______________________

Installation Date

Location

Application

PUMP RATING

Capacity (GPM) __________________________ Total Head (ft) _______________________________

Suction Pressure _________________________ Speed (RPM) ________________________________

Liquid __________________________________ Temperature ________________________________

Specific Gravity __________________________ Viscosity ____________________________________

Impeller Diameter (inches) ____________________________ __________________________________

PUMP MATERIALS

Casings ___________________ Impeller ________ ___________ Diffuser _______________________

Shaft ____________________________________ Wear Rin g ________________________________

O-rings _______________________________ Beari ng Frame _______________________________

Mechanical Seal, Suction End (Low Pressure) ______________________________________________

Mechanical Seal, discharge End (High Pressure) ____________________________________________

DRIVER DATA

Motor _________________ Make _______________________ _ Serial No. ______________________

Type __________________ Frame _______________________ AC or DC ______________________

HP ____________________ RPM ________________________ Volts _________________________

Phase _________________ Cycles _______________________

INSPECTION DATE

NOTES ON INSPECTION AND REPAIRS

REPAIR TIME

REPAIRS

COST

REMARKS

TABLE OF CONTENTS

LOCATION/DESCRIPTION PAGE

• SERVICE RECORD PAGE ...............FRONT

• NOTES ON INSPECTION AND

REPAIRS...........................................FRONT

I. GENERAL INFORMATION .........1

A. Preface....................................1

B. Pump Identification .................1

C. Parts Inventory Guide.............1

D. Parts Ordering.........................1

E. Safety Precautions..................1

II. INSPECTION AND STORAGE ...2

A. Inspection Upon Arrival...........2

B. Storage of Pump.....................2

III. INSTALLATION ...........................4

IV. ALIGNMENT................................4

V. OPERATION................................4

A. Prestart Cautions....................4

B. Starting the Pump...................4

C. Stopping the Pump .................4

VI. MAINTENANCE...........................5

A. Field Inspection.......................5

B. Stuffing Box.............................5

C. Bearing Temperature..............5

D. Bearing Lubrication.................5

VII. TROUBLESHOOTING.................6

VIII. SERVICE AND REPAIR..............9

A. Disassembly and Assembly....9

B. Parts Inspection......................14

LOCATION/DESCRIPTION PAGE

C. Adjusting Impeller Clearance

on Pump Equipped with

Semi-Open Impeller................16

D. Replacement of Optional

Wear Ring on Pump Equipped

with Enclosed Impeller............16

IX. PARTS LIST AND FIGURES...... 17

LIST OF TABLES

TABLE TITLE PAGE

A. Recommended Torque Values .....5

1. Troubleshooting ............................7

2. Throttle Bushing Dimensions........ 15

3. Enclosed Impeller Clearance........ 15

4. Impeller/Wear Ring Matching

Materials........................................16

5. Recommended Spare Parts..........17

6. Pump Parts List for GVC 1520 and

GVC 1530/1540 ............................18

7. Pump Parts List for GVT 1520 and

GVT 1530/1540............................. 18

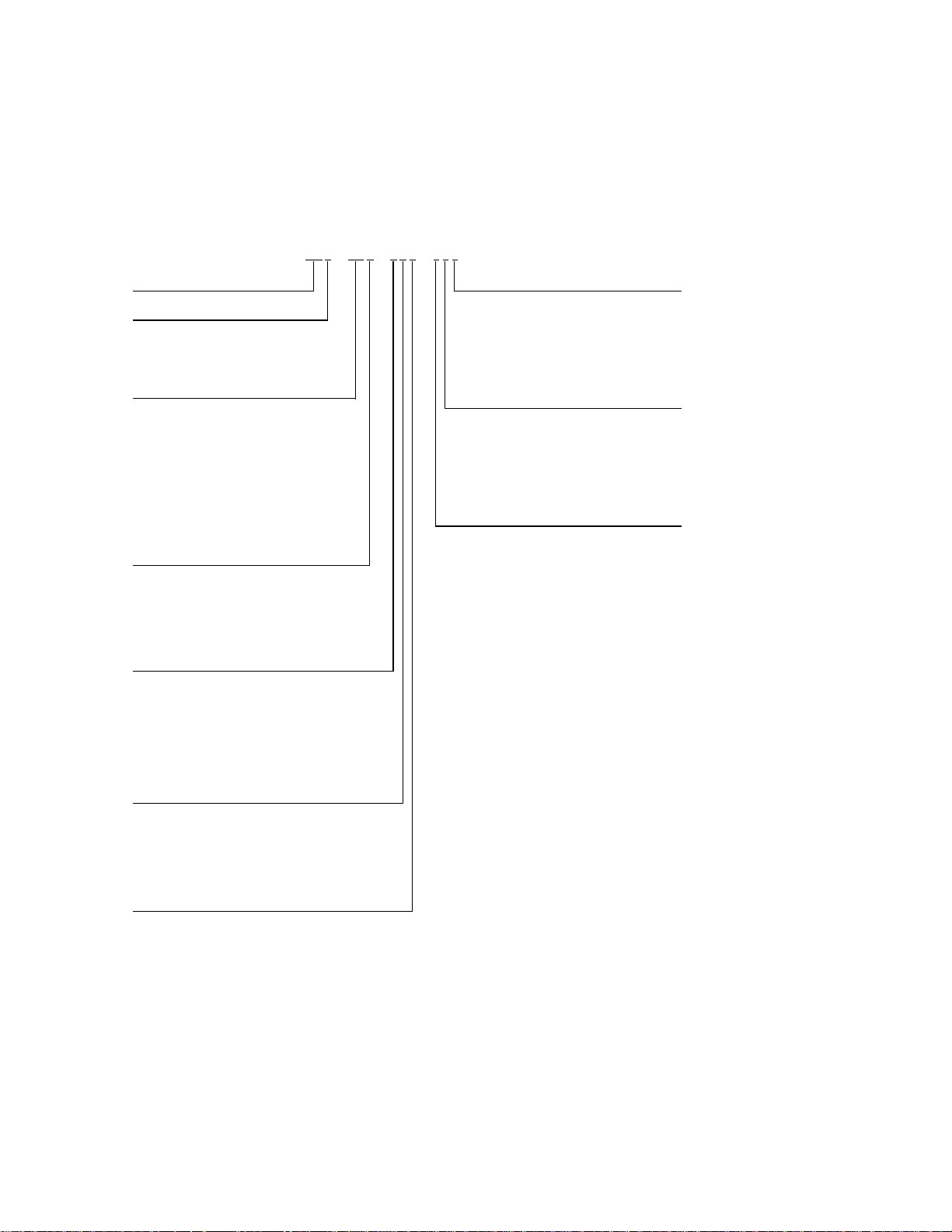

LIST OF ILLUSTRATIONS

FIGURE TITLE PAGE

A. Ordering Codes.............................3

1. GVC (1520 Frame)

Sectional Drawing .........................19

2. GVC (1530 Frame)

Sectional Drawing .........................20

3. GVC (1540 Frame)

Sectional Drawing .........................21

4. GVT (1520 Frame)

Sectional Drawing .........................22

5. GVT (1530 Frame)

Sectional Drawing .........................23

6. GVT (1540 Frame)

Sectional Drawing .........................24

7. Optional Wear Ring....................... 25

i

I. GENERAL INFORMATION

A. PREFACE. General vertical cantilevered

(GVC) pumps are designed for industrial service. All

wetted surfaces are available in all iron, stainless

fitted, and stainless steel construction. The general

vertical top pullout (GVT) design provides fast, easy

access to all working parts without disconnecting

pipes.

B. PUMP IDENTIFICATION. The type of pump,

pump size, operating data, and serial number are all

stamped on the nameplate attached to the pump.

Pump specifications should be recorded upon receipt

of the pumping unit. Record all necessary information

on the pump service record page and inspection and

repair record provided at the front of this manual.

When ordering spare parts, check to make sure that

the serial number and model number of the pump are

correct. When ordering a pump, refer to Figure A,

Ordering Codes. This information must be included in

all correspondence regarding the unit. This will ensure

that the correct pump and/or parts are ordered in a

timely manner.

C. PARTS INVENTORY GUIDE. To avoid

unnecessary delays during maintenance of pump,

spare parts should be readily available for normal

service. Most matters can be handled with proper

usage of this manual. For every one to three pumps,

stock one spare set consisting of items listed in Table

5, Recommended Spare Parts. Part numbers

correspond to the drawings (figures 1 through 7)

found at the back of this manual.

A nameplate is attached to each pump. The data on

the nameplate should be recorded and filed for easy

reference. Nameplate data should be furnished to

Carver Pump Company or its representative when

ordering spare parts or requesting information.

D. PARTS ORDERING. Carver Pump Company

strives to provide prompt, accurate service. To ensure

quality customer service, please provide the following

information:

• Serial number of pump (located on

nameplate)

• Part name (refer to Table 6 and Table 7)

• Item number (refer to Table 6, Table 7,

and figures 1 through 7)

• Quantity of parts needed

Carver may ship an interchangeable part that is not

identical in appearance or symbol. This is done only if

the part has been improved. Examine the parts

carefully on receipt before calling the factory or a

company representative. Never return parts to the

factory without authorization from Carver Pump

Company.

If an impeller is ordered, specify diameter across

blade tips. Check to make sure diameter was NOT

trimmed further than diameter shown on Carver Pump

Company records.

If a motor/motor parts are ordered, specify the name

of the manufacturer and all other data found on the

driver nameplate.

E. SAFETY PRECUATIONS. This manual

contains descriptions and instructions, which are the

result of carefully conducted engineering and

research efforts. The manual is written with the intent

to provide instructions for the safe and efficient

installation, operation, and maintenance of the pump.

Failure or neglect to properly install, operate, or

maintain the pump may result in personal injury,

property damage, or unnecessary damage to the

pump and/or parts.

Variations exist in both the equipment used with these

pumps and in particular, installation of the pump and

driver. Therefore, specific operating instructions are

not within the scope of this manual. This manual

contains general rules for installation, operation, and

maintenance of the pump.

Observe and understand all caution or danger tags

attached to the equipment. Observe and understand

all cautions and warnings included in this manual.

The following general safety precautions do not relate

to any specific procedure within this manual but are

pertinent to providing a safe working environment for

personnel.

CAUTION

Various federal, state and local laws and the

regulations concerning OSHA affect

installation, use, and operation of pumping

equipment. Compliance with such laws

relating to the proper installation and safe

operation of pumping equipment is the

responsibility of the equipment owner and all

necessary steps should be taken by the

owner to assure compliance with such laws

before operating the equipment.

PUMP

1. Hydro suction case separately if unit

hydro is greater than 620 PSIG.

2. Isolate pump for system hydro.

3. Do NOT exceed maximum suction

pressure of 415 PSIG on suction case.

4. Do NOT exceed maximum discharge

pressure of 1200 PSIG on discharge

case.

DRIVER

5. Prior to working on pump or driver,

6. All circuits NOT known to be dead must

7. Do NOT wear loose or torn clothing

8. While working near electricity, do NOT

ensure all switches and circuit breakers

have been locked in the open (off)

position and tagged, “Out of Service.”

be considered live at all times.

around rotating machines. Do NOT wear

jewelry or watches around rotating

machines.

use metal rules, flashlights, metallic

1

pencils, or any other objects having

exposed conducting material.

9. Ensure you are NOT grounded while

adjusting electrical equipment or using

measuring equipment.

10. In general, use only one hand when

servicing live electrical equipment.

11. De-energize all electrical equipment

before connecting or disconnecting

meters or test leads.

12. When connecting a meter to terminals

for measurement, use a range higher

than the expected voltage.

13. Check to make sure the frame of the

driver and starter panel are securely

grounded before operating pumping unit

or performing any tests or

measurements.

14. If a test meter is held or adjusted while

voltage is applied, ground case of meter

before starting measurement. Do NOT

touch live equipment while holding

meter. Some moving vane-type meters

should not be grounded nor held during

measurements.

15. Do NOT use test equipment known to

be damaged or in poor condition.

16. Reference Table A, Torque Values, to

avoid equipment damage and injury to

personnel.

II. INSPECTION AND STORAGE

A. INSPECTION UPON ARRIVAL. Upon

receipt of the shipment, check for missing or

damaged items. Unpack and inspect the pump,

driver assemblies, and individual parts. Carefully

inspect all boxes and packing material for loose

parts before discarding. Immediately report any

missing parts or damage incurred during

shipment to the factory and to the transportation

company. File your “damaged and/or lost in

shipment” claim with the carrier.

NOTE

The pump and equipment, as shipped from

Carver Pump Company, have appropriate

protection for short-term storage. If the

equipment is NOT immediately installed and

operated, store the equipment in a covered,

clean, dry, well-ventilated location, free from

vibrations, moisture, and rapid or wide

variations in temperature.

B. STORAGE OF PUMP. If the equipment is

NOT immediately installed and operated, Carver

Pump Company recommends rotating each shaft

several revolutions at least once every two weeks to

prevent flat spots on ball bearings.

Consider a unit to be in storage when any of the

following situations occur:

• The pump has been delivered to the job site and

is waiting to be installed.

• The pump has been installed but operation is

delayed pending completion of construction.

• There are long (30 days or more) periods

between operating cycles.

• The plant (or department) is shut down for

periods of longer than 30 days.

CAUTION

A pump, which is made of cast or ductile iron

that sits in extreme heat, high humidity, or

full or partially full water over 30 days will

rust and will most likely seize. If the pump

rusts and/or seizes, a complete overhaul and

repair may be necessary to refurbish the

pump.

Storage requirements vary depending on the

length of storage, the climatic environment,

and the equipment. For storage periods of

three months or longer, contact a

representative from Carver Pump Company

for specific instructions. Improper storage will

damage the equipment and will require nonwarranty restoration and/or non-warranty

product failures. Refer to Section VIII,

Service and Repair, for pump disassembly

and assembly procedures. When

disassembling the pump, replace and repair

rusted parts, as necessary.

NOTE

If the customer anticipates the

pump/equipment will be subject to an

extended period of storage after installation,

(for example, a unit used for seasonal

operation), contact a representative from

Carver Pump Company. If this is the case,

Carver will provide specific instructions for

the equipment during the extended period of

storage. In general, if a pump is to be shut

down for an extended period, the following

steps are recommended:

1. Shut down the pumping unit in

accordance with the operating

procedures outlined throughout this

manual.

2. Shut off system suction and discharge

valves.

3. Drain the unit.

4. Fill unit with mineral oil or suitable non-

corrosive protectant that is compatible

with the system.

5. Provide pump and motor with a

protective cover.

2

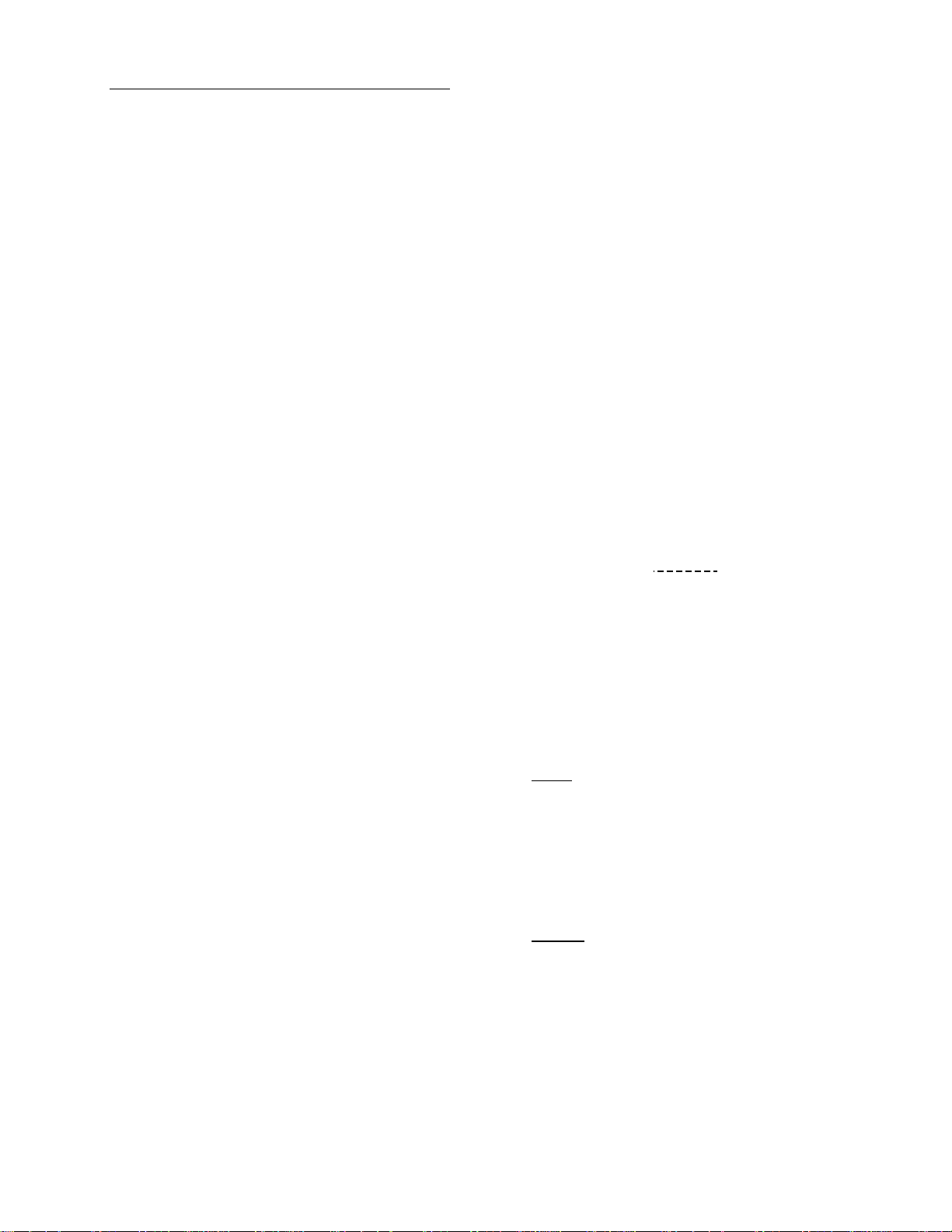

The following Ordering Code defines the new

g

g

g

g

g

g

g

g

g

g

Q

g

g

g

g

A

g

g

A

g

g

g

g

g

g

g

g

g

Q

Q

g

g

g

g

g

g

g

g

g, g

g

g

GV Series pump and pump/motor and top plate

arrangements. When quoting or ordering a GV

Ordering Code enables Carver Pump Company

to accept orders quickly, assuring timely and

correct manufacture of the desired pump.

pump, this Ordering Code must be used. This

EXAMPLE

---

Pump Series Coupling, Motor Mounting Bracket and Motor

GV - General Vertical A - Standard couplin

Mountin

Style C - Standard coupling, TEFC motor, standard efficiency

C - Cantilever desi

T - Top pull out desi

S - Sump desi

Casin

Nozzle and Impeller S i ze s

BA - 1 1/4 x 1 x 7 DA - 2 x 1 x 11 Motor Ratin

BB - 1 1/2 x 1 1/4 x 7 DB - 4 x 2 x 11 A - 1.5 HP @ 1750 RPM K - 15 HP @ 1750 RPM V - 75 HP @ 1750 RPM

BC - 2 1/2 x 2 x 7 DC - 4 x 3 x 11 B - 2 . 0 H P @ 17 50 R P M M - 15 HP @ 3500 RPM W - 100 HP @ 1750 RPM

BD - 3 x 2 1/2 x 7 DD - 5 x 4 x 11 C - 3.0 HP @ 1750 RPM N - 20 HP @ 1750 RPM

BE - 4 x 3 x 7 DE - 8 x 6 x 11 D - 5.0 HP @ 1750 RPM P - 20 HP @ 3500 RPM X - S p e ci al or over 100 HP

BF - 5 x 4 x 7 E - 5.0 H P @ 35 00 R P M

CA - 1 1/2 x 1 1/4 x 10 EB - 2 1/2 x 2 x 13 G - 7.5 HP @ 35 00 R P M S - 40 HP @ 1750 RPM

CB - 2 x 1 1/2 x 10 EC - 3 x 2 1/2 x 13 H - 10 HP @ 1750 RPM T - 50 HP @ 1750 RPM

CC - 2 1/2 x 2 x 10 ED - 4 x 3 x 13 J - 10 HP @ 3500 RPM U - 60 HP @ 1750 RPM

CD - 3 x 2 1/2 x 10 EE - 5 x 4 x 13

CE - 4 x 3 x 10 EF - 6 x 5 x 13

CF - 5 x 4 x 10 EG - 8 x 6 x 13 (GVC & T only) Top Plate and Dischar

CG - 6 x 5 x 10 A - Small steel top plate (no dischar

Basic Mate rials and Construction

ll cast iron construction

A -

316 stainless steel fitted cast iron construction

B -

ll 316 stainless steel construction for major components

C -

- Special

X

Column Depth (1.0 and 2.0 ft for GVC & T only) L - L

A - 1.0 ft (GVC & T) L - 11.0 ft (GVS only) M - L

B - 2.0 ft (GVC & T) M - 12.0 ft (GVS only)

C - 4.0 ft (GVS only) P - 14.0 ft (GVS only) P - L

D - 5.0 ft (GVS only)

E - 6.0 ft (GVS only) R - 16.0 ft (GVS only)

F - 7.0 ft (GVS only) S - 17.0 ft (GVS only) R - Lar

G - 8.0 ft (GVS only) T - 18.0 ft (GVS only) S - Lar

J - 9.0 ft (GVS only) U - 19.0 ft (GVS only) T - Lar

K - 10.0 ft (GVS only) V - 20.0 ft (GVS only)

Throttle Bushin

A - Teflon bushin

B - 17-4 PH bushin

C - Bronze lineshaft bearin

D - Bronze lineshaft bearin

E - Carbon lineshaft bearin

X - Special

n D - S tandard coupling, TEFC motor, Hostile Duty

n E - Standard coupling, X-P motor, standard efficiency

n

EA - 2 1/2 x 1 1/2 x 13 F - 7.5 HP @ 17 50 R P M R - 30 HP @ 1750 RPM Z - No motor - bare pump

N - 13.0 ft (GVS only) N - L

- 15.0 ft (GVS only)

, Lineshaft Bearing and Flush Lines W - Large 316 SS top plate, double oversized 316 SS discharge (GVC & T only)

(standard for GVC & T)

, 416 SS shaft sleeve (GVC & T only) X - Special

reased for life (standard for GVS) Z - No top plate or discharge pipe - bare pump only (standard for GVC & T)

, externally flushed (GVS only)

, externally flushed (GVS only)

Z Z ZB A ZG V B E AC

B - Standard couplin

X - Special couplin

Z - No couplin

B - Small steel top plate (no dischar

C - Small 316 SS top plate (no dischar

D - L

. steel plate, no underliner, standard steel discharge pipe (standard for GVS)

E - L

. steel plate, no underliner, oversized steel discharge pipe (GVC & T only)

F - L

. steel plate, no underliner, dbl. oversized steel discharge pipe (GVC & T only)

. steel plate, 316 SS underliner, standard size steel discharge pipe

G - L

H - L

. steel plate, 316 SS underliner, oversized steel discharge GVC & T only)

J - L

. steel plate, 316 SS underliner, dbl. oversized steel discharge (GVC & T only)

. steel plate, no underliner, standard size 316 SS discharge pipe

K - L

. steel plate, no underliner, oversized 316 SS discharge (GVC & T only)

. steel plate, no underliner, dbl. oversized 316 SS discharge (GVC & T only)

. steel plate, 316 SS underliner, standard size 316 SS discharge pipe

. steel plate, 316 SS underliner, oversized 316 SS discharge (GVC & T only)

- Lg. steel plate, 316 SS underliner, dbl. o'sized 316 SS discharge (GVC & T only)

e 316 SS top plate, standard size steel discharge pipe

e 316 SS top plate, oversized steel discharge (GVC & T only)

e 316 SS top plate, double oversized steel discharge (GVC & T only)

U - Lar

e 316 SS top plate, standard size 316 SS discharge pipe

V - Lar

e 316 SS top plate, oversized 316 SS discharge (GVC and GVT only)

, ODP motor, standard efficiency

, ODP motor, Hostile Duty

, motor enclosure or motor speed

or motor - bare pump only

(when require d)

- 25 HP @ 1750 RPM

e Pipe Arrangement

e pipe), no underliner (GVC & T only)

e pipe), 316 SS underliner (GVC & T only)

e pipe), no underliner

Inlet Pipe and Strainer

A - Zinc plated steel strainer with steel tailpipe

B - 304 SS strainer with 316 SS tailpipe

X - Special strainer and/or tailpipe

Z - No strainer or tailpipe (standard)

* Casing Nozzle and Impeller Sizes containing codes BA through BF and CA through CG have semi-open impellers. Casing Nozzle

and Impeller Sizes containing codes DA through DE and EA through EG have closed impellers.

Figure A. Ordering Codes

3

III. INSTALLATION.

V. OPERATION.

Skilled personnel should install the pump in

accordance with engineering standards. Faulty

installation will result in operating troubles and

premature wear of parts.

The pump and driver should be easily accessed with

enough headroom to perform periodic inspection and

maintenance. The pump should always be

submerged enough to prevent vortexes from forming,

which might allow air to enter the suction.

When pump is supplied with coupling, motor, and

baseplate, the complete set is assembled at Carver

Pump Company. After ascertaining that the unit has

suffered no damage in transit, one may install the

pumping unit. Proceed as follows:

1. Make sure the mounting surface is level.

Attach the base to the mounting surface.

Check that pump rotates freely.

CAUTION

Pipe strain will cause wear and/or damage to

parts.

2. Connect discharge piping. Extreme care

should be taken when connecting new piping

lines to be sure that no foreign matter such

as dirt, chips, tools, etc., is in the piping,

tank, or return piping as the debris will be

drawn into the pump and cause excessive

damage. Any debris caught in the pump

passageways will throw the pumping unit out

of balance.

3. Connect any necessary auxiliary piping and

gauge lines.

4. Since the pumping unit is shipped with

bearings packed, initial greasing will not be

necessary unless pumping unit has been in

storage for an extended period of time (refer

to section II).

5. Turn pump and motor shafts by hand to be

sure they rotate freely.

6. Connect wiring to motor. Due to high voltage

required to operate the pumping unit,

personnel working with the equipment

should be familiar with electrical safety

practices and modern methods of

resuscitation.

7. Connect electrical power supply to motor.

8. Open system valves.

IV. ALIGNMENT.

A flexible coupling connects the pump and motor.

The motor bracket aligns the pump and motor. No

further alignment is necessary.

A. PRESTART CAUTIONS.

1. Before starting or operating the pump, read

this entire manual, especially the following

instructions.

2. Before starting the pump, rotate shaft by

hand to assure all moving parts are free.

3. Before starting the pump, install closed

guards around all exposed rotating parts.

4. Observe all caution or danger tags attached

to the equipment.

5. Never run pump dry. Dry running may result

in pump seizure.

6. If excessive vibration or noise occurs during

operation, shut the pump down and consult a

Carver representative.

7. Use of a check valve in discharge piping is

recommended if there is a high volume of

reverse flow.

8. Check level in tank to see that the pump is

submerged in fluid.

B. STARTING THE PUMP. The pumping unit will

operate without operator intervention once system

valves have been adjusted to the specified pumping

conditions. The casing of the pump will be submerged

in the fluid being pumped, thus rendering it selfpriming. Proceed with operation as follows:

1. Make sure no one is working on the pumping

unit.

2. If the pumping unit has been idle for a period

of time, make sure unit is firmly attached to

its foundation.

3. Open valves to pressure gauges in system.

CAUTION

Check level of liquid in tank to be sure

casing is under liquid level.

4. Jog starter switch on motor to check

direction of rotation. Direction of rotation is

clockwise from fan end of motor.

5. Partially open discharge valve.

6. Start the pumping unit in accordance with

the directions on the electrical power supply.

7. Slowly adjust discharge valve to operating

condition required.

8. Pumping unit is now in full operation.

C. STOPPING THE PUMP. To stop the pump,

use the following process:

1. If pump is being stopped for overhaul, slowly

close the discharge valve. Otherwise leave

discharge valve set at condition.

2. Stop the pumping unit in accordance with the

directions on the electrical power supply.

3. If the pump is being stopped for overhaul,

close pressure gauge valves.

4

4. The pumping unit is now in the off position.

VI. MAINTENANCE.

Generally, the pump does not require continuous

supervision. Occasional visual checks are

recommended. Data should be recorded for each

pump to keep track of maintenance, which has been

performed and note operational problems. A pump

service record page is provided for this purpose in the

front matter of this manual.

Before disassembly/assembly, review Table A,

Torque Values to avoid equipment damage and injury

to personnel.

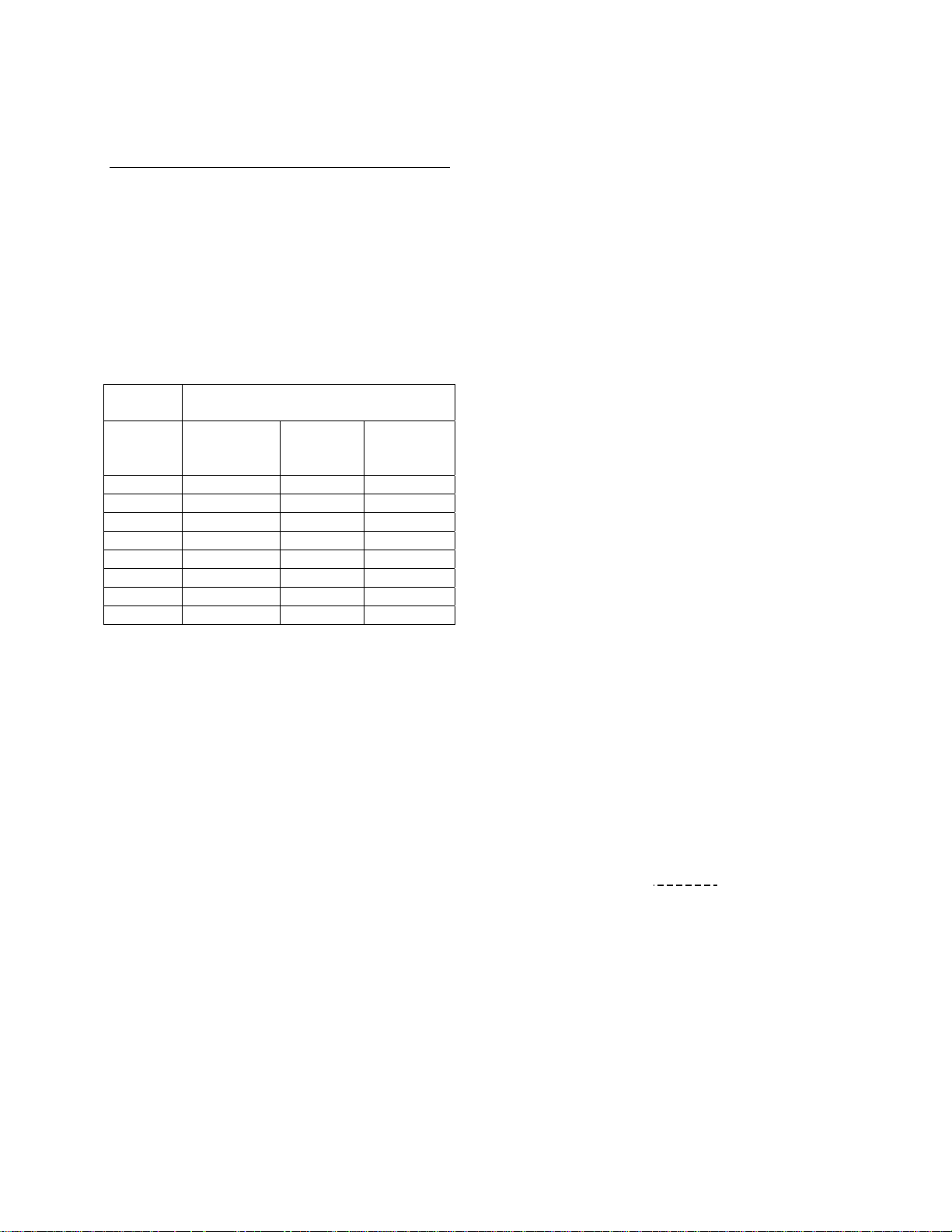

Table A. Recommended Torque Values (ft-lbs)

Bolt

Size

Composite

¼”-20 5 5 7

5/16”-18 11 11 12

3/8”-16 18 18 21

½”-13 33 39 45

5/8”-11 54 83 97

¾”-10 80 105 132

7/8”-9 109 160 203

1”-8 144 236 300

A. FIELD INSPECTION. Shutdown is not

required. Perform field inspection at regular intervals

and cover the following procedures:

1. Check and record the suction and discharge

pressures to establish differential head. It

should conform to the pump nameplate.

2. Check and record the power input and speed

of the driver.

3. Check and record pumping temperatures.

4. Check pump for quiet running.

B. STUFFING BOX. The stuffing box is equipped

with a throttle bushing which requires no regular

maintenance. The inside diameter of the throttle

bushing will increase with wear. The throttle bushing

should be inspected after pump disassembly. The

throttle bushing requires replacement if the inside

diameter is more than 0.020 inch out of round.

C. BEARING TEMPERATURE. Bearing

temperature should be monitored periodically. Normal

operating temperatures are 120 degrees F to 160

degrees F, depending on the ambient temperature.

Bearings may appear to run hot when pump is first

started. This is caused by the shaft seal, not the

bearing. When the seal is seated, temperature should

drop to normal.

Material

Steel (or

otherwise

noted)

316

Stainless

Steel

Check bearing temperature by placing a pyrometer

against the bearing frame while pump is running. A

temperature rise above 180 degrees F indicates

possible damage that requires checking. The most

common cause of high bearing temperatures is

overgreased bearings.

D. BEARING LUBRICATION. Lubrication

frequency depends on operating conditions. Normal

duty calls for relubrication every 1000 hours of

operation. Bearings are lubricated at Carver Pump

Company with Amoco Rykon Premium Grease No.

2EP, non-soap, polyurea thickened grease with a

drop point of 450 degrees F. This grease was

selected due to its suitability to extreme pressures

and its high temperature stability. Never mix greases

with differing properties.

Polyurea base greases are NOT compatible with

lithium or soda soap base greases. Therefore, the

type of grease added should not vary. However, if it is

necessary to change grease types, the bearings,

bearing frame, and bearing cap/cartridge should be

thoroughly cleaned and flushed with suitable solvent

to remove all traces of old grease. Disassemble

pump, remove shaft and bearings from bearing frame,

and follow these procedures:

1. Place bearings, bearing frame, and

bearing cap/cartridge in a wire or mesh

basket and suspend the basket in a light

mineral solvent. Allow it to soak,

preferably overnight.

2. After soaking and cleaning, the bearings,

bearing frame, and bearing cap/cartridge

should be rinsed in a clean, light mineral

solvent and agitated vigorously to remove all

loosened hard grease and dirt.

3. Dip bearings in clean, light oil and spin by

hand to determine that all foreign matter has

been removed.

4. After cleaning, repack bearings half full on

both sides with a good quality ball bearing

grease.

To relubricate bearings use the following procedure:

CAUTION

Overgreasing creates heat and is the cause

of many problems requiring repair. DO NOT

OVERGREASE.

1. Never relubricate pump bearings while unit is

running. If necessary, shut down pump

according to section V, paragraph C.

2. Remove plugs opposite grease fittings on

both ends of bearing frame.

5

Loading...

Loading...