Carver 2157 MONTEGO, 2557 MONTEGO, 2357 MONTEGO, 2767 SANTEGO, 2587 ALLEGRA Owner's Manual

...

r-

i.

'

~~"~".~

SEPTEMBER 1988

MODELS

2157 MONTEGO

2357 MONTEGO

2557 MONTEGO

2587 ALLEGRA

2757 MONTEGO

, 2767 SANTEGO

OWNER'S

M'ANUAL·

.,---

:,.......--....

..

OMSB

~~~~~~"

CARVER----,

~

"

~rver

Boat, Corporation

.,fSula'ski,

WI

54162-1010

TABLE OF CONTENTS

SECTION DESCRIPTION

PAGE

SECTION

A·

WARRANTY & SERVICE INFORMATION

A-1

CARVER WARRANTY POLICY ....................................................................................

A1

A-2 PRE-DELIVERY SERVICE ........................ , ...................................................................

A1

A-3

WARRANTY INFORMATION ........................................................................................

A1

A-4 SECOND OWNER REGISTRATION ..............................................................................

A1

SECTION B • ENGINES & DRIVE SYSTEMS

B-1

GENERAL .................. , ...................................................................................................

B1

B-2 ENGINE EXHAUST .............~ ..........................................................................................

81

B-3

STERN DRIVE SYSTEMS ............................................................................................

B2

B-4 ENGINE COOLING SYSTEMS ......................................................................................

B2

B-5 PROPELLERS

..

.............. .............. ........ ............................... ............ ......... ............. .......

B3

B-5A

Diameter .................................................................................................................. 83

B-5B Pitch ........................................................................................................................

B3

B-SC

Prop Slip .................................................................................................................. 83

B-6 ENGINE INSTRUMENTATION ...................................................................................... 83

B-6A

Tachometer..............................................................................................................

B4

B-6B

Temperature Gauge ..................... , ..........................................................................

B4

B-6C

Oil Pressure Gauge .................................................................................................. 84

B-6D

Voltmeter.. ........ ..... ........ ...... ................ ........................................ ...................... .......

B4

8-6E

Fuel Gauge ............................................................................................................... 84

8-6F

Power Trim Gauge .................................................................................................. 84

B-6G

Engine Alarm Systems ........................................................................... .................

84

8-6H

Engine Synchronizer ................................................................................................ 84

B-61

Instrument Maintenance ..........................................................................................

B4

SECTION C • CONTROL SYSTEMS

C-1

GENERAL

..

: ...................................................................................................................

C1

C-2 CONTROL OPERATION ................................................................................................

'C1

C-3 NEUTRAL SAFETY SWITCH ......................................................................... :

..

: ...........

C1

C-4 DUAL STATION CONTROLS ........................................................................................

C1

C-5 CONTROL SYSTEM MAINTENANCE ............................................................................

C1

SECTION 0 • STEERING SYSTEMS

D-1

GENERAL ......................................................................................................................

D1

D-1

A Mechanical Steering .... ............................................................................................

D1

D-18 Hydraulic Steering............................. ............ ...........................................................

D1

D-2 OUTDRIVE POSITION INDICATOR .............................. : ...............................................

D1

D-3

PROPELLER TORQUE ............................................................... , ..................................

D1

D-4 POWER STEERIt'ltG .............................. ............. ............. ............ ...................

...

............

D1

D-5

POWER STEERING MAINTENANCE ............................................................................

D2

SECTION E • ELECTRICAL SYSTEMS

E-1

GENERAL ......................................................................................................................

E1

E-2 BATTERY SYSTEMS ....................................................................................................

E1

E-2A Single Battery Systems ............. .......... ............. .............. ............... ...........................

E1

OMSB

CARVER

E-2A1 Installation ..........................................................................................................

E1

E-2A2

Operation ..........................................................................................................

E1

E-2B Dual Battery Systems ................. ...................... ...... .................... .............................

E1

E-2B1

Installation ..........................................................................................................

E1

E-2B2

Operation ...... ............................. ..... ........... ....................................................... E2

E-3

BATTERY SYSTEM MAINTENANCE ............................................................................ E2

E-4 VOLTMETER USE

& OPERATION ................................................................................ E2

E-5

12

VOLT

ELECTRICAL EQUIPMENT ............................................................................ E3

E-5A Helm Equipment .......................................... ............................................................

E3

E-5B Interior Equipment .................................................................................................... E4

E-5C Head Electrical Equipment.............. ................................ .......................................... E4

E-5D Installation of Additional 12 Volt Equipment .............................................................. E4

120

VOLT

ELECTRICALSYSTEM ...................... ............................................................ E4

E-7 DOCKSIDE ELECTRICAL

SYSTEM

.............................................................................. E4

E-8

120

VOLT

DOCKSIDE OPERATION ............................................................................. .

E-8A

General .................................................................................................................... E5

E-8B

Shore Power Connections .................................. ........... ........................................... E5

E-8C Polarity Indicator ........................................... ............... ............................................ E6

E-9

ELECTRICAL SYSTEM MAINTENANCE ........................................................................ E6

E-10

ELECTROLYSIS

& CORROSION .................................................................................. E6

OA

Electrolysis .............................................................................................................. E6

E-10B

Galvanic Corrosion .......... .......................................................................................

.E6

SECTION

F·

FUEL SYSTEMS

F-1

GASOLINE FUEL

SYSTEMS

........................................................................................

F1

F-1

A System Testing ........................................................................................................

F1

F-1

B Fuel Fills ............. ........ ................... ............................. ........................... ....... .... .......

F1

F-1C Fuel Vents .......................................................................................... : ......................

F1

F-i

D Anti-Syphon Valves ..................................................................................................

F1

F-1

E Fuel Gauge ..............................................................................................................

F1

F-i

F Fuel Filters ..............................................................................................................

Fi

F-i

G Use and Maintenance ..............................................................................................

F1

F-i

H Fume Detector .......................................................................................................... F2

F-2 FUELING INSTRUCTIONS ............................................................................................ F2

SECTION G • WATER SYSTEMS

G-1

GENERAL ......................................................................................................................

G1

. G-2 PRESSURIZED WATER SYSTEM ................................................................................

G1

G-2A

Water

Supply Tanks ................................................................................................

Gi

G-2B Priming the System ..................................................................................................

G1

G-2C System Operation ....................................................................................................

Gi

G-2D Water Heating Systems ......................................................... ; ................................... G2

G-2E

Shower .................................................................................................................... G2

G-3

WATER SYSTEM MAINTENANCE ................................................................................

G2

G-4

COCKPIT

WASHDOWN ...................................................... : .........................................

G2

SECTION

H·

VENTILATION & DRAINAGE

H-1

ENGINE

COMPARTMENT

VENTILATION ....................................................................

Hi

H-1A Gravity Ventilation System

..~ .....................................................................................

Hi

H-iB

Forced Air Ventilation ............................................................................................

:.

Hi

H-1C Engine Compartment Ventilation Maintenance ..........................................................

Hi

H-2

CABIN VENTILATION ....................................................................................................

Hi

H-3

HULL DRAINAGE SYSTEMS ........................................................................................

Hi

OMSB

CARVER

2

H-3A Garboard Drain ........................................................................................................

H1

H-3B

Bilge Pumps ............................. , ............................................................................... H2

H-3C

Bilge Compartment Drainage.................................................................................... H2

SECTION I • INTERIOR EQUIPMENT

i-1

HEADS

1-1

A Self-Contained Head.......... ............... .......................................................................

11

1-1

B Manually-Operated Head ..........................................................................................

11

1-1

C Electric Head ............................................................... ;........... ............ ............. ........

11

1-1

D Crown Electric Head ................................................................................................

11

1-1

E Auxiliary Holding Tank ..............................................................................................

11

1-2

REFRIGERATORS ........................................................................................................

12

1-3

STOVES ..................... .................... ................................................................ ........... ....

12

1-3A

Alcohol Stoves ....................... ........................................................................... ......

12

1-3B

Alcohol/Electric Stoves ........................... : ................................................................

12

1-4

STEREO EQUIPMENT ..................................................................................................

12

1-5

AIR CONDITIONING ......................................................................................................

12

SECTION J • EXTERIOR &

~AFETY

EQUIPMENT

J-1

SPOTLIGHT ..................................................................................................................

J1

J-S

TRIM TABS ....................................................................................................................

J1

J-SA

Operation .................................................................................................................

J1

J-SB

Correct Usage ............................................................................ : .............................

J2

J-B

RAILS & DECK HARDWARE ........................................................................................ J2

J-2

COMPASS ....................................................................................................................

J1

J-3

ENGINE HOUR METER .................................................................................................

J1

J-4 DEPTH SOUNDERS ......................................................................................................

J1

J·4A 21,

23 & 2S

Foot Models ...........................................................................................

J1

J·4B

27 Foot Models ........................................................................................................

J1

J-7

SWIM PLATFORMS ...................................................................................................... J3

J-8

BOW PULPITS .............................................................................................................. J3

J-9

FIRE EXTINGUISHER SYSTEM .................................................................................... J3

SECTION K • SEATING

&WEATHER COVERS

K-1

V-BERTH FILLER CUSHIONS ......................................................................................

K1

K-S

DRAPERIES & WINDOW COVERS ......................... ............. .................... ............. ....... K2

K-B

CARVER WEATHER COVERS ............... ........................... ......... .......................... .........

K2

K·2

DINETIE

BERTHS .......................................................................................................

,:

K1

K-3 CONVERTIBLE STERN SEATS ....................................................................................

K1

K-4 UPHOLSTERY MAINTENANCE ..................... .............. ............. ...................... ........... ....

K1

K-4A Exterior Upholstery ..................................................................................................

K1

K-4B Interior Upholstery .............. ................ ................... .................. ........ .........................

K1

K-4C Upholstery Replacement ...........................................................................................

K1

K-4D Exterior Carpets ......................................... ; ............................................................

K1

K-4E Interior Carpets ........................................................................................................

K1

K-7 WINTER STORAGE COVERS ..................................... ' ....................................... , .........

K3

SECTION L • FIBERGLASS

HULL

&COMPONENTS

L-1

GENERAL ...................................................................................................................... L1

L-S

HULL SUPPORT ..................................................... : ......................................................

L2

L-B

FIBERGLASS REPAIRS ........ : ....................................................................................... L2

L-2 FIBERGLASS COMPONENT CONSTRUCTION ... : ........................................................ L

1

L-3 ADDITIONAL EQUIPMENT INSTALLATION

..

; ............. ~ ................................................. L1

L-4 FIBERGLASS CARE .........................

~........

....................... ............... .......... .................... L1

OMSB

CARVER

3

"------------

-~~---.,,-~-

.~.----~-..~--""-.-",,"-----.,,--

---

SECTION M • WOODWORK CARE &MAINTENANCE

M-1

TEAK

CARE

& MAINTENANCE ....................................................................................

M1

M-2

DECRAGARD

CARE

& MAINTENANCE ........................................................................

M1

M-3

HIGH-PRESSURE LAMINATE CARE ............................................................................

M1

M-4

PLEXIGLASS

CARE

......................................................................................................

M1

M-5

DASH

PANELS

...

: ..........................................................................................................

M1

SECTION N • GENERAL MAINTENANCE

N-1

PRIOR

TO

LIFTING

FOR

WINTER LAY-UP ..................................................................

N1

N-2 AFTER LIFTING ............................................................................................................

N1

N-3

PRIOR

TO

WINTER STORAGE ....................................................................................

N1

SECTION

O·

OPERATION

0-1 GENERAL ...................................................................................................................... 01

0-2

COMPONENT SYSTEMS .............................................................................................. 01

0-3

SAFETY EQUIPMENT .................................................................................................. 01

0-4

RULES

OF

THE

ROAD

.................................................................................................. 01

0-5

PRE-CRUISE SYSTEM

CHECK

.................................................................................... 01

0-5A Before Starting the Engine ....................................................................................... :

01

0-5B After Starting the Engine ......... .............................. ............ ....................................... 01

0-6

GROUNDING & TOWING ..............................................................................................

02

0-7

GLOSSARy................. ......... ........................... ....................................... ........................

02

OMSB

CARVER

4

I

f'.

(

(

'-

/ '

J

.

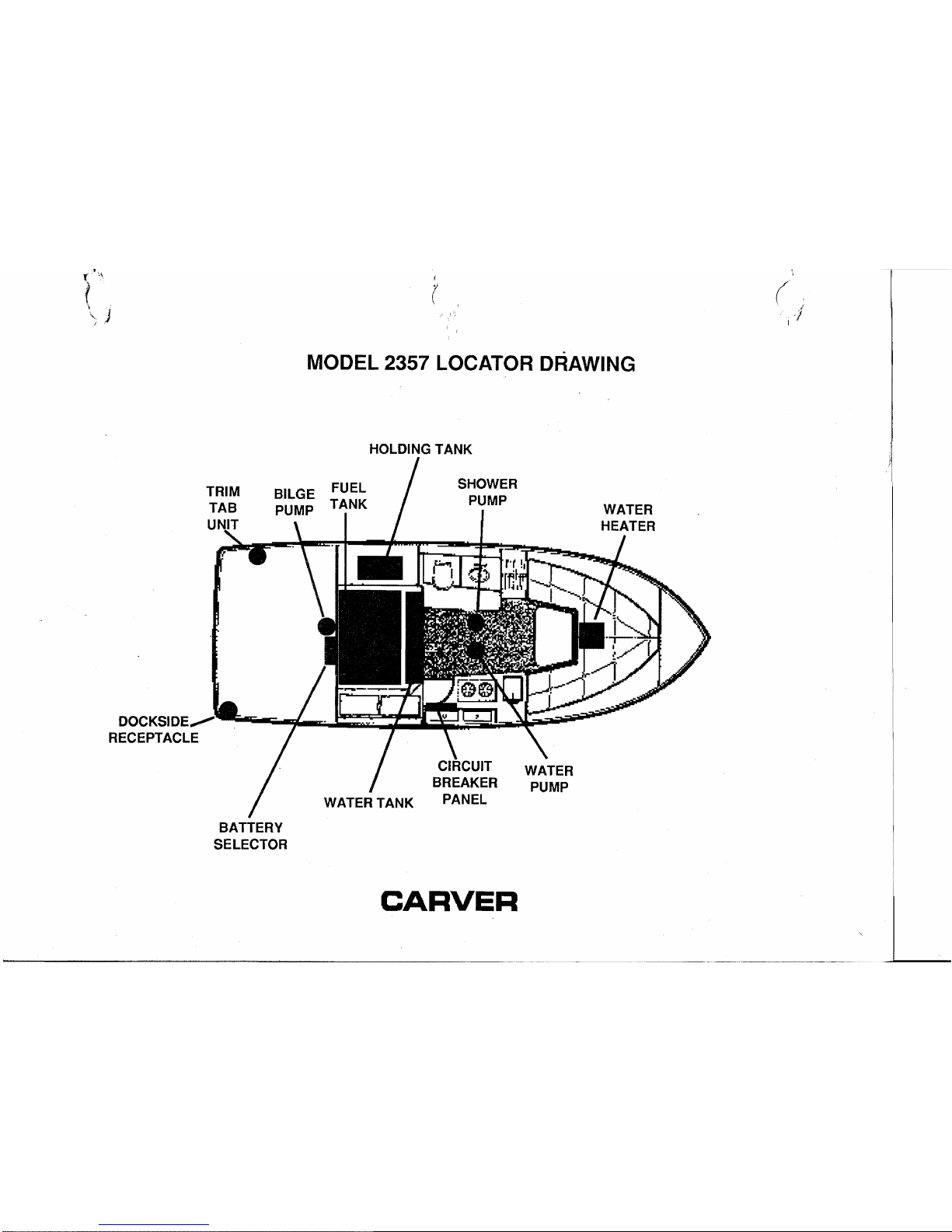

MODEL 2357 LOCATOR DRAWING

HOLDING

TANK

DOCKSI

RECEPTACLE

FUEL

TANK

SHOWER

PUMP

CIRCUIT

BREAKER

PANEL

BATTERY

SELECTOR

CARVER

ENGINES

& DRIVE

SYSTEMS

B-1

GENERAL

Carver Boat Corporation does not manufacture engines, stern drives or v-drives. These components are

built by manufacturers that are specialists in this field.

Because

of

the technica I nature of the engine and drive

systems, all manufacturers

of

these items require that

warranty and service problems be taken directly to

them for resolution. The Service Department of Carver

Boat Corporation stands ready to assist boat owners

when communicating with the manufacturers of engines and drive systems. Prior to contacting the Carver

Service Department, thoroughly review any problem

with your Carver dealer.

In

compliance with the Federal Safe Boating Act

of

1971, all engine manufacturers require their products to

be registered. A registration card

is

furnished with each

new engine. When selling a Carver boat, the dealer,

along with the purchaser, should complete the information requested on these cards and return them to the

respective engine manufacturer. (Engine registration

cards can be found in this manual).

Most manufacturers

of

the various marine power

components used

in

these boats provides an owners

manual with the product. These publications are included with this manual. Read the manual(s) carefully

and become completely familiar with the proper care

and operation of the engine and drive system.

B-2

ENGINE EXHAUST

Do Not inhale exhaust fumes! Exhaust contains carbon

monoxide which is colorless and odorless. Carbon

monoxi(:le

is

a dangerous gas that is potentially lethal.

The

following

suggestions

can

help

prevent

ex-

haust

fumes

from

entering

your

boat:

1.

Do Not allow the boat to remain stationary with the

engines operating for an extended period of time.

2.

Use extreme caution while operating the engines

in

confined areas such as enclosed slips, congested

piers, or

in

any area where the exhau!)t outlets are

facing

or

near a bulkhead or wall structure

of

any kind.

Operation under such conditions could easily lead to

exhaust gasses (carbon monoxide) entering the boat.

even though you may have all the hatches, windows,

doors and portholes closed.

3.

Neveroperatethegeneratorwhiletheboat

is

moored

against any other boat, dock

or

wall structure that

is

against

or

near,the exhaust outlet. Again, operation

under such conditions could easily lead to exhaust

gasses (carbon monoxide) entering the boat orthe boat

to which you are moored, even though you may have all

the hatches, windows, doors, and portholes closed,

4.

Persons sleeping can be easily overcome by carbon

monoxide because they are unaware of its presence.

Sleeping while the engines or generator are running

is

llQ1

recommended. If persons are sleeping aboard while

OMSB

81

CARVER

underway, or while the generator

is

running, those

awake should be extremely watchful for carbon monoxide accumulation in the cabin; especially the sleeping

areas. Open forward facing windows or deck hatches

to provide adequate fresh air ventilation. Keep hatches,

windows, and doorways that face aft or towards the

exhaust discharge closed.

5.

Ventilate your cabin while underway. Open a forward

hatch, porthole, or window to allow

airto

travel through

the cabin. Be very careful of operating the boat with the

cabin door

or

other windows, hatches, or portholes that

face aft, open. The natural vaccuum created during

operation may allow exhaust gasses to be drawn into

the cabin.

6.

Inspect the engines exhaust system frequently.

7.

Have a competent marine engine service technician

inspect the exhaust system whenever the boat

is

in for

service, or

if a change is noted in the sound

of

the

engines.

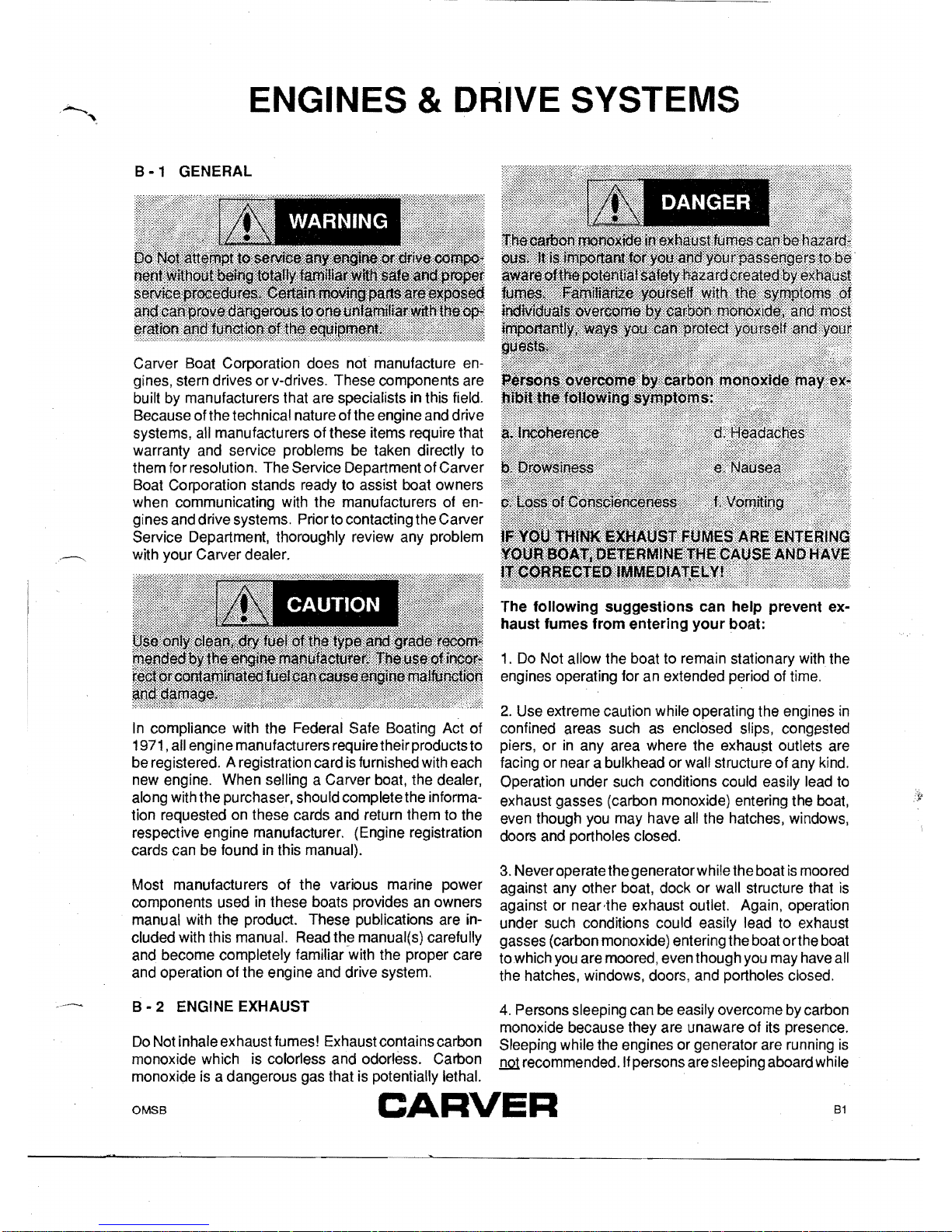

B-3

STERN DRIVE SYSTEMS

A stern drive or inboard/outboard propulsion system

has a piston engine equipped with special marine

components mounted near the transom and coupled to

an

external outdrive type transmission unit.

Thistype

of system

is

depicted in Figure

B1.

Consult the Engine Owners Manual that has been

provided with this manual for additional information

regarding operation and maintenance.

B - 4 ENGINE COOLING SYSTEMS

All marine engines use surface water as a cooling

medium. The cooling water employed enters the system through a water intake and

is

relinquished through

the exhaust manifolding system.

Most stern drive units have the water intake and ex-

haust system incorporated into the outdrive. See the

Engine Owners Manual for additional information.

Installation of "Fresh Water Cooling" provides adequate

engine cooling without exposing the internal engine

cooling system to the detrimental effects of surface

water. Fresh Water Cooling

is

recommended when the

boat will be operated in salt, highly polluted, or silt laden

water. Ask a Carver dealer for recommendations

regarding the necessity of fresh water cooling

in

the

boating area to be used. The Engine Owners Manual

provides additional information regarding service and

maintenance

of

this equipment.

FIGURE

B1

• TYPICAL STERN DRIVE

82

OMS8

CARVER

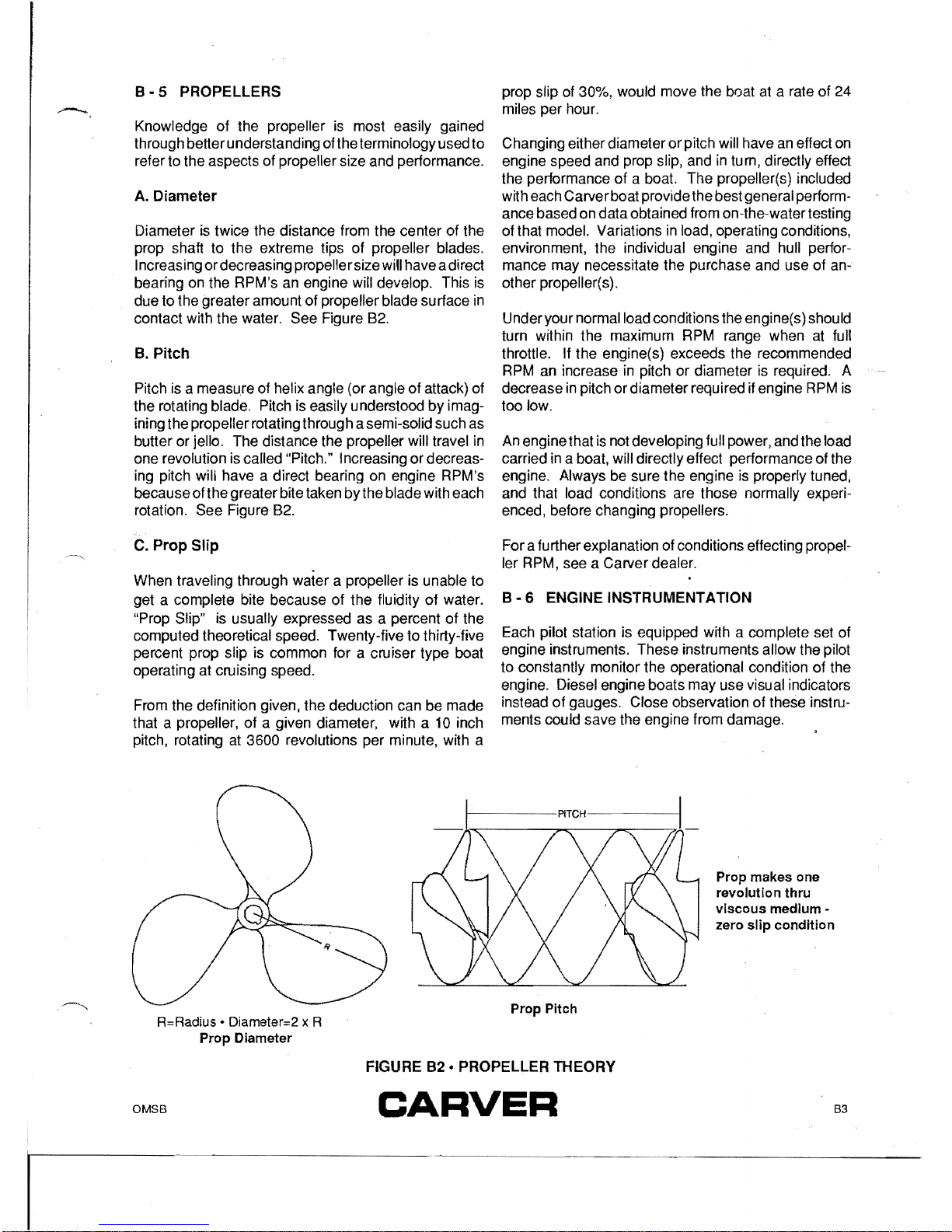

8 - 5 PROPELLERS

Knowledge of the propeller

is

most easily gained

through better understanding of the terminology used

to

refer to the aspects of propeller size and performance.

A.

Diameter

Diameter is twice the distance from the center of the

prop shaft

to

the

extreme tips

of

propeller blades.

I ncreasing or decreasing propelle r size will have a di rect

bearing on the RPM's an engine will develop. This is

due

to

the greater amount of propeller blade su rface in

contact with the water.

See

Figure 82.

8.

Pitch

Pitch is a measure of helix angle (or angle

of

attack) of

the rotating blade. Pitch is easily understood

by

imagining the propeller rotating through a semi-solid such as

butter or jello.

The

distance the propeller will travel in

one revolution is called "Pitch." Increasing

or

decreasing pitch will have a direct bearing on engine RPM's

because of the greater bite taken

by

the blade with each

rotation. See Figure

82.

C.

Prop Slip

When traveling through water a propeller is unable

to

get a complete bite because

of

the fluidity

of

water.

"Prop Slip" is usually expressed as a percent

of

the

computed theoretical speed. Twenty-five to thirty-five

percent prop slip is common for a cruiser type boat

operating at cruising speed.

From the definition given, the deduction can be made

that a

propeller,

of

a given diameter, with a 10 inch

pitch, rotating at 3600 revolutions per minute, with a

prop slip of 30%, would move the boat at a rate of 24

miles per hour.

Changing either diameter

or

pitch will have an effect on

engine speed and prop slip, and in turn, directly effect

the performance of a boat.

The

propeller(s) included

with each Carver boat provide the best general performance based on data obtained from on-the-water testing

of that model. Variations in load, operating conditions,

environment, the individual engine and hull performance may necessitate the purchase and use

of

an-

other propeller(s).

Under your normal load conditions the engine(s) should

turn within the maximum RPM range when at full

throttle.

If the engine(s) exceeds the recommended

RPM an increase in pitch or diameter is required. A

decrease in pitch or diameter required if engine RPM is

too

low.

An engine that is not developing full power, and the load

carried in a boat, will directly effect performance of the

engine. Always be sure

the

engine is properly tuned,

and that load conditions are those normally experienced, before changing propellers.

For a further explanation of conditions effecting propeller RPM, see a Carver dealer.

8 - 6 ENGINE INSTRUMENTATION

Each pilot station is equipped with a complete set of

engine instruments. These instruments allow the pilot

to constantly monitor

the

operational condition of the

engine. Diesel engine boats may use visual indicators

instead

of

gauges. Close observation of these instru-

ments could save the engine from damage.

Prop makes one

revolution thru

viscous

medium -

zero

slip

condition

..

~

R=Radius • Diameter=2 x R

Prop Diameter

Prop Pitch

FIGURE

82

• PROPELLER THEORY

OMSB

B3

CARVER

A.

Tachometer

The Tachometer indicates the speed of the engine

in

revolutions per minute. This speed is not the boat

speed nor necessarily the speed of the propeller. The

Tachometer may not register zero with the Ignition Key

in

the OFF position.

B.

Temperature

Gauge

The temperature gauge monitors the cooling system of

the engine. A sudden increase

in

the temperature cou

Id

be a signal of a blocked cooling passage or a water

pump malfunction.

C.

Oil

Pressure

Gauge

The Oil Pressure Gauge provides an indication of the

pressure

in

the engine lubrication system. A drop

in

oil

pressure

is

a possible indication of oil pump or leakage

problems.

D.

Voltmeter

The voltmeter monitors the battery condition. See Section E for additional information on voltmeter operation.

E.

Fuel

Gauge

The Fuel Gauge displays the level of fuel that

is

present

in

the fuel tank(s). See section E for more detailed

information on fuel gauge operation.

F.

Power

Trim

Gauge

Boats equipped with MerCruiser Stern Drives also have

a "Power Trim Gauge." This gauge provides a visual

indication of the inward-outward position

of

the

outdrive. If the boat is equipped with a second control

station, an optional Power Trim Gauge can

be

added to

that station.

G.

Engine

Alarm

Systems

Engine alarm systems are installed on some models

with specific types of engines. The alarm

is

an audible

alarm that is mounted in the helm area;

it

is

actuated by

engine water temperature and engine oil pressure

senders. The alarm will sound in the event of low engine

oil pressure or high engine water temperature.

. The engine alarm will sound during engine startup, or

whenever the Ignition Switch

is

positioned to

ON

and

the engine is not operating. The alarm sounds under

these conditions because engine oil pressure

is

low; the

alarm will cease to sound as soon as engine oil pressure

rises to the proper level.

IMPORTANT: The engine alarm systems installed

in

these boats monitors only engine water temperature

and engine oil pressure. Always maintain a close visual

watch

on

the drive(s), transmission(s), engine fluid

levels, bilge water level, etc.

H.

Engine

Synchronizer

Most dual engine Carver models can be equipped with

an optional engine synchronizer. This instrument compares the electrical signals generated by the. engines

and converts those signals to a visual meter indication

of engine speed difference. The meter movement

responds to changes in throttfe position. When the

needle

is

centered, the engines are

in

proper synchron-

ization. '

I.

Instrument

Maintenance

Electrical protection for instruments and ignition circuitry is provided by a fuse

or

cirucit breaker on the

instrument panel.

Periodically, spray the Ignition Switch(s) with a contact

cleaner/lubricant such as LPS,

CRCor

WD40. The

B4

OMSB

CARVER

Ignition Switch(s) and

aI/

instruments, controls,

etc.

should be protected from the weather when not

in

use.

Carver offers appropriate weather covers for each

model. Excessive exposure can lead to gauge and

Ignition Switch difficulties.

Electronic gauges are affected by static electricity that

builds-up on the glass face. Periodic washing of the

gauge face with warm water and mild liquid detergent

will help eliminate the static electricity problem and

improve gauge accuracy.

OMSB

85

CARVE'R

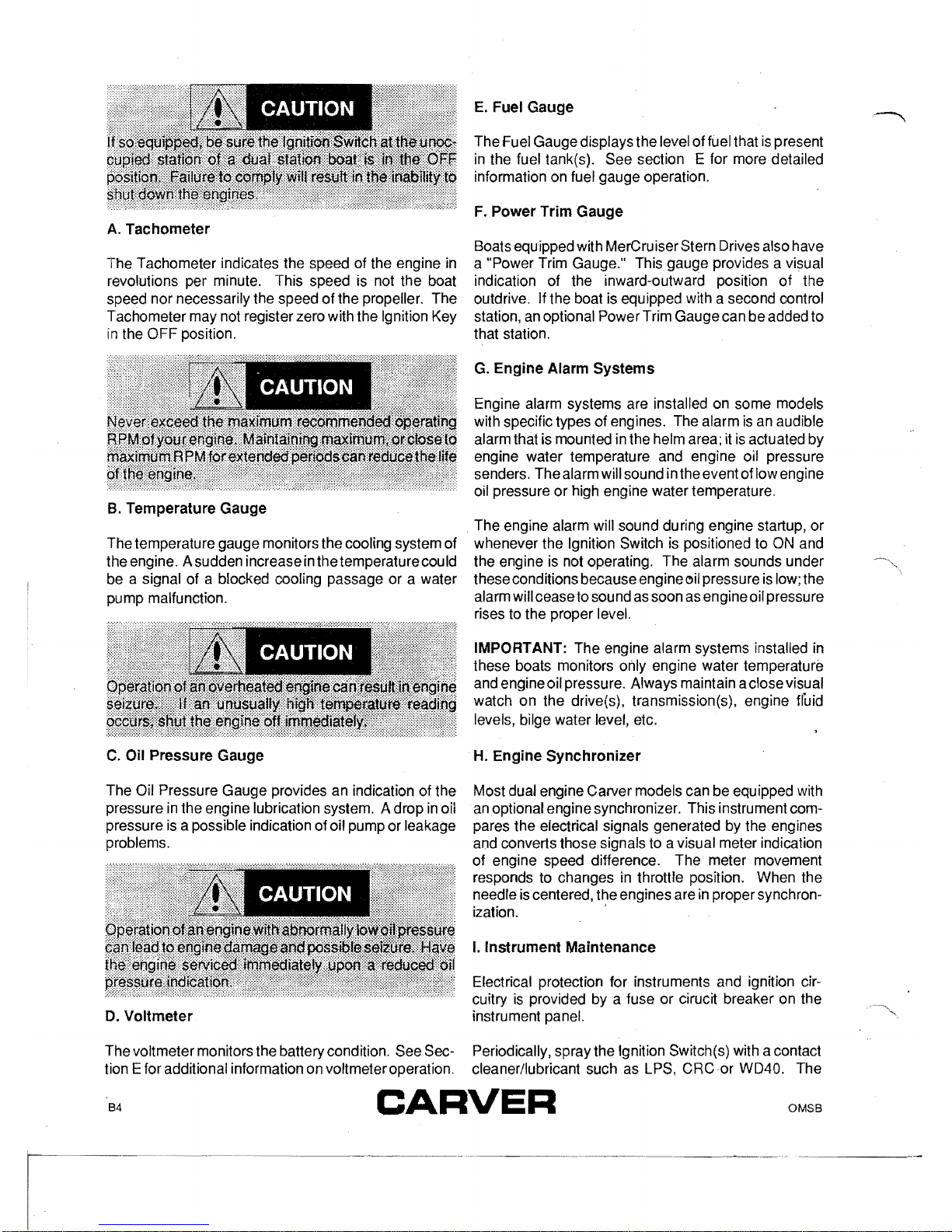

PROPULSION EQUIPMENT

PROP

ENGINES REDUCTION

MODEL

16 X 14

4.3L

MERe

2157 3.7L

MERe

1.84:1

16 X

16

5.7L

MERe

1.84:1

16 X 16

171

VOLVO

1.50:1

16 X 13

205 VOL

va

DUO PROP

2.15:1

8-6

2.3:1

14-1/2 X 17

5.7L

MERe

1.84:1

4.3L

MERe

2357

1.50:1 .

14-1/2 X 17

.

8-5

~

271

VOL

va

DUO PROP

2.3:1

205 VOL

va

DUO PROP

8-5

1.95:1

2557 Single

16 X 16

7.4L

8RAVO

MERe

5.7L

MERe

1.50:1

15-1/2 X 17

RH

SS

271

VOLVO

DUQPROP

1.5:1

8-5

1.95;1

.~-""~-------'-'~---'~--'---.

Twin

13-3/4 X

21

171

VOLVO

1.84:1

3.7L

MERe

16 X

17

2.15:1

Single

2587

5.7L

MERe

1.50:1

.16X16

7.4L

8RAVO

MERe

15-1/2 X 17

RH

SS

271

VOLVO DUO PROP

1.5:1

1.95:1

8-5

TWIN

5.0L

MERe

14 X 19

231

VOLVO DUO PROP

1.5:1

1.95:1

8-6

2757 Single-Gas

8-4

271

VOLVO DUO PROP

1

:95:1

r-'~~-

.......~......

~-

.~-~.

,

3.7L

MERe

Twin-Gas

1.84:1 14 X 19

4.3L

MERe

1.84:1 13-3/4 X 219

171

VOLVO

2.15:1 16 X 15

205 VOL

va

DUO PROP

8-7

2.3:1

---

..

---~.---

...

-----

...

--.~~-~~---~--~.

"--'~-----~---~~---'-

Twin-Diesel

AQAD

31

VOLVO DUO PROP 2:3:1

8-5

2767 Single-Gas

271

VOLVO DUO PROP 1

:95:1

8-3

.------.-------~-

...

------.--.-.

---

Twin-Gas---"--'--'

3.7L

MERe

14 X 17

4.3L

MERe

1.84:1

13-3/4 X

21

171

VOLVO

1.84:1

16 X 15

_~05

V_QLVODUP

PROE_.__.

2.15:1

8-6

2.3:1

Twin-Diesel

8-5

AQAD

31

VOLVO DUO PROP

2:3:1

B6

OMSB

CARVER

Tachometer

c:

III

...

purple

blue

bla

k

purple

ellow/red

:t

.0

..

-

V-drive

011

lender

1--~--4-~P

i

nk

$

-

..

-

red

V-drive

light

$

If.

0 e

qui

p p e d ............

..I..-L-"'-""--I..-L.

....

Engine

Harnel

•

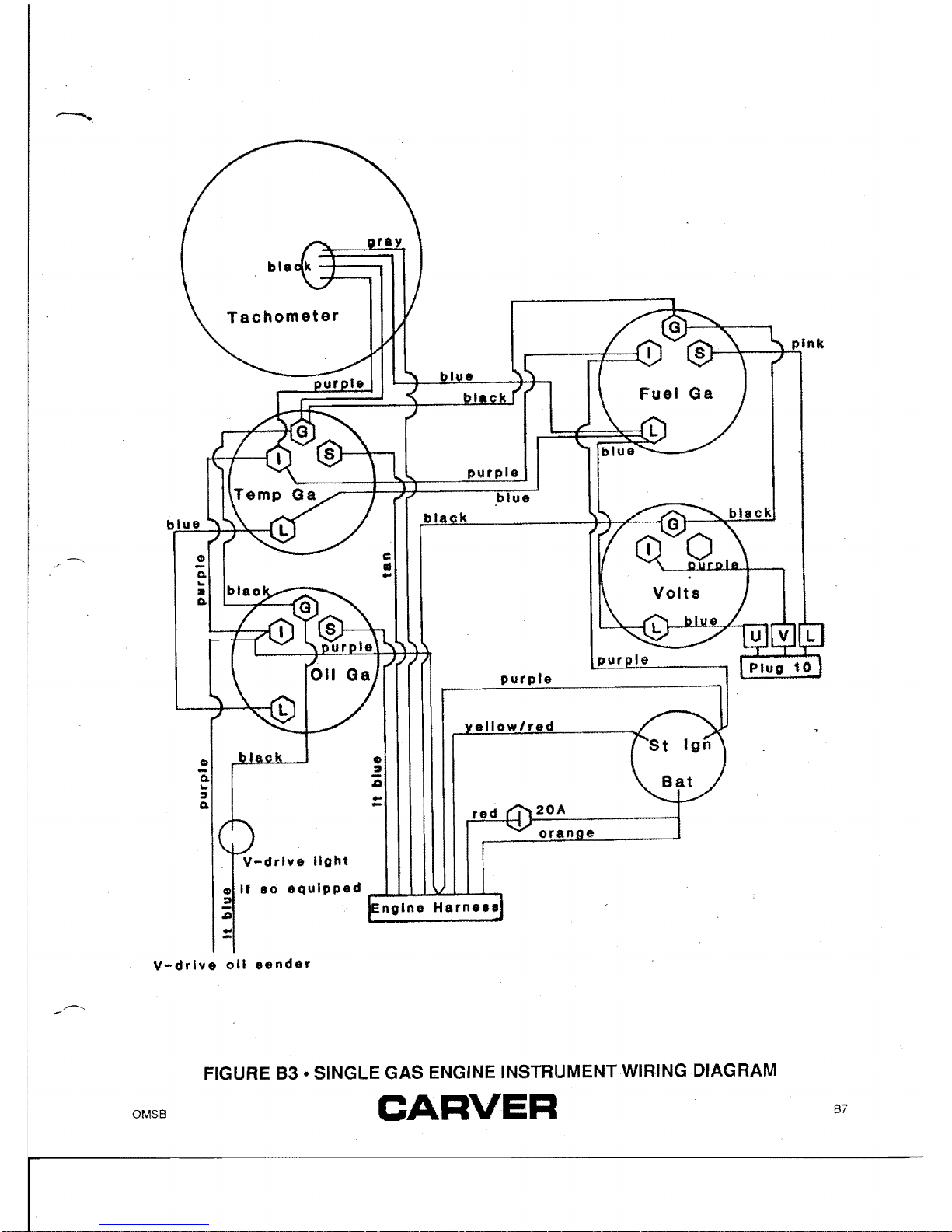

FIGURE

83

• SINGLE GAS ENGINE INSTRUMENT WIRING DIAGRAM

OMS8

CARVER

87

black

black

Tachometer

Tachometer

fIJ

Q.

...

Jtt.

fIJ

if

so

equipped

:)

Q.

Q.

..

U

...

:J

:::II

Q.

•

-

.Q

-

Q

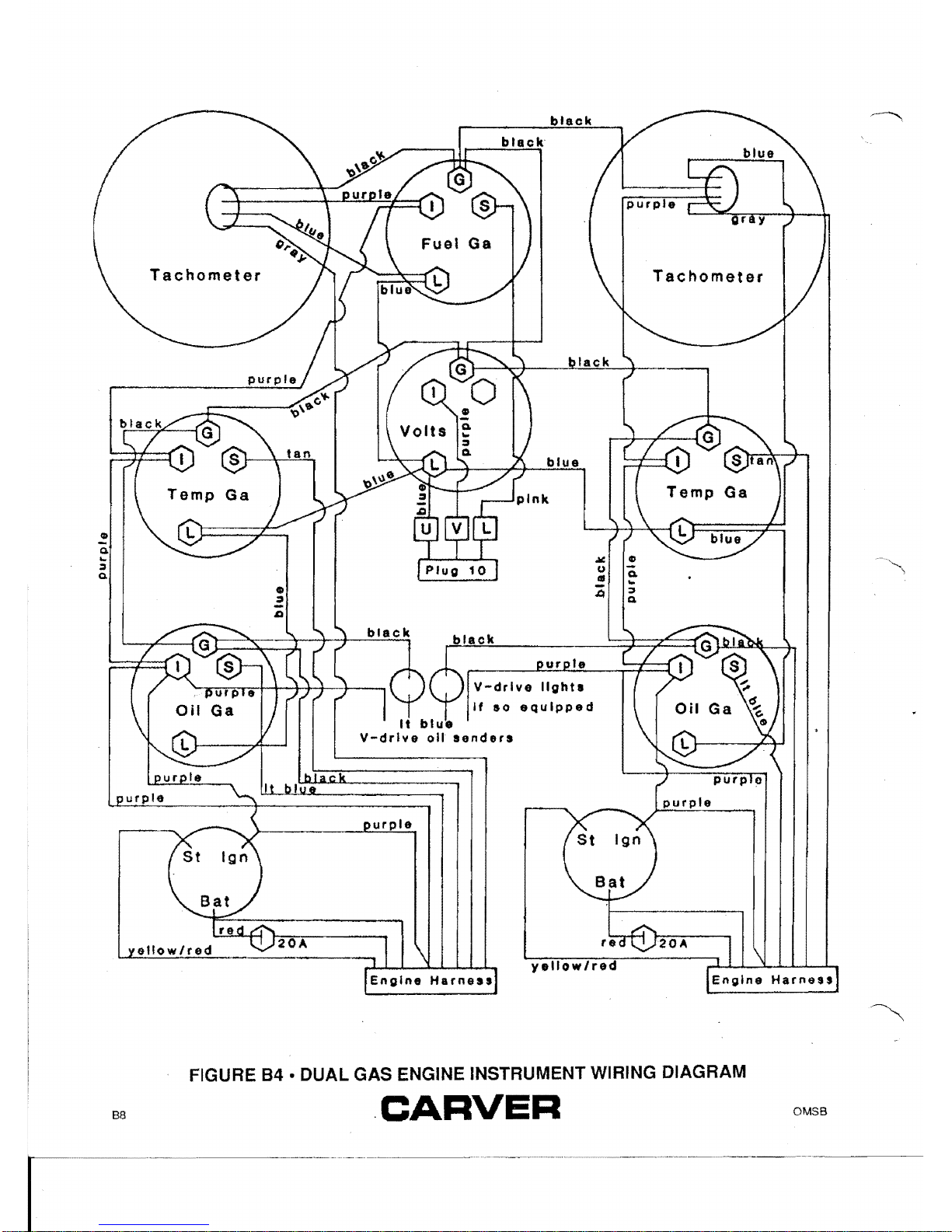

FIGURE

84

• DUAL GAS ENGINE INSTRUMENT WIRING DIAGRAM

OMSB

.

CARVER

88

\

)

)

)

o

:!:

(f)

:!!

OJ

Single

Engine

G)

Dual

Engine

c:

1

JJ

m

[D

01

•

en

z

G)

r-

m

Ro

I

Single

;statron

o

c:

l>

r-

~

<

o

r-

<

0

__

m

z

Abbt"~v.ated

Wirs

CQ(ot"s

~

~

I

I I

'.

---

_4_

.-J

n I

R'

I

--.---:~

~-~

'1

r1\

k

bl

~

=:f!0.:t!

II

~I",

li--1

.

.Ji.

f

I

kl

~

~

Alo".

0i

I

~

"

I:L~

kl-

fn-

.

15

@

;:~"

'@Ke

m

G)

lJ

m

z

z

en

-I

JJ

c:

s:

m

z

-I

§

JJ

Z

G)

o

:.;:

G)

JJ

l>

s:

b'lack-k

bhHJI-b

rcd-r

yeHo'fr-Y

g.f.on-n

whlhl-W

~fay-o

..

ortkng4t""O

o

'"

brown-bn

N"l~:

To

ola.I,

I

turn

kay

1eo

degrEt198

\-

____

t~

.&con~

'ON'

po.i.

~5

-.

I

~

tlon

~

Key

Stop

(I

II " Y

~~~

Stop

DUII11Stalion

I

~

CONTROL SYSTEMS

C-1

GENERAL

The remote control systems which permit operation of

the engine's throttle and shift mechanisms consist of

three major components, the control, the throttle and

the shift cables. The various types of controls and their

operation are discussed in section C-2.

The cables are

all push-pull type. Two cables are

required. One connects the remote throttle control to

the carburetor and the other connects the remote shift

control to the outdrive or transmission shift linkage.

C - 2 CONTROL OPERATION

The various mounting locations, number of control

stations with which the boat is equipped and the type of

engine installed are all important

in

determining the type

of control to be used. Each control is equipped with a

means of permitting the engine to be operated at high

speed while in neutral for cold starting and warm-up

purposes .

.

/'--.

During the general operation of a dual engine boat,

it

is

adventageous both engines should be operated

at

the

same rpm. This reduces noise, and vibration and can

increase engine efficiency. Setting the throttles so the

engines are running the same rpm (synchronized) can

be done by the engine sounds

or

you can purchase

an

instrument (Engine Synchronizer) as described in

Section

B.

Attempting to synchronize the engines

solely by using tachometer readings or control lever

plac~ment

generally will not work. When the engines

are

In

proper synchronization, the throttle levers may

not necessarily be even.

See the information provided by the control manufac-

turer. Details on co ntrol operation and maintenance are

provided therein. Also see the Engine Owners Manual.

C - 3 NEUTRAL SAFETY SWITCH

Every control system has a neutral safety switch incor-

porated into it. This device prohibits the engine from

being started while the shift lever is in position other

than the neutral position.

If

the engine will not start

slight movement of the shift lever may be necessary

t~

locate the neutral position and disengage the safety cutout switch. Control or cable adjustments are required

to correct this condition should it persist.

.See

your

Carver dealer for necessary control and cable adjustments.

C - 4

DUAL

STATION CONTROLS

Boats equipped with a dual station control system utilize

"station-to-station" cables to interconnect the upper

and the lower stations. Due to the added machinery, a

dual station control system

is

inherently stiffer operating

than a single station. This

is

usually more noticeable

at

the upper station.

C - 5 CONTROL SYSTEM MAINTENANCE

Periodic inspections of the control(s), cables, and all

connections should be made. Signs of rust, corrosion,

wear, cable jacket cracks or other deterioration

requ

ire

immediate system servicing. If your unit

is

equipped

with electric shift, inspect the shift wire for fraying,

embrittlement and insulation cracks. Repair

all

noted

deficiencies.

>

Generally, periodic lubrication of all moving parts and

connections with a light, waterproof grease

is

in

order.

Cables can be lubricated by positioning them to their

fullest extension and applying light grease

to

the inner

cable near the jacket. Working the cables back and

forth will distribute the grease

in

the inner cable.

Re-

apply the grease if necessary.

Lubrication should be performed as often

as

necessary

to keep the system operating smoothly. Cable manufacturers such as Teleflex and Morse often offer special

tools to make cable lubrication easier.

Cable and control adjustments may become necessary. Adjustment screws

in

the control, on the cables

and in the linkage are provided.

OMSB

C1

CARVER

r-------------------~---

.........--.......--..

Other lubrication, adjustment and maintenance instructions are included

in

the information provided by the

control manufacturers.

C2

OMSB

CARVER

STEERING SYSTEMS

0-1

GENERAL

A.

Mechanical Steering

Most single station Carver boats use a rack and pinion

type mechanical steering system.

In

this system, a

pinion gear in the steering helm drives a gear rack

attached to the helm end of the steering cable. A rotary

rack is sometimes used. Though the appearance

is

different, the concept is the same. The steering cable

is

of

the push-pull type. As the wheel turns, the pinion

drives the rack which pushes or pulls the steering cable.

The steering cable on a stern drive model connects to

the outdrive steering linkage,

orthe

power steering unit

if so equipped.

B.

Hydraulic Steering

Most dual station Carver models use hydraulic steering.

The Hydrau lic Steering System consists of three major

components: the helm assembly, a pressurized reservoir, and the hydraulic cylinder. The helm assembly

acts as a pump to move the oil through the system. In

many aspects this type of steering is similar to the

mechanical system. Instead of activating a cable,

turning of the helm causes fluid in the hydraulic hoses

toflow

and activate the hydraulic cylinder causing the

rudders

or

outdrive to turn.

As

the wheel

is

rotated, a slight clicking sound may be

noted. This clicking sou

nd

is

the opening and closing of

the valves

in

the helm unit and is normal.

As the steering wheel is turned, the water flow past the

rudders,

or

outdrive, places a load on the steering

system. The effort required to turn the steering wheel

remains constant regardless of speed or outdrive posi-

tion. This

is

an advantage when the boat is "on plane".

The lack of steering effort can

be

a disadvantage at

lower speeds because the effort

is

not reduced to where

it

can turn lock-to-Iock easily.

The torque tab, on stern drive models with hydraulic

steering, must be properly adjusted; see section D-3.

Though the helmsman may not feel propeller torque on

the wheel, an improperly adjusted torque tab can cause

steering difficulties.

For additional information, see the Steering System

Manufacturer's literature that is included with this

manual.

0-2

'OUTDRIVE POSITION INDICATOR

Some Morse helm assemblies are equipped with a

rudder position indicator. This device indicates the

location of the stern drive relative to the straight ahead

position. The position indicator operates mechanically.

Proper adjustment and free operation are essential

if

proper rudder position indications are to be provided.

Periodic lubrication of all moving parts within the rudder

position indicator is necessary

to

maintain smooth

operation.

o -3 PROPELLER TORQUE

Propeller rotation by a single engine installation will

exert a directional force on the steering system. This

action can cause steering to be harder

in

one direction

than the other; this is referred to as propeller torque.

Stern drive units are equipped with an adjustable tab on

the drive unit to compensate for porpeller torque. This

. tab is used to attain a neutral steering condition

at

normal operating speed. When this condition

is

at-

tained, equal force will be required to turn the steering

wheel to both port and starboard. See the Engine

Owners Manual for more data.

Propeller torqu e can also prevent the boat from following a straight line, or to wander when operated at very

low speed. This condition is normal and can be corrected by increasing engine rpm. Wind, water currents

and play at steering conditions can cause equivalent

effects.

0-4

POWER STEERING

Boats equipped with MerCruiserstern drives are, orcan

be, equipped with MerCruiser power steering. This

is

a

"power assist" system and can greatly reduce steering

efforts. However, this system is not a full power

steering system as used in automobiles, some steering

tension remains

in

the system.

Upon commissioning the boat, the system must be

purged of air. Should steering difficulty increase with

OMSB

D1

CARVER

------

..

---

time, additional bleeding ofthe system may be required.

See a dealer; adjustments on a power steering unit

must be performed by a qualified service technician.

Proper power steering fluid level must be maintained.

See the information provided by the power steering

manufacturer for additional information.

D - 5 POWER STEERING MAINTENANCE

Make a periodic inspection of

all

steering cables, link-

age and helm assemblies. Immediately correct signs of

corrosion, cracking, loosening

of

fastenings, excessive

wear, or deterioration. Failure to

do

so could lead to

steering system failure and loss of control.

Adjust the

helm and cable assembly so that the system

is

centered with the rudders

or

outdrive in the straight

ahead position. The steering wheel should be able to be

rotated an equal number of turns to port and starboard

from the straight ahead position. If adjustment becomes necessary, see your Carver dealer.

All

cables, helm assemblies, and steering connections

should be periodically lubricated with a light, waterproof

grease. See the manufacturers information provided

with this manual.

Hydraulic steering systems must have

all air purged

from system periodically. Some hydraulic steering

systems must be pressurized to achieve optimum

operation. These systems usually require 20-30 psi

pressure. Review the information provide(j

by

the

hydraulic steering manufacturer for proper system

specifications and details regarding system service and

maintenance.

OMSB

D2

CARVER

ELECTRICAL SYSTEMS

E-1

GENERAL

All electrical equipment

on

Carver boats operates on

either 12 volt

DC

or 120 volt (220 volts on 50 Hertz

models) AC electrical power. An understanding of the

systems and their operation can be easily gained

through a study of the major components which

comprise the electrical circuitry. Section E describes the 12

volt system and the related operation. Also

in

Section E

is

a description of the 120 (220) volt system.

E - 2

BATTERY

SYSTEMS

A

Single

Battery

Systems

A 1

Installation

A single 12 volt

DC

battery

is

standard equipment on

certain models. A Battery Selector Switch (see the

Locator Drawing

in

Section 0 for the exact location

of

the Battery Selector Switch) is provided on models with

2 batteries.

Connect the battery

in

the following manner:

1. Connect the red battery cable from the Battery

Selector Switch to the positive

(+) terminal of the

battery.

2. Connect the black cable from the engine to the

negative (-) battery terminal.

3. Also connect the black lead from the power trim

pump, if so equipped, to the negative

(-)

battery termi-

nal.

4.

Other black leads for 12 voltequipment, such as

those labelled A, A

1,

and AD, must also be connected

to

the negative (-) battery terminal.

A2

Operation

All factory installed 12 volt equipment, except for the

automatic bilge pumps and

the

voltmeter, are con-

nected to and controlled by the Battery Selector Switch

or

the main circuit protection device (either fuse

or

circuit breaker).

The OFF position of the Battery Selector Switch will

completely shut off 12 volt electrical power. The only

exceptions are the voltmeter (described in Section

E)

and automatic bilge pump (described in Section E).

Always turn the Battery Selector Switch to the OFF

position

or

place the main circuit breaker

in

the OFF

position when the boat

is

left unattended for an ex-

tended period.

Positioning the Battery Selector Switch to the

#1

posi-

tion will provide power to the 12 volt electrical system.

In single battery installations, the

#2

position of the

Battery Selector Switch is not functional.

I NPORT A NT: Extended use

of

12 volt equ ipment with-

out operating the engine

or

charging the battery cou

Id

seriously damage the battery.

B Dual

Battery

Systems

B1

Installation

The Battery Selector Switch (see the Locator Drawing

in

Section 0 for the exact location

o.f

the Battery

Selector Switch) that

is

provided

on

models with two

batteries enables

DC

power to be used from either

or

both batteries.

When installing the batteries, proceed as follows:

1.

Connect each

of

the two red cables leading from the

Battery Selector Switch to the positive (+) terminal on

each

of

the two batteries.

2.

Connect each of the black cables from the engine to

each

of

the negative (-) battery terminals. On dual

engine boats there will be one black cable coming from

each engine. Single engine boats will have two black

cables coming from one engine. Any black leads for the

power trim pump, etc. must also be connected to the

negative

(-)

battery terminal.

OMSB

E1

CARVER

Loading...

Loading...