Carrier 50BV020-064 User Manual

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Catalog No. 04-53500001-01 Printed in U.S.A. Form 50BV-3SI Pg 1 10-08 Replaces: 50BV-2SI

Installation, Start-Up and

Service Instructions

CONTENTS

Page

SAFETY CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . .1,2

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

MAJOR SYSTEM COMPONENTS . . . . . . . . . . . . . . . . . 2

Constant Volume (CV) Units. . . . . . . . . . . . . . . . . . . . . . 2

Variable Air Volume (VAV) Units . . . . . . . . . . . . . . . . . . 2

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-30

Step 1 — Complete Pre-Installation Checks . . . . . . 3

• EXAMINE THE UNIT

• UNIT STORAGE

• MODULAR UNITS

Step 2 — Rig and Place Unit . . . . . . . . . . . . . . . . . . . . . 3

• REMOVE PACKAGING

• UNIT LOCATION

• UNIT PLACEMENT

• ACOUSTICAL CONSIDERATIONS

• ASSEMBLING MODULAR UNITS

Step 3 — Install Ductwork. . . . . . . . . . . . . . . . . . . . . . . 19

• DUCT STATIC PRESSURE PROBE AND TUBING

( VAV O nl y)

• DUCT HIGH-STATIC (DHS) LIMIT SWITCH (VAV Only)

Step 4 — Make Piping Connections . . . . . . . . . . . . . 21

• CONDENSER WATER PIPING (Water-Cooled Only)

• EVAPORATOR CONDENSATE DRAIN

• HOT WATER HEATING COIL (Optional)

• WATER ECONOMIZER (Optional)

• REMOTE REFRIGERANT PIPING

(Remote Air-Cooled Only)

Step 5 — Complete Electrical Connections. . . . . . 24

• POWER WIRING

• CONTROL WIRING (CV Only)

• REMOTE CONDENSER FAN CONTACTOR WIRING

• CONTROL WIRING (VAV Only)

• SUPPLY AIR TEMPERATURE SENSOR (SAT)

• SMOKE DETECTOR/FIRE ALARM SHUTDOWN (FSD)

• ALARM (ALARM) AND WARNING (WARN) OUTPUTS

• REMOTE OCCUPANCY (ROCC)

• RETURN AIR TEMPERATURE SENSOR (RAS)

START-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-48

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

• CRANKCASE HEATERS

• CONFIRM THE INPUT POWER PHASE SEQUENCE

• INTERNAL WIRING

• RETURN-AIR FILTERS

• COMPRESSOR MOUNTING

• REFRIGERANT SERVICE PORTS

CV Unit Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

• EVAPORATOR FAN

•COOLING

• HEATING (Heat Pump Units Only)

VAV Unit Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

• PERFORM AUTOMATIC RUN TEST

•CHECK VFD

• POWER UP LID DISPLAY

Page

• LOG ON TO THE LID DISPLAY

• CHANGE THE DEFAULT PASSWORD

• SET THE CLOCK

• CONFIGURE SCHEDULES

• PROGRAM SET POINTS

• CHECK SYSTEM PARAMETERS

• DISPLAY ALARM HISTORY

• CONFIGURE THE CUSTOM PROGRAMMING

SELECTIONS

• SET CONTROLLER ADDRESS

• LOG OFF FROM THE CONTROLLER

Sequence of Operation (CV Only) . . . . . . . . . . . . . . . 47

• WATER ECONOMIZER COOLING

Sequence of Operation (VAV Only) . . . . . . . . . . . . . . 48

• SUPPLY FAN

• COMPRESSOR COOLING

• WATER ECONOMIZER COOLING

• COOLING RESET

Diagnostic Features (CV Only) . . . . . . . . . . . . . . . . . . 48

VAV Control and VFD Diagnostics. . . . . . . . . . . . . . . 48

SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Compressor Rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Fan Motor Replacement. . . . . . . . . . . . . . . . . . . . . . . . . 49

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49-51

Cleaning Unit Exterior. . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Coil Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Air Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Condensate Drains. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Water-Cooled Condensers . . . . . . . . . . . . . . . . . . . . . . 49

• GRAVITY FLOW METHOD

• FORCED CIRCULATION METHOD

Fan Motor Lubrication. . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Fan Bearing Lubrication . . . . . . . . . . . . . . . . . . . . . . . . 50

Fan Sheaves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

•ALIGNMENT

Evaporator Fan Performance Adjustment . . . . . . . 51

• BELT TENSION ADJUSTMENT

Charging the System. . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

• REMOTE AIR-COOLED UNITS

Compressor Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . 51-65

Forcing and Clearing an Input or Output

(VAV only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

START-UP CHECKLIST . . . . . . . . . . . . . . . . . . .CL-1, CL-2

SAFETY CONSIDERATIONS

Installing, starting up, and servicing air-conditioning

components and equipment can be dangerous. Only trained,

qualified installers and service mechanics should install, start-

up, and service this equipment.

When working on the equipment, observe precautions in

the literature and on tags, stickers, and labels attached to the

OMNIZONE™

50BV020-064

Water-Cooled and Remote Air-Cooled

Indoor Self-Contained Systems and

Water-Cooled Heat Pumps

2

equipment. Follow all safety codes. Wear safety glasses and

work gloves.

GENERAL

Omnizone™ 50BV indoor packaged units are very flexible

for a variety of applications. These self-contained units are

available as water-cooled or remote air-cooled air conditioning

units. The 50BV units are available with either constant vol-

ume (CV) or variable air volume (VAV) controls. In addition,

the 50BV unit is available as a water-cooled heat pump. Final-

ly, Omnizone 50BV units are available in two cabinet styles.

Nominal 18 through 30-ton units are constructed in a single-

piece, unpainted galvanized cabinet. Nominal 30 through

60-ton units are available as modular units, and can be taken

apart for easier installation. Modular units are built using an un-

painted, galvanized steel cabinet with steel framework, and can

be easily disassembled without breaking the refrigerant lines.

See Table 1 for a model number reference by application.

Each unit contains multiple scroll compressors piped in

separate refrigerant circuits. Each water-cooled circuit includes

a coaxial (tube-in-tube) condenser, TXV (thermostatic expan-

sion valve), individual evaporator coils, and all interconnecting

piping. Water-cooled units are shipped fully charged with

refrigerant. Remote air-cooled units are shipped with a nitrogen

holding charge.

Each unit is equipped with one or two forward-curved cen-

trifugal blowers, to ensure quiet air delivery to the conditioned

space. Constant volume units operate at a single, adjustable fan

speed and provide zone temperature control using a standard

commercial thermostat. For VAV applications, the unit is sup-

plied with a variable frequency drive(s) (VFD) that automati-

cally adjusts blower speed to maintain a constant, adjustable

duct static pressure. Compressors are automatically staged to

provide supply air temperature control (VAV applications) or

zone temperature control using a two-stage commercial ther-

mostat (CV applications).

The 50BV units have removable access panels for easy

servicing. These panels allow access to controls, compressors,

condensers, VFD(s) (if applicable), evaporator motors, blow-

ers, belts, pulleys, and refrigeration components.

MAJOR SYSTEM COMPONENTS

Constant Volume (CV) Units

MAIN CONTROL BOARD (MCB) — The main control

board for the 50BVC, E, Q, T, U, and V units provides both

controls and diagnostics including:

• Condensate Overflow Protection

prevents unit operation in

the event that the drain pan clogs (optional sensors

required).

• Random Start

provides a programmable start with a range

of 30 to 60 seconds.

• Anti-short Cycle Timer

provides a 5-minute delay to pre-

vent compressor short cycling.

• Low Pressure Bypass Timer

bypasses the low-pressure

switch for 90 seconds to avoid nuisance trips during cold

start-up.

• High Pressure Switch Delay

is a one-second delay that pre-

vents nuisance trips at start-up.

• Brownout/Surge/Power Interruption Protection

is a

20-second moving scale that works in conjunction with the

random start timer to delay unit start when a nuisance lock-

out would otherwise have occurred. This allows the water

pumps to restart and establish water flow.

• Alarm Output

contacts provide remote fault indication.

• Test/Service Pin is a jumper that reduces all time delay

settings to 6 seconds during troubleshooting or operation

verification.

• Reset

occurs after a 5-minute delay when a fault condition

occurs. When the timer expires, the unit will restart. If the

same condition occurs a second time, the unit will be locked

out.

• Lockout Reset

requires that the unit power be cycled at the

unit controller via either the thermostat or unit disconnect.

NOTE: The refrigerant circuits on dual compressor models

are completely independent. If either stage has a fault condi-

tion the remaining stage will continue to operate without

interruption. A freeze (optional sensor required) or condensate

overflow lockout will shut down both refrigerant circuits.

• LEDs

are provided for diagnostic purposes.

Variable Air Volume (VAV) Units — The 50BVJ, K,

W, and X units come equipped with a Carrier 6400 Comfort

Controller and a VFD. Refer to the 50BV,XJ Controls, Opera-

tion and Troubleshooting manual for details.

NOTE: The VAV units utilize face split coils and should not

be operated below 50% of nominal airflow to prevent coil

freezing.

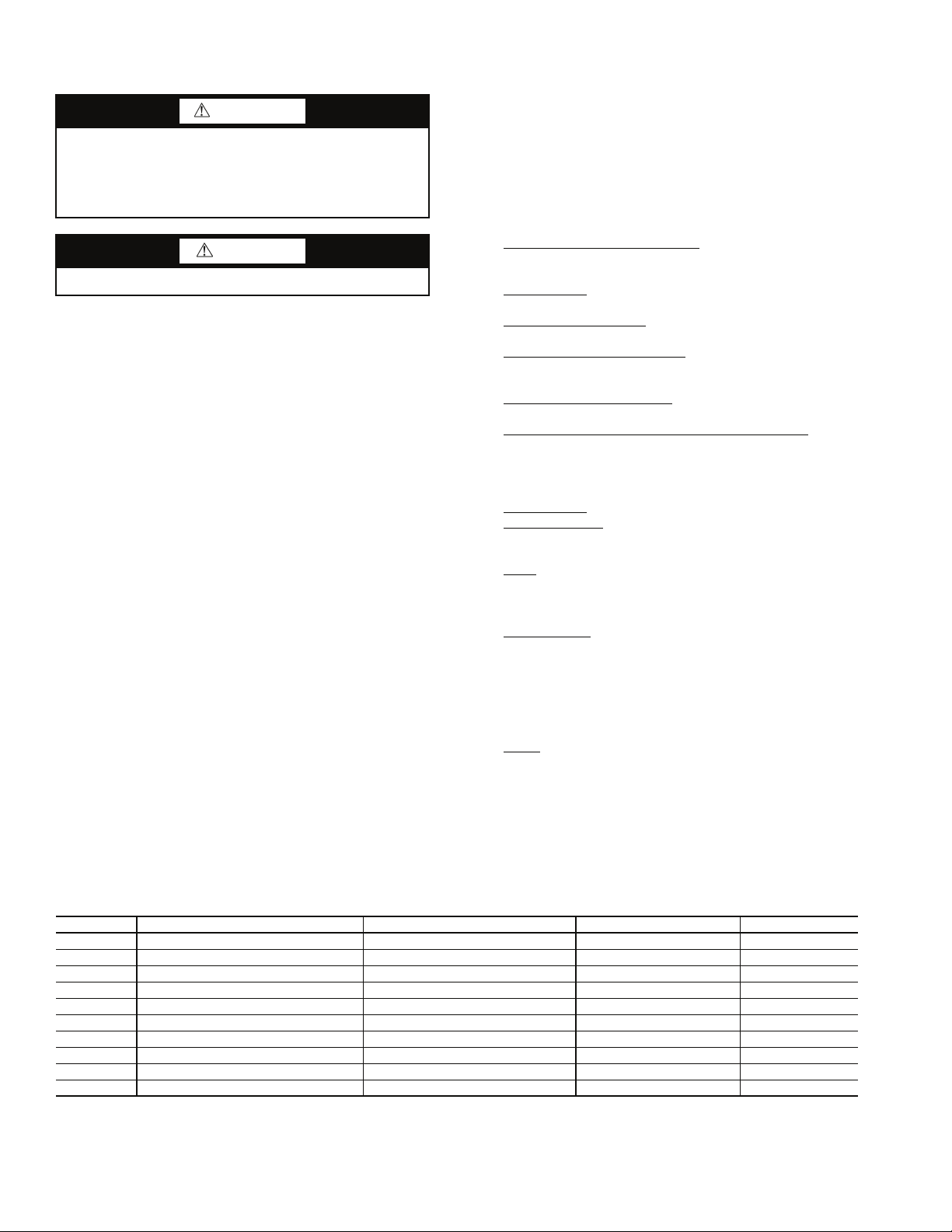

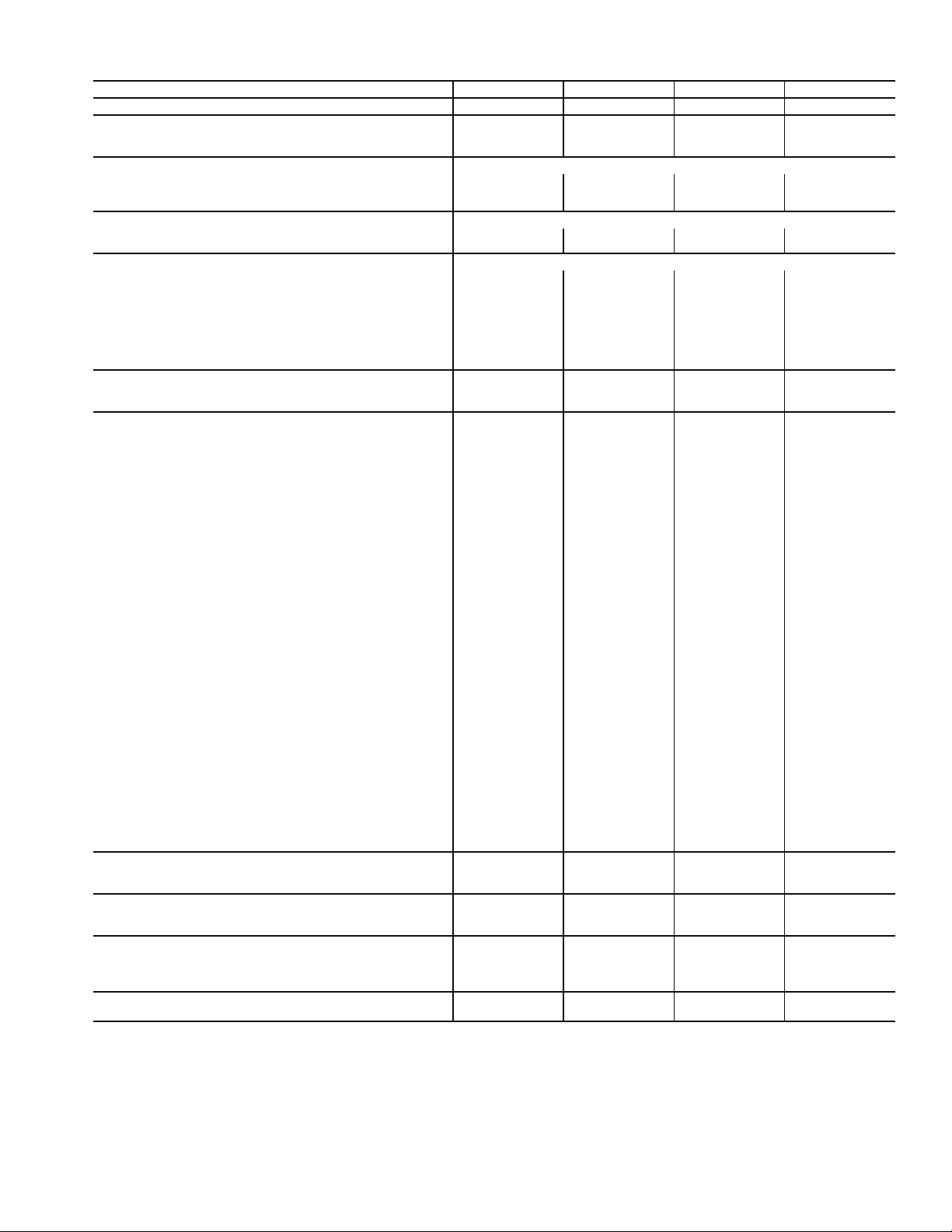

Table 1 — Model Number Reference By Application Type

LEGEND

*All units are cooling only unless specified.

WARNING

Before performing service or maintenance operations on

unit, turn off main power switch to unit and open all dis-

connects. More than one disconnect switch may be

required to deenergize this equipment. Electric shock haz-

ard can cause injury or death.

CAUTION

Use care in handling, rigging, and setting bulky equipment.

MODEL TYPE* AVAILABLE CAPACITY CONSTRUCTION CONTROLS

50BVC Water-Cooled 18 to 30 nominal tons Single-piece CV

50BVE Remote Air-Cooled 18 to 30 nominal tons Single-piece CV

50BVQ Water-Cooled Heat Pump 18 to 30 nominal tons Single-piece CV

50BVJ Water-Cooled 18 to 30 nominal tons Single-piece VAV

50BVK Remote Air-Cooled 18 to 30 nominal tons Single-piece VAV

50BVT Water-Cooled 30 to 60 nominal tons Modular CV

50BVU Remote Air-Cooled 30 to 60 nominal tons Modular CV

50BVV Water-Cooled Heat Pump 30 to 60 nominal tons Modular CV

50BVW Water-Cooled 30 to 60 nominal tons Modular VAV

50BVX Remote Air-Cooled 30 to 60 nominal tons Modular VAV

CV — Constant Volume

VAV — Variable Air Volume

3

INSTALLATION

Omnizone™ 50BV units are intended for indoor installa-

tion only. Determine building alterations required to run piping,

wiring, and ductwork. Read all installation instructions before

installing the unit.

Step 1 — Complete Pre-Installation Checks

EXAMINE THE UNIT — Examine the unit for shipping

damage. File a claim with the transit company if damage is

found. Check the shipment for completeness. Verify that the

nameplate electrical requirements match the available power

supply.

UNIT STORAGE — The 50BV units are designed and pack-

aged for indoor storage and use only. If the equipment is not

needed for immediate installation upon its arrival at the job site,

it should be left in its shipping carton and stored in a clean, dry

area. Units must only be stored or moved in the normal upright

position, as indicated by the “UP” arrows on each carton, at all

times. DO NOT STACK UNITS.

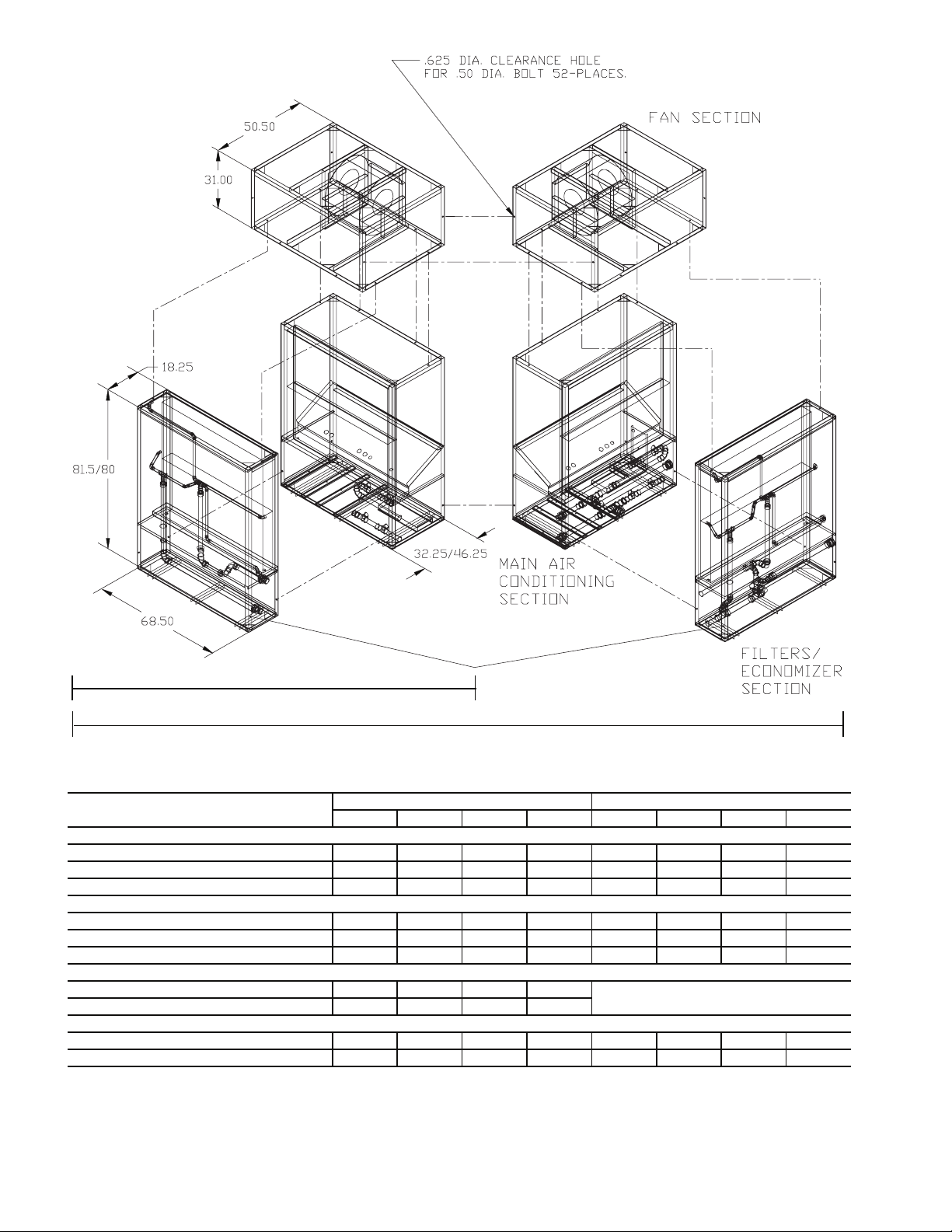

MODULAR UNITS — The 50BVT,U,V,W,X units are shipped

in multiple sections for easy movement and installation. The

separate modules will pass through a standard 36-in. steel-

framed door or service elevator. Circuit integrity is maintained

because none of the refrigerant piping requires disconnection.

Water piping connections are made with the use of heavy-duty

bronze-bodied unions so no field welding or brazing is required.

See Table 2 for the number of sections per unit.

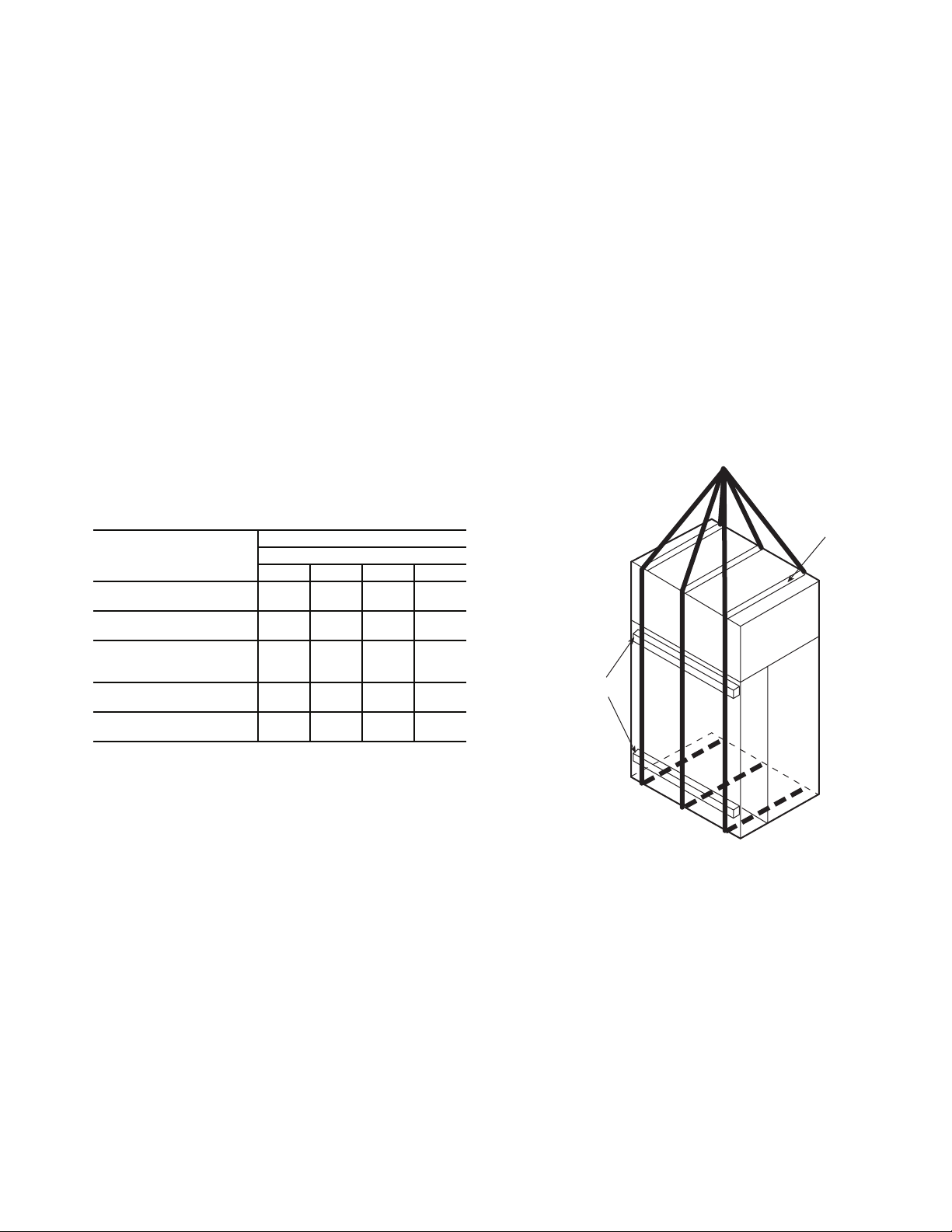

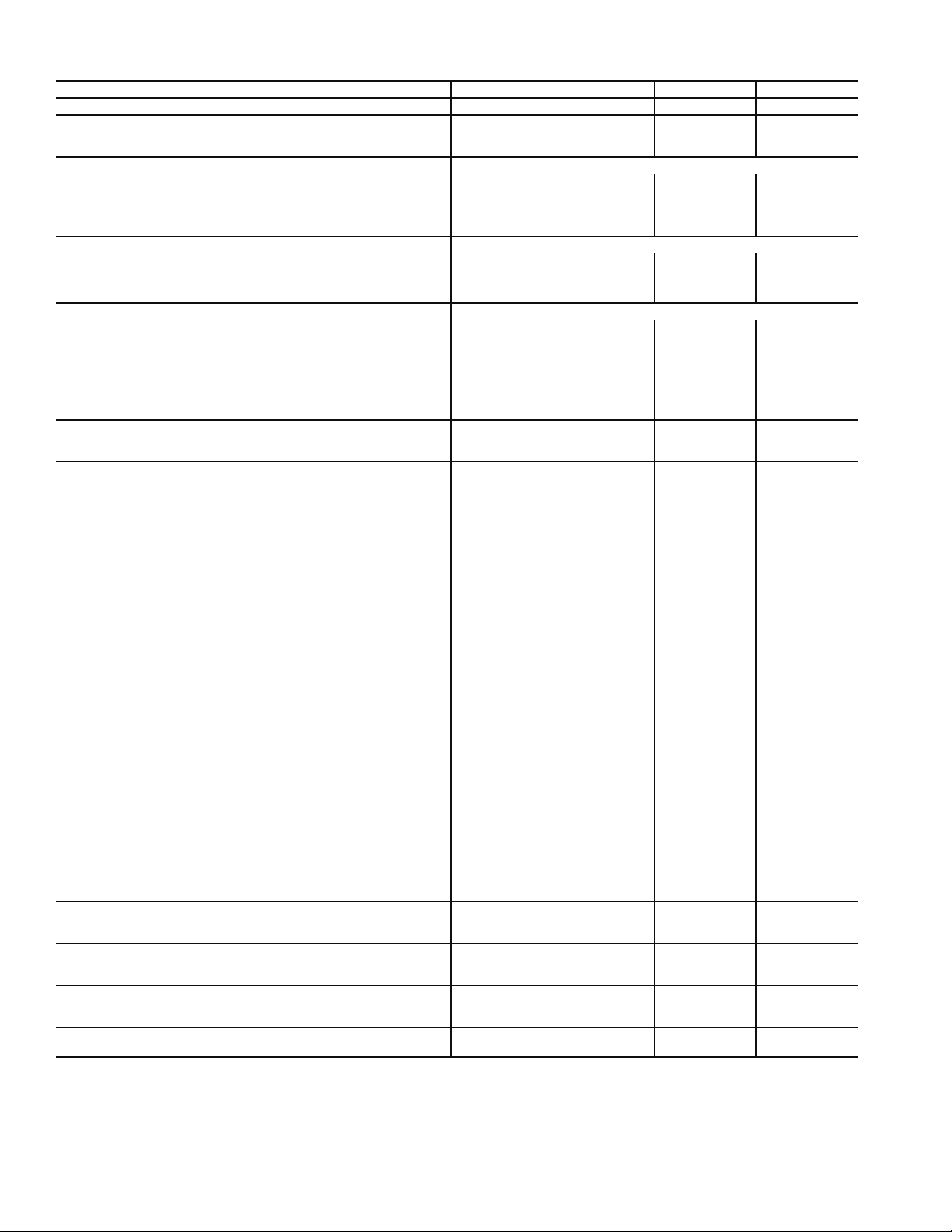

Table 2 — Modular Unit Shipping Table

NOTE: Units ship with the main air conditioning, economizer/

filter, and, when selected, the reheat coil sections assembled

together. These can be easily disassembled, as required, in the

field. The fan section(s) always ships separately.

Step 2 — Rig and Place Unit — Use proper lifting

and handling practices to avoid damage to the unit. Move

modular units with a fork truck using the baserails provided, or

use spreader bars and lifting straps as shown in Fig. 1.

For single piece units, use spreader bars and rigging straps if

lifting with a crane to avoid damage to the unit. Otherwise,

move with a fork truck using the shipping pallet.

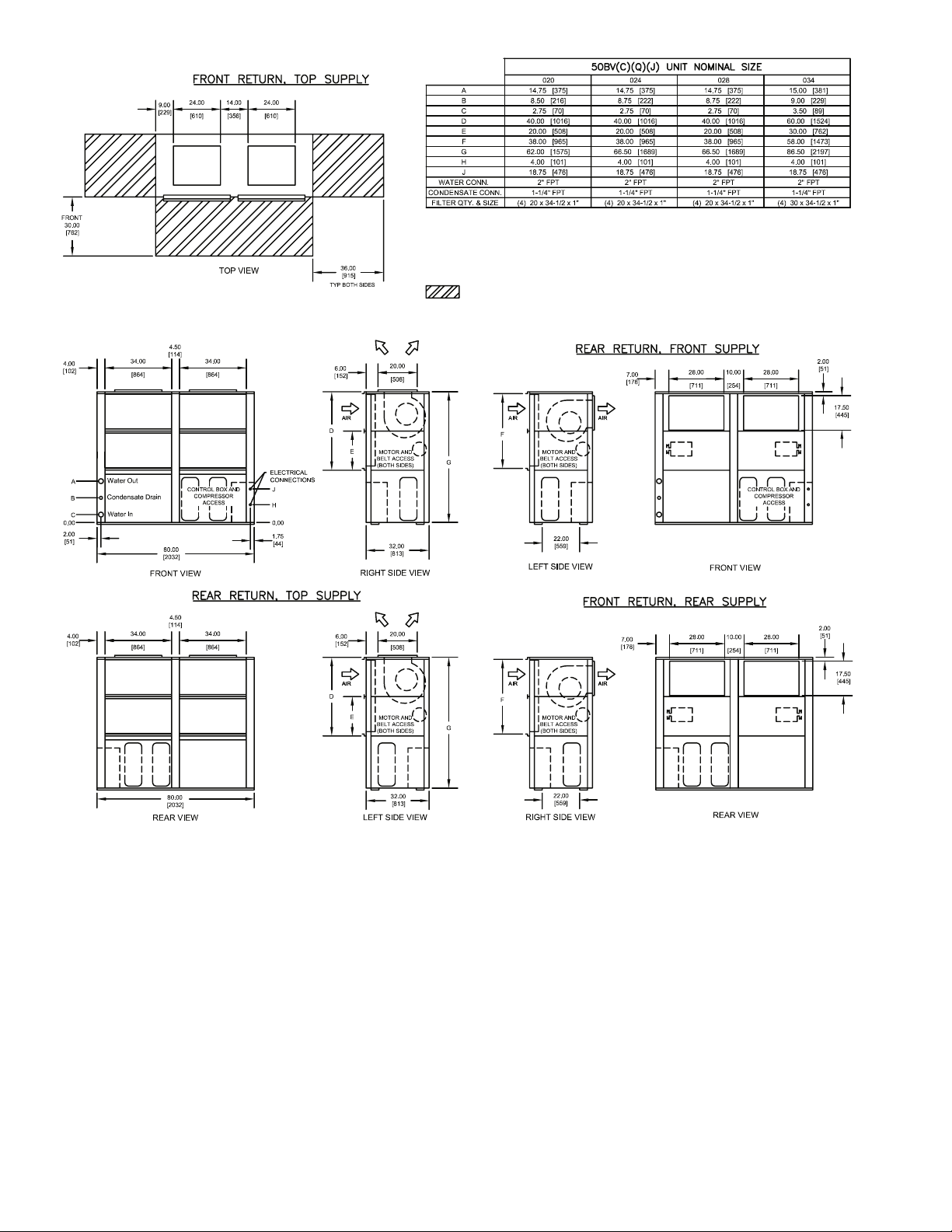

Refer to Fig. 2-14 for unit dimensions.

Refer to Tables 3A and 3B for physical data.

REMOVE PACKAGING — Remove all protective plastic,

remove and discard unit top cover protector, filter cover,

controller display protector, and water piping connection

packaging.

UNIT LOCATION — Locate the unit in an indoor area

that allows easy removal of the filters, access panels, and

accessories. Make certain enough space is available for service

personnel to perform maintenance or repairs. Provide sufficient

room to make all water, duct, and electrical connections. If the

unit is located in a small mechanical equipment room, make

sure adequate space is available for air to return freely to the

unit. These units are not approved for outdoor installations and

must be installed inside the structure. Do not locate in areas

that are subject to freezing.

UNIT PLACEMENT — Ensure that the floor is structurally

strong enough to support the weight of the equipment with

minimum deflection. A good, level floor is required for proper

unit operation and to ensure proper fit-up and alignment of all

bolt together and union coupled modules on modular units.

SECTIONS

NUMBER OF SECTIONS

50BVT, U, V, W, X

034 044 054 064

Main Air Conditioning

Weight (lb) (each)

1

2100

2

1825

2

2200

2

2225

Reheat Coil Option

Weight (lb) (each)

1

40

2

40

2

40

2

40

Economizer/Filter

Filter Section Weight (lb)

Economizer Weight (lb)

1

310

200

2

310

200

2

310

200

2

310

200

Fan Section

Weight (lb) (each)

1

650

2

650

2

650

2

650

Tot al U ni t

Weight (lb)

4

3300

8

5400

8

6150

8

6150

USE

SPREADER

BAR TO

PREVENT

DAMAGE

TO UNIT

4 X 4 ABOVE

AND BELOW

RETURN DUCT

CONNECTIONS

Fig. 1 — Modular Unit Rigging

a50-7257ef

4

STANDARD

BLOWER

ORIENTATION

OPTIONAL

BLOWER

ORIENTATION

STANDARD

BLOWER

ORIENTATION

OPTIONAL

BLOWER

ORIENTATION

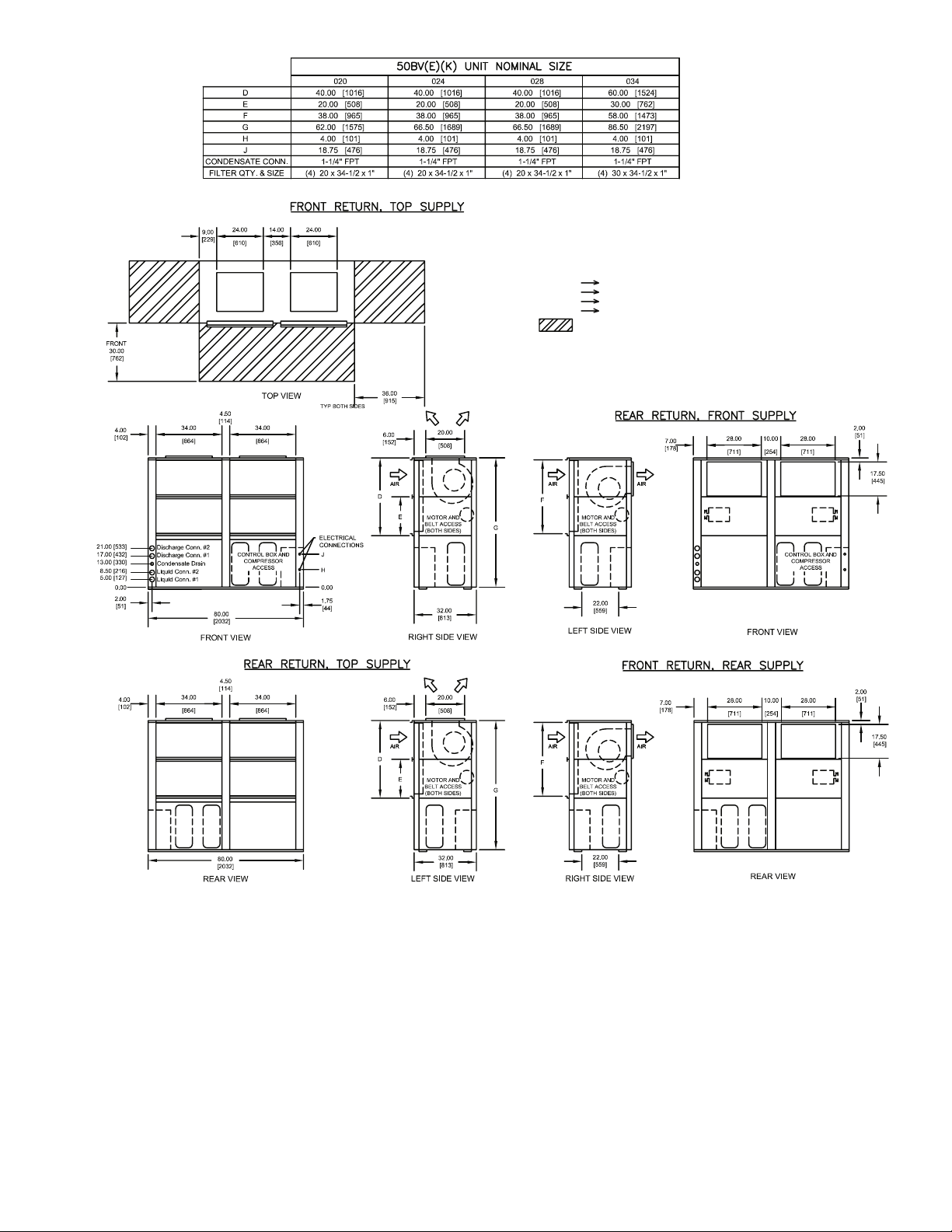

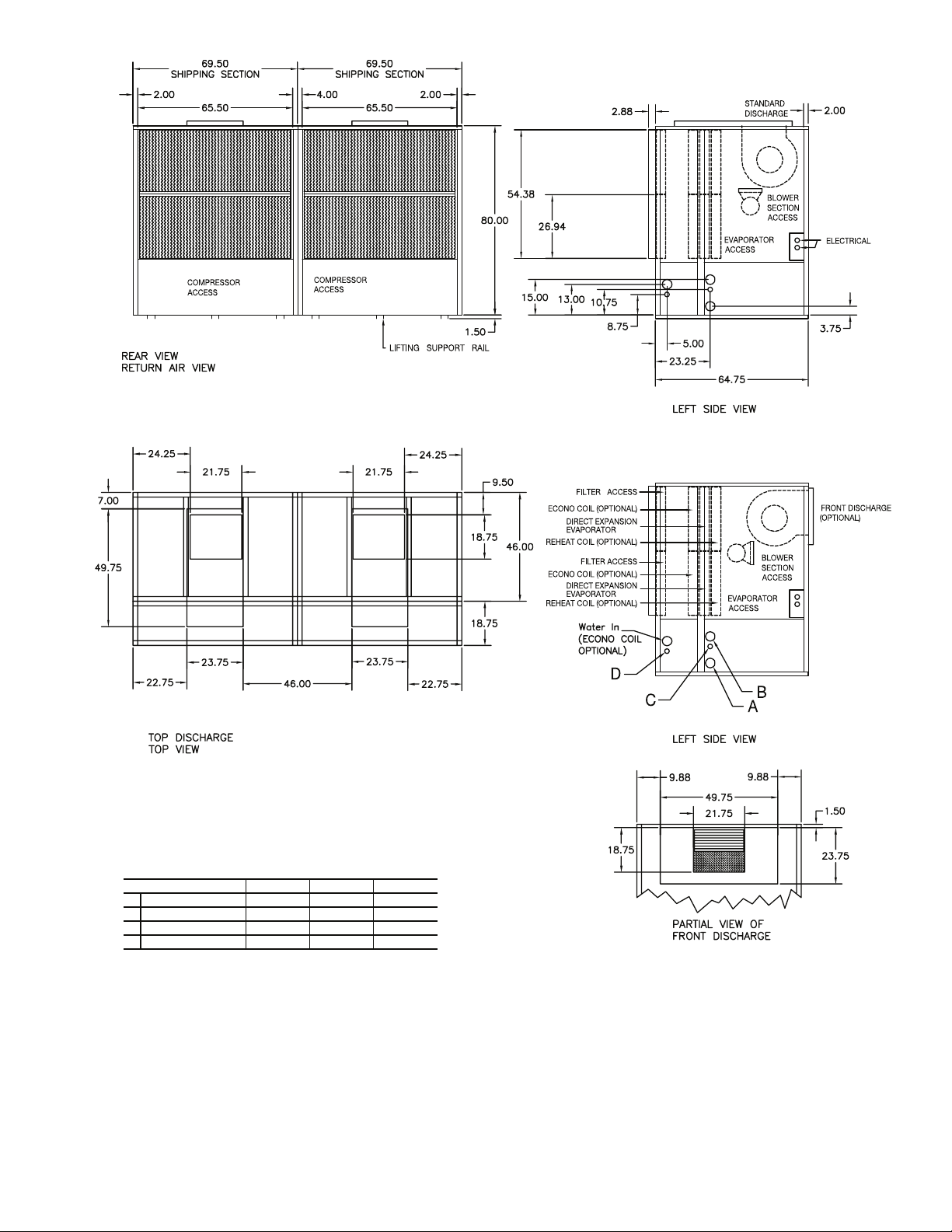

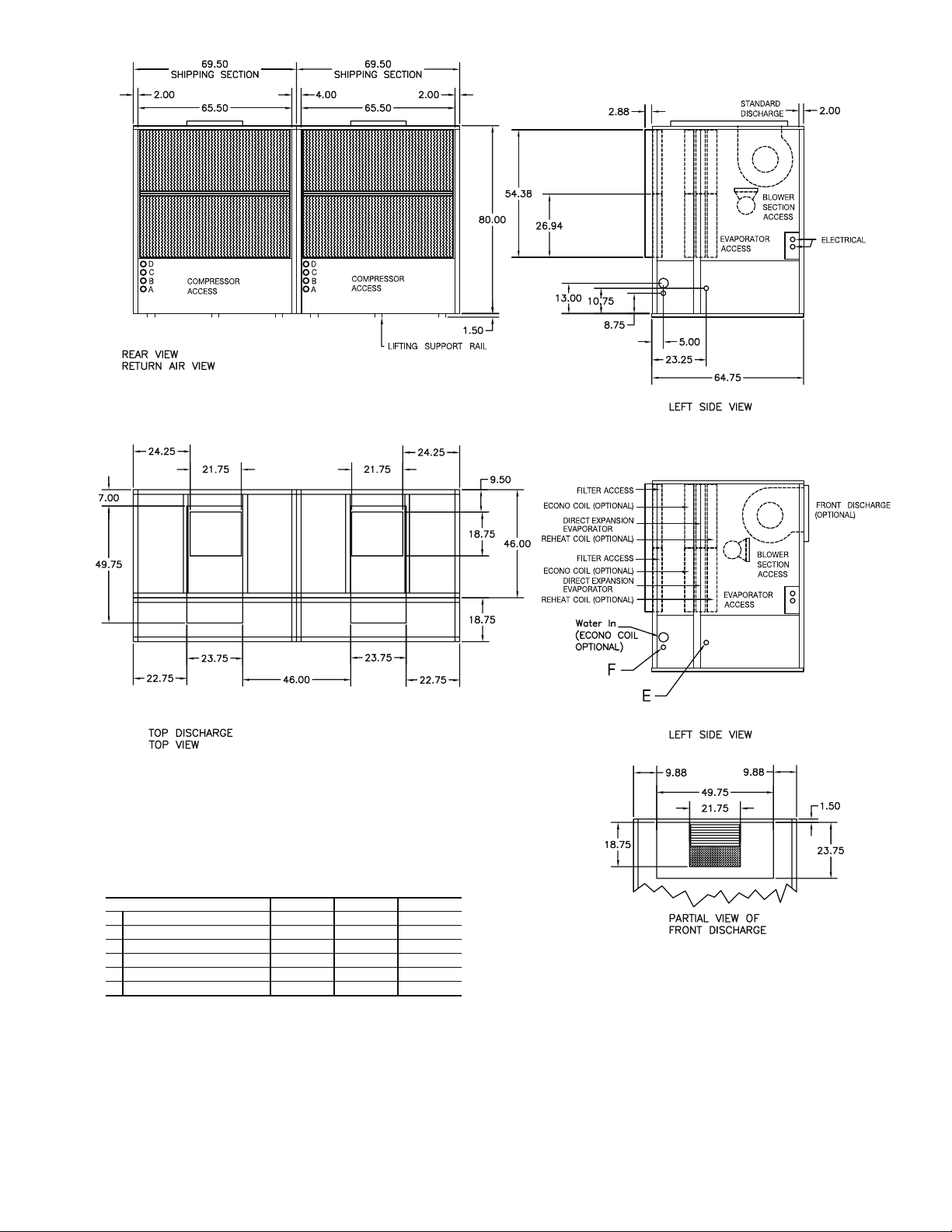

Fig. 2 — 50BVC,J,Q020-034 Dimensions

NOTES:

1. Dimensions in inches [mm].

2. VAV models (50BVJ) are rear return, top supply only.

3. Compressor, controls, and condenser access are through front panels.

4. Field power connections are 1-3/4 inches. Control connections are 7/8 inches.

5. Optional blower orientation is selected in model number nomenclature as option 9 in FIOP section

(digits 15 and 16).

Shows recommended minimum service clearances.

a50-8199

5

STANDARD

BLOWER

ORIENTATION

OPTIONAL

BLOWER

ORIENTATION

STANDARD

BLOWER

ORIENTATION

OPTIONAL

BLOWER

ORIENTATION

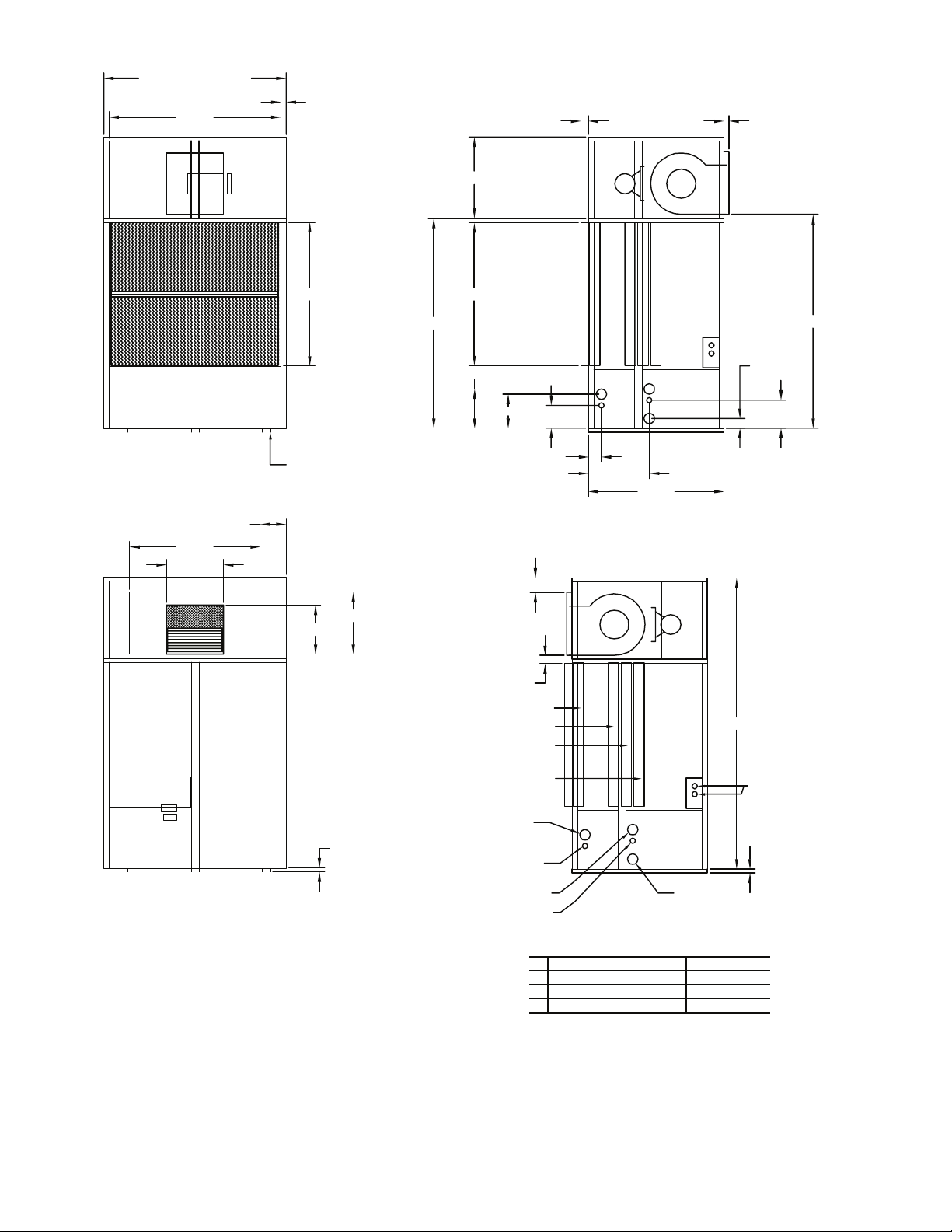

Fig. 3 — 50BVE,K020-034 Dimensions

NOTES:

1. Dimensions in inches [mm].

2. VAV models (50BVK) are rear return, top supply only.

3. Compressor, controls, and condenser access are through front panels.

4. Field power connections are 1-3/4 inches. Control connections are 7/8 inches.

5. Discharge (hot gas) connections are 1-1/8 in. OD.

6. Liquid line connections are 7/8 in. OD.

7. Optional blower orientation is selected in model number nomenclature as

option 9 in FIOP section (digits 15 and 16).

RECOMMENDED CONDENSER MATCHES:

50BV020 one (1) 09DK020 (50/50 split each)

50BV024 one (1) 09DK024 (50/50 split each)

50BV028 one (1) 09DK028 (50/50 split each)

50BV034 one (1) 09DK034 (50/50 split each)

Shows recommended minimum service clearances.

a50-8200

6

REAR VIEW

RETURN AIR VIEW

LEFT SIDE VIEW

80.00

FRONT VIEW

54.38

8.75

15.00

13.00

31.00

BLOWER

SECTION

ACCESS

EVAPORATOR

ACCESS

2.88

2.00

EVAPORATOR

ACCESS

BLOWER

SECTION

ACCESS

LEFT SIDE VIEW

FILTER ACCESS

ECONO COIL (Optional)

DIRECT EXPANSION

EVAPORATOR

REHEAT COIL (Optional)

STANDARD

DISCHARGE

REAR DISCHARGE

(Optional)

WATER IN

(ECONO COIL

OPTIONAL)

ELECTRICAL

81.50

BLOWER

SECTION

ACCESS

COMPRESSOR

ACCESS

COMPRESSOR

ACCESS

EVAPORATOR

ACCESS

EVAPORATOR

ACCESS

ELECTRICAL BOX

ACCESS

ELECTRICAL BOX

23.75

18.75

49.75

21.75

9.88

111.00

3.19

5.50

65.50

54.75

2.00

23.25

5.00

51.63

1.50

1.50

LIFTING SUPPORT RAIL

69.50

SHIPPING SECTION

10.75

3.75

B

A

C

D

a50-8201

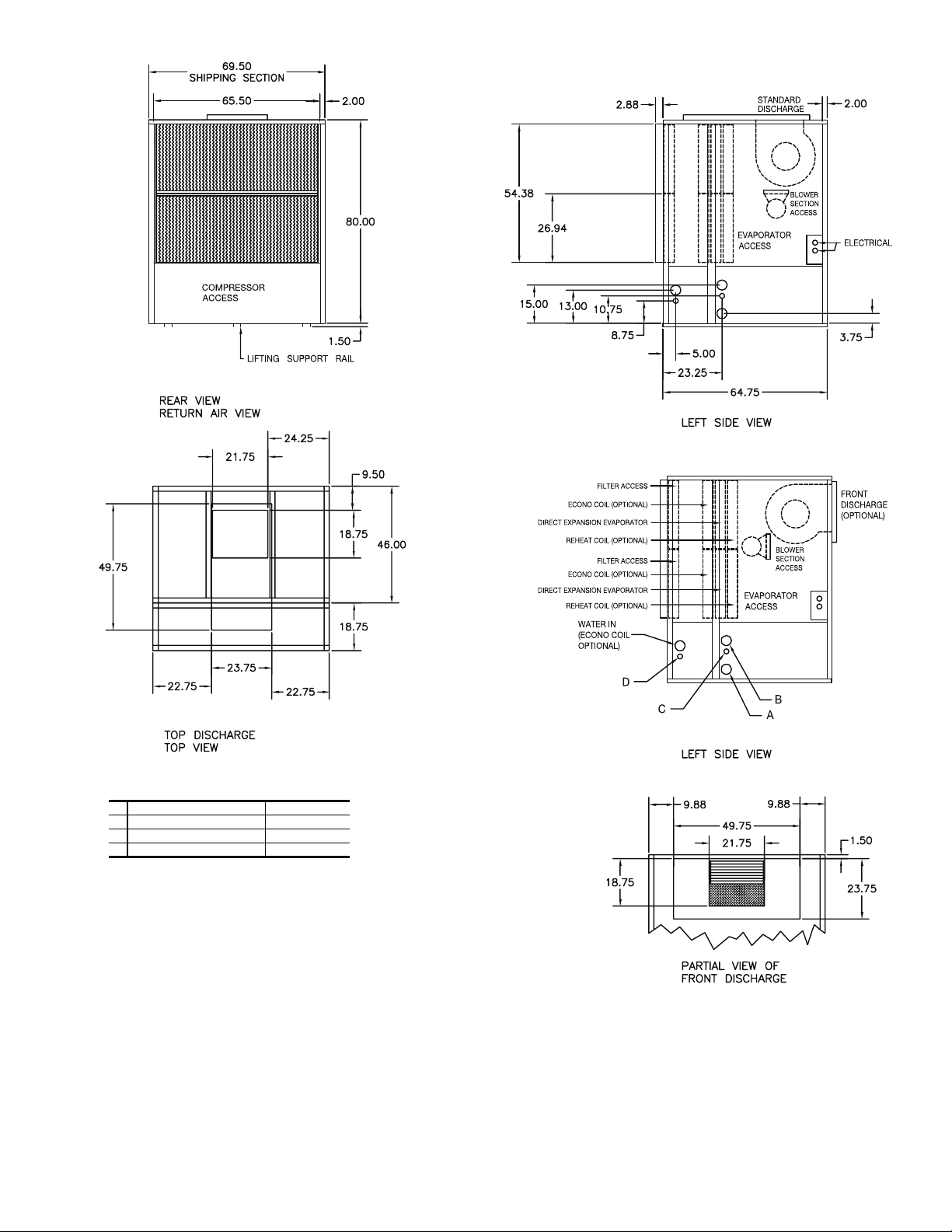

NOTES:

1. Dimensions in inches.

2. All units are rear return airflow configuration.

3. Constant volume units are available with front or rear air supply.

4. VAV units (50BVW) are available with rear supply only.

5. Recommended minimum service clearances are as follows:

a. Front and rear — 30 in. (762 mm)

b. Left or right side — 65 in. (1651 mm) for coil removal

c. Side opposite coil removal — 20 in. (508 mm)

CONNECTIONS

REPLACEMENT FILTERS : EIGHT (8) AT 17 x 27 x 4 INCHES.

A WATER OUT 2-1/2 in. FPT

B WATER IN 2-1/2 in. FPT

C CONDENSATE DRAIN 1-1/4 in. FPT

D ECONOMIZER DRAIN 1-1/4 in. FPT

Fig. 4 — 50BVT,V,W034 (High-Boy) Dimensions

7

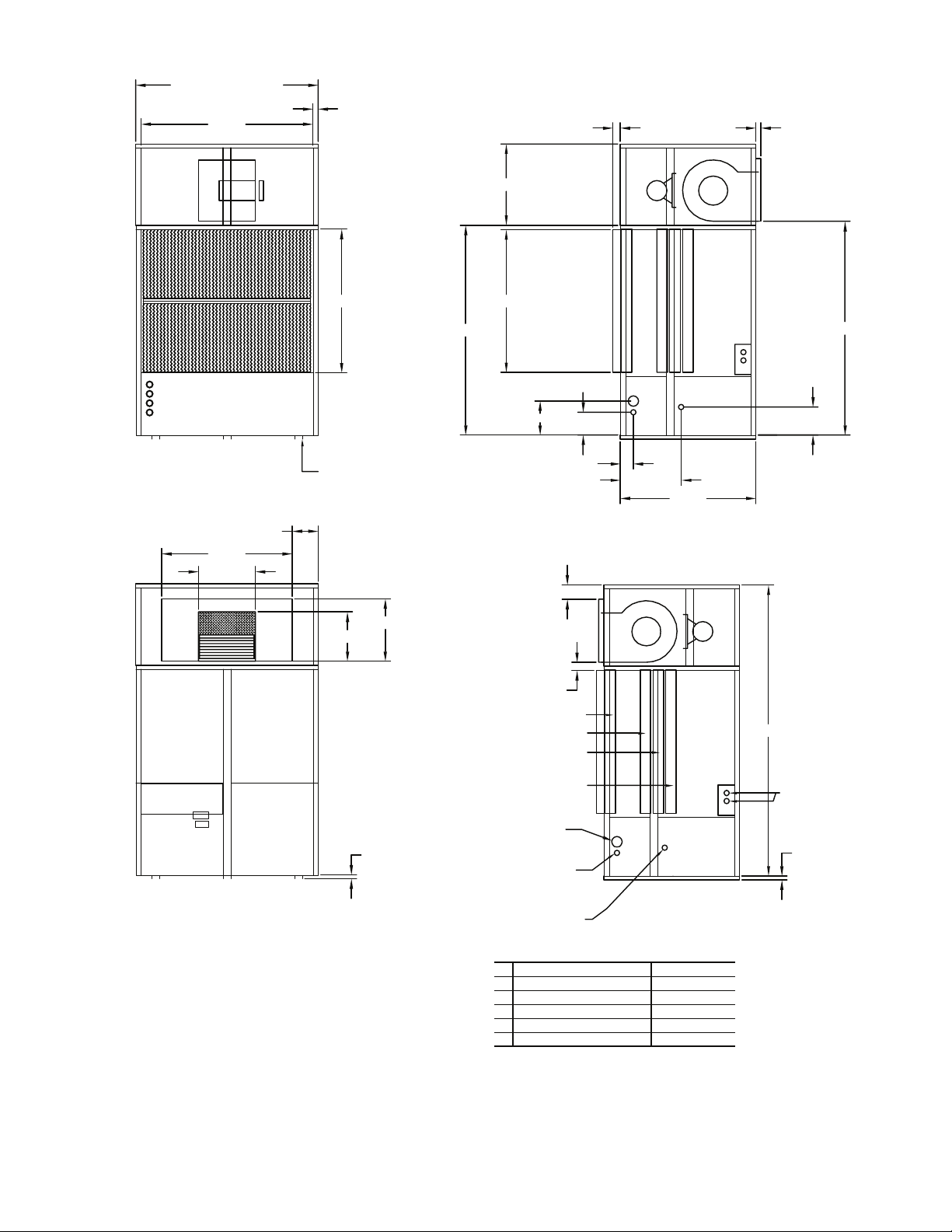

Fig. 5 — 50BVT,V,W034 (Low-Boy) Dimensions

a50-8202

NOTES:

1. Dimensions in inches.

2. All units are rear return airflow configuration.

3. Recommended minimum service clearances are as follows:

a. Front and rear — 30 in. (762 mm)

b. Left or right side — 65 in. (1651 mm) for coil removal

c. Side opposite coil removal — 20 in. (508 mm)

CONNECTIONS

REPLACEMENT FILTERS : EIGHT (8) AT 17 x 27 x 4 INCHES.

A WATER OUT 2-1/2 in. FPT

B WATER IN 2-1/2 in. FPT

C CONDENSATE DRAIN 1-1/4 in. FPT

D ECONOMIZER DRAIN 1-1/4 in. FPT

a50-8202.eps

8

REAR VIEW

RETURN AIR VIEW

LEFT SIDE VIEW

80.00

FRONT VIEW

54.38

8.75

15.00

13.00

31.00

COMPRESSOR

ACCESS

EVAPORATOR

ACCESS

EVAPORATOR

ACCESS

ELECTRICAL BOX

ACCESS

COMPRESSOR

ACCESS

BLOWER

SECTION

ACCESS

BLOWER

SECTION

ACCESS

EVAPORATOR

ACCESS

ELECTRICAL BOX

2.88

21.75

49.75

2.00

EVAPORATOR

ACCESS

BLOWER

SECTION

ACCESS

LEFT SIDE VIEW

FILTER ACCESS

ECONO COIL (OPTIONAL)

DIRECT EXPANSION

EVAPORATOR

REHEAT COIL (OPTIONAL)

STANDARD

DISCHARGE

REAR DISCHARGE

(OPTIONAL)

WATER IN

(ECONO COIL

OPTIONAL)

ELECTRICAL

81.50

BLOWER

SECTION

ACCESS

COMPRESSOR

ACCESS

COMPRESSOR

ACCESS

EVAPORATOR

ACCESS

EVAPORATOR

ACCESS

ELECTRICAL BOX

ACCESS

ELECTRICAL BOX

139.00

23.75

18.75

49.75

21.75

9.88

19.75

9.88

111.00

3.19

5.50

65.50 65.50

4.00

54.75

2.00 2.00

23.25

5.00

51.63

1.50

1.50

LIFTING SUPPORT RAIL

69.50

SHIPPING SECTION

69.50

SHIPPING SECTION

10.75

3.75

A

B

C

D

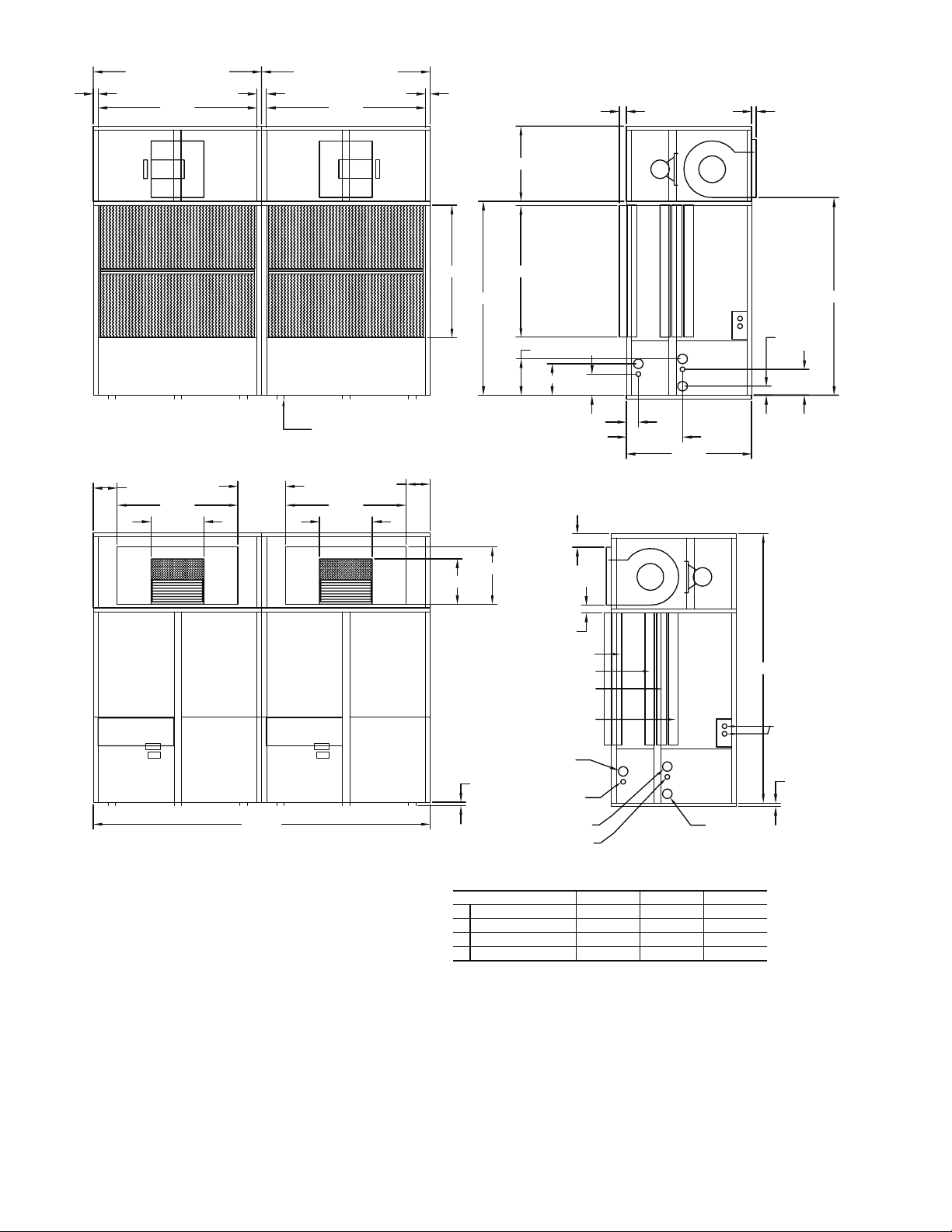

NOTES:

1. Dimensions in inches.

2. All units are rear return airflow configuration.

3. CV units are available with front or rear air supply.

4. VAV units (50BVW) are available with rear supply only.

5. Recommended minimum service clearances are as follows:

a. Front and rear — 30 in. (762 mm)

b. Left and right sides — 65 in. (1651 mm) for coil removal

CONNECTIONS

REPLACEMENT FILTERS : SIXTEEN (16) AT 17 x 27 x 4 INCHES.

UNIT SIZE 044 054 064

A WATER OUT 2-1/2 in. FPT 3 in. FPT 3 in. FPT

B WATER IN 2-1/2 in. FPT 3 in. FPT 3 in. FPT

C CONDENSATE DRAIN 1-1/4 in. FPT 1-1/4 in. FPT 1-1/4 in. FPT

D ECONOMIZER DRAIN 1-1/4 in. FPT 1-1/4 in. FPT 1-1/4 in. FPT

a50-8203

Fig. 6 — 50BVT,V,W044-064 (High-Boy) Dimensions

9

Fig. 7 — 50BVT,V,W044-064 (Low-Boy) Dimensions

CONNECTIONS

REPLACEMENT FILTERS : SIXTEEN (16) AT 17 x 27 x 4 INCHES.

UNIT SIZE 044 054 064

A WATER OUT 2-1/2 in. FPT 3 in. FPT 3 in. FPT

B WATER IN 2-1/2 in. FPT 3 in. FPT 3 in. FPT

C CONDENSATE DRAIN 1-1/4 in. FPT 1-1/4 in. FPT 1-1/4 in. FPT

D ECONOMIZER DRAIN 1-1/4 in. FPT 1-1/4 in. FPT 1-1/4 in. FPT

NOTES:

1. Dimensions in inches.

2. All units are rear return airflow configuration.

3. Recommended minimum service clearances are as follows:

a. Front and rear — 30 in. (762 mm)

b. Left and right sides — 65 in. (1651 mm) for coil removal

a50-8204

10

REAR VIEW

RETURN AIR VIEW

LEFT SIDE VIEW

80.00

FRONT VIEW

54.38

8.75

13.00

31.00

BLOWER

SECTION

ACCESS

EVAPORATOR

ACCESS

2.88

2.00

EVAPORATOR

ACCESS

BLOWER

SECTION

ACCESS

LEFT SIDE VIEW

FILTER ACCESS

ECONO COIL (Optional)

DIRECT EXPANSION

EVAPORATOR

REHEAT COIL (Optional)

STANDARD

DISCHARGE

REAR DISCHARGE

(Optional)

WATER IN

(ECONO COIL

OPTIONAL)

ELECTRICAL

81.50

BLOWER

SECTION

ACCESS

COMPRESSOR

ACCESS

COMPRESSOR

ACCESS

EVAPORATOR

ACCESS

EVAPORATOR

ACCESS

ELECTRICAL BOX

ACCESS

ELECTRICAL BOX

23.75

18.75

49.75

21.75

9.88

111.00

3.19

5.50

65.50

54.75

2.00

23.25

5.00

51.63

1.50

1.50

LIFTING SUPPORT RAIL

69.50

SHIPPING SECTION

10.75

E

F

A

B

C

D

NOTES:

1. Dimensions in inches.

2. All units are rear return airflow configuration.

3. Constant volume units are available with front or rear air supply.

4. VAV units (50BVX) are available with rear supply only.

5. Recommended condenser match is ONE (1) 09DK034 (50/50 split).

6. Use proper piping practice for remote refr igerant connections. Refer to

Carrier System Design Manual Part 3.

7. Recommended minimum service clearances are as follows:

a. Front and rear — 30 in. (762 mm)

b. Left or right side — 65 in. (1651 mm) for coil removal

c. Side opposite coil removal — 20 in. (508 mm)

CONNECTIONS

REPLACEMENT FILTERS : EIGHT (8) AT 17 x 27 x 4 INCHES.

A LIQUID LINE CIRCUIT 1 7/8 in. OD

B LIQUID LINE CIRCUIT 2 7/8 in. OD

C DISCHARGE LINE CIRCUIT 1 1-1/8 in. OD

D DISCHARGE LINE CIRCUIT 2 1-1/8 in. OD

E CONDENSATE DRAIN 1-1/4 in. FPT

F ECONOMIZER DRAIN 1-1/4 in. FPT

a50-8205

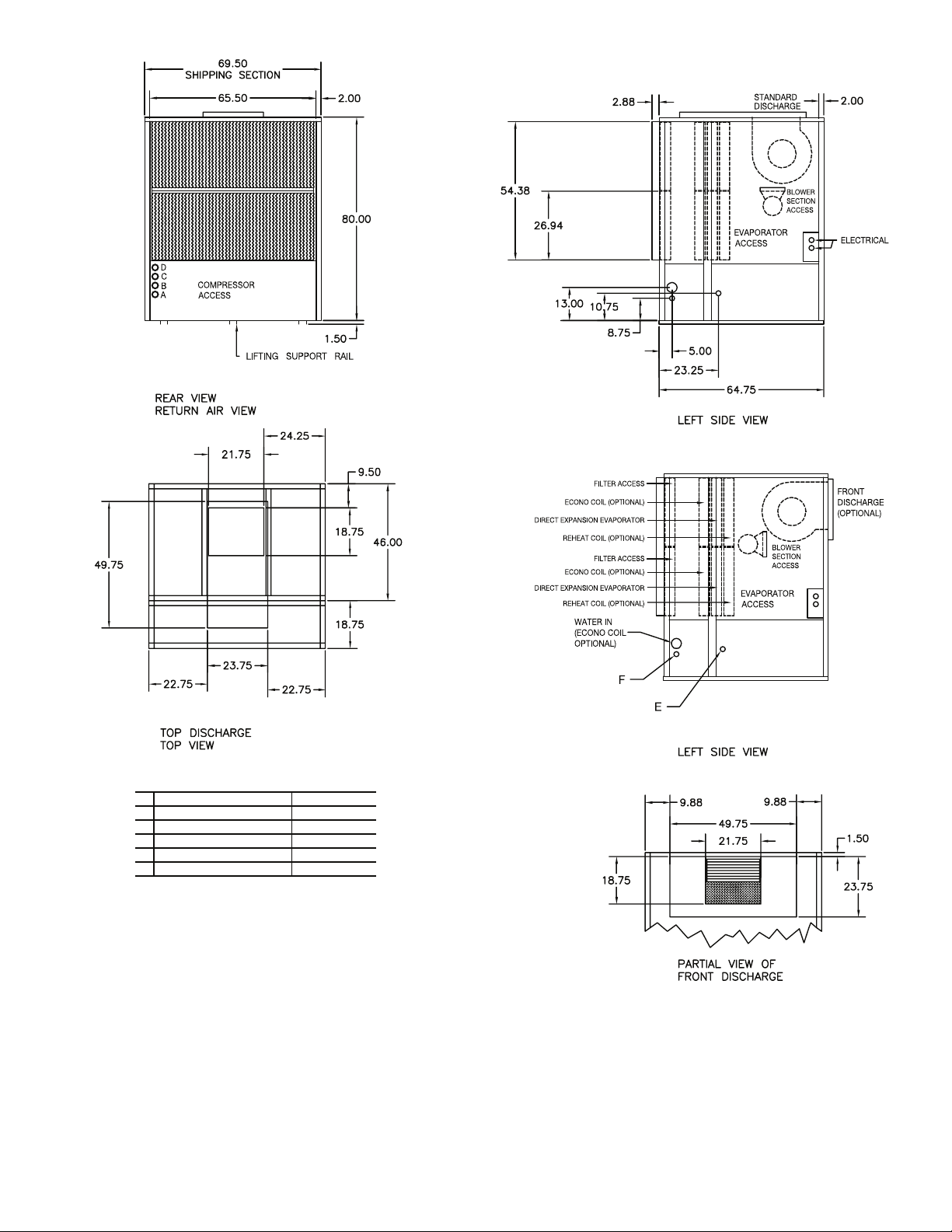

Fig. 8 — 50BVU,X034 (High-Boy) Dimensions

11

a50-8206

Fig. 9 — 50BVU,X034 (Low-Boy) Dimensions

NOTES:

1. Dimensions in inches.

2. All units are rear return airflow configuration.

3. Recommended condenser match is ONE (1) 09DK034 (50/50 split).

4. Use proper piping practice for remote refrigerant connections. Refer to

Carrier System Design Manual Part 3.

5. Recommended minimum service clearances are as follows:

a. Front and rear — 30 in. (762 mm)

b. Left or right side — 65 in. (1651 mm) for coil removal

c. Side opposite coil removal — 20 in. (508 mm)

CONNECTIONS

REPLACEMENT FILTERS : EIGHT (8) AT 17 x 27 x 4 INCHES.

A LIQUID LINE CIRCUIT 1 7/8 in. OD

B LIQUID LINE CIRCUIT 2 7/8 in. OD

C DISCHARGE LINE CIRCUIT 1 1-1/8 in. OD

D DISCHARGE LINE CIRCUIT 2 1-1/8 in. OD

E CONDENSATE DRAIN 1-1/4 in. FPT

F ECONOMIZER DRAIN 1-1/4 in. FPT

a50-8206

12

REAR VIEW

RETURN AIR VIEW

LEFT SIDE VIEW

80.00

FRONT VIEW

54.38

8.75

13.00

31.00

COMPRESSOR

ACCESS

EVAPORATOR

ACCESS

EVAPORATOR

ACCESS

ELECTRICAL BOX

ACCESS

COMPRESSOR

ACCESS

BLOWER

SECTION

ACCESS

BLOWER

SECTION

ACCESS

EVAPORATOR

ACCESS

ELECTRICAL BOX

2.88

21.75

49.75

2.00

EVAPORATOR

ACCESS

BLOWER

SECTION

ACCESS

LEFT SIDE VIEW

FILTER ACCESS

ECONO COIL (OPTIONAL)

DIRECT EXPANSION

EVAPORATOR

REHEAT COIL (OPTIONAL)

STANDARD

DISCHARGE

REAR DISCHARGE

(OPTIONAL)

WATER IN

(ECONO COIL

OPTIONAL)

ELECTRICAL

81.50

BLOWER

SECTION

ACCESS

COMPRESSOR

ACCESS

COMPRESSOR

ACCESS

EVAPORATOR

ACCESS

EVAPORATOR

ACCESS

ELECTRICAL BOX

ACCESS

ELECTRICAL BOX

139.00

23.75

18.75

49.75

21.75

9.88

19.75

9.88

111.00

3.19

5.50

65.50 65.50

4.00

54.75

2.00 2.00

23.25

5.00

51.63

1.50

1.50

LIFTING SUPPORT RAIL

69.50

SHIPPING SECTION

69.50

SHIPPING SECTION

10.75

E

F

A

B

C

D

A

B

C

D

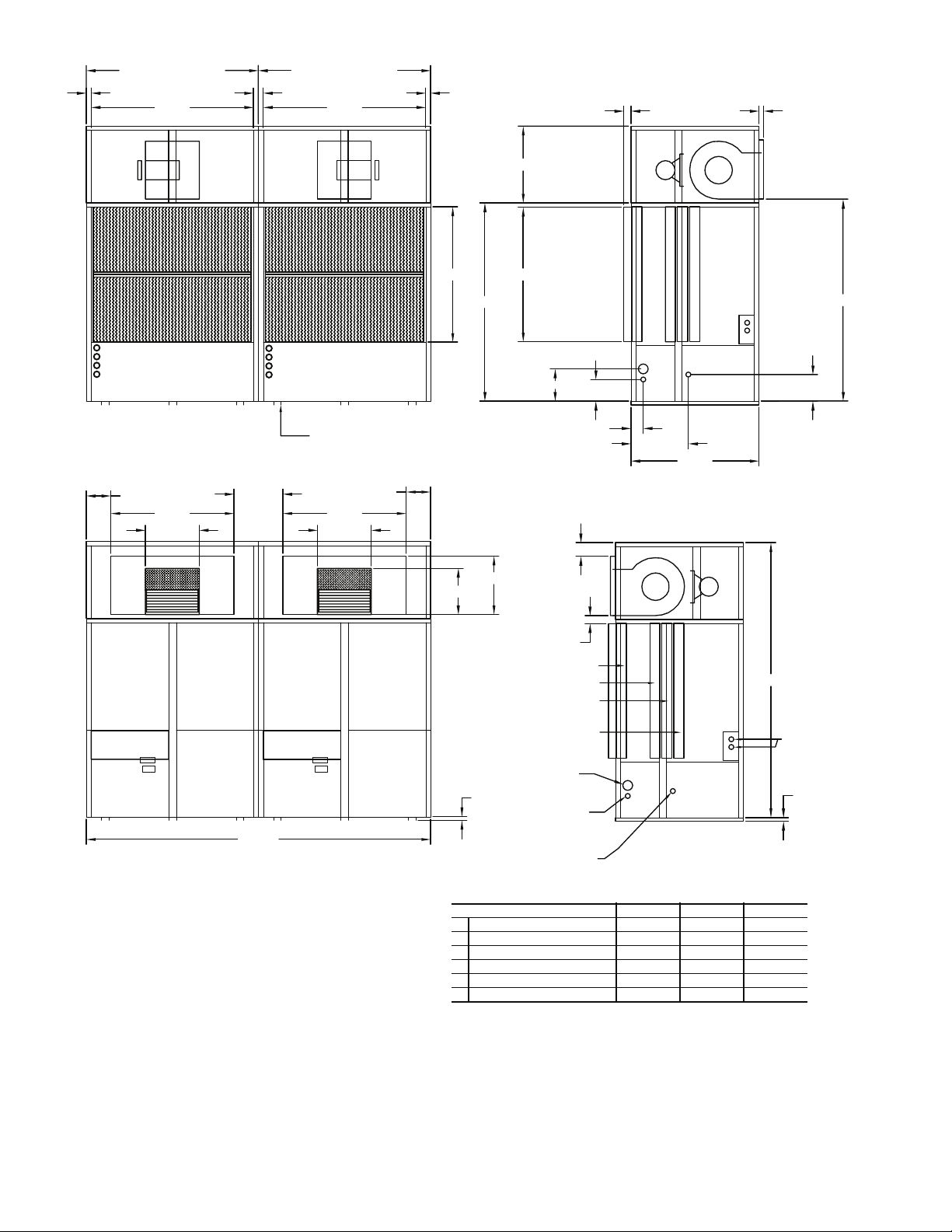

Fig. 10 — 50BVU,X044-064 (High-Boy) Dimensions

NOTES:

1. Dimensions in inches.

2. All units are rear return airflow configuration.

3. CV units are available with front or rear air supply.

4. VAV units (50BVX) are available with rear supply only.

5. Use proper piping practice for remote refrigerant connections. Refer to

Carrier System Design Manual Part 3.

6. Recommended minimum service clearances are as follows:

a. Front and rear — 30 in. (762 mm)

b. Left and right sides — 65 in. (1651 mm) for coil removal

CONNECTIONS

REPLACEMENT FILTERS : SIXTEEN (16) AT 17 x 27 x 4 INCHES.

UNIT SIZE 044 054 064

A LIQUID LINE CIRCUIT 1, 2 7/8 in. OD 7/8 in. OD 7/8 in. OD

B LIQUID LINE CIRCUIT 3, 4 7/8 in. OD 7/8 in. OD 7/8 in. OD

C DISCHARGE LINE CIRCUIT 1, 2 1-1/8 in. OD 1-1/8 in. OD 1-1/8 in. OD

D DISCHARGE LINE CIRCUIT 3, 4 1-1/8 in. OD 1-1/8 in. OD 1-1/8 in. OD

E CONDENSATE DRAIN 1-1/4 in. FPT 1-1/4 in. FPT 1-1/4 in. FPT

F ECONOMIZER DRAIN 1-1/4 in. FPT 1-1/4 in. FPT 1-1/4 in. FPT

a50-8207

13

a50-8208

NOTES:

1. Dimensions in inches.

2. All units are rear return airflow configuration.

3. Use proper piping practice for remote refrigerant connections. Refer to

Carrier System Design Manual Part 3.

4. Recommended minimum service clearances are as follows:

a. Front and rear — 30 in. (762 mm)

b. Left and right sides — 65 in. (1651 mm) for coil removal

CONNECTIONS

REPLACEMENT FILTERS : SIXTEEN (16) AT 17 x 27 x 4 INCHES.

UNIT SIZE 044 054 064

A LIQUID LINE CIRCUIT 1, 2 7/8 in. OD 7/8 in. OD 7/8 in. OD

B LIQUID LINE CIRCUIT 3, 4 7/8 in. OD 7/8 in. OD 7/8 in. OD

C DISCHARGE LINE CIRCUIT 1, 2 1-1/8 in. OD 1-1/8 in. OD 1-1/8 in. OD

D DISCHARGE LINE CIRCUIT 3, 4 1-1/8 in. OD 1-1/8 in. OD 1-1/8 in. OD

E CONDENSATE DRAIN 1-1/4 in. FPT 1-1/4 in. FPT 1-1/4 in. FPT

F ECONOMIZER DRAIN 1-1/4 in. FPT 1-1/4 in. FPT 1-1/4 in. FPT

Fig. 11 — 50BVU,X044-064 (Low-Boy) Dimensions

14

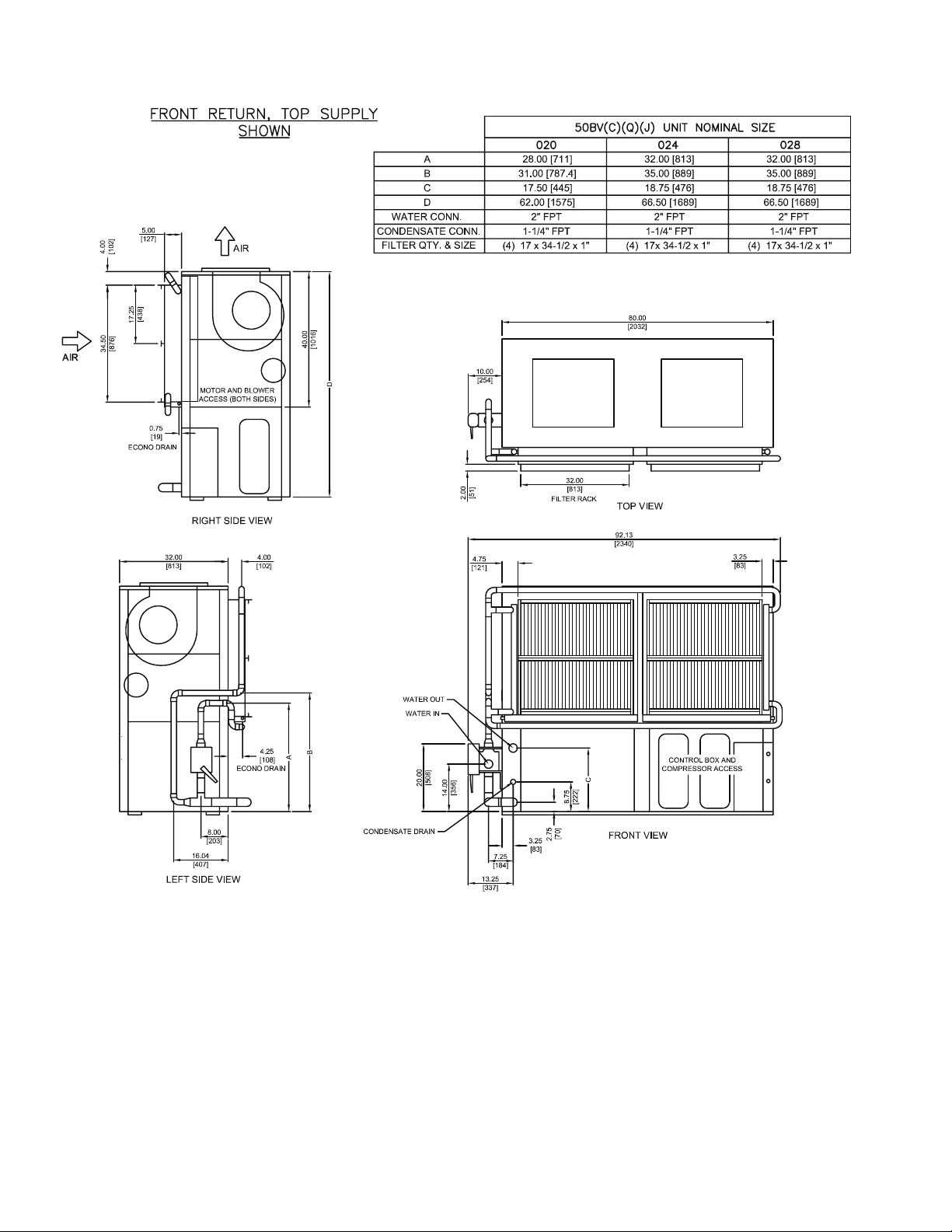

Fig. 12 — 50BVC,J,Q020-028 with Optional Waterside Economizer Dimensions

NOTES:

1. Dimensions in inches [mm].

2. Refer to base unit certified drawing for additional unit dimensions, service

clearance, and alternate airflow configurations.

a50-7306ef

15

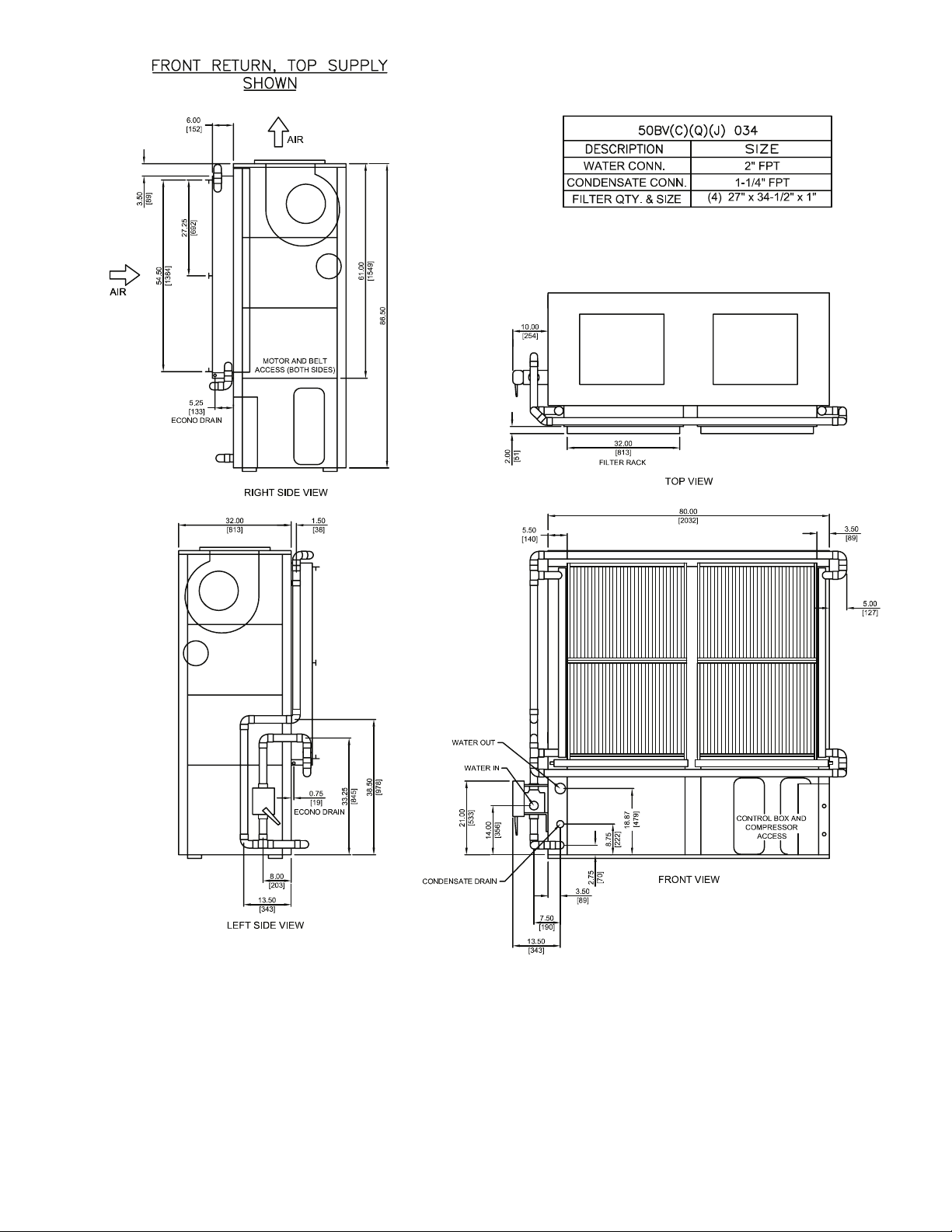

Fig. 13 — 50BVC,J,Q034 with Optional Waterside Economizer Dimensions

NOTES:

1. Dimensions in inches [mm].

2. Refer to base unit certified drawing for additional unit dimensions, service

clearances, and alternate airflow configurations.

a50-7307ef

16

*

*

a50-8235

Shipping Weights (lb)

*High-boy/low-boy.

50BVT,U,V,W,X UNIT

HIGH-BOY UNIT LOW-BOY UNIT

034 044 054 064 034 044 054 064

MAIN AIR CONDITIONING SECTION (EACH)

NUMBER OF SECTIONS 12221222

SECTION WEIGHT 1450 1175 1550 1575 2100 1825 2200 2225

REHEAT COIL OPTION 40 40 40 40 40 40 40 40

FILTER/ECONOMIZER SECTION (EACH)

NUMBER OF SECTIONS 12221222

FILTER SECTION 310 310 310 310 310 310 310 310

ECONOMIZER OPTION 200 200 200 200 200 200 200 200

FAN SECTION (EACH)

NUMBER OF SECTIONS 1222

INCLUDED IN

AIR CONDITIONING SECTION

FAN SECTION 650 650 650 650

TOTAL UN IT

NUMBER OF SECTIONS 36662444

UNIT WITH OPTIONS 2650 4750 5500 5550 2650 4750 5500 5550

Size 034 Units

Size 044-064 Units

Fig. 14 — Modular Shipping Weights — 50BVT,U,V,W,X

17

Table 3A — Physical Data — 50BVC,E,J,K,Q

LEGEND *R-410A models.

UNIT 50BVC,E,J,K,Q 020 024 028 034

NOMINAL CAPACITY (Tons) 18 20 25 30

OPERATING WEIGHT (lb)

50BVC,Q…50BVJ 1192…1227 1378…1413 1428…1473 1680…1725

50BVE…50BVK 1110…1145 1290…1325 1320…1365 1520…1565

COMPRESSOR Copeland Scroll

Quantity 2222

Number of Refrigerant Circuits 2222

Oil (ounces) Ckt 1…Ckt 2 85…85 110…110 110…110 140…140

REFRIGERANT TYPE R-22 or R-410A

Expansion Device TXVTXVTXVTXV

Operating Charge (lb) Ckt 1…Ckt 2 8.1…8.1 9.1…9.1 9.1…9.1 18.0…18.0

CONDENSER (50BVC,Q,J only) Tube-in-Tube Coaxial

Quantity of Manifolded Circuits 2222

Nominal Flow Rate (GPM) 54 60 75 90

Water Flow Range (GPM) 36-72 40-80 50-100 60-120

Max. Water Working Pressure (PSIG) 400 400 400 400

Max. Refrig. Working Pressure (PSIG) 450 (600*) 450 (600*) 450 (600*) 450 (600*)

Min. Entering Water Temp. (°F) 50 50 50 50

Max. Entering Water Temp. (°F) 110 110 110 110

Waterside Volume (gal) 3.6 4.0 5.0 6.0

EVAPORATOR COIL

Rows…Fins/in. 3…14 3…14 3…14 3…14

Total Face Area (sq ft) 18.1 18.1 18.1 22.0

EVAPORATOR FAN

Quantity…Size 2…15x15 2…15x15 2…15x15 2…15x15

Type Drive Belt Belt Belt Belt

Nominal CFM 7200 8000 10,000 12,000

Std Motor Qty…HP…Frame Size 2…1.5…56 2…2…56H 2…3…56HZ 2…5…56HZ

Alt 1 Motor Qty…HP…Frame Size 2…2…56H 2…3…56HZ 2…5…56HZ —

Alt 2 Motor Qty…HP…Frame Size 2…3…56HZ 2…5…56HZ — —

Alt 3 Motor Qty…HP…Frame Size 2…5…56HZ — — —

Motor Nominal RPM (1.5, 2, 3, HP) 1725 1725 1725 —

Motor Nominal RPM (5 HP) 3450 3450 3450 3450

Fan Drive RPM Range

Std Fan Drive (1.5, 2, 3 HP) 753-952 753-952 753-952 —

Std Fan Drive (5 HP) 967-1290 967-1290 967-1290 967-1290

Med Static Fan Drive (1.5, 2, 3 HP) 872-1071 872-1071 872-1071 —

Motor Bearing Type Ball Ball Ball Ball

Maximum Allowable RPM 1300 1300 1300 1300

Motor Pulley Pitch Diameter

Std Fan Drive (1.5, 2, 3 HP) 3.7-4.7 3.7-4.7 3.7-4.7 —

Std Fan Drive (5 HP) 2.9-3.9 2.9-3.9 2.9-3.9 2.9-3.9

Med Static Fan Drive (1.5, 2, 3 HP) 4.3-5.3 4.3-5.3 4.3-5.3 —

Motor Shaft Diameter (in.) (1.5, 2 HP)

5

/

8

5

/

8

——

Motor Shaft Diameter (in.) (3, 5 HP)

7

/

8

7

/

8

7

/

8

7

/

8

Belt, Qty…Type…Length (in.)

Std Fan Drive (1.5, 2 HP) 1…B…39 1…B…39 — —

Std Fan Drive (3 HP) 2…B…39 2…B…39 2…B…39 —

Std Fan Drive (5 HP) 2...BX…42 2...BX…42 2...BX…42 2...BX…42

Med Static Fan Drive (1.5, 2 HP) 1…B…40 1…B…40 — —

Med Static Fan Drive (3 HP) 2…B…40 2…B…40 2…B…40 —

Pulley Center Line Distance (in.) 10.1…10.9 10.1…10.9 10.1…10.9 10.1…10.9

Speed Change Per Full Turn of

Moveable Pulley Flange (RPM)

Std Fan Drive (1.5, 2, 3 HP) 33 33 33 —

Std Fan Drive (5 HP) 54 54 54 54

Med Static Fan Drive (1.5, 2, 3 HP) 33 33 33 —

Fan Shaft Diameter (in.) 1111

HIGH PRESSURE SWITCHES (PSIG)

Cutout 380 (420*) ± 10 380 (420*) ± 10 380 (420*) ± 10 380 (420*) ± 10

Reset (Auto) 300 (420*) ± 15 300 (420*) ± 15 300 (420*) ± 15 300 (420*) ± 15

LOW PRESSURE SWITCHES (PSIG)

Cutout 20 (40*) ± 3 20 (40*) ± 3 20 (40*) ± 3 20 (40*) ± 3

Reset (Auto) 40 (60*) ± 5 40 (60*) ± 5 40 (60*) ± 5 40 (60*) ± 5

REMOTE REFRIGERANT CONNECTIONS

(50BVE,K Only)

Discharge (Hot Gas) Connection (in.) Qty…Size 2…1

1

/

8

2…1

1

/

8

2…1

1

/

8

2…1

1

/

8

Liquid Connection (in.) Qty…Size 2…

7

/

8

2…

7

/

8

2…

7

/

8

2…

7

/

8

RETURN AIR FILTERS

Quantity…Size (in.) 4…20x34.5x1 4…20x34.5x1 4…20x34.5x1 4…30x34.5x1

TXV — Thermostatic Expansion Valve

18

Table 3B — Physical Data — 50BVT,U,V,W,X

UNIT 50BVT,U,V,W,X 034 044 054 064

NOMINAL CAPACITY (Tons) 30 40 50 60

OPERATING WEIGHT (lb)

50BVT,V…50BVW 2580…2645 4334…4404 5198…5298 5230…5330

50BVU…50BVX 2420…2485 4094…4164 4938…5038 4970…5070

COMPRESSOR Copeland Scroll

Quantity 2444

Number of Refrigerant Circuits 2444

Oil (oz.)

Circuit 1…Circuit 2 140…140 110…110 140…140 140…140

Circuit 3…Circuit 4 — 110…110 140…140 140…140

REFRIGERANT TYPE R-22

Expansion Device TXV TXV TXV TXV

Operating Charge (lb)

Circuit 1…Circuit 2 18.0…18.0 10.0…10.0 18.0…18.0 18.0…18.0

Circuit 3…Circuit 4 — 10.0…10.0 18.0…18.0 18.0…18.0

CONDENSER (50BVT,V,W only) Tube-in-Tube Coaxial

Quantity of Manifolded Circuits 2444

Nominal Flow Rate (GPM) 90 120 150 180

Water Flow Range (GPM) 60-120 80-160 100-200 120-240

Max. Water Working Pressure (PSIG) 400 400 400 400

Max. Refrig. Working Pressure (PSIG) 450 450 450 450

Min. Entering Water Temp. (°F) 50 50 50 50

Max. Entering Water Temp. (°F) 110 110 110 110

Waterside Volume (gal) 6.0 9.0 11.3 13.5

EVAPORATOR COIL

Rows…Fins/in. 4…12 3…12 4…12 4…12

Total Face Area (sq ft) 23.2 46.4 46.4 46.4

EVAPORATOR FAN

Quantity…Size 1…18x18 2…18x18 2…18x18 2…18x18

Type Drive Belt Belt Belt Belt

Nominal CFM 12,000 16,000 20,000 24,000

Motor Option 1 Qty…HP…Frame Size 1…7.5…213T 2…7.5…213T 2…7.5…213T 2…7.5…213T

Motor Option 2 Qty…HP…Frame Size 1…10…215T 2…10…215T 2…10…215T 2…10…215T

Motor Option 3 Qty…HP…Frame Size 1…15…254T 2…15…254T 2…15…254T 2…15…254T

Motor Option 4 Qty…HP…Frame Size 1…20…256T — 2…20…256T 2…20…256T

Motor Nominal RPM 1750 1750 1750 1750

Fan Drive RPM Range

Standard (7.5 HP) 780-960 780-960 780-960 780-960

Standard (10, 15, 20 HP), Med Static (7.5 HP) 805-991 805-991 805-991 805-991

Med Static (10, 15, 20 HP), High Static (7.5 HP) 960-1146 960-1146 960-1146 960-1146

High Static (10, 15, 20 HP) 1119-1335 1119-1335 1119-1335 1119-1335

Motor Bearing Type Ball Ball Ball Ball

Maximum Allowable RPM 1450 1450 1450 1450

Motor Pulley Pitch Diameter

Std Fan Drive (7.5 HP) 5.2-6.4 5.2-6.4 5.2-6.4 5.2-6.4

Std Fan Drive (10, 15, 20 HP), Med Static (7.5 HP) 4.8-6.0 4.8-6.0 4.8-6.0 4.8-6.0

Med Static Fan Drive (10, 15, 20 HP), High Static (7.5 HP) 5.8-7.0 5.8-7.0 5.8-7.0 5.8-7.0

High Static Fan Drive (10, 15, 20 HP) 5.8-7.0 5.8-7.0 5.8-7.0 5.8-7.0

Motor Shaft Diameter (in.) (7.5, 10 HP) 1

3

/

8

1

3

/

8

1

3

/

8

1

3

/

8

Motor Shaft Diameter (in.) (15, 20 HP) 1

5

/

8

1

5

/

8

1

5

/

8

1

5

/

8

Belt, Qty…Type…Length (in.)

Std Fan Drive (7.5 HP) 2…B…48 2...B...48 2…B…48 2…B…48

Std Fan Drive (10, 15, 20 HP), Med Static (7.5 HP) 2…B…46 2…B…46 2…B…46 2…B…46

Med Static Fan Drive (10, 15, 20 HP), High Static 7.5 HP) 2…B…48 2…B…48 2…B…48 2…B…48

High Static Fan Drive (10, 15, 20 HP) 2…B…45 2…B…45 2…B…45 2…B…45

Pulley Center Line Distance (in.) 10.2-11.4 10.2-11.4 10.2-11.4 10.2-11.4

Speed Change Per Full Turn of Moveable Pulley Flange (RPM)

Std Fan Drive (7.5 HP) 36 36 36 36

Std Fan Drive (10, 15, 20 HP), Med Static (7.5 HP) 31 31 31 31

Med Static Fan Drive (10, 15, 20 HP), High Static (7.5 HP) 31 31 31 31

High Static Fan Drive (10, 15, 20 HP) 36 36 36 36

Fan Shaft Diameter (in.) 1

7

/

16

1

7

/

16

1

7

/

16

1

7

/

16

HIGH PRESSURE SWITCHES (PSIG)

Cutout 380 ± 10 380 ± 10 380 ± 10 380 ± 10

Reset (Auto) 300 ± 15 300 ± 15 300 ± 15 300 ± 15

LOW PRESSURE SWITCHES (PSIG)

Cutout 20 ± 3 20 ± 3 20 ± 3 20 ± 3

Reset (Auto) 40 ± 5 40 ± 5 40 ± 5 40 ± 5

REMOTE REFRIGERANT CONNECTIONS (50BVU,X Only)

Discharge (Hot Gas) Connection (in.) Qty…Size 2…1

1

/

8

4…1

1

/

8

4…1

1

/

8

4…1

1

/

8

Liquid Connection (in.) Qty…Size 2…

7

/

8

4…

7

/

8

4…

7

/

8

4…

7

/

8

RETURN AIR FILTERS

Quantity…Size (in.) 8…17x27x4 16…17x27x4 16…17x27x4 16…17x27x4

19

ACOUSTICAL CONSIDERATIONS — Proper acoustical

considerations are a critical part of every system’s design and

operation. Each system design and installation should be

reviewed for its own unique requirements. For job specific

requirements, contact an acoustical consultant for guidance and

recommendations.

In general, to reduce noise, consider the following:

• Locate mechanical room and ducts away from noise

sensitive locations. Whenever possible, work with the

architect to locate the equipment rooms around the

perimeters of restrooms, hallways, fire escapes, stair

wells, etc., to reduce noise transmission. This allows not

only for isolation from radiated sound but also enables

the contractor to route duct systems around sensitive

locations.

• Construct the equipment room of concrete block or use a

double offset stud wall with interwoven insulation. Seal

all penetrations.

• Design the system for low total static pressure.

• Use suitable vibration isolation pads or isolation springs

according to the design engineer's specifications.

• A flexible canvas duct connector is recommended on

both the supply and return air sides of units to be

connected to system ductwork.

• Use a minimum of 15 ft of return ductwork between the

last air terminal or diffuser and the unit.

• Insulate supply and return ducts with 2-in., 3-lb density

insulation.

• Round duct is recommended. If rectangular ductwork is

used, keep aspect ratios as small as possible (i.e., as close

to square as possible).

• Avoid any direct line of sight from return air grilles

into the unit's return. If return air is to be ducted to an

equipment room, an elbow should be installed within the

equipment room.

• Running a return air drop to near the floor of the room

will aid in sound attenuation.

• Do not exceed the recommended supply duct velocity of

2,000 fpm.

• Do not exceed the recommended return duct velocity of

1,000 fpm.

• Use turning vanes on 90-degree elbows.

• Place isolation springs under each corner and under each

compressor if utilized.

ASSEMBLING MODULAR UNITS — 50BVT,U,V,W,X

30 to 60 ton units ship in the number of pieces shown in Table

2. Reassemble the unit. Use the loose hardware provided in the

main air-conditioning section and the instructions below.

1. The filter/economizer section ships bolted to the main air-

conditioning section and can be removed in the field.

When reattaching the filter/economizer section to the

main air-conditioning section, place the filter side of the

filter/economizer section facing out and away from the

main air conditioning section.

2. If the unit has 2 filter/economizer and 2 main air-

conditioning sections (40 through 60 ton units), bolt the

remaining filter/economizer section and main air-

conditioning section together, as in Step 1.

3. For units with 2 filter/economizer and 2 main air-

conditioning sections, use the provided unions to assem-

ble the water connections between the 2 additional

sections joined in Step 2.

4. For units with multiple air conditioning sections, connect

the condensate drain hoses from the “B” side of the unit

to the drain manifold on the “A” side of the unit.

5. For unit sizes 044-064, connect power wiring from the

main terminal block in the “A” side of the unit to the

power terminal block in the “B” side of the unit.

6. For VAV units only, connect the plenum tubing, coiled

behind the VAV control panel, to the bulkhead fittings

located in the discharge of the supply fan. This connects

the high pressure supply to the high side of the duct high

static pressure switch.

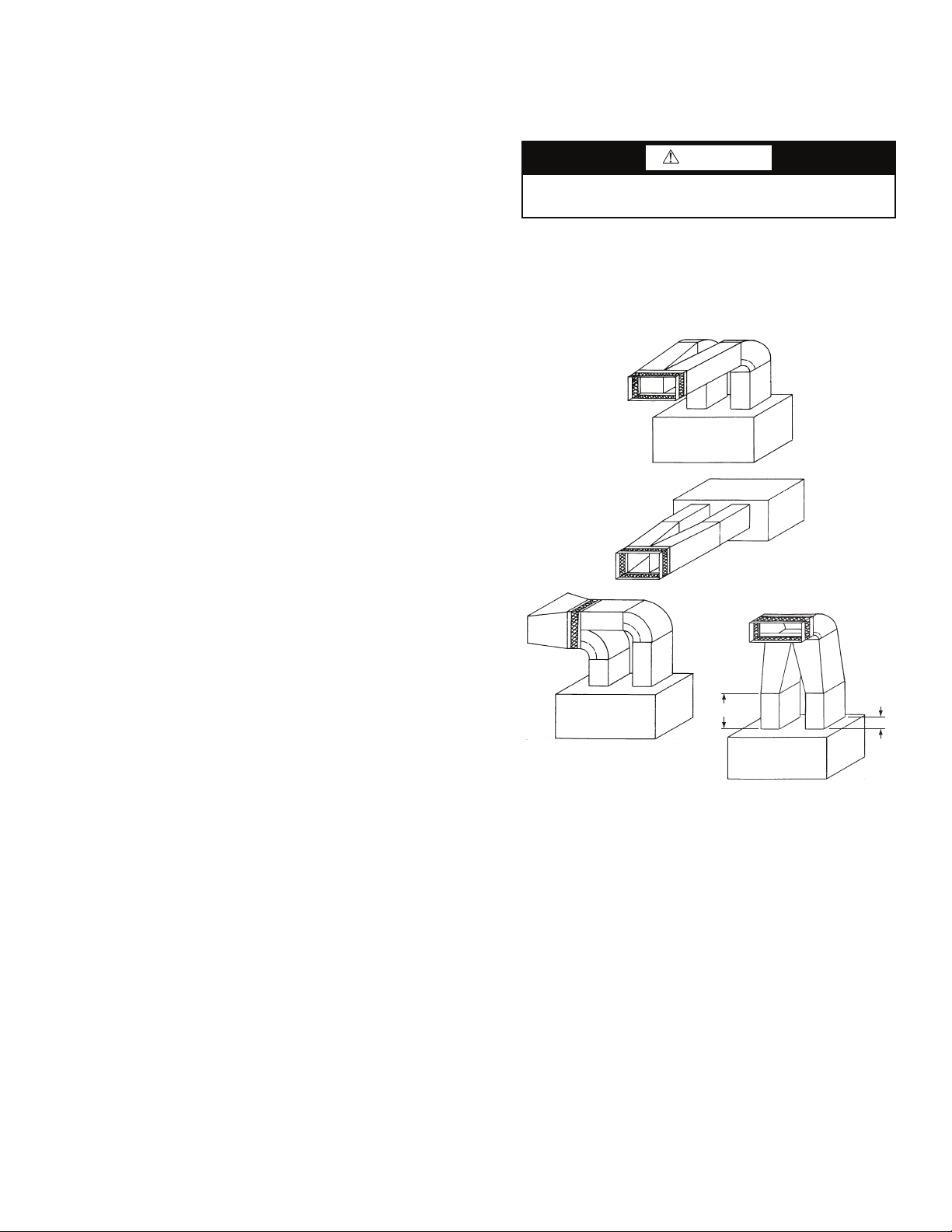

Step 3 — Install Ductwork — The VAV units must

use a “pair of pants” configuration as shown in Fig. 15. Refer

to the Carrier System Design Manual or ASHRAE (American

Society of Heating, Refrigerating and Air Conditioning Engi-

neers) standards for the recommended duct connection to unit

with 2 fans.

A supply air outlet collar and return air duct flange are pro-

vided on all units to facilitate duct connections. Refer to dimen-

sional drawings (Fig. 2-14) for connection sizes and locations.

A flexible canvas duct connector is recommended on both

supply and return air sides of the units to be connected to the

system ductwork.

All metal ductwork should be adequately insulated to avoid

heat loss or gain and to prevent condensation from forming on

the duct walls. Uninsulated ductwork is not recommended, as

the unit's performance will be adversely affected.

Do not connect discharge ducts directly to the blower

outlet(s). The factory filter should be left in place on a free

return system.

If the unit will be installed in a new installation, the duct

system should be designed in accordance with the System De-

sign Manual, Part 2 and with ASHRAE (American Society of

Heating, Refrigeration and Air Conditioning Engineers) proce-

dures for duct sizing. If the unit will be connected to an existing

duct system, check that the existing duct system has the capaci-

ty to handle the required airflow for the unit application at an

CAUTION

Remove all shipping blocks, if any, under blower housing

or damage to the fan may occur.

Fig. 15 — Typical Fan Discharge Connections for

Multiple Fan Units

NOTE: A = 1

1

/

2

to 2

1

/

2

B

A

B

a50-8357.eps

20

acceptable system static pressure. If the existing duct system is

too small, larger ductwork must be installed.

The duct system and diffusers should be sized to handle the

design airflow volumes quietly. To maximize sound attenuation

of the unit's blower(s), the supply and return air plenums should

be insulated for a length of at least 15 ft from the unit. Direct line

of sight from return air grilles into the unit's return should be

avoided. If return air is to be ducted to an equipment room, an

elbow should be installed within the equipment room. Running a

return air drop to near the floor of the room will aid in sound

attenuation. Avoid transmitting vibrations generated by the

movement of air in the ducting to the walls of the building. This

is especially important where ductwork penetrates walls. The

maximum recommended return air velocity is 1,000 fpm. Lower

return air velocities will result in lower sound power levels. The

use of round supply duct plenums should be considered, as it

will significantly reduce low frequency sound at the equipment

room. If rectangular supply plenums are used, the aspect ratio of

the duct should be kept as small as possible (i.e., as close to

square as possible). The large, flat surface areas associated with

large aspect ratio duct systems will transmit sound to the space,

and the potential for duct-generated noise is increased. The max-

imum recommended supply air duct velocity is 2,000 fpm.

Units with two fans should have a properly designed “pair

of pants” duct connection. An adequate straight length of

ducting from the unit should be allowed before elbows are

installed. If connecting an elbow directly to the fan outlet, a

minimum straight length of 2 fan diameters from the fan outlet

is recommended. Elbows should turn in the direction of fan ro-

tation, if possible. Abrupt turns will generate air turbulence and

excessive noise. Turning vanes should be used in all short radi-

us bends. Ensure that ducting does not obstruct access to the

unit for routine servicing.

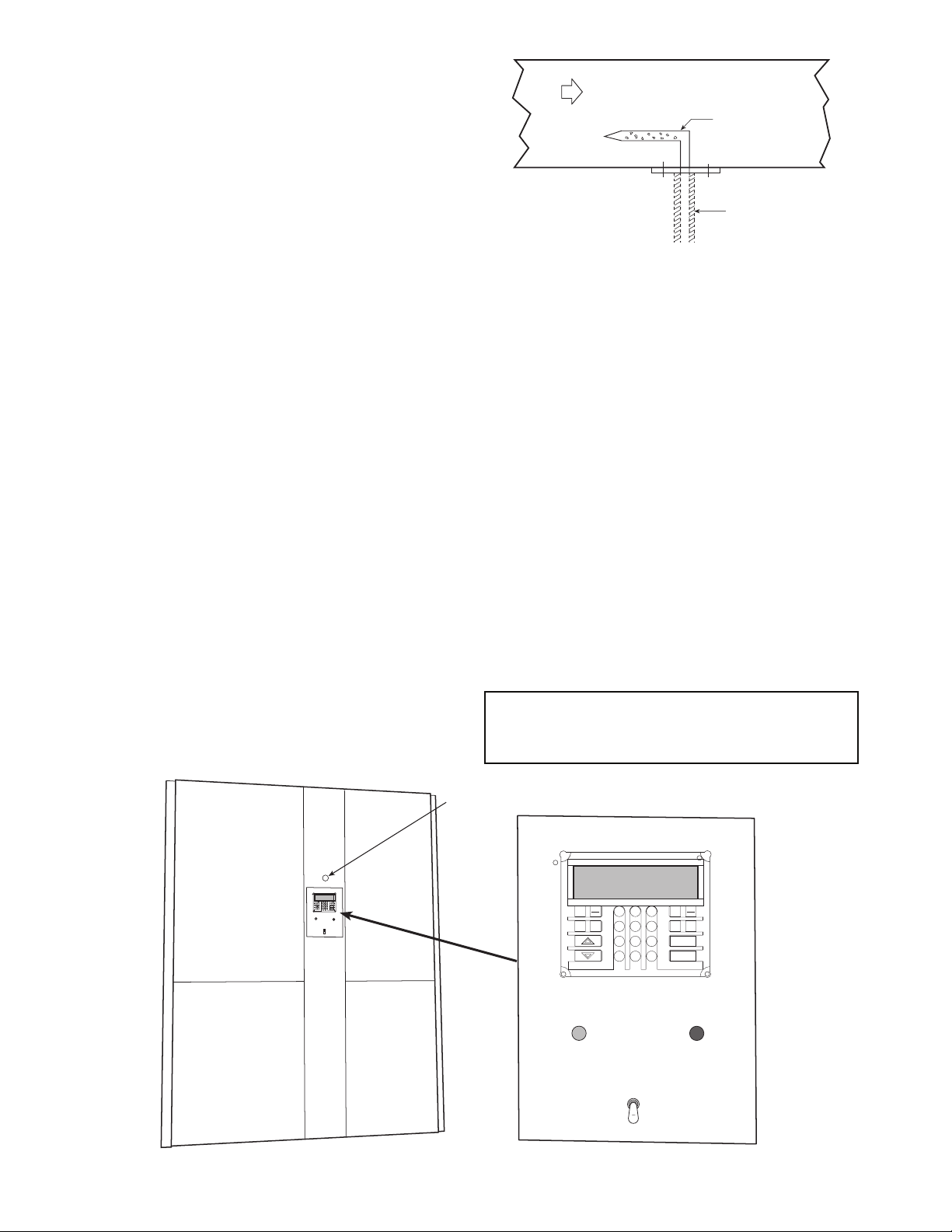

DUCT STATIC PRESSURE PROBE AND TUBING (VAV

Only) — On VAV systems, the duct static pressure sensor and

tubing are field-mounted. The sensor tubing sensing point

should be located near the end of the main supply trunk duct in

a position free from turbulence effects and at least 10 duct di-

ameters downstream and 4 duct diameters upstream from any

major transitions or branch take-offs. Incorrectly placing the

sensing point could result in improper operation of the entire

VAV s y st e m .

Install the factory-supplied duct static pressure probe with

the tip facing into the airflow. See Fig. 16.

Use

1

/

4

-in. OD approved polyethylene tubing for up to

50 ft (

3

/

8

-in. OD for 50 to 100 ft) to connect the probe to the

bulkhead fitting mounted above the unit display panel

(Fig. 17). Carefully route the tubing from the probe to this

bulkhead fitting.

The static pressure control should be adjusted so that, at full

airflow, all of the remote VAV terminal boxes receive the

minimum static pressure required plus any downstream resis-

tance. Control the system to the lowest static pressure set point

that will satisfy airflow requirements. Lower static pressure set

points reduce total required brake horsepower and reduce

generated sound levels.

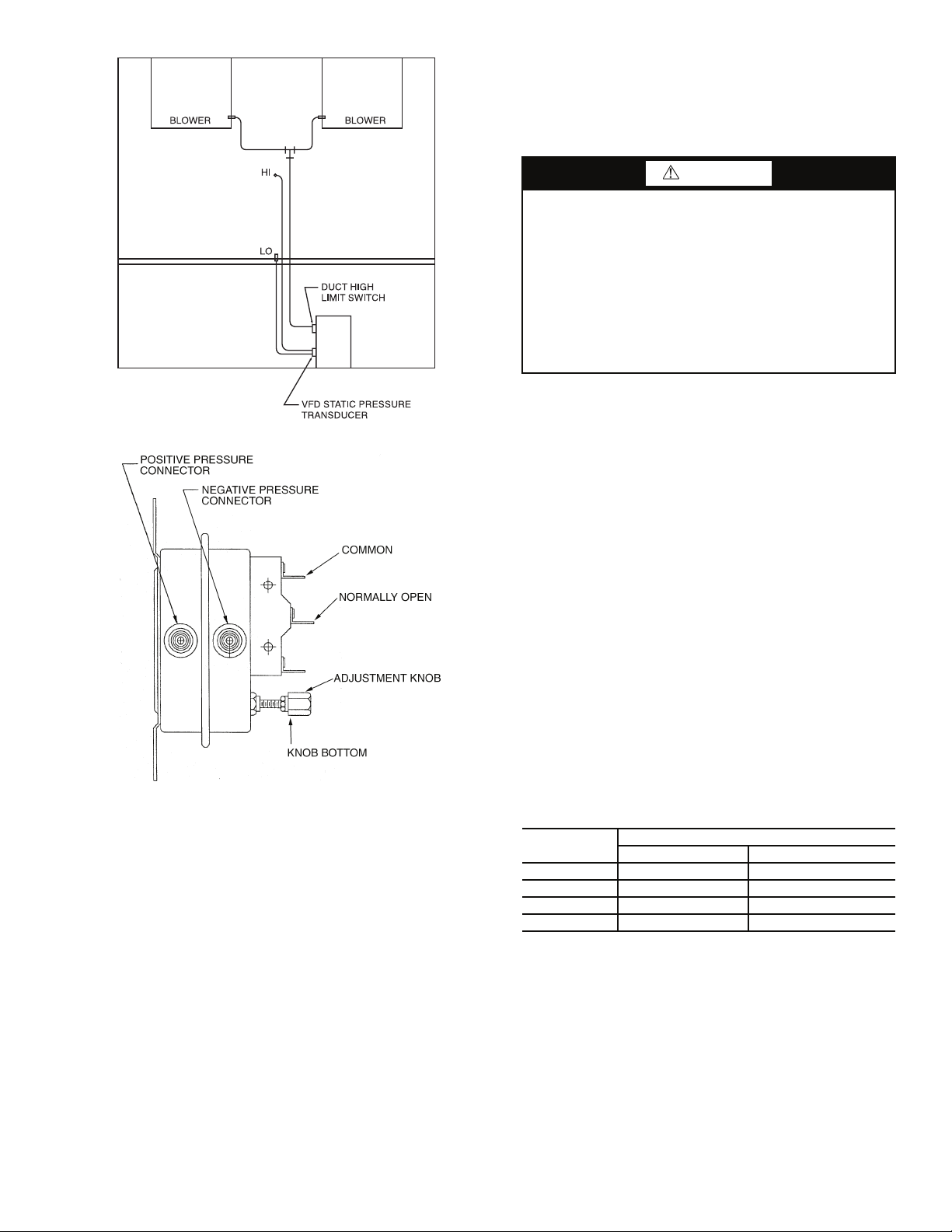

DUCT HIGH-STATIC (DHS) LIMIT SWITCH (VAV

Only) — The duct high static limit switch is a mechanical

safety that prevents duct overpressurization. The switch is lo-

cated on the side of the VAV low voltage control panel

(Fig. 18) and is factory set at 3 in. wg. To make an adjustment

using an accurate differential pressure gage, connect low side

and high side to gage and pressure source. Place a voltmeter

across common and normally open contacts. Rotate the adjust-

ment knob (Fig. 19) clockwise to increase pressure setting and

counterclockwise to decrease pressure setting. When the bot-

tom of the adjustment knob is approximately

1

/

8

-in. from the

switch body, the switch will trip at approximately 3 in. wg.

IMPORTANT: Use tubing that complies with local codes.

Improper location or installation of the supply duct pres-

sure tubing will result in unsatisfactory unit operation and

poor performance.

AIRFLOW

PROBE

TUBING

Fig. 16 — Duct Static Pressure Probe

(P/N 39EK20462)

a50-7138ef

WARNING

ALARM

REMOTE

LOCAL

OFF

ENTER

CLEAR

SRVC

HISTALGO

TEST

ALRM

3

6

9

1

2

4

5

7

8

0

.

–

STAT

SET

SCHD

EXPN

EDIT

WARNING

ALARM

REMOTE

LOCAL

OFF

ENTER

CLEAR

SRVC

HIST ALGO

TEST

ALRM

3

6

9

1

2

4

5

7

8

0

.

–

STAT

SET

SCHD

EXPN

EDIT

DUCT STATIC

PRESSURE

PROBE

BULKHEAD

FITTING

Fig. 17 — Display Panel Location on Unit Front Panel

a50-7267ef

21

Step 4 — Make Piping Connections

CONDENSER WATER PIPING (Water-Cooled Only) —

Always follow national and local codes when installing water

piping to ensure a safe and proper installation. Connections to

the unit should incorporate vibration eliminators to reduce

noise and vibration to the building, and shutoff valves to facili-

tate servicing.

Prior to connecting the unit(s) to the condenser water

system, the system should be flushed to remove foreign

material that could cause condenser fouling. Install a screen

strainer with a minimum of 20 mesh ahead of the condenser

inlet to prevent condenser fouling and internal condenser tube

damage from foreign material.

Supply and return water piping must be at least as large as

the unit connections, and larger for long runs. Refer to the

System Design Manual, Part 3, and standard piping practice,

when sizing, planning, and routing water piping. See dimen-

sion drawings (Fig. 2-14) for water connection sizes and

locations.

Units are furnished standard with a copper heat exchanger.

A cupronickel heat exchanger is also available as a

factory-installed option. Copper is adequate for closed loop

systems where good quality water is available. In conditions

where scale formation or water treatment is questionable, the

optional cupronickel heat exchanger should be used. Where the

water is especially corrosive or could lead to excessive fouling,

intermediate plate frame heat exchangers are recommended.

The unit is capable of operating with entering water temper-

atures as low as 50 F, without the need for head pressure

control. If the entering water temperature is expected to be

lower, or more stable unit operation is desired, a field-supplied

water-regulating valve may be used.

This unit has multiple independent refrigerant circuits with

separate condensers. The individual condensers are manifolded

together on the waterside to provide easy, single-point water

connections. In order to achieve proper head pressure control

when a water-regulating valve is used, a temperature-actuated

valve is recommended. This allows any of the independent

refrigerant circuits to operate while still modulating condenser

water flow in response to loop water temperature.

A glycol solution should be used if ambient temperatures

are expected to fall below freezing or if the loop water temper-

ature is below 50 F while operating in the reverse cycle heating

mode (heat pump units only). Refer to Table 4, which

lists freezing points of glycol at different concentrations. A

minimum concentration of 20% is recommended. Water

pressure drop will increase and unit performance will decrease

with increasing glycol concentrations.

Units with factory-installed waterside economizers have

cooling water passing through the economizer and condenser

in series while operating in the economizer mode. During

normal operation, water bypasses the economizer coil.

Table 4 — Glycol Freezing Points

All manual flow valves used in the system should be of the

ball valve design. Globe or gate valves must not be used due to

high pressure drops and poor throttling characteristics.

Do not exceed recommended condenser fluid flow rates

shown in Tables 5A and 5B. Serious damage or erosion of the

heat exchanger tubes could occur. Piping systems should not

exceed 10 fps fluid velocities to ensure quietness and tube wall

integrity. Refer to Tables 5A and 5B for condenser water pres-

sure drop versus flow rate. Flow rates outside of the published

range should not be used.

Ball valves should be installed in the supply and return lines

for unit isolation and water flow balancing.

CAUTION

Galvanized pipe or fittings are not recommended with

50BV units due to the possibility of galvanic corrosion

caused by dissimilar metals. When selecting piping

materials, use only approved piping materials that meet

applicable codes and that will handle the temperatures and

pressures that may be experienced in the application.

Piping systems will sweat if low temperature fluid is used

in the system. For these applications, supply and return

water piping should be insulated to protect from condensa-

tion damage. The minimum recommended entering water

temperature to the unit is 50 F.

% GLYCOL

FREEZE POINT (° F)

Ethylene Glycol Proplylene Glycol

20 18 19

30 79

40 –7 –5

50 –28 –27

Fig. 19 — DHS Limit Switch (P/N 190060)

a50-7268tf

Fig. 18 — DHS Pressure Limit Location

a50-8253

Loading...

Loading...