Carrier 38AKS014-024, 30GT015-035 User Manual

38AKS014-024 30GT015-035 Accessory Hot Gas Bypass 50/60 Hz

Installation Instructions

Part No. 30GT911054

GENERAL

These installation instructions cover field installation of the accessory hot gas bypass valve, pilot valve, and hot gas solenoid. For 30GT units, these instructions are intended for units with a starting serial number of 2294F--- or higher. The hot gas bypass package is not required on 30GT015, 50 Hz units or on 30GT020, 60 Hz units, since these 2 units have hot gas bypass installed as standard from the factory. See table below for a listing of package contents.

Follow all safety codes. Wear safety glasses and work gloves. Use care in handling equipment.

Be sure power to equipment is shut off before performing maintenance or service functions. Electrical shock may cause personal injury.

NOTE: Since the 30GT015-035 and 38AKS014-024 units are single-circuit units, only one accessory package is required per unit.

ACCESSORY PACKAGE CONTENTS

ITEM |

QUANTITY |

PART NO. |

|

Pilot Valve |

1 |

EF11BS038 |

|

Hot Gas Solenoid |

1 |

EF19XS024 |

|

With Clip |

|||

|

|

||

Hot Gas Bypass |

1 |

EA52DC421 |

|

Valve |

|||

|

|

INSTALLATION IN 30GT

AIR-COOLED CHILLERS

Step 1 — Install Piping

Shut off all power to the unit and remove refrigerant charge before continuing with this accessory installation. Failure to do so may result in personal injury.

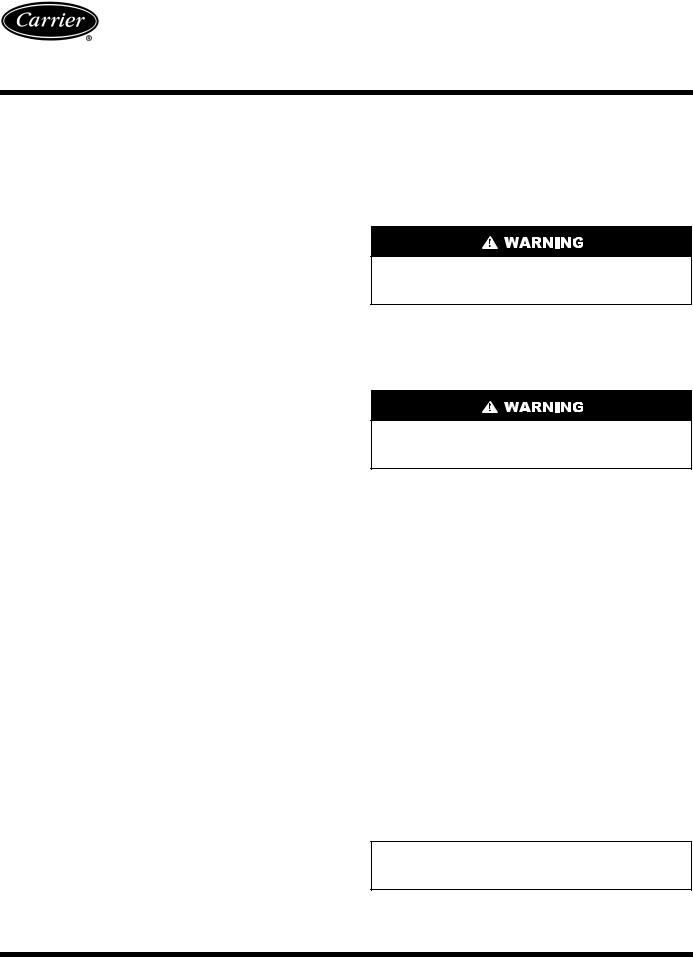

See Fig. 1 for a schematic of the unit piping.

In addition, the following parts will need to be field-supplied:

•1/4-in. refrigerant grade copper tubing (amount will vary

with application)

•3/8-in. refrigerant grade copper tubing (amount will vary

with application)

•5/8-in. refrigerant grade copper tubing (amount will vary

with application)

•For 30GT units, one manual shut-off valve for 5/8-in. line

•One 3-way-tee with an internal branch OR one standard 3-way tee (depending on application - see Pilot Valve and Hot Gas Solenoid section for more information)

•For 38AKS/indoor coil split system, an auxiliary side connector may be required.

Examine Package Contents — Examine each item in the package. If any part is damaged or missing, file a claim immediately with the shipper. See table above for accessory package contents.

SAFETY CONSIDERATIONS

Installing, starting up, and servicing air-conditioning equipment can be hazardous due to system pressures, electrical components, and equipment location.

Only trained, qualified installers and service technicians should install, start up, and service this equipment.

When working on air-conditioning equipment, observe precautions in the literature and on tags, stickers, and labels attached to the equipment.

BYPASS LINE — Install the 5/8 in., field-supplied line between the factory-supplied stubs in the discharge line (from the compressor) and in the liquid line between the expansion valve and cooler. See Fig. 2.

NOTE: The stubs are sealed as shipped from the factory.

Install the field-supplied shut-off valve in the bypass line as close to the discharge line as possible. The shut-off valve will aid in the pumpdown of the low side when closed.

HOT GAS BYPASS VALVE — Install the valve in the bypass line near the shut-off valve installed in the Bypass Line section above. The bypass valve has 5/8 in. ODF inlet and outlet (one each), and a 3/8 in. ODM equalizer port (sweat connection). To ensure proper operation, the valve should be installed in a horizontal section of the bypass line and the pilot valve should be installed above bypass valve body.

PILOT VALVE AND HOT GAS SOLENOID — Install the hot gas solenoid onto the pilot valve. The solenoid fits over the stem of the valve and attaches with the supplied clip on the top (over the coil).

Install the pilot valve/solenoid assembly in the external equalizer line of the bypass valve (3/8 in. ODF equalizer port). The pilot valve has a 3/8 in. ODF inlet and a 1/4 in. SAE (Society of Automotive Engineers, U.S.A.) connection to the TXV (thermostatic expansion valve) equalizer line.

IMPORTANT: Be sure the sweat connection on the hot gas bypass valve is facing the pilot valve/solenoid assembly in the equalizer line (See Fig. 1).

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book |

1 |

2 |

4 |

PC 111 |

Catalog No. 533-00067 |

Printed in U.S.A. |

Form 30GT/38AKS-1SI |

Pg 1 |

1-05 |

Replaces: 30GT-35SI |

Tab |

3a |

5c |

2a |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LEGEND

TXV — Thermostatic Expansion Valve

Factory Piping

Field Piping

NOTE: The bypass valve in this package has 5/8 in. connections and can be used directly on 30GT015035 units.

Fig. 1 — 30GT Piping Schematic

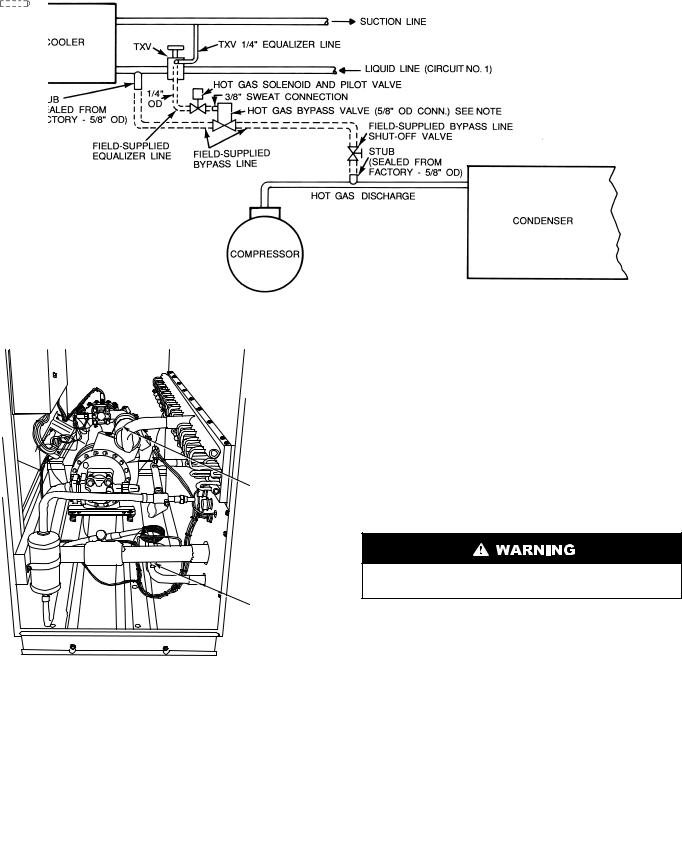

DISCHARGE STUB (HIDDEN)

Install the field-supplied 1/4 in. OD tubing from the SAE connection to the TXV equalizer line. If the connection is made directly to the TXV, use the field-supplied, 3-way tee with an internal branch (install horizontally in the line with the internal branch attaching directly to the TXV). If the connection is made into the equalizer line, use the field-supplied, standard 3- way tee.

Step 2 — Dehydrate and Recharge the Circuit — When piping is completed, leak test the assembly and replace the filter drier cores. Then evacuate, dehydrate, and recharge the circuit, using approved refrigeration practices.

LIQUID

STUB

Fig. 2 — 30GT Stub Locations

Step 3 — Install Control Wiring

Be sure all power to the unit is off before proceeding, and that all disconnects are open and tagged.

Follow all local codes and NEC (National Electrical Code, U.S.A.) when installing control wiring. All wire must be a minimum of 16 AWG (American Wire Gage, U.S.A.).

Connect control wires as shown in Fig. 3. At hot gas solenoid (HGS), connect to brown and orange wires as shown.

|

LEGEND |

|

|

COM — Common |

NC — Normally Closed |

TC — |

Temperature Controller |

HGS — Hot Gas Solenoid |

NO — Normally Open |

U1 — |

Unloader 1 |

Fig. 3 — 30GT Hot Gas Solenoid Wiring

2

Loading...

Loading...