Campbell Hausfeld HV2500, HV3000, HU502000AV, HU500000AV User Manual

See Warranty on page 4 for important information about commercial use of this product.

Operating Instructions & Parts Manual |

HV2000 and HV3000 Series |

|

|

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described. Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or property damage! Retain instructions for future reference.

|

HVLP |

BUILT TO LAST |

Turbine |

Attention: Campbell Hausfeld recommends that servicing other than that shown in the instruction manual should be performed by an authorized service facility. NOT INTENDED FOR CONTINUOUS USE.

Description

Campbell Hausfeld HVLP turbines are designed to generate a High Volume of Low Pressure air for operating HVLP spray guns. These turbines operate differently than air compressors because turbines do not require an air tank to hold compressed air. Since there is no compression of air, HVLP turbines do not create condensation in the air hoses as compressors often do. Consequently, the project is not at risk of condensation contaminating the coating material. The air generated by the turbine is generally warm due to the air working in the turbine. The warm air can be a benefit for accelerating drying in less than ideal weather conditions and for drying the spray gun components. HVLP turbines are portable, can be plugged into standard outlets and operate and sound similar to shop-vacs.

Unpacking

When unpacking the unit, inspect carefully for any damage that may have occurred during transit. Make sure any loose fittings, bolts, etc., are tightened before putting sprayer into service. Each unit has been tested before shipment. Do not readjust or modify the turbine components.

Specifications

MODEL HV2000

CFM . . . . . . . .54 CFM at turbine outlet Operating Pressure . . . . . . . .4 PSI Max. Motor Type . . . . . . .Brush type, 2 stage,

. . . . . . . . . . . . . . . . . . . . . . . .Tangential Hose Length . . . . . . .15 ft. (30 ft. Max.) Transfer Efficiency . . . . . . . . .86% Max. Weight . . . . . . . . . . . . . . . . . .15 Pounds Voltage . . . . . . . . . . . . .120V, 10.1 Amp Stub Hose . . . . . . . . . . . . . . . . . . . . . .No Storage Compartment . . . . . . . . . . .Yes

MODEL HV2500

CFM . . . . . . . .58 CFM at turbine outlet Operating Pressure . . . . . . . .5 PSI Max. Motor Type . . . . . . .Brush type, 2 stage,

. . . . . . . . . . . . . . . . . . . . . . . .Tangential Hose Length . . . . . . .25 ft. (40 ft. Max.) Transfer Efficiency . . . . . . . . .86% Max. Weight . . . . . . . . . . . . . . . . . .26 Pounds Voltage . . . . . . . . . . . . . .120V, 11 Amp Stub Hose . . . . . . . . . . . . . . . . . . . . . .Yes Storage Compartment . . . . . . . . . . .Yes

MODEL HV3000

CFM . . . . . . . .65 CFM at turbine outlet Operating Pressure . . . . . . . .6 PSI Max. Motor Type . . . . . . .Brush type, 3 stage,

. . . . . . . . . . . . . . . . . . . . . . . .Tangential Hose Length . . . . . . .25 ft. (50 ft. Max.) Transfer Efficiency . . . . . . . . .86% Max. Weight . . . . . . . . . . . . . . . . . .28 Pounds Voltage . . . . . . . . . . . . .120V, 13.8 Amp Stub Hose . . . . . . . . . . . . . . . . . . . . . .Yes Storage Compartment . . . . . . . . . . .Yes

COMPONENTS

(1) Turbine

(1)Hose and quick connect fitting assemble and clean the unit (storage

compartment)

(1)Wrench - the only tool needed to assemble and clean the unit (storage

compartment)

(1) Viscosity stick storage compartment)

(1) Cleaning brush ( storage compartment)

REMINDER: Keep your dated proof of purchase for warranty purposes! Attach it to this manual or file it for safekeeping.

© 2003 Campbell Hausfeld/Scott Fetzer |

For parts, product & service information |

IN206600AV 2/03 |

visit www.chpower.com

NOTE: Note means any additional information pertaining to the product or its proper usage.

Read all instructions and safety precautions before operating the unit.

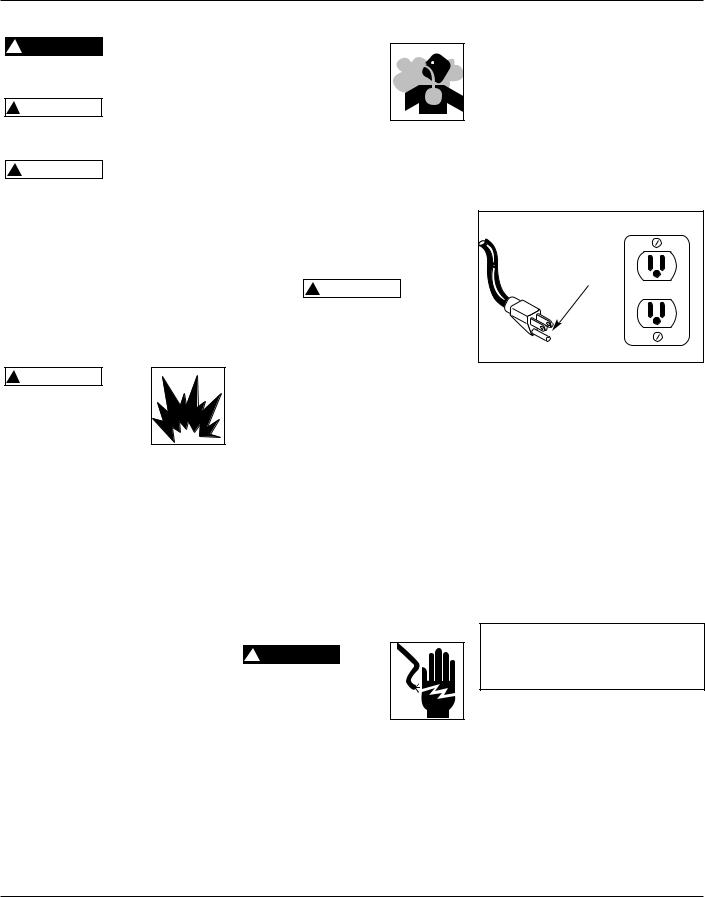

! WARNING

Risk of fire or explosion! Solvent and paint fumes can explode or ignite, causing severe injury and property damage.

Paints and solvents containing HALOGENATED HYDROCARBONS can react explosively with aluminum. Always check the product’s label before using these materials in the unit.

Make sure the room is well-ventilated.

Avoid all ignition sources, such as static electricity sparks, open flames, hot objects, sparks from connecting and disconnecting power cords, and working light switches.

Follow the material and solvent manufacturers’ safety precautions and warnings. Do not use liquids with flash points less than 100 degrees Fahrenheit (38 degrees Celsius).

Do not carry TURBINE while spraying.

Keep the turbine at the maximum distance from the spraying area.

Static electricity can be produced by HVLP spraying. Make sure any electrically conductive object being sprayed is grounded to prevent static sparking. The sprayer is grounded through the electric cord. If an extension cord is necessary, the cord

must be a grounded, 115 volt, three wire type cord.

Hazardous vapors: Paints, solvents, insecticides, and other materials may be harmful if inhaled, causing severe nausea, fainting, or poisoning.

Use a respirator or mask whenever there is a chance that vapors may be inhaled. Read all instructions with the mask to ensure that the mask will provide the necessary protection against the inhalation of harmful vapors.

NEVER point the spray gun at any part of the body, or at anyone else.

! CAUTION

Tipping the gun causes the gun to clog. Dried spray material also clogs the pressure delivery tube and fittings. The spray gun does not function when clogging occurs.

When not in use, be sure to disconnect the hose and place the gun on a solid, level surface to avoid tipping.

GROUNDING INSTRUCTIONS

This product must be properly grounded. In the event of an electrical short circuit, grounding reduces the risk of electrical shock by providing an alternate path for the electrical current.

This product is equipped with a cord that has a ground wire and an appropriate ground plug. Plug the unit into an outlet that is properly installed and grounded in accordance with local codes and ordinances.

! DANGER

Improper installation of the ground plug can result in the risk of electrical shock. If repair

or replacement of the plug or cord is necessary, do not connect the ground wire to either flat blade terminal. The wire with green insulation (with or without a yellow stripe) is the grounding wire.

1.For any question regarding proper installation of the ground plug, consult a qualified (licensed or certified) electrician.

2.Do not modify the plug provided. If the plug does not fit the outlet, have the proper outlet installed by a qualified electrician.

3.This product is for use on a nominal 120-volt circuit and has a grounding plug that looks like the plug in Figure 2. Make sure that the product is connected to an outlet having the same configuration as the plug. No adapters should be used with this product.

Grounding

Pin

TEST RESET

Figure 2 - Grounding Plug

4.If an extension cord is required, use only a three wire extension cord that has the same configuration as the unit cord, including the (round) ground terminal. Make sure that the extension cord is plugged into a properly grounded receptacle.

5.When using an extension cord, be sure it is in good condition and heavy enough to meet the specifications in the chart below. If an extension cord is needed, the following wire sizes must be used (See Chart 1).

25’ cord . . . . . . . .10,12, or 14 Gauge 50’ cord . . . . . . . . . . .10 or 12 Gauge 100’ cord . . . . . . . . . . . . . . .10 Gauge

Chart 1 Extension Cord Requirements

For Information About

This Product

Call 1-800-626-4401

www.chpower.com

2

Operating Instructions and Parts Manual

Maintenance

Be sure the air filter is clean. A dirty air filter restricts air flow and can cause the motor to overheat.

IMPORTANT: Keep the unit at the maximum distance from the spray area to extend filter life.

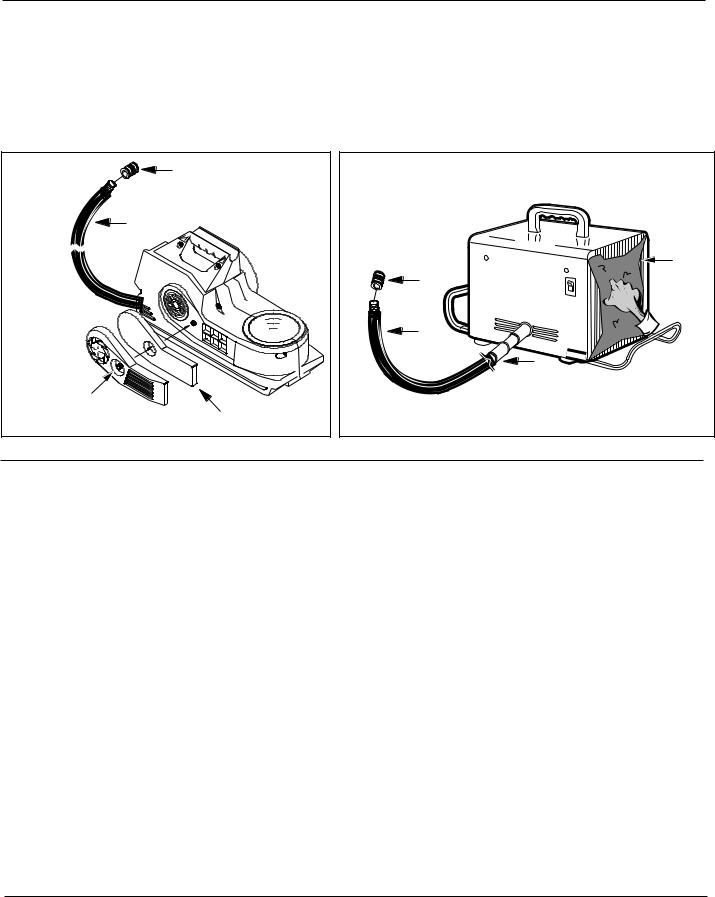

MODEL HV2000

1.Remove the filter grille thumbscrew with a screw driver to access the filter (See Figure 3).

2.Clean the filter with mild soapy water and pat dry.

3.Replace filter if built-up with paint.

MODEL HV2500 AND HV3000

1.Squeeze and pull to remove both filters (See Figure 4).

2.Clean the filter with mild soapy water and pat dry or replace filter if built-up with paint.

3.Squeeze and tuck to install filter.

Model HV2000 |

3 |

Models HV2500 or HV3000 |

|

|

|

|

2 |

|

|

|

1 |

|

|

3 |

|

|

2 |

|

|

4 |

Filter |

|

|

Housing |

|

1 |

Thumbscrew |

|

|

Figure 3 |

|

Figure 4 |

Replacement Parts List

|

Ref |

|

|

Part Number For Model Number |

|

|

|

|

|

|

|

|

|

|

|

|

No. |

Description |

HV2000 |

HV2500 |

HV3000 |

Qty |

|

|

|

|

|

|

|

|

|

1 |

Filter |

MP3021 |

— |

— |

1 |

|

|

|

|

Filter pack |

— |

HV012600AJ |

HV012600AJ |

2 |

|

2 |

Hose 15’ |

MP3106 |

— |

— |

1 |

|

|

|

|

Hose 25’ |

— |

HV012500AJ |

HV012500AJ |

1 |

|

3 |

Quick connect coupler |

HV002200AV |

HV002200AV |

HV002200AV |

1 |

|

|

4 |

Stub hose |

— |

HA222503AV |

HA222503AV |

1 |

|

|

|

Accessories |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ref |

|

|

|

|

|

|

|

No. |

Description |

|

Part Number |

Qty |

|

|

|

|

|

|

|

|

|

|

1 |

5' Whip Hose (Use with any model) |

HV012400AJ |

1 |

|

|

||

2 |

Multi-Purpose Case |

|

HV7008 |

1 |

|

|

|

Troubleshooting Chart

|

Symptom |

Possible Cause(s) |

Corrective Action |

|

|

|

|

|

|

|

Poor air flow |

1. Hose restricted or kinked |

1. Keep air hose straight |

|

|

|

2. Restricted filter |

2. Clean or replace filter |

|

|

|

|

|

|

|

Unusual grinding noise |

Damaged turbine motor |

Contact Service Center |

|

For Information About This Product

Call 1-800-626-4401

www.chpower.com

3

Operating Instructions and Parts Manual

Limited Warranty

1.DURATION: From the date of purchase by the original purchaser as follows: Standard Duty Paint Application Systems and all Paint Application Accessories - 1 year, Serious Duty Paint Application Systems - 3 years, Extreme Duty Paint Application Systems - 5 years.

2.WHO GIVES THIS WARRANTY (WARRANTOR): Campbell Hausfeld/A Scott Fetzer Company, 100 Production Drive, Harrison, Ohio, 45030, Telephone: 1-800-626-4401.

3.WHO RECEIVES THIS WARRANTY (PURCHASER): The original purchaser (other than for purposes of resale or rental) of the Campbell Hausfeld Product.

4.WHAT PRODUCTS ARE COVERED BY THIS WARRANTY: All non-compressor driven paint application systems, HVLP spraying systems, and paint application accessories supplied or manufactured by the Warrantor.

5.WHAT IS COVERED UNDER THIS WARRANTY: Defects in material and workmanship which occur within the duration of the warranty period. Warrantor will also cover normal wear items for a period of thirty days from the date of original purchase against defects in material and workmanship. These wear items are: HVLP-filters, motor brushes, gun packing, gun canister seal, gun check valve and gun air flow ring; Airless-inlet valve, outlet valve, gun valve, filters, tips, all seals and o- rings.

6.WHAT IS NOT COVERED UNDER THIS WARRANTY:

A.Implied warranties, including those of merchantability and FITNESS FOR A PARTICULAR PURPOSE ARE LIMITED FROM THE DATE OF ORIGINAL PURCHASE AS STATED IN THE DURATION. If standard duty product is used for commercial or industrial purposes, the warranty will apply for ninety (90) days from the date of original purchase. If product is used for rental purposes, the warranty will apply for ninety (90) days from the date of original purchase. Some states do not allow limitation on how long an implied warranty lasts, so the above limitations may not apply to you.

B.ANY INCIDENTAL, INDIRECT, OR CONSEQUENTIAL LOSS, DAMAGE , OR EXPENSE THAT MAY RESULT FROM ANY DEFECT, FAILURE, OR MALFUNCTION OF THE CAMPBELL HAUSFELD PRODUCT. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you.

C.Any failure that results from an accident, purchaser’s abuse, neglect or failure to operate products in accordance with instructions provided in the owner’s manual(s) supplied with product. Accident, purchaser’s abuse, neglect or failure to operate products in accordance with instructions shall also include the removal or alteration of any safety devices. If such safety devices are removed or altered, this warranty is void.

D.Normal adjustments which are explained in the owner’s manual(s) provided with the product.

E.Items or services that are normally required to maintain the product: HVLP-filters, motor brushes, gun packing, gun canister seal, gun check valve and gun air flow ring; Airless-inlet valve, outlet valve, gun valve, filters, tips, all seals and o-rings., or any other expendable part not specifically listed, will only be covered for thirty days from date of original purchase.

7.RESPONSIBILITIES OF WARRANTOR UNDER THIS WARRANTY: Repair or replace, at Warrantor’s option, products or components which are defective, have malfunctioned and/or failed to conform within duration of the warranty period.

8.RESPONSIBILITIES OF PURCHASER UNDER THIS WARRANTY:

A.Provide dated proof of purchase and maintenance records.

B.Deliver or ship the Campbell Hausfeld product or component to the nearest Campbell Hausfeld Authorized Service Center. Freight costs, if any, must be borne by the purchaser.

C.Use reasonable care in the operation and maintenance of the products as described in the owner’s manual(s).

9.WHEN WARRANTOR WILL PERFORM REPAIR OR REPLACEMENT UNDER THIS WARRANTY: Repair or replacement will be scheduled and serviced according to the normal work flow at the servicing location, and depending on the availability of replacement parts.

This Limited Warranty applies in the U.S., Canada and Mexico only and gives you specific legal rights. You may also have other rights which vary from state to state, or country to country.

www.chpower.com

4

Voir la Garantie à la page 8 pour de l’information importante sur l’utilisation commercial de ce produit.

Instructions D’Utilisation Et Manuel De Pièces |

Série HV2000 et HV3000 |

|

|

S’il vous plaît lire et conserver ces instructions. Lire attentivement avant de monter, installer, utilise de procéder à l’entretien du produit décrit. Se protéger ainsi que les autres en observant toutes les instructions de sécurité, sinon, il y a risque de blessure et/ou dégâts matériels. Conserver ces instructions comme référence.

Turbine HVLP

Turbine HVLP

BUILT TO LAST

Attention: Campbell Hausfeld recommande que l’entretien autre que celui décrit dans le manuel d’instruction devrait être performé par un centre de service authorisé. PAS CONÇU POUR L’USAGE CONTINU.

Description

Les turbines HVLP Campbell Hausfeld sont conçus pour produire une Volume d’air Haute à Basse Pression pour actionner les pistolets pulvérisateurs HVLP. Ces turbines n’exigent pas de réservoirs à air pour contenir de l’air comprimé. Puisque il n’y a pas d’air comprimé, les turbines HVLP ne produisent pas de condensation dans les tuyaux d’air. Il n’y a pas de risque de dommage au projet causé par la condensation dans l’enduit. L’air produit par la turbine est chaud ce qui est avantageux pour le séchage accéléré des enduits sous les conditions de température qui ne sont pas idéales et pour le séchage des pièces détachées du pistolet. Les turbines HVLP sont portatives, peuvent étre branchées dans les prises de courants standards. Les turbines fonctionnent et produisent un bruit comme un aspirateur shop-vac sec/humide.

Déballage

Lors du déballage du modèle, l’examiner soigneusement pour rechercher toute trace de dommage susceptible de s’être produit en cours de transport. Serrer tous raccords, boulons, etc., qui sont désserrés avant de mettre le pulvérisateur en marche. Chaque modèle a été éprouvé avant l’expédition. Ne pas régler à nouveau ou modifier les pièces de la turbine.

Figure 1

Spécifications

MODEL HV2000

CFM . . . . . . . . . . .54 CFM (1,53 M3/min) à la sortie de la turbine Pression de Service . . . . .27,6 kPa Max.

Type de moteur . .Type balai, 2 étapes, Tangentiel Longueur de Tuyau . . . . . . . . . . . .4,6 M (9,1 M Max.)

Efficacité du Transfert . . . . . .86% Max. Poids . . . . . . . . . . . . . . . . . . . . . . .6,8 Kg Voltage . . . . . . . . . . . .120V, . 10.1 Amp Tuyau Court . . . . . . . . . . . . . . . . . . .Non Compartiment D’entreposage . . . . .Oui

MODEL HV2500

CFM . . . . . . . . . . .58 CFM (1,64 M3/min) à la sortie de la turbine Pression de Service . . . . .34,5 kPa Max.

Type de moteur . .Type balai, 2 étapes, Tangentiel Longueur de Tuyau . . . . . . . . . . .7,62 M (12,2 M Max.)

Efficacité du Transfert . . . . . .86% Max. Poids . . . . . . . . . . . . . . . . . . . . . .11,8 Kg Voltage . . . . . . . . . . . . .120V, . 11 Amp Tuyau Court . . . . . . . . . . . . . . . . . . . .Oui Compartiment D’entreposage . . . . .Oui

MODEL HV3000

CFM . . . . . . . . . . .65 CFM (1,84 M3/min) à la sortie de la turbine Pression de Service . . . . .41,4 kPa Max.

Type de moteur . .Type balai, 2 étapes, Tangentiel Longueur de Tuyau . . . . . . . . . . .7,62 M (15,24 M Max.)

Efficacité du Transfert . . . . . .86% Max. Poids . . . . . . . . . . . . . . . . . . . . . .12,7 Kg Voltage . . . . . . . . . . . .120V, . 13.8 Amp Tuyau Court . . . . . . . . . . . . . . . . . . . .Oui Compartiment D’entreposage . . . . .Oui

PIÉCES DÉTACHÉES

(1) Turbine

(1)Tuyau et raccord rapide (dans l'entrepôt du modèle)

(1) Clé - le seul outil nécessaire pour assembler et nettoyer le modèle (dans l'entrepôt du modèle)

(1)Tige de viscosité (dans l'entrepôt du modèle)

(1)Brosse pour nettoyage (dans l'entrepôt du modèle)

MÉMENTO: Gardez votre preuve datée d'achat à fin de la garantie!

Joignez-la à ce manuel ou classez-la dans un dossier pour plus de sécurité.

© 2003 Campbell Hausfeld/Scott Fetzer |

IN206600AV 2/03 |

5-FR

Loading...

Loading...