Campbell Hausfeld WG2060, WG2064 User Manual

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described.

Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or

property damage! Retain instructions for future reference.

IN972700AV 11/04

Operating Instructions & Parts Manual Models WG2060 and WG2064

Wire Feed

Arc Welder

Description

This Campbell Hausfeld wire feed welder

is designed to be used on standard 115V

household current. The welder is

equipped with infinite wire speed

control to accurately select the proper

wire feed rate needed for various

welding conditions. Internal components

are thermostatically protected.

This welding system is designed for use

with the Flux Cored Arc Welding

(FCAW) or the Gas Metal Arc Welding

(GMAW) process. As delivered from the

factory, this welder can weld with .024”

(.6mm) to .030” (.8mm) diameter wire in

MIG and .030” (.8mm) to .035” (.9mm)

diameter wire in flux core. A starter

spool of .035” (.9mm) flux cored wire is

included.

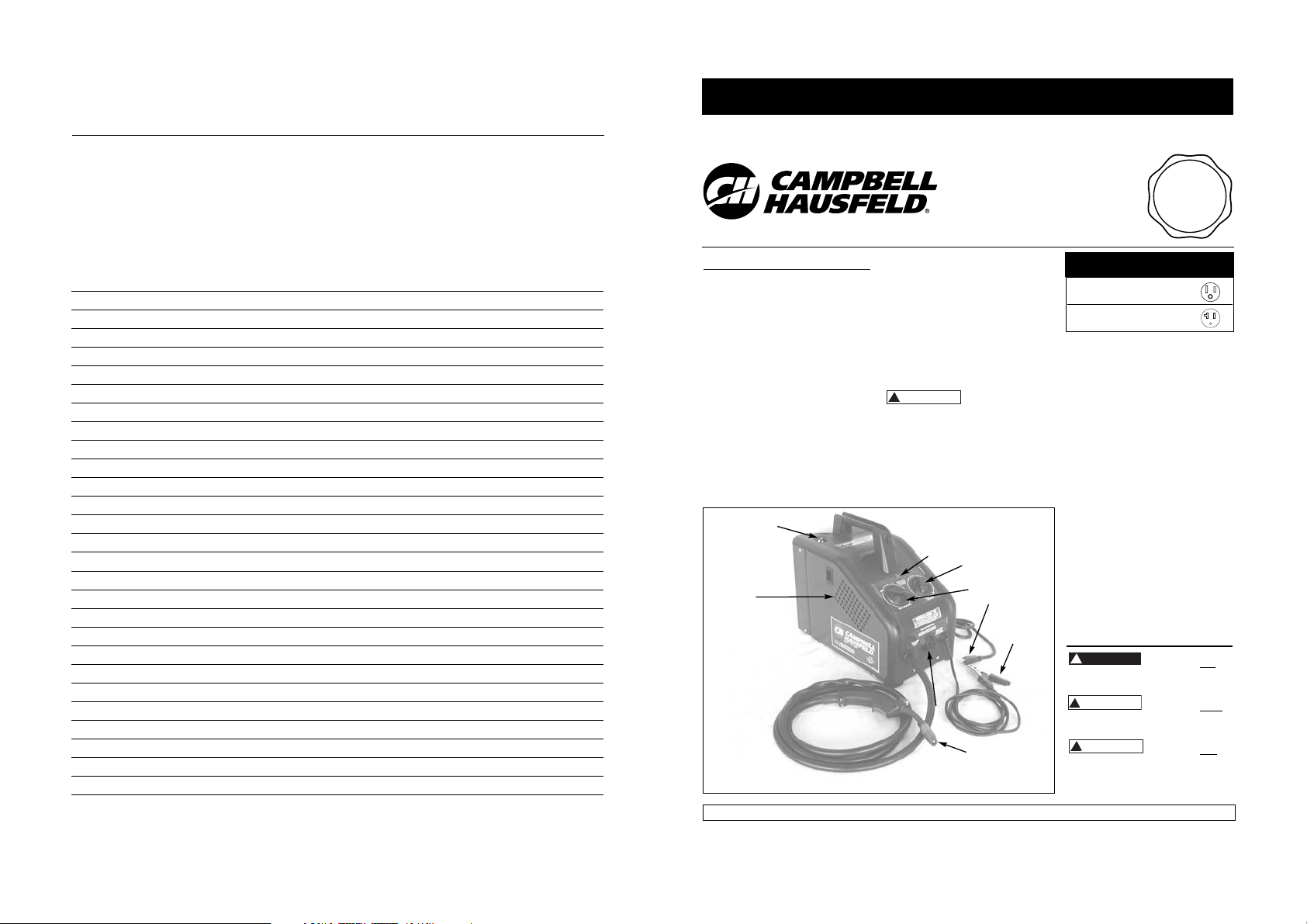

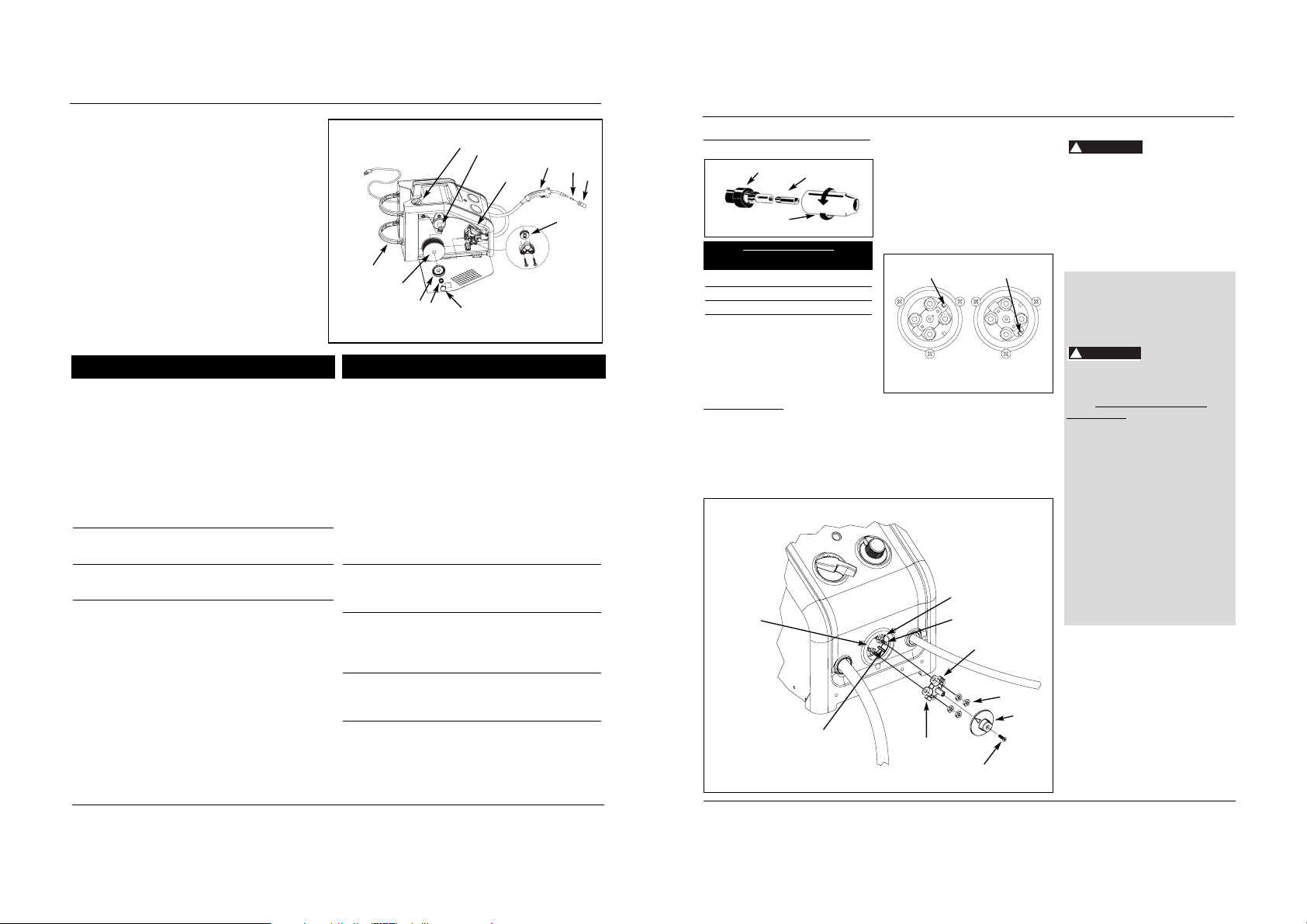

COMPONENTS AND CONTROLS

1. Work Clamp – connects to work

piece.

2. Wire Feed Gun with .035” tip.

3. Power Cord – plug into 115 volt

outlet.

4. Light – illuminates if thermostat has

automatically shut welder off.

5. Infinite Wire Speed Control – turn

clockwise to increase wire speed and

counterclockwise to decrease wire

speed.

6. Off/Heat Selector - Selects welding

power and turns welder on. Four

selections are possible: 1 – 2 – 3 – 4.

7. Polarity Box - For changing to

electrode positive or negative polarity.

8. MIG Gas Hookup

9. Wire Feed Compartment

General Safety

Danger means a

hazard that will

cause death or serious injury if the

warning is ignored.

Warning means a

hazard that could

cause death or serious injury if the

warning is ignored.

Caution means a

hazard that may

cause minor or moderate injury if the

warning is ignored. It also may mean a

hazard that will only cause damage to

property.

R

See page 7 for supply cable

replacement instructions.

Unpacking

Welding accessories are packed inside

the wire feed compartment on the

side of the welder. When unpacking,

inspect carefully for any damage that may

have occurred during transit. Make sure

any loose fittings and screws, etc., are

tightened before putting unit into service.

Report any missing or damaged

items by calling 1-800-746-5641.

CIRCUIT REQUIREMENTS

This equipment

requires a dedicated

115 volt circuit. Refer to the following

chart for correct circuit breaker or fuse

rating. Do not run other appliances, lights

or tools on this circuit while operating

this equipment. Extension cords are not

recommended. Blown fuses and tripped

circuit breakers can result from failure to

comply with this recommendation.

For parts, manuals, product & service information

visit www.chpower.com

© 2004 Campbell Hausfeld/Scott Fetzer

REMINDER: Keep your dated proof of purchase for warranty purposes! Attach it to this manual or file it for safekeeping.

Heat Circuit Breaker or

Selector Slow Blow Fuse

1-2-3 15 amp

4 20 amp

Figure 1 - Welder Components and Controls

3

1

6

4

8

9

5

2

7

Notes

Notes

Notas

44

Wire Feed Arc Welder

Soudeur à l’Arc Alimenté en Fil

Soldadora Por Arco Con Alimentación de Cable

T

I

L

BUILT TO LAST

A

U

Q

Assistance?

Call Us First!

1-800-746-5641

A

Y

A

R

U

S

S

Need

N

C

E

P

R

O

G

R

A

M

!

CAUTION

!

DANGE

!

WARNING

!

CAUTION

Notes

Notes

Notas

43

Models WG2060 and WG2064

Modèles WG2060 et WG2064

Modelos WG2060 y WG2064

2

Wire Feed Arc Welder

General Safety

(Continued)

NOTE: Note means any additional

information pertaining to the product

or its proper usage.

Always keep a fire

extinguisher accessible

while performing arc

welding operations.

Before starting or

servicing any electric arc welder, read

and understand all

instructions. Failure

to follow safety

precautions or

instructions can

cause equipment

damage and/or serious personal

injury or death.

All installation, maintenance, repair

and operation of this equipment

should be performed by qualified

persons only in accordance with

national, state, and local codes.

Improper use of electric

arc welders can cause

electric shock, injury,

and death! Take all

precautions described in

this manual to reduce the possibility of

electric shock.

Verify all components of the arc

welder are clean and in good

condition prior to operating welder.

Be sure insulation on all cables, wire

feed gun and power cord is not

damaged. Always repair or replace

damaged components before

operating the welder. Always keep

welder panels, shields, etc. in place

when operating welder.

Always wear dry, protective

clothing, welding gloves and

insulated footwear when operating

unit.

Always operate welder in a clean,

dry, well ventilated area. Do not

operate welder in humid, wet, rainy

or poorly ventilated areas.

Be sure work piece is properly

supported and grounded prior to

beginning any electric arc welding

operation.

Spread out coiled welding cable

before use to avoid overheating and

damage to insulation.

Never immerse

wire or wire feed

gun in water. If welder becomes wet for

any reason, be absolutely certain it is

completely clean and dry before use!

Always shut equipment off and

unplug power cord prior to moving

the unit.

Always attach the work lead first.

Verify work piece is securely

grounded.

Always shut off electric arc welding

equipment when not in use and cut off

any excess wire from wire feed gun.

Never allow any part of the body to

touch flux-cored wire and ground or

grounded work piece at the same

time.

Awkward welding conditions and

positions can be electrically hazardous.

When crouching, kneeling or at

elevations, be sure to insulate all

conductive parts, wear appropriate

protective clothing and take

precautions to prevent injury from falls.

Never attempt to use this equipment

at current settings or duty cycles higher

than specified on equipment labels.

Never use an electric arc welder to

thaw frozen pipes.

Flying sparks and hot

metal can cause injury.

As welds cool, slag can

be thrown off. Take all

precautions described in

this manual to reduce

the possibility of injury from flying

sparks and hot metal.

Wear ANSI approved face shield or

safety glasses with side shield

protection when chipping or

grinding metal parts.

Wear ear plugs when welding

overhead to prevent spatter or slag

from falling into ears.

R

Electric arc welding

operations produce

intense light and heat

and ultraviolet (UV)

rays. This intense light

and UV rays can cause injury to eyes and

skin. Take all precautions described in

this manual to reduce the possibility of

injury to eyes and skin.

All persons operating this equipment

or in the area while equipment is in

use, must wear protective welding gear

including: welding helmet or shield

with at least shade 10 lens, flame

resistant clothing, leather welding

gloves and full foot protection.

Never look at arc

welding operations

without eye protection as described

above. Never use a shade filter lens

that is cracked, broken, or rated below

number 10. Warn others in the area not

to look at the arc.

Electric arc welding

operations cause sparks

and heat metal to

temperatures that can

cause severe burns! Use

protective gloves and clothing when

performing any metal working

operation. Take all precautions described

in this manual to reduce the possibility

of skin and clothing burns.

Make sure all persons in welding

area are protected from heat, sparks

and ultraviolet rays. Use additional

face shields and flame resistant

barriers as needed.

Never touch work pieces until

completely cooled.

Heat and sparks

produced during

electric arc welding and

other metal working

operations can ignite

flammable and explosive materials!

Take all precautions described in this

manual to reduce the possibility of

flames and explosions.

Remove all flammable materials

within 35 feet (10.7 meters) of

welding arc. If removal is not

possible, tightly cover flammable

materials with fire proof covers.

!

www.chpower.com

WARNING

!

WARNING

!

WARNING

!

DANGE

MANUAL

!

WARNING

!

WARNING

!

WARNING

!

WARNING

Garantía Limitada

Garantía Limitada 5-3-1

1.Duración: El fabricante garantiza que reparará, sin costo alguno, por piezas o mano de obra, la soldadora, pistola de

soldadura o cables que demuestren estar defectuosos, en material o mano de obra, durante el(los) siguiente(s) periodo(s) a

partir de la fecha de compra al por menor original:

Por 5 años: el transformador y rectificador de la soldadora.

Por 3 años: toda la soldadora (salvo las abrazaderas, pistola de soldadura, sujetador de electrodo, cables o accesorios

embalados con la soldadora).

Por 1 año: las abrazaderas de soldadura, pistola MIG, sujetador de electrodo, accesorios y cables de soldadura (como

sea pertinente).

2.¿Quién emite esta garantía? (Garante)

Campbell Hausfeld / A Scott Fetzer Company

100 Production Drive

Harrison, OH 45030

Teléfono: (513)-367-4811

3.¿Quién recibe esta garantía? (Comprador): El comprador original del producto Campbell Hausfeld.

4.¿Qué es lo que cubre esta garantía?: Defectos de material y mano de obra que ocurran dentro del período de duración

de la garantía. Esta garantía se extiende solamente a la soldadora, el transformador y rectificador de la soldadora, pistola

de soldadura o sujetador de electrodo y cables.

5.¿Qué es lo que no cubre esta garantía?:

A.Las garantías implícitas, incluyendo las de comerciabilidad e IDONEIDAD PARA UN FIN PARTICULAR, SE LIMITAN A LA

DURACIÓN DE ESTA GARANTÍA EXPRESA. Luego de este periodo, todos los riesgos de pérdida, por cualquier razón,

corren por cuenta del comprador. Algunos estados no permiten la limitación de la duración de una garantía implícita,

de modo que estas restricciones tal vez no rijan para Ud.

B.CUALQUIER PERDIDA, DAÑO O GASTO INCIDENTAL, INDIRECTO O RESULTANTE QUE PUEDA DERIVARSE DE CUALQUIER

DEFECTO, FALLA O MAL FUNCIONAMIENTO DEL PRODUCTO DE CAMPBELL HAUSFELD. Algunos estados no permiten la

exclusión o limitación de los daños incidentales o derivados, por lo que esta restricción tal vez no rija para Ud.

C.Esta garantía no se aplica a cualquier accesorio incluido en el producto que está sujeto a desgaste por uso; la reparación

o cambio de este accesorio correrá por cuenta del propietario. Estos artículos MIG incluyen, sin sentido limitativo, a las

puntas de contacto, boquillas, revestimientos de pistola, rodillos de mando, limpiador de cable de fieltro. Además, esta

garantía no se extiende a los daños causados por el cambio o mantenimiento fuera de tiempo de cualquiera de las

piezas CONSUMIBLES enumeradas anteriormente.

D.Cualquier falla que resulte de un accidente, mal uso del comprador, negligencia u omisión en operar los productos de

acuerdo a las instrucciones provistas en el manual del propietario suministrado con el producto.

E. Servicio de pre-entrega, es decir, ensamblaje y ajuste.

7.Responsabilidades del garante bajo esta garantía: Reparar o reemplazar, a opción del garante, los productos o

componentes que hayan funcionado mal dentro del período de garantía.

8.Responsabilidades del comprador bajo esta garantía:

A.Entregar o enviar el producto o componente de Campbell Hausfeld al Centro de Servicio Autorizado de Campbell

Hausfeld más cercano. Los costos de envío, si los hubiera, serán por cuenta del comprador.

B.Hacer uso de un cuidado razonable en la operación y mantenimiento de los productos descritos en el manual del

propietario.

9.¿Cuándo efectuará el garante la reparación o reemplazo bajo esta garantía?: La reparación o reemplazo se

programará y efectuará de acuerdo al flujo normal de trabajo en la localidad de servicio y dependiendo de la

disponibilidad de repuestos.

Esta garantía limitada le proporciona a Ud. derechos legales específicos y es probable que Ud. tenga otros derechos, los

cuales varían de un estado a otro.

42 Sp

Soldadora Por Arco Con Alimentación de Cable

General Safety

(Continued)

Do not operate any electric arc

welder in areas where flammable or

explosive vapors may be present.

Take precautions to ensure flying

sparks and heat do not cause flames

in hidden areas, cracks, etc.

Fire hazard! Do not

weld on containers

or pipes that contain or have contained

flammable materials or gaseous or liquid

combustibles.

Arc welding closed

cylinders or containers

such as tanks or drums

can cause explosion if

not properly vented!

Verify that any cylinder or container to

be welded has an adequate ventilation

hole, so that expanding gases can be

released.

Do not breathe fumes

produced by arc

welding operation.

These fumes are

dangerous. If welding

area cannot be adequately ventilated,

be sure to use an air-supplied

respirator.

Keep head and face out of welding

fumes.

Extremely toxic fumes are created

when galvanized or cadmium plated

metals or metals which contain zinc,

mercury or beryllium are heated.

Complete the following precautions

before performing electric arc

welding operations on these metals:

a. Remove coating from base metal.

b. Make sure welding area is well

ventilated.

c. Use an air-supplied respirator.

The electromagnetic field

generated during arc

welding may interfere

with the operation of

various electrical and

electronic devices such as cardiac

pacemakers. Persons using such devices

should consult with their physician prior

equipment, and CGA publication P-1

listed in Safety Standards.

Never use

flammable gasses

with MIG welders. Only inert or nonflammable gasses such as carbon

dioxide, argon, helium or mixtures of

one or more of these gasses are

suitable for MIG welding.

Never lift cylinders

off the ground by

their valves or caps or with chains or

slings.

ADDITIONAL SAFETY STANDARDS

ANSI Standard Z49.1 from American

Welding Society, 550 N.W. Le June Rd.

Miami, FL 33126

Safety and Health Standards

OSHA 29 CFR 1910, from Superintendent

of Documents, U.S. Government Printing

Office, Washington, D.C. 20402

National Electrical Code

NFPA Standard 70, from National Fire

Protection Association, Batterymarch

Park, Quincy, MA 02269

Safe Handling of Compressed Gases

in Cylinders

CGA Pamphlet P-1, from Compressed Gas

Association, 1235 Jefferson Davis

Highway, Suite 501, Arlington, VA 22202

Code for Safety in Welding and

Cutting

CSA Standard W117.2, from Canadian

Standards Association, Standards Sales,

178 Rexdale Boulevard, Rexdale, Ontario,

Canada M9W 1R3

Cutting And Welding Processes

NFPA Standard 51B, from National Fire

Protection Association, Batterymarch

Park, Quincy, MA 02269

Safe Practices For Occupational And

Educational Eye And Face Protection

ANSI Standard Z87.1, from American

National Standards Institute, 1430

Broadway, New York, NY 10018

Refer to Material Safety Data Sheets and

manufacturers instructions for metals,

wire, coatings and cleaners.

R

3

to performing any electric arc welding

operations.

Route wire gun and work cables

together and secure with tape when

possible.

Never wrap arc welder cables around

the body.

Always position wire gun and work

leads on the same side of the body.

Exposure to electromagnetic fields

during welding may have other

health effects which are not known.

Always be sure

welding area is

secure and free of hazards (sparks,

flames, glowing metal or slag) prior to

leaving. Be sure equipment is turned off

and excess wire is cut off. Be sure cables

are loosely coiled and out of the way. Be

sure all metal and slag has cooled.

Cylinders can explode if damaged.

Shielding gas cylinders

contain gas under high

pressure. If damaged, a

cylinder can explode.

Since gas cylinders are

normally part of the

welding process, be

sure to treat them carefully.

Protect compressed gas cylinders

from excessive heat, mechanical

shocks and arcs.

Install and secure cylinders in an

upright position by chaining them

to stationary support or equipment

cylinder rack to prevent falling or

tipping.

Keep cylinders away from any

welding or other electrical circuits.

Never allow a welding electrode to

touch any cylinder.

Use only correct shielding gas

cylinders, regulators, hoses and

fittings designed for the specific

application; maintain all parts

properly.

Turn face away from valve outlet

when opening cylinder valve.

Keep protective cap in place over

valve except when cylinder is in use

or connected for use.

Read and follow instructions on

compressed gas cylinders, associated

R

Models WG2060 and WG2064

www.chpower.com

!

WARNING

!

WARNING

!

WARNING

!

WARNING

!

WARNING

!

DANGE

!

DANGE

!

WARNING

41 Sp

Corriente alterna o CA – corriente

eléctrica que invierte periódicamente la

dirección. La corriente de ciclo de

sesenta viaja en ambas direcciones,

sesenta veces por segundo.

Longitud del arco - la distancia entre el

extremo del electrodo y la punta donde el

arco hace contacto con la superficie de

trabajo.

Metal de base – el material que va a ser

soldado.

Unión plana – una unión entre las dos

partes alineadas aproximadamente en el

mismo plano.

Cráter – charco de metal fundido o

bolsillo que se forma cuando el arco se

pone en contacto con el metal de base.

Corriente continua o CC – corriente

eléctrica que circula solamente en una

dirección. La polaridad (+ o -) determina

en qué dirección está circulando la

corriente.

Polaridad inversa de CC – ocurre cuando

el sujetador del electrodo está

conectado al polo positivo de la

máquina soldadora. La polaridad

inversa dirige más calor para fundir al

electrodo que a la pieza de trabajo. Se

utiliza en materiales más delgados.

Polaridad directa de CC - ocurre cuando

el sujetador del electrodo está

conectado al polo negativo de la

máquina soldadora. Con la polaridad

directa se dirige más calor hacia la pieza

de trabajo para una mejor penetración

en materiales más gruesos.

Electrodo – un alambre de metal

revestido que tiene aproximadamente la

misma composición que el material que

va a ser soldado.

Soldadura en ángulo –

aproximadamente un triángulo en

sección transversal, que une dos

superficies con ángulos rectos en cada

uno en una unión de solapa, en T o de

ángulo.

Glosario de Términos de Soldadura

Modelos WG2060 y WG2064

Fundente - un material, que al

calentarse, emite un gas que cubre el

área donde va a soldar. Este gas protege

los metales que va a soldar contra las

impurezas presentes en el aire.

Soldadura por arco de núcleo fundente

(FCAW) – también llamado Sin gas, es

un proceso de soldadura utilizado con

una máquina soldadora de alimentación

de cable. El cable de soldadura es

tubular que contiene dentro material

fundente como protección.

Soldadura por arco de metal de gas

(GMAW) – también llamado MIG, es un

proceso de soldadura utilizado con una

máquina soldadora de alimentación de

cable. El cable es sólido y se utiliza un gas

inerte como protección.

Soldadura por arco de tungsteno de gas

(GTAW) – también llamado TIG, es un

proceso de soldadura utilizado con un

equipo soldador con un generador de

alta frecuencia. El arco se crea entre un

electrodo de tungsteno no consumible y

la pieza de trabajo. El metal de relleno

se puede o no utilizar.

Unión de solapa – una unión entre dos

partes superpuestas en planos paralelos.

Voltaje de circuito abierto (OCV) – el

voltaje entre el electrodo y la

abrazadera de trabajo de la máquina

soldadora, cuando no circula corriente

(no suelda). El OCV determina cuán

rápido se golpea el arco.

Superposición – ocurre cuando el

amperaje está configurado demasiado

bajo. En este caso, el metal fundido cae

del electrodo sin realmente fundir el

metal de base.

Porosidad – bolsillos o cavidades de

gases, formados durante la

solidificación. Debilitan la soldadura.

Penetración – la profundidad en la pieza

de trabajo que ha sido afectada por el

calor por el arco durante el proceso de

soldadura. Una buena soldadura logra

100% de penetración, lo cual significa

que todo el espesor de la pieza de

trabajo ha sido calentado y

resolidificado. El área afectada por el

calor se debe ver fácilmente al lado

opuesto de la soldadura.

Soldadura por arco de metal blindado

(SMAW) – también llamada Soldadura

con Varilla, es un proceso de soldadura

que utiliza un electrodo consumible para

sostener el arco. El blindaje se obtiene

por la fundición del revestimiento del

fundente en el electrodo.

Escoria – una capa de hollín de

fundente que protege la soldadura de

los óxidos y otros contaminantes

mientras la soldadura se está

solidificando (enfriando). La escoria

debe retirarse luego de que la

soldadura haya enfriado.

Salpicadura – partículas de metal que

saltan de la soldadura, que se enfrían y

endurecen en la superficie de trabajo.

La salpicadura se puede disminuir

aplicando un aerosol resistente a

salpicaduras en la pieza de trabajo antes

de soldar.

Soldadura por puntos – soldadura hecha

para sostener las partes en la alineación

correcta hasta realizar las soldaduras

finales.

Angulo de propagación – el ángulo del

electrodo en la línea de soldadura.

Varía entre 5° y 45° dependiendo de las

condiciones de soldadura.

Unión en T – realizada al colocar el

borde de una pieza o metal en la

superficie de la otra pieza a

aproximadamente un ángulo de 90°.

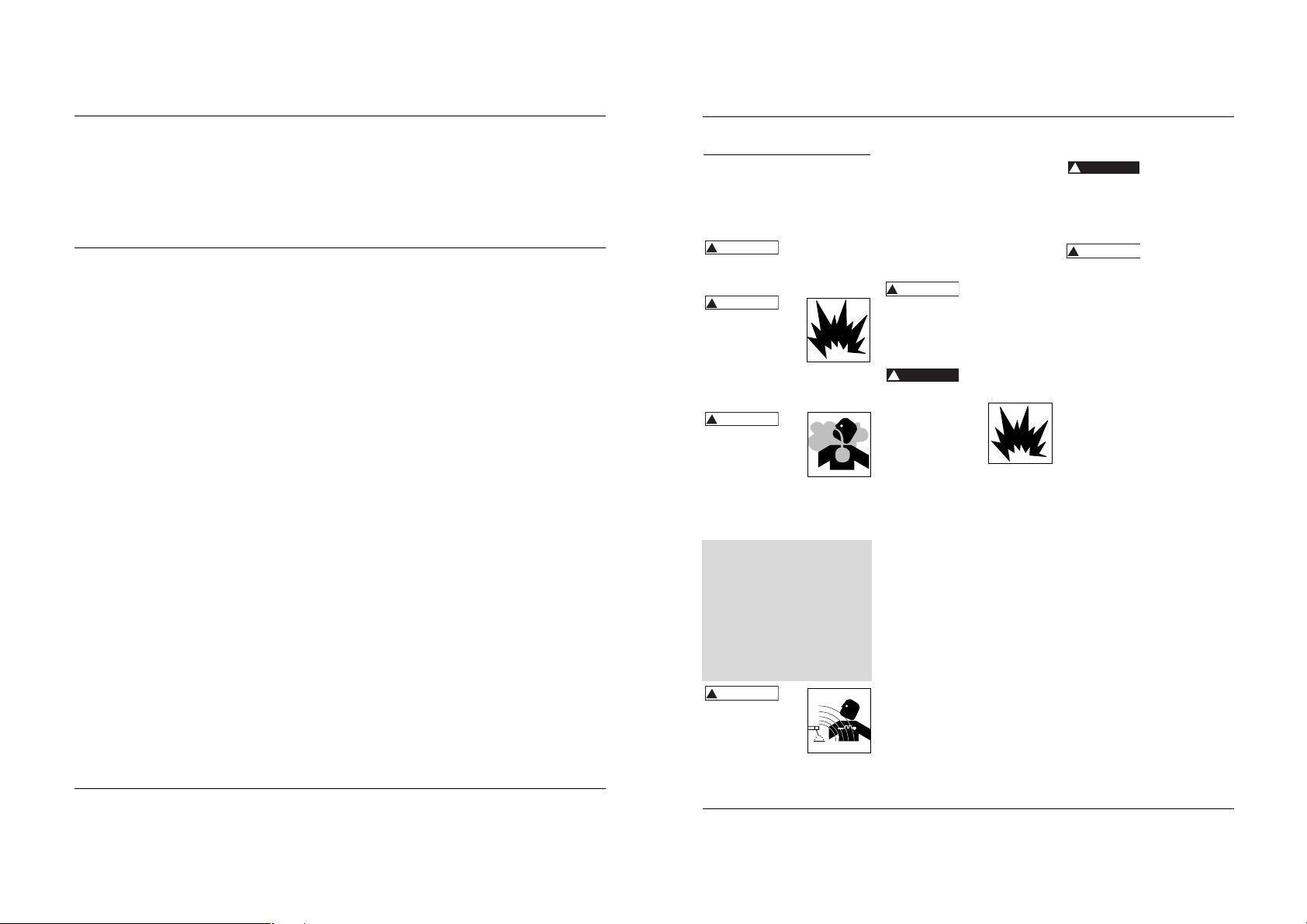

2. Remove the spool quick lock by

pushing in and rotating 1/4 turn

counterclockwise. Then remove

knob, spring and spool spacer.

3. Flip tensioning screw down on drive

mechanism. This allows initial

feeding of wire into gun liner by

hand.

4. Install wire spool onto spindle so

wire can come off spool on the end

closest to the wire feed guide tube.

Do not cut the wire loose yet.

Install spool spacer, spring and quick

lock knob by pushing in and turning

knob 1/4 rotation clockwise.

5. Hold wire and cut the wire end from

spool. Do not allow wire to

unravel. Be sure end of wire is

straight and free of burrs.

6. Feed wire through wire feed guide

tube, over the groove in drive roller

and into gun liner. Flip tensioning

screw up and adjust tension by rotating

4

Wire Feed Arc Welder

Installation

LOCATION

Selecting the proper location can

significantly increase performance,

reliability and life of the arc welder.

For best results locate welder in a

clean and dry environment. Dust

and dirt in the welder retain

moisture and increase wear of

moving parts.

Place welder in an area with at least

twelve inches (305 mm) of ventilation

space at both the front and rear of

unit. Keep all obstructions out of this

ventilation space.

Store welding wire in a clean, dry

location with low humidity to

prevent oxidation.

Use a properly grounded receptacle

for the welder and ensure welder is

the only load on power supply

circuit. Refer to chart on page 1 for

correct circuit capacity.

Use of an extension cord is not

recommended for electric arc welding

machines. Voltage drop in the

extension cord may significantly

degrade performance of the welder.

Assembly

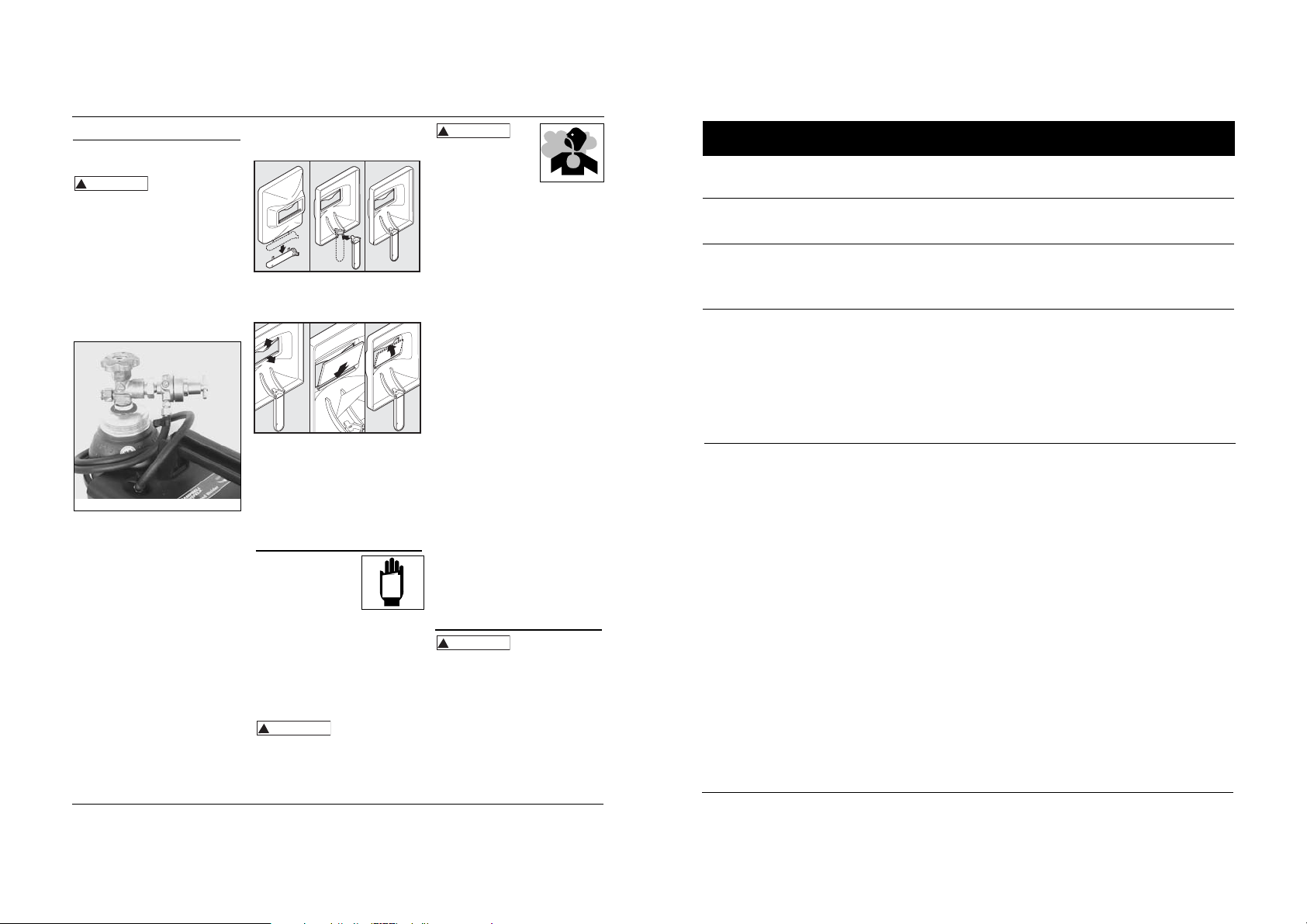

BOTTLE RETAINER ASSEMBLY

Attach bottle retainer to welder as

shown (Fig. 2).

WIRE INSTALLATION

NOTE: Before installing welding wire,

be sure:

a. Diameter of welding wire matches

groove in drive roller on wire feed

mechanism (See Fig. 3). The drive

roller is marked with metric sizes:

.6mm = .024”, .8 - .9mm = .030 –

.035”

b. Wire matches contact tip in end of

gun. (See Fig. 4).

A mismatch on any item could cause the

wire to slip and bind.

NOTE: Always maintain control of loose

end of welding wire to prevent

unspooling.

1. Verify unit is off and open door

panel to expose wire feed

mechanism.

tensioning screw knob. Do not over

tighten.

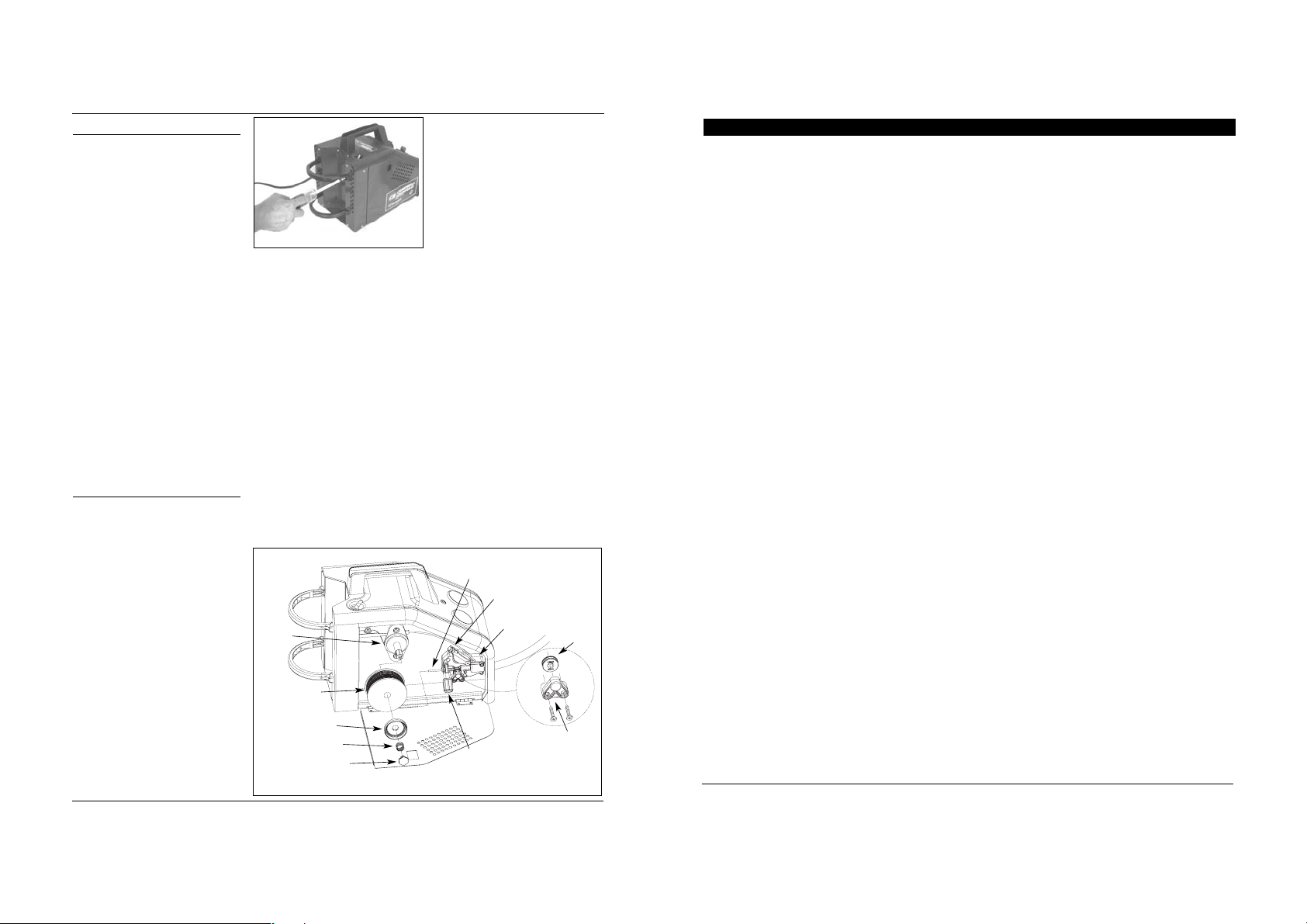

7. Remove nozzle by turning counterclockwise, then unscrew contact tip

from end of welding torch (See

Figure 4). Plug welder into a proper

power supply receptacle.

8. Turn on welder and set wire speed

rate to 10. Activate gun trigger until

wire feeds out past the torch end.

Turn welder off.

9. Carefully slip contact tip over wire

and screw tip into torch end. Install

nozzle by turning clockwise (See

Figure 4). Cut wire off approximately

1/4 inch from nozzle end.

DUTY CYCLE / THERMOSTATIC

PROTECTION

Welder duty cycle is the percentage of

actual weld time that can occur in a ten

minute interval. For example, at a 20%

duty cycle, actual welding can occur for

two minutes, then the welder must cool

for eight minutes.

Internal components of this welder are

protected from overheating with an

automatic thermal switch. A yellow

lamp is illuminated on the front

panel if the duty cycle is exceeded.

Welding operations may continue when

the yellow lamp is no longer illuminated.

Figure 2 - Bottle Retainer Assembly

www.chpower.com

Spindle

Welding wire

Tensioner ring

Tension spring

Retainer

Tensioner knob

Guide tube

Tensioner arm

Drive deck

Roller

support

Drive

roller

Figure 3 - Weld Wire Routing

2. Remove cover screw and polarity

cover.

3. Remove four nuts from polarity

studs.

4. Pull out polarity bus bar and rotate

it 90°. Reinsert aligning groove with

the correct rib in polarity box.

Upper right rib marks the MIG

position; lower right rib marks the

Flux position. (See Figure 4c.)

5. Reinstall four nuts and tighten

securely.

6. Reinstall polarity cover and cover

screw.

7. Make sure arrow on polarity cover

points to desired setting.

Assembly (Continued)

POLARITY

MIG welding wire requires electrode

positive electrical polarity. Flux welding

wire requires electrode negative

electrical polarity. The welder is factory

set for flux welding wire.

To Change Polarity

(See Figure 4b)

NOTE: The arrow on the Polarity Cover

points to the current polarity setting.

TOOLS NEEDED: Phillips screwdriver

and 10mm socket wrench.

1. Unplug power cord from socket.

40 Sp

1 Ensamble del soplete y la manguera

(MIG, 2,44 m, WG2060) WC403660AV 1

Ensamble del soplete y la manguera

(MIG, 3,05 m, WG2064) WC404100AV 1

2 Punta de contacto - 0,035” (0,9 mm) WT501400AV 1

Punta de contacto opcional – 0,024”

(0,6 mm) Paq. 4 WT501200AJ †

Punta de contacto opcional – 0,030”

(0,8 mm) Paq. 4 WT501300AJ †

Punta de contacto opcional – 0,035”

(0,9 mm) Paq. 4 WT501400AJ †

3 Boquilla WT502100AV 1

4 Portabobinas WC500805AV 1

5 Ensamble de la placa de conducción WC500800AJ 1

6 Vástago y rejilla WC707018AV 1

7 Retén de la bobina WC707024AV 1

8 Resorte del retén de la bobina WC707026AV 1

9 Anillo del retén de la bobina WC707023AV 1

10 Alambre de soldar con fundente – 0,030”

(0,8 mm) Bobina de 2 lb. (0,9 kg) (E71T-GS) WE200001AV †

Alambre de soldar con fundente – 0,030”

(0,8 mm) Bobina de 10 lb. (4,54 kg) (E71T-GS WE201000AV †

Alambre de soldar con fundente – 0,035”

(0,9 mm) Bobina de 2 lb. (0,9 kg) (E71T-GS) WE200501AV †

Alambre de soldar con fundente – 0,035”

(0,9 mm) Bobina de 10 lb. (4,54 kg) (E71T-GS) WE201500AV †

Alambre de soldar MIG – 0,024”

(0,6 mm) Bobina de 2 lb (0,9 kg) (ER70S6) WE300001AV †

Alambre de soldar MIG – 0,024”

(0,6 mm) Bobina de 11 lb. (5 kg) (ER70S6) WE301500AV †

No de No De

Ref. Descripción Componente Cant

Modelos WG2060 y WG2064

Alambre de soldar MIG – 0,030” (0,8 mm)

Bobina de 2 lb. (0,9 kg) (ER70S6) WE 300501AV †

Alambre de soldar MIG – 0,030” (0,8 mm)

Bobina de 11 lb. (5 kg) (ER70S6) WE 302000AV †

Alambre de soldar MIG – 0,035” (0,9 mm)

Bobina de 2 lb. (0,9 kg) (ER70S6) WE 301001AV †

Alambre de soldar MIG – 0,035” (0,9 mm)

Bobina de 11 lb. (5 kg) (ER70S6) WE 302500AV †

Alambre de soldar MIG – 0,030” (0,8 mm)

1 lb (0,45 kg) de aluminio (ER5356) WE 303001AV †

11 Retén del recipiente con 4 tornillos WC302600AJ 1

12 Conexión dentada de la manguera

(externa) WC403900AV 1

Accesorio de conexión rápida

(interna) WC403901AV 1

13 Manguera de gas – 22” (56 cm) WC403902AV 1

14 Abrazadera de la manguera WC403903AV 2

15 Regulador (WG2060) WC803500AV 1

Regulador (WG2064) WC803600AV 1

16 Máscara de mano

(no se incluyen lentes) WC801700AV 1

17 Lentes oscuros

(para máscara de mano) WC801100AV 1

18 Martillo/cepillo cincelador WC803400AV 1

19 Etiqueta adhesiva de seguridad DK688509AV 1

20 Juego de la barra de polaridad WC403128AV 1

21 Pinza de tierra (WG2060) WC100300AV 1

Pinza de tierra (WG2064) WC100600AV 1

22 Guantes para soldar (sólo WG2064) WT200501AV 1

No se muestra

† Accesorio opcional

No de No De

Ref. Descripción Componente Cant

Soldadora Por Arco Con Alimentación de Cable

3

4

1

8

9

2

11

10

7

12

6

5

Figura 14 - Piezas de Repuesto

Para Ordenar Repuestos o

Asistencia Técnica, Sírvase Llamar

al Distribuidor Más Cercano a Su

Domicilio

Dirija toda la correspondencia a:

Campbell Hausfeld

Attn: Customer Service

100 Mundy Memorial Drive

Mt. Juliet, TN 37122 U.S.A.

Sírvase suministrarnos la siguiente información:

- Número del modelo

- Número de Serie (de haberlo)

- Descripción y número del repuesto según la

lista de repuestos

Shielding Gas Preparation

Improper handling

and maintenance of

compressed gas cylinders and regulators

can result in serious injury or death!

Always secure gas cylinders to tank

bracket kit, a wall or other fixed support

to prevent cylinder from falling over.

Read, understand and follow all

compressed gas and equipment

warnings in the safety instructions.

NOTE: Shielding gas is not required if

flux-core welding wire is used.

GAS TYPES

There are 3 types of gas generally used

for gas metal arc welding; 100% argon,

a mixture of 75% argon and 25%

carbon dioxide (C25) or 100% carbon

dioxide.

Use ONLY the type

of gas recommended

for your welder. Use ONLY an inert, nonflammable type of gas. Failure to do so

will result in a very hazardous situation.

NOTE: 100% carbon dioxide is not

recommended due to unsatisfactory

weld beads.

The 75/25 mixture is recommended for

general steel welding. For aluminum

welding, use 100% argon. Cylinders of

either type gas may be obtained at your

local welding supply outlet. Secure

cylinder in place on your welding

machine or other support to prevent the

cylinder from falling over.

Obtaining Correct Gas Type. The gas

used in any welding application for your

welder must be an INERT, NONFLAMMABLE TYPE. You can get the type

of gas needed from a nearby welding

gas distributor (often found in the

yellow pages under “Welders” or

‘Welding Equipment”).

REGULATOR

An adjustable regulator without gauges

is supplied with the WG2060. The

regulator supplied with the WG2064

includes two gauges. The regulator

provides a constant shielding gas pressure

and flow rate during the welding process.

Each regulator is designed to be used

with a specific gas or mixture of gases.

The argon and argon mixture use the

same thread type. The 100% carbon

dioxide uses a different thread type. An

adapter is available at your local welding

gas supplier to change between the two.

R

5

Models WG2060 and WG2064

www.chpower.com

Contact Tip Markings

Mark Wire Size

0.6 mm .024"

0.8 mm .030”

0.9 mm .035”

Torch Diffuser

Contact Tip

Nozzle

Figure 4 - Torch Nozzle

Figure 4b

Polarity box

Flux rib

Polarity bus bar

Nuts

Cover screw

Polarity

cover

Groove

Polarity studs

MIG rib

Figure 4c

MIG position

Flux position

Upper right—

MIG rib

Lower right—

Flux rib

!

DANGER

!

DANGE

39 Sp

Table de Detección y Solución de Problemas - Soldadura

Síntoma Causas Posibles Medida Correctiva

Reborde es muy

delgado en algunos

sitios

Reborde es muy

grueso en algunos

sitios

Los bordes de la

soldadura están

disparejos

La soldadura no

penetra el metal que

desea soldar

El electrodo salpica y

se pega

1. La velocidad de desplazamiento varia o

es rápida

2. El nivel del amperaje es muy bajo

1. La velocidad de desplazamiento varia o

es muy lenta

2. El nivel del amperaje es muy alto

1. La velocidad de desplazamiento es

muy rápida

2. La velocidad de alimentación es muy

rápida

3. El nivel del amperaje es muy alto

1. La velocidad de desplazamiento no es

consistente

2. El nivel de energía es muy bajo

3. Se terminó el gas o el nivel de gas es

muy bajo

4. Está usando el gas incorrecto

(aluminio)

5. El cordón de extensión es muy largo

6. (Aluminio) Posiblemente se están

formando residuos de óxido en la

superficie

1. El alambre está húmedo

2. La velocidad del alambre está muy

rápida

3. Está utilizando el alambre inadecuado

4. Se terminó el gas o el nivel de gas es

muy bajo

1. Debe reducirla y mantenerla constante

2. Debe aumentarlo

1. Debe aumentarla y mantenerla constante

2. Debe bajarlo

1. Debe reducirla

2. Debe aumentarla

3. Debe bajarlo

1. Disminuya la velocidad y manténgala constante

2. Aumente el nivel de energía de suministro

3. Use gas, para soldar con gases inertes (MIG) o llene la boqtella

4. Use sólo 100% Argón

5. Nunca use cordones de extensión de más de 6,10 m (20 pies)

6. Limpie bien la superficie con un cepillo de acero inoxidable

sólamente

1. Use un alambre seco y siempre debe almacenarlo e un sitio

seco

2. Reduzca la velocidad del alambre

3. Use alambre de fundente revestido cuando no esté utilizando

gases

4. Use gas, para soldar con gases inertes (MIG) o llene la boqtella

Modelos WG2060 y WG2064

2. To attach the handle, place shield on

a flat surface and press handle into

place – see Figure 6.

3. Insert filter lens exactly as shown in

Figure 7.

NOTE: If you have never welded

before or have little experience, a

full face helmet is recommended.

Both hands are needed to stabilize

and control the angle and arc

length of the torch.

Operation

1. Be sure to read,

understand and comply

with all precautions in

the General Safety

Information section. Be

sure to read entire "Welding

Guidelines" section before using this

equipment.

2. Turn welder off.

3. Verify surfaces of metals to be joined

are free from dirt, rust, paint, oil,

scale or other contaminants. These

contaminants make welding difficult

and cause poor welds.

All persons

operating this

equipment or in the area while

equipment is in use must wear

protective welding gear including: eye

protection with proper shade, flame

resistant clothing, leather welding

gloves and full foot protection.

Assembly (Continued)

HOSE AND REGULATOR HOOKUP

PROCEDURE

Cylinder gas is under high pressure.

Point cylinder outlet away from

yourself and any bystanders before

opening.

1. With cylinder securely installed, stand

on side of cylinder opposite cylinder

outlet then remove cylinder cap and

open valve slightly by turning

counterclockwise. When gas is

emitted from cylinder, close valve by

turning clockwise. This will blow out

dust or dirt that may have

accumulated around valve seat.

2. Install regulator onto cylinder valve.

Tighten stem nut securely to gas

valve.

3. Install one end of gas hose to fitting

on the top of welder and other end of

hose to fitting on regulator using hose

clamps on each connection. Make sure

gas hose is not kinked or twisted.

4. While standing opposite cylinder

outlet, slowly open cylinder valve.

Inspect for leaks in the connections.

5. Pull trigger on gun to allow gas to

flow. Adjust gas regulator to

maximum flow by rotating clockwise.

Release trigger.

6. Remember to close gas cylinder valve

when finished welding.

Handshield Assembly

1. Cut detachable handle away from

shield. Trim the excess plastic to

remove sharp edges – see Figure 6.

6

Wire Feed Arc Welder

If heating, welding or

cutting galvanized, zinc

plated, lead, or cadmium

plated materials, refer to

the General Safety

Information Section for instructions.

Extremely toxic fumes are created when

these metals are heated.

4. Connect work clamp to work piece or

workbench (if metal). Make sure

contact is secure. Avoid surfaces with

paint, varnish, corrosion or nonmetallic materials.

5. Rotate Wire Speed Control to setting

number 5 to start, then adjust as

needed after test.

6. Plug power cord into a proper

voltage receptacle with proper circuit

capacity (see circuit requirements on

front page).

7. Switch welder on to desired heat

setting per decal inside wire feed

compartment.

NOTE: These settings are general

guidelines only. Heat setting may vary

according to welding conditions and

materials.

8. Verify wire is extended 1/4” from

contact tip. If not, squeeze trigger to

feed additional wire, release trigger,

turn welder off, and cut wire to

proper length. Then, switch back on

to desired heat setting.

9. Position wire feed gun near work

piece, lower welding helmet by

nodding head or positioning the hand

shield, and squeeze gun trigger. Adjust

heat setting and wire speed as needed.

10. When finished welding, turn welder

off and store properly.

Maintenance

Disconnect power

supply and turn

machine off before inspecting or

servicing any components. Keep wire

compartment cover closed at all times

unless wire needs to be changed.

BEFORE EVERY USE:

1. Check condition of weld cables and

immediately repair or replace any

cables with damaged insulation.

2. Check condition of power cord and

immediately repair or replace any

cord if damaged.

!

www.chpower.com

Figure 5 - Hose and Regulator Hookup

Figure 6

Figure 7

WARNING

!

WARNING

!

WARNING

MANUAL

!

WARNING

WIRE TYPE AND SIZE

The correct choice of wire type

involves a variety of factors, such as

welding position, work piece material

type, thickness, and condition of

surface to be welded. The American

Welding Society, AWS, has set up

certain requirements for each type of

wire.

FLUX-CORED WIRE

E - 7 0 T - GS

Weld strength, times

10,000 pounds per

square inch

Welding positions (0

for flat or horizontal,

1 for any position)

Tubular flux-cored wire

Flux type

38 Sp

Soldadora Por Arco Con Alimentación de Cable

Table de Detección y Solución de Problemas - Soldadora

Síntoma Causas Posibles Medida Correctiva

1. Excedio el ciclo de trabajo

2. La pinza está mal conectada

3. El interruptor está dañado

4. El cortacircuito se activó o el

fusible está quemado

1. La boquilla de la pistola es de

un tamaño incorrecto

2. El forro de la pistola está

obstruído o dañado

3. La boquilla de la pistola está

obstruída o dañada

4. El rodillo está desgastado

5. No hay suficiente tensión

Hay escoria dentro de la boquilla

pistola

1. Hay mal contacto

2. Está usando un cordón de

extensión demasiado largo

1. El alambre está atascado

2. Se terminó el alambre

3. No hay suficiente tensión

4. El forro del alambre está

dañado

1. Espere que la soldadora se enfríe, cuando el bombillo se

apague

2. Cerciórese de que las conexiones estén bien hechas y de que la

superficie esté limpia

3. Reemplace el interruptor

4. Reduzca la carga del circuito, active el cortacircuito o

reemplace el fusible

1. Use una boquilla adecuada

2. Límpielo o reemplácelo

3. Límpiela o reemplácela

4. Reemplácelo

5. Apriete el tornillo

Cerciórese de que todas las conexiones esten bien aseguradas, y

de que la superfice este limpia.

1. Cercórese de que todas las conexiones estén bien aseguradas y

que la superficie de contacto esté limpia

2. Nunca use cordones de extensión de más de 6,10 m (20 pies)

1. Recargue el alambre (1-5 acero dulce; 5-10 aluminio)

2. Reemplace el carrete

3. Apriete los tornillos si el cable se desliza

4. Reemplace el forro

No funciona

El alambre se enrolla en la

bobina

Ocurre un arco entre la

boquilla de la pistola y la

superficie de trabajo

La pinza de trabajo y/o el

cable se calientan

El alambre no circula

(Aluminio) el alambre se

quema en el extremo de la

boquillla o (Aluminio) se

forman burbujas en el

metal o se funde

completamente

La soldadura se ampolla y

salpica

5. El fusible está quemado

(WG3060)

6. El alambre está desconectado

internamente

7. La boquilla de contacto está

obstruida

1. La velocidad de alimentación es

muy lenta

2. La velocidad de desplazamiento

es muy baja o la energía es muy

alta

1. Ajustes de velocidad del cable

2. Punta de contacto demasiado

grande

3. Polaridad conectada

incorrectamente

4. Resbala el portabobinas

5. Tanque de gas vacío

5. Reemplace el fusible en el tablero de control, dentro de la

soldadora (3,15 amp de accón retardada)

6. Llame al 1-800-746-5641 (en EUA) para recibir asistenciia

7. Reemplace la boquilla de contacto

1. Use velocidades entre 7 - 10

2. Aumente la velocidad de desplazamiento o disminuya la

energía

1. Ajuste el valor correcto

2. Remplace la punta de contacto

3. Invierta la polaridad

4. Aumente la tensión

5. Remplace el tanque de gas

7

Welding Guidelines

Models WG2060 and WG2064

Supply Cable Replacement

1. Verify that welder is OFF and

power cord disconnected.

2. Remove welder side panel to

expose switches.

3. Disconnect the black power cord

wire connected to the switch

and the white cord wire from

the transformer windings.

4. Disconnect the green power

cord wire connected to welder

base.

5. Loosen the cord strain relief

screw(s) and pull cord out of

strain relief and wire post.

6. Install new cord in reverse order.

General

This welding machine can utilize the Flux

Cored Arc Welding (FCAW) process or

the Gas Metal Arc Welding (GMAW)

process. The weld must be protected

(shielded) from contaminants in the air

while it is molten. The FCAW process uses

a tubular wire with a flux material inside.

The flux creates a shielding gas when

melted. The GMAW process uses inert

gas to shield the weld while molten.

When current is produced by a

transformer (welding machine) and flows

through the circuit to the weld wire, an

arc is formed between the end of the

weld wire and the work piece. This arc

melts the wire and the work piece. The

melted metal of the weld wire flows into

the molten crater and forms a bond with

the work piece as shown (Figure 8).

Arc Welding Basics

Five basic techniques affect weld quality.

These are: wire selection, heat setting,

weld angle, wire speed, and travel

speed. An understanding of these

techniques is necessary for effective

welds.

HEAT SETTING

The correct heat involves the adjustment

of the welding machine to the required

setting. Heat or voltage is regulated by a

switch on the welder. The heat setting

used depends on the size (diameter) and

type of wire, position of the weld, and

the thickness of the work piece. Consult

specifications listed on the welder. It is

suggested that the welder practice with

scrap metal to adjust settings, and

compare welds with Figure 10.

www.chpower.com

Maintenance

(Continued)

3. Inspect the condition of the gun tip

and nozzle. Remove any weld slag.

Replace gun tip or nozzle if damaged.

Do not operate this

welding machine

with cracked or missing insulation on

welding cables, wire feed gun or power

cord.

EVERY 3 MONTHS:

1. Replace any unreadable safety labels

on the welder.

2. Use compressed air to blow all dust

and lint from ventilation openings.

3. Clean wire groove on drive roller.

Remove wire from feed mechanism,

remove screws from drive roller

housing. Use a small wire brush to

clean drive roll. Replace if worn or

damaged

Consumable and Wear Parts

The following parts require routine

maintenance:

• Wire feed drive roller

• Gun liner - replace if worn

• Nozzle/contact tips

• Wire - This welder will accept either 4”

or 8” diameter spools. Flux-Cored

welding wire is susceptible to

moisture and oxidizes over time, so it

is important to select a spool size that

will be used within approximately 6

months. For mild steel welding, AWS

ER70S6 solid wire or AWS E71T-GS

Flux-Cored wire is recommended.

CHANGING WIRE SIZES

This welder is setup for .035 (.9mm)

wire. If a different wire size is used, the

wire feed drive roller and contact tip

may need changing. There are two

grooves in the drive roller. The small

groove is for .024 (.6mm) wire and the

other is for .030-.035 (.8-.9mm) wire.

Remove the roller cover and flip the

drive roller to choose the correct

groove (See parts breakdown). The

contact tip should also match the wire

diameter used. The tip diameter is

marked on the contact tip in inches or

millimeters.

!

WARNING

Loading...

Loading...