Campbell Hausfeld TL1017, TL1049, TL1002 User Manual

CAMPBELL HAUSFELD

OPERATING INSTRUCTIONS

IMPACT WRENCH

MODELS TL1002, TL1017 AND TL1049

READ CAREFULLY BEFORE ATTEMPTING TO ASSEMBLE, INSTALL, OPERATE OR MAINTAIN THE PRODUCT DESCRIBED. PROTECT YOURSELF AND OTHERS BY OBSERVING ALL SAFETY INFORMATION. FAILURE TO COMPLY WITH INSTRUCTIONS COULD RESULT IN PERSONAL INJURY AND/OR PROPERTY DAMAGE. RETAIN INSTRUCTIONS FOR FUTURE REFERENCE.

Description |

General Safety (Continued) |

Do-It-Yourself (DIY) impact wrenches are air tools designed for removing and installing nuts and bolts such as lug nuts, exhaust system clamps, etc.

9.Always use attachments designed for use with air powered tools. Do not use damaged or worn attachments.

Unpacking

When unpacking this product, carefully inspect for any damage that may have occurred during transit. Make sure any loose fittings, bolts, etc., are tightened before putting this product into service.

General Safety Information

This product is a part of a high pressure system and the following safety precautions must be followed at all times along with any other existing safety rules.

1.Read all manuals included with this product carefully. Be thoroughly familiar with the controls and the proper use of the equipment.

2.Only persons well acquainted with these rules of safe operation should be allowed to use the air tool.

! WARNING !

DO NOT USE HAND-TOOL SOCKETS. USE IM- PACT-QUALITY SOCKETS ONLY. HAND-TOOL SOCKETS ARE "GLASS-HARD" AND WILL SHATTER AND CAN CAUSE SERIOUS PERSONAL INJURY IF USED WITH AIR TOOLS.

10.Never trigger the tool when not applied to a work object. Attachments must be securely attached. Loose attachments can cause serious injury.

11.Protect air lines from damage or puncture.

12.Never point an air tool at oneself or any other person. Serious injury could occur.

13.Check air hoses for weak or worn condition before each use. Make sure all connections are secure.

! DANGER ! |

! WARNING ! |

DO NOT EXCEED MAXIMUM OPERATING PRESSURE OF THE AIR TOOL (90 PSI). THE AIR TOOL COULD EXPLODE AND RESULT IN DEATH OR SERIOUS PERSONAL INJURY.

3.Do not exceed any pressure rating of any component in the system.

4.Disconnect the air tool from air supply before changing tools or attachments, servicing and during nonoperation.

5.Always wear safety glasses during operation.

6.Do not wear loose fitting clothing, scarves, or neck ties. Loose clothing may become caught in moving parts and result in serious personal injury.

7.Do not wear jewelry when operating any tool.

Jewelry may become caught in moving parts and result in serious personal injury.

8.Do not depress trigger when connecting the air supply hose.

RELEASE ALL PRESSURE FROM THE SYSTEM BEFORE ATTEMPTING TO INSTALL, SERVICE, RELOCATE OR PERFORM ANY MAINTENANCE.

14.Keep all nuts, bolts and screws tight and ensure equipment is in safe working condition.

15.Do not put hands near or under moving parts.

Operation

LUBRICATION

Proper lubrication is the owner's responsibility. Failure to lubricate the air tool properly will dramatically shorten the life of the tool and will void the warranty.

! CAUTION

This impact wrench REQUIRES lubrication BEFORE the initial use and BEFORE and AFTER each additional use.

Impact wrenches require lubrication throughout the life of the tool and must be lubricated in two separate areas:

– 1 – |

IN230000AV 9/93 |

|

IN230000AV |

MODELS TL1002, TL1017 AND TL1049 |

|

|

Operation (Continued)

ANVIL |

OIL PORT |

REMOVE |

|

|

|

|

OIL PORT |

|||||

HOLE ON |

EXHAUST |

ANVIL |

HOLE |

|||||||||

|

BACK SIDE |

SCREW FOR |

PORT |

|

|

|

||||||

|

|

|

|

|

||||||||

|

|

|

|

|

OIL PORT |

UNDER- |

|

|

|

|

||

|

|

|

|

|

HOLE FORWARD |

|

|

|

|

|||

|

|

|

|

|

NEATH |

|

|

|

|

|||

|

|

|

|

|

LEVER |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

EXHAUST PORT |

ANVIL |

|

|

|

|

|

|

FORWARD/ |

||||

|

|

|

|

|

|

|

||||||

FORWARD/ |

|

|

|

|

|

|

|

REVERSE |

||||

|

|

|

|

|

|

|

SWITCH |

|||||

REVERSE |

|

|

|

|

|

|

|

|||||

|

|

|

|

TRIGGER |

||||||||

BUTTON |

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|||||

|

TRIGGER |

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

REVERSE |

|

|

|

|

|

|

|

|

REGULATOR |

|

|

|

1/4" NPT |

REGULATOR |

|

|

||||

|

|

|

|

LEVER |

|

|

||||||

|

|

|||||||||||

|

|

|

|

|

FEMALE |

|

|

|

|

|||

1/4" NPT FEMALE |

|

|

1/4" NPT FEMALE |

|||||||||

REGULATOR |

AIR INLET |

|

||||||||||

|

AIR INLET |

|

|

|

|

|

AIR INLET |

|||||

|

|

|

|

MODEL |

|

MODEL |

|

|

|

MODEL |

||

|

|

|

|

TL1002 |

|

TL1017 |

|

|

|

TL1049 |

||

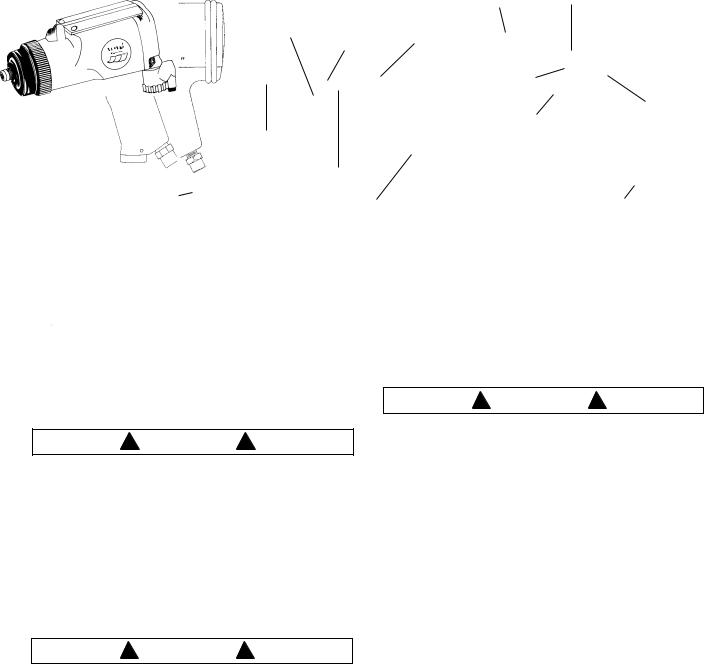

Figure 1 Impact Wrench Features

the air motor and the impact mechanism. Follow the outlined procedures and refer to Figure 1 for details. Campbell Hausfeld air tool oil (ST127000AV) is recommended because this oil cleans, lubricates and inhibits rust all in one step.

Air Motor Lubrication.

The motor must be lubricated daily. An air motor cannot be oiled too often.

! WARNING !

DISCONNECT THE IMPACT WRENCH FROM THE AIR SUPPLY BEFORE LUBRICATING.

1.Disconnect the impact wrench from the air supply.

2.Turn the impact wrench upside down.

3.Simultaneously (at the same time), pull the trigger and pour a teaspoon of Campbell Hausfeld oil in the air inlet. Then, push the forward and reverse button in both directions.

! WARNING !

AFTER AN AIR TOOL HAS BEEN LUBRICATED, OIL WILL DISCHARGE THROUGH THE EXHAUST PORT DURING THE FIRST FEW SECONDS OF OPERATION. THUS, THE EXHAUST PORT MUST BE COVERED WITH A TOWEL BEFORE APPLYING AIR PRESSURE. FAILURE TO COVER THE EXHAUST PORT CAN RESULT IN SERIOUS INJURY.

4.Connect the impact wrench to the air supply and cover the exhaust port with a towel (See Figure 1). Run the impact wrench in both the forward and

reverse directions for 20 to 30 seconds. Oil will discharge from the exhaust port when air pressure is applied.

Impact Mechanism Lubrication.

The impact mechanism should be lubricated monthly.

! WARNING !

DISCONNECT THE IMPACT WRENCH FROM THE AIR SUPPLY BEFORE LUBRICATING.

1.Disconnect the impact wrench from the air supply.

2.Remove the allen head screw from the oil port hole on the right side of the tool that has "OIL" stamped below the hole for model TL1002. For model TL1049, the screw is located on the left hand side of the tool near the exhaust port. For model TL1017, the screw is located in front of the forward/reverse lever.

3.Put three teaspoons of Campbell Hausfeld air tool oil in the oil port hole. Replace the screw.

4.Reconnect the air supply to the impact wrench and run for 20 to 30 seconds. Lubricate the entire impact mechanism by rotating the tool upside down and sideways while running the tool.

5.Remove the screw and hold the oil port hole over a suitable container to allow excess oil to drain.

6.If the oil is dirty, repeat the procedure above until the oil comes out clear. Install the screw and tighten. The residual oil remaining in the impact mechanism chamber is all that is needed for proper lubrication.

– 2 –

Loading...

Loading...