Campbell Hausfeld SB524000, IN729000AV, SB5240 User Manual

See Warranty on page 10 for important information about commercial use of this product.

Operating Instructions |

SB524000 |

|

|

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described. Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or property damage! Retain instructions for future reference.

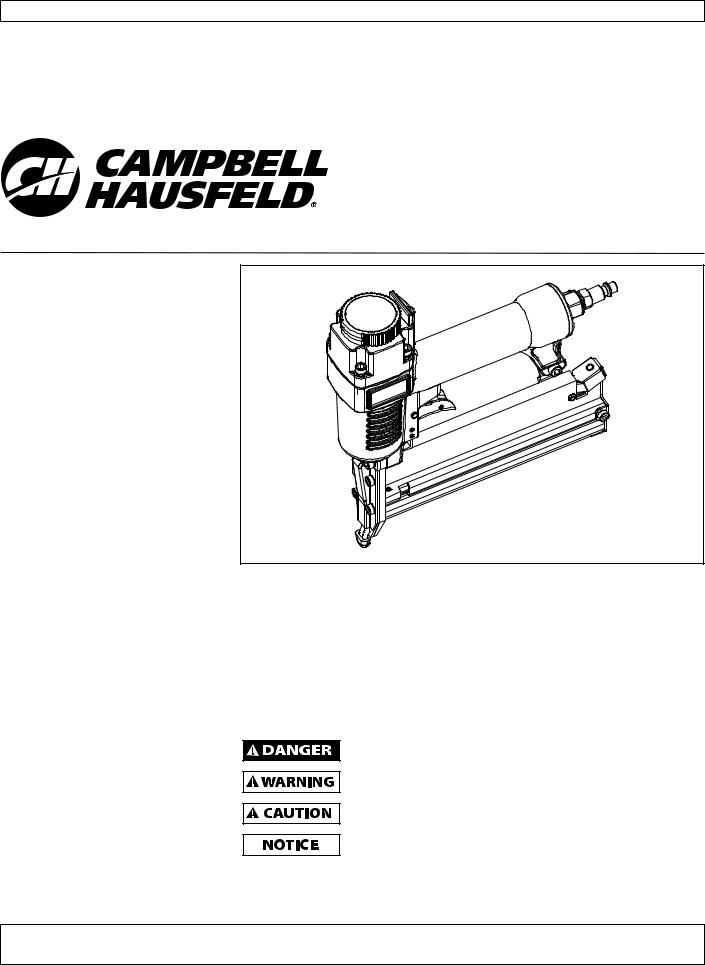

2 inch 2-in-1 Nailer/Stapler

Table of Contents |

|

Description . . . . . . . . . . . . . . . . . . . . . . |

1 |

Unpacking . . . . . . . . . . . . . . . . . . . . . . .1

Safety Guidelines . . . . . . . . . . . . . . . . .1

Important Safety Instructions . . . . . . .2

Tool Components and Specifications . .2

Operating the Tool . . . . . . . . . . . . . . . .4

Recommended Hookup . . . . . . . . . . . .5

Maintenance . . . . . . . . . . . . . . . . . . . . .7

Storage . . . . . . . . . . . . . . . . . . . . . . . . . |

7 |

Fasteners . . . . . . . . . . . . . . . . . . . . . . . .8

Troubleshooting Chart .. .. .. .. .. .. .. .. .. .. .. .. ..9

Warranty . . . . . . . . . . . . . . . . . . . . . . .10

Description

This tool is designed for decorative trim, molding, window casings, furniture trim, picture frame assembly, cabinetry, casebacks, and crafts.. Features include: convenient top loading magazine which holds up to 100 brads or staples, adjustable depth control, adjustable exhaust nose..

Unpacking

After unpacking the unit, inspect carefully for any damage that may have occurred during transit.. Check for loose, missing or damaged parts.. Make sure to tighten fittings, bolts, etc.., before putting unit into service..

Check to be sure all supplied accessories are enclosed with the unit.. In case of questions, damaged or missing parts, please call 1-800-543-6400 for customer assistance..

Figure 1 - Model SB524000

Read & Follow All Instructions

Save These Instructions

Do Not Discard

Safety Guidelines

This manual contains information that is very important to know and understand.. This information is provided for SAFETY and to PREVENT EQUIPMENT PROBLEMS.. To help recognize this information, observe the following symbols..

Danger indicates an imminently hazardous situation which, if not avoided, WILL result in death or serious injury.

Warning indicates a potentially hazardous situation which, if not avoided, COULD result in death or serious injury.

Caution indicates a potentially hazardous situation which, if not avoided, MAY result in minor or moderate injury.

Notice indicates important information, that if not followed, may cause damage to equipment.

NOTE: Information that requires special attention..

REMINDER: Keep your dated proof of purchase for warranty purposes! Attach it to this manual or file it for safekeeping.

© 2009 Campbell Hausfeld/Scott Fetzer |

For parts, product & service information |

IN729000AV 9/09 |

|

visit www.chpower.com |

|

Operating Instructions

Important Safety Instructions |

|

|

equipment.. Follow all instructions.. |

Personal Safety |

|||||||

INSTRUCTIONS PERTAINING TO A |

|

|

Contact your Campbell Hausfeld |

a.. |

Stay alert. Watch what you are |

||||||

|

|

representative if you have any |

|||||||||

|

|

|

doing and use common sense |

||||||||

RISK OF FIRE, ELECTRIC SHOCK, OR |

|

|

|

||||||||

|

|

questions.. |

|

||||||||

|

|

|

when operating the tool. Do not |

||||||||

INJURY TO PERSONS |

|

|

|

||||||||

|

|

|

|

|

|

||||||

c. |

Only persons well acquainted with |

|

use the tool while tired or under |

||||||||

|

|

|

When using tools, |

|

|||||||

|

|

|

|

|

these rules of safe operation should |

|

the influence of drugs, alcohol, |

||||

|

|

|

|

|

|

||||||

|

|

|

basic precautions |

|

|

|

|||||

|

|

|

|

|

|

||||||

|

|

|

|

|

be allowed to use the unit.. |

|

or medication. A moment of |

||||

should always be followed, including |

|

|

|

||||||||

the following: |

|

|

|

Read and |

|

inattention while operating the |

|||||

|

|

|

|

||||||||

California proposition 65 |

|

|

|

understand tool |

|

tool increases the risk of injury to |

|||||

|

|

|

|

||||||||

labels and manual. Failure to follow |

|

persons.. |

|||||||||

|

|

|

This product or |

|

|||||||

|

|

|

warnings, dangers, and cautions could |

b.. |

Dress properly. Do not wear loose |

||||||

|

|

|

|||||||||

|

|

|

|||||||||

|

|

|

its power cord may |

result in DEATH or SERIOUS INJURY. |

|||||||

|

|

|

|||||||||

|

|

|

|

clothing or jewelry. Contain long |

|||||||

contain chemicals known to the State |

Work Area |

|

|||||||||

of California to cause cancer and birth |

|

hair. Keep hair, clothing, and |

|||||||||

defects or other reproductive harm. |

a.. |

Keep the work area clean and well |

|

gloves away from moving parts. |

|||||||

Wash hands after handling. |

|

||||||||||

|

|

lighted. Cluttered benches and dark |

|

Loose clothes, jewelry, or long |

|||||||

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

areas increase the risks of electric |

|

hair increases the risk of injury to |

||

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

shock, fire, and injury to persons.. |

|

persons as a result of being caught |

||

You can create dust when |

|

|

|

|

|||||||

|

b.. |

Do not operate the tool |

|

|

in moving parts.. |

||||||

|

|

|

|||||||||

you cut, sand, drill or grind |

|

|

|

|

|||||||

|

|

|

in explosive atmospheres, |

|

c.. |

Avoid unintentional starting. |

|||||

|

|

|

|

|

|

|

|

||||

materials such as wood, |

|

|

|||||||||

|

|

such as in the presence of |

|

|

Be sure the switch is off before |

||||||

paint, metal, concrete, cement, or other |

|

|

|

|

|||||||

masonry. This dust often contains |

|

|

flammable liquids, gases, |

|

|

connecting to the air supply. Do not |

|||||

|

|

|

|

||||||||

chemicals known to cause cancer, birth |

|

|

or dust. The tool is able to create |

|

carry the tool with your finger on |

||||||

defects, or other reproductive harm. |

|

|

sparks resulting in the ignition of |

|

the switch or connect the tool to th |

||||||

Wear protective gear. |

|

|

|

||||||||

|

|

the dust or fumes.. |

|

air supply with the switch on.. |

|||||||

|

|

|

|

|

|

|

|

||||

General |

c.. |

Keep bystanders, children, and |

d.. |

Do not overreach. Keep proper |

|||||||

|

|

|

|

|

|||||||

|

|

|

visitors away while operating the |

|

footing and balance at all times. |

||||||

a.. To reduce the risks of |

|

|

|

|

|||||||

|

electric shock, fire, and |

|

|

|

tool. Distractions are able to result in |

|

Proper footing and balance enables |

||||

|

injury to persons, read all |

|

|

|

the loss of control of the tool.. |

|

better control of the tool in |

||||

|

the instructions before |

|

|

|

|

|

|

|

unexpected situations.. |

||

|

|

|

|

|

|

|

|

||||

|

using the tool. |

|

|

|

|

|

e.. |

Use safety equipment. A dust mask, |

|||

|

|

|

|

|

|

|

|

|

|

||

b. Be thoroughly familiar with the |

|

|

|

|

|

|

non-skid safety shoes and a hard |

||||

|

controls and the proper use of the |

|

|

|

|

|

|

|

|||

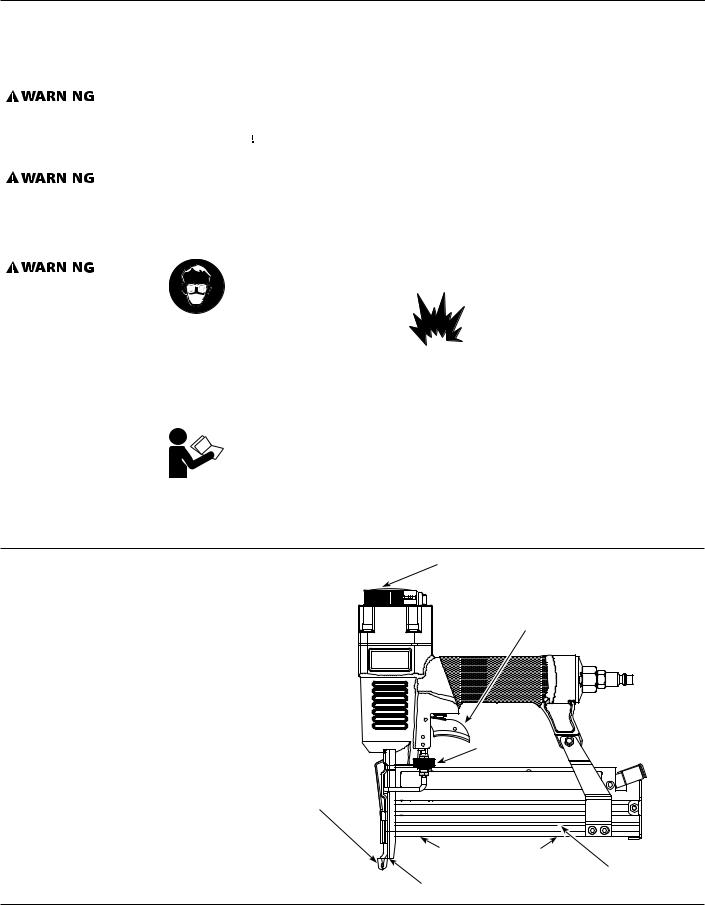

Tool Components and Specifications

• Requires: 0..4 SCFM with 10 |

|

|

fasteners per minute @ 90 psi |

|

|

• Air inlet: 1/4 inch NPT |

|

|

• MAGAZINE CAPACITY: 100 fasteners per |

|

|

load, 18 gauge |

|

|

• BRADS: 3/8 inch to 2 inch |

|

|

• STAPLES: 1/2 inch to 1-1/2 inch; |

|

|

1/4 inch crown |

|

|

• WEIGHT: 3 lbs.., 1 oz.. |

|

|

• LENGTH: 9-3/4 inch |

|

|

• HEIGHT: 9-1/2 inch |

Work |

|

• MAXIMUM PRESSURE: 120 psi |

||

Contact |

||

• PRESSURE RANGE: 70 psi - 120 psi |

Element |

|

|

Adjustable Direction

Exhaust Deflector

Trigger

Adjustable |

Depth Control |

Nail Loading Area |

Magazine

Nail Discharge Area

www.chpower.com

2

|

|

|

|

SB524000 |

|

Important Safety Instructions |

d.. |

Disconnect the tool from the |

Never attach air line to tool or carry |

||

(Continued) |

|

air source before making any |

tool while touching the trigger. The tool |

||

|

could eject a fastener which will result |

||||

|

hat must be used for the applicable |

|

adjustments, changing accessories, |

||

|

|

in death or serious personal injury. |

|||

|

|

or storing the tool. Such preventive |

|||

|

conditions.. |

|

|

||

|

|

safety measures reduce the risk of |

|

||

f.. |

Always wear eye |

|

|

||

|

starting the tool unintentionally.. |

|

|||

|

protection. |

|

Always disconnect the |

||

|

e.. |

Store the tool when it is idle out |

|||

g.. |

Always wear hearing |

tool from the power |

|||

|

of reach of children and other |

source when unattended, |

|||

|

protection when using |

|

|||

|

|

untrained persons. A tool is |

performing any maintenance or repair, |

||

|

the tool. Prolonged exposure to |

|

|||

|

|

dangerous in the hands of untrained |

loading or unloading, clearing a jam, |

||

|

high intensity noise is able to cause |

|

or moving the tool to a new location. |

||

|

|

users.. |

|||

|

hearing loss.. |

|

Do not load the tool with fasteners |

||

|

|

|

|||

h.. |

Do not attach the hose or tool to |

f.. |

Maintain the tool with care. Keep |

when either the trigger is depressed |

|

|

a cutting tool sharp and clean.. A |

or the Work Contact Element (WCE) is |

|||

|

your body. Attach the hose to the |

|

engaged. The tool could eject a fastener |

||

|

|

properly maintained tool, with sharp |

|||

|

structure to reduce the risk of loss of |

|

causing death or serious personal |

||

|

|

cutting edges reduces the risk of |

|||

|

balance if the hose shifts.. |

|

injury. |

||

|

|

binding and is easier to control.. |

|

||

i.. |

Always assume that the tool |

|

|

||

g.. Check for misalignment or binding |

|

||||

|

contains fasteners. Do not point |

|

|||

|

|

of moving parts, breakage of parts, |

Always fit tool with a |

||

|

the tool toward yourself or anyone |

|

|||

|

|

and any other condition that affects |

fitting or hose coupling |

||

|

whether it contains fasteners or not.. |

|

|||

|

|

the tool’s operation. If damaged, |

on or near the tool in |

||

|

|

|

|||

j. |

Do not nail on |

|

such a manner that all compressed air |

||

|

have the tool serviced before using.. |

||||

|

top of another |

|

in the tool is discharged at the time the |

||

|

|

Many accidents are caused by poorly |

|||

|

|

fitting or hose coupling is disconnected. |

|||

|

nail. This is able to cause the nail to |

|

|||

|

|

maintained tools.. There is a risk of |

|||

|

|

Do not use a check valve or any other |

|||

|

be deflected and hit someone, or |

|

|||

|

|

bursting if the tool is damaged.. |

fitting which allows air to remain in the |

||

|

cause the tool to react and result in a |

|

|||

|

risk of injury to persons. |

h.. Use only accessories that are |

tool. Death or serious personal injury |

||

|

could occur. |

||||

|

|

||||

k.. |

Remove finger |

|

identified by the manufacturer for |

||

|

|

||||

|

from the trigger |

|

the specific tool model. Use of an |

|

|

|

when not driving fasteners. Never |

|

accessory not intended for use with |

|

|

|

carry the tool with finger on trigger, |

|

Never place hands or any |

||

|

|

the specific tool model, increases the |

|||

|

the tool is able to fire a fastener. |

|

other body parts in the |

||

|

|

risk of injury to persons.. |

|||

|

Always remain in a |

|

fastener discharge area of |

||

|

i. |

Selecting an appropriate tool |

the tool. The tool might eject a fastener |

||

|

firmly balanced |

||||

|

and could result in death or serious |

||||

position when using or handling the |

|

actuation system, taking into |

|||

|

personal injury. |

||||

tool. |

|

consideration the work application |

|||

|

|

||||

|

Avoid long extended |

|

for which the tool is used.. |

|

|

|

periods of work |

|

Never use |

Never carry the tool by |

|

with the tool. Stop using the tool if you |

|

||||

|

gasoline |

||||

feel pain in hands or arms. |

|

the air hose or pull the |

|||

or other flammable liquids |

|||||

|

|

hose to move the tool |

|||

Tool Use and Care |

to clean the tool. Never use |

||||

or a compressor. Keep hoses away from |

|||||

the tool in the presence of |

|||||

a.. |

Use clamps or another practical way |

heat, oil and sharp edges. Replace any |

|||

flammable liquids or gases. Vapors |

|||||

hose that is damaged, weak or worn. |

|||||

|

to secure and support the workpiece |

could ignite by a spark and cause an |

|||

|

Personal injury or tool damage could |

||||

|

to a stable platform. Holding the |

explosion which will result in death or |

|||

|

occur. |

||||

|

work by hand or against the body is |

serious personal injury. |

Always assume the |

||

|

|

|

|||

|

unstable and is able to lead to loss |

|

|

||

|

|

|

tool contains |

||

|

of control.. |

Do not remove, tamper |

fasteners. Respect the tool as a working |

||

b.. |

Do not force the tool. Use the |

implement; no horseplay. Always keep |

|||

with, or otherwise |

others at a safe distance from the work |

||||

|

correct tool for the application.. The |

||||

|

cause the Work Contact |

area in case of accidental discharge of |

|||

|

correct tool will do the job better |

Element (WCE) or trigger to become |

fasteners. Do not point the tool toward |

||

|

and safer at the rate for which the |

inoperable. Do not operate any tool |

yourself or anyone whether it contains |

||

|

tool is designed.. |

which has been modified in a like |

fasteners or not. Accidental triggering |

||

|

fashion. Death or serious personal |

of the tool could result in death or |

|||

c.. |

Do not use the tool if the switch |

||||

injury could result. |

serious personal injury. |

||||

|

does not turn the tool on or off. Any |

|

|

|

|

|

tool that cannot be controlled with |

|

|

|

|

|

the switch is dangerous and must be |

Do not touch the trigger |

|

||

|

repaired.. |

unless driving fasteners. |

|

||

www.chpower.com

3

Operating Instructions

Important Safety Instructions (Continued)

Do not drive a fastener on top of other fasteners. The fastener

could glance and cause death or a serious puncture wound.

! WARNING

Do not operate or allow anyone else to operate the tool if any warnings

or warning labels are not legible. Warnings or warning labels are located on the tool magazine and body.

Do not drop or throw the tool.

Dropping or throwing the tool can result in damage that will make the tool unusable or unsafe. If the tool has been dropped or thrown, examine the tool closely for bent, cracked or broken parts and air leaks. STOP and repair before using or serious injury could occur.

Always check that the Work Contact

Element (WCE) is operating properly. A fastener could accidentally be driven if the WCE is not working properly. Personal injury may occur (See "Checking the Work Contact Element" Section).

Avoid using the tool when the

magazine is empty. Accelerated wear on the tool may occur.

Clean and check all air supply hoses

and fittings before connecting the tool to an air supply. Replace any damaged or worn hoses or fittings. Tool performance or durability may be reduced.

Service

a..Tool service must be performed only by qualified repair personnel.

b..When servicing a tool, use only identical replacement parts. Use only authorized parts.

c..Use only the lubricants supplied with the tool or specified by the manufacturer.

Do not make any modifications to

the tool without first obtaining written approval from Campbell Hausfeld. Do not use the tool if any shields or guards are removed or altered. Do not use the tool as a hammer. Personal injury or tool damage may occur.

Disconnect air supply and release

tension from the pusher before attempting to clear jams because fasteners can be ejected from the front of the tool. Personal injury may occur.

Air Source

a..Never connect to an air source that is capable of exceeding 200 psi.

Over pressurizing the tool is able to result in bursting, abnormal operation, breakage of the tool or serious injury to persons.. Use only clean, dry, regulated compressed air at the rated pressure or within the rated pressure range as marked on

the tool.. Always verify prior to using the tool that the air source has been adjusted to the rated air pressure or within the rated air-pressure range..

b..Never use oxygen, carbon dioxide, combustible gases or any bottled gas as an air source for the tool.

Such gases are capable of explosion and serious injury to persons..

Do not use any type of reactive gases, including, but not limited to, oxygen and

combustible gases, as a power source. Use filtered, lubricated, regulated compressed air only. Use of a reactive gas instead of compressed air may cause the tool to explode which will cause death or serious personal injury.

Use only a pressure-regulated compressed air source to limit the air pressure supplied to

the tool. The regulated pressure must not exceed 120 psi. If the regulator fails, the pressure delivered to the tool must not exceed 200 psi. The tool

could explode which will cause death or serious personal injury.

Save These Instructions

Do Not Discard

Operating The Tool

Lubrication

This tool requires lubrication before using the tool for the first time and before each use.. If an inline oiler is used, manual lubrication through the air inlet is not required on a daily basis..

The work surface can become

damaged by excessive lubrication. Proper lubrication is the owner’s responsibility. Failure to lubricate the tool properly will dramatically

shorten the life of the tool and void the warranty.

1. Disconnect the air supply from the tool to add lubricant..

2.Turn the tool so the air inlet is facing up.. Place 4-5 drops of 30 W non-detergent oil into air inlet.. Do not use detergent oils, oil

additives, or air tool oils.. Air tool oils contain solvents which will damage the tool’s internal components..

3.After adding oil, run

tool briefly.. Wipe off any excess oil from the cap exhaust..

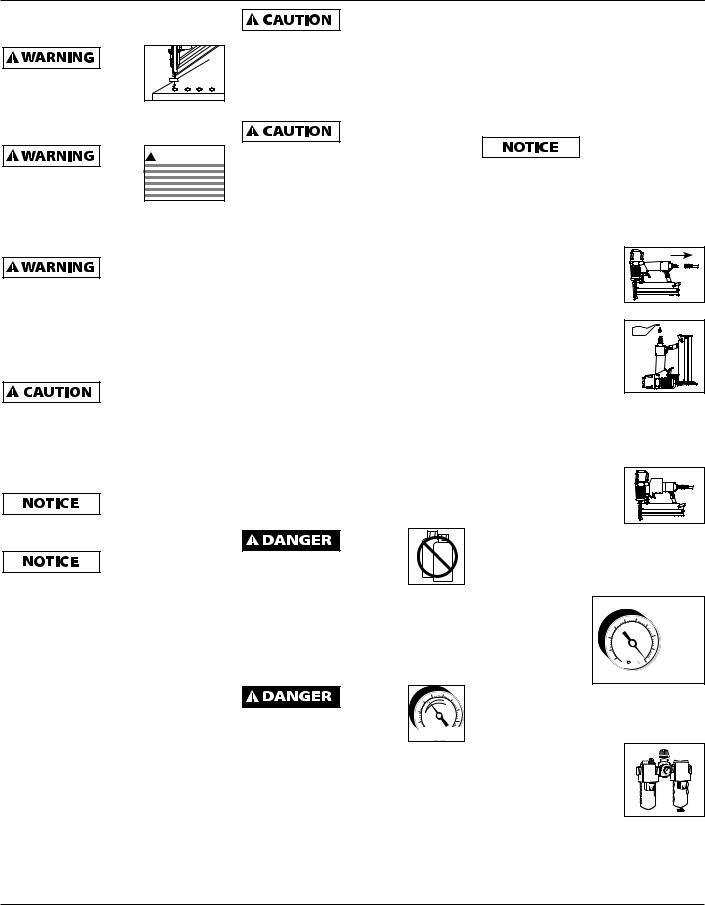

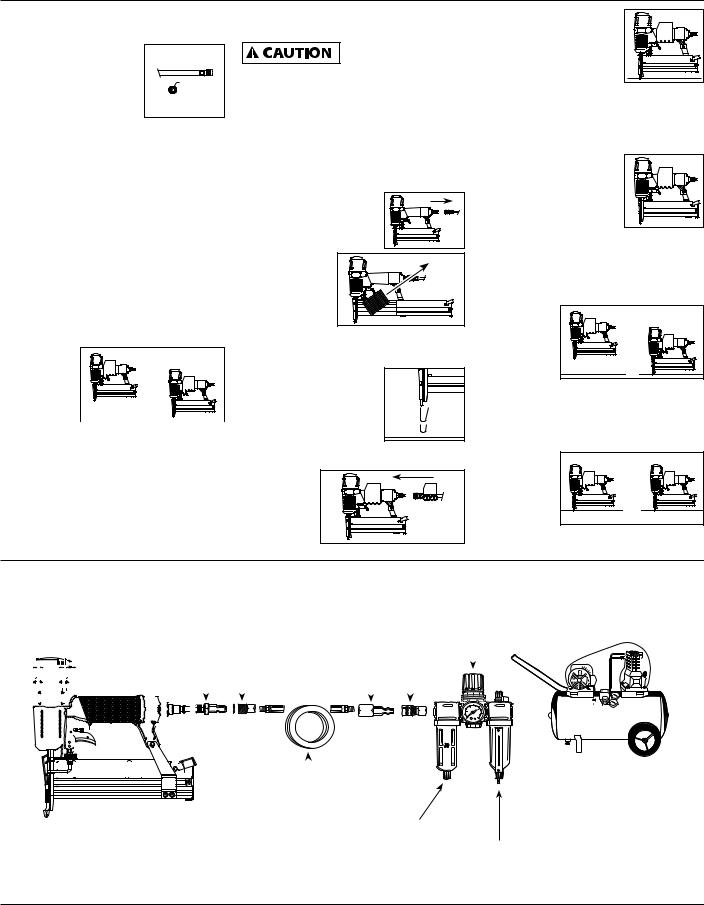

Recommended Hookup

The illustration below shows the recommended hookup for the tool..

1. The air

compressor must be able

to maintain a minimum of 70 psi when the

tool is being used.. An inadequate air supply can cause a loss of power and inconsistent driving..

2. An oiler can be used to provide oil circulation through the tool.. A filter can be used to remove liquid and solid

impurities which can rust or “gum up” internal parts of the tool..

www.chpower.com

4

SB524000

Operating The Tool (Continued)

3. Use 1/4 inch air hoses with a minimum working pressure of 150 psi.. Use 3/8 inch air hoses for 50 foot run or longer.. For

better performance, install a 3/8 inch quick plug (1/4 inch NPT threads) with an inside diameter of ..315 inch (8mm) on the tool and a 3/8 inch quick coupler on the air hose..

4.Use a pressure regulator on the compressor, with an operating pressure of 0 psi - 125 psi.. A pressure regulator is required to control

the operating pressure of the tool between 70 psi and 120 psi..

Single SEQUENTIAL Mode

This mode

requires the

trigger to be pulled

each time

a fastener is driven.. The tool can be actuated by depressing the WCE against the work surface followed by pulling the trigger..

a fastener is driven.. The tool can be actuated by depressing the WCE against the work surface followed by pulling the trigger..

The trigger must be released to reset the tool before another fastener can be driven..

Checking the Work Contact Element (WCE)

Check the operation of the Work Contact

Element (WCE) trip mechanism before each use. The WCE must move freely without binding through its entire travel distance. The WCE spring must return the WCE to its fully extended position after being depressed. Do not operate the tool if the WCE trip mechanism is not operating properly. Personal injury may occur.

1. Disconnect the air supply from the tool..

2. Remove all fasteners from the magazine (see Loading/ Unloading)..

3.Make sure the trigger and work contact

element (WCE) move freely up and down without sticking or binding..

4. Reconnect air supply to the tool..

5. Depress the Work

Contact Element (WCE) against the work surface without

pulling the trigger.. The tool must not

operate.. Do not use the tool if it operates without pulling the trigger.. Personal injury may result..

6.Remove the tool from the work surface.. The Work Contact Element (WCE) must return to its original

down position.. The tool must not operate.. Do not use the tool if it operates while lifted from the work surface.. Personal injury may result..

7.Pull the trigger and depress the work contact

element (WCE) against the work surface.. The tool MUST NOT operate..

8.Depress the Work Contact Element (WCE)

against the work surface.. Pull the trigger.. The tool MUST operate..

Recommended Hookup

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Quick |

Regulator |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Quick |

|

|

Quick Plug |

Coupler |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

Quick Plug Coupler |

|

|

(Optional) |

(Optional) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Air Hose

Lubricator

Filter

www.chpower.com

5

Operating Instructions

Operating The Tool (Continued)

An improperly functioning tool

must not be used. Do not actuate the tool unless the tool is placed firmly against the work piece.

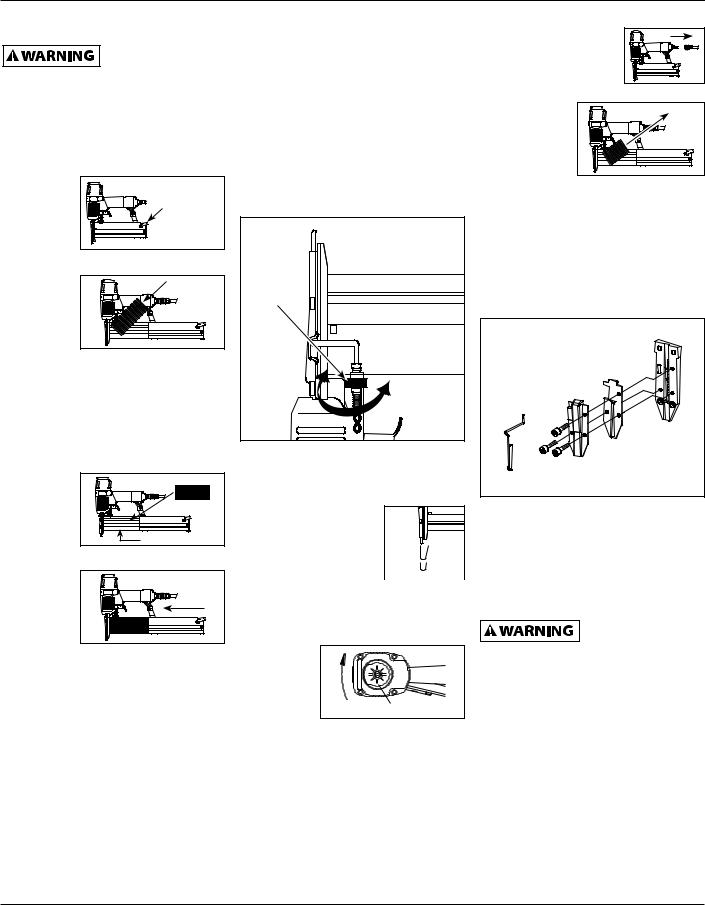

LOADING/UNLOADING THE TOOL

1.Always disconnect the tool from the air supply before loading fasteners..

2.Push

down on LatchButton

the latch button..

Pull back on the magazine cover..

3a. For nails,

insert a stick of

Campbell

Hausfeld

nails or equivalent (see “Fasteners” section) into the magazine.. Make sure the pointed ends of the fasteners are resting on the bottom ledge of the magazine when loading.. Make sure the nails are not dirty or damaged..

3b. |

For |

|

|

staples, |

|

|

load a clip |

|

|

of staples |

Magazine Rail |

|

with the |

|

|

|

|

|

crowns straddling the magazine rail.. |

|

4. |

Push the |

|

|

magazine |

|

|

cover |

|

|

forward |

|

|

until latch |

|

|

button pops up.. |

|

5.Always unload all fasteners before removing tool from service.. Unloading is the reverse of loading, except that you must disconnect the air supply before unloading..

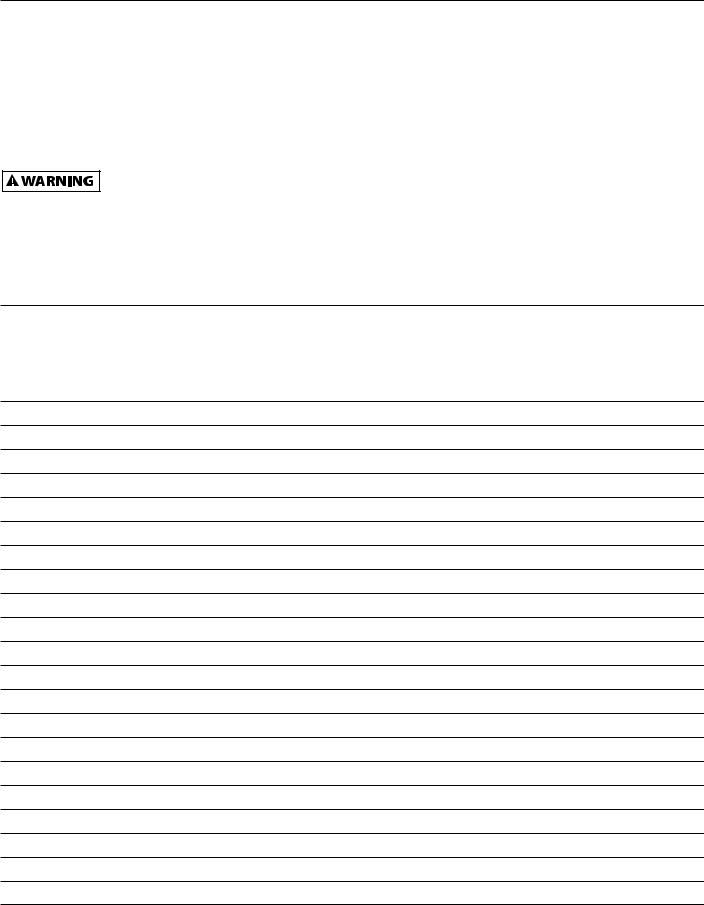

ADJUSTING THE FASTENER PENETRATION

The tool is equipped with an adjustable depth of drive feature.. This allows the user to determine how deep a fastener will be driven into the work surface..

1.Adjust operating pressure so fasteners are driven consistently.. Do not exceed 120 psi..

2.For shallow penetration, turn the wheel (C) to right to the extent desired..

(C) |

3.For deeper penetration, turn the wheel (C) to left to the extent desired..

4.Make sure trigger and work contact element

(WCE) move freely up and down without binding or sticking  after each adjustment..

after each adjustment..

Adjusting The Direction Of The Exhaust

The tool is equipped with an

adjustable  Rotate direction

Rotate direction

exhaust deflector.. This is intended to allow the user to change the direction of the exhaust.. Simply twist the deflector to any direction desired..

CLEARING A JAM FROM THE TOOL

1. Disconnect the air supply from the tool..

2. Remove all

nails from the magazine

(See Loading/ Unloading

The Nailer)..

Failure to do so will cause the nails to eject from the front of the nailer when the nose assembly is removed..

3.Loosen cap screws on nose of tool.. Slide nose downward and remove from tool to expose jammed fastener..

4.Reinstall nose assembly in reverse order in step #3..

5.Make sure the trigger and Work Contact Element (WCE) move freely up and down without sticking or binding..

Failure to remove all fasteners will cause the fasteners to eject from the

front of the tool.

www.chpower.com

6

SB524000

Maintenance

Technical Support

Please call our Tool Hotline at 1-800- 543-6400 with any questions regarding the operation or repair of this tool or for additional copies of this manual..

Fastener And Replacement Parts

Use only genuine Campbell Hausfeld

18 gauge fasteners (or equivalent - see Fastener Interchange Information). Tool performance, safety and durability could be reduced if improper fasteners are used. When ordering replacement parts or fasteners, specify by part number.

Tool Repair

Only qualified personnel should repair the tool, and they should use genuine Campbell Hausfeld replacement parts and accessories, or parts and accessories which perform equivalently..

Assembly Procedure For Seals

When repairing a tool, the internal parts must be cleaned and lubricated.. Parker O-lube or equivalent must be used on all o-rings.. Each o-ring must be coated with O-lube before assembling.. A small amount of oil must be used on all moving surfaces and pivots..

After reassembling, a few drops of 30W non-detergent oil or equivalent, must be added through the air line before

testing..

Storage

The unit should be stored in a cool, dry place..

Notes

www.chpower.com

7

Operating Instructions

Fasteners

Nails

The following Campbell Hausfeld Brad nails are available at local retail stores.. For help locating any item, call customer service at 1-800-543-6400.. Campbell Hausfeld nails meet or exceed ASTM Standard F1667..

Model # |

Length |

Shank Gauge |

Finish |

Head |

Collation |

Nails per Pack |

Nails per |

|

|

|

|

|

|

|

Box |

FB001600 |

5/8 inch |

18 Gauge |

Galvanized |

Brad /Brown |

Adhesive |

100 |

5000 |

FB002000 |

3/4 inch |

18 Gauge |

Galvanized |

Brad /Brown |

Adhesive |

100 |

5000 |

FB002500 |

1 inch |

18 Gauge |

Galvanized |

Brad /Brown |

Adhesive |

100 |

5000 |

FB003000 |

1-1/4 inch |

18 Gauge |

Galvanized |

Brad /Brown |

Adhesive |

100 |

5000 |

FB004000 |

1-1/2 inch |

18 Gauge |

Galvanized |

Brad /Brown |

Adhesive |

100 |

5000 |

FB004500 |

1-3/4 inch |

18 Gauge |

Galvanized |

Brad /Brown |

Adhesive |

100 |

5000 |

FB005000 |

2 inch |

18 Gauge |

Galvanized |

Brad /Brown |

Adhesive |

100 |

5000 |

FB180016 |

5/8 inch |

18 Gauge |

Galvanized |

Brad /Brown |

Adhesive |

100 |

1000 |

FB180025 |

1 inch |

18 Gauge |

Galvanized |

Brad /Brown |

Adhesive |

100 |

1000 |

FB180030 |

1-1/4 inch |

18 Gauge |

Galvanized |

Brad /Brown |

Adhesive |

100 |

1000 |

FB180040 |

1-1/2 inch |

18 Gauge |

Galvanized |

Brad /Brown |

Adhesive |

100 |

1000 |

FB180050 |

2 inch |

18 Gauge |

Galvanized |

Brad /Brown |

Adhesive |

100 |

1000 |

Interchange Information

Can use brad nails from the following branded air-powered brad nailers: Bostitch BT125SK-2 & BT200K-2, Campbell Hausfeld NB0030 & NB0040, DeWalt D51238K, Paslode T125-F18 & T200-F18, Porter Cable BN125 & BN200, and Senco Finish Pro 15 & 18..

Staples

The following Campbell Hausfeld staples are available at local retail stores.. If you need help locating any item, call customer service at 1-800-543-6400.. Campbell Hausfeld staples meet or exceed astm Standard F1667..

Model # |

Length |

Wire |

Crown Size |

Point |

Finish |

Collation |

Staples Per |

Staples |

|

|

Diameter |

|

|

|

|

Stick |

Per Box |

FN158K00 |

1/2 inch |

18 Gauge |

1/4 inch |

Chisel |

Galvanized/ |

Adhesive |

100 |

5000 |

|

|

|

|

|

Vinyl Coated |

|

|

|

FN168K00 |

5/8 inch |

18 Gauge |

1/4 inch |

Chisel |

Galvanized/ |

Adhesive |

100 |

5000 |

|

|

|

|

|

Vinyl Coated |

|

|

|

FN180615 |

1/2 inch |

18 Gauge |

1/4 inch |

Chisel |

Galvanized/ |

Adhesive |

100 |

1000 |

|

|

|

|

|

Vinyl Coated |

|

|

|

FN180620 |

3/4 inch |

18 Gauge |

1/4 inch |

Chisel |

Galvanized/ |

Adhesive |

100 |

1000 |

|

|

|

|

|

Vinyl Coated |

|

|

|

FN180625 |

1 inch |

18 Gauge |

1/4 inch |

Chisel |

Galvanized/ |

Adhesive |

100 |

1000 |

|

|

|

|

|

Vinyl Coated |

|

|

|

FN180630 |

1-1/4 inch |

18 Gauge |

1/4 inch |

Chisel |

Galvanized/ |

Adhesive |

100 |

1000 |

|

|

|

|

|

Vinyl Coated |

|

|

|

FN208K00 |

3/4 inch |

18 Gauge |

1/4 inch |

Chisel |

Galvanized/ |

Adhesive |

100 |

5000 |

|

|

|

|

|

Vinyl Coated |

|

|

|

FN258K00 |

1 inch |

18 Gauge |

1/4 inch |

Chisel |

Galvanized/ |

Adhesive |

100 |

5000 |

|

|

|

|

|

Vinyl Coated |

|

|

|

Interchange Information

Staples used in the SB524000 will also work in: Senco LN4450, SJS-LR, SKS L11-15, Hitachi N3804A, Duofast BN-1832S, KN1848, Stan-Tech SDS 18-14, Atro Minor 90/30, 90/32, 90/40, and Porter Cable NS100..

www.chpower.com

8

SB524000

Troubleshooting Chart

Stop using tool immediately if any of the following problems occur. Serious personal injury could result. Any repairs or replacements must be done by a Qualified Service Person or Authorized Service Center.

Symptom |

Possible Cause(s) |

Corrective Action |

||

Air leaking at trigger valve |

O-Rings in trigger valve housing are |

Replace O-Rings.. Check operation of Work |

||

|

damaged |

Contact Element (WCE) |

||

|

|

|

|

|

Air leaking between housing |

1. |

Loose screws in housing |

1. |

Tighten screws |

and nose |

2. |

Damaged O-Rings |

2. |

Replace O-Rings |

|

||||

|

3. |

Damage to bumper |

3. |

Replace bumper |

|

|

|

|

|

Air leaking between housing |

1. Loose screws |

1. |

Tighten screws |

|

and cap |

2. |

Damaged gasket |

2. |

Replace gasket |

|

||||

|

|

|

|

|

Tool skips driving fastener |

1. Worn bumper |

1. |

Replace bumper |

|

|

2. |

Dirt in nose piece |

2. |

Clean drive channel |

|

3. |

Dirt or damage prevent fasteners or |

3. |

Clean magazine |

|

|

pusher from moving freely in magazine |

|

|

|

4. |

Damaged pusher spring |

4. |

Replace spring |

|

5. |

Inadequate air flow to tool |

5. |

Check fitting, hose or compressor |

|

6. |

Worn O-Ring on piston or lack of lubri- |

6. |

Replace and lubricate O-Rings |

|

|

cation |

|

|

|

7. |

Damaged O-Ring on trigger valve |

7. |

Replace O-Rings |

|

8. |

Air leaks |

8. |

Tighten screws and fittings |

|

9. |

Cap gasket leaking |

9. |

Replace gasket |

|

|

|

|

|

Tool runs slow or has loss of |

1. |

Tool not lubricated sufficiently |

1. |

Lubricate tool |

power |

2. |

Broken spring in cylinder cap |

2. |

Replace spring |

|

||||

|

3. |

Exhaust port in cap is blocked |

3. |

Replace damaged internal parts |

|

|

|

|

|

Fasteners are jammed in tool |

1. Guide on driver is worn |

1. |

Replace guide |

|

|

2. |

Fasteners are not correct size |

2. |

Use only recommended fasteners |

|

3. |

Fasteners are bent |

3. |

Replace with undamaged fasteners |

|

4. |

Magazine or nose screws are loose |

4. |

Tighten screws |

|

5. |

Driver is damaged |

5. |

Replace driver |

www.chpower.com

9

Operating Instructions

Limited Warranty

1.DURATION: From the date of purchase by the original purchaser as follows: Campbell Hausfeld (Standard Duty and Unannounced) – One (1) Year, (Serious Duty) – Two (2) Years, (Extreme Duty) – Three (3) Years; IronForce by Campbell Hausfeld – One (1) Year; Farmhand – Three (3) Years; Maxus – Five (5) Years..

2.WHO GIVES THIS WARRANTY (WARRANTOR): Campbell Hausfeld / Scott Fetzer Company, 100 Production Drive, Harrison, Ohio, 45030, Telephone: (800) 543-6400

3..WHO RECEIVES THIS WARRANTY (PURCHASER): The original purchaser (other than for purposes of resale) of the Campbell Hausfeld product..

4..WHAT PRODUCTS ARE COVERED BY THIS WARRANTY: Any Campbell Hausfeld nailer, stapler, air tool, spray gun, inflator or air accessory supplied or manufactured by Warrantor..

5..WHAT IS COVERED UNDER THIS WARRANTY: Substantial defects in material and workmanship which occur within the duration of the warranty period..

6..WHAT IS NOT COVERED UNDER THIS WARRANTY:

A.Implied warranties, including those of merchantability and FITNESS FOR A PARTICULAR PURPOSE ARE LIMITED FROM THE DATE OF ORIGINAL PURCHASE AS STATED IN THE DURATION.. If this product is used for commercial, industrial or rental purposes, the warranty will apply for ninety (90) days from the date of purchase.. Some States do not allow limitation on how long an implied warranty lasts, so the above limitations may not apply to you..

B.ANY INCIDENTAL, INDIRECT, OR CONSEQUENTIAL LOSS, DAMAGE, OR EXPENSE THAT MAY RESULT FROM ANY DEFECT, FAILURE, OR MALFUNCTION OF THE CAMPBELL HAUSFELD PRODUCT.. Some States do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you..

C.Any failure that results from an accident, purchaser’s abuse, neglect or failure to operate products in accordance with instructions provided in the owner’s manual(s) supplied with product.. Accident, purchaser’s abuse, neglect or failure to operate products in accordance with instructions shall also include the removal or alteration of any safety devices.. If such safety devices are removed or altered, this warranty is void..

D.Normal adjustments which are explained in the owner’s manual(s) provided with the product..

E.Items or service that are normally required to maintain the product, i..e.. o-rings, springs, bumpers, debris shields, driver blades, fuses, batteries, gaskets, packings or seals, fluid nozzles, needles, sandblast nozzles, lubricants, material hoses, filter elements, motor vanes, abrasives, blades, cut-off wheels, chisels, chisel retainers, cutters, collets, chucks, rivet jaws, screw driver bits, sanding pads, back-up pads, impact mechanism, or any other expendable part not specifically listed.. These items will only be covered for ninety (90) days from date of original purchase.. Underlined items are warranted for defects in material and workmanship only..

F..Cosmetic defects that do not interfere with the product’s function..

7.RESPONSIBILITIES OF WARRANTOR UNDER THIS WARRANTY: Repair or replace, at Warrantor’s option, products or components which are defective, have malfunctioned and/or failed to conform within duration of the warranty period..

8.RESPONSIBILITIES OF PURCHASER UNDER THIS WARRANTY:

A.Provide dated proof of purchase and maintenance records..

B.Call 1-800-424-8936 to obtain your warranty service options.. Freight costs must be borne by the purchaser..

C.Use reasonable care in the operation and maintenance of the products as described in the owner’s manual(s)..

9.WHEN WARRANTOR WILL PERFORM REPAIR OR REPLACEMENT UNDER THIS WARRANTY: Repair or replacement will be scheduled and serviced according to the normal work flow at the servicing location, and depending on the availability of replacement parts..

This Limited Warranty applies in the United States, Canada and Mexico only and gives you specific legal rights.. You may also have other rights which vary from state to state or country to country..

www.chpower.com

10

Loading...

Loading...