Campbell Hausfeld CHN50399 User Manual

36

Operating Instructions and Parts Manual

Instructions d’Utilisation et Manual de Pièces

Manual de Instrucciones y Lista de Piezas

Notes

Notas

This manual contains safety,

operational and maintenance

information. Contact your Campbell

Hausfeld representative if you have

any questions.

Table of Contents

General Safety . . . . . . . . . . . . 1-3

Specifications . . . . . . . . . . . . . . . 2

Operating The Nailer . . . . . . . 4-7

Troubleshooting . . . . . . . . . . . . 7

Parts List . . . . . . . . . . . . . . . . . 8-9

Warranty . . . . . . . . . . . . . . . . . 10

Description

This nailer is designed for use in

installing 3/4" and 1/2" thick

unfinished hardwood flooring. It can

be used to install pre-finished flooring

however caution must be used so the

finish is not damaged by the tool.

UNPACKING

When unpacking, check and make sure

that all the accessories are included. If

anything is missing or broken, please

call 1-800-543-6400 first for assistance.

General Safety

Information

This manual contains information that

is very important to know and

understand. This information is

provided for SAFETY and to PREVENT

EQUIPMENT PROBLEMS. To help

recognize this information, observe the

following symbols.

Danger

indicates

an imminently hazardous situation

which, if not avoided, will result in

death or serious injury.

Warning

indicates

a potentially hazardous situation

which, if not avoided, COULD result in

death or serious injury.

Caution

indicates

a potentially hazardous situation

which, if not avoided, MAY result in

minor or moderate injury.

Notice

indicates

important information, that if not

followed, may cause damage to

equipment.

CALIFORNIA PROPOSITION 65

You can create dust when

you cut, sand, drill or grind

materials such as wood, paint, metal,

concrete, cement, or other masonry.

This dust often contains chemicals

known to cause cancer, birth defects,

or other reproductive harm.

Wear protective gear.

Operating Instructions and Parts Manual Model CHN50399

BUILT TO LAST

Flooring

Nailer / Stapler

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described.

Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury, death and/or

property damage! Retain instructions for future reference.

IN715200AV 3/07

© 2007 Campbell Hausfeld/Scott Fetzer

See Warranty on page 10 for important information about commercial use of this product.

For parts, product & service information

visit www.chpower.com

Locate model number on magazine

and date code on tool body; record

below:

Model No. ________________________

Date Code ________________

Retain these numbers for

future reference.

REMINDER: Keep your dated proof of purchase for warranty purposes! Attach it to this manual or file it for safekeeping.

35

Model

Modèle CHN50399

Modelo

Notes

Notas

2

General Safety

Information (Continued)

OPERATOR’S RESPONSIBILITY:

The tool operator is responsible for:

• Reading and understanding tool

labels and manual.

• Selecting an appropriate tool

actuation system, taking into

consideration the work application

for which the tool is used.

• The safe use of the tool.

• Ensuring that the tool

is used only when the

operator and all other

personnel in the work

area are wearing ANSI

Z87 eye protection equipment, and

when required, other appropriate

protection equipment such as head,

hearing and foot protection

equipment. Serious eye or

permanent hearing loss could

result.

• Assuring that the tool is kept in

safe working order as described in

this manual.

EMPLOYER’S RESPONSIBILITY:

• Selecting an appropriate tool

actuation system, taking into

consideration the work application

for which the tool is used.

• Ensuring that this manual is

available to operators and

personnel performing

maintenance.

• The safe use of the tool.

• Enforcing that the tool

is used only when the

operator and all other

personnel in the work

area are wearing ANSI

Z87 eye protection equipment, and

when required, other appropriate

protection equipment such as head,

hearing and foot protection

equipment. Serious eye or

permanent hearing loss could

result.

• Assuring that the tool is kept in

safe working order as described in

this manual.

• Assuring the proper maintenance

of all tools in employer’s

possession.

• Ensuring that tools which require

repair are not further used before

repair. Tags and physical

segregation are recommended

means of control.

Read and understand

tool labels and manual.

Failure to follow

warnings, dangers, and

cautions could result in

DEATH or SERIOUS INJURY.

Do not use any type of

reactive gases,

including, but not

limited to, oxygen and

combustible gases, as a

power source. Use filtered,

lubricated, regulated compressed air

only. Use of a reactive gas instead of

compressed air may cause the nailer

to explode which will cause death or

serious personal injury.

Use only a pressure-

regulated compressed

air source to limit the

air pressure supplied to

the tool. The regulated

pressure must not exceed 90 psi. If

the regulator fails, the pressure

delivered to the tool must not

exceed 200 psi. The nailer could

explode which will cause death or

serious personal injury.

Never use gasoline or

other flammable liquids

to clean the nailer.

Never use the nailer in

the presence of

flammable liquids or gases. Vapors

could ignite by a spark and cause an

explosion which will result in death

or serious personal injury.

Operating Instructions and Parts Manual

• REQUIRES: 4.3 Avg SCFM using

60 fasteners at 80 psi

• AIR INLET: 1/4" NPT

• FASTENER SIZE RANGE:

15 1/2 gauge 1/2" crown

flooring staples: 1 1/2" to 2"

16 gauge L- head flooring

cleats: 1 1/2" to 2"

• MAGAZINE CAPACITY:

110 fasteners

• WEIGHT: 10.0 lbs.

• LENGTH: 16.5"

• HEIGHT: 23"

• MAXIMUM PRESSURE: 90 psi

• PRESSURE RANGE: 70 - 90 psi

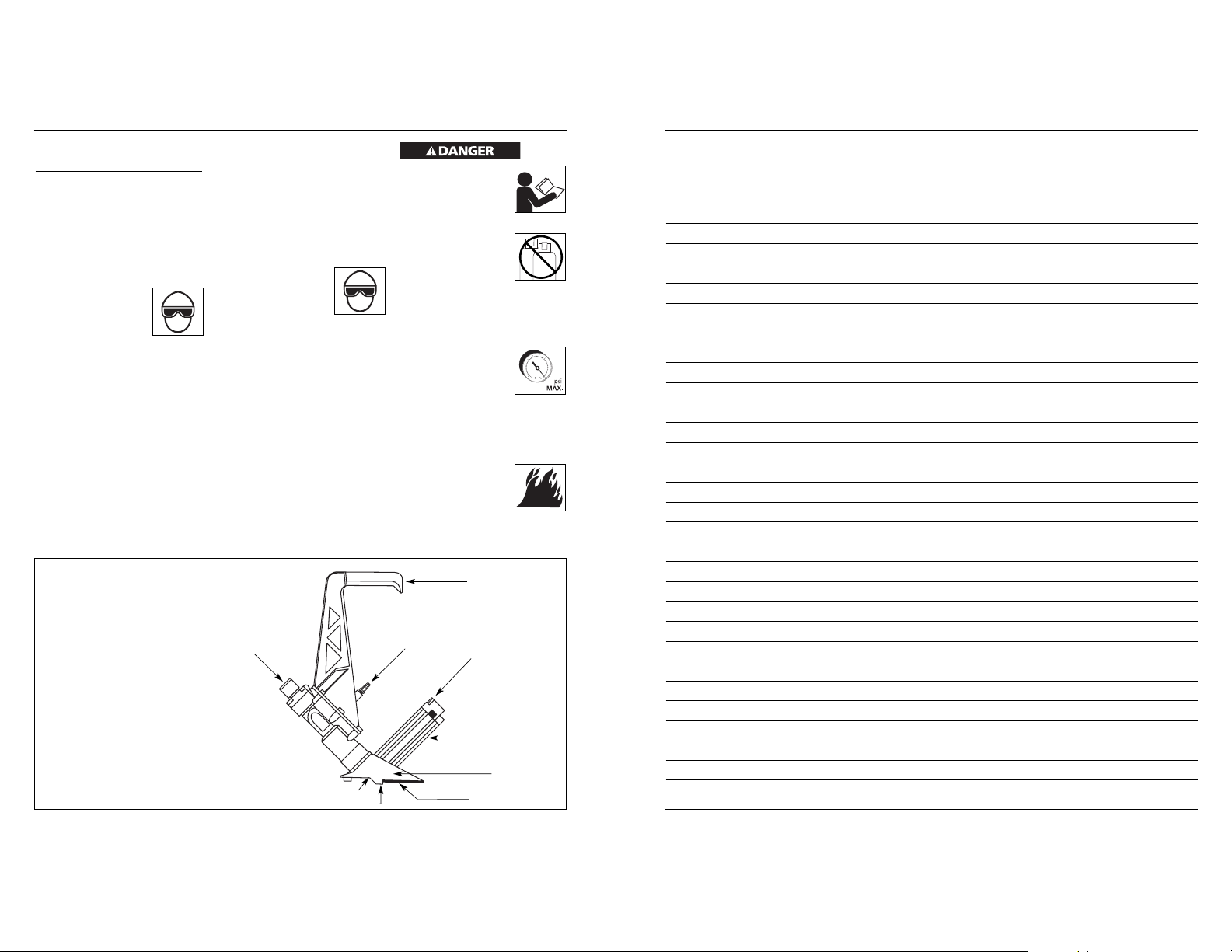

Nailer / Stapler Components And Specifications

www.chpower.com

Magazine

O

CO

2

90

Carry handle

Rubber bumper

Inlet

Magazine lock button

Shoe

Shoe plate

Nose

Fastener ejection area

34 Sp

Modelo CHN50399

Manual de Instrucciones y Lista de Piezas

Garantía Limitada

1 DURACION: A partir de la fecha de compra por el comprador original tal como se especifica a continuación: Productos

Estándard (Standard Duty) - Un año, Productos Resistentes (Serious Duty) -Dos años, Productos Robustos (Extreme Duty)

- Tres años.

2. QUIEN OTORGA ESTA GARANTIA (EL GARANTE: Campbell Hausfeld / The Scott Fetzer Company 100 Production Drive,

Harrison, Ohio 45030 Teléfono: (800) 543-6400

3. QUIEN RECIBE ESTA GARANTIA (EL COMPRADOR): El comprador original (que no sea un revendedor) del producto

Campbell Hausfeld.

4. PRODUCTOS CUBIERTOS POR ESTA GARANTIA: Cualquier clavadora, grapadora, herramienta neumática,

pistola pulverizadora, inflador o accesorio neumático suministrado o fabricado por el Garante.

5. COBERTURA DE LA GARANTIA: Los defectos substanciales de material y fabricación que ocurran dentro del período

de validez de la garantía.

6. LO QUE NO ESTA CUBIERTO POR ESTA GARANTIA:

A. Las garantías implícitas, incluyendo aquellas de comercialidad E IDONEIDAD PARA FINES PARTICULARES,

ESTAN LIMITADOS A LO ESPECIFICADO EN EL PARRAFO DE DURACION. Si este producto es empleado para uso

comercial, industrial o para renta, la garantía será aplicable por noventa (90) días a partir de la fecha de compra.

En algunos estados no se permiten limitaciones a la duración de las garantías implícitas, por lo tanto, en tales casos

esta limitación no es aplicable.

B. CUALQUIER PERDIDA DAÑO INCIDENTAL, INDIRECTO O CONSECUENTE QUE PUEDA RESULTAR DE UN DEFECTO,

FALLA O MALFUNCIONAMIENTO DEL PRODUCTO CAMPBELL HAUSFELD. En algunos estados no se permite la

exclusión o limitación de daños incidentales o consecuentes, por lo tanto, en tales casos esta limitación o exclusión

no es aplicable

C. Cualquier falla que resulte de un accidente, abuso, negligencia o incumplimiento de las instrucciones de

funcionamiento y uso indicadas en el (los) manual(es) que se adjunta(n) al producto. Dichos accidentes,

abusos por parte del comprador, o falta de operar el producto siguiendo las instrucciones del manual de

instrucciones suministrado también debe incluir la desconexión o modificación de los instrumentos de seguridad.

Si dichos instrumentos de seguridad son desconectados, la garantía quedaría cancelada.

D. Los ajustes normales explicados en el(los) manual(es) suministrado(s) con el producto.

E. Artículos o servicios normalmente requeridos para el mantenimiento del producto, tales como: anillos en O,

resortes, amortiguadores, defensas, hojas de impulsor

, fusibles, baterías, empaques, almohadillas o sellos, boquillas

de fluído, agujas, boquillas para rociar arena

, lubricantes, mangueras de material, elementos filtrantes, álabes de

motores, abrasivos, hojillas, discos para cortar, cinceles, retenes para cinceles, cortadores, collarines, mandriles,

mordazas para remachadoras, brocas para desarmadores

, almohadillas para lijar, soportes de almohadillas,

mecanismo de impacto

o cualquier otro artículo desgastable que no se haya enumerado específicamente.

Estos artículos sólo estarán cubiertos bajo esta garantía por noventa (90) días a partir de la fecha de

compra original. Los artículos subrayados sólo están garantizados por defectos de material o fabricación

.

7. RESPONSABILIDADES DEL GARANTE BAJO ESTA GARANTIA: Reparar o reemplazar, como lo decida el Garante,

los productos o componentes que estén defectuosos, se hayan dañado o hayan dejado de funcionar adecuadamente,

durante el período de validez de la garantía

8. RESPONSABILIDADES DEL COMPRADOR BAJO ESTA GARANTIA:

A. Suministrar prueba fechada de compra y la historia de mantenimiento del producto.

B. Entregar o enviar el producto o componente Campbell Hausfeld al Centro de Servicio autorizado Campbell

Hausfeld más cercano. Los gastos de flete, de haberlos, deben ser pagados por el comprador.

C. Seguir las instrucciones sobre operación y mantenimiento del producto, tal como se indica(n) en el (los) manual(es)

del propietario

9. CUANDO EFECTUARA EL GARANTE LA REPARACION O REEMPLAZO CUBIERTO BAJO ESTA GARANTIA: La reparación

o reemplazo dependerá del flujo normal de trabajo del centro de servicio y de la disponibilidad de repuestos.

Esta garantía limitada es válida sólo en los EE.UU., Canadá y México y otorga derechos legales específicos. Usted también

puede tener otros derechos que varían de un Estado a otro. o de un país a otro.

3

General Safety

Information (Continued)

Make sure tool is securely placed

before firing (see Operating the

Nailer section). If tool is not securely

placed, there is a risk of flying

fasteners that may cause death or

serious injury.

Make sure mallet head is secure to

mallet handle. Do not use if head is

not secure. A non-secure head may

fly off and cause death or severe

personal injury.

Always use the rubber end of the

mallet only for striking the rubber

bumper. Damage to the tool may

occur if you use the metal end. The

metal end is only to be used for

racking the flooring boards.

Always disconnect the

tool from the power

source when

unattended, performing

any maintenance or

repair, clearing a jam, or

moving the tool to a new location.

Always reconnect the air line

BEFORE loading any fasteners.

Always fit tool with a

fitting or hose coupling

on or near the tool in

such a manner that all

compressed air in the

tool is discharged at the

time the fitting or hose coupling is

disconnected. Do not use a check

valve or any other fitting which

allows air to remain in the nailer.

Death or serious personal injury

could occur.

Do not make any modifications to

the tool without first obtaining

written approval from Campbell

Hausfeld. Do not use the nailer if

any shields or guards are removed

or altered. Do not use the nailer as a

hammer. Personal injury or tool

damage may occur.

Avoid long extended periods of

work with the nailer. Stop using the

nailer if you feel pain in hands or

arms.

Do not place tool on pre-finished

flooring in an abusive manner.

Careless placement of the tool may

mar or damage the flooring.

Avoid using the nailer when the

magazine is empty. Accelerated

wear on the nailer may occur.

Clean and check all air supply hoses

and fittings before connecting the

nailer to an air supply. Replace any

damaged or worn hoses or fittings.

Tool performance or durability may

be reduced.

Air compressors providing air to the

nailer should follow the

requirements established by the

American National Standards

Institute Standard B19.3-1991;

Safety Standard for Compressors for

Process Industries. Contact your air

compressor manufacturer for

information.

Never carry the

nailer by the air

hose or pull the

hose to move the

nailer or a

compressor. Keep

hoses away from

heat, oil and sharp

edges. Replace any hose that is

damaged, weak or worn. Personal

injury or tool damage could occur.

Do not operate

or allow

anyone else to

operate the

nailer if any

warnings or

warning labels

are not legible. Warnings or

warning labels are located on the

nailer magazine and body.

Do not drive a nail on top of other

nails. The nail could glance and

cause death or a serious puncture

wound.

Always assume the nailer contains

nails. Respect the tool as a working

implement; no horseplay. Always

keep others at a safe distance from

the work area in case of accidental

discharge of nails. Do not point the

tool toward yourself or anyone

whether it contains fasteners or not.

Accidental triggering of the nailer

could result in death or serious

personal injury.

Do not drop or throw the tool.

Dropping or throwing the tool can

result in damage that will make the

tool unusable or unsafe. If the tool

has been dropped or thrown,

examine the tool closely for bent,

cracked or broken parts and air

leaks. STOP and repair before using

or serious injury could occur.

Model CHN50399

www.chpower.com

The DANGER, WARNING, CAUTION,

and NOTICE notifications and

instructions in this manual cannot

cover all possible conditions and

situations that may occur. It must be

understood by the operator that

common sense and caution are factors

which cannot be built into this

product, but must be supplied by the

operator.

!

WARNING

READ ALL FLOORING MANUFACTURER

WARNINGS, PROCEDURES, AND

INSTRUCTIONS BEFORE

USING THIS

TOOL. THE INFORMATION PROVIDED

BY THE FLOORING MANUFACTURER

MUST BE FOLLOWED.

Lista de Repuestos

No. de Número de

Ref Descripción Repuesto Ctd

No. de Número de

Ref Descripción Repuesto Ctd

33 Sp

Modelo CHN50399

1 Cabeza del pistón SX140100AV 1

2 Anillo en O - 19.2 x 1.8 1

3 Anillo en O - 15.9 x 1.8 1

4 Cilindro de válvula SX140400AV 1

5 Anillo en O - 42.5 x 5.4 1

6 Anillo en O - 17.5 x 2.6 1

7 Anillo en O - 57.4 x 3.5 1

8 Ensamblaje del pistón SX140800AV 1

9 Defensa de caucho SX140900AV 1

10 Tornillo - M5 x 20 1

11 Sombrerete SX141100AV 1

12 Tornillo - M4 x 20 1

13 Arandela de resorte 1

14 Actuador SX141400AV 1

15 Anillo en O - 54.2 x 3.5 1

16 Sello 1

17 Cuerpo -- 1

18 Defensa SX141800AV 1

19 Boquilla SX141900AV 1

20 Tornillo - M3 x 20 1

21 Pasador de resorte - 3 x 14 1

22 Protector contra el polvo SX142200AV 1

23 Tornillo - M5 x 14 1

24 Arandela de resorte 1

25 Guía de la cuchilla SX142500AV 1

26 Guía de puntillas dentadas SX142600AV 1

27 Zapata -- 1

28 Pata de goma SX142800AV 2

29 Casquillo SX142900AV 1

30 Tornillo - M6 x 16 1

31a Placa de zapata gruesa,

5/16" (8 mm) SX143100AV 1

31b Placa de zapata delgada,

1/4" (6 mm) SX143200AV 1

32 Tornillo - M6 x 12 1

33 Pasador de resorte - 2 x 14 1

34 Cargador SX143500AV 1

35 Arandela de resorte 1

36 Tornillo - M6 x 35 1

37 Impulsor SX143800AV 1

38 Resorte de empuje SX143900AV 2

39 Placa terminal del cargador SX144000AV 1

40 Tapa del extremo

del cargador SX144100AV 1

41 Tornillo 1

42 Resorte SX144300AV 1

43 Tornillo - M4 x 16 1

44 Placa tope SX144500AV 1

45 Botón de seguro

del cargador SX144600AV 1

46 Tuerca - M4 1

47 Arandela 1

48 Buje SX144900AV 1

49 Pasador de resorte - 3 x 12 1

50 Gancho de seguro

del cargador SX145100AV 1

51 Tornillo - M3 x 5 1

52 Arandela 1

53 Arandela de resorte 1

54 Resorte de hoja SX145500AV 1

55 Tornillo - M3 x 8 1

56 Puerta del cargador SX145700AV 1

57 Pasador de resorte - 2.5 x 10 1

58 Tornillo - M3 x 6 1

59 Magneto SX146000AV 3

60 Riel SX146100AV 1

61 Empaque SX146200AV 1

62 Brazo -- 1

63 Tornillo - M6 x 25 1

64 Tapón de aire 1

65 Llave 5 mm 1

66 Llave 4 mm 1

67 Llave 3 mm 1

68 Soporte de llaves 1

69 Martillo SX147000AV 1

REPLACEMENT PARTS KITS

Juego completo

de anillos en O SKN09100AV

Juego de llaves SKN09200AV

Artículo estándar de ferretería - disponible en su

ferretería local

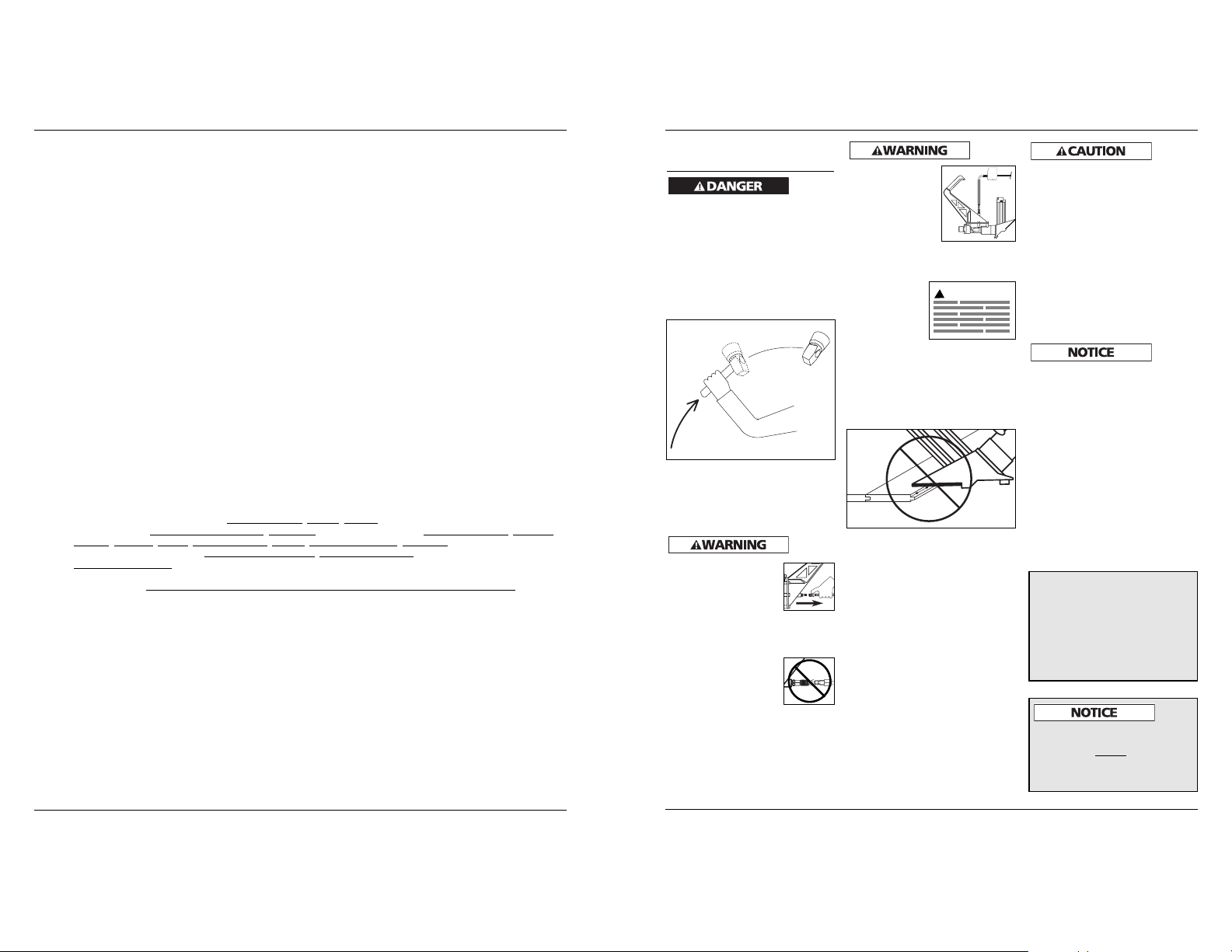

Operating The Nailer

LUBRICATION

This nailer requires lubrication before

using the nailer for the first time and

before each use. If an inline oiler is

used, manual lubrication through the

air inlet is not required on a daily

basis.

The work

surface

can become damaged by excessive

lubrication. Proper lubrication is the

owner’s responsibility. Failure to

lubricate the nailer properly will

dramatically shorten the life of the

nailer and void your warranty.

1. Disconnect the air

supply from the nailer

to add lubricant.

2. Turn the nailer

so the air inlet

is facing up.

Place 4-5 drops

of 30 W non-

detergent oil

into air inlet.

Do not use

detergent oils,

oil additives, or

air tool oils which contain solvents.

This will damage the nailer’s

internal components.

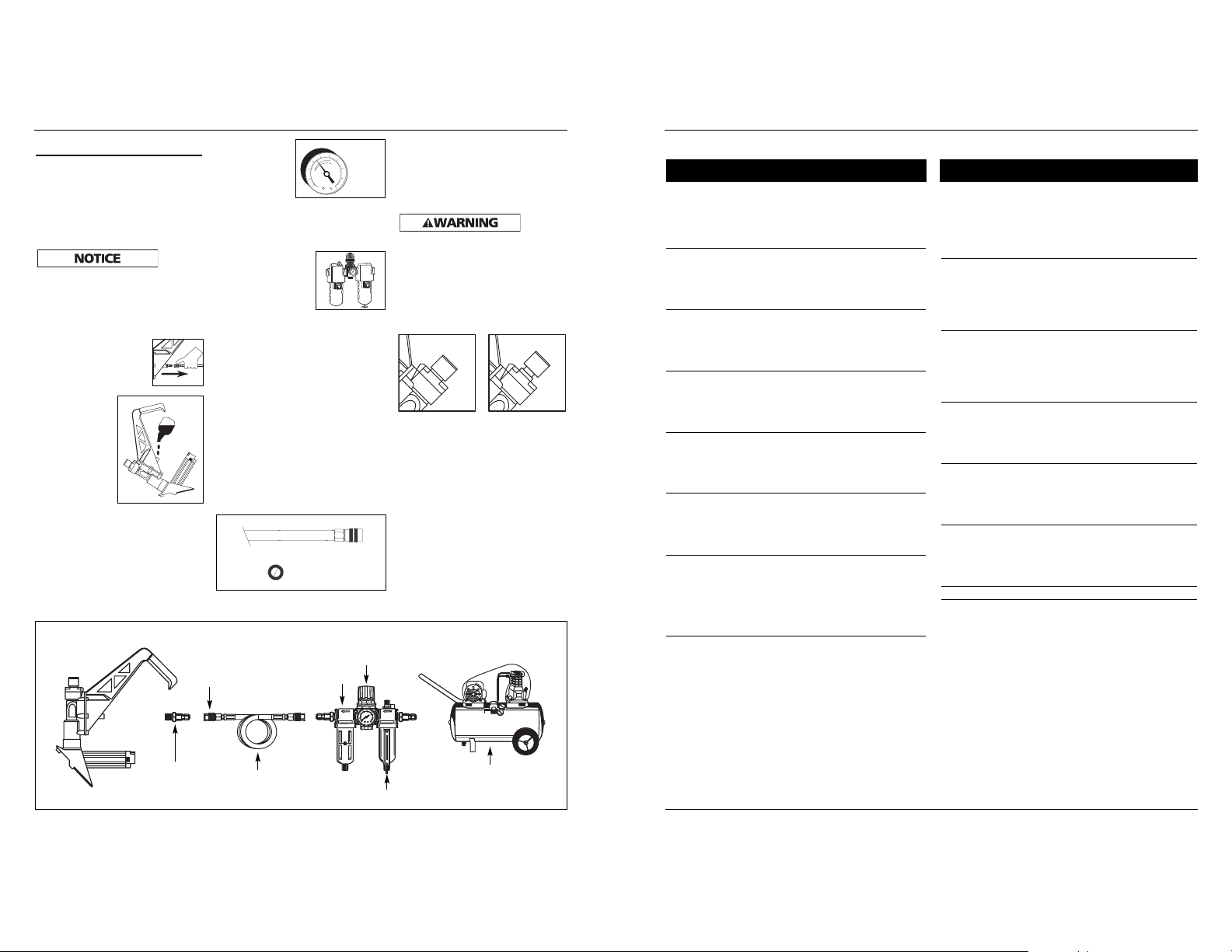

RECOMMENDED HOOKUP

The illustration below shows the

recommended hookup for the nailer.

1. The air

compressor

must be able

to maintain a

minimum of

70 psi when the nailer is being

used. An inadequate air supply can

cause a loss of power and

inconsistent driving.

2. An oiler can be

used to provide oil

circulation through

the nailer. A filter

can be used to

remove liquid and solid impurities

which can rust or “gum up”

internal parts of the nailer.

3. Always use air supply hoses with a

minimum working pressure rating

equal to or greater than the

pressure from the power source if

a regulator fails, or 150 psi,

whichever is greater. Use 3/8" air

hose for runs up to 50'. Use 1/2" air

hoses for 50' run or longer. For

better performance, install a 3/8"

quick plug (1/4" NPT threads) with

an inside diameter of .315" (8 mm)

on the nailer and a 3/8" quick

coupler on the air hose.

Operating Instructions and Parts Manual

4

www.chpower.com

150 psi or greater

3/8" I.D.

70 psi

Min.

90 psi

Max.

Recommended Hookup

Quick

Plug

Quick

Coupler

Air

Hose

Air Supply

Oiler

Regulator

Filter

4. Use a pressure regulator on the

compressor, with an operating

pressure of 0 - 125 psi. A pressure

regulator is required to control the

operating pressure of the nailer

between 70 and 90 psi.

An

improperly functioning tool must not

be used. Do not actuate the tool unless

the tool is placed firmly against the

work piece.

Note: Make sure the rubber bumper

on the flooring nailer is in the up

position before adding the air hose,

if not, the nailer may cycle (see below).

Rubber Bumper

Down Position

Rubber Bumper

Up Position

32 Sp

Manual de Instrucciones y Lista de Piezas

Para Ordenar Repuestos o Asistencia Técnica, Sírvase Llamar

al Distribuidor Más Cercano a Su Domicilio

Sírvase proporcionar la siguiente información:

- Número de modelo

- Número de serie (si tiene)

- Descripción y número de la pieza como se muestra en la lista de repuestos

Dirija toda la correspondencia a:

Campbell Hausfeld

Attn: Customer Service

100 Production Drive

Harrison, OH 45030 U.S.A.

14

1

3

4

6

7

2

5

8

9

10

11

12

13

15

16

17

18

19

33

20

21

22

23

24

25

26

10

64

69

28

30

29

31b

32

27

36

35

37

38

34

58

60

59

39

13

12

23

40

41

42

43

48

44

45

46

47

49

54

50

46

53

52

51

55

57

56

62

61

35

63

68

67

66

65

31a

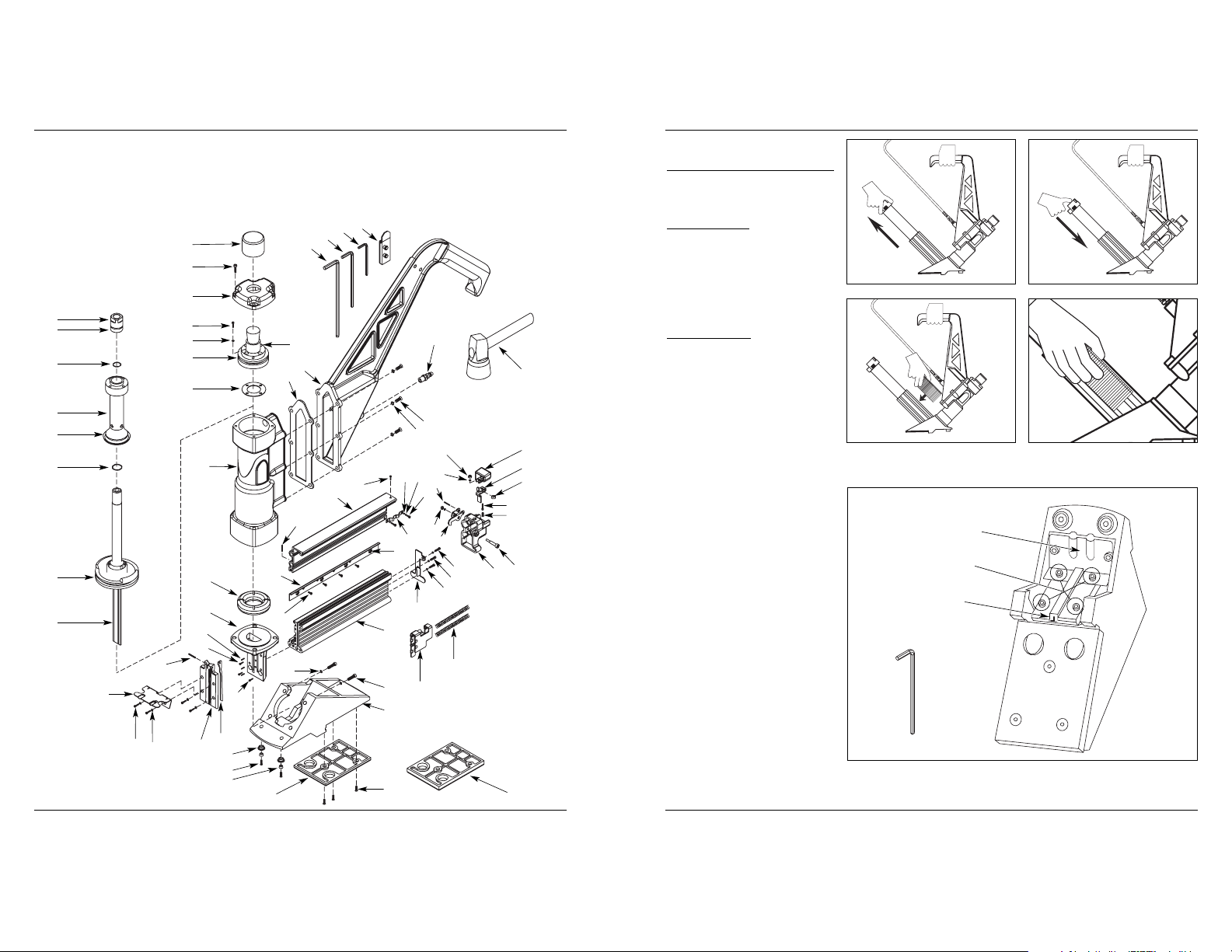

Figure 5

Operating The Nailer

(Continued)

LOADING/UNLOADING THE NAILER

Always connect the tool to the air

supply before loading fasteners.

Loading the staples

1. Hold the tool firmly, press the lock

and pull the magazine door

(See figure 1).

2. Place the staples straddling the top

of the magazine (See figure 2).

3. Push and lock the magazine door

back in place (See figure 3).

Loading the L cleats

1. Hold the tool firmly, press the

lock and pull the magazine

(See figure 1).

2. Place the specified type and size of

L cleats in the magazine from side.

The head of the L cleats should be

inserted into the notch on the fixed

magazine (See figure 4).

3. Push and lock the magazine door

back in place (See figure 3).

CLEARING A JAM FROM THE NAILER

(SEE FIGURE 5)

1. Disconnect the air supply from the

nailer.

2. Remove staples or L cleats from

magazine.

3. Using provided 4 mm wrench,

remove the four nose plate screws,

washers, nose plate, and dust

shield.

4. Using a small tool, pick out the

jammed fastener.

5. Reattach all hardware (apply a

good quantity of threadlock glue

on screw threads before installing;

tighten firmly).

Model CHN50399

5

www.chpower.com

Figure 1

Figure 2

Figure 3

Figure 4

4 mm Wrench

Nose Plate Screws

Nose Plate

Dust shield

31 Sp

Modelo CHN50399

Notas

Operating The Nailer

(Continued)

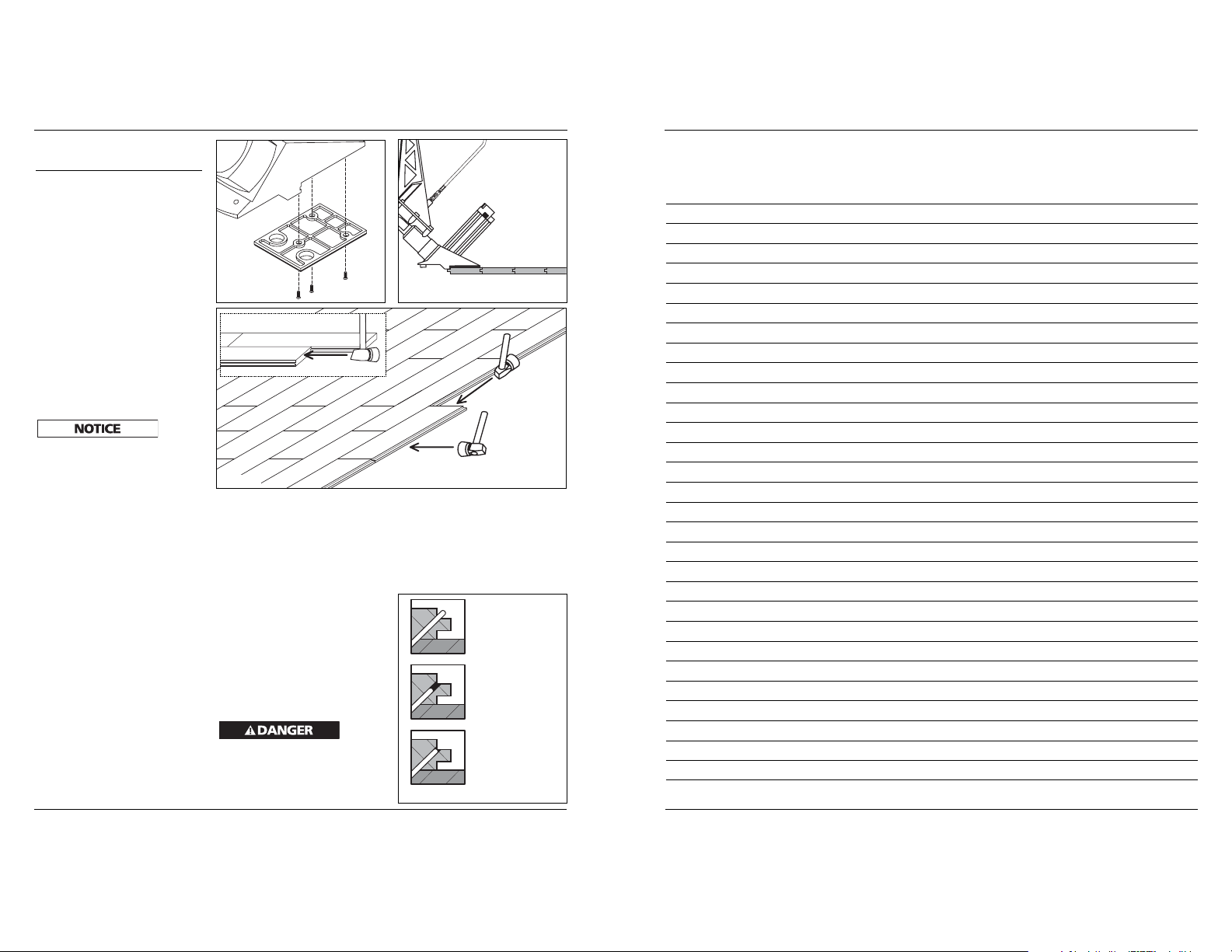

CHANGING SHOE PLATES

1. Disconnect the air supply from

the nailer.

2. Using provided 4 mm wrench,

remove the three shoe screws.

3. Remove shoe plate; place new or

alternate shoe. Make sure shoe is in

the “up” position when attaching

(See Figure 6).

4. Reattach screws (apply a good

quantity of threadlock glue on

screw threads before installing;

tighten firmly).

SHOE PLATE SIZES

There are two shoe plates included

with this tool. The 1/4" thin plate is for

use on 3/4" thick hardwood flooring.

The 5/16" thick plate is for use on 1/2"

thick hardwood flooring.

To

prevent

damage to the flooring, use the correct

shoe for the flooring being installed.

RACKING THE FLOORING

(SEE FIGURE 7)

First refer to flooring manufacturer’s

preparation procedures regarding

moisture content and floor

preparation before laying the flooring

boards.

To correctly install hardwood flooring,

it must be properly racked before

being nailed into place. After placing

the first board, follow these

instructions to rack the flooring:

1. Place flooring groove onto the

tongue of previously installed

board.

2. Use the rubber end of the mallet to

“pop” the tongue into the groove.

3. Use the metal end of the mallet to

rack the board tightly against

adjacent board.

FIRING THE NAILER

1. Connect the air supply to the nailer.

Note: Make sure the rubber bumper

on the flooring nailer is in the up

position before adding the air hose,

if not, the nailer may cycle.

2. Load fasteners (see Loading the

Nailer Section).

3. Place the tool on the floor as

shown in Figure 8 with the shoe

plate resting on the racked floor

board. Make sure the fastener

ejection nozzle is firmly placed

against the board tongue.

4. Strike the tools rubber bumper

firmly with the rubber end of the

mallet. The tool should cycle and

drive fastener into floor board.

Do NOT

fire the

tool unless it is securely placed. If tool

is not securely placed, there is a risk of

flying fasteners that may cause death

or serious injury.

Operating Instructions and Parts Manual

6

www.chpower.com

UP Position of

Shoe plate

Figure 6

Figure 7

Alternate Racking View

Racking

Popping

Figure 8

FASTENER DEPTH & PLACEMENT

Refer to Figure 9 for correct depth

placement of fasteners in hardwood

tongue. Use a scrap piece of the

flooring to help determine correct air

pressure settings. Damage to the

tongue upon installation will make

remaining project difficult.

Fastener seated High

Air Pressure too LOW

Figure 9

Fastener seated Low

Air Pressure too HIGH

Fastener seated

Correctly

Air Pressure set

Correctly

Loading...

Loading...