CVMAAR

MULTIPOISE OIL FURNACE

INPUT CAPACITIES 70,000 ---154,000

Installation Instructions

THIS BOOKLET CONTAINS

IMPORTANT INFORMATION

INSTALLER: Use the information in this

booklet to install the appliance and affix this

booklet adjacent to the appliance after

installation.

A11540

USER: Keep this booklet of information for

future reference.

SERVICER: Use the information in this booklet

to service the appliance and affix the booklet

adjacent to the appliance after servicing.

Use of the AHRI Certified TM Mark indicates a

C US

Copyright 2012 CAC / BDP D 7310 W. Morris St. D Indianapolis, IN 46231 Printed i n U.S.A. Edition Date: 02/12

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

manufacturer’s participation in the program. For

verification of certification for individual products,

go to www.ahridirectory.org.

Catalog No: IM---CVM---03 / X40191 Rev. C

Replaces: IM --- CVM---02 / X40191 Rev. B

TABLE OF CONTENTS

1.0 SAFETY REGULATIONS---------------------------------------3

1.1 DANGER, WARNING AND CAUTION--------------------3

1.2 SAFETY INSTALLATION REQUIREMENTS------------3

2.0 INSTALLATION ---------------------------------------------------3

2.1 GENERAL -------------------------------------------------------3

2.2 SAFE INSTALLATION REQUIREMENTS----------------4

2.3 SAFETY RULES -----------------------------------------------4

2.3.1 Detector

2.3.2 Freezing temperatures and your building

2.4 LOCATION ------------------------------------------------------5

2.4.1 Air for combustion and ventilation

2.4.2 Duct recommendations

2.4.3 Venting instructions (chimney installation)

2.4.4 Draft Regulator

2.4.5 Blocked vent shut-off (BVSO) for chimney

venting

2.4.6 Oil burner

2.4.7 Electrical system

2.4.8 24V Wiring

2.4.9 Accessory installation

2.4.10 Air filter

2.4.11 Air Conditioner (or Heat Pump)

2.4.12 Horizontal or downflow installation

3.0 OPERATION-----------------------------------------------------11

3.1 SUPPLY AIR ADJUSTMENTS----------------------------11

3.2 OPERATIONAL CHECKLIST----------------------------- 11

3.3 PURGING THE OIL LINE----------------------------------12

3.4 COMBUSTION CHECK ------------------------------------12

3.5 SEQUENCE OF OPERATION---------------------------- 13

3.5.1 Oil fired heating mode

3.5.2 Cooling mode

3.5.3 Continuous Blower Mode

3.5.4 Heat Pump – Heating / Cooling Mode

3.5.5 Defrost Mode

3.6 LIMIT CONTROL CHECK----------------------------------14

--------------------------------------------------4

---------------------------------------------------7

-------------------------------------------------10

----------4

-------------------5

--------------------------------6

--------6

-----------------------------------------7

------------------------------------------------8

---------------------------------------9

---------------------------------------------10

-------------------------------10

--------------------11

----------------11

-------------------------------13

-----------------------------------------13

---------------------------13

------------13

------------------------------------------14

FIGURES

Figure 1 : Counterflow position, flue pipe protection ..................5

Figure 2 : Wiring diagram,BVSO................................................7

Figure 3 : BVSO device wiring, upflow installation with vertical

exhaut.......................................................................8

Figure 4 : BVSO device wiring, upflow installation with vertical

exhaust.....................................................................9

Figure 5 : BVSO device wiring, upflow installation with horizontal

exhaust.....................................................................9

Figure 6: BVSO device wiring, horizontal installation with

horizontal exhaust.....................................................9

Figure 7: BVSO device wiring, horizontal installation with vertical

exhaust.....................................................................9

Figure 8: BVSO device wiring, downflow installation..................9

Figure 9 : 24 VAC Oil Furnace Wiring with Air Conditioner......10

Figure 10 : 24 VAC Oil Furnace Wiring with Heat Pump..........10

Figure 11 : Model CVM Size 105.............................................19

Figure 12 : Model CVM Size 120.............................................20

Figure 13 : Wiring diagram CVM..............................................21

Figure 14 : Parts list CVMAAR036105.....................................22

Figure 15 : Parts list CVMAAR060120.....................................24

TABLES

Table 1 : Minimum dimensions required in ventilation openings 5

Table 2 : Filter rack flange dimensions for return air duct ........11

Table 3 : Supply air adjustments, heating mode......................11

Table 4 : Supply air adjustments, air conditioning mode..........11

Table 5 : CFM adjustments, all modes.....................................12

Table 6 : Delay adjustments, heating mode.............................12

Table 7 : Technical Specifications ...........................................16

Table 8 : Air Flow Data, Size 105.............................................17

Table 9 : Air Flow Data, Size 120.............................................18

Table 10 : Minimum clearances to combustible materials........19

Table 11 : Minimum clearances to combustible materials........20

Table 12 : Parts list CVMAAR036105......................................23

Table 13 : Parts list - CBMAAA060120....................................25

4.0 MAINTENANCE -------------------------------------------------14

4.1 HEAT EXCHANGER CLEANING ------------------------ 14

4.2 BLOWER REMOVAL----------------------------------------14

4.3 BLOCKED VENT SHUT OFF (BVSO) CLEANING----14

5.0 FURNACE INFORMATION----------------------------------- 15

2

1.0 SAFETY REGULATIONS

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPOURS AND LIQUIDS IN THE VICINITY

OF THIS OR ANY OTHER APPLIANCE.

DO NOT ATTEMPT TO START THE BURNER WHEN

EXCESS OIL HAS ACCUMULATED, WHEN THE

FURNACE IS FULL OF VAPOUR OR WHEN THE

COMBUSTION CHAMBER IS VERY HOT.

1.1 DANGER, WARNING AND CAUTION

The words DANGER, WARNING and CAUTION are used to

identify the levels of seriousness of certain hazards. It is

important that you understand their meaning. You will notice

these words in the manual as follows:

DANGER

Immediate hazards which WILL result in death or

serious bodily and/or material damage.

WARNING

Hazards or unsafe practices which CAN result in death

or serious bodily and /or material damage.

CAUTION

Hazards or unsafe practices which CAN result in minor

bodily and /or material damage.

1.2 SAFETY INSTALLATION REQUIREMENTS

WARNING

For use with grade 2 fuel oil maximum. Do NOT use

gasoline, crankcase oil or any oil containing gasoline.

WARNING

Never burn garbage or paper in the heating system and

never leave rags or paper around the unit.

CAUTION

These instructions are intended for the sole use of

qualified personnel trained in installing this type of

furnace. Installation of this furnace by an unqualified

person can lead to hazardous conditions, resulting in

bodily harm and/or equipment damage.

IMPORTANT: All local and national code requirements

governing the installation of oil burning equipment, wiring

and flue connections must be followed. Some of the codes

that may be applicable are:

CSA B139 Installation Code for Oil Burning

Equipment

ANSI/NFPA 31 Installation of Oil Burning Equipment

ANSI/NFPA 90B Warm Air Heating and Air Conditioning

Systems

ANSI/NFPA 211 Chimneys, Fireplaces, Vents and Solid

Fuel Burning Appliances

ANSI/NFPA 70 National Electrical Code

CSA C22.2 No.3 Canadian Electrical Code

Only the latest issues of the above codes should be used,

and are available from either:

The National Fire Protection Agency

1 Batterymarch Park

Quincy, MA 02269

or

The Canadian Standards Association

178 Rexdale Blvd.

Rexdale, Ontario M9W 1R3

CAUTION

ENVIRONMENTAL HAZARD

Failure to follow this caution may result in

environmental pollution.

Remove and recycle all components or materials (i.e.

oil, electrical and electronic components, insulation,

etc.) before unit final disposal.

2.0 INSTALLATION

2.1 GENERAL

This central heating unit is a true multi-position unit, in that it

can operate in four different configurations, i.e., upflow,

counter flow (downflow), and horizontal (both left-to-right

and right-to-left airflow).

Very few modifications are required during installation, to

change the furnace from one configuration to another. The

furnace is shipped in the upflow configuration; however,

instructions on how to change to the other configurations are

included in this manual.

The furnace is shipped complete with burner and controls. It

requires a 115VAC line voltage connection to the control

panel, thermostat hook-up as shown on the wiring diagram,

one or more oil line connections, suitable ductwork and

connection to a properly sized vent.

The air handling capacity of this furnace is designed for

cooling as well. Please refer to Table 6 for the expected

airflow at various external static pressures.

3

2.2 SAFE INSTALLATION REQUIREMENTS

WARNING

Installation or repairs performed by unqualified persons

can result in hazards to them and others. Installation

MUST conform to local codes or, in the absence of

same, to codes of the country having jurisdiction.

The information contained in this manual is intended for

use by a qualified service technician familiar with safety

procedures and quipped with the proper tools and test

instruments.

Failure to carefully read and follow all instructions in

this manual can result in death, furnace malfunction

and/or property damage.

WARNING

FIRE HAZARD

The furnace must be installed in a level position, never

where it will slope toward the front. If the furnace is not

installed level, oil will drain into the furnace vestibule

and create a fire hazard.

NOTE: It is the personal responsibility and obligation of the

customer to contact a qualified installer to ensure that the

installation conforms to governing local and/or national

codes and ordinances

a. This furnace is NOT approved for installation in mobile

homes, trailers or recreational vehicles;

b. Do NOT use this furnace as a construction heater or to

heat a building under construction;

c. There must be a sufficient supply of fresh air for

combustion as well as ventilation in the area where the

furnace is located;

d. Use only the type of fuel oil approved for this furnace

(see section 1.2 of this manual). Overfiring will result in

heat exchanger failure and cause dangerous operating

conditions;

e. Visually check all oil line joints for signs of leakage;

f. Connect furnace to the chimney;

g. The points in Part 3 “Operation” are vital to the proper

and safe operation of the heating system. Take the time

to ensure that all steps were followed;

h. Follow the regulations of the NFPA No.31 (in the USA)

and CSA B-139 (in Canada) or local codes for placing

and installing the oil storage tank;

i. Follow a regular service and maintenance schedule for

efficient and safe operation;

j. Before servicing, allow furnace to cool down. Always

shut off electricity and fuel to furnace when servicing.

This will prevent electrical shock or burns;

k. Seal supply and return air ducts;

l. The vent system MUST be checked to determine that it

is the correct type and size;

m. Install correct filter type and size;

n. Unit MUST be installed so that electrical components

are protected from direct contact with water.

2.3 SAFETY RULES

Your unit is built to provide many years of safe and

dependable service, provided it is properly installed and

maintained. However, abuse and/or improper use can

shorten the life of the unit and create hazards for you, the

owner.

2.3.1 Detector

a. The U.S. Consumer Product Safety Commission

recommends that users of oil-burning appliances install

carbon monoxide detectors. There can be various

sources of carbon monoxide in a building or dwelling.

The sources could be gas-fired clothes dryers, gas

cooking stoves, water heaters, furnaces, gas-fired

fireplaces, wood fireplaces, and several other items.

Carbon monoxide can cause serious bodily injury

and/or death. Therefore, to help alert people to

potentially dangerous carbon monoxide levels, you

should have carbon monoxide detectors listed by a

nationally recognised agency (ex. Underwriters

Laboratories or International Approval Services)

installed and maintained in the building or dwelling (see

Note below).

b. There can be numerous sources of fire or smoke in a

building or dwelling. Fire or smoke can cause serious

bodily injury, death, and/or property damage. Therefore,

in order to alert people to potentially dangerous fire or

smoke, you should have fire and smoke detectors listed

by Underwriters Laboratories installed and maintained

in the building or dwelling (see Note below).

NOTE: The manufacturer of your furnace does not test any

detectors and makes no representations regarding any

brand or type of detector.

CAUTION

Ensure that the area around the combustion air intake is

free of snow, ice and debris.

2.3.2 Freezing temperatures and your building

WARNING

FREEZING TEMPERATURE WARNING

Turn off water supply.

If your heater remains shut off during cold weather, the

water pipes could freeze and burst, resulting in serious

water damage.

If the structure is unattended during cold weather you should

take the following precautions:

a. Turn off main water supply into the structure and drain

the water lines if possible. Open faucets in appropriate

areas;

b. Have someone check the structure frequently during

cold weather to make sure it is warm enough to prevent

pipes from freezing. Contact a qualified service agency,

if required.

4

2.4 LOCATION

KLADC0201DET

CAUTION

This furnace is not watertight and is not designed for

outdoor installation. This furnace shall be installed in

such a manner as to protect the electrical components

from water. Outdoor installation will lead to hazardous

electrical conditions and to premature furnace failure.

CAUTION

If this furnace is installed in an attic, it is important to

keep insulation at least 0.3 m (12") away from any

furnace openings. Some types of insulating material

may be combustible.

The unit must be installed in a location where the ambient

and return air temperature is over 15°C (60°F).

This furnace is approved for reduced clearances to

combustible construction. Therefore, it may be installed in a

closet or similar enclosure. As this unit may be installed as

an upflow, counter flow, or horizontal furnace, it may be

located in a basement, on the same level as the area to be

heated, suspended, or in a crawlspace. In any case, the unit

should always be installed level.

In a basement, or when installed on the floor (as in a

crawlspace), it is recommended that the unit be installed on

a concrete pad that is 2.5 cm to 5.0 cm (1" to 2") thick.

When installed in the counter flow position, this furnace

must not be installed on combustible flooring, unless the

approved sub-base is used (Model # KLASB0601DET).

Since the flue pipe is in counter flow position, be sure that

the clearances from the flue pipe to combustible

construction are maintained. Also, it is recommended to use

the flue pipe protection kit KLADC0101DET or

KLADC0201DET. Please refer to the Figure 1 and the

installation instructions included with the kit.

Figure 1 : Counterflow position, flue pipe protection

KLADC0101DET/

DNS-0278 Rev. A

When installed in an horizontal position, the furnace may be

suspended by using an angle iron frame, as long as the total

weight of both the furnace and the frame are included in the

calculations. Other methods of suspension are acceptable.

When installed in the horizontal position, this furnace must

not be installed on combustible flooring, unless the

approved sub-base is used (Model KLASB0701DET).

The required minimum clearances for this furnace in all

positions are specified in Tables 7 and 8.

The furnace should be located as closely as possible to the

chimney or vent in order to keep vent connections short and

direct. The furnace should also be located near the centre of

the air distribution system.

2.4.1 Air for combustion and ventilation

This furnace should be installed in a location in which the

facilities for ventilation permit satisfactory combustion of oil,

proper venting and the maintenance of ambient

temperatures at safe limits under normal conditions of use.

The location should not interfere with the proper circulation

of air within the confined space. Refer to the CAN/CSAB139 installation code for complete regulations, and for

guidance on retrofit applications.

When this furnace is installed in a closet or similar

enclosure, 2 ventilation openings are required for

combustion air. The openings should be located about 15.2

cm (6") from the top and the bottom of the enclosure at the

front of the furnace. Table 1 indicates the minimum

dimensions required for each of these two ventilation

openings.

Table 1 : Minimum dimensions required in ventilation

Input

(BTU/h)

openings

Width Height

75,000 – 105,000 45.72 cm (18") 20.32 cm (8")

120,000 – 155,000 50.80 cm (20") 25.40 cm (10")

WARNING

Do not block the combustion air openings in the

furnace. Any blockage will result in improper

combustion and may result in a fire hazard and/or cause

bodily harm.

The barometric draft regulator included with the furnace,

shall be installed in the same room or enclosure as the

furnace, in such a manner as to prevent any difference in

pressure between the regulator and the combustion air

supply.

Air requirements for the operation of exhaust fans, kitchen

ventilation systems, clothes dryers, and fireplaces shall be

considered in determining the adequacy of the space to

provide combustion air requirements.

In unconfined spaces, in buildings of conventional frame,

brick or stone construction, infiltration may be adequate to

provide air for combustion, ventilation and dilution of flue

gases. This determination must be made on an individual

installation basis and must take into consideration the

overall volume of the unconfined space, the number of

windows and ventilation openings, the number of doors to

5

the outside, internal doors which can close off the

unconfined space and the overall air tightness of the

building construction.

Many new buildings and homes (and older ones that have

been weatherized must be considered as being tight

construction and, therefore, infiltration will not be sufficient to

supply the necessary air for combustion and ventilation.

A building can be considered as being of tight construction

when:

a. Walls and ceilings exposed to the outside have a

continuous water vapour retarder with a rating of one

perm or less, openings have gaskets or are sealed

and/or;

b. Weather-stripping has been added on operable

windows and doors, and/or;

c. Caulking or sealant has been applied to areas such as

joints around window and doorframes, between sole

plates and floors, between wall-ceiling joints, between

wall panels, at penetrations for plumbing, electrical and

fuel lines and at other openings.

2.4.2 Duct recommendations

WARNING

When ducting supplies air to a space other than where

the furnace is located, the return air must be sealed and

also be directed to the space other than where the

furnace is located. Incorrect ductwork termination and

sealing will create a hazardous condition that can lead

to bodily harm.

CAUTION

Return air grilles and warm air registers must not be

obstructed.

IMPORTANT: The dampers should be adequate to prevent

cooled air from entering the furnace, and if manually

operated, must be equipped with the means to prevent

operation of either the cooling unit or the furnace, unless the

damper is in the full cool or heat position.

NOTE: The back should not be cut out for return air

ducting.

The proper sizing of warm air ducts is necessary to ensure

satisfactory furnace operation. Ductwork should be in

accordance with the latest editions of NFPA-90A

(Installation of Air Conditioning and Ventilating Systems)

and NFPA-90B (Warm Air Heating and Air Conditioning

Systems) or Canadian equivalent.

The supply ductwork should be attached to the flanged

opening provided at the discharge end of the furnace. See

Figures 10 and 11, for the dimensions of this opening.

Knockouts are provided on both sides of the furnace to cut

the required size of opening for the installation of the return

air ductwork. This can be done on either the right or the left

side of the furnace. See Table 2 for location and

dimensions.

Also, there is provision on this furnace for a bottom return air

duct. Knockouts are provided in the floor of the furnace to

facilitate the cut-out requirement for the air filter rack and

return ductwork. (We recommend the use of this opening for

horizontal and counterflow installations).

The following recommendations should be followed when

installing ductwork:

a. Install locking type dampers in all branches of the

individual ducts to facilitate balancing the system.

Dampers should be adjusted such a way as to ensure

the proper static pressure at the outlet of the furnace;

b. A flexible duct connector of non-combustible material

should be installed at the unit on both the supply and

return air side. In applications where an extremely quiet

operation is necessary, the first 3 m (10') of supply and

return ducts should be internally lined with acoustical

material (if possible);

c. In cases where the return air grille is located close to

the fan inlet, there should be at least one 90o turn

between fan inlet and grille. Further reduction in sound

level can be accomplished by installing acoustical

turning vanes or lining the duct as described in item b.

above;

d. When a single air grille is used, the duct between grille

and furnace must be the same size as the return air

opening in the furnace.

When installing the furnace with cooling equipment for year

round operation, the following recommendations must be

followed for tandem or parallel air flow:

WARNING

POISONOUS CARBON MONOXIDE GAS HAZARD

Install the evaporator coil on the supply side of the

furnace ducting ONLY.

An evaporator coil installed on the return air side of the

ducting can cause condensation to form inside the heat

exchanger, resulting in heat exchanger failure. This in

turn can result in death, bodily injury.

a. On tandem airflow applications, the coil is mounted

after the furnace in an enclosure in the supply air

stream. The furnace blower is used for both heating and

cooling airflow;

b. On parallel airflow installation, dampers must be

provided to direct air over the furnace heat exchanger

when heat is desired and over the cooling coil when

cooling is desired.

2.4.3 Venting instructions (chimney installation)

The furnace must be vented to the outside, in accordance

with local codes and other authorities having jurisdiction.

CAUTION

Oil fired appliances must be connected to flues having

sufficient draft at all times to ensure safe and proper

combustion.

For additional venting information please refer to

ANSI/NFPA 211 Chimneys, Fireplaces, Vents and Solid

Fuel Burning Appliances and/or the CSA B139 Installation

Code.

6

This furnace is certified for use with a Type “L” vent

(maximum flue gas temperature 302°C (575°F)). The f lue

pipe clearance knockout in the front top or side panel should

be removed. Install the flue elbow so that it exits the furnace

cabinet through that opening.

Pre-installation vent system inspection

Before this furnace is installed, it is strongly recommended

that any existing vent system be completely inspected.

On any chimney or vent, this should include the following:

a. Inspection for any deterioration in the chimney or vent.

If deterioration is discovered, the chimney must be

repaired or the vent replaced;

b. Inspection to ascertain that the vent system is clear and

free of obstructions. Any blockages must be removed

before installing this furnace;

c. Cleaning the chimney or vent if previously used for

venting a solid fuel burning appliance or fireplace;

d. Confirming that all unused chimney or vent connections

are properly sealed;

e. Verification that the chimney is properly lined and sized

per the applicable codes. (Please refer to list of codes

in Part 1.2)

Masonry Chimneys

This furnace may be vented into an existing masonry

chimney. However, it must not be vented into a chimney

servicing a solid fuel-burning appliance. Before venting this

furnace into a chimney, the chimney must be checked for

deterioration and repaired if necessary. The chimney must

be properly lined and sized per local and/or national codes.

The chimney must be of sufficient area to accommodate the

total flue products of all appliances vented into the chimney.

The following requirements are provided for a safe venting

system:

a. Ensure that the chimney flue is clear of any dirt or

debris;

b. Ensure that the chimney is not servicing an open

fireplace;

c. Never reduce the pipe size below the outlet size of the

furnace;

d. All pipes should be supported, using the proper clamps

and/or straps. These supports should be installed at

least every 4 feet;

e. All horizontal runs of pipe should have at least 20 mm

of upward slope per 1 m (1/4” per 1');

f. All runs of pipe should be as short as possible with as

few turns as possible;

g. Seams should be tightly joined and checked for leaks;

h. The flue pipe must not extend into the chimney but be

flush with the inside wall;

i. The chimney must extend 0.9 m (3') above the highest

point where it passes through a roof of a building and at

least 0.6 m (2') higher than any portion of a building

within a horizontal distance of 3 m (10'). It shall also be

extended at least 1.5 m (5') above the highest

connected equipment flue collar;

j. Check local codes for any variances.

Factory Built Chimneys

Approved factory built chimneys may be used. Refer to

chimney manufacturer’s instructions for proper installation.

2.4.4 Draft Regulator

The draft regulator supplied with the furnace must be used

for proper functioning. Installation instructions are included

with the control.

2.4.5 Blocked vent shut-off (BVSO)

For chimney venting

All oil furnaces installed in Canada must have a blocked

vent shut-off.

WARNING

It is imperative that this device be installed by a

qualified agency.

This device is designed to detect the insufficient evacuation

of combustion gases in the event of a vent blockage. In such

a case the thermal switch will shut down the oil burner. The

device will then need to be re-armed MANUALLY.

Please refer to Figures 2 to 8, the wiring diagrams, Figures

12 and 13, and the detailed instructions supplied with the

BVSO for the installation and wiring procedures. The length

of wires supplied with the unit is such that the safety device

must be installed between the flue outlet of the appliance

and the draft regulator, as indicated in the instructions.

Figure 2 : Wiring diagram,BVSO

For more details, refer to the instructions supplied with the

device itself, as well as section 3 of this manual.

7

DNS-01340 Rev A

Electrical kit supplied.

electrical kit.

WARNING

FIRE, CARBON MONOXIDE POISONINC HAZARD

Failure to follow this warning could result in personal

injury, death, and/or property damage.

DO NOT reset the device or restart the furnace unless

the cause of the interruption has been identified and

corrected by a qualified agency. Ensure that the blocked

vent shut-off has been cleaned by a qualified agency

before placing into service. Annual inspection and

cleaning of the blocked vent shut-off by a qualified

agency is required.

WARNING

FIRE, CARBON MONOXIDE POISONINC HAZARD

Failure to follow this warning could result in personal

injury, death, and/or property damage.

The blocked vent shut-off MUST be inspected and

maintained annually by a qualified agency.

Figure 3 : Blocked vent shut-off device wiring, upflow installation with vertical exhaut

The position of the hole

in the vent is subject to

the length of the

2.4.6 Oil burner

This furnace is supplied with a high pressure atomizing

retention head type Riello burner for use with not heavier

than grade 2 Fuel Oil. Refer to the Technical Specifications,

Table 5 for the insertion length.

Oil Connections

Complete instructions for installation of the fuel oil piping will

be found in the oil burner installation instructions included

with the furnace.

Connect the green

ground wire to a

cabinet screw.

It is also essential that the BVSO be maintained annually.

For more details please refer to the instructions supplied

with the device itself, as well as Section 4 of this Manual.

WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

Disconnect electrical power supply to the furnace

before wiring the blocked vent shut-off.

CAUTION

CUT HAZARD

Failure to follow this caution may result in personal

injury.

Sheet metal parts may have sharp edges or burrs. Use

care and wear appropriate protective clothing, safety

glasses, and gloves when handling parts and servicing

furnaces.

Blocked Vent Shut-Off

device BVSO.

Use the three wire

fasteners. The wires

must not come in

contact with the flue and

cleaning pipes.

Connect the wires to

the free Limit Control

terminals.

DNS-1043 Rev. A

Oil line entry holes are located in the side panels. Two holes

are provided on each side, so that a two-pipe system can be

used if desired.

A 10-micron (or finer) oil filter should be used with all oil

burners, installed as closely as possible to the burner.

8

Figure 4 : Blocked vent shut-off device wiring, upflow

contacts (See Figure 2)

installation with vertical exhaust

Connection to

high limit contacts

DNS-1043 Rev A

Figure 5 : Blocked vent shut-off device wiring, upflow

installation with horizontal exhaust

Figure 7: Blocked vent shut-off device wiring, horizontal

installation with vertical exhaust

DNS-1043 Rev A

Connection to

high limit contacts

Figure 8: Blocked vent shut-off device wiring, downflow

installation

Connection to

high limit contacts

DNS-1043 Rev A

Figure 6: Blocked vent shut-off device wiring, horizontal

installation with horizontal exhaust

Connection to

high limit contacts

DNS-1043 Rev A

DNS-1043 Rev A

Connection to high limit

DNS-1043 Rev A

2.4.7 Electrical system

WARNING

The unit cabinet must have an uninterrupted or

unbroken electrical ground to minimize personal injury

if an electrical fault should occur. A green ground screw

is provided in the control box for this connection.

The appliance must be installed in accordance with the

current ANSI/NFPA 70 National Electrical Code, CSA C22.1

Canadian Electrical Code Part 1 and/or local codes.

The control system depends on the correct polarity of the

power supply. Connect “HOT” wire (H) and “NEUTRAL” wire

(N) as shown in Figures 12 and 13.

9

A separate line voltage supply should be used with fused

disconnect switch or circuit breaker between the main power

panel and the unit.

Use only copper wire for 115V supply service to the unit.

Metallic conduit (where required/used) may terminate at the

side panel of the unit. It is not necessary to extend the

conduit inside the unit from the side panel to the control box.

When replacing any original furnace wiring, use only 105oC,

16 AWG copper wire.

2.4.3 24V Wiring

Instructions for wiring thermostat (field supplied) are packed

in the thermostat box. Make thermostat connections as

shown in Figures 9 and 10. Thermostat wire connections at

R and W are the minimum required for oil heating operation.

2.4.4 Accessory installation

General

When installing optional accessories on this appliance,

follow manufacturer’s Installation Instructions included with

accessory.

Auxiliary terminals

The HUM 120 VAC terminals on the electronic control board

are tied directly to the #8 pin of the 9-pin connector and

provide a 120 VAC signal whenever the burner is energized,

see Figure 13. The 120 VAC and neutral terminals can be

used for accessory wiring. See Electronic Air Cleaner and

Humidifier sections for further information.

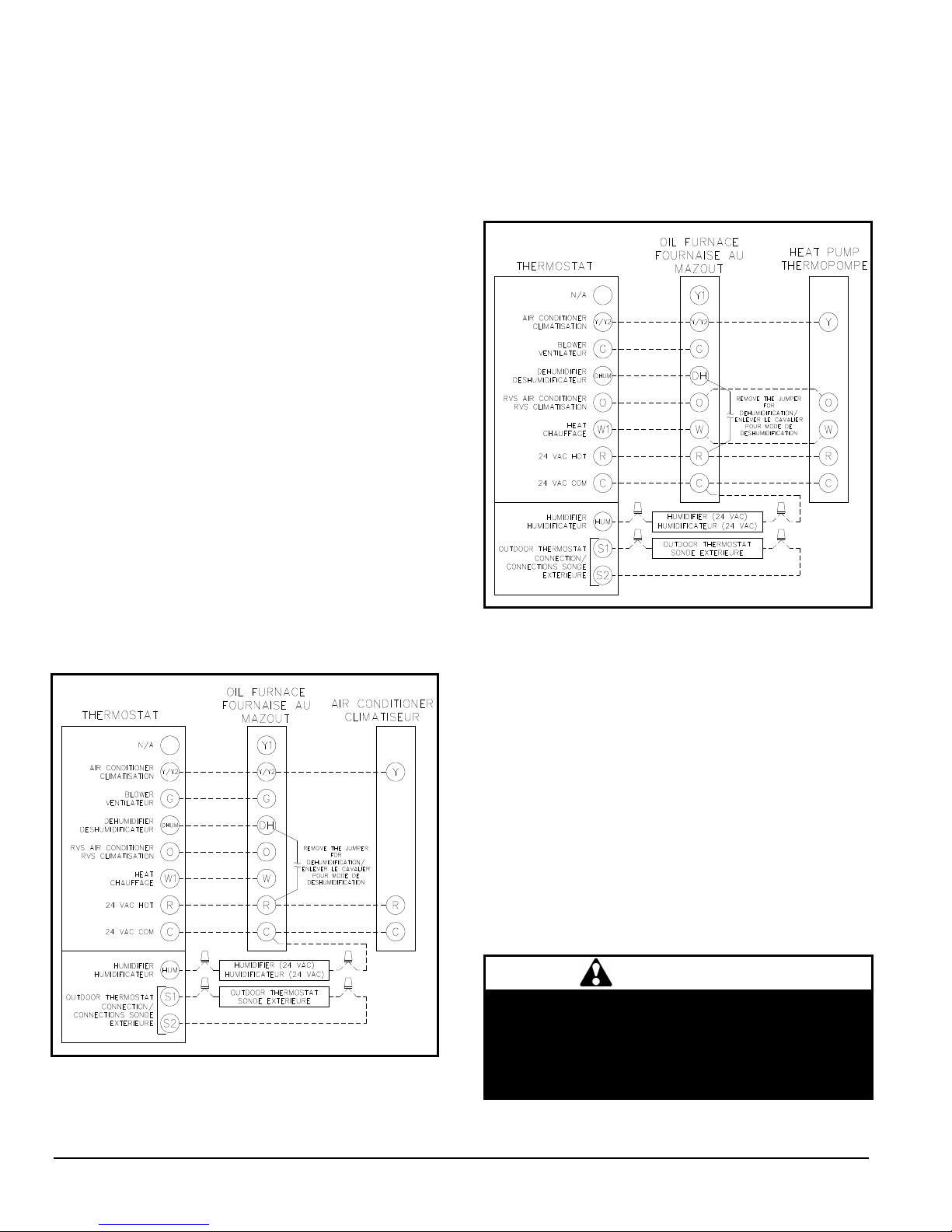

Figure 9 : 24 VAC Oil Furnace Wiring with Air

Conditioner

constant 120 VAC power, the airflow sensor turns on the

electronic air cleaner when the furnace blower is operating.

Humidifier / Humidistat

A 24 VAC signal can be connected, sourced from the W and

C terminals on the electronic control board or a 120 VAC

signal from the HUM 120 VAC or N terminals, when a heat

source must be used.

Figure 10 : 24 VAC Oil Furnace Wiring with Heat Pump

DNS-1025 Rev D

Dehumidification capability with standard Humidistat

Dehumidification on systems using a variable speed motor

is better than on most other systems. If this feature is

required, the terminals on the electronic control board permit

the wiring of a standard humidistat. Refer to Figures 9 and

10 for wiring instructions.

A furnace equipped with a variable speed motor will detect

the opening of the humidistat contact and reduce the airflow

to 85% of nominal cooling airflow. This will increase its

capacity to dehumidify up to the point where the humidistat

detects an acceptable level of humidity in the air. At that

point the unit return to 100% of its cooling airflow.

To activate this mode, remove the jumper between DH

and R of the electronic board and wire in a standard

humidistat on these terminals.

2.4.8 Air filter

Electronic Air Cleaner

When adding an electronic air cleaner to this unit, use an

Airflow Sensor kit. As the air cleaner is connected to

DNS-1024 Rev D

DANGER

Do not use this furnace as a construction heater. Use of

this furnace as a construction heater exposes it to

abnormal conditions, contaminated combustion air and

the lack of air filters. Failure to follow this warning can

lead to premature furnace failure and/or vent failure that

could result in a fire hazard and/or bodily harm.

An external filter rack is provided as standard equipment

with this furnace. The filter rack can be installed on the right

10

or left side panel, or on the bottom of the furnace to

accommodate the return air ductwork. A sufficient clearance

should be provided for air filter access. Please refer to Table

2 for filter rack flange dimensions for return air duct.

Table 2 : Filter rack flange dimensions for return air duct

Model Air Filter Size Flange Opening

CBM SIZE 105

CBM SIZE 120

16" x 24" 15" x 23"

40.64 x 60.96 cm 38.10 X 58.42 cm

20" x 30" 17" x 29"

45.72 X 76.20 cm 43.18 X 73.66 cm

2.4.9 Air Conditioner (or Heat Pump)

An air conditioning coil may be installed on the supply air

side ONLY.

WARNING

POISONOUS CARBON MONOXIDE GAS HAZARD

Install the evaporator coil on the supply side of the

furnace ducting ONLY.

An evaporator coil installed on the return air side of the

ducting can cause condensation to form inside the heat

exchanger, resulting in heat exchanger failure. This in

turn can result in death, bodily injury.

No minimum clearance is required between the bottom of

the coil drain pan and the top of the heat exchanger. If a

heat pump is installed, a “dual-energy” thermostat, or other

control is required, in order to prevent the simultaneous

operation of the furnace and the heat pump. It also prevents

a direct transition from heating by way of the heat pump to

heating with oil. Refer to the thermostat instructions or those

of another control used for the proper wiring.

If a coil blower compartment is used, install air tight,

motorized and automatic air dampers. Cold air coming from

the coil and passing across the furnace can cause

condensation and shorten the life of the heat exchanger.

2.4.10 Horizontal or downflow installation

1. On horizontal installations, determine which “side” will

become the “top”, when the unit is laid down. Remove

the flue pipe clearance knockout from the top front of

that side panel. Install the flue elbow so that it exits the

cabinet of the furnace through that opening;

2. On counterflow Installations, the flue pipe must exit the

cabinet through one of the side panel openings (as

above), then extended up the side of the furnace.

Ensure that adequate clearances to combustibles are

observed. It may be necessary to install a sheet-metal

shield on an adjacent wall to prevent any possibility of a

fire hazard;

3. Remove the burner by unscrewing the mounting nuts.

Avoid putting undue strain on burner wiring. It may be

necessary to disconnect the burner wiring in some

cases. Reinstall the burner in the proper position.

IMPORTANT: The burner must always be installed in the

upright position with the ignition control on top.

3.0 OPERATION

3.1 SUPPLY AIR ADJUSTMENTS

This furnace is equipped with an ECM variable speed motor.

The blower is adjusted at the factory to deliver the required

oil heating airflow at 0.75 USGPH and 3.0 tons of cooling on

models with a maximum input of 105,000 BTU/H. The same

applies to units with 0.85 USGPH input, 5 tons of cooling

and a maximum input of 154,000 BTUH.

Refer to Tables 3 to 6 for information on how to adjust the

DIP switches for other blower speeds for heating and

cooling.

Table 3 : Supply air adjustments, heating mode

CVM 105

SW1 – HEAT

DIP Switch Positions

1 2 POSITION

Output

USGPH

OFF OFF A 0.75

ON OFF B 0.65

OFF ON C 0.50

ON ON D ALL

CVM 120

SW1 – HEAT

DIP Switch Positions

1 2 POSITION

Output

USGPH

OFF OFF A 0.85

ON OFF B 1.00

OFF ON C 1.10

ON ON D N/A

3.2 OPERATIONAL CHECKLIST

Before starting up the unit, be sure to check that the

following items are in compliance:

1. The electrical installation, the oil supply system, the

venting system, combustion air supply and ventilation;

2. The blower access door is in place and the blower rail

locking screws are well tightened;

3. The Blocked Vent Shut-Off (BVSO) is installed

according to instructions (for chimney venting);

4. The oil supply valve is open;

Table 4 : Supply air adjustments, air conditioning mode

CVM 105

SW2 – COOL

DIP Switch Positions

Output

1 2 POSITION

OFF OFF A 3.0

ON OFF B 2.5

OFF ON C 2.0

ON ON D 1.5

CVM 120

SW2 – COOL

Output

DIP Switch Positions

1 2 POSITION

OFF OFF A 5.0

ON OFF B 4.0

OFF ON C 3.5

ON ON D 3.0

11

Tons

Tons

Table 5 : CFM adjustments, all modes

CVM 105

SW3 – ADJ (Adjustment)

DIP Switch Positions

1 2 POSITION

CFM HTG.

% increase

or decrease

CFM A/C

% increase

or decrease

OFF OFF A 0% 0%

ON OFF B +10% +10%

OFF ON C -10% -10%

ON ON D N/A 0%

CVM 120

SW3 – ADJ (Adjustment)

DIP Switch Positions

1 2 POSITION

CFM HTG.

% increase

or decrease

CFM A/C

% increase

or decrease

OFF OFF A 0% 0%

ON OFF B +10% +10%

OFF ON C -10% -10%

ON ON D N/A 0%

Table 6 : Delay adjustments, heating mode

CVM 105

SW4 – Delay

DIP Switch Positions

1 2 POSITION

Output

USGPH

OFF OFF A 0.75

ON OFF B 0.65

OFF ON C 0.50

ON ON D ALL

CVM 120

SW4 – Delay

DIP Switch Positions

1 2 POSITION

Output

USGPH

OFF OFF A 0.85

ON OFF B 1.00

OFF ON C 1.10

ON ON D N/A

5. The flame observation door and the two clean-out

access doors (located at the front of the unit) or well

closed;

6. The burner ‘’Reset’’ button is well pushed in or rearmed;

7. The preliminary air adjustments on the burner comply

with the technical specifications in this manual;

8. The blower adjustments are appropriate and according

to the specifications in this manual;

9. The thermostat of the room is in the heating mode and

is set higher than the ambient temperature.

To start the unit, turn the main electrical switch on.

CAUTION

Do not tamper with the unit or its controls. Call a

qualified service technician.

3.3 PURGING THE OIL LINE

1. A 10-micron (or less) oil filter should be installed as

closely to the burner as possible with all oil burners, but

it is essential for burners with a low firing rate. We

recommend the use of a low pressure drop oil filter with

a capacity greater than that of the fuel pump;

2. On a new installation, the air trapped in the oil line

leading from the tank to the nozzle must be thoroughly

purged in order to prevent excessive after drip. The oil

pump is equipped with a special fitting that facilitates

the purging of any air between it and the tank. The

proper procedure for performing this operation is as

follows:

a. Place a piece of 1/4” diameter clear plastic tubing

over the purge fitting on the oil pump;

b. Start the oil burner, then open the purge fitting and

allow the burner to run until the purge tube is

completely free of air bubbles;

c. At this point tighten the purge fitting, which will

allow the oil to run to the nozzle and fire the burner.

If the purging takes longer than 15 seconds and no

flame has been established the burner will stop.

Push the reset button on top of the Primary Control

to restart the burner.

For detailed information on the operation of the Primary

Control please refer to the instructions included with the

furnace or the burner.

3.4 COMBUSTION CHECK

IMPORTANT: The combustion check verification MUST be

performed after the nozzle replacement or the burner

cleaning. After these manipulations, the combustion

parameters are necessarily modified. Refer also to the

burner instruction manual.

IMPORTANT: The heat exchanger metal surfaces may

have oil and the baffle insulation also contains binders.

These products will burn or evaporate when the unit

operates for the first time. Because of this, the smoke

reading may be inexact during the first minutes of operation.

Therefore, the unit must operate during at least 60 minutes

before taking any readings to adjust the combustion quality.

Let the unit cool down before making any adjustments.

In order to obtain optimum performance from the oil burner,

the following set-up procedures must be followed by

referring to the Technical Specifications, Table 5 in this

manual:

1. A test kit to measure the smoke, flue draft and over-fire

pressure should be used in order to obtain the proper

air band setting. Although all of the above

measurements are required for optimum set up and

efficiency, the most important reading that must be

taken is the smoke number in the flue pipe, downstream

from the regulator;

2. The proper smoke number, as established by way of

engineering tests, is between 0 and 1. This degree of

smoke emission is commonly referred to as a “trace”. It

is recommended that a Bacharach True Spot Smoke

Test kit or equivalent be used;

3. Follow the next steps to do the combustion check

verification:

a. Drill a minimum proper diameter (about 9/32”) test

hole in the flue pipe, approximately 18 inches from

the furnace breech;

b. From a cold start, let the unit operate for about 5

minutes;

c. Set the burner air setting until you have between 0

and 1 on the Bacharach Scale (or a “trace”);

12

d. Take a CO2 sample at the same test location where

the smoke reading was taken and make note of it;

e. Adjust the burner air setting to obtain a CO2 reading

1.5% lower (or a O2 reading 2.0% higher) than the

reading associated with the “trace” of smoke;

f. This method of adjusting the burner will result in

clean combustion (Bacharach smoke scale

between 0 and a trace) and ensure the proper

functioning of the system.

4. A barometric draft regulator, supplied with the furnace,

must be installed, in order to ensure proper draft

through the furnace. The barometric damper must be

mounted with the hinge pins in a horizontal position and

the face of the damper vertical for proper functioning,

(see instructions included with damper). After the

furnace has been firing for at least five minutes, the

draft regulator should be set to between -0.025" W.C.

and -0.035" W.C.;

5. The over fire pressure that is taken through the

observation door located in the centre of the front panel

above the burner is a measurement that is necessary to

determine if there is a blockage in the heat exchanger

or the flue pipe. Please refer to the Technical

Specifications in this manual for over fire pressure

values. A high pressure condition may be caused by

excessive combustion air due to the air band being too

wide open or a lack of flue draft (chimney effect) or

some other blockage, such as soot in the secondary

section of the heat exchanger or the use of an oversize

nozzle input or high pressure pump;

6. After all the set up procedures mentioned above have

been completed, the burner should be fired and an

inspection mirror should be used to observe the flame

pattern at the tip of the nozzle. Any irregularities such

as burning to one side or pulsating flame patterns

should be corrected by changing the nozzle.

3.5 SEQUENCE OF OPERATION

Using schematic diagram in Figure 13, follow the sequences

of operation through the different modes.

NOTE: ECM variable speed motors deliver infinitely variable

CFMs. At start-up the motor increases its speed gradually,

in order to lower noise perception. ECM motors ramp down

in the same gradual fashion as they do on start-up. ECMs

are energized by 120V, whenever power is available to the

furnace control. However, they operate only when 24V

motor control signals are received.

3.5.1 Oil fired heating mode

1. The thermostat closes R to W.

2. Burner motor fan pre-purges the combustion chamber

for 10 to 15 seconds, establishing the combustion air

pattern. During this time a spark is also established.

The fan starts at 13% of nominal heating for a period

equivalent to the “Pre-Run Delay”. Refer to Tables 8

and 9 ;

3. The solenoid valve opens and a flame is established. A

short time after that, the ignition transformer ceases

sparking.

4. After the “Pre-Run Delay” the blower slightly increases

its speed for a period of time equivalent to the “ShortRun Delay”. Refer to Tables 8 and 9.

5. After the “Short-Run Delay” the blower increases its

speed in order to reach the CFMs indicated in Tables 8

and 9.

6. The call for heat is satisfied.

7. The solenoid valve closes, the burner motor stops and

the flame extinguishes.

8. The blower slows down gradually to 38% of nominal

CFMs for a period of 3 minutes and then stops.

3.5.2 Cooling mode

NOTE: On units using a 2-stage compressor, the terminal

Y1 must be used. Once the Y1 terminal on the electronic

control receives a 24 V signal, the airflow is reduced by 20%

percent. If a single stage compressor is used, do not use the

Y1 terminal.

1. The R - G-and R - Y/Y2 thermostat contacts close. The

R-Y/Y2 circuit starts the outdoor unit, and the R - G

circuit starts the blower at cooling speed. Refer to

Tables 8 and 9.

2. When the call for cooling is satisfied, the R - G and R Y/Y2 thermostat contacts open. The cooling unit stops

and furnace blower stops after a period of 3 minutes.

3.5.3 Continuous Blower Mode

1. When the R – G thermostat contacts close, the blower

functions at 64%, 75% or 86% of cooling airflow,

depending on the adjustment of the DIP switches. Refer

to Tables 8 and 9.

2. 2. When the R – G thermostat contacts open, the

blower stops immediately.

3.5.4 Heat Pump – Heating / Cooling Mode

NOTE 1: On units using 2-stage compressors, terminal Y1

must be used. When Y1 on the electronic control board

receives a 24 V signal, the airflow is cut by 20%. If a single

stage compressor is used, do NOT use terminal Y1.

NOTE 2: A dual-fuel thermostat is required when a variable

speed furnace is used with a heat pump. See dual-fuel

thermostat Installation Instructions for interface connections.

The interface prevents simultaneous operation of both the

furnace and heat pump and prevents direct transition from

heat pump to furnace operation.

Cooling Mode

1. The thermostat contacts R - G, R - Y/Y2 and R - O

close. The R - Y/Y2 circuit starts-up the outdoor cooling

unit, the R - O maintains the reversing valve in the

cooling mode and the R - G circuit starts-up the blower

at cooling speed. Refer to Tables 8 and 9.

2. When the call for cooling is satisfied, the R - G, R Y/Y2 and R - O contacts open. The cooling unit stops

and the furnace blower stops after for a period of 3

minutes.

Heating Mode Thermo Pump

1. The thermostat contacts R - G and R - Y/Y2 close. The

R - G circuit starts-up the blower at heating speed by

way of the Thermo Pump. Refer to Tables 8 and 9.

13

2. When the call for heat is satisfied, the thermostat

contacts open and the furnace blower stop after a

period of 3 minutes.

3.5.5 Defrost Mode

When the R - W and R - Y/Y2 circuits are closed by the

thermostat and the heat pump, the electronic control startsup the burner and the blower in the oil heating mode during

defrosts.

3.6 LIMIT CONTROL CHECK

After the furnace has been in operation for at least 15

minutes, restrict the return air supply by blocking the filters

or closing the return registers and allow the furnace to shut

down on High Limit. The burner will shut OFF but the main

blower should continue to run.

Remove the restriction and the burner should come back on

in a few minutes.

4.0 MAINTENANCE

WARNING

Before performing any service functions, make sure that

all utilities are turned ‘’OFF’’ upstream from the

appliance, unless operations specifically require the

power to be on. Failure to comply with this warning will

cause a fire hazard and/or bodily harm.

This furnace should never be operated without an air filter.

Disposable filters should be replaced at least once a year. If

equipped to provide cooling, filters should be replaced at a

minimum of twice a year.

To avoid personal injury, make sure the power is “OFF”

before servicing.

ALWAYS KEEP THE OIL VALVE CLOSED IF THE

BURNER IS SHUT DOWN FOR AN EXTENDED PERIOD

OF TIME.

For optimum performance, the oil burner nozzle should be

replaced at least once a year.

The procedure for the installation and/or replacement of a

nozzle is outlined in the oil burner instruction manual which

is supplied with the furnace.

After replacing the nozzle, the burner should be adjusted in

accordance with the “COMBUSTION CHECK” section of this

manual.

4.1 HEAT EXCHANGER CLEANING

Normally, it is not necessary to clean the heat exchanger or

flue pipe every year, but it is advisable to have a qualified

service technician check the unit before each heating

season to determine whether cleaning or replacement of

parts is required.

If cleaning is necessary, the following steps should be taken:

1. Turn “OFF” all utilities upstream from the furnace;

2. Disconnect the flue pipe (only with chimney venting and

rigid flue pipe);

3. Remove the breech plate;

4. Remove the radiator baffle;

5. Disconnect the oil line and remove the oil burner from

the furnace;

6. Open the two cleanout doors located in the upper part

of the front panel of the furnace;

7. Clean the secondary tubes and the primary cylinder

with a stiff brush and a vacuum cleaner;

8. Before reassembly, the heat exchanger and combustion

chamber should be inspected to determine if

replacement is required;

9. After cleaning, replace the radiator baffle, flue collar

plate, oil burner and close the two clean out access

doors. Reconnect the flue pipe and oil line;

10. Readjust burner for proper operation.

4.2 BLOWER REMOVAL

To remove the blower from the furnace:

1. Turn “OFF” all utilities upstream from the furnace;

2. Remove the burner access door and blower door;

3. Remove the blower retaining screw (on the blower

partition panel);

4. Remove the control box cover and disconnect the

thermostat and power wires from the board;

5. Slide the blower on the rails toward the front of the unit;

6. Reverse the above steps to reinstall the blower. Please

refer to the wiring diagram, Figure 13 in this manual, or

the diagram located on the inside of the blower door to

properly rewire the unit.

CAUTION

Be sure that the blower is adequately supported when

sliding it off the mounting rails, especially in the

horizontal or counter flow positions, in order to prevent

dropping it and injuring yourself or damaging the

blower.

4.3 BLOCKED VENT SHUT OFF (BVSO) CLEANING

For continued safe operation, the Blocked Vent Shut-Off

System (BVSO) needs to be inspected and maintained

annually by a qualified service technician.

WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

Disconnect electrical power supply to the furnace

before servicing the blocked vent shut-off.

1. Remove the two screws holding down the BVSO

assembly cover;

14

2. Remove the cover;

3. Remove the two screws holding the control box to the

heat transfer tube assembly. Sliding the control box in the

appropriate direction will unlock it form the heat transfer

tube assembly;

4. Carefully remove any build-up from the thermal switch

surface;

CAUTION

Do not dent or scratch the surface of the thermal

switch. If the thermal switch is damaged, it must be

replaced.

5.0 FURNACE INFORMATION

Model:

Furnace installation date:

Service telephone #-Day:

Dealer name and address:

START-UP RESULTS

Nozzle:

Burner adjustments:

CO2 :

Gross stack temperature:

Ambient temperature:

Chimney draft :

Overfire draft :

Test performed by:

Primary air

Fine air

Drawer Assembly

% Smoke

scale:

5. Clear and remove any build-up or obstruction inside the

heat transfer tube;

6. Re-mount, lock and fasten the control box with the 2

screws removed in step 3;

7. Re-attach the assembly cover with the screws removed in

step 1;

8. Re-establish power to the appliance.

Serial number:

Night:

Pressure:

(Bacharach)

°F

°F

" W.C.

" W.C.

lb/po2

15

Table 7 : Technical Specifications

Adjust fan speed for air temperature rise of 55 to 85 F.

X

** Dip switches on the electronic board must be adjusted according to heat input and cooling capacity.

Model: CVM 75 90 105 120 140 155

RATING AND PERFORMANCE

Firing rate (USGPH)* 0.5 0.65 0.75 0.85 1.00 1.10

Input (BTU/h)* 70 000 91 000 105 000 119 000 140 000 154 000

Heating capacity (BTU/h)* 56 000 72 000 85 000 100 000 117 000 127 000

Heating temperature rise*

Flue draft with chimney (inch of w .c.)

Overfire pressure w ith chimney (inch of w .c.)

RIELLO BURNER; 40-F (chimney vent)

Burner tube insertion length

30 - 47°C (55 - 85°F) 30 - 47°C (55 - 85°F)

-0.06" to -0.025" -0.06" to -0.025"

max +0.025" max +0.025"

F3 head with VSBT F5 head with VSBT

3 9/16 ''

3 9/16 ''

Nozzle (Delavan) 0.40 - 70A 0.50 - 70W 0.65 - 70W 0.75 - 70B 0.85 - 70W 1.00 - 70W

Pump pressure (PSIG)* 155 170 135 130 140 125

Combustion air adjustment (turbulator/damper) 0 / 3 0 / 3.5 0 / 4 0 / 3 0 / 3.5 0 / 4

AFUE % (From CSA B212 standard and Canadian regulation) 82.9 82.4 81.8 ▲85.1 83.8 83.0

AFUE % max. (From ASHRAE 103 stadard and US regulation) 82.0 81.6 82.3 ▲85.7 84.9 84.3

ELECTRICAL SYSTEM

Volts - Hertz - Phase

Rated current (Amps)

Minimum ampacity for wire sizing

Max. w ire lenght (ft.)

Max. fuse size (Amps)

Control transformer

External control power available Heating

Cooling

115 - 60 - 1 115 - 60 - 1

12.2 15.7

13.7 18.1

26 26

15 20

40 VA 40 VA

40 VA 40 VA

30 VA 30 VA

BLOWER DATA

Motor (HP)

Blow er w heel size (in.)

Filter quantity and size

1/2 HP ECM 1.0 HP ECM

10" X 10"

12" X 10"

(1X) 16" X 24" (1X) 20" X 30"

GENERAL INFORMATION

Overall dimensions (w idth x depth x height)

Supply air opening (width x depth)

Return air opening (depth x height, with factory filter rack)

Filter size

Shipping weight

Air conditioning, maximum output (tons) at 0.5 SP

20" x 35" x 48¾" 20" x 39½" x 53"

18.625" x 20" 19" x 24"

15" x 23" 17" x 29"

16" x 24" 20" x 30"

100 kg / 221 lbs 122 kg / 270 lbs

3 tons 5 tons

* INPUT & OUTPUT ADJUSTMENT (see information below )

=

Pump pressure can be increased up to 180 PSIG (200 PSIG with Beckett burner at 1.10 USGPH)

Adjust flue gas temperature between 400 and 575 F.

Refer to air flow tables of the instruction manual.

16

Loading...

Loading...