Bryant 310AAV User Manual

310AAV/JAV Induced-Combustion 4-Way Multipoise Furnace

Installation, Start-up, Operating, and

Service and Maintenance Instructions

-Series C

The 310AAV/JAV 4-Way Multipoise Gas Furnace was designed by Bryant dealers for Bryant dealers. Applications are easy with 4-way multipoise design, through-the-furnace downflow venting, 13 different venting options, and a door designed for easy service access. An inner blower door is provided for tighter sealing in sensitive applications. The 310AAV/JAV furnace is approved for use with natural or propane gas, and the 310JAV is also approved for use in Low NOx Air Quality Management Districts.

STANDARD FEATURES

•Noise elimination combustion system

•Microprocessor based control center

Adjustable heating air temperature rise LED diagnostics and self test feature

•Patented blocked vent safeguard to ensure proper furnace venting

•All models are Chimney Friendly when used with accessory vent kit

•Four-position furnace: upflow, horizontal right, horizontal left,

downflow

Thirteen different vent options

•Heat pump compatible

•Hot surface ignition (HSI)

•Residential installations eligible for consumer financing through the Comfort Credit Program

•Twinning in Upflow, Downflow and Horizontal

LIMITED WARRANTY

•20-year warranty on “Super S™” heat exchanger

•5-year parts warranty on all other components

Catalog No: 5331-012 |

Form No. II 310A-45-5 |

5-05 |

Single-Stage

Induced-Combustion

4-Way Multipoise Furnace

Cancels: II 310A-45-4/IM-PG8J-04

II310A-45-5/IM-PG8J-05

Installation, Start-up, Operating, and

Service and Maintenance Instructions

Series 120/C

NOTE: Read the entire instruction manual before starting the installation.

This symbol → indicates a change since the last issue.

→ Portions of the text and tables are reprinted from NFPA 54/ANSI Z223.1-2002©, with permission of National Fire Protection Association, Quincy, MA 02269 and American Gas Association, Washington DC 20001. This reprinted material is not the complete and official position of the NFPA or ANSI on the referenced subject, which is represented only by the standard in its entirety.

TABLE OF CONTENTS |

|

SAFETY CONSIDERATIONS ..................................................... |

2 |

INTRODUCTION .......................................................................... |

4 |

CODES AND STANDARDS........................................................ |

4 |

Safety......................................................................................... |

5 |

General Installation................................................................... |

5 |

Combustion and Ventilation Air .............................................. |

5 |

Duct Systems ............................................................................ |

5 |

Acoustical Lining and Fibrous Glass Duct.............................. |

5 |

Gas Piping and Gas Pipe Pressure Testing.............................. |

5 |

Electrical Connections .............................................................. |

5 |

ELECTROSTATIC DISCHARGE (ESD) PRECAUTIONS |

|

PROCEDURE ................................................................................ |

5 |

LOCATION.................................................................................... |

5 |

General ...................................................................................... |

5 |

Location Relative to Cooling Equipment ................................ |

7 |

AIR FOR COMBUSTION AND VENTILATION ...................... |

7 |

INSTALLATION ......................................................................... |

10 |

Upflow Installation ................................................................. |

10 |

Bottom Return Air Inlet .................................................... |

10 |

Side Return Air Inlet......................................................... |

10 |

Leveling Legs (If Desired)................................................ |

10 |

Downflow Installation ............................................................ |

10 |

Bottom Return Air Inlet .................................................... |

11 |

Horizontal Installation ............................................................ |

11 |

Suspended Furnace Support .............................................. |

11 |

Platform Furnace Support ................................................. |

11 |

Roll-Out Protection............................................................ |

11 |

Bottom Return Air Inlet .................................................... |

11 |

Side Return Air Inlet......................................................... |

11 |

Filter Arrangement.................................................................. |

11 |

Air Ducts................................................................................. |

11 |

General Requirements ....................................................... |

11 |

Ductwork Acoustical Treatment ....................................... |

12 |

Supply Air Connections .................................................... |

12 |

Return Air Connections..................................................... |

14 |

Gas Piping............................................................................... |

15 |

Electrical Connections ............................................................ |

19 |

115-V Wiring..................................................................... |

19 |

J-Box Relocation ............................................................... |

20 |

Electrical Connection to J-Box ......................................... |

21 |

Power Cord Installation in Furnace J-Box ....................... |

21 |

BX Cable Installation in Furnace J-Box .......................... |

22 |

24-V Wiring....................................................................... |

22 |

Accessories ........................................................................ |

22 |

Venting.................................................................................... |

22 |

General Venting Requirements ......................................... |

23 |

Masonry Chimney Requirements...................................... |

23 |

Appliance Application Requirements ............................... |

24 |

Additional Venting Requirements..................................... |

26 |

Sidewall Venting ............................................................... |

26 |

START-UP, ADJUSTMENT, AND SAFETY CHECK ............ |

27 |

General .................................................................................... |

27 |

Start-Up Procedures ................................................................ |

27 |

Adjustments............................................................................. |

31 |

Check Safety Controls ............................................................ |

34 |

Checklist.................................................................................. |

35 |

SERVICE AND MAINTENANCE PROCEDURES.................. |

35 |

Introduction ............................................................................. |

35 |

General............................................................................... |

35 |

Electrical Controls and Wiring ......................................... |

36 |

Care and Maintenance ............................................................ |

37 |

Cleaning and/or Replacing Air Filter ............................... |

37 |

Blower Motor and Wheel.................................................. |

37 |

Cleaning Heat Exchanger.................................................. |

40 |

Sequence of Operation............................................................ |

44 |

Wiring Diagrams..................................................................... |

45 |

Troubleshooting ...................................................................... |

45 |

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book |

1 |

4 |

PC 101 |

Catalog No. See Cover |

Printed in U.S.A. |

Form 58ST-13SI |

Pg 1 |

5-05 |

Replaces: 58ST-12SI |

Tab |

6a |

8a |

|

|

|

|

|

|

|

26-1/8" |

28-7/8" |

|

|

|

|

(FLUE COLLAR) |

|

|

|

25-1/4" |

A |

|

22-9/16" |

|

|

|

|

|

JUNCTION BOX |

F D |

5-15/16" |

LOCATION |

|

7/8" DIA |

|

|

ACCESSORY |

1/2" DIA THERMOSTAT |

|

|

WIRE ENTRY |

|

|

3-15/16" |

|

|

LEFT HAND GAS |

|

|

ENTRY |

|

33-5/16" |

|

24-7/8" |

|

|

|

|

|

7/8" DIA. ACCESSORY |

|

|

|

11/16" |

|

5-1/2" |

E |

21-5/8" |

1-11/16" |

|

|

BOTTOM INLET |

|

|

|

24" CASING

NOTES:

|

|

|

|

2-7/16" |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1-5/16" |

|

|

|

|

|

|

|

|

|

|

|

AIRFLOW |

|

|

|

|

|

|

||||||||||||

13/16" |

|

|

|

|

|

|

|

19" |

|

|

|

|

|

|

|

13/16" |

|

|

|

|

||||||||||||||

|

1-1/8" |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

OUTLET |

|

|

|

|

|

|

|||||||||||||||

|

|

4-13/16" |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

1/2" DIA. K.O.THERMOSTAT |

|

|

|

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

WIRE ENTRY |

11/16"7- |

9-5/8" |

|

||||||||||||||||||

|

|

8-9/16" |

|

|

|

|

|

|

|

|

|

|

1-3/4" DIA.RIGHT HAND |

|

|

|

|

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

3/4" |

|

|

|

|||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

GAS ENTRY |

|

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

11-1/2" |

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

7/8" DIA. K.O. WIRE ENTRY |

|

|

|

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||

|

|

ALTERNATE |

|

|

|

|

|

|

|

|

||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

JUNCTION BOX |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

LOCATIONS (TYP) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

VENT OUTLET |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

5 PLACES (TYP) |

|

|

|

|

7/8" DIA. ACCESSORY |

|

14-7/8" |

|

|

|

|||||||||||||||||||||||

|

|

|

|

|||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||

5-1/2" |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

11/16" |

3-3/4" |

|

|

|

|

|

|

|

|

|

|

|

1-1/2" |

|

|

|

|

|

|

|

|

|

|

|

1-1/4" |

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

22-1/16" |

|

|

|

|

|

|

|

1" |

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SIDE INLET |

|

|

|

|

|

|

|||||||||||||

A04037

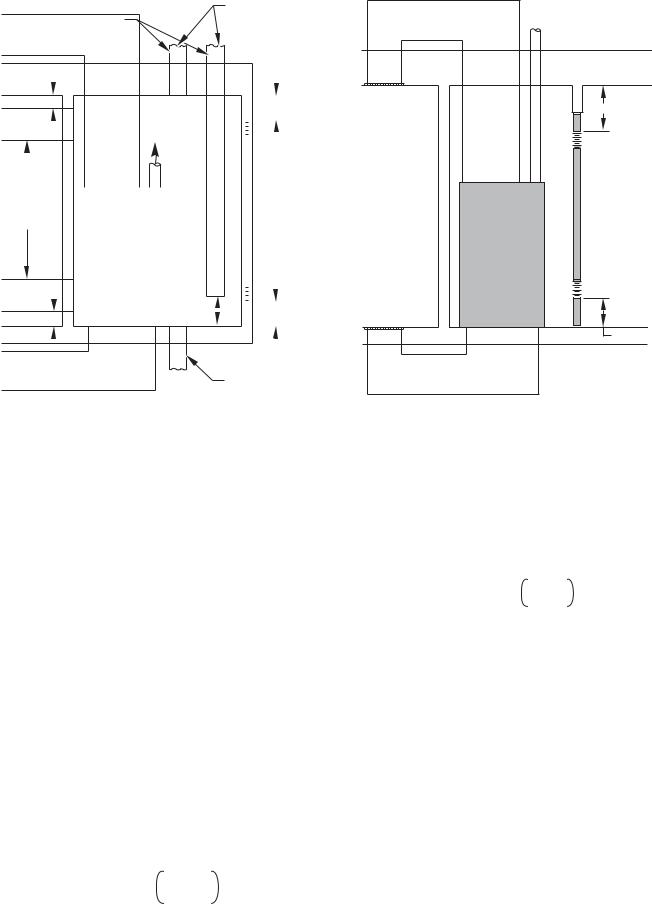

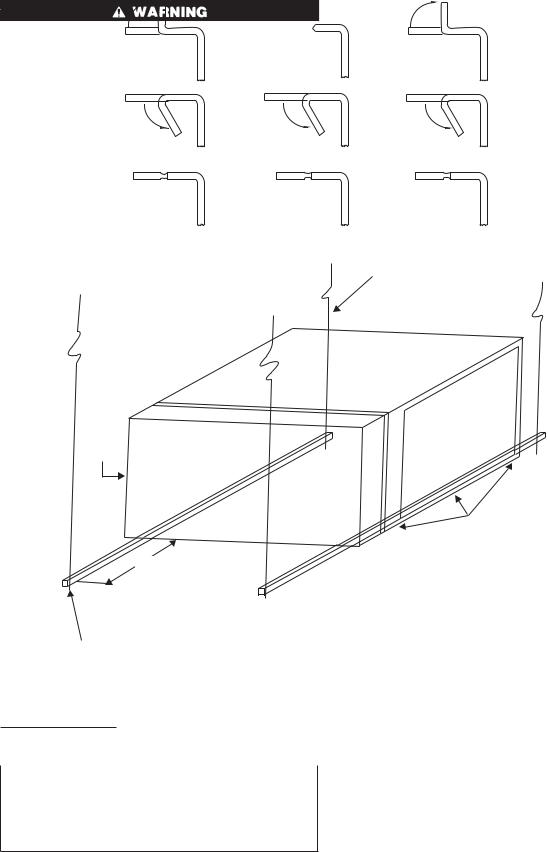

1.Two additional 7/8-in. diameter holes are located in the top plate.

2.Minimum return-air openings ar furnace, based on metal duct. If flex duct is used, see flex duct manufacturer’s recommendations for equivalent diameters.

a.For 800 CFM-16-in. round or 14 1/2 x 12-in. rectangle.

b.For 1200 CFM-20-in. round or 14 1/2 x 19 1/2-in. rectangle.

c.For 1600 CFM-22-in. round or 14 1/2 x 22-in. rectangle.

d.For airflow requirements above 1800 CFM, see Air Delivery table in Product Data literature for specific

use of single side inlets. The use of both side inlets, a combination of 1 side and the bottom, or the bottom only will ensure adequate return air openings for airflow requirements above 1800 CFM.

→ Fig. 1—Dimensional Drawing

SAFETY CONSIDERATIONS

FIRE, EXPLOSION, ELECTRICAL SHOCK, AND CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in dangerous operation, serious injury, death, or property damage. Improper installation, adjustment, alteration, service, maintenance, or use can cause carbon monoxide poisoning, explosion, fire, electrical shock, or other conditions which may cause personal injury or property damage. Consult a qualified service agency, local gas supplier, or your distributor or branch for information or assistance. The qualified service agency must use only factory-authorized and listed kits or accessories when modifying this product.

FURNACE RELIABILITY HAZARD

Improper installation or misapplication of furnace may require excessive servicing or cause premature component failure.

Application of this furnace should be indoors with special attention given to vent sizing and material, gas input rate, air temperature rise, unit leveling, and unit sizing.

Installing and servicing heating equipment can be hazardous due to gas and electrical components. Only trained and qualified personnel should install, repair, or service heating equipment.

Untrained personnel can perform basic maintenance functions such as cleaning and replacing air filters. All other operations must be performed by trained service personnel. When working on heating equipment, observe precautions in literature, on tags, and on labels attached to or shipped with furnace and other safety precautions that may apply.

These instructions cover minimum requirements and conform to existing national standards and safety codes. In some instances, these instructions exceed certain local codes and ordinances, especially those that may not have kept up with changing residential construction practices. We require these instructions as a minimum for a safe installation.

CUT HAZARD

Failure to follow this caution may result in personal injury. Sheet metal parts may have sharp edges or burrs. Use care and wear appropriate protective clothing, safety glasses and gloves when handling parts and servicing furnaces.

Wear safety glasses and work gloves. Have fire extinguisher available during start-up and adjustment procedures and service calls.

This is the safety-alert symbol  . When you see this symbol on the furnace and in instructions or manuals, be alert to the potential for personal injury.

. When you see this symbol on the furnace and in instructions or manuals, be alert to the potential for personal injury.

Understand the signal words DANGER, WARNING, and CAUTION. These words are used with the safety-alert symbol. DANGER identifies the most serious hazards which will result in severe personal injury or death. WARNING signifies a hazard which could result in personal injury or death. CAUTION is used to identify hazards which may result in minor personal injury or product and property damage. NOTE is used to highlight suggestions which will result in enhanced installation, reliability, or operation.

1.Use only with type of gas approved for this furnace. Refer to the furnace rating plate.

2.Install this furnace only in a location and position as specified in the “Location” section of these instructions.

2

INSTALLATION

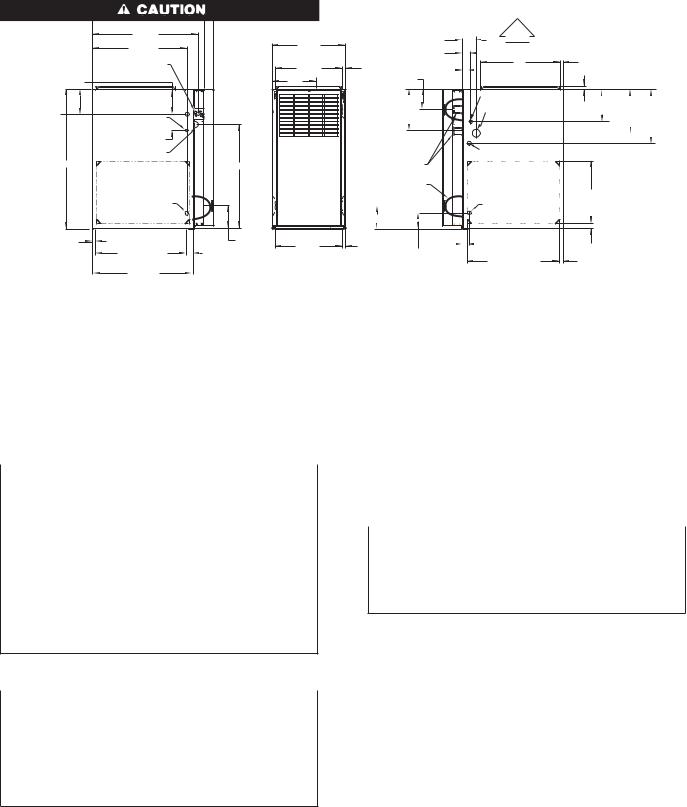

MINIMUM INCHES CLEARANCE TO COMBUSTIBLE CONSTRUCTION

DISTANCE MINIMALE EN POUCES AUX CONSTRUCTIONS COMBUSTIBLES

This forced air furnace is equipped for use with natural gas at altitudes 0-10,000 ft (0-3,050m).

An accessory kit, supplied by the manufacturer, shall be used to convert to propane gas use or may be required for some natural gas applications.

This furnace is for indoor installation in a building constructed on site.

This furnace may be installed on combustible flooring in alcove or closet at minimum clearance as indicated by the diagram from combusitble material.

This furnace may be used with a Type B-1 Vent and may be vented in common with other gas fired appliances.

Cette fournaise à air pulsé est équipée

pour utilisation avec gaz naturel et altitudes comprises entre 0-3,050m (0-10,000 pi).

Utiliser une trousse de conversion, fournie par le fabricant, pour passer au gaz propane ou pour certaines installations au gaz naturel.

Cette fournaise est prévue pour être installée dans un bâtiment construit sur place.

Cette fournaise peut être installée sur

un plancher combustible dans une alcôve ou dans un garde-robe en respectant le minimum d'espace libre des matériaux combustibles, tel qu´indiqué sur le diagramme.

Cette fournaise peut être utilisée avec un conduit d´évacuation de Type B-1 ou connectée au conduit ommun d 'autres appareils à gaz.

This furnace is approved for UPFLOW, DOWNFLOW, and HORIZONTAL installations.

Cette fournaise est approuvée pour l 'installation HORIZONTALE et la circulation d 'air VERS LE HAUT et VERS LE BAS.

Clearance arrows |

1" |

Les fléches de dégagement |

||

/TOPPLENUM CHAMBRED'AIR/DESSUS |

||||

R I |

E |

Ô |

||

do not change with |

|

|

ne change pas avec |

|

furnace orientation. |

l 'orientation de la fournaise. |

|

0" |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0" |

|

|

|

B |

A |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

E |

|

* |

|

||

A |

|

|

C |

|

|

|

|

|

|

|

|

|

|

|

D |

|

|

|

|||||

R |

|

|

K |

|

|

|

|

|

|

|

|

|

I |

|

TÈ |

|

|||||||

|

|

|

È |

|

|

|

|

|

|

|

|

|

S |

|

|

||||||||

|

|

|

|

R |

|

|

|

|

|

|

C |

|

SE |

C |

|

|

|

|

|

|

|

||

|

|

|

|

|

E |

|

|

|

|

A |

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

N |

|

|

I |

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

R |

|

A |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

U |

|

|

N |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

F |

|

R |

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

U |

|

|

|

|

T |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

O |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

F |

|

|

|

|

|

N |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

O |

T |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

F |

|

|

N |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

V |

|

S E |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

A |

|

|

|

R VI |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ENT |

R |

C |

|

|

|||

|

|

|

|

|

|

E |

|

|

|

F R |

|

|

|

|

E |

T I |

E |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

ID |

|

|

|

O |

|

|

|

|

E |

|

|

|||||||

|

|

|

|

S |

|

|

|

|

A |

|

|

N T |

|

|

|

|

N |

24" |

|||||

|

|

|

|

|

ÔTÉ |

|

|

|

|

V A |

|

|

|

|

|

|

|||||||

*0" |

|

|

C |

|

|

|

|

|

|

|

|

N T 3"MIN |

|

|

|

|

|

|

MIN |

||||

|

|

|

|

|

BOTTOM DESSOUS |

|

|

|

|

|

|

|

Ø |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Clearance in inches |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

" |

|

|

|

|

|

|

|

Dégagement (po). |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

† |

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Vent Clearance to combustibles:

For Single Wall vents 6 inches (6 po). For Type B-1 vent type 1 inch (1 po).

Dégagement de l´évent avec combustibles:

Pour conduit d´évacuation à paroi simple 6 po (6 inches). Pour conduit d´évacuation de Type B-1 1 po (1 inch).

MINIMUM INCHES CLEARANCE TO COMBUSTIBLE CONSTRUCTION

|

DOWNFLOW POSITIONS: |

† |

Installation on non-combusibible floors only. |

|

For Installation on combustible flooring only when installed on special base, Part No. KGASB0201ALL, |

|

Coil Assembly, Part No. CD5 or CK5, or Coil Casing, Part No. KCAKC. |

Ø |

18 inches front clearance required for alcove. |

*Indicates supply or return sides when furnace is in the horizontal position. Line contact only permissible between lines formed by intersections of the Top and two Sides of the furnace jacket, and building joists,

studs or framing.

DÉGAGEMENT MINIMUM EN POUCES AVEC ÉLÉMENTS

DE CONSTRUCTION COMBUSTIBLES

POUR LA POSITION COURANT DESCENDANT:

†Pour l´installation sur plancher non combustible seulement.

Pour l´installation sur un plancher combustible seulement quand on utilise la base spéciale, pièce

nº |

KGASB0201ALL, l´ensemble serpentin, pièce nº CD5 ou CK5, ou le carter de serpentin, pièce |

nº |

KCAKC. |

Ø Dans une alcôve, on doit maintenir un dégagement à l´avant de 18 po (450mm).

*La poistion indiquée concerne le côté d´entrée ou de retour quand la fournaise est dans la position horizontale.

Le contact n´est permis qu´entre les lignes formées par les intersections du dessus et des deux côtés de la cherrise de la fournaise et les solives, montant sous cadre de charpente.

327590-101 REV. C

A04123

→ Fig. 2—Clearances to Combustibles

3

→ Table 1—Dimensions (IN.)

|

|

D |

E |

F |

|

|

|

|

|

C.L. TOP AND |

FLUE |

|

|||

FURNACE |

A |

SUPPLY-AIR |

RETURN-AIR |

|

|||

BOTTOM |

COLLAR* |

SHIP WT. (LB) |

|||||

SIZE |

CABINET WIDTH |

WIDTH |

WIDTH |

||||

FLUE COLLAR |

(IN.) |

|

|||||

|

|

(IN.) |

(IN.) |

|

|||

|

|

(IN.) |

|

|

|||

|

|

|

|

|

|

||

045-08/024045 |

14-3/16 |

12-9/16 |

12-11/16 |

9-5/16 |

4 |

104 |

|

045-12/036045 |

14-3/16 |

12-9/16 |

12-11/16 |

9-5/16 |

4 |

107 |

|

070-08/024070 |

14-3/16 |

12-9/16 |

12-11/16 |

9-5/16 |

4 |

111 |

|

070-12/036070 |

14-3/16 |

12-9/16 |

12-11/16 |

9-5/16 |

4 |

115 |

|

070-16/048070 |

17-1/2 |

15-7/8 |

16 |

11-9/16 |

4 |

126 |

|

090-14/042090 |

17-1/2 |

15-7/8 |

16 |

11-9/16 |

4 |

127 |

|

090-16/048090 |

21 |

19-3/8 |

19-1/2 |

13-5/16 |

4 |

140 |

|

090-20/060090 |

21 |

19-3/8 |

19-1/2 |

13-5/16 |

4 |

146 |

|

110-12/036110 |

17-1/2 |

15-7/8 |

16 |

11-9/16 |

4 |

135 |

|

110-16/048110 |

21 |

19-3/8 |

19-1/2 |

13-5/16 |

4 |

146 |

|

110-22/066110 |

21 |

19-3/8 |

19-1/2 |

13-5/16 |

4 |

152 |

|

135-16/048135 |

21 |

19-3/8 |

19-1/2 |

13-5/16 |

4 |

149 |

|

135-22/066135 |

24-1/2 |

22-7/8 |

23 |

15-1/16 |

4 |

163 |

|

155-20/060155 |

24-1/2 |

22-7/8 |

23 |

15-1/16 |

4 |

170 |

|

|

|

|

|

|

|

|

* 5” or 6” vent connector may be required in some cases.

3.Provide adequate combustion and ventilation air to the furnace space as specified in “Air for Combustion and Ventilation” section.

4.Combustion products must be discharged outdoors. Connect this furnace to an approved vent system only, as specified in the “Venting” section of these instructions.

5.Never test for gas leaks with an open flame. Use a commercially available soap solution made specifically for the detection of leaks to check all connections, as specified in the “Gas Piping” section.

6.Always install furnace to operate within the furnace’s intended temperature-rise range with a duct system which has an external static pressure within the allowable range, as specified in the “Start-Up, Adjustments, and Safety Check” section. See furnace rating plate.

7.When a furnace is installed so that supply ducts carry air circulated by the furnace to areas outside the space containing the furnace, the return air shall also be handled by duct(s) sealed to the furnace casing and terminating outside the space containing the furnace. See “Air Ducts” section.

8.A gas-fired furnace for installation in a residential garage must be installed as specified in the warning box in the “Location” section.

→9. The furnace is not to be used for temporary heating of buildings or structures under construction. See page 7 caution box regarding the heating of buildings under construction.

10.These Multipoise Gas-Fired Furnaces are CSA (formerly A.G.A. and C.G.A.) design-certified for use with natural and propane gases (see furnace rating plate) and for installation in alcoves, attics, basements, closets, utility rooms, crawlspaces, and garages. The furnace is factory-shipped for use with natural gas. A CSA listed gas conversion kit is required to convert furnace for use with propane gas.

11.See Fig. 2 for required clearances to combustible construction.

12.Maintain a 1-in. clearance from combustible materials to supply air ductwork for a distance of 36 inches horizontally from the furnace. See NFPA 90B or local code for further requirements.

13.These furnaces SHALL NOT be installed directly on carpeting, tile, or any other combustible material other than wood flooring. In downflow installations, factory accessory floor base MUST be used when installed on combustible materials and wood flooring. Special base is not required when this furnace is installed on manufacturer’s Coil Assembly Part No. CD5 or CK5, or when Coil Box Part No. KCAKC is used. See Fig. 2 for clearance to combustible construction information.

INTRODUCTION

→ This Series 120/C 4–way multipoise Category I fan-assisted furnace is CSA design-certified. A Category I fan-assisted furnace is an appliance equipped with an integral mechanical means to either draw or force products of combustion through the combustion chamber and/or heat exchanger. The furnace is factoryshipped for use with natural gas. A CSA (A.G.A. and C.G.A.) listed gas conversion kit is required to convert furnace for use with propane gas. This furnace is not approved for installation in mobile homes, recreational vehicles, or outdoors.

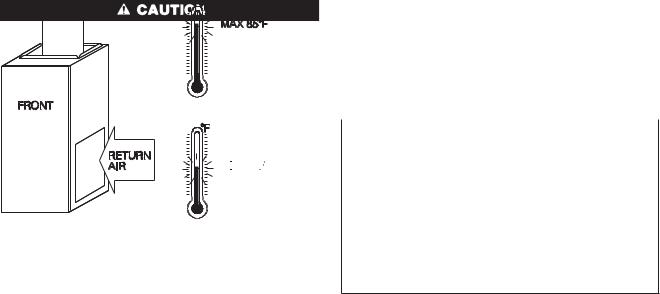

This furnace is designed for minimum continuous return-air temperature of 60°F db or intermittent operation down to 55°F db such as when used with a night setback thermostat. Return-air temperature must not exceed 85°F db. Failure to follow these return-air temperature limits may affect reliability of heat exchangers, motors, and controls. (See Fig. 3.)

For accessory installation details, refer to the applicable instruction literature.

NOTE: Remove all shipping brackets and materials before operating the furnace.

CODES AND STANDARDS

Follow all national and local codes and standards in addition to these instructions. The installation must comply with regulations of the serving gas supplier, local building, heating, plumbing, and other codes. In absence of local codes, the installation must comply with the national codes listed below and all authorities having jurisdiction.

4

60

60

A02055

Fig. 3—Return Air Temperature

In the United States and Canada, follow all codes and standards for the following:

Step 1—Safety

•US: National Fuel Gas Code (NFGC) NFPA 54–2002/ANSI Z223.1–2002 and the Installation Standards, Warm Air Heating and Air Conditioning Systems ANSI/NFPA 90B

→• CANADA: CSA B149.1-00 National Standard of Canada Natural Gas and Propane Installation Codes (NSCNGPIC)

Step 2—General Installation

•US: Current edition of the NFGC and the NFPA 90B. For copies, contact the National Fire Protection Association Inc., Batterymarch Park, Quincy, MA 02269 (www.NFPA.org); or for only the NFGC, contact the American Gas Association, 400 N. Capitol Street, N.W., Washington, DC 20001 (www.AGA.org).

•CANADA: NSCNGPIC. For a copy, contact Standard Sales, CSA International, 178 Rexdale Boulevard, Etobicoke (Toronto), Ontario, M9W 1R3 Canada

Step 3—Combustion and Ventilation Air

→• US: Section 8.3 of the NFGC, Air for Combustion and Ventilation

•CANADA: Part 7 of NSCNGPIC, Venting Systems and Air Supply for Appliances

Step 4—Duct Systems

→• US and CANADA: Air Conditioning Contractors Association (ACCA) Manual D, Sheet Metal and Air Conditioning Contractors National Association (SMACNA), or American Society of Heating, Refrigeration, and Air Conditioning Engineers (ASHRAE) 2001 Fundamentals Handbook Chapter 34 or 2000 HVAC Systems and Equipment Handbook Chapters 9 and 16.

Step 5—Acoustical Lining and Fibrous Glass Duct

•US and CANADA: current edition of SMACNA and NFPA 90B as tested by UL Standard 181 for Class I Rigid Air Ducts

Step 6—Gas Piping and Gas Pipe Pressure Testing

•US: NFGC; chapters 5, 6, 7, and 12 and National Plumbing Codes

•CANADA: NSCNGPIC Parts 3, 4, and 5, and Appendices A, B, E and H.

Step 7—Electrical Connections

•US: National Electrical Code (NEC) ANSI/NFPA 70–2002

•CANADA: Canadian Electrical Code CSA C22.1

→Step 8—Venting

•US: NFGC; chapters 10 and 13

•CANADA: NSCNGPIC Part 7 and Appendix C

ELECTROSTATIC DISCHARGE (ESD) PRECAUTIONS

PROCEDURE

→FURNACE RELIABILITY HAZARD

Improper installation or service of furnace may cause premature furnace component failure.

Electrostatic discharge can affect electronic components. Take precautions during furnace installation and servicing to protect the furnace electronic control. Precautions will prevent electrostatic discharges from personnel and hand tools which are held during the procedure. These precautions will help to avoid exposing the control to electrostatic discharge by putting the furnace, the control, and the person at the same electrostatic potential.

1.Disconnect all power to the furnace. Multiple disconnects may be required. DO NOT TOUCH THE CONTROL OR ANY WIRE CONNECTED TO THE CONTROL PRIOR TO DISCHARGING YOUR BODY’S ELECTROSTATIC CHARGE TO GROUND.

2.Firmly touch the clean, unpainted, metal surface of the furnace chassis which is close to the control. Tools held in a person’s hand during grounding will be satisfactorily discharged.

3.After touching the chassis, you may proceed to service the control or connecting wires as long as you do nothing to recharge your body with static electricity (for example; DO NOT move or shuffle your feet, do not touch ungrounded objects, etc.).

4.If you touch ungrounded objects (and recharge your body with static electricity), firmly touch a clean, unpainted metal surface of the furnace again before touching control or wires.

5.Use this procedure for installed and uninstalled (ungrounded) furnaces.

6.Before removing a new control from its container, discharge your body’s electrostatic charge to ground to protect the control from damage. If the control is to be installed in a furnace, follow items 1 through 4 before bringing the control or yourself in contact with the furnace. Put all used and new controls into containers before touching ungrounded objects.

7.An ESD service kit (available from commercial sources) may also be used to prevent ESD damage.

LOCATION

GENERAL

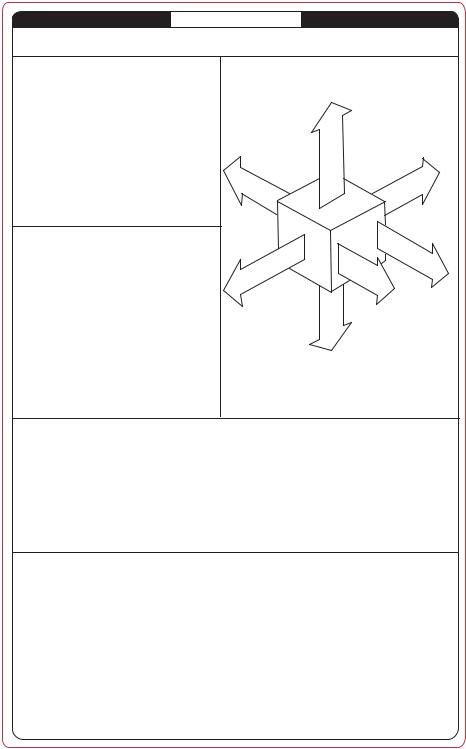

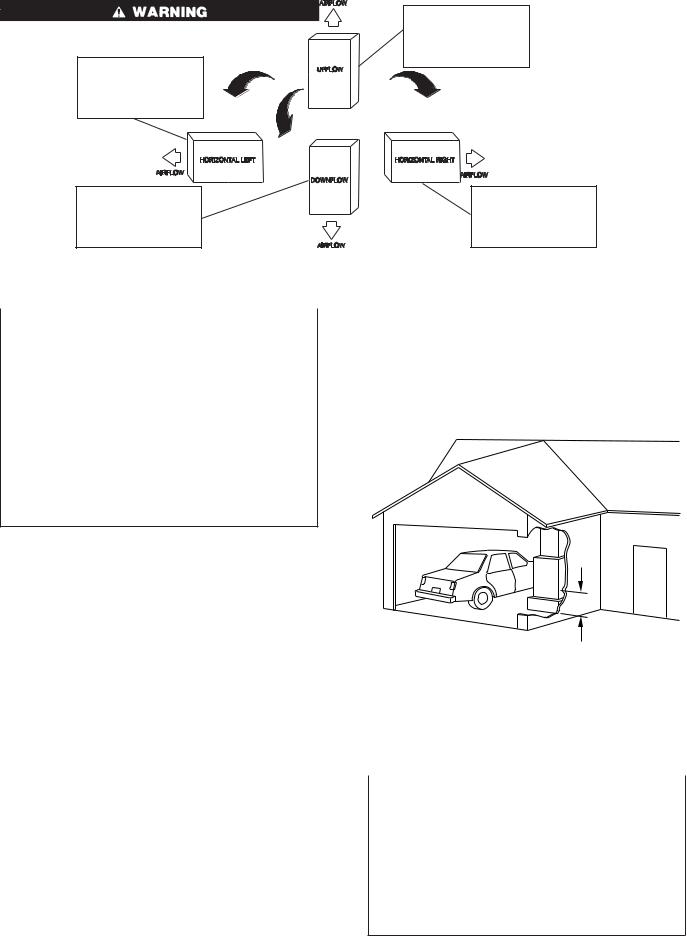

Some assembly and modifications are required when used in any of the four applications shown in Fig. 4.

This furnace must:

•be installed so the electrical components are protected from water.

•not be installed directly on any combustible material other than wood flooring (refer to SAFETY CONSIDERATIONS).

•be located close to the chimney or vent and attached to an air distribution system. Refer to Air Ducts section.

•be provided ample space for servicing and cleaning. Always comply with minimum fire protection clearances shown on the furnace clearance to combustible construction label.

5

THE BLOWER IS LOCATED TO THE RIGHT OF THE BURNER SECTION, AND AIR CONDITIONED AIR IS DISCHARGED TO THE LEFT.

THE BLOWER IS

LOCATED ABOVE THE BURNER SECTION, AND CONDITIONED AIR IS DISCHARGED DOWNWARD

THE BLOWER IS

LOCATED BELOW THE

BURNER SECTION, AND

CONDITIONED AIR IS

DISCHARGED UPWARD.

THE BLOWER IS

LOCATED TO THE LEFT

OF THE BURNER SECTION,

AND CONDITIONED AIR IS

DISCHARGED TO THE RIGHT.

A02097

Fig. 4—Multipoise Orientations

→CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in personal injury or death, and unit component damage.

Corrosive or contaminated air may cause failure of parts containing flue gas, which could leak into the living space. Air for combustion must not be contaminated by halogen compounds, which include fluoride, chloride, bromide, and iodide. These elements can corrode heat exchangers and shorten furnace life. Air contaminants are found in aerosol sprays, detergents, bleaches, cleaning solvents, salts, air fresheners, and other household products. Do not install furnace in a corrosive or contaminated atmosphere. Make sure all combustion and circulating air requirements are met, in addition to all local codes and ordinances.

→The following types of furnace installations may require OUTDOOR AIR for combustion due to chemical exposures:

•Commercial buildings

•Buildings with indoor pools

•Laundry rooms

•Hobby or craft rooms, and

•Chemical storage areas

→If air is exposed to the following substances, it should not be used for combustion air, and outdoor air may be required for combustion:

•Permanent wave solutions

•Chlorinated waxes and cleaners

•Chlorine based swimming pool chemicals

•Water softening chemicals

•De-icing salts or chemicals

•Carbon tetrachloride

•Halogen type refrigerants

•Cleaning solvents (such as perchloroethylene)

•Printing inks, paint removers, varnishes, etc.

•Hydrochloric acid

•Cements and glues

•Antistatic fabric softeners for clothes dryers

•Masonry acid washing materials

All fuel-burning equipment must be supplied with air for fuel combustion. Sufficient air must be provided to avoid negative pressure in the equipment room or space. A positive seal must be made between the furnace cabinet and the return-air duct to prevent pulling air from the burner area and from draft safeguard opening.

18-IN. MINIMUM

TO BURNERS

A93044

Fig. 5—Installation in a Garage

FIRE, INJURY OR DEATH HAZARD

Improper location or inadequate protection could result in fire or explosion.

When the furnace is installed in a residential garage, the burners and ignition sources must be located at least 18 inches above the floor. The furnace must be located or protected to avoid damage by vehicles. When the furnace is installed in a public garage, airplane hangar, or other building having a hazardous atmosphere, the furnace must be installed in accordance with the NFGC or NSCNGPIC. (See Fig. 5.)

6

→PERSONAL INJURY AND/OR PROPERTY DAMAGE HAZARD

Improper use or installation of this furnace may cause premature furnace component failure.

This gas furnace may be used for heating buildings under construction provided that:

-The furnace is permanently installed with all electrical wiring, piping, venting and ducting installed according to these installation instructions. A return air duct is provided, sealed to the furnace casing, and terminated outside the space containing the furnace. This prevents a negative pressure condition as created by the circulating air blower, causing a flame rollout and/or drawing combustion products into the

structure.

-The furnace is controlled by a thermostat. It may not be ″hot wired″ to provide heat continuously to the structure without thermostatic control.

-Clean outside air is provided for combustion. This is to minimize the corrosive effects of adhesives, sealers and other construction materials. It also prevents the entrainment of drywall dust into combustion air, which can cause fouling and plugging of furnace components.

-The temperature of the return air to the furnace is maintained between 55°F (13°C) and 80°F (27°C), with no evening setback or shutdown. The use of the furnace while the structure is under construction is deemed to be intermittent operation per our installation instructions.

-The air temperature rise is within the rated rise range on the furnace rating plate, and the firing rate has been set to the nameplate value.

-The filters used to clean the circulating air during the construction process must be either changed or thoroughly cleaned prior to occupancy.

-The furnace, ductwork and filters are cleaned as necessary to remove drywall dust and construction debris from all HVAC system components after construction is completed. -Verify proper furnace operating conditions including ignition, gas input rate, air temperature rise, and venting according to these installation instructions.

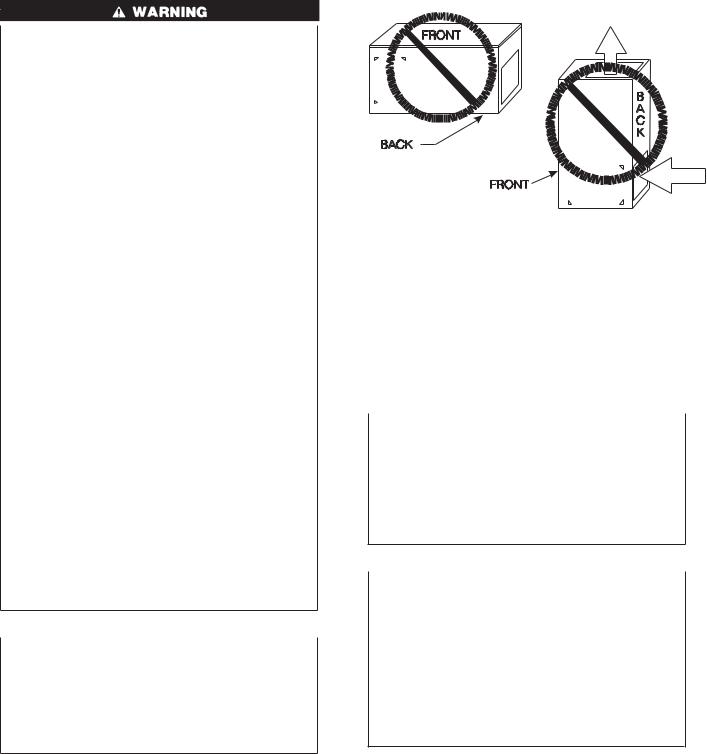

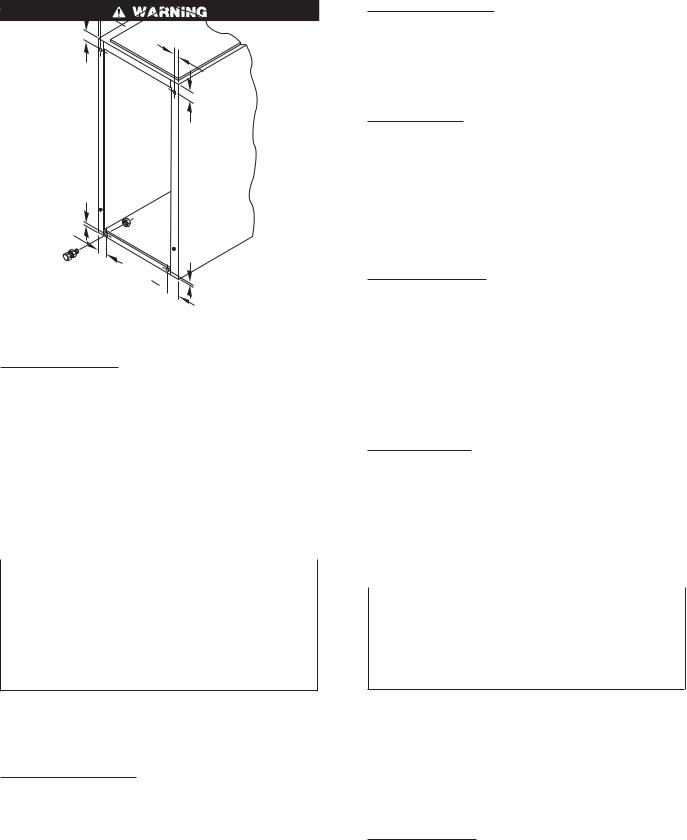

→FIRE, INJURY OR DEATH HAZARD

Failure to follow this warning could result in unsafe furnace operation.

DO NOT install the furnace on its back or hang furnace with control compartment facing downward. Safety control operation will be adversely affected. Never connect return-air ducts to back of furnace. (See Fig. 6.)

LOCATION RELATIVE TO COOLING EQUIPMENT

The cooling coil must be installed parallel with, or on the downstream side of the unit to avoid condensation in the heat exchangers. When installed parallel with the furnace, dampers or other flow control must prevent chilled air from entering the furnace. If the dampers are manually operated, they must be equipped with means to prevent operation of either unit unless the damper is in the full-heat or full-cool position.

A02054

Fig. 6—Prohibit Installation on Back

AIR FOR COMBUSTION AND VENTILATION

Provisions for adequate combustion, ventilation, and dilution air must be provided in accordance with:

•U.S. installations: Section 8.3 of the NFGC, Air for Combustion and Ventilation, and applicable provisions of the local building codes.

•Canadian installations: Part 7 of the NSCNGPIC, Venting Systems and Air Supply for Appliances, and all authorities having jurisdiction.

→FURNACE CORROSION HAZARD

Failure to follow this caution may result in furnace damage. Air for combustion must not be contaminated by halogen compounds, which include fluoride, chloride, bromide, and iodide. These elements can corrode heat exchangers and shorten furnace life. Air contaminants are found in aerosol sprays, detergents, bleaches, cleaning solvents, salts, air fresheners, and other household products.

→CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in personal injury or death.

The operation of exhaust fans, kitchen ventilation fans, clothes dryers, attic exhaust fans or fireplaces could create a NEGATIVE PRESSURE CONDITION at the furnace. Make-up air MUST be provided for the ventilation devices, in addition to that required by the furnace. Refer to Carbon Monoxide Hazard warning in venting section of these instructions to determine if an adequate amount of make-up air is available.

→The requirements for combustion and ventilation air depend upon whether or not the furnace is located in a space having a volume of at least 50 cubic feet per 1,000 Btuh input rating for all gas appliances installed in the space.

•Spaces having less than 50 cubic feet per 1,000 Btuh require the OUTDOOR COMBUSTION AIR METHOD.

•Spaces having at least 50 cubic feet per 1,000 Btuh may use the

INDOOR COMBUSTION AIR, STANDARD or KNOWNAIR INFILTRATION METHOD.

7

→Table 2–Minimum Free Area Required for Each Combustion Air Opening or Duct to Outdoors

|

TWO HORIZONTAL DUCTS |

SINGLE DUCT OR OPENING |

TWO OPENINGS OR VERTICAL DUCTS |

||||

FURNACE |

(1 SQ. IN./2,000 BTUH) (1,100 SQ. MM/KW) |

(1 SQ. IN./3,000 BTUH) (734 SQ. MM/KW) |

(1 SQ. IN./4,000 BTUH) (550 SQ. MM/KW) |

||||

INPUT |

Free Area of |

Round Duct |

Free Area of |

Round Duct |

Free Area of |

Round Duct |

|

(BTUH) |

Opening and Duct |

Opening and Duct |

Opening and Duct |

||||

(in. Dia) |

(in. Dia) |

(In. Dia) |

|||||

|

(Sq. In.) |

(sq In.) |

(Sq In.) |

||||

|

|

|

|

||||

|

|

|

|

|

|

|

|

44,000 |

22 |

6 |

14.7 |

5 |

11 |

4 |

|

66,000 |

33 |

7 |

22 |

6 |

16.5 |

5 |

|

88,000 |

44 |

8 |

29.3 |

7 |

22 |

6 |

|

110,000 |

55 |

9 |

36.7 |

7 |

27.5 |

6 |

|

132,000 |

66 |

10 |

44 |

8 |

33 |

7 |

|

154,000 |

77 |

10 |

51.3 |

9 |

38.5 |

8 |

|

|

|

|

|

|

|

|

|

EXAMPLES: Determining Free Area

FURNACE |

|

WATER HEATER |

|

TOTAL INPUT |

|

|

|

110,000 |

+ |

30,000 |

= |

(140,000 divided by 4,000) |

= |

35.0 |

Sq. In. for each two Vertical Ducts or Openings |

66,000 |

+ |

40,000 |

= |

(106,000 divided by 3,000) |

= |

35.3 |

Sq. In. for a Single Duct or Opening |

88,000 |

+ |

30,000 |

= |

(118,000 divided by 2,000) |

= |

59.0 |

Sq. In. for each of two Horizontal Ducts |

|

|

|

|

|

|

|

|

→ Table 3–Minimum Space Volumes for 100% Combustion, Ventilation, and

Dilution from Indoors

|

OTHER THAN FAN-ASSISTED TOTAL |

|

|

|

FAN-ASSISTED TOTAL |

|

|

|||

ACH |

(1,000’S BTUH GAS INPUT RATE) |

|

|

(1,000’S BTUH GAS INPUT RATE) |

|

|||||

30 |

40 |

50 |

44 |

66 |

|

88 |

110 |

132 |

154 |

|

|

|

|||||||||

|

|

|

|

Space Volume (ft3) |

|

|

|

|

|

|

0.60 |

1,050 |

1,400 |

1,750 |

1,100 |

1,650 |

|

2,200 |

2,750 |

3,300 |

3,850 |

0.50 |

1,260 |

1,680 |

2,100 |

1,320 |

1,980 |

|

2,640 |

3,300 |

3,960 |

4,620 |

0.40 |

1,575 |

2,100 |

2,625 |

1,650 |

2,475 |

|

3,300 |

4,125 |

4,950 |

5,775 |

0.30 |

2,100 |

2,800 |

3,500 |

2,200 |

3,300 |

|

4,400 |

5,500 |

6,600 |

7,700 |

0.20 |

3,150 |

4,200 |

5,250 |

3,300 |

4,950 |

|

6,600 |

8,250 |

9,900 |

11,550 |

0.10 |

6,300 |

8,400 |

10,500 |

6,600 |

9,900 |

|

13,200 |

16,500 |

19,800 |

23,100 |

0.00 |

NP |

NP |

NP |

NP |

NP |

|

NP |

NP |

NP |

NP |

|

|

|

|

|

|

|

|

|

|

|

NP = Not Permitted

→Outdoor Combustion Air Method

1.Provide the space with sufficient air for proper combustion, ventilation, and dilution of flue gases using permanent horizontal or vertical duct(s) or opening(s) directly communicating with the outdoors or spaces that freely communicate with the outdoors.

2.Fig. 7 illustrates how to provide TWO OUTDOOR OPENINGS, one inlet and one outlet combustion and ventilation air opening, to the outdoors.

a.One opening MUST commence within 12″ (300 mm) of

the ceiling and the second opening MUST commence within 12″ (300 mm) of the floor.

b.Size openings and ducts per Fig. 7 and Table 2.

c.TWO HORIZONTAL DUCTS require 1 square inch of free area per 2,000 Btuh (1,100 mm2/kW) of combined input for all gas appliances in the space per Fig. 7 and Table 2.

d.TWO OPENINGS OR VERTICAL DUCTS require 1 square inch of free area per 4,000 Btuh (550 mm2/kW) for combined input of all gas appliances in the space per Fig. 7 and Table 2.

3.ONE OUTDOOR OPENING requires:

a.1 square inch of free area per 3,000 Btuh (734 mm2/kW) for combined input of all gas appliances in the space per Table 2 and

b.Not less than the sum of the areas of all vent connectors in the space.

The opening shall commence within 12″ (300 mm) of the ceiling. Appliances in the space shall have clearances of at least 1″ (25 mm) from the sides and back and 6″ (150 mm) from the front. The opening shall directly communicate with the outdoors or shall communicate through a vertical or horizontal duct to the outdoors or spaces (crawl or attic) that freely communicate with the outdoors.

Indoor Combustion Air© NFPA & AGA

→Standard and Known-Air-Infiltration Rate Methods

Indoor air is permitted for combustion, ventilation, and dilution, if the Standard or Known-Air-Infiltration Method is used.

CARBON MONOXIDE POISONING HAZARD

Failure to supply outdoor air via grilles or ducts could result in death and/or personal injury.

Many homes require air to be supplied from outdoors for furnace combustion, ventilation, and dilution of flue gases. The furnace combustion air supply must be provided in accordance with this instruction manual.

8

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 SQ IN. |

|||||||

|

|

|

|

|

|

|

|

DUCTS |

|

|

|

|

|

|

PER 4000 |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BTUH* |

||||||||

|

|

|

|

|

|

|

|

TO |

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OUTDOORS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

12″ MAX |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

D |

|

|

|

|

|

|

12″ |

|

|||||||||

1 SQ IN. |

|

|

|

|

|

B |

CIRCULATING DUCTSAIR |

VENT |

|

|

|

|

|

|

MAX |

|||||||

PER 2000 |

|

|

|

|

|

|

THROUGH |

|

|

F |

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

BTUH* |

|

|

|

ROOF |

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 SQ IN. |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PER |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

4000 |

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BTUH* |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OUTDOORS |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

DUCTS |

|

|

FRONT AIR BE |

|

|

|

|

|

|

|

|

|

||||||||||

TO |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

OUTDOORS |

|

|

ATLEAST 3 IN. |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

BTUH* |

|

|

|

|

|

|

|

CLEARANCEIN COMBUSTIONOF OPENINGSSHALL |

|

|

|

|

|

|

|

|

|

12″ |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 SQ IN. |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PER |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

4000 |

|

||||||||

1 SQ IN. |

|

|

|

|

|

|

E |

|

|

G |

|

|

|

BTUH* |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

PER 2000 |

|

|

|

|

A |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

12″ MAX |

|

|

|

|

|

C |

|

|

|

|

|

|

|

MAX |

||||||||

|

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

12″ |

MAX |

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

CIRCULATING AIR DUCTS |

|

|

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

DUCT |

|

|

1 SQ IN. |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

TO |

|

|

PER 4000 |

||||||||

|

|

|

|

|

|

|

|

|

OUTDOORS |

|

|

BTUH* |

||||||||||

*Minimum dimensions of 3 in.

NOTE: Use any of the following combinations of openings:

A & B C & D D & E F & G

A03174

→ Fig. 7—Air for Combustion, Ventilation and

Dilution for Outdoors

The Standard Method:

1.The space has no less volume than 50 cubic feet per 1,000 Btuh of the maximum input ratings for all gas appliances installed in the space and

2.The air infiltration rate is not known to be less than 0.40 air changes per hour (ACH).

The Known Air Infiltration Rate Method shall be used, if the infiltration rate is known to be:

1.Less than 0.40 ACH and

2.Equal to or greater than 0.10 ACH

Infiltration rates greater than 0.60 ACH shall not be used. The minimum required volume of the space varies with the number of ACH and shall be determined per Table 3 or Equations 1 and 2. Determine the minimum required volume for each appliance in the space and add the volumes together to get the total minimum required volume for the space.

Table 3-Minimum Space Volumes were determined by using the following equations from the National Fuel Gas Code ANSI Z223.1-2002/NFPA 54-2002,8.3.2.2:

1.For other than fan-assisted appliances, such as a draft hood-equipped water heater:

Volume |

= |

21ft3 |

I other |

Other |

|

ACH |

1000 Btu/hr |

A04002

CIRCULATING AIR |

VENT THROUGH ROOF |

|||

DUCTS |

||||

|

|

|

||

|

AIR |

|

12" MAX |

|

|

FRONT OF COMBUSTION |

SHALL BE AT LEAST3 IN. |

1 SQ IN. |

|

|

PER 1000 |

|||

|

BTUH* IN DOOR |

|||

|

OR WALL |

|||

INTERIOR |

UNCONFINED |

|||

SPACE |

||||

HEATED |

||||

SPACE |

|

|||

|

6" MIN |

|||

|

(FRONT)† |

|||

|

CLEARANCE IN |

OPENINGS |

||

|

1 SQ IN. |

|||

|

PER 1000 |

|||

|

BTUH* IN DOOR |

|||

|

OR WALL |

|||

|

|

|||

|

|

|

12" MAX |

|

CIRCULATING AIR DUCTS

*Minimum opening size is 100 sq in. with minimum dimensions of 3 in.

† Minimum of 3 in.. when type-B1 vent is used.

A03175

→ Fig. 8—Air for Combustion, Ventilation and

Dilution from Indoors

2. For fan-assisted appliances such as this furnace:

Volume |

= |

15ft3 |

I fan |

Fan |

|

ACH |

1000 Btu/hr |

A04003

If:

Iother = combined input of all other than fan-assisted appliances in Btu/hr

Ifan = combined input of all fan-assisted appliances in Btu/hr

ACH = air changes per hour (ACH shall not exceed 0.60.)

→The following requirements apply to the Standard Method and to the Known Air Infiltration Rate Method.

1.Adjoining rooms can be considered part of a space if:

a.There are no closable doors between rooms.

b.Combining spaces on same floor level. Each opening shall have free area of at least 1 in.2/1,000 Btuh (2,000 mm2/kW) of the total input rating of all gas appliances in the space,

but not less than 100 in.2 (0.06 m2). One opening shall commence within 12″ (300 mm) of the ceiling and the second opening shall commence within 12″ (300 mm) of the floor. The minimum dimension of air openings shall be at least 3 in. (80 mm). (See Fig. 8.)

9

c.Combining space on different floor levels. The volumes of spaces on different floor levels shall be considered as communicating spaces if connected by one or more permanent openings in doors or floors having free area of at least 2 in.2/1,000 Btuh (4,400 mm2/kW) of total input rating of all gas appliances.

2.An attic or crawlspace may be considered a space that freely communicates with the outdoors provided there are adequate permanent ventilation openings directly to outdoors having free area of at least 1-in.2/4,000 Btuh of total input rating for all gas appliances in the space.

3.In spaces that use the Indoor Combustion Air Method, infiltration should be adequate to provide air for combustion, permanent ventilation and dilution of flue gases. However, in buildings with unusually tight construction, additional air MUST be provided using the methods described in the

Outdoor Combustion Air Method section.

Unusually tight construction is defined as Construction with:

a.Walls and ceilings exposed to the outdoors have a continuous, sealed vapor barrier. Openings are gasketed or sealed and

b.Doors and openable windows are weatherstripped and

c.Other openings are caulked or sealed. These include joints around window and door frames, between sole plates and floors, between wall-ceiling joints, between wall panels, at penetrations for plumbing, electrical and gas lines, etc.

→Combination of Indoor and Outdoor Air

1.Indoor openings shall comply with the Indoor Combustion Air Method below and,

2.Outdoor openings shall be located as required in the Outdoor Combustion Air Method mentioned previously and,

3.Outdoor openings shall be sized as follows:

a.Calculate the Ratio of all Indoor Space volume divided by required volume for Indoor Combustion Air Method below.

b.Outdoor opening size reduction Factor is 1 minus the Ratio in a. above.

c.Minimum size of Outdoor openings shall be the size required in Outdoor Combustion Air Method above multiplied by reduction Factor in b. above. The minimum dimension of air openings shall be not less than 3 in. (80 mm).

INSTALLATION

UPFLOW INSTALLATION

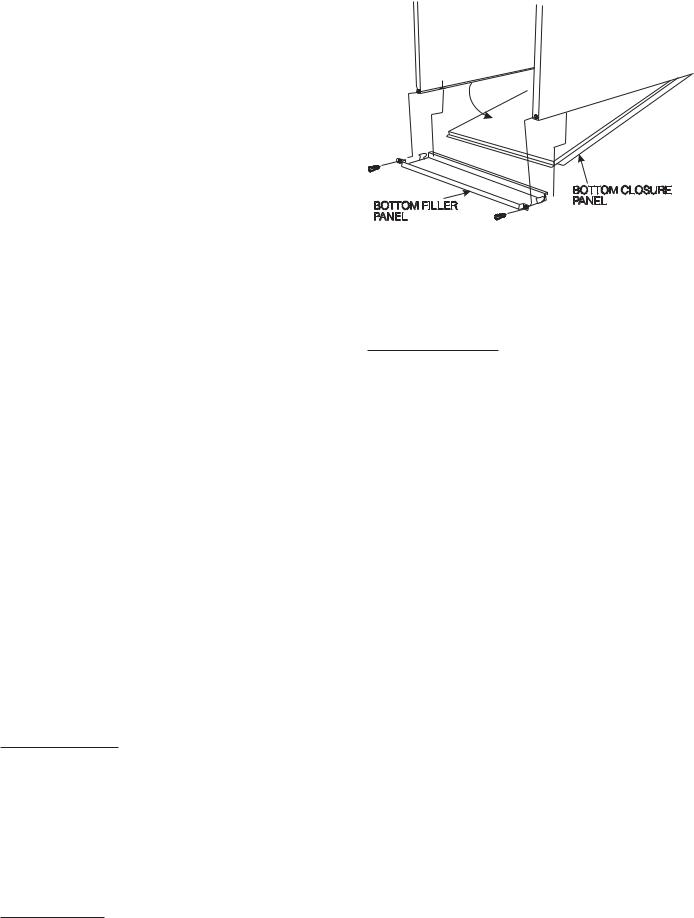

Bottom Return Air Inlet

These furnaces are shipped with bottom closure panel installed in bottom return-air opening. Remove and discard this panel when bottom return air is used. To remove bottom closure panel, perform the following:

1.Tilt or raise furnace and remove 2 screws holding bottom filler panel. (See Fig. 9.)

2.Rotate bottom filler panel downward to release holding tabs.

3.Remove bottom closure panel.

4.Reinstall bottom filler panel and screws.

Side Return Air Inlet

These furnaces are shipped with bottom closure panel installed in bottom return-air opening. This panel MUST be in place when only side return air is used.

A02098

Fig. 9—Removing Bottom Closure Panel

NOTE: Side return-air openings can be used in UPFLOW and most HORIZONTAL configurations. Do not use side return-air openings in DOWNFLOW configuration.

Leveling Legs (If Desired)

In upflow position with side return inlet(s), leveling legs may be used. (See Fig. 10.) Install field-supplied, 5/16 X 1-1/2 in. (max) corrosion-resistant machine bolts, washers and nuts.

NOTE: Bottom closure must be used when leveling legs are used. It may be necessary to remove and reinstall bottom closure panel to install leveling legs. To remove bottom closure panel, see Item 1. in Bottom Return Air Inlet section.

To install leveling legs:

1.Position furnace on its back. Locate and drill a hole in each bottom corner of furnace. (See Fig. 10.)

2.For each leg, install nut on bolt and then install bolt and nut in hole. (Install flat washer if desired.)

3.Install another nut on other side of furnace base. (Install flat washer if desired.)

4.Adjust outside nut to provide desired height, and tighten inside nut to secure arrangement.

5.Reinstall bottom closure panel if removed.

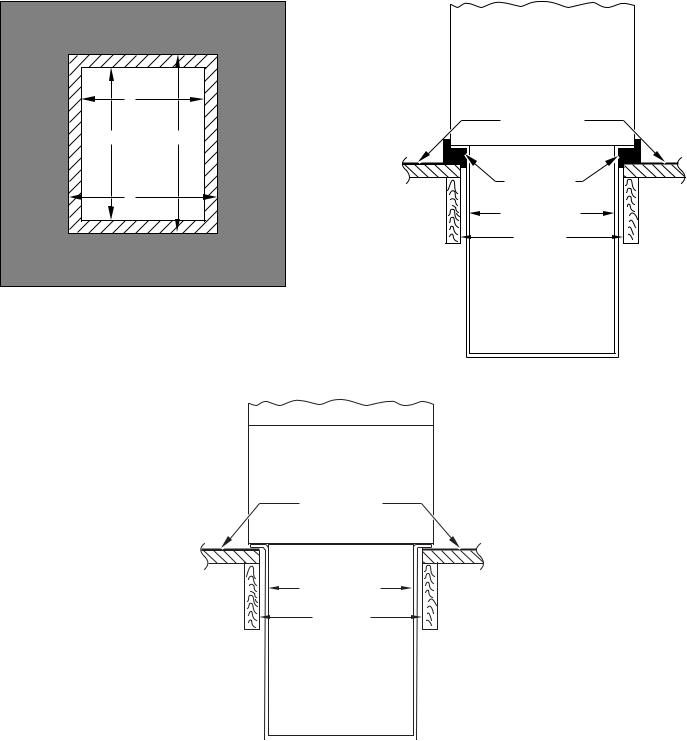

DOWNFLOW INSTALLATION

NOTE: For downflow applications, this furnace is approved for use on combustible flooring when any one of the following 3 accessories are used:

•Special Base, KGASB

•Cased Coil Assembly Part No. CD5 or CK5

•Coil Box Part No. KCAKC

1.Determine application being installed from Table 3.

2.Construct hole in floor per Table 3 and Fig. 11.

3.Construct plenum to dimensions specified in Table 3 and Fig.

4.If downflow subbase, KGASB is used, install as shown in Fig.

12.If Coil Assembly Part No. CD5 or CK5 or Coil Box Part No. KCAKC is used, install as shown in Fig. 13.

NOTE: It is recommended that the perforated supply-air duct flanges be completely folded over or removed from furnace when installing the furnace on a factory-supplied cased coil or coil box. To remove the supply-air duct flange, use wide duct pliers or hand seamers to bend flange back and forth until it breaks off. Be careful of sharp edges. (See Fig. 14.)

10

5⁄16″

5⁄16″

1 3⁄4″

1 3⁄4″

5⁄16″

5⁄16″

1 3⁄4″

1 3⁄4″

A02071

Fig. 10—Leveling Legs

Bottom Return Air Inlet

These furnaces are shipped with bottom closure panel installed in bottom return-air opening. Remove and discard this panel when bottom return air is used. To remove bottom closure panel, perform the following:

1.Tilt or raise furnace and remove 2 screws holding bottom filler panel. (See Fig. 9.)

2.Rotate bottom filler panel downward to release holding tabs.

3.Remove bottom closure panel.

4.Reinstall bottom filler panel and screws.

HORIZONTAL INSTALLATION

→FIRE, EXPLOSION, AND CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in dangerous operation, serious injury, death or property damage.

Do not install the furnace on its back or hang furnace with control compartment facing downward. Safety control operation will be adversely affected. Never connect return-air ducts to the back of the furnace.

The furnace can be installed horizontally in an attic or crawl space on either the left-hand (LH) or right-hand (RH) side. The furnace can be hung from floor joists, rafters or trusses or installed on a non-combustible platform, blocks, bricks or pad.

Suspended Furnace Support

The furnace may be supported under each end with threaded rod, angle iron or metal plumber’s strap as shown. (See Fig. 15 and 16.) Secure angle iron to bottom of furnace as shown. Heavy-gauge sheet metal straps (plumber’s straps) may be used to suspend the furnace from each bottom corner. To prevent screws from pulling out, use 2 #8 x ¾-in. screws into the side and 2 #8 x ¾-in. screws in the bottom of the furnace casing for each strap. (See Fig. 15 and 16.)

→If the screws are attached to ONLY the furnace sides and not the bottom, the straps must be vertical against the furnace sides and not pull away from the furnace sides, so that the strap attachment screws are not in tension (are loaded in shear) for reliable support.

Platform Furnace Support

Construct working platform at location where all required furnace clearances are met. (See Fig. 2 and 17.) For furnaces with 1-in. clearance requirement on side, set furnace on non-combustible blocks, bricks or angle iron. For crawlspace installations, if the furnace is not suspended from the floor joists, the ground underneath furnace must be level and the furnace set on blocks or bricks.

Roll-Out Protection

Provide a minimum 17-3/4″ X 22″ piece of sheet metal for flame roll-out protection in front of burner area for furnaces closer than 12 inches above the combustible deck or suspended furnaces closer than 12-in. to joists. The sheet metal MUST extend underneath the furnace casing by 1 in. with the door removed.

The bottom closure panel on furnaces of widths 17-1/2 in. and larger may be used for flame roll-out protection when bottom of furnace is used for return air connection. See Fig. 17 for proper orientation of roll-out shield.

Bottom Return Air Inlet

These furnaces are shipped with bottom closure panel installed in bottom return-air opening. Remove and discard this panel when bottom return air is used. To remove bottom closure panel, perform the following:

1.Tilt or raise furnace and remove 2 screws holding bottom filler panel. (See Fig. 9.)

2.Rotate bottom filler panel downward to release holding tabs.

3.Remove bottom closure panel.

4.Reinstall bottom filler panel and screws.

Side Return Air Inlet

These furnaces are shipped with bottom closure panel installed in bottom return-air opening. This panel MUST be in place when side return air inlet(s) is used without a bottom return air linlet.

Not all horizontal furnaces are approved for side return air connections (See Fig. 20.)

FILTER ARRANGEMENT

FIRE, CARBON MONOXIDE AND POISONING HAZARD

Failure to follow this warning could result in fire, personal injury, or death.

Never operate a furnace without a filter or with filter access door removed.

There are no provisions for an internal filter rack in these furnaces. A field-supplied accessory external filter rack is required.

This furnace requires KGAFR0301ALL 1″ external filter rack or a suitable field-supplied substitute, such as the Media Cabinet.

Refer to the instructions supplied with external filter rack for assembly and installation options.

AIR DUCTS

General Requirements

The duct system should be designed and sized according to accepted national standards such as those published by: Air Conditioning Contractors Association (ACCA), Sheet Metal and Air Conditioning Contractors National Association (SMACNA) or American Society of Heating, Refrigerating and Air Conditioning Engineers (ASHRAE) or consult The Air Systems Design Guidelines reference tables available from your local distributor. The duct system should be sized to handle the required system design

11

Table 4—Opening Dimensions (In.)

FURNACE |

|

PLENUM OPENING |

FLOOR OPENING |

|||

CASING |

APPLICATION |

|

|

|

|

|

A |

B |

C |

D |

|||

WIDTH |

|

|||||

|