Brother MA4-B972C Manual

CONTENTS

1. |

Specification ··· ··· ···· ·· ···· ···· ··· ·· ·· ······ ······ ······· ·· ···· ................................ |

|

|

|

|

|

·.. ......... ............ ............ |

1 |

||||||||||||||||||||

2. |

}.'eatures ····························································. ·... |

······················. · |

... |

·. ··················.. |

· · · · · · · · ·. · · |

2 |

||||||||||||||||||||||

:~. |

Operation······························································································································ |

3 |

||||||||||||||||||||||||||

A) |

Sc\\·ing Speed· .. ··· .. ·· .. ············· .... |

|

·· .. |

·..... |

··· ... |

··· ... ·................. |

|

··· .. |

|

·· .. |

·.... |

|

·· ............... |

|

····· |

............ |

|

3 |

||||||||||

B) |

:\Iotor, motor pu1Jey and belt ......... |

|

|

·....... |

|

···· ... |

··· ·.. ·....................... |

|

|

|

|

·............................. |

|

|

|

...... |

· |

·· |

3 |

|||||||||

C) |

Setting up |

·........ |

|

·.... |

·... |

·.. |

····· ··..... |

|

·.... |

|

··.... |

··........ |

|

··· .............. |

|

·...... |

|

·.... |

... |

· |

·... .. .. .. |

.. .... |

.. ............ ... |

|

|

3 |

||

D) Oiling, draining and maintenance |

..... |

|

.... .. |

.. .. |

.. .. |

.. ... ...... |

...... |

...... .... |

|

.. |

.. .......... |

|

.... |

.. ...... |

...... ...... ... |

|

|

4 |

||||||||||

I~) |

1\eedle cooler device |

........................... |

|

|

|

|

|

|

.............................................................................. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5 |

||||

I•') |

l\Iachine operating direction······· .. |

··· ............ |

|

|

···· ............................... |

|

|

|

|

... |

· |

·................................ |

|

|

|

|

6 |

|||||||||||

(;) |

Installing |

needles .......... |

|

·· ..... |

|

·... |

··· ··· |

... |

.... .. |

... |

............ |

|

...... |

...... ... ... |

|

... |

......... |

|

............ |

......... |

...... ... |

|

|

6 |

||||

II) 'J'hreading ........................................................................................................................ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6 |

|||

I ) |

Stitches······························································································································ |

7 |

||||||||||||||||||||||||||

.l |

) |

'I'hrL~ad tension |

····································································································.. |

· · · · · · · · · · · · |

7 |

|||||||||||||||||||||||

|

1. Adjustlnent of thread take-up |

...... |

|

·..... |

·...................................... |

|

|

|

|

|

|

|

·.. .............. |

· |

|

·..... |

·........ ..... |

· |

|

7 |

||||||||

|

2. Adjusting double chain stitch needle thread guide |

............................................. |

|

|

|

|

|

|

|

·........ .... .. |

|

|

7 |

|||||||||||||||

|

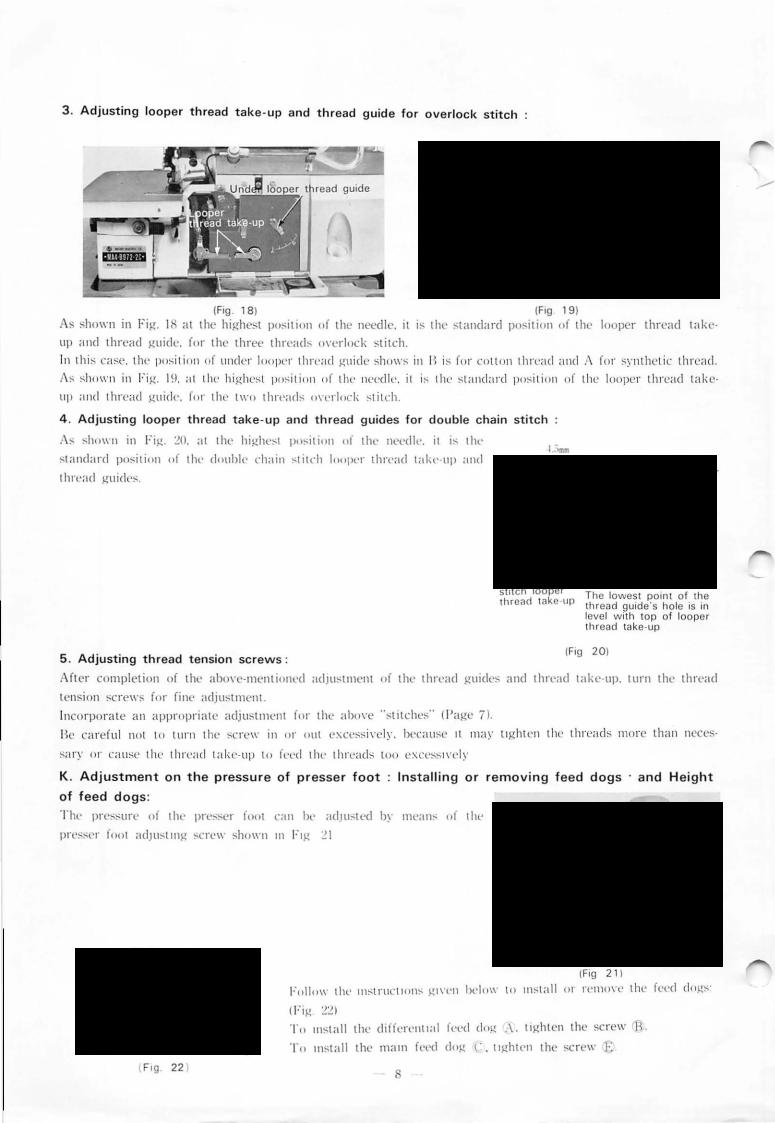

:~. Adjusting looper thread take-up and thread |

guide |

for |

overlock |

stitch................................. |

|

|

|

|

H |

||||||||||||||||||

|

4. Adjusting looper thread take-up and thread guides for |

double |

|

chain |

stitch |

..... .. |

.. ...... ......... |

|

|

H |

||||||||||||||||||

|

5. Adjusting thread tension screws |

.............. |

|

|

|

·.... |

·............ |

|

·........ |

· |

.............. |

|

|

·.... |

··........ |

·.. ...... .. |

· |

· · |

8 |

|||||||||

K) |

Adjustment on pressure of presser foot: |

installing and removing feed dogs: and height of feed dogs |

8 |

|||||||||||||||||||||||||

L) |

Adjusting |

stitch |

|

\\·idth |

·.......................... |

|

|

|

|

|

|

·...................................... |

|

|

|

|

|

|

|

·.. ............ ... .................. |

9 |

|||||||

l\,1) |

Adjusting |

stitch |

length ..................... |

|

|

|

|

|

|

·.. ······ .................. |

|

|

|

··· ......... |

··· .. |

·... |

|

·................. |

|

··· ... |

·········· |

10 |

||||||

1\) |

Adjusting |

differential |

feed |

|

............ |

|

|

·..... |

··· .... |

·· ..................... |

|

··· ·........ |

|

........... |

· |

|

·· ··.. |

·· ··..... ... |

···· ·· |

10 |

||||||||

4. |

Adjustn1ent |

··························································································································· |

11 |

|||||||||||||||||||||||||

1\) |

IIeight of |

needles ........ |

|

·· .... |

|

· ............ |

|

|

·.... |

·.. |

·............ |

|

·.............. |

|

·.. |

·.... |

|

····· .... |

·.............. |

|

·· .... .... |

····· |

· |

11 |

||||

B) |

I~L'lation between needle and under looper .................................... |

|

|

|

|

|

|

·.... |

|

.... ......... |

...... |

... .. .... ...... |

|

|

II |

|||||||||||||

C) |

Installing |

needle |

guard |

··· ··· ·· ·· ·· ···· ·· ·· ···· ·· ···· ······ ···· ····· ··· ··· ··· ··· ·· ·· ·· ··· ·· ···· ··· ······ ·· ···· ··· ··· ··· ·· ···· |

11 |

|||||||||||||||||||||||

D) i\Iatching needle guard and needJe..... |

|

.... .... |

.. |

.......... |

|

.............. |

......... |

|

|

... .. |

|

.... ... .. .. |

.. .. .. |

..... ...... .... .. |

|

|

11 |

|||||||||||

E) |

I~L·Iation of needle with under looper and over looper ................................................ |

|

|

|

|

|

|

|

.... ... |

· |

· |

12 |

||||||||||||||||

F) |

I~L'lation between needle and double chain stitch looper |

·.. ......... ......... .... .. ... ...... ......... ...... ... |

12 |

|||||||||||||||||||||||||

(;) Installing double chain stitch needle guard........................................................................... |

|

|

|

|

|

|

|

|

|

|

|

|

|

13 |

||||||||||||||

II) Installing and maintenance of knives |

.................................................................................. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

13 |

||||||||||||

5. |

'I'rouble shooting ............ |

|

|

|

··· ...... |

|

·.... |

|

·... |

·..... |

·.... |

|

·.................................... |

|

|

|

|

|

|

··· ......... |

......... |

............ ... |

|

|

I-I |

|||

i\) |

·rhread breaks |

··· ··· ······ ··· ··· ·· ·· ·· ······ ··· ··· ··· ···· ·· ···· ··· ·· ······ ···· ·· ··· ······ ··· ······ ······ ··· ······ ······· ·· ···· ·· |

1-1 |

|||||||||||||||||||||||||

I~) |

Skip stitching··················································· .... |

······························································ |

1-1 |

|||||||||||||||||||||||||

C) |

1\eedle breaks |

······ ·· ···· ··· ··· ·· ···· ·· ···· ·· ···· ·· ···· ······ ········· ··· ··· ··· ··· ···· ·· ··· ···· ·· ··· ·· ·· ·· ·· ·· ·· ·· ···· ······ ··· |

I-I |

|||||||||||||||||||||||||

IJ) |

hnperfect |

chaining-off ... |

···· |

.... ·.. |

·· .... |

|

·· .... |

·· .. |

··· .. |

·· ................... |

|

·· .. |

·.... |

|

·... .... |

· |

···· ... |

·....................... |

|

|

|

l;j |

||||||

E) |

Improper |

thread |

tension .. |

·.. |

· ···.... |

|

··.. |

·..... |

·.... |

|

··................... |

|

|

·... ·.. |

·..... |

|

·.. |

· ···.. ·· ··.......... |

|

··... .. |

· · · ·.. ... |

15 |

||||||

F) |

Poor trin1n1ing |

perforrnance .. ··.... |

|

·... |

·..... |

·.... |

|

··....................... |

|

|

·.. |

·.... |

|

·... ....... |

· |

··.................... |

|

|

·.. ... |

15 |

||||||||

(;) |

Irregular stitches ........................................................................ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

....................................... |

|

|

|

|

|

|

16 |

||||

II) |

Excessi\·e |

wrink1es along |

stitches |

...... |

|

··· ....... |

|

·· ................................................ |

|

|

|

|

|

|

|

···· ·· ......... ...... |

|

|

Iti |

|||||||||

I ) |

1\eedlcs produce |

too |

large |

holes··· ...... |

|

··· ............................ |

|

|

|

|

······ ........... |

|

|

|

········· |

........................ |

|

|

|

I6 |

||||||||

From the library of: Superior Sewing Machine & Supply LLC

SUB-CLASS LIST AND EXPLANATION ON THE MEDALLION

|

|

|

|

|

|

|

|

|

|

|

Overcdgc hight;:{l~nlT\\\\\C\\\1\T\\\\1\\\Im |

|

||||||

|

|

|

|

|

|

|

|

|

|

|

Needle gauge |

- |

! \j_\j_lj_\j~ \,l\j\,l\jU\._,_'.Ju_'/ |

|

||||

|

|

|

|

|

|

|

|

|

|

|

Sewing width |

---- - - - -- ------- - -- ~ |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

Sub-cia~~ |

|

|

|

|

|

|

|

-3C |

|

|

-5C |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

Needle gauge |

|

|

|

|

|

|

|

3mm |

· |

. |

5mm |

|

|||

|

------- -~ |

|

|

|

|

|

|

|

|

--- ---·· ~ . |

|

|

||||||

|

|

|

Overedge bight |

|

|

3mm |

|

|

|

|

5mm |

|

|

5mm |

|

|||

|

|

|

|

|

|

-- ---------- --· |

-----~11~!11 |

|

|

-------- -· |

|

|

|

|

||||

|

|

|

Sewing |

width |

t |

|

|

- · . . -- |

|

|

lOmm |

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

8mm |

|

|

|

|||

|

|

|

|

|

|

|

--~ |

|

2 |

|

|

2 |

- |

|||||

|

|

|

No._ of |

nc<:_dles_ _ ____ __ |

|

-- |

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|||||||||||

|

~ |

. |

|

thread~ |

1 |

A........ |

:) |

|

5 |

|

|

5 |

|

|||||

|

|

|

|

|

- |

----------~ |

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

No. of |

|

|

|

f |

H........ |

4 |

|

4 |

|

|

4 |

|

|||

|

|

------- |

|

|

-----------·· |

|

----- |

----------- |

-- --- |

|

|

|

|

|||||

|

|

|

Differ~~nt~a~~ed_ratio |

_ _ ____ |

___ 1.5-0.~- |

__ |

1.5-0.7 |

|

|

1.5-0.7 |

|

|||||||

|

|

|

|

|

|

|

||||||||||||

|

I |

------_ ~eec~:_coolc~ |

-----1 |

Equipped |

__ _ |

Equipped |

|

Equipped |

|

|||||||||

|

|

U~e |

|

|

|

|

For thin |

work |

medium work |

|

For medium heavy work |

|

||||||

|

----- |

|

|

- |

|

|

---- - ---- |

---- |

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|||||||||

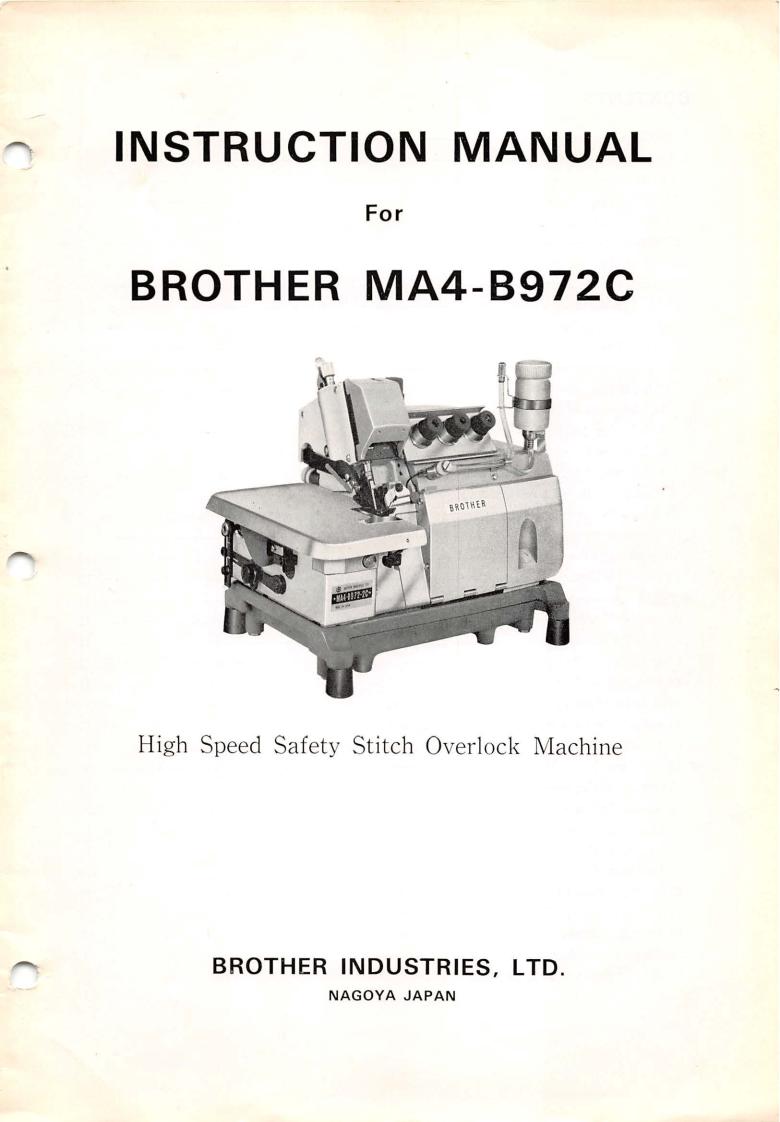

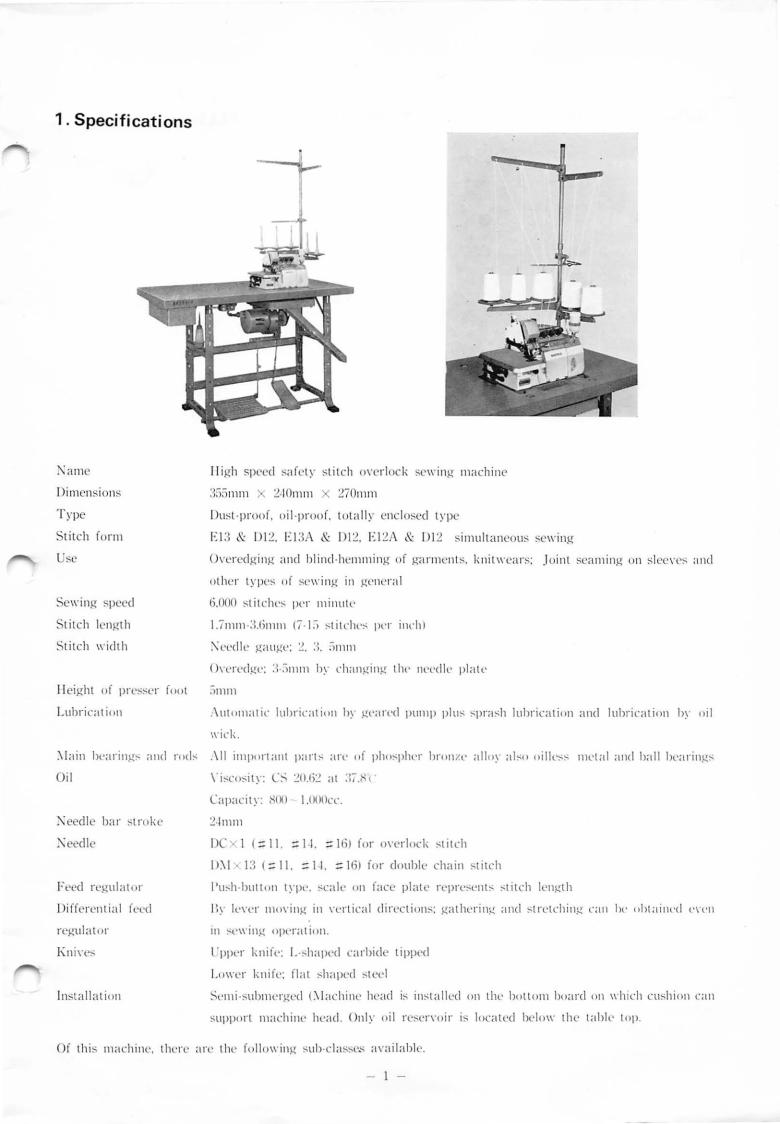

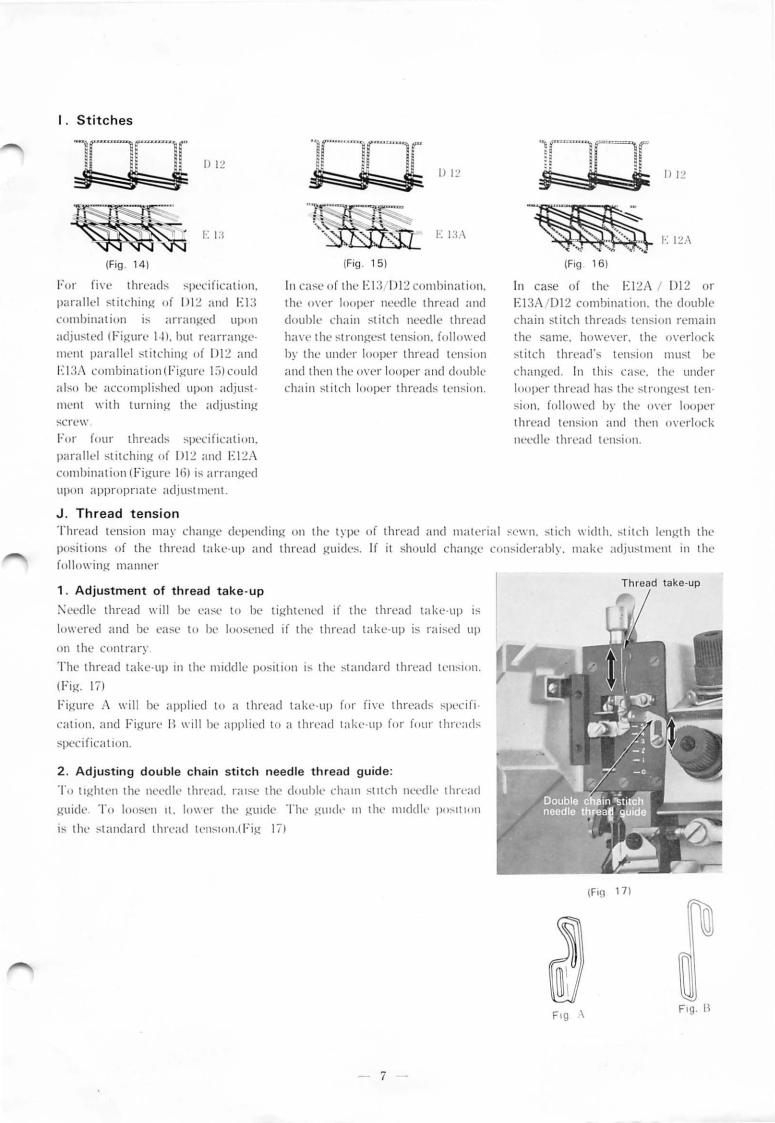

2. Features

The cxtcn~ive design of various components and lubrication system and also the addition of the needle cooler

device on this model assure the normal operation of maximum high speed of 6,000 stitches per |

minute. without |

|

|

any |

troubles. |

|

|

A) |

Combined lubrication system of forced lubrication by geared pump, sprash lubrication and oil wick lubrication. |

||

B) Unique design of needle bar mechanism has lessened its weight as we11 as ensures forced |

lubrication to its |

~ |

|

every working part. |

|

......_ |

|

C)Exclusively designed over looper mechanism has made the use of light alloy possible and also ensures smooth lubrication to the end.

D)Holders are made of duralmin to decrease weight. Main rods and bushings are made of phospher bronze a11oy.

E)Major moving parts are perfectly lubricated inside the totally enclosed main body, so they will never be exposed to outside dusts.

*The upper knife is L-shaped to make the threading and replacement of the needle easy. Besides the carbide

tip promises long durability of the knife.

*Stitch can be easily regulated by push-button. with the scale on the face plate, thus it is-unnecessary to change

the eccentrics when you would like to change the stitch length_

*Differential feed can be easily adjusted by the lever for gathering or stretching without soiling your hands.

This also applies for the instantaneous differential adjustment obtainable.

*Durable chain stitch looper's movement in forward-backward direction can be adjusted to obtain the proper

amount of clearance between the looper and needle according to the size of needle.

*Thread tension of the double chain stitch looper can be easily adjusted without opening the cover.

*Ample space on the cloth plate allows easy sewing operation and if you want. double chain stitch with edge

cutting work can be obtained without using the overedging mechanism.

*Oil level in the oil reservoir is shmn1 on the special oil gauge on the front side of the machine. *Lubrication can be easily checked through the oil window in the top cover.

*Needle cooler device ensures perfect sewing operation even with synthetic materials and threads at the high

speed of 6,000 stitches per minute. |

|

*Colour combination of TAN -BEIGE is in |

well harmony with your modern factory, and operator's atigue can |

be lessened. |

|

*As differental radio can be adjusted up |

to 2.5. this is suitable for sewing of cloth which is ease to spread |

such as knitted fabric. |

|

|

2 |

From the library of: Superior Sewing Machine & Supply LLC

3. Operation

A. Sewing speed

lVlaxtmum speed of thts machine is 6,000 stitches per minute. For the first 100 actual working hours, however. the new machme should be operated at about 5,000 s.p.m. so that all the working parts are well run-in. After thts runnmg-m penod. ~'OU may operate the machine at maximum speed of 6.000 stitches per minute. This is destrable for machine's long life.

B. Motor, motor pulley and belt.

I)Use a clutch motor, l/2 Hp, 2 pole, single or three phase. Our motor available is Models 1\;'lD-344 (single phase) and MD-354 (three phase)

2)Use M-type V-belt.

3)Machine speed (s.p.m.), diameter of motor pulley and length of motor belt ts related to the fo])owing table.

|

|

|

|

|

|

|

|

|

|

Outside diameter of pulley and length of V-belt |

|

||||||||||||||

|

|

|

|

|

|

|

|||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Stitches per minute |

|

50 |

|

Hz |

|

|

|

_ |

j__ Pulley |

|

60Hz |

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

Pulley |

|

V-belt |

|

|

V-belt |

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5,200 |

|

115mm |

|

39inch |

|

|

|

|

95mm |

38inch |

|||||||||||||

-------~-- |

|

|

|

----··- |

|

|

|

|

|

|

|

-- - ----------- |

|

|

|

|

|||||||||

5,500 |

|

120 |

|

II |

|

39 |

II |

|

|

|

100 |

II |

38 |

II |

|||||||||||

6,000 |

|

|

|

|

|

|

|

|

|

39 |

|

|

----- |

--- ----- |

------------ |

|

|

|

|||||||

|

130 |

|

II |

|

" |

|

|

|

110 |

" |

|

|

|

38 |

" |

||||||||||

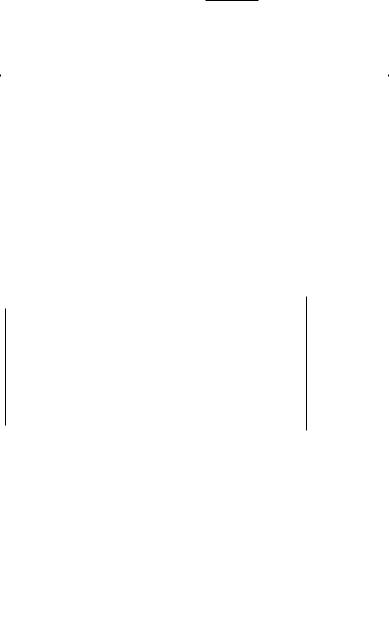

C. Setting up |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

This machine is normally set up as semi-submerged type. |

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

Necessary parts and accessories for setting up this |

machine are contained together with the machine head. |

||||||||||||||||||||||||

If you have purchased |

this machine as head |

only, |

make the |

table |

top as per |

attached |

table sheet. also refer |

||||||||||||||||||

to Fig. 1. which shows the parts necessary for setting up this machine and also the measurement to mount the

bottom board to the table top as semi-submerged type.

\Vith our Brother clutch motor. Models MD-344 and MD-354. there is no anxiety to set the machine to the

bottom board, however. if you would use with other brand clutch motor, please make sure to have proper holes

on the bottom board. |

18. 4 Centre of V-belt |

|

2571 |

Centre of machine pullt•y

'-!~

275 -1

Cushion base

Figures are m milimcter |

(Fig. 1) |

-3 -

From the library of: Superior Sewing Machine & Supply LLC

Loading...

Loading...