Brother HL-820, HL-1040 User Manual

© Copyright Brother 1998 All rights reserved.

No part of this publication may be reproduced in any form or by any means without permission in writing from the publisher.

Specifications are subject to change without notice.

Trademarks:

The brother logo is a registered trademark of Brother Industries, Ltd.

Apple, the Apple Logo, and Macintosh are trademarks, registered in the United States and other countries, and True Type is a trademark of Apple computer, Inc.

Epson is a registered trademark and FX-80 and FX-850 are trademarks of Seiko Epson Corporation.

Hewlett Packard is a registered trademark and HP Laser Jet is a trademark of Hewlett Packard Company.

IBM, IBM PC and Proprinter are registered trademarks of International Business Machines Corporation.

Microsoft and MS-DOS are registered trademarks of Microsoft Corporation.

Windows is a registered trademark of Microsoft Corporation in the U.S. and other countries.

PREFACE

This service manual contains basic information required for after-sales service of the laser printer (here- in-after referred to as "this machine" or "the printer"). This information is vital to the service technician to maintain the high printing quality and performance of the printers.

This service manual covers the HL-820, 1020, 1040 and 1050 laser printers. (Note that any figures for the printer body are based on the HL-1040 printer.)

This manual consists of the following chapters:

CHAPTER I : FEATURES AND SPECIFICATIONS

Features, specifications, etc.

CHAPTER II : THEORY OF OPERATION

Basic operation of the mechanical system, the electrical system and the electrical circuits, and their timing information.

CHAPTER III : DISASSEMBLY AND REASSEMBLY

Procedures for disassembling and reassembling the mechanical system.

CHAPTER IV : MAINTENANCE AND TROUBLESHOOTING

Reference values and adjustments, troubleshooting image defects, troubleshooting malfunctions, etc.

APPENDICES :SERIAL NO. DESCRIPTIONS, CONNECTION DIAGRAMS, PCB CIRCUIT DIAGRAMS.

Information in this manual is subject to change due to improvement or re-design of the product. All relevant information in such cases will be supplied in service information bulletins (Technical Information).

A thorough understanding of this printer, based on information in this service manual and service information bulletins, is required for maintaining its print quality performance and for improving the practical ability to find the cause of problems.

CONTENTS

CHAPTER I FEATURES AND SPECIFICATIONS |

..........................................I-1 |

||

1. |

FEATURES ......................................................................................................................... |

I-1 |

|

2. |

SPECIFICATIONS .............................................................................................................. |

I-3 |

|

|

2.1 |

Printing....................................................................................................................................... |

I-3 |

|

2.2 |

Functions ................................................................................................................................... |

I-3 |

|

2.3 |

Electrical and Mechanical .......................................................................................................... |

I-4 |

|

2.4 |

Paper Specification .................................................................................................................... |

I-5 |

|

2.5 |

Print Delivery.............................................................................................................................. |

I-5 |

|

2.6 |

Paper ......................................................................................................................................... |

I-6 |

|

2.7 |

Effective Printing Area ............................................................................................................... |

I-7 |

3. |

SAFETY INFORMATION .................................................................................................... |

I-9 |

|

|

3.1 |

Laser Safety (110 - 120V Model only) ....................................................................................... |

I-9 |

|

3.2 |

FDA Regulations (110 - 120V Model only) ................................................................................ |

I-9 |

|

3.3 |

Caution for Laser Product........................................................................................................ |

I-10 |

CHAPTER II THEORY OF OPERATION ........................................................ |

II-1 |

|||

1. |

ELECTRONICS.................................................................................................................. |

II-1 |

||

|

1.1 |

General Block Diagram............................................................................................................. |

II-1 |

|

|

1.2 |

Main PCB Block Diagram ......................................................................................................... |

II-4 |

|

|

1.3 |

Main PCB.................................................................................................................................. |

II-7 |

|

|

|

1.3.1 |

CPU Core .................................................................................................................... |

II-7 |

|

|

1.3.2 |

ASIC ............................................................................................................................ |

II-9 |

|

|

1.3.3 |

ROM .......................................................................................................................... |

II-15 |

|

|

1.3.4 |

DRAM ........................................................................................................................ |

II-16 |

|

|

1.3.5 |

Optional RAM ............................................................................................................ |

II-17 |

|

|

1.3.6 |

Optional Serial I/O ..................................................................................................... |

II-18 |

|

|

1.3.7 |

EEPROM ................................................................................................................... |

II-18 |

|

|

1.3.8 |

Reset Circuit .............................................................................................................. |

II-19 |

|

|

1.3.9 |

CDCC I/O .................................................................................................................. |

II-19 |

|

|

1.3.10 |

Engine I/O .................................................................................................................. |

II-21 |

|

|

1.3.11 |

Paper Feed Motor Drive Circuit ................................................................................. |

II-23 |

|

1.4 |

Panel Sensor PCB .................................................................................................................. |

II-24 |

|

|

1.5 |

Power Supply.......................................................................................................................... |

II-24 |

|

|

|

1.5.1 |

Low - voltage Power Supply ........................................................................................ |

II-24 |

|

|

1.5.2 |

High - voltage Power Supply, SR PCB ........................................................................ |

II-25 |

2. |

MECHANICS |

.................................................................................................................... |

II-26 |

|

|

2.1 |

Overview of Printing Mechanism ............................................................................................ |

II-26 |

|

|

2.2 |

Paper Transfer........................................................................................................................ |

II-27 |

|

|

|

2.2.1 ............................................................................................................. |

Paper Supply |

II-27 |

|

|

2.2.2 ..................................................................................................... |

Paper Registration |

II-27 |

|

|

2.2.3 ................................................................................................................ |

Paper Eject |

II-28 |

i

|

2.3 |

Sensors |

................................................................................................................................... |

II-29 |

|

|

2.3.1 |

Cover Sensor............................................................................................................. |

II-29 |

|

|

2.3.2 |

Toner Empty Sensor.................................................................................................. |

II-29 |

|

2.4 |

Drum Unit................................................................................................................................ |

II-30 |

|

|

|

2.4.1 |

Photosensitive Drum ................................................................................................. |

II-30 |

|

|

2.4.2 |

Primary Charger ........................................................................................................ |

II-30 |

|

|

2.4.3 |

Developer Roller........................................................................................................ |

II-30 |

|

|

2.4.4 |

Transfer Roller........................................................................................................... |

II-30 |

|

|

2.4.5 |

Cleaner Roller............................................................................................................ |

II-30 |

|

|

2.4.6 |

Erase Lamp .............................................................................................................. |

II-30 |

|

2.5 |

Print Process .......................................................................................................................... |

II-30 |

|

|

|

2.5.1 |

Charging ................................................................................................................... |

II-30 |

|

|

2.5.2 |

Exposure Stage ......................................................................................................... |

II-31 |

|

|

2.5.3 |

Developing................................................................................................................. |

II-32 |

|

|

2.5.4 |

Transfer ..................................................................................................................... |

II-32 |

|

|

2.5.5 |

Drum Cleaning Stage ................................................................................................ |

II-33 |

|

|

2.5.6 |

Erasing Stage ............................................................................................................ |

II-33 |

|

|

2.5.7 |

Fixing Stage............................................................................................................... |

II-33 |

CHAPTER III DISASSEMBLY AND REASSEMBLY....................................... |

III-1 |

|||

1. |

SAFETY PRECAUTIONS.................................................................................................. |

III-1 |

||

2. |

DISASSEMBLY FLOW...................................................................................................... |

III-2 |

||

3. |

DISASSEMBLY PROCEDURE ......................................................................................... |

III-3 |

||

|

3.1 |

Output Tray ASSY ................................................................................................................... |

III-3 |

|

|

3.2 |

Drum Unit................................................................................................................................. |

III-3 |

|

|

3.3 |

Top Cover ................................................................................................................................ |

III-4 |

|

|

3.4 |

Rear Cover .............................................................................................................................. |

III-4 |

|

|

3.5 |

MP Sheet Feeder ASSY .......................................................................................................... |

III-5 |

|

|

3.6 |

Fixing Unit ................................................................................................................................ |

III-6 |

|

|

3.7 |

Scanner Unit ............................................................................................................................ |

III-8 |

|

|

3.8 |

Main PCB ASSY .................................................................................................................... |

III-10 |

|

|

3.9 |

Base Plate ASSY ................................................................................................................... |

III-10 |

|

|

3.10 |

Panel Sensor PCB ASSY ...................................................................................................... |

III-11 |

|

|

3.11 |

Low-voltage Power Supply PCB ASSY ................................................................................. |

III-12 |

|

|

3.12 |

High-voltage Power Supply PCB ASSY................................................................................. |

III-13 |

|

|

3.13 |

Sub Fan Motor ASSY ............................................................................................................ |

III-14 |

|

|

3.14 |

Fan Motor ASSY ................................................................................................................... |

III-14 |

|

|

3.15 |

Drive Unit ............................................................................................................................... |

III-15 |

|

|

3.16 |

Main Motor ASSY .................................................................................................................. |

III-16 |

|

|

3.17 |

Sub Motor ASSY.................................................................................................................... |

III-16 |

|

|

3.18 |

Paper Support........................................................................................................................ |

III-17 |

|

|

3.19 |

Extension Support Wire ......................................................................................................... |

III-17 |

|

4. |

PACKING........................................................................................................................ |

|

III-18 |

|

ii

CHAPTER IV MAINTENANCE AND TROUBLESHOOTING.......................... |

IV-1 |

||

1. |

INTRODUCTION .............................................................................................................. |

IV-1 |

|

|

1.1 |

Initial Check........................................................................................................................ |

IV-1 |

|

1.2 |

Basic Procedure ................................................................................................................. |

IV-2 |

2. |

CONSUMABLE PARTS.................................................................................................... |

IV-3 |

|

|

2.1 |

Drum Unit........................................................................................................................... |

IV-3 |

|

2.2 |

Toner Cartridge .................................................................................................................. |

IV-3 |

|

2.3 |

Periodical Replacement Parts............................................................................................. |

IV-3 |

3. |

IMAGE DEFECTS ............................................................................................................ |

IV-4 |

|

|

3.1 |

Image Defect Examples ..................................................................................................... |

IV-4 |

|

3.2 |

Troubleshooting Image Defects .......................................................................................... |

IV-5 |

|

3.3 |

Location of High-voltage Contacts and Grounding Contacts.............................................. |

IV-19 |

|

3.4 |

Location of Feed Roller Shaft and Grounding Contacts..................................................... |

IV-20 |

4. |

PAPER JAM ................................................................................................................... |

IV-21 |

|

5. |

TROUBLESHOOTING MALFUNCTIONS....................................................................... |

IV-22 |

|

6. |

INSPECTION MODE ...................................................................................................... |

IV-27 |

|

|

6.1 |

Incorporated Inspection Modes......................................................................................... |

IV-27 |

|

6.2 |

Error Codes...................................................................................................................... |

IV-29 |

APPENDICES |

|

||

1. |

Serial No. Descriptions ...................................................................................................... |

A-1 |

|

2. |

Connection Diagram, HL-820/1020 ................................................................................... |

A-2 |

|

3. |

Connection Diagram, HL-1040 .......................................................................................... |

A-3 |

|

4. |

Connection Diagram, HL-1050 .......................................................................................... |

A-4 |

|

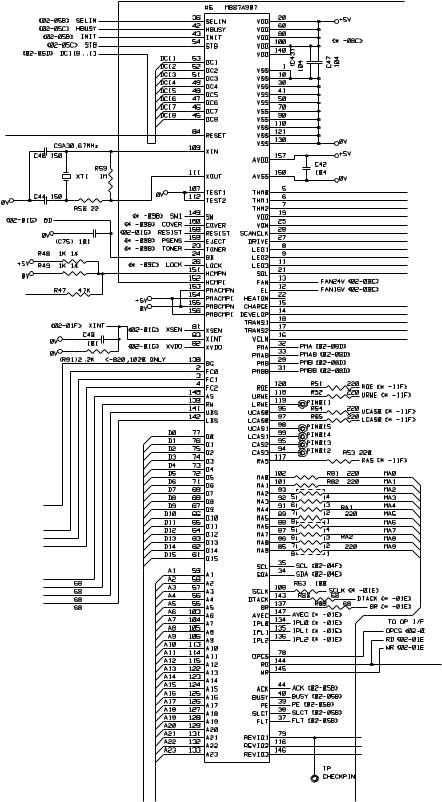

5. |

Main PCB Circuit Diagram, (HL-820/1020/1040), (1/2)...................................................... |

A-5 |

|

6. |

Main PCB Circuit Diagram, (HL-820/1020/1040), (2/2)...................................................... |

A-6 |

|

7. |

Main PCB Circuit Diagram, (HL-1050), (1/5)...................................................................... |

A-7 |

|

8. |

Main PCB Circuit Diagram, (HL-1050), (2/5)...................................................................... |

A-8 |

|

9. |

Main PCB Circuit Diagram, (HL-1050), (3/5)...................................................................... |

A-9 |

|

10. Main PCB Circuit Diagram, (HL-1050), (4/5).................................................................... |

A-10 |

||

11. Main PCB Circuit Diagram, (HL-1050), (5/5).................................................................... |

A-11 |

||

12. Panel Sensor PCB Circuit Diagram ................................................................................. |

A-12 |

||

13. Low-voltage Power Supply PCB Circuit Diagram, HL-820/1020/1040 (110 - 120V) ........ |

A-13 |

||

14. Low-voltage Power Supply PCB Circuit Diagram, HL-820/1020/1040 (220 - 240V) ........ |

A-14 |

||

15. Low-voltage Power Supply PCB Circuit Diagram, HL-1050 (110 - 120V) ........................ |

A-15 |

||

16. Low-voltage Power Supply PCB Circuit Diagram, HL-1050 (220 - 240V) ........................ |

A-16 |

||

17. High-voltage Power Supply PCB Circuit Diagram............................................................ |

A-17 |

||

18. How to Know Drum Unit Life & Page Counter ................................................................. |

A-18 |

||

19. Diameter / Circumference of Rollers ................................................................................ |

A-20 |

||

iii

CHAPTER I FEATURES AND SPECIFICATIONS

1.FEATURES

This printer has the following features:

High Resolution and Fast Printing Speed

<HL-820>

True 600 dots per inch (dpi) with microfine toner and 8 pages per minute (ppm) printing speed (A4 or Letter paper).

<HL-1040/1020>

True 600 dots per inch (dpi) with microfine toner and 10 pages per minute (ppm) printing speed (A4 or Letter paper).

<HL-1050>

True 600 dots per inch (dpi) and 1200 x 600 dpi for graphics with microfine toner and 10 pages per minute (ppm) printing speed (A4 or Letter paper).

Enhanced Printing Performance and User-Friendly Operation for Windows

The dedicated printer driver and TrueTypeTM-compatible fonts for Microsoft® Windows 3.1 and Windows 95 are available on the floppy disk and CD-ROM supplied with your printer. You can easily install them into your Windows system using our installer program. The driver supports our unique compression mode to enhance printing speed in Windows applications and allows you to set various printer settings including toner saving mode, custom paper size, sleep mode, gray scale adjustment, resolution, and so forth. You can easily setup these print options in the graphic dialog boxes through the Printer Setup menu within the Windows Control Panel.

Printer Status Monitor with Bi-directional Parallel Interface

The printer driver can monitor your printer’s status using bi-directional parallel communications.

The printer status monitor program can show the current status of your printer. When printing, an animated dialog box appears on your computer screen to show the current printing process. If an error occurs, a dialog box will appear to let you know what to correct. For example: when your printer is out of paper, the dialog box will display “No Paper” and instructions for the corrective action to take.

Versatile Paper Handling

The printer has a multi-purpose sheet feeder and a straight paper path mechanism. Using this mechanism, you can load A4, letter, legal, B5, A5, A6, and executive sizes of paper, and various types of media including envelopes, organizer paper, or your custom paper size. The multi-purpose sheet feeder also allows manual paper loading, so you can also use labels and transparencies.

Environment-Friendly

Economy Printing Mode

This feature will cut your printing cost by saving toner. It is useful to obtain draft copies for proof-reading. You can select from two economy modes, 25% toner saving and 50% toner saving, through the Windows printer driver supplied with your printer.

Sleep Mode (Power Save Mode)

Sleep mode automatically reduces power consumption when the printer is not in use. The printer consumes less than 13W when in sleep mode.

I-1

Low Running Cost

The toner cartridge is separate from the drum unit. You need to replace only the toner cartridge after around 2,400 pages, which is cost effective and ecologically friendly.

The actual number of pages printed with each toner cartridge may vary depending on your average type of print job.

Enhanced Memory Management

The printer provides its own data compression technology in its printer hardware and the supplied printer driver software, which can automatically compress graphic data and font data efficiently into the printer's memory. You can avoid memory errors and print most full page 600dpi graphic and text data, including large fonts, with the standard printer memory.

Remote Printer Console Program for DOS (for HL-1040/1050 only)

The utility program, Remote Printer Console (RPC), is available on the floppy disk and CD-ROM supplied with your printer. When you operate your computer in the DOS (Disk Operating System) environment, this program allows you to easily change the default settings of the printer such as fonts, page setup, emulations and so on.

This program also provides a status monitor program, which is a Terminate-and-Stay Resident (TSR) program. It can monitor the printer status while running in the background and report the current status or errors on your computer screen.

Popular Printer Emulation Support (for HL-1040/1050 only)

These printers support the following printer emulation modes;

The HL-1040 supports HP LaserJet IIP, Epson FX-850, and IBM Proprinter XL The HL-1050 supports HP LaserJet 6P/6L, Epson FX-850 and IBM Proprinter XL.

When you use DOS application software or Windows™ version 3.0 or earlier, you can use any of these emulations to operate the printer in the 300 dpi resolution mode. The printers also support Auto-emulation switching between HP and Epson or HP and IBM. If you want to set the printer emulation, you can do it using the Remote Printer Console Program.

USB Interface (for HL-1050 only)

The Universal Serial Bus Interface is an interface which allows the printer to connect to multiple peripheral devices.

High Resolution Control & Advanced Photoscale Technology (for HL-1050 only)

High resolution control (HRC) technology provides clear and crisp printouts. Use this function to get smooth text print quality.

Advanced Photoscale Technology enables the printer to print graphics in 256 grayscales, producing nearly photographic quality. Use this function when you want to print photographic images.

Optional Apple Macintosh® Interface (for HL-1040/1050 only)

An optional Apple Macintosh serial interface is available which allows your printer to be connected to Apple Macintosh computers. With this option, you can use your printer with both an IBM PC (or compatible) and an Apple Macintosh at the same time. This optional interface board can be used as an RS-422A interface for Macintosh or an RS-232C serial interface for an IBM PC or compatible.

I-2

2.SPECIFICATIONS

2.1 |

Printing |

|

|

|

Print method |

Electrophotography by semiconductor laser beam scanning |

|

|

Laser: |

Wave length: |

780nm |

|

|

Output: |

5mW max |

|

Resolution |

HL-820/1020: |

600 x 600dots/inch (for Windows) |

|

|

HL-1040: |

600 x 600dots/inch (for Windows or DOS) |

|

|

|

300 x 300dots/inch (under Apple Macintosh, DOS, |

|

|

|

or other operating system) |

|

|

HL-1050: |

1200(H) x 600(V)dots/inch (for Windows DIB |

|

|

|

graphics) |

|

|

|

600 x 600dots/inch (for Windows or DOS) |

|

|

|

300 x 300dpi (under Apple Macintosh using |

|

|

|

optional RS-100M) |

|

Print speed |

HL-820: |

Up to 8 pages/minute |

|

|

HL-1020/1040/1050: Up to 10 pages/minute |

|

|

|

(when loading Letter-size paper from the multipurpose sheet feeder) |

|

|

Warm-up |

Max. 30 seconds at 23°C (73.4°F) |

|

|

First print |

15 seconds |

|

|

|

(when loading Letter-size paper from the multipurpose sheet feeder) |

|

|

Print media |

Toner cartridge |

|

|

|

Life Expectancy: 2,400 pages/cartridge |

|

|

|

(when printing A4 or letter-size paper at 5% print coverage) |

|

|

Developer |

Drum unit, separated from toner cartridge |

|

|

|

Life Expectancy: 20,000 pages/drum unit at 20 pages per job |

|

|

|

|

8,000 pages at 1 page per job |

2.2 |

Functions |

|

|

|

CPU |

HL-820/1020/1040: MC68EC000 16Mhz |

|

|

|

HL-1050: |

MB86831 66Mhz |

|

Emulation |

HL-820/1020: |

Brother Printing Solution for Windows |

|

|

HL-1040: |

Brother Printing Solution for Windows |

|

|

|

Automatic emulation selection among HP LaserJet |

|

|

|

IIP (PCL level 4), EPSON FX-850, and IBM |

|

|

|

Proprinter XL |

|

|

HL-1050: |

Brother Printing Solution for Windows |

|

|

|

Automatic emulation selection among HP LaserJet |

|

|

|

6P (PCL level 6), EPSON FX-850, and IBM |

|

|

|

Proprinter XL |

|

Printer driver |

WindowsTM 3.1/3.11, Windows 95 and Windows NT 4.0 driver, |

|

|

|

supporting Brother Native Compression mode and bi-directional |

|

capability.

Optional Macintosh driver available for System 6.0.7 or higher (for HL1040/1050 only)

I-3

PR99017

Interface |

Bi-directional parallel |

|

|

Universal Serial Bus (USB) (HL-1050 only) |

|

|

RS-422A/RS-232C serial (RS-100M) is optionally available. (HL- |

|

|

1040/1050 only) |

|

Memory |

HL-820/1020/1040: 2.0 Mbytes |

|

|

HL-1050: |

4.0 Mbytes |

|

|

Expandable up to 36 Mbytes by installing an |

|

|

industry standard SIMM |

Control panel |

1 switch and 4 lamps |

|

Diagnostics |

Self-diagnostic program |

|

2.3Electrical and Mechanical

Power source |

U.S.A. and Canada: |

AC 110 to 120V, 50Hz/60Hz |

|

|

Europe and Australia: |

AC 220 to 240V, 50Hz/60Hz |

|

Power consumption Printing (peak): |

820W or less |

||

|

Printing (average): 280W or less |

||

|

Standing by: |

60W or less |

|

|

Sleep: |

13W or less |

|

Noise |

Printing: |

49dB A or less |

|

|

Standing by: |

33dB A or less |

|

Temperature |

Operating: |

10 to 32.5°C (50 to 90.5°F) |

|

|

Storage: |

0 to 40°C (38 to 104°F) |

|

Humidity |

Operating: |

20 to 80% (non condensing) |

|

|

Storage: |

10 to 85% (non condensing) |

|

Dimensions |

390 x 365 x 245 mm (15.4 x 14.4 x 9.7 inches) |

||

(W x D x H) |

(when the output tray is closed.) |

||

Weight |

Approx. 7.2kg (15.7lb.) including the drum unit and toner cartridge |

||

Note:

NThe peak figure of power consumption is worked out when the halogen heater lamp is turned ON.

NThe peak figure of power consumption is worked out excluding inrush current value.

NBe sure that the peak figure of power consumption is reference value and should be used inside the Brother offices only.

I-4

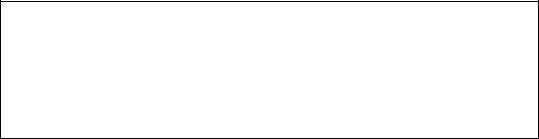

2.4Paper Loading

(1)Multi-purpose sheet feeder loading

Paper size: A4, Letter, Legal, B5, A5, A6, and Executive. Other sizes of media that can be handled by the feed mechanism can be loaded.

69.8 to 229 mm

105 to 356mm (face down)

Feeding direction

|

Feedable paper weight: |

60 (16lb.) to 158 (42lb.) g/m2 |

|

Maximum load height : |

22mm (200 sheets of 80g/m2 paper) letter or A4 size |

|

Setting method: |

Pull the MP sheet feeder cover toward you, insert the |

|

|

stack of paper into the feeder, aligning the top edge of |

|

|

the sheets, then push the cover back to its original |

|

|

position. |

(2) |

Manual slot loading |

|

|

Paper size: |

Same as in (1) for the multi-purpose sheet feeder. |

|

Feedable paper weight: |

Same as in (1) for the multi-purpose sheet feeder. |

|

Setting methods: |

Place the side of the paper to be printed on face down |

|

|

into the manual feed slot after selecting orientation. Align |

|

|

the paper at the center of the manual feed slot, and be |

|

|

sure to insert it fully into the feed slot. Move the paper |

|

|

guide of the manual feed slot to the paper width. |

Cautions:

Before loading paper with holes such as organizer sheets, be sure to fan the stack well.

When printing on the back of pre-printed paper, be sure to straighten the paper as much as possible.

2.5Print Delivery

(1)With the output tray opened

Tray capacity: Maximum 100 sheets (80g/m2), face-down only

(2)With the output tray closed

Tray capacity: 1 sheet (80g/m2), face-down only

Note: |

|

|

|

Face down: |

Deliver the printed face of the paper downward. |

|

Environment : |

23°C |

I-5

PR98184

2.6Paper

(1)Paper type

(a)Normal paper (60 to 157g/m2, specified types of high-quality paper)

•A4 size

•Letter size

•Legal size

•B5 (JIS ISO) size

•A5 size

•A6 size

•Executive size

*The recommended types of plain paper are as follows: Letter : Xerox 4200 (75g/m2)

A4 : Xerox 80 Premier Paper (80g/m2)

(b)Special paper (specified types)

• Labels

• Envelopes (DL, C4, C5, COM10, Monarch)

• Organizers (K, L, and J sizes of DAY-TIMERS)

(C)Other detailed specifications

|

Cut Sheet |

Envelope |

|

Basis Weight |

60 to 158 g/m2 (16 to 42 lb.) |

75 to 90 g/m2 (20 to 24 lb.) |

|

|

|

single thickness |

|

|

0.03 to 0.08 in. |

0.0033 to 0.0058 in. |

|

Caliper |

(0.084 to 0.14 mm) |

||

(0.08 to 0.2 mm) |

|||

|

single thickness |

||

|

|

||

Moisture Content |

4% to 6% by weight |

4% to 6% by weight |

|

Smoothness |

100 to 250 (Sheffield) |

100 to 250 (Sheffield) |

|

|

|

|

Caution:

Although the printer can handle 9 inches (229mm) width paper such as the C4 size envelope, you may get stains on the paper outside 8.5 inches width or on the back of the paper.

It is recommended to use long-grained paper for the best print quality. If short-grained paper is being used, it might be the cause of paper jams.

Use neutral paper. Do not use acid paper to avoid any damage to the printer drum unit.

(2)Paper feed conditions

Type |

|

Name |

Feeder |

Manual feed |

|

|

|

|

|

|

|

|

|

2 |

|

|

|

|

60 to 80 g/m |

(200 sheets) |

|||

|

|

|

|

||

Normal paper (cut sheet) |

2 |

|

|

|

|

80 g/m paper (Legal) |

(100 sheets) |

||||

|

|

|

|

||

|

158 g/m |

2 |

|

|

|

|

|

(30 sheets) |

|||

|

|

|

|

||

|

Labels |

|

|

|

|

|

|

(50 sheets) |

|||

|

|

|

|

||

Special paper (cut sheet) |

Envelopes |

|

|

||

(10 sheets) |

|||||

|

|

|

|

||

|

Organizers |

|

|

||

|

(10 sheets) |

||||

|

|

|

|

||

I-6

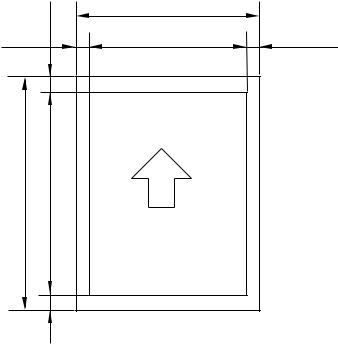

2.7 Effective Printing Area

Printable area

|

A |

|

|

F |

|

E |

C |

E |

B |

D |

|

F |

The effective printing area means the area within which the printing of all the data received without any omissions can be guaranteed.

I-7

|

|

|

|

|

|

|

PR98184 |

The table below shows the effective printing areas. |

|

|

|

||||

|

|

|

|

|

|

|

|

Size |

A |

B |

C |

|

D |

E |

F |

|

|

|

|

|

|

|

|

|

210.0mm |

297.0mm |

203.2mm |

|

288.5mm |

3.4mm |

4.23mm |

A 4 |

8.27” |

11.69” |

8.0” |

|

11.36” |

0.13” |

0.17” |

|

(2,480 dots) |

(3,507 dots) |

(2,400 dots) |

|

(3,407 dots) |

(40 dots) |

(50 dots) |

|

215.9mm |

279.4mm |

203.2mm |

|

270.9mm |

6.35mm |

|

Letter |

8.5” |

11.0” |

8.0” |

|

10.67” |

0.25” |

|

|

(2,550 dots) |

(3,300 dots) |

(2,400 dots) |

|

(3,200 dots) |

(75 dots) |

|

|

215.9mm |

355.6mm |

203.2mm |

|

347.1mm |

|

|

Legal |

8.5” |

14.0” |

8.0” |

|

13.67” |

|

|

|

(2,550 dots) |

(4,200 dots) |

(2,400 dots) |

|

(4,100 dots) |

|

|

|

182.0mm |

257.0mm |

173.5mm |

|

248.5mm |

6.01mm |

|

B 5 (JIS) |

7.16” |

10.12” |

6.83” |

|

9.78” |

0.24” |

|

|

(2,149 dots) |

(3,035 dots) |

(2,007 dots) |

|

(2,935 dots) |

(71 dots) |

|

|

176.0mm |

250.0mm |

164.0mm |

|

241.5mm |

|

|

B 5 (ISO) |

6.93” |

9.84” |

6.46” |

|

9.5” |

|

|

|

(2,078 dots) |

(2,952 dots) |

(1,936 dots) |

|

(2,852 dots) |

|

|

|

184.15mm |

266.7mm |

175.7mm |

|

258.2mm |

6.35mm |

|

Executive |

7.25” |

10.5” |

6.92” |

|

10.17” |

0.25” |

|

|

(2,175 dots) |

(3,150 dots) |

(2,025 dots) |

|

(3,050 dots) |

(75 dots) |

|

|

148.5mm |

210.0mm |

136.5mm |

|

201.5mm |

6.01mm |

|

A 5 |

5.85” |

8.27” |

5.37” |

|

7.93” |

0.24” |

|

|

(1,754 dots) |

(2,480 dots) |

(1,612 dots) |

|

(2,380 dots) |

(71 dots) |

|

|

105.0mm |

148.5mm |

93.0mm |

|

140.0mm |

|

|

A6 |

4.13” |

5.85” |

3.66” |

|

5.51” |

|

|

|

(1,240 dots) |

(1,754 dots) |

(1,098 dots) |

|

(1,654 dots) |

|

|

Organizer |

69.85mm |

127.0mm |

56.2mm |

|

118.5mm |

6.35mm |

|

(J size) |

2.75” |

5.0” |

2.21” |

|

4.66” |

0.25” |

|

|

(825 dots) |

(1,500 dots) |

(675 dots) |

|

(1,400 dots) |

(75 dots) |

|

Organizer |

95.25mm |

171.45mm |

86.78mm |

|

162.98mm |

|

|

3.75” |

6.75” |

3.42” |

|

6.42” |

|

|

|

(K size) |

|

||||||

(1,125 dots) |

(2,025 dots) |

(975 dots) |

|

(1,925 dots) |

|

|

|

|

|

|

|

||||

Organizer |

139.7mm |

215.9mm |

131.23mm |

|

207.43mm |

|

|

5.5” |

8.5” |

5.17” |

|

8.17” |

|

|

|

(L size) |

|

||||||

(1,650 dots) |

(2,550 dots) |

(1,500 dots) |

|

(2,450 dots) |

|

|

|

|

|

|

|

||||

|

104.78mm |

241.3mm |

92.11mm |

|

232.8mm |

|

|

COM-10 |

4.125” |

9.5” |

3.63” |

|

9.16” |

|

|

|

(1,237 dots) |

(2,850 dots) |

(1,087 dots) |

|

(2,750 dots) |

|

|

|

98.43mm |

190.5mm |

85.7mm |

|

182.0mm |

|

|

MONARCH |

3.875” |

7.5” |

3.37” |

|

7.16” |

|

|

|

(1,162 dots) |

(2,250 dots) |

(1,012 dots) |

|

(2,150 dots) |

|

|

|

228.6mm |

304.8mm |

203.2mm |

|

296.3mm |

12.7mm |

|

C 4 |

9.0” |

12.0” |

8.0” |

|

11.66” |

0.5” |

|

|

(2,700 dots) |

(3,600 dots) |

(2,400 dots) |

|

(3,500 dots) |

(150 dots) |

|

|

162mm |

229mm |

150.0mm |

|

220.5mm |

6.01mm |

|

C 5 |

6.38” |

9.01” |

5.9” |

|

8.68” |

0.24” |

|

|

(1,913 dots) |

(2,704 dots) |

(1,771 dots) |

|

(2,604 dots) |

(71 dots) |

|

|

110mm |

220mm |

98.0mm |

|

211.5mm |

|

|

DL |

4.33” |

8.66” |

3.86” |

|

8.33” |

|

|

|

(1,299 dots) |

(2,598 dots) |

(1,157 dots) |

|

(2,498 dots) |

|

|

(Note that the paper sizes indicated here should conform to the nominal dimensions specified by JIS.)

A4 paper must accommodate 80 characters printed in pica pitch (203.2 mm).

The dot size is based on 300 dpi resolution.

Organizer is not supported by any printer emulations (commands).

I-8

3.SAFETY INFORMATION

3.1Laser Safety (110 - 120V Model only)

This printer is certified as a Class 1 laser product under the US Department of Health and Human Services (DHHS) Radiation Performance Standard according to the Radiation Control for Health and Safety Act of 1968. This means that the printer does not produce hazardous laser radiation.

Since radiation emitted inside the printer is completely confined within the protective housings and external covers, the laser beam cannot escape from the machine during any phase of user operation.

3.2FDA Regulations (110 - 120V Model only)

The US Food and Drug Administration (FDA) has implemented regulations for laser products manufactured on and after August 2, 1976. Compliance is mandatory for products marketed in the United States. One of the following labels on the back of the printer indicates compliance with the FDA regulations and must be attached to laser products marketed in the United States.

The label for Japanese manufactured products

MANUFACTURED: |

K |

BROTHER INDUSTRIES, LTD. |

|

15-1, Naeshiro-cho, Mizuho-ku, Nagoya 467-8561, Japan. This product complies with FDA radiation

performance standards, 21 CFR Subchapter J.

The label for Chinese manufactured products

MANUFACTURED : |

C |

BROTHER Corporation (Asia) Ltd. |

|

Shenzen Buji Nan Ling Factory |

|

Gold Garden Ind., Nan Ling Village, Buji, Rong Gang, |

|

Shenzhen, CHINA |

|

This product complies with FDA radiation |

|

performance standards, 21 CFR Subchapter J. |

|

I-9

3.3Caution for Laser Product (Warnhinweis für Laserdrucker)

CAUTION: |

When the machine during servicing is operated with the cover open, the |

|

regulations of VBG 93 and the performance instructions for VBG 93 are |

|

valid. |

CAUTION: |

In case of any trouble with the laser unit, replace the laser unit itself. To |

|

prevent direct exposure to the laser beam, do not try to open the enclosure |

|

of the laser unit. |

ACHTUNG: Im Falle von Störungen der Lasereinheit muß diese ersetzt werden. Das Gehäuse der Lasereinheit darf nicht geöffnet werden, da sonst Laserstrahlen austreten können.

(1)Location of the laser beam window.

Window

Fig. 1-1

(2)Location of Caution Label for Laser Product. (200V only)

CLASS 1LASER PRODUCT

APPAREIL Å LASER DE CLASSE 1

LASER KLASSE 1 PRODUKT

Fig. 1-2

I-10

CHAPTER II THEORY OF OPERATION

1.ELECTRONICS

1.1General Block Diagram

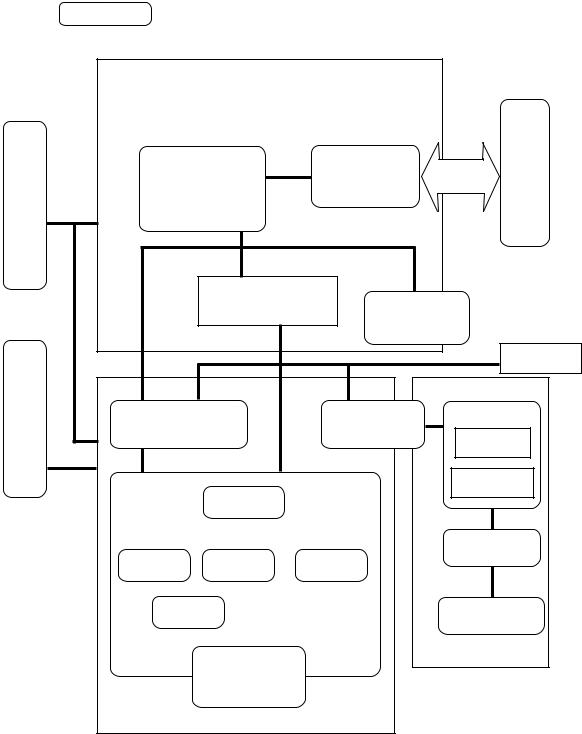

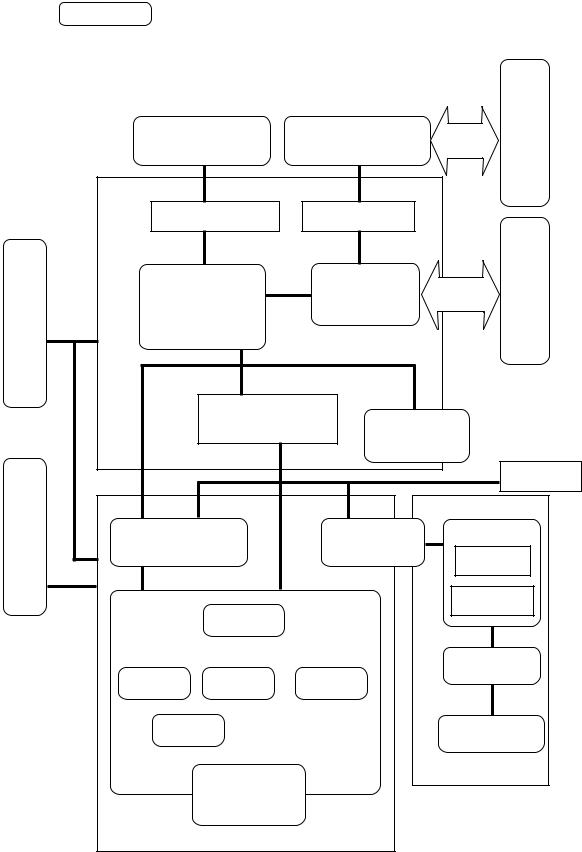

HL-820/1020

Fig. 2-1 shows a general block diagram of the HL-820/1020 printer.

Low-voltage power supply block

High-voltage power supply block

Control system |

|

|

device |

Interface block |

External |

|

|

Video control block |

|

Engine control block |

|

Operation block |

|

(Operation |

panel) |

Erase lamp

Laser scanner unit |

Drive block |

Paper tray unit |

|

|

|||

(Stepping motor) |

|

||

|

|

Paper tray |

|

|

|

|

|

Drum unit |

|

|

Manual feed |

|

|

|

|

|

Transfer block |

|

|

|

|

Cleaner |

Fixing unit |

Developing |

Drum |

|

|

block |

block |

|

|

|

|

||

Charging |

|

Paper eject block |

|

block |

|

|

|

|

|

|

|

|

|

|

Paper feed system |

|

Toner cartridge |

|

|

Image generation system

Fig. 2-1

II-1

HL-1040

Fig. 2-2 shows a general block diagram of the HL-1040 printer.

Low-voltage power supply block

High-voltage power supply block

Optional I/F board |

device |

|

External |

||

(Mac. RS-232C) |

||

|

Control system |

|

Expansion I/O |

|

|

device |

Interface block |

External |

|

|

Video control block |

|

Engine control block |

|

Operation block |

|

(Operation |

panel) |

Erase lamp

Laser scanner unit |

Drive block |

Paper tray unit |

|

|

|||

(Stepping motor) |

|

||

|

|

Paper tray |

|

|

|

|

|

Drum unit |

|

|

Manual feed |

|

|

|

|

|

Transfer block |

|

|

|

|

Cleaner |

Fixing unit |

Developing |

Drum |

|

|

block |

block |

|

|

|

|

||

Charging |

|

Paper eject block |

|

block |

|

|

|

|

|

|

|

|

|

|

Paper feed system |

|

Toner cartridge |

|

|

Image generation system

Fig. 2-2

II-2

HL-1050

Fig. 2-3 shows a general block diagram of the HL-1050 printer.

Low-voltage power supply block

High-voltage power supply block

Optional RAM (SIMM) |

Optional I/F board |

device |

|

External |

|||

(max. 32Mbytes) |

(Mac. RS-232C) |

||

|

Control system |

|

|

Expansion memory I/O |

Expansion I/O |

|

|

|

device |

|

Interface block |

External |

|

|

|

Video control block |

|

|

Engine control block |

Operation block |

|

|

||

|

(Operation |

panel) |

Erase lamp

Laser scanner unit |

Drive block |

Paper tray unit |

|

|

|||

(Stepping motor) |

|

||

|

|

Paper tray |

|

|

|

|

|

Drum unit |

|

|

Manual feed |

|

|

|

|

|

Transfer block |

|

|

|

|

Cleaner |

Fixing unit |

Developing |

Drum |

|

|

block |

block |

|

|

|

|

||

Charging |

|

Paper eject block |

|

block |

|

|

|

|

|

|

|

|

|

|

Paper feed system |

|

Toner cartridge |

|

|

Image generation system

Fig. 2-3

II-3

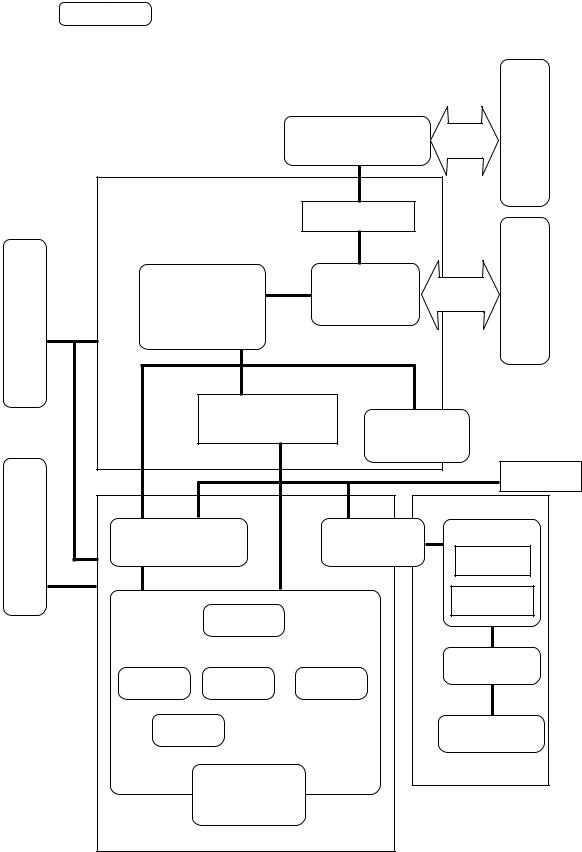

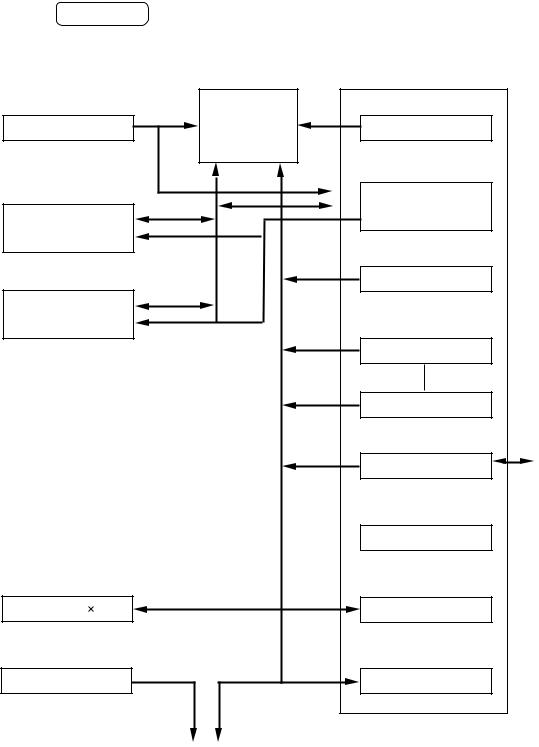

1.2Main PCB Block Diagram

HL-820/1020

Fig. 2-4 shows the block diagram of the main PCB.

|

|

|

|

A S I C |

|

|

|

CPU Core |

|

|

|

Reset Circuit |

(MC68EC000) |

Oscillator (15.3MHz) |

|

||

|

|

BUS |

INT |

|

|

|

|

|

|

Address Decoder |

|

Program + Font ROM |

|

|

DRAM Control |

|

|

512 Kbytes |

|

|

|

|

|

|

|

|

|

Timer |

|

RAM |

|

|

|

|

|

(2.0 Mbytes) |

|

|

|

|

|

|

|

|

|

FIFO |

|

|

|

|

|

DATA EXTENSION |

|

|

|

|

|

CDCC Parallel I/O |

To PC |

|

|

|

|

|

|

|

|

|

|

Soft Support |

|

EEPROM (128 |

8 bits) |

|

|

EEPROM I/O |

|

Motor Driver |

|

|

Engine Control I/O |

|

|

To Panel Sensor PCB

Fig. 2-4

II-4

HL-1040

Fig. 2-5 shows the block diagram of the main PCB.

|

|

|

|

A S I C |

|

|

|

CPU Core |

|

|

|

Reset Circuit |

(MC68EC000) |

Oscillator (15.3MHz) |

|

||

|

|

BUS |

INT |

|

|

|

|

|

|

Address Decoder |

|

Program + Font ROM |

|

|

DRAM Control |

|

|

512 Kbytes |

|

|

|

|

|

|

|

|

|

Timer |

|

RAM |

|

|

|

|

|

(2.0 Mbytes) |

|

|

|

|

|

|

|

|

|

FIFO |

|

Option Serial I/O |

|

|

DATA EXTENSION |

|

|

|

|

|

|

||

(RS232C & RS422A) |

|

|

|

|

|

|

|

|

|

CDCC Parallel I/O |

To PC |

|

|

|

|

|

|

|

|

|

|

Soft Support |

|

EEPROM (128 |

8 bits) |

|

|

EEPROM I/O |

|

Motor Driver |

|

|

Engine Control I/O |

|

|

To Panel Sensor PCB

Fig. 2-5

II-5

HL-1050

Fig. 2-6 shows the block diagram of the main PCB.

|

|

|

A S I C |

|

|

CPU Core |

|

|

|

Reset Circuit |

(MB86831) |

Oscillator (33.3MHz) |

|

|

|

BUS |

INT |

|

|

|

|

|

Address Decoder |

|

Program + Font ROM |

|

|

DRAM Control |

|

4.0 Mbytes |

|

|

|

|

|

|

|

Timer |

|

RAM |

|

|

|

|

(4.0 Mbytes) |

|

|

|

|

|

|

|

FIFO |

|

Option RAM (SIMM) |

|

|

|

|

(max. 32Mbytes) |

|

|

CDCC Parallel I/O |

To PC |

|

|

|

|

|

|

|

|

USB I/O |

To PC |

|

|

|

|

|

Option Serial I/O |

|

|

|

|

(RS232C & RS422A) |

|

|

|

|

|

|

|

Soft Support |

|

EEPROM (512 x 8 bits) |

|

|

EEPROM I/O |

|

Motor Driver |

|

|

Engine Control I/O |

|

|

To Panel Sensor PCB |

|

|

|

Fig. 2-6

II-6

1.3Main PCB

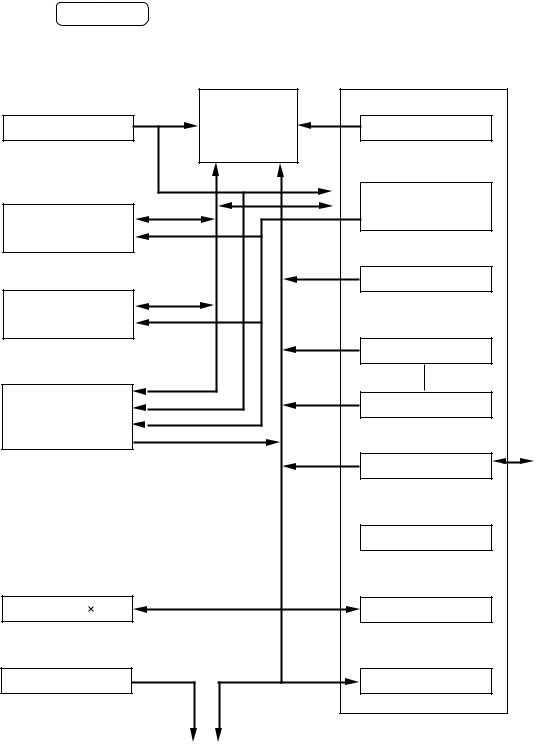

1.3.1CPU Core HL-820/1020/1040

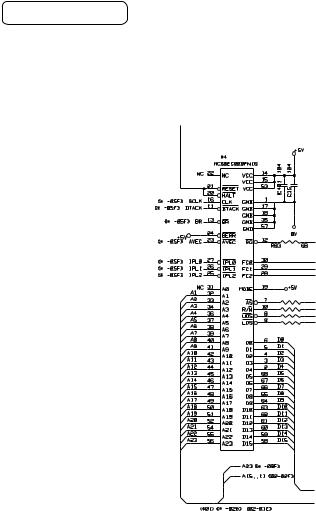

Fig. 2-7 shows the CPU circuit block on the main PCB.

The CPU is a Motorola MC68EC000FN16 which is driven with a clock frequency of 15.3MHz. This clock frequency is made by dividing the source clock of 30.67 MHz into two.

Fig. 2-7

II-7

HL-1050

Fig. 2-8 shows the CPU circuit block on the main PCB.

The CPU is a Motorola MB86831 which is driven with a clock frequency of 33MHz. The CPU itself runs at 66MHz.

Fig. 2-8

II-8

1.3.2ASIC

HL-820/1020/1040

The ASIC is composed of a Cell Based IC that contains the following functional blocks.

(1)Oscillator circuit

Generates the main clock for the CPU by dividing the source clock frequency into two.

(2)Address decoder

Generates the CS for each device.

(3)DRAM control

Generates the RAS, CAS, WE, OE and MA signals for the DRAM and controls refresh processing (CAS before RAS self-refreshing method).

(4)Interrupt control

Interrupt levels: |

|

|

|

Priority |

High |

7 |

NMI |

|

|

6 |

FIFO |

|

|

5 |

EXINT(Option Serial I/O) |

|

|

4 |

BD / Timer 1 |

|

|

3 |

SCANINT |

|

|

2 |

CDCC / BOISE / DATA EXTENSION |

|

Low |

1 |

Timer 2 |

(5)Timers

The following timers are incorporated:

Timer 1 |

16-bit timer |

Timer 2 |

10-bit timer |

Timer 3 |

Watch-dog timer |

(6)FIFO

A 5,120-bit FIFO is incorporated. Data for one raster scan is transferred from the RAM to the FIFO by DMA transmission and is output as serial video data. The data cycle is 10.22 MHz.

(7)CDCC parallel I/O <Data receiving>

There are two modes in this unit. One is the CPU receiving mode and the other is the DMA receiving mode. In the CPU receiving mode the CPU receives the command data from the PC, and after the CPU is switched to the DMA mode, it receives the image data and writes to the DRAM directly.

II-9

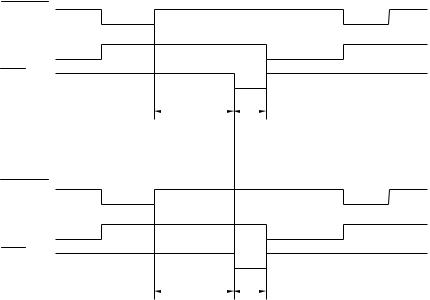

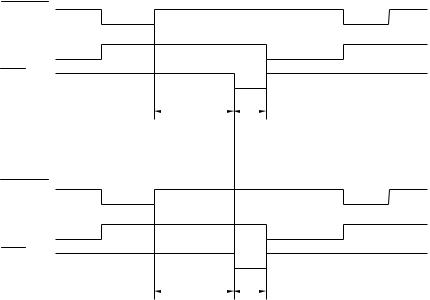

CPU Receive Mode

STROBE

BUSY

ACK

90 µsec |

0.5 µsec |

|

|

|

|

DMA Receive Mode

STROBE

BUSY

ACK

1.5 µsec |

0.5 µsec |

|

|

|

|

BUSY goes HIGH at the falling edge of STROBE. The data (8 bits) from the PC is latched in the data buffer at the rising edge of STROBE. The pulse width of ACK differs according to the speed MODE as shown above. BUSY goes LOW at the rising edge of ACK.

<IEEE1284 support>

This supports the IEEE1284 data transfer with the following modes.

Nibble mode

Byte mode

(8)Data expansion

This circuit expands the compressed image data received from the PC, and writes the bit map data to the FIFO.

(9)Software support

Supports 16 x 16 rotation, bit expansion, and bit search.

(10)EEPROM I/O

One output port and one I/O port are assigned.

II-10

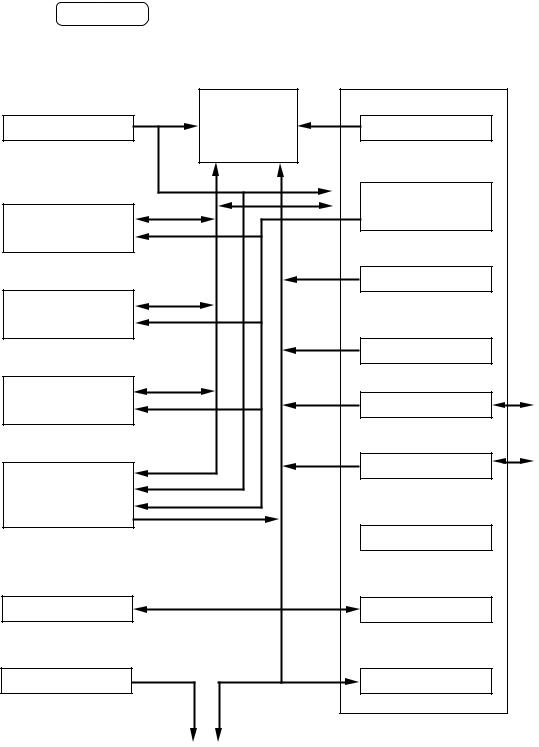

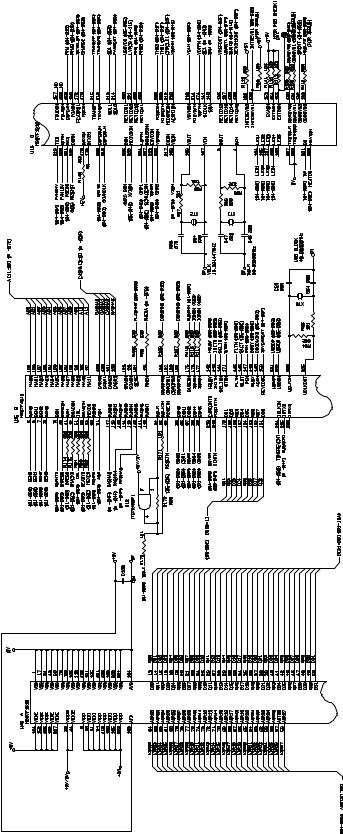

(11)Engine control I/O

This I/O is used for the connection to the panel sensor PCB. It controls the main motor, solenoid, sensors, etc.

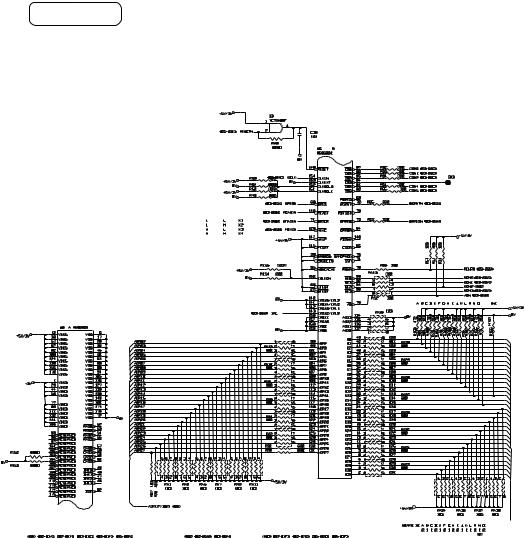

Fig. 2-9

II-11

HL-1050

The ASIC is composed of a Cell Based IC that contains the following functional blocks.

(1)Oscillator circuit

Generates the main clock for the CPU.

(2)Address decoder

Generates the CS for each device.

(3)DRAM control

Generates the RAS, CAS, WE, OE and MA signals for the DRAM and controls refresh processing (CAS before RAS self-refreshing method).

(4)Interrupt control

Interrupt levels: |

|

|

|

Priority |

High |

10 |

|

|

|

9 |

|

|

|

8 |

|

|

|

|

7 |

|

|

|

|

|

|

6 |

|

|

|

|

5 |

|

|

|

|

|

|

4 |

|

|

|

3 |

|

|

|

2 |

|

|

Low |

1 |

|

Note:

Reserve interrupt 1 (for debug) Watch Dog Timer

LSB EMPTY (for VDO FIFO) Timer 1

USB

XIO interrupt (RS-100M) or MIO interrupt BD (for engine check)

Reserve interrupt 2 CDCC

Timer 2

All the interrupts can be masked.

The priority of levels 7, 6, and 5 are changeable from the program.

(5)Timers

The following timers are incorporated:

Timer 1 |

32-bit timer |

Timer 2 |

32-bit timer |

Timer 3 |

Watch-dog timer |

(6)FIFO

A 10Kbit FIFO is included. Data for one raster scan is transferred from the RAM to the FIFO by DMA transmission and is output as serial video data. The data cycle is 10.43MHz.

(7)Parallel I/O

<Data receive Mode>

There are two modes in this unit. One is the CPU receive mode and the other is the DMA receive mode. In the CPU receive mode the CPU receives the command data from the PC, and after the CPU is switched to the DMA mode, it receives the image data and writes it to the DRAM directly.

II-12

CPU Receive Mode

STROBE

BUSY

ACK

90 µsec |

0.5 µsec |

|

|

|

|

DMA Receive Mode

STROBE

BUSY

ACK

1.5 µsec |

0.5 µsec |

|

|

|

|

BUSY goes HIGH at the falling edge of the STROBE signal. The data (8 bits) from the PC is latched into the data buffer at the rising edge of the STROBE signal. The pulse width of ACK varies according to the speed MODE as shown above. BUSY goes LOW on the rising edge of ACK.

<IEEE1284 support>

This supports the IEEE1284 data transfer with the following mode.

Nibble mode

Byte mode

ECP mode

(8)Data expansion

This circuit expands the compressed image data received from the PC, and writes the bit map data to the FIFO.

(9)Software support

Supports 16 x 16 rotation, bit expansion, bit search, and decimal point conversion.

(10)EEPROM I/O

One output port and one I/O port are assigned.

II-13

(11)Engine control I/O

This I/O is used for the connection to the panel sensor PCB. It controls the main motor, solenoid, sensors, etc.

Fig. 2-10

II-14

Loading...

Loading...