Brother HE-800A User Manual

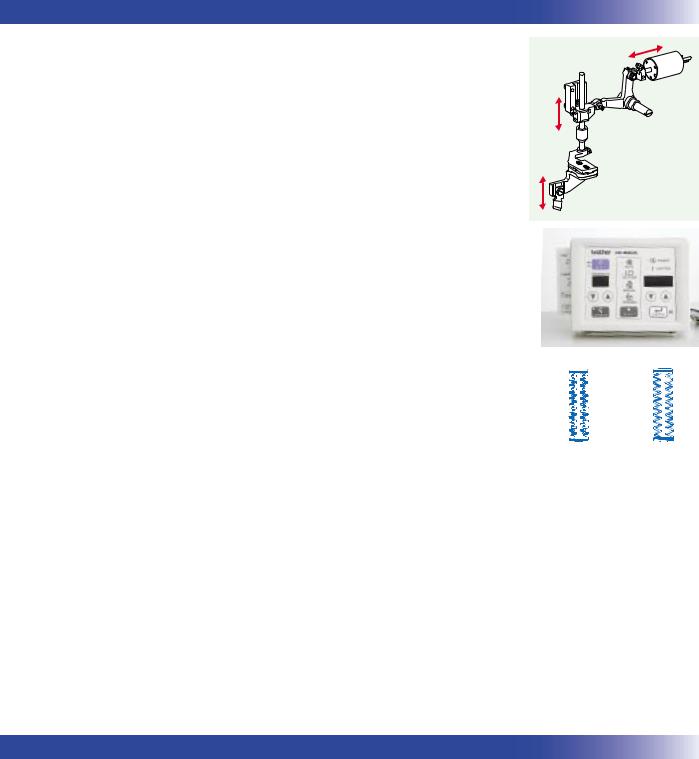

Electronic lockstich button holer

HE-800A

•21 built-in patterns plus original patterns

•Adjustable presser foot lifter height makes insertion and removal of the material easier

•Quick and accurate double position cutter operation

•PD-8000 Programmer uses easy-to-use icon display (Optional product)

HE-800A

PD-8000

Electronic operation provides a much greater number of pattern variations and a dramatic improvement in sewing quality

21 built-in sewing patterns plus original patterns

Program selection is as easy as pressing a button. 90 separate programs can be stored in memory. Furthermore, you can add up to 9 original patterns with programming software for electronic pattern sewer

Rectangle |

Rectangle-radial |

Rectangle-round |

Rectangle-taper tack |

Rectangle-tack |

Radial-rectangle |

Radial |

Radial-round |

Radial-taper tack |

Radial-tack |

Bar tack |

Round-rectangle |

Round-radial |

Round |

Round-taper tack |

Round-tack |

Eyelet-rectangle |

Eyelet-radial |

Eyelet-round |

Eyelet-taper tack |

Eyelet-tack |

|

Easy operation

Easy positioning

•The presser foot lifter is driven by a pulse motor, so that the height can be adjusted as desired (standard function) for when the pedal is at the neutral position and when it is depressed forward (two stages) and backward. This makes insertion and removal of the material easier and reduces working fatigue.

•The presser foot rises only by the height necessary, so that the time needed for it to rise and drop can be shortened.

Easy operation

No need for adjustments such as replacing cutter cams when changing number of stitches

The cutter vertical movements is driven by a double position solenoid. If not using a cutter, the cutter operation can be deactivated at the press of a key. The cutter operates without slowing down the sewing machine, and the cutter response time is also fast, so that cycle time is reduced and productivity is increased.

Simple and easy-to-use operation panel

There is a program memo pocket provided on the back of the panel. This lets the operator keep necessary information such as a parameter table, program notes and an error code table on hand for easy reference. The operator can select panel position whichever above or below the work table.

Purl stitch / Whip stitch

The upper thread tension is controlled by a solenoid, so that setting between purl stitches and whip stitches can be done simply by selecting them on the operation panel. Fine adjustments to the upper thread tension are made using a thread tension nut. The same method that operators have become used to allows the optimum thread tension to be easily obtained.

Ideal for sewing vertical buttonholes

Double position solenoid

Purl stitch |

|

Whip stitch |

|

|

|

A wider operating area is available when the machine head is positioned horizontally on the work table.

Quiet operating environment

Adoption of a clutchless mechanism ensures quieter operating environment and increased durability.

Easy threading

The needle bar can be moved to the right as a matter of course, and this makes threading much easier.

Accurate home position detection

The home position sensor incorporates a nonoptical proximity sensor, so the sensor is not subject to operating errors from oil or dust, and cleaning oil and dust from the sensor are also unnecessary.

Thread trimming speed can be set

The lower thread trimming mechanism operates in conjunction with the presser foot lifter mechanism, and is driven by a pulse motor. As a result, the thread trimmer driving speed can also be changed at the operation panel.

Gives perfect sewing finishes

Wide sewing range

The thread take-up, rotary hook and thread path mechanisms provide ideal balance, so that attractive buttonholes can be sewn in a variety of different materials under a variety conditions.

Accurate cutter operation

The cutter vertical movements is driven by a double position solenoid, so that the material is cut more acurately.

Clean finish with no upper thread trailing length

Attractive finishes are obtained with no upper thread trailing at the sewing end. This ensures a stable and consistent high-quality sewing finish is always obtained.

Better stitches at the sewing start

Adoption of a bobbin presser prevents the bobbin from spinning free when the lower thread is trimmed. This makes lower thread feeding more stable and produces better stitches at the sewing start. And the lower thread holding device holds the lower thread at the sewing start to ensure that the thread end is sewn into the seam properly.

Loading...

Loading...