Brother FAX8200P, FAX8000P, FAX3650, FAX3550 Service Manual

FACSIMILE EQUIPMENT

SERVICE MANUAL

MODEL: FAX3550/3650/8000P/8200P MFC4450/4550/4550plus MFC6550MC/7550MC/7650MC MFC9000/9500

© Copyright Brother 1998

All rights reserved.

No part of this publication may be reproduced in any form or by any means without permission in writing from the publisher.

Specifications are subject to change without notice.

PREFACE

This publication is a Service Manual covering the specifications, construction, theory of operation, and maintenance of the Brother facsimile equipment. It includes information required for field troubleshooting and repair—disassembly, reassembly, and adjustment—so that service personnel will be able to understand equipment function, to rapidly repair the equipment and order any necessary spare parts.

To perform appropriate maintenance so that the facsimile equipment is always in best condition for the customer, the service personnel must adequately understand and apply this manual.

This manual is made up of six chapters and appendices.

CHAPTER I. |

GENERAL DESCRIPTION |

CHAPTER II. |

INSTALLATION |

CHAPTER III. |

THEORY OF OPERATION |

CHAPTER IV. |

DISASSEMBLY/REASSEMBLY AND LUBRICATION |

CHAPTER V. |

MAINTENANCE MODE |

CHAPTER VI. |

ERROR INDICATION AND TROUBLESHOOTING |

APPENDICES |

Circuit Diagrams |

This manual describes the model and its versions to be destined for major countries. The specifications and functions are subject to change depending upon each destination.

SAFETY INFORMATION

Laser Safety (110 - 120V Model only)

This printer is certified as a Class 1 laser product under the US Department of Health and Human Services (DHHS) Radiation Performance Standard according to the Radiation Control for Health and Safety Act of 1968. This means that the printer does not produce hazardous laser radiation.

Since radiation emitted inside the printer is completely confined within the protective housings and external covers, the laser beam cannot escape from the machine during any phase of user operation.

CDRH Regulations (110 - 120V Model only)

The Center for Device and Radiological Health (CDRH) of the US Food and Drug Administration implemented regulations for laser products on August 2, 1976. These regulations apply to laser products manufactured from August 1, 1976. Compliance is mandatory for products marketed in the United States. The label shown below indicates compliance with the CDRH regulations and must be attached to laser products marketed in the United States.

The label for Japanese products

MANUFACTURED: |

AUGUST |

1998 |

K |

BROTHER INDUSTRIES, LTD.

15-1 Naeshiro-cho Mizuho-ku Nagoya 467-8561, Japan.

This product complies with FDA radiation

performance standards, 21 CFR Subchapter J.

CHAPTER I.

GENERAL DESCRIPTION

CONTENTS

1. |

EQUIPMENT OUTLINE ................................................................................. |

I-1 |

|

|

1.1 |

External Appearance and Weight ........................................................... |

I-1 |

|

1.2 |

Components ............................................................................................ |

I-1 |

2. |

SPECIFICATIONS .......................................................................................... |

I-2 |

|

1. EQUIPMENT OUTLINE

1.1External Appearance and Weight

The figure below shows the equipment appearance and approximate dimensions.

251 (H)

383 (W) |

452 (D) |

||

(Unit: mm) |

|||

(excluding the handset) |

|||

|

|||

Weight: Machine proper |

Approx. 8.5 kg (excluding the drum unit and toner cartridge) |

||

In package |

Approx. 13.5 kg |

(FAX3550/3650/8000P/8200P) |

|

|

Approx. 14 kg |

(MFC4450/4550/4550plus/6550MC/7550MC/ |

|

|

|

7650MC/9000/9500) |

|

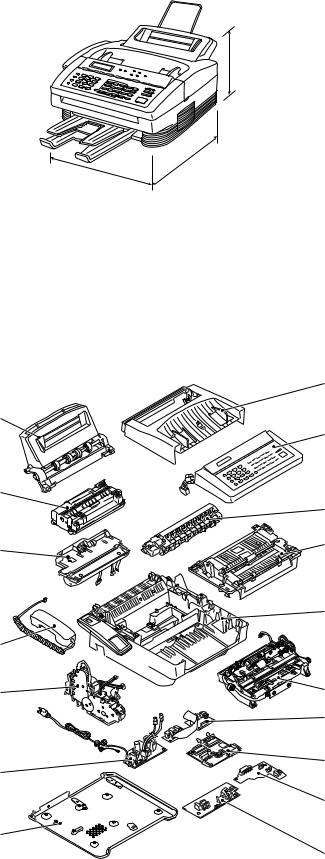

1.2Components

The equipment consists of the following major components:

Multi-purpose sheet feeder

Drum unit with toner cartridge loaded

Laser unit

Handset

Gear drive unit

Low-voltage power supply ASSY

Bottom plate

Top cover

Control panel ASSY

Heat-fixing unit

Inner cover

Main cover

Scanner frame ASSY NCU PCB ASSY

Main PCB

Relay PCB

High-voltage power supply ASSY

I –1

2. SPECIFICATIONS

(1/2)

MODEL |

FAX3550 |

MFC4550 |

MFC6550MC |

MFC7550MC |

COLOR |

1267 |

1138 |

1138 |

1138 |

|

|

|

|

|

PRINTER |

Option |

|

|

|

Engine |

— |

HL-720 |

HL-730 |

HL-730 |

|

|

|

|

|

PPM |

— |

6 |

6 |

6 |

|

|

|

|

|

dpi |

— |

600 x 600 |

600 x 600 |

600 x 600 |

|

|

|

|

|

Paper Capacity |

200 |

200 |

200 |

200 |

Standards |

— |

Windows GDI (600x600) |

Windows GDI (600x600) |

Windows GDI (600x600) |

Emulation |

— |

No |

PCL4 (300x300) |

PCL4 (300x300) |

Memory (Typical) |

— |

512 KB |

512 KB |

1 MB |

Memory (Min.) |

— |

300 KB |

400 KB |

1 MB |

|

|

|

|

|

Fonts Resident |

— |

No |

24-bit map (PCL4 Comp) |

24-bit map (PCL4 Comp) |

|

|

|

|

|

Fonts Disk Based |

— |

No |

Yes |

Yes |

|

|

|

|

|

Paper Handling |

LTR, LGL, A4 |

LTR, LGL, EXE, A4, B5, A5 |

LTR, LGL, EXE, A4, B5, A5 |

LTR, LGL, EXE, A4, B5, A5 |

|

|

|

|

|

Multi-purpose Sheet |

Custom Size (2.85x5-8x14) |

Custom Size (2.85x5-8x14) |

Custom Size (2.85x5-8x14) |

Custom Size (2.85x5-8x14) |

Feeder |

Envelope (BL/C5/COM 10/Mona) |

Envelope (BL/C5/COM 10/Mona) |

Envelope (BL/C5/COM 10/Mona) |

Envelope (BL/C5/COM 10/Mona) |

|

|

|

|

|

Printer Driver |

— |

Windows 3.1, 95 Driver with |

Windows 3.1, 95 Driver with |

Windows 3.1, 95 Driver with |

|

|

Auto Installer Program |

Auto Installer Program |

Auto Installer Program |

|

|

|

|

|

Toner Life (5%/page) |

2200 pages |

2200 pages |

2200 pages |

2200 pages |

|

|

|

|

|

Utility Software |

— |

— |

RPC |

RPC |

|

|

|

|

|

|

|

|

|

|

SCANNER |

Option |

|

|

|

|

|

|

|

|

Color/Mono |

— |

Mono |

Mono |

Mono |

|

|

|

|

|

Gray Scale |

— |

64 |

256 |

256 |

|

|

|

|

|

dpi |

— |

400 x 400 |

600 x 600 |

600 x 600 |

|

|

|

|

|

Twain |

— |

Yes |

Yes |

Yes |

|

|

|

|

|

ADF Capacity (pages) |

(30) |

30 |

30 |

30 |

Formats |

— |

TIFF/BMP (by M/L) |

TIFF/BMP (by M/L) |

TIFF/BMP (by M/L) |

OCR |

— |

Option |

Yes |

Yes |

|

|

|

|

|

|

|

|

|

|

COPY |

|

|

|

|

|

|

|

|

|

dpi |

200 x 400 |

200 x 400 |

600 class |

600 class |

No. of Copies |

1-99 |

1-99 |

1-99 |

1-99 |

Sorting |

No |

No |

Yes |

Yes |

Reduction/Enlargement |

50-200% |

50-200% |

50-200% |

50-200% |

|

|

|

|

|

FAX |

|

|

|

|

Modem |

ROCKWELL V12 |

ROCKWELL V12 |

ROCKWELL V24 |

ROCKWELL V24 |

Modem Speed |

14400 bps (FAX only) |

14400 bps (FAX only) |

14400 bps (FAX only) |

14400 bps (FAX only) |

CCITT Group |

G3 |

G3 |

G3 |

G3 |

Coding Method |

MH/MR/MMR |

MH/MR/MMR |

MH/MR/MMR |

MH/MR/MMR |

Transmission Speed |

6 sec. |

6 sec. |

6 sec. |

6 sec. |

Input/Output Width |

8.5"/8.5" |

8.5"/8.5" |

8.5"/8.5" |

8.5"/8.5" |

LCD Size |

16 x 1 |

16 x 2 |

16 x 2 |

16 x 2 |

Super Fine |

Yes (Send only) |

Yes (Send only) |

Yes (Send only) |

Yes |

|

|

|

|

|

Gray Scale |

64 |

64 |

64 |

64 |

|

|

|

|

|

Smoothing |

Yes |

Yes |

Yes |

Yes |

|

|

|

|

|

Handset |

Yes |

Yes |

Yes |

Yes |

|

|

|

|

|

One-touch Dial |

20 x 2 |

12 x 2 |

12 x 2 |

12 x 2 |

|

|

|

|

|

Speed Dial |

100 |

36 |

36 |

100 |

|

|

|

|

|

Telephone Index |

Yes |

Yes |

Yes |

Yes |

|

|

|

|

|

Contrast |

Super L/Auto/Super D |

Super L/Auto/Super D |

Super L/Auto/Super D |

Super L/Auto/Super D |

Multi-resolution Transmission |

Yes |

Yes |

Yes |

Yes |

|

|

|

|

|

FAX/TEL Switch |

Yes |

Yes |

Yes |

Yes |

|

|

|

|

|

Distinctive Ringing |

Yes |

Yes |

Yes |

Yes |

|

|

|

|

|

Caller ID |

Yes |

Yes |

Yes |

Yes |

|

|

|

|

|

Next FAX-reservation |

Yes |

Yes |

Yes |

Yes |

|

|

|

|

|

Help |

Yes |

Yes |

Yes |

Yes |

|

|

|

|

|

TAD Interface |

Yes |

Yes |

Yes |

Yes |

|

|

|

|

|

I –2

(1/2)

MODEL |

FAX3650 |

MFC4450 |

MFC4550plus |

MFC7650MC |

COLOR |

1267 |

1138 |

1138 |

1138 |

PRINTER |

Option |

|

|

|

Engine |

— |

HL-720 |

HL-720 |

HL-730 |

|

|

|

|

|

PPM |

— |

6 |

6 |

6 |

|

|

|

|

|

dpi |

200 x 200 |

600 x 600 |

600 x 600 |

600 x 600 |

|

|

|

|

|

Paper Capacity |

200 |

200 |

200 |

200 |

|

|

|

|

|

Standards |

Windows GDI (200x200) |

Windows GDI (600x600) |

Windows GDI (600x600) |

Windows GDI (600x600) |

|

|

|

|

|

Emulation |

— |

No |

PCL4 (300x300) |

PCL4 (300x300) |

|

|

|

|

|

Memory (Typical) |

— |

512 KB |

512 KB |

1 MB |

Memory (Min.) |

— |

300 KB |

400 KB |

600 KB |

Fonts Resident |

— |

No |

24-bit map (PCL4 Comp) |

24-bit map (PCL4 Comp) |

|

|

|

|

|

Fonts Disk Based |

— |

No |

Yes |

Yes |

|

|

|

|

|

Paper Handling |

LTR, LGL, A4 |

LTR, LGL, A4, B5, A5 |

LTR, LGL, A4, B5, A5 |

LTR, LGL, A4, B5, A5 |

|

|

|

|

|

Multi-purpose Sheet |

— |

Custom Size (2.85x5-8x14) |

Custom Size (2.85x5-8x14) |

Custom Size (2.85x5-8x14) |

Feeder |

|

Envelope (BL/C5/COM 10/Mona) |

Envelope (BL/C5/COM 10/Mona) |

Envelope (BL/C5/COM 10/Mona) |

|

|

|

|

|

Printer Driver |

— |

Windows 3.1, 95 Driver with |

Windows 3.1, 95 Driver with |

Windows 3.1, 95 Driver with |

|

|

Auto Installer Program |

Auto Installer Program |

Auto Installer Program |

|

|

|

|

|

Toner Life (5%/page) |

2200 pages |

2200 pages |

2200 pages |

2200 pages |

|

|

|

|

|

Utility Software |

— |

— |

RPC |

RPC |

|

|

|

|

|

|

|

|

|

|

SCANNER |

Option |

|

|

|

|

|

|

|

|

Color/Mono |

— |

Mono |

Mono |

Mono |

|

|

|

|

|

Gray Scale |

— |

64 |

64 |

256 |

|

|

|

|

|

dpi |

— |

400 x 400 |

400 x 400 |

600 x 600 |

|

|

|

|

|

Twain |

— |

Yes |

Yes |

Yes |

|

|

|

|

|

ADF Capacity (pages) |

— |

30 |

30 |

30 |

|

|

|

|

|

Formats (Import) |

— |

TIFF/BMP/PCX/DCX/BTF/BTX/UNI |

TIFF/BMP/PCX/DCX/BTF/BTX/MAX |

TIFF/BMP/PCX/DCX/BTF/BTX/MAX |

Formats (Export) |

— |

TIFF/BMP/UNI |

TIFF/BMP/MAX |

TIFF/BMP/MAX |

|

|

|

|

|

OCR |

— |

Option |

Yes |

Yes |

|

|

|

|

|

|

|

|

|

|

COPY |

|

|

|

|

|

|

|

|

|

dpi |

200 x 400 |

200 x 400 |

200 x 400 |

600 class |

No. of Copies |

1-99 |

1-99 |

1-99 |

1-99 |

Sorting |

Yes |

No |

No |

Yes |

Reduction/Enlargement |

50-200% |

50-200% |

50-200% |

50-200% |

|

|

|

|

|

FAX |

|

|

|

|

Modem |

ROCKWELL V12 |

Toshiba |

ROCKWELL V12 |

ROCKWELL V24 |

Modem Speed |

14400 bps (FAX only) |

9600 bps (FAX only) |

14400 bps (FAX only) |

14400 bps (FAX only) |

CCITT Group |

G3 |

G3 |

G3 |

G3 |

Coding Method |

MH/MR/MMR |

MH/MR/MMR |

MH/MR/MMR |

MH/MR/MMR |

Transmission Speed |

6 sec. |

9 sec. |

6 sec. |

6 sec. |

Input/Output Width |

8.5"/8.5" |

8.5"/8.5" |

8.5"/8.5" |

8.5"/8.5" |

LCD Size |

16 x 1 |

16 x 2 |

16 x 2 |

16 x 2 |

Super Fine |

Yes |

Yes |

Yes |

Yes |

|

|

|

|

|

Gray Scale |

64 |

64 |

64 |

64 |

|

|

|

|

|

Smoothing |

Yes |

Yes |

Yes |

Yes |

|

|

|

|

|

Handset |

Yes |

No |

Yes |

Yes |

|

|

|

|

|

One-touch Dial |

20 x 2 |

12 x 2 |

12 x 2 |

12 x 2 |

|

|

|

|

|

Speed Dial |

100 |

36 |

36 |

100 |

Telephone Index |

Yes |

Yes |

Yes |

Yes |

Contrast |

Super L/Auto/Super D |

Super L/Auto/Super D |

Super L/Auto/Super D |

Super L/Auto/Super D |

Multi-resolution Transmission |

Yes |

Yes |

Yes |

Yes |

FAX/TEL Switch |

Yes |

Yes (with External) |

Yes |

Yes |

|

|

|

|

|

Distinctive Ringing |

Yes |

Yes (with External) |

Yes |

Yes |

|

|

|

|

|

Caller ID |

Yes |

No |

Yes |

Yes |

|

|

|

|

|

Next FAX-reservation |

Yes |

Yes |

Yes |

Yes |

|

|

|

|

|

Help |

Yes |

Yes |

Yes |

Yes |

|

|

|

|

|

TAD Interface |

Yes |

Yes |

Yes |

Yes |

|

|

|

|

|

I –3

(1/2)

MODEL |

FAX8000P |

MFC9000 |

MFC9500 |

FAX8200P |

COLOR |

1138 |

1138 |

1138 |

1138 |

|

|

|

|

|

PRINTER |

Option |

|

|

Option |

Engine |

— |

HL-730 |

HL-730 |

— |

|

|

|

|

|

PPM |

— |

6 |

6 |

— |

|

|

|

|

|

dpi |

— |

600 x 600 (GDI) / 300 x 300 (PCL4) |

600 x 600 (GDI) / 300 x 300 (PCL4) |

— |

|

|

|

|

|

Paper Capacity |

200 |

200 |

200 |

200 |

Standards |

— |

Windows GDI |

Windows GDI |

— |

Emulation |

— |

PCL4 |

PCL4 |

— |

Memory (Typical) |

— |

512 KB |

512 KB |

— |

Memory (Min.) |

— |

400 KB |

400 KB |

— |

|

|

|

|

|

Fonts Resident |

— |

24-bit map (PCL4 Comp) |

24-bit map (PCL4 Comp) |

— |

|

|

|

|

|

Fonts Disk Based |

— |

Yes |

Yes |

— |

|

|

|

|

|

Paper Handling |

A4, B5, A5 |

A4, B5, A5 |

A4, B5, A5 |

A4 |

|

|

|

|

|

Multi-purpose Tray |

Custom Size (73x127-126x350 mm) |

Custom Size (73x127-216x350 mm) |

Custom Size (73x127-216x350 mm) |

— |

|

Envelope (DL/C5/COM 10/Mona) |

Envelope (DL/C5/COM 10/Mona) |

Envelope (DL/C5/COM 10/Mona) |

|

|

|

|

|

|

Printer Driver |

— |

Windows 3.1, 95 Driver with |

Windows 3.1, 95 Driver with |

— |

|

|

Auto Installer Program |

Auto Installer Program |

|

|

|

Mac Driver (Option) |

Mac Driver (Option) |

|

|

|

|

|

|

Toner Life (5%/page) |

2200 pages |

2200 pages |

2200 pages |

2200 pages |

|

|

|

|

|

Utility Software |

— |

Remote Priter Console (RPC) |

Remote Printer Console (RPC) |

— |

|

|

|

|

|

|

|

|

|

|

SCANNER |

Option |

|

|

Option |

|

|

|

|

|

Color/Mono |

— |

Mono |

Mono |

— |

|

|

|

|

|

Gray Scale |

— |

256 |

256 |

— |

|

|

|

|

|

dpi |

— |

600 x 600 |

600 x 600 |

— |

|

|

|

|

|

Twain |

— |

Yes |

Yes |

— |

|

|

|

|

|

ADF Capacity (pages) |

30 |

30 |

30 |

— |

|

|

|

|

|

Formats |

— |

TIFF/BMP |

TIFF/BMP |

— |

|

|

|

|

|

OCR |

— |

Option |

Yes |

— |

|

|

|

|

|

|

|

|

|

|

COPY |

|

|

|

|

|

|

|

|

|

dpi |

200 x 400 |

300 x 400 |

300 x 400 |

200 x 400 |

No. of Copies |

1-99 |

1-99 |

1-99 |

1-99 |

|

|

|

|

|

Sorting |

Available with optional memory |

Yes |

Yes |

Yes |

|

|

|

|

|

Reduction/Enlargement |

50-200% |

50-200% |

50-200% |

50-200% |

|

|

|

|

|

|

|

|

|

|

FAX |

|

|

|

|

Modem |

ROCKWELL V12 |

ROCKWELL V12 |

ROCKWELL V24 |

ROCKWELL V12 |

Modem Speed |

14400 bps (FAX only) |

14400 bps (FAX only) |

14400 bps (FAX only) |

14400 bps (FAX only) |

CCITT Group |

G3 |

G3 |

G3 |

G3 |

Coding Method |

MH/MR/MMR |

MH/MR/MMR |

MH/MR/MMR |

MH/MR/MMR |

Transmission Speed |

6 sec. |

6 sec. |

6 sec. |

6 sec. |

|

|

|

|

|

Input/Output Width |

8.5"/8.5" |

8.5"/8.5" |

8.5"/8.5" |

8.5"/8.5" |

|

|

|

|

|

LCD Size |

16 x 1 |

16 x 2 (STN) |

16 x 2 (STN) |

16 x 1 |

|

|

|

|

|

Super Fine (Send) |

Yes |

Yes |

Yes |

Yes |

|

|

|

|

|

Super Fine (Receive) |

Available with optional memory |

Available with optional memory |

Available with optional memory |

Yes |

|

|

|

|

|

Gray Scale |

64 |

64 |

64 |

64 |

|

|

|

|

|

Smoothing |

Yes |

Yes |

Yes |

Yes |

|

|

|

|

|

Handset |

No |

No |

No |

No |

|

|

|

|

|

One-touch Dial |

20 x 2 |

12 x 2 |

12 x 2 |

20 x 2 |

|

|

|

|

|

Speed Dial |

100 |

100 |

100 |

100 |

|

|

|

|

|

Telephone Index |

Yes |

Yes |

Yes |

Yes |

|

|

|

|

|

Contrast |

Light/Auto/Dark |

Light/Auto/Dark |

Light/Auto/Dark |

Light/Auto/Dark |

|

|

|

|

|

Multi-resolution Transmission |

Yes |

Yes |

Yes |

Yes |

|

|

|

|

|

FAX/TEL Switch |

Yes |

Yes |

Yes |

Yes |

|

|

|

|

|

Distinctive Ringing |

Yes |

Yes |

Yes |

— |

|

|

|

|

|

Caller ID |

Yes (U.K., Sweden, Holland and France) |

Yes (U.K., Sweden, Holland and France) |

Yes (U.K., Sweden, Holland and France) |

Yes (U.K., Sweden, Holland and France) |

|

|

|

|

|

Next FAX-reservation |

Yes |

Yes |

Yes |

Yes |

|

|

|

|

|

Help |

Yes |

Yes |

Yes |

Yes |

|

|

|

|

|

TAD Interface |

Yes |

Yes |

Yes |

Yes |

|

|

|

|

|

I –4

(2/2)

MODEL |

FAX3550 |

MFC4550 |

MFC6550MC |

MFC7550MC |

|

|

|

|

|

FAX |

|

|

|

|

|

|

|

|

|

Coverpage |

Yes, Super |

Yes, Super |

Yes, Super |

Yes, Super |

|

|

|

|

|

Polling Type |

Std/Del/Seq |

Std/Del/Seq |

Std/Del/Seq |

Std/Del/Seq |

|

|

|

|

|

Receive password |

Yes |

Yes |

Yes |

Yes |

|

|

|

|

|

Delayed Transmission |

Yes, 3 timings |

Yes, 3 timings |

Yes, 3 timings |

Yes, 3 timings |

|

|

|

|

|

Call Reservation |

Yes |

Yes |

Yes |

Yes |

|

|

|

|

|

Callback Message |

Yes |

Yes |

Yes |

Yes |

|

|

|

|

|

Page Memory (TX)* |

300 KB (30 pgs: MMR) |

200 KB (20 pgs: MMR) |

300 KB (30 pgs: MMR) |

700 KB (70 pgs: MMR) |

|

|

|

|

|

Out-of-paper Reception* |

400 KB (40 pgs: MMR) |

400 KB (40 pgs: MMR) |

600 KB (60 pgs: MMR) |

1.5 MB (150 pgs: MMR) |

|

|

|

|

|

Super Quick Scan |

Yes |

Yes |

Yes |

Yes |

|

|

|

|

|

Auto Reduction |

Yes |

Yes |

Yes |

Yes |

|

|

|

|

|

ECM |

Yes |

Yes |

Yes |

Yes |

|

|

|

|

|

Broadcasting |

Yes |

Yes |

Yes |

Yes |

|

|

|

|

|

Multi Transmission |

Yes |

Yes |

Yes |

Yes |

|

|

|

|

|

|

|

|

|

|

MESSAGE CENTER |

|

|

|

|

|

|

|

|

|

TAD Feature |

No |

No |

Yes (Hardware & PC) |

Yes (Hardware & PC) |

|

|

|

|

|

ICM Recording Time |

No |

No |

Hardware: 15 min. |

Hardware: 30 min. |

|

|

|

|

|

Paging |

No |

No |

Yes (Hardware & PC) |

Yes (Hardware & PC) |

|

|

|

|

|

Toll Saver |

No |

No |

Yes (Hardware & PC) |

Yes (Hardware & PC) |

|

|

|

|

|

OGM |

No |

No |

Yes (Hardware & PC) |

Yes (Hardware & PC) |

|

|

|

|

|

Mail Box |

No |

No |

Yes (PC only) |

Yes (PC only) |

|

|

|

|

|

Fax-on-demand |

No |

No |

Yes (PC only) |

Yes (PC only) |

|

|

|

|

|

Voice-on-demand |

No |

No |

Yes (PC only) |

Yes (PC only) |

|

|

|

|

|

FAX Forwarding |

Yes |

Yes |

Yes |

Yes |

|

|

|

|

|

FAX Retrieval |

Yes |

Yes |

Yes |

Yes |

|

|

|

|

|

|

|

|

|

|

MACHINE MEMORY |

0.75 MB |

0.75 MB |

1 MB |

2 MB |

|

|

|

|

|

|

|

|

|

|

OPTIONAL MEMORY |

1 or 2 MB |

1 or 2 MB |

1 or 2 MB |

1 or 2 MB |

(FAX & PRINTER FLEX) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PC FAX (Send/Receive) |

Option |

Yes (by M/L) |

Yes (by M/L) |

Yes (by M/L) |

|

|

|

|

|

Standard |

— |

Class 1, 2 |

Class 1, 2 |

Class 1, 2 |

|

|

|

|

|

|

|

|

|

|

DATA MODEM |

No |

No |

No |

No |

|

|

|

|

|

|

|

|

|

|

INTERFACE |

|

|

|

|

|

|

|

|

|

Printer Interface |

— |

Centronics parallel (w/o cable) |

Centronics parallel (w/o cable) |

Centronics parallel (w/o cable) |

|

|

MULTI-FUNCTION LINK PRO |

MULTI-FUNCTION LINK PRO |

MULTI-FUNCTION LINK PRO |

|

|

|

|

|

PC Interface |

RS-232C |

— |

— |

— |

|

(8-pin modular connector) |

|

|

|

|

MULTI-FUNCTION LINK |

|

|

|

|

|

|

|

|

Extended I/O Interface |

— |

— |

RS-232C and RS-422 |

RS-232C and RS-422 |

|

|

|

||

|

|

|

(supported by an optional serial |

(supported by an optional serial |

|

|

|

interface board RS-100M) |

interface board RS-100M) |

|

|

|

|

|

|

|

|

|

|

Simultaneous |

|

|

|

|

|

|

|

|

|

Sends FAX and Prints |

— |

Yes |

Yes |

Yes |

|

|

|

|

|

Receives FAX and Prints |

— |

Yes |

Yes |

Yes |

|

|

|

|

|

Receives FAX and Scans |

— |

Yes |

Yes |

Yes |

|

|

|

|

|

Prints and Scans |

— |

Yes |

Yes |

Yes |

|

|

|

|

|

Receives FAX and Copies |

— |

Yes |

Yes |

Yes |

|

|

|

|

|

Prints and Copies |

— |

Yes |

Yes |

Yes |

|

|

|

|

|

* CCITT#1 Chart in the Standard Mode, MMR

I –5

(2/2)

MODEL |

FAX3650 |

MFC4450 |

MFC4550plus |

MFC7650MC |

|

|

|

|

|

FAX |

|

|

|

|

|

|

|

|

|

Coverpage |

Yes, Super |

Yes, Super |

Yes, Super |

Yes, Super |

|

|

|

|

|

Polling Type |

Std/Del/Seq |

Std/Del/Seq |

Std/Del/Seq |

Std/Del/Seq |

|

|

|

|

|

Delayed Transmission |

Yes, 13 timings |

Yes, 3 timings |

Yes, 3 timings |

Yes, 13 timings |

|

|

|

|

|

Call Reservation |

Yes |

Yes (with External) |

Yes |

Yes |

|

|

|

|

|

Callback Message |

Yes |

Yes |

Yes |

Yes |

|

|

|

|

|

Page Memory (TX)* |

1 MB (100 pgs: MMR) |

300 KB (30 pgs: MMR) |

300 KB (30 pgs: MMR) |

800 KB (80 pgs: MMR) |

|

|

|

|

|

Out-of-paper Reception* |

1.1 MB (110 pgs: MMR) |

600 KB (60 pgs: MMR) |

600 KB (60 pgs: MMR) |

1.0 MB (100 pgs: MMR) |

|

|

|

|

|

Super Quick Scan |

Yes |

Yes |

Yes |

Yes |

|

|

|

|

|

ECM |

Yes |

Yes |

Yes |

Yes |

|

|

|

|

|

Broadcasting |

Yes |

Yes |

Yes |

Yes |

|

|

|

|

|

Multi Transmission |

No |

Yes |

Yes |

No |

|

|

|

|

|

|

|

|

|

|

MESSAGE CENTER |

|

|

|

|

|

|

|

|

|

ICM Recording Time |

No |

No |

No |

Hardware: 30 min. |

|

|

|

|

|

Paging |

Yes (Hardware & PC) |

Yes (Hardware & PC) |

Yes (Hardware & PC) |

Yes (Hardware & PC) |

|

|

|

|

|

Toll Saver |

No |

No |

No |

Yes (Hardware & PC) |

|

|

|

|

|

OGM |

No |

No |

No |

Yes (Hardware & PC) |

|

|

|

|

|

Mail Box |

No |

No |

Yes (PC only) |

Yes (PC only) |

|

|

|

|

|

Fax-on-demand |

No |

No |

No |

Yes (PC only) |

|

|

|

|

|

Voice-on-demand |

No |

No |

No |

Yes (PC only) |

|

|

|

|

|

FAX Forwarding |

Yes |

Yes |

Yes |

Yes |

|

|

|

|

|

FAX Retrieval |

Yes |

Yes |

Yes |

Yes |

|

|

|

|

|

|

|

|

|

|

MACHINE MEMORY |

2 MB |

1 MB |

1 MB |

2 MB |

|

|

|

|

|

OPTIONAL MEMORY |

1 or 2 MB |

No |

1 or 2 MB |

1 or 2 MB |

(FAX & PRINTER FLEX) |

|

|

|

|

|

|

|

|

|

PC FAX (Send/Receive) |

Option |

Yes (by M/L) |

Yes (by M/L) |

Yes (by M/L) |

Standard |

— |

SMSI |

SMSI |

SMSI |

|

|

|

|

|

DATA MODEM |

No |

No |

No |

No |

|

|

|

|

|

INTERFACE |

|

|

|

|

Printer Interface |

— |

Centronics parallel (w/o cable) |

Centronics parallel (w/o cable) |

Centronics parallel (w/o cable) |

|

|

MULTI-FUNCTION LINK PRO |

MULTI-FUNCTION LINK PRO |

MULTI-FUNCTION LINK PRO |

PC Interface |

RS-232C |

— |

— |

— |

|

(8-pin modular connector) |

|

|

|

|

MULTI-FUNCTION LINK |

|

|

|

|

|

|

|

|

Extended I/O Interface |

— |

— |

— |

RS-232C and RS-422 |

|

|

|

|

|

|

|

|

|

(supported by an optional serial |

|

|

|

|

interface board RS-100M) |

|

|

|

|

|

|

|

|

|

|

Simultaneous |

|

|

|

|

|

|

|

|

|

Sends FAX and Prints |

— |

Yes |

Yes |

Yes |

|

|

|

|

|

Receives FAX and Prints |

— |

Yes |

Yes |

Yes |

|

|

|

|

|

Receives FAX and Scans |

— |

Yes |

Yes |

Yes |

|

|

|

|

|

Prints and Scans |

— |

Yes |

Yes |

Yes |

|

|

|

|

|

Receives FAX and Copies |

— |

Yes |

Yes |

Yes |

|

|

|

|

|

Prints and Copies |

— |

Yes |

Yes |

Yes |

|

|

|

|

|

* CCITT#1 Chart in the Standard Mode, MMR

I –6

(2/2)

MODEL |

FAX8000P |

MFC9000 |

MFC9500 |

FAX8200P |

FAX |

|

|

|

|

|

|

|

|

|

Coverpage |

Yes, Super |

Yes, Super |

Yes, Super |

Yes, Super |

|

|

|

|

|

Polling Type |

Std/Del/Seq/Sec |

Std/Del/Seq/Sec |

Std/Del/Seq/Sec |

Std/Del/Seq/Sec |

|

|

|

|

|

Receive password |

Yes/Plus |

Yes/Plus |

Yes/Plus |

Yes/Plus |

|

|

|

|

|

Delayed Transmission |

Yes, 3 timings |

Yes, 3 timings |

Yes, 3 timings |

Yes, 3 timings |

|

|

|

|

|

Call Reservation |

Yes |

Yes |

Yes |

Yes |

|

|

|

|

|

Callback Message |

Yes |

Yes |

Yes |

Yes |

|

|

|

|

|

Page Memory (TX)* |

300 KB (30 pgs: MMR) |

300 KB (30 pgs: MMR) |

300 KB (30 pgs: MMR) |

1 MB (100 pgs: MMR) |

|

|

|

|

|

Out-of-paper Reception* |

400 KB (40 pgs: MMR) |

600 KB (40 pgs: MMR) |

600 KB (60 pgs: MMR) |

1.1 MB (110 pgs: MMR) |

|

|

|

|

|

Super Quick Scan |

Yes |

Yes |

Yes |

Yes |

|

|

|

|

|

Auto Reduction |

Yes |

Yes |

Yes |

Yes |

|

|

|

|

|

ECM |

Yes |

Yes |

Yes |

Yes |

|

|

|

|

|

Broadcasting |

Up to 140 destinations |

Up to 124 destinations |

Up to 124 destinations |

Up to 190 destinations |

|

|

|

|

|

Multi Transmission |

Yes |

Yes |

Yes |

Yes |

|

|

|

|

|

|

|

|

|

|

MESSAGE CENTER |

|

|

|

|

|

|

|

|

|

TAD Feature |

No |

No |

Yes (Hardware & PC) |

No |

|

|

|

|

|

ICM Recording Time |

No |

No |

Hardware: 15 min. |

No |

|

|

|

|

|

Paging |

No |

No |

Yes (Hardware & PC) |

No |

|

|

|

|

|

Toll Saver |

No |

No |

Yes (Hardware & PC) |

No |

|

|

|

|

|

OGM |

UK/SWISS/AUS/GER |

UK/SWISS |

Yes (Hardware & PC) |

UK/SWISS/GER |

|

|

|

|

|

Mail Box |

No |

No |

Yes (PC only) |

No |

|

|

|

|

|

Fax-on-demand |

No |

No |

Yes (PC only) |

No |

|

|

|

|

|

Voice-on-demand |

No |

No |

Yes (PC only) |

No |

|

|

|

|

|

FAX Forwarding |

Yes |

Yes |

Yes |

Yes |

|

|

|

|

|

FAX Retrieval |

Yes |

Yes |

Yes |

Yes |

|

|

|

|

|

|

|

|

|

|

MACHINE MEMORY |

0.75 MB |

1 MB |

1 MB |

2 MB |

|

|

|

|

|

|

|

|

|

|

OPTIONAL MEMORY |

1 or 2 MB |

1 or 2 MB |

1 or 2 MB |

1 or 2 MB |

(FAX & PRINTER FLEX) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PC FAX (Send/Receive) |

Option |

Yes |

Yes |

Option |

|

|

|

|

|

Standard |

— |

Class 2 |

Class 2 |

— |

|

|

|

|

|

|

|

|

|

|

DATA MODEM |

No |

No |

No |

No |

|

|

|

|

|

|

|

|

|

|

INTERFACE |

|

|

|

|

|

|

|

|

|

Printer Interface |

— |

Centronics parallel (w/o cable) |

Centronics parallel (w/o cable) |

— |

|

|

MULTI-FUNCTION LINK PRO |

MULTI-FUNCTION LINK PRO |

|

|

|

|

|

|

PC Interface |

RS-232C |

— |

— |

RS-232C |

|

(8-pin modular connector) |

|

|

(8-pin modular connector) |

|

CONNECT 5000 INTERFACE |

|

|

CONNECT 5000 INTERFACE |

|

|

|

|

|

Extended I/O Interface |

— |

RS-232C and RS-422 |

RS-232C and RS-422 |

— |

|

|

|

||

|

|

(supported by an optional serial |

(supported by an optional serial |

|

|

|

interface board RS-100M) |

interface board RS-100M) |

|

|

|

|

|

|

|

|

|

|

|

Simultaneous |

|

|

|

|

Sends FAX and Prints |

— |

Yes |

Yes |

— |

Receives FAX and Prints |

— |

Yes |

Yes |

— |

Receives FAX and Scans |

— |

Yes |

Yes |

— |

Prints and Scans |

— |

Yes |

Yes |

— |

Receives FAX and Copies |

— |

Yes |

Yes |

— |

|

|

|

|

|

Prints and Copies |

— |

Yes |

Yes |

— |

|

|

|

|

|

* CCITT#1 Chart in the Standard Mode, MMR

I –7

CHAPTER II.

INSTALLATION

CONTENTS

1. INSTALLING THE UPDATE DATA TO THE FACSIMILE EQUIPMENT............... |

II-1 |

1.INSTALLING THE UPDATE DATA TO THE FACSIMILE EQUIPMENT

If the program version is updated or the main PCB is replaced, install the update program onto the flash ROM of the main PCB.

The program installation requires a host computer satisfying the following requirements:

- CPU |

Pentium 75 or higher |

- RAM |

8MB or greater (16MB recommended for Windows® 95) |

- OS |

Windows® 3.1/3.11 or Windows® 95 |

Connecting the equipment to your computer

(1)Make sure that the equipment's power cord is unplugged from a wall socket.

(2)Make sure that your computer is powered off.

(3)Connect the interface cable to the parallel interface port on the back of the equipment and secure it with the lock wires.

(4)Connect the other end of the interface cable to the printer port of your computer and secure it with the two screws.

(5)Power on your computer.

(6)Plug the equipment's power cord into a wall socket.

Interface cable

Lock

wires

Host computer

II - 1

Installing the update data onto the flash ROM of the facsimile equipment

(1)Load the floppy disk which stores the update data and transfer utility into the floppy disk drive of your computer.

(Or, copy the update data and transfer utility onto the same directory of the hard disk.)

(2)Click the Start button, point to Programs, and then click MS-DOS Prompt to open an MSDOS window.

(3)Type the drive letter where the update data and transfer utility are located. If it is a floppy disk drive, type A:\ from the command line and press the ENTER key.

(4)Check that your computer is connected with the facsimile equipment correctly.

(5)To start the transfer utility transmitting the update data to the flash ROM of the facsimile equipment, type the following:

A:\ICEN filename /b

Then press the ENTER key.

The equipment beeps and shows the "CONNECTING" on the LCD for one second.

Then, the equipment shows the "DOWNLOADING" on the LCD and starts receiving data downloaded from the host computer.

During downloading, the equipment beeps intermittently.

Upon completion of the downloading, the equipment beeps continuously.

II - 2

CHAPTER III.

THEORY OF OPERATION

CONTENTS

1. |

OVERVIEW ..................................................................................................... |

|

III-1 |

||

2. |

MECHANISMS ................................................................................................ |

III-2 |

|||

|

2.1 |

Scanner Mechanism .............................................................................. |

III-3 |

||

|

|

2.1.1 |

Document feeding and ejecting mechanism ................................... |

III-3 |

|

|

|

2.1.2 |

Document scanning mechanism ..................................................... |

III-3 |

|

|

2.2 |

Laser Printing Mechanism...................................................................... |

III-4 |

||

|

|

2.2.1 Paper pulling-in, registration, feeding, and ejecting mechanism ..... |

III-4 |

||

|

|

2.2.2 |

Print process mechanism ................................................................ |

III-6 |

|

|

|

|

(1) |

Charging process .................................................................... |

III-7 |

|

|

|

(2) |

Exposing process .................................................................... |

III-7 |

|

|

|

(3) |

Developing process ................................................................. |

III-8 |

|

|

|

(4) |

Transferring process ................................................................ |

III-8 |

|

|

|

(5) |

Erasing process ....................................................................... |

III-8 |

|

|

2.2.3 |

Heat-fixing mechanism ................................................................... |

III-9 |

|

|

2.3 |

Sensors and Actuators ........................................................................... |

III-10 |

||

3. CONTROL ELECTRONICS ........................................................................... |

III-12 |

||

3.1 |

Configuration ........................................................................................... |

III-12 |

|

3.2 |

Main PCB ................................................................................................ |

III-13 |

|

3.3 |

Relay PCB .............................................................................................. |

III-23 |

|

3.4 |

NCU PCB ................................................................................................ |

III-24 |

|

3.5 |

Control Panel PCB ................................................................................. |

III-27 |

|

3.6 |

Power Supply PCBs ............................................................................... |

III-28 |

|

|

[ 1 ] |

Low-voltage power supply PCB .................................................. |

III-28 |

|

[ 2 ] |

High-voltage power supply PCB ................................................. |

III-29 |

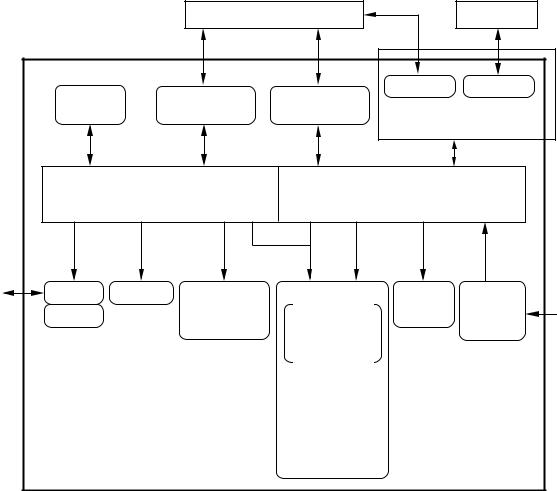

1. OVERVIEW

|

|

|

PC/AT |

|

MAC |

|

|

|

|

|

|

|

RS-232C |

RS-422 |

|

|

Control |

|

RS-232C |

Centronics |

|

|

|

|

panel |

|

(Modular connector) |

parallel interface |

Optional serial interface |

|

|

|

|

|

|

[MFC4450/ |

(Extended I/O connector) |

|

|

|

|

|

[FAX3550/3650/ |

|

|

|

|

|

|

|

8000P/8200P] |

4550/4550plus/ |

|

[MFC6550MC/7550MC/ |

|

|

|

|

|

6550MC/7550MC/7650MC/ |

|

||

|

|

|

|

9000/9500] |

|

7650MC/9000/9500] |

|

|

|

Fax Control Section |

Laser Printing Control Section |

|

|||

|

|

|

|

Printer |

|

|

|

|

|

|

|

data |

|

|

|

|

|

|

Fax data |

|

|

|

|

Line |

NCU |

Speaker |

Scanner unit |

Laser printing unit |

Paper |

Lowand |

|

|

|

|

- LED array |

Charging, exposing, |

feeding |

high-voltage |

AC |

|

Handset |

|

- CCD unit |

mechanism |

power |

||

|

|

|

- Scanner motor |

developing, |

|

supplies |

|

|

|

|

transferring, erasing, |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

and heat-fixing |

|

|

|

|

|

|

|

processes |

|

|

|

|

|

|

|

- Electrical charger |

|

|

|

|

|

|

|

- Laser unit |

|

|

|

|

|

|

|

(including the polygon |

|

|

|

|

|

|

|

motor) |

|

|

|

|

|

|

|

- Laser-sensitive drum |

|

|

|

|

|

|

|

- Developer roller |

|

|

|

|

|

|

|

- Transfer roller |

|

|

|

|

|

|

|

- Eraser lamp |

|

|

|

|

|

|

|

- Heater roller |

|

|

|

|

|

|

|

- Main motor |

|

|

|

III –1

2. MECHANISMS

The equipment is classified into the following mechanisms:

■ SCANNER MECHANISM |

– |

Document feeding and ejecting mechanism |

|

– |

Document scanning mechanism |

■ LASER PRINTING MECHANISM |

– |

Paper pulling-in, registration, feeding, and |

|

|

ejecting mechanisms |

– Print process mechanism (consisting of charging, exposing, developing, transferring, and erasing processes)

– Heat-fixing mechanism

■ SENSORS AND ACTUATORS

Paper pulling-in and registration mechanism

Document feeding and ejecting mecha-

nism SCANNER

MECHANISM

Document scanning mechanism

Paper ejecting mechanism

Heat-fixing mechanism

With paper feeding

Print process mechanism  mechanism

mechanism

LASER PRINTING

MECHANISM

III –2

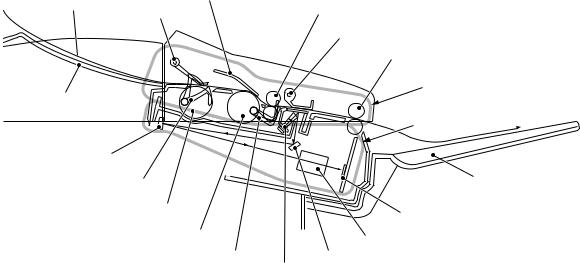

2.1Scanner Mechanism

|

ADF parts |

|

|

Document |

Nip-related |

Document feed roller ASSY |

|

|

parts |

|

|

|

|

|

|

|

|

Document pressure bar |

|

|

|

Document ejection roller ASSY |

|

|

|

Document feeding and |

|

|

|

ejecting mechanism |

|

Document stacker |

|

Document scanning |

|

|

|

|

|

|

|

mechanism |

|

2nd mirror |

|

|

|

Document front sensor actuator |

Document tray |

||

Document take-in roller ASSY |

CCD unit |

(Front) |

|

|

Separation roller ASSY |

Lens |

|

|

Document rear sensor actuator |

1st mirror |

|

|

|

LED array |

|

2.1.1Document feeding and ejecting mechanism

This mechanism consists of the document stacker, automatic document feeder (ADF), document feed roller ASSY, and document sensors. (For details about the sensors, refer to Section 2.3.)

If the operator sets documents on the document stacker and starts the scanning operation, the scanner motor rotates so that the ADF (which consists of the document take-in roller ASSY, separation roller ASSY, ADF parts and nip-related parts) feeds those documents into the equipment, starting from the bottom sheet to the top, page by page. Each document advances with the document feed roller ASSY to the scanner, and then it is fed out of the equipment with the document ejection roller ASSY.

2.1.2Document scanning mechanism

The scanner uses a charge coupled device (CCD) image sensor.

As illustrated above, the LED array illuminates a document and the reflected light of the scanned image data is transmitted via the mirrors into the lens which reduces the scanned data so as to form the image on the CCD.

III –3

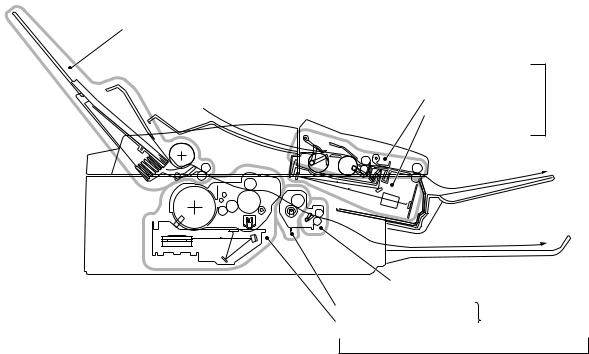

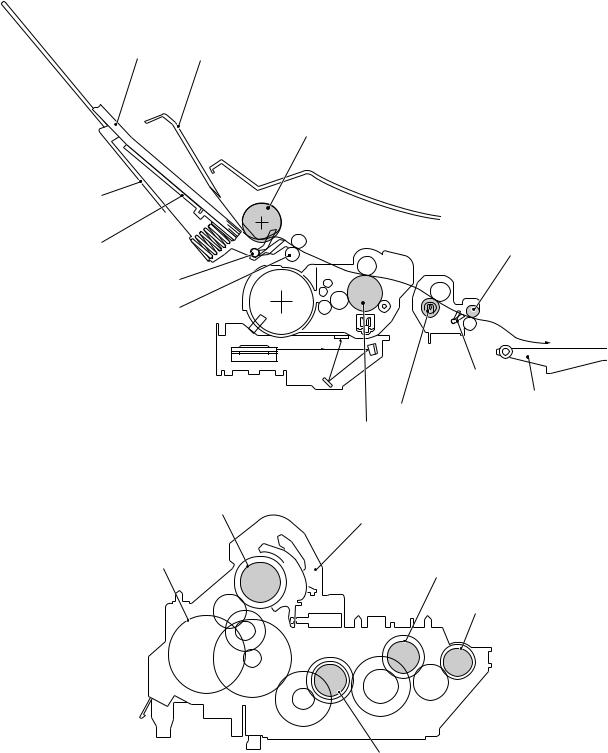

2.2Laser Printing Mechanism

2.2.1Paper pulling-in, registration, feeding, and ejecting mechanism

Paper pulling-in and registration mechanism

Paper |

Sheet feeder cover |

Paper feeding mechanism

Pull-in roller

Paper ejecting mechanism

Multi-purpose sheet feeder

Hopper |

Paper ejection roller |

Registration sensor actuator

Registration roller

Paper ejection sensor actuator

Paper tray

Heater roller

Laser-sensitive drum

Pull-in roller drive gear

|

Gear drive unit |

Main motor |

Heater roller drive gear |

|

|

|

Paper ejection |

|

roller drive gear |

Drum drive gear

III –4

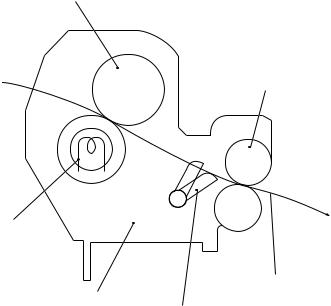

Paper pulling-in and registration mechanism

Solenoid lever |

|

|

|

Clutch release lever |

Pull-in roller drive gear |

|

|

Solenoid spring |

Intermediate gear |

Planetary |

|

gear |

|||

|

|||

Clutch spring |

Clutch gear |

system |

|

|

|||

|

|

||

Paper feed solenoid |

|

(Front) |

|

|

|

Gear drive unit |

|

Heater roller drive gear |

|

Paper ejection |

Main motor |

roller drive gear |

|

|

Gear 20/90 |

|

Drum drive gear |

The paper pulling-in and registration mechanism consists of the pull-in roller gear (incorporated in the multi-purpose sheet feeder), planetary gear system, paper feed solenoid, solenoid lever, clutch release lever, and registration sensor. (For the details about the sensor, refer to Section 2.3.)

If the main motor rotates clockwise, the rotation is transmitted to the intermediate gear of the planetary gear system. As the intermediate gear rotates, the pull-in roller drive gear also rotates since the clutch gear is locked by the solenoid lever and the clutch release lever. Accordingly, the pull-in roller in the multi-purpose sheet feeder rotates to pull in paper into the equipment, a sheet at a time.

If the paper feed solenoid is retracted and the clutch release lever is operated according to the cam profile of the pull-in roller gear so as to release the clutch gear, the clutch gear rotates and the pull-in roller drive gear does not rotate. In this way, the clutch gear switches the transmission of the motor rotation on and off to the pull-in roller drive gear.

The solenoid on/off timing and the clutch release lever timing allow this mechanism to pull in a sheet and register it against the registration roller.

Paper feeding and ejecting mechanism

If the main motor rotates clockwise, the rotation is transmitted via the gear train to the drum drive gear, heater roller drive gear, and paper ejection roller drive gear.

After the paper passes through the heat-fixing process, it will be ejected onto the paper tray.

If the leading edge of the paper pushes up the actuator of the paper ejection sensor, the photo sensor becomes opened, signaling the start of paper ejection. If the trailing edge has passed through the sensor actuator, the sensor becomes closed, signaling the completion of paper ejection. Then, the main motor stops rotation.

III –5

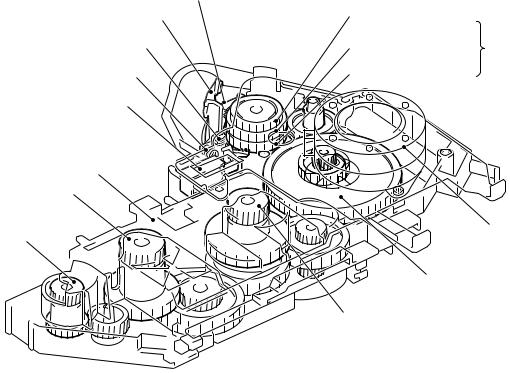

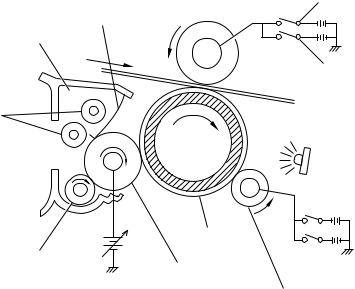

2.2.2Print process mechanism

Paper |

Transfer roller |

Drum unit

Toner augers

Toner cartridge |

|

|

Developer |

Toner sensor |

roller |

Laser-sensitive drum

Toner supply roller

Cleaner roller

Charger (Corona wire)

Polygon mirror |

|

Polygon motor |

Mirror |

|

Laser unit

Mirror

Cover glass

The print process unit works with laser beam, electrical charges, and toner. The graph below shows the transition of electrical charge on the surface of the laser-sensitive drum through the five processes: charging, exposing, developing, transferring, and erasing processes.

A single cycle of laser-sensitive drum operation

Electrical charge on the drum surface (V)

+1000

+700

+400

+300

|

(a) |

|

|

1 |

image with toner. |

|

|

|

|

||

|

|

|

|

(a) Unexposed area (Non-image area) |

|

|

|

|

|

(b) Exposed area (Image area) |

|

1 |

2 |

3 |

4 |

2 |

Exposes the drum surface to a laser beam to |

|

|

|

|

|

form a latent image and develops the latent |

|

|

|

|

3 |

Transfers the toner-formed image from the |

|

|

|

|

|

drum to paper. |

|

(b) |

|

|

4 |

Erases the residual potential. |

|

|

|

|

|

Time

III –6

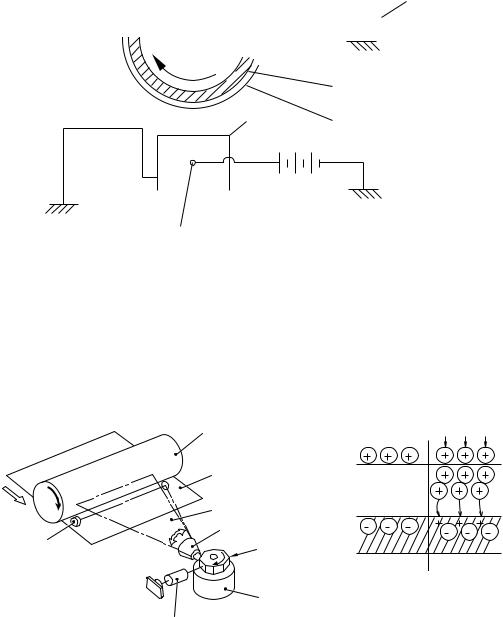

(1) Charging process

The high-voltage power supply applies DC bias to the corona wire to generate ion on the grid. The ion uniformly charges the surface of the laser-sensitive drum to approx. 1000V which is kept by the varister grounding the grid to the frame.

|

|

|

|

|

|

|

|

Approx. 280V |

|

|

|

Positive charging |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||

+ |

-- |

|

|

|

|

|

|

|

|

source |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

+ |

- |

- |

|

|

|

|

|

|

|

|

|

|

|

|

||

+ |

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

++--- - - - - |

|

Aluminum drum |

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|||||||||

|

Approx. 1000V |

+ |

+ + + |

+ |

Grid |

Laser-sensitive layer |

|

|

Drum |

|||||||

|

|

|

+ |

+ |

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

+ |

+ |

|

|

|

|

|

|

|

|

|

|

Varister |

|

|

|

|

+ |

+ |

+ |

|

|

|

|

|

|

|

|

|

|

|

|

|

+ + + + |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

High-voltage |

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

power source |

|

|

|

|

|

|

|

|

|

|

|

|

|

Corona wire |

|

|

|

|

|

|

|

|

|

||

(2) Exposing process

When the laser-sensitive drum holds a positive electrical charge, the laser beam issued from the laser unit scans the drum according to the print image to expose the drum surface for neutralizing the spots where black should be, forming an electrostatic latent image.

Laser-sensitive drum |

Laser beam |

|

Paper

Laser beam f θ lens

Laser detector

Polygon mirror

Laser diode

Polygon motor

Lens

III –7

(3) Developing process

The developing process develops an electrostatic latent image formed on the drum in the exposing process, into a toner image.

The developer roller attracts the toner particles fed from the toner cartridge by the toner supply roller, and then conveys them to the contact section with the laser-sensitive drum.

On the contact section between the developer roller and drum, the positive toner particles stick to the neutralized spots on the drum according to the principles of attraction and repulsion, transforming a latent image into a toner image.

The toner augers (which agitate toner particles in the chamber) and the blade allow toner particles to be fed onto the developer roller at an even thickness.

Switch “a” (ON for the transfer process)

Transfer roller

Blade

Chamber

Switch “b” (ON for repulsing toner from the transfer roller)

Toner augers

Toner

Eraser lamp

Laser-sensitive drum

Toner supply roller |

DC bias |

Developer roller

Cleaner roller

(4) Transferring process

When a paper passes between the drum and the transfer roller, the switch “a” (see the above illustration) is turned on to negatively charge the transfer roller. The toner is positive, so the toner image formed on the drum will be transferred onto the paper according to the same principle as for the developing process.

If the toner image fails to stick to the paper due to paper jam or other errors, it will stick to the transfer roller. To repulse this toner, the switch “b” (see the above illustration) is turned on to positively charge the transfer roller. The toner returns from the transfer roller to the drum.

Cleaning the drum

In the transferring process, not all the toner particles on the drum are transferred onto the paper but some toner particles remain on the drum. The cleaner roller cleans the drum surface and collects the residual toner. When printing starts or during non-printing, the toner collected on the cleaner roller will be discharged onto the drum and returned to the chamber through the developer roller for recycling in the subsequent developing process.

(5) Erasing process

The eraser lamp emits light to expose the drum surface, which erases the residual electrical charge.

III –8

2.2.3Heat-fixing mechanism

Pressure roller

(Paper ejection roller)

Heater roller

(including the FU lamp)

Paper

Heat-fixing unit

(Paper ejection sensor actuator)

As the paper passes between the heater roller and the pressure roller in the fixing unit, the heater roller fuses the toner on the paper.

III –9

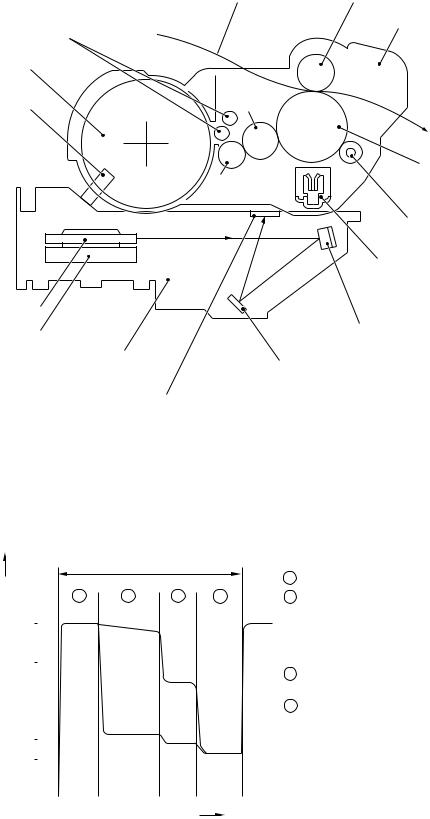

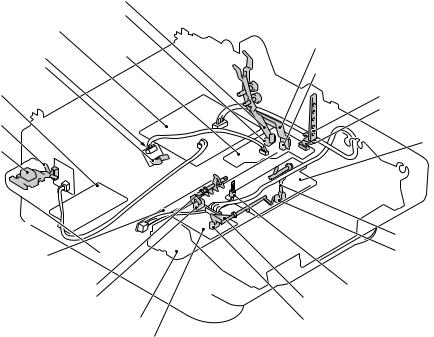

2.3Sensors and Actuators

This equipment has ten sensors: two microswitches, six photosensors and two thermisters as described below.

Sensor name |

Type |

Located on |

|

|

|

Hook switch sensor |

Microswitch |

Hook switch PCB |

Cover sensor |

Microswitch |

Relay PCB |

Registration sensor |

Photosensor (PC1) |

Relay PCB |

Sheet feeder cover sensor |

Photosensor (PC2) |

Relay PCB |

Paper ejection sensor |

Photosensor (PC1) |

High-voltage power supply PCB |

Document front sensor |

Photosensor (PC1) |

Document sensor PCB |

Document rear sensor |

Photosensor (PC2) |

Document sensor PCB |

Toner sensor |

Photosensor (PH1) |

Toner sensor PCB (on the laser unit) |

Toner thermister |

P1 |

Toner sensor PCB (on the laser unit) |

Heater thermister |

__ |

Fixing unit |

|

|

|

•Hook switch sensor which detects whether the handset is placed on the handset mount.

•Cover sensor which detects whether the top cover is closed.

•Registration sensor which detects the leading and trailing edges of paper, which allows the controller to determine the registration timing and check paper jam.

•Sheet feeder cover sensor which detects whether the sheet feeder cover is closed.

•Paper ejection sensor which detects whether the recording paper goes out of the equipment.

•Document front sensor which detects the presence of documents.

•Document rear sensor which detects the leading and trailing edges of pages to tell the control circuitry when the leading edge of a new page has reached the starting position and when the scan for that page is over.

•Toner sensor which detects whether there is toner or a toner cartridge is loaded.

•Toner thermister which detects the temperature of the toner cartridge.

•Heater thermister which detects the temperature of the heater roller of the fixing unit.

These photosensors are a photointerrupter consisting of a light-emitting diode and a lightsensitive transistor. Each of them has an actuator separately arranged as shown on the next page.

III –10

Registration sensor actuator |

|

||

Registration sensor (Photosensor) |

|

||

(Main PCB) |

|

|

|

Toner thermister |

(Relay PCB) |

Sheet feeder cover sensor actuator |

|

(On back of PCB) |

Sheet feeder cover sensor |

||

|

|||

Toner sensor |

|

||

|

(Photosensor) |

||

(Low-voltage power |

|

Cover sensor actuator |

|

supply PCB) |

|

||

|

Cover sensor (Microswitch) |

||

Hook switch sensor |

|

||

|

|

||

(Microswitch) |

|

(High-voltage power |

|

Hook switch sensor |

(Toner |

supply PCB) |

|

actuator |

|

||

sensor |

|

||

|

|

||

|

PCB) |

|

|

|

|

Paper ejection sensor |

|

|

|

actuator |

|

(Eraser lamp board) |

|

Paper ejection sensor |

|

|

(Photosensor) |

||

|

|

||

Document front sensor actuator |

|

Heater thermister |

|

Document front sensor (Photosensor) |

|

Document rear sensor actuator |

|

(Fixing unit) |

Document rear sensor |

||

(Photosensor) |

|||

|

|

||

(Document sensor PCB) |

|

||

Location of Sensors and Actuators

III –11

Loading...

Loading...