Brother BAS-016B Instruction Manual

BAS-016B

INSTRUCTION MANUAL

Please read this manual before using the machine.

Please keep this manual within easy reach for quick reference.

ELECTRONIC LOCKSTITCH BUTTON SEWER WITH BUTTON FEEDER

Thank you very much for buying a BROTHER sewing machine. Before using your new machine, please read the safety instructions below and the explanations given in the instruction manual.

With industrial sewing machines, it is normal to carry out work while positioned directly in front of moving parts such as the needle and thread take-up lever, and consequently there is always a danger of injury that can be caused by these parts. Follow the instructions from training personnel and instructors regarding safe and correct operation before operating the machine so that you will know how to use it correctly.

SAFETY INSTRUCTIONS

1. Safety indications and their meanings

This instruction manual and the indications and symbols that are used on the machine itself are provided in order to ensure safe operation of this machine and to prevent accidents and injury to yourself or other people.

The meanings of these indications and symbols are given below.

Indications

Theinstructionswhichfollowthistermindicatesituationswhere failureto follow theinstructions DANGER will almost certainly result in death or severe injury.

The instructions which follow this term indicate situations where failure to follow the instruc-

CAUTION tions could cause injury when using the machine or physical damage to equipment and surroundings.

Symbols

................ This symbol ( ) indicates something that you should be careful of. The picture inside the triangle indicates the nature of the caution that must be taken.

) indicates something that you should be careful of. The picture inside the triangle indicates the nature of the caution that must be taken.

(For example, the symbol at left means “beware of injury”.)

................ This symbol ( |

) indicates something that you must not do. |

................ This symbol ( |

) indicates something that you must do. The picture inside the circle indicates the nature |

of the thing that must be done.

(For example, the symbol at left means “you must make the ground connection”.)

BAS-016B

i |

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com |

2. Notes on safety

DANGER

DANGER

Wait at least 5 minutes after turning off the power switch and disconnecting the power cord from the wall outlet before opening the face plate of the control box. Touching areas where high voltages are present can result in severe injury.

CAUTION

CAUTION

Environmental requirements

Use the sewing machine in an area which is free from sources of strong electrical noise such as highfrequency welders.

Sources of strong electrical noise may cause problems with correct operation.

Any fluctuations in the power supply voltage should be within ± 10% of the rated voltage for the machine. Voltage fluctuations which are greater than this may cause problems with correct operation.

The power supply capacity should be greater than the requirements for the sewing machine's electrical consumption.

Insufficient power supply capacity may cause problems with correct operation.

The ambient temperature should be within the range of 5°C to 35 °C during use.

Temperatures which are lower or higher than this may cause problems with correct operation.

The relative humidity should be within the range of 45% to 85% during use, and no dew formation should occur in any devices.

Excessively dry or humid environments and dew formation may cause problems with correct operation.

Avoid exposure to direct sunlight during use. Exposure to direct sunlight may cause problems with correct operation.

In the event of an electrical storm, turn off the power and disconnect the power cord from the wall outlet. Lightning may cause problems with correct operation.

Installation

Machine installation should only be carried out by a qualified technician.

Contact your Brother dealer or a qualified electrician for any electrical work that may need to be done.

The sewing machine weighs more than 52 kg. The installation should be carried out by two or more people.

Do not connect the power cord until installation is complete, otherwise the machine may operate if the foot switch is depressed by mistake, which could result in injury.

Hold the machine head with both hands when tilting it back or returning it to its original position. Furthmore, after tilring back the machine head, do not push the face plate side or the pulley side from above, as this could cause the machine head to topple over, which may result in personal injury or damage to the machine.

Be sure to connect the ground. If the ground connection is not secure, you run a high risk of receiving a serious electric shock, and problems with correct operation may also occur.

All cords should be secured at least 25 mm away from any moving parts. Furthermore, do not excessively bend the cords or secure them too firmly with staples, otherwise there is the danger that fire or electric shocks could occur.

Install the belt covers to the machine head and motor.

If using a work table which has casters, the casters should be secured in such a way so that they cannot move.

Be sure to wear protective goggles and gloves when handling the lubricating oil and grease, so that they do not get into your eyes or onto your skin, otherwise inflammation can result.

Furthermore, do not drink the oil or eat the grease under any circumstances, as they can cause vomiting and diarrhoea.

Keep the oil out of the reach of children.

BAS-016B

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com |

ii |

CAUTION

CAUTION

Sewing

This sewing machine should only be used by operators who have received the necessary training in safe use beforehand.

The sewing machine should not be used for any applications other than sewing.

Be sure to wear protective goggles when using the machine.

If goggles are not worn, there is the danger that if a needle breaks, parts of the broken needle may enter your eyes and injury may result.

Set the needle to the needle up stop position before turning on the power.

If this is not done, the wiper may strike the needle, which might cause the needle to break.

Turn off the power switch at the following times, otherwise the machine may operate if the foot switch is depressed by mistake, which could result in injury.

•When threading the needle

•When replacing the needle and bobbin

•When not using the machine and when leaving the machine unattended

If using a work table which has casters, the casters should be secured in such a way so that they cannot move.

Attach all safety devices before using the sewing machine. If the machine is used without these devices attached, injury may result.

Do not touch any of the moving parts or press any objects against the machine while sewing, as this may result in personal injury or damage to the machine.

If an error occurs in machine operation, or if abnormal noises or smells are noticed, immediately turn off the power switch. Then contact your nearest Brother dealer or a qualified technician.

If the machine develops a problem, contact your nearest Brother dealer or a qualified technician.

Cleaning

Set the needle to the needle up stop position before turning on the power.

If this is not done, the wiper may strike the needle, which might cause the needle to break.

Turn off the power switch before carrying out cleaning, otherwise the machine may operate if the foot switch is depressed by mistake, which could result in injury.

Be sure to wear protective goggles and gloves when handling the lubricating oil and grease, so that they do not get into your eyes or onto your skin, otherwise inflammation can result.

Furthermore, do not drink the oil or eat the grease under any circumstances, as they can cause vomiting and diarrhoea.

Keep the oil out of the reach of children.

Maintenance and inspection

Maintenance and inspection of the sewing machine should only be carried out by a qualified technician.

Ask your Brother dealer or a qualified electrician to carry out any maintenance and inspection of the electrical system.

Set the needle to the needle up stop position before turning on the power.

If this is not done, the wiper may strike the needle, which might cause the needle to break.

Turn off the power switch and disconnect the power cord from the wall outlet at the following times, otherwise the machine may operate if the foot switch is depressed by mistake, which could result in injury.

•When carrying out inspection, adjustment and maintenance

•When replacing consumable parts such as the rotary hook

If the power switch needs to be left on when carrying out some adjustment, be extremely careful to observe all safety precautions.

Hold the machine head with both hands when tilting it back or returning it to its original position. Furthermore, after tilting back the machine head, do not push the face plate side or the pulley side from above, as this could cause the machine head to topple over, which may result in personal injury or damage to the machine.

Use only the proper replacement parts as specified by Brother.

If any safety devices have been removed, be absolutely sure to re-install them to their original positions and check that they operate correctly before using the machine.

Any problems in machine operation which result from unauthorized modifications to the machine will not be covered by the warranty.

BAS-016B

iii |

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com |

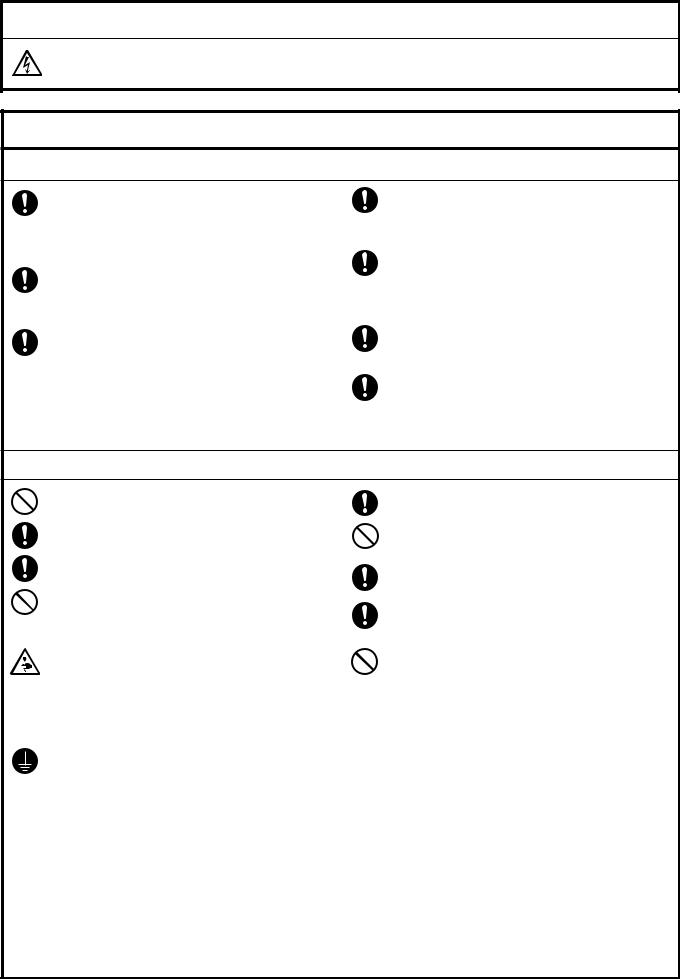

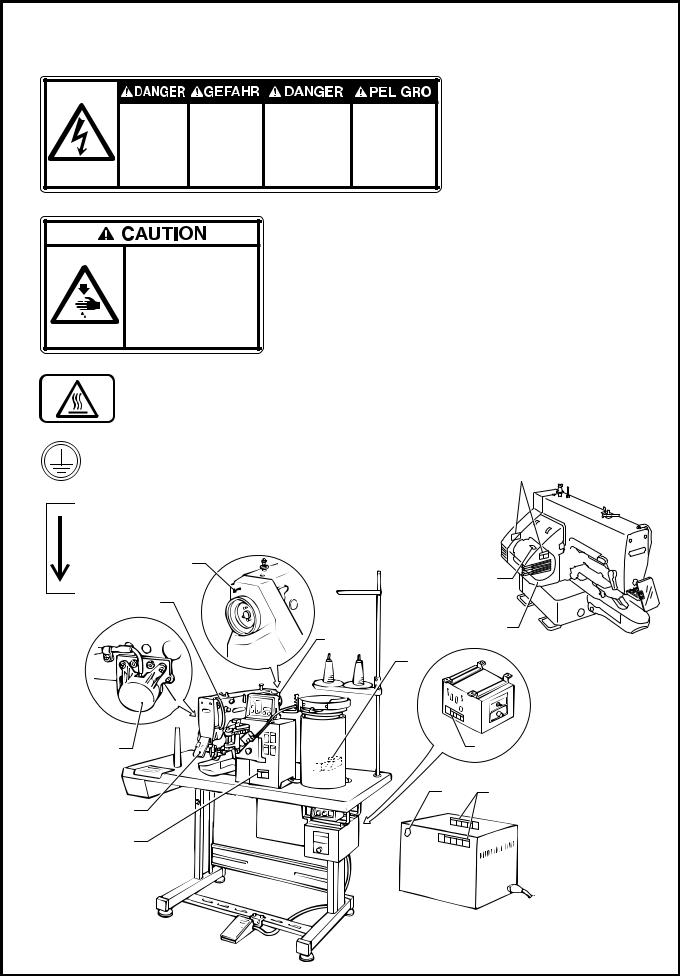

3. Warning labels

The following warning labels appear on the sewing machine.

Please follow the instructions on the labels at all times when using the machine. If the labels have been removed or are difficult to read, please contact your nearest Brother dealer.

1

|

|

|

|

|

|

|

Hazardous voltage |

Hochspannung |

Un voltage non adapt |

Un voltaje inadecuado |

|||

will cause injury. |

verletzungsgefahr! |

provoque des blessures. |

puede provocar las |

|||

Turn off main |

Bitte schalten sie den |

Eteindrel’interrupteur et |

heridas. |

|||

Apagar el interruptor |

||||||

switch and wait 5 |

hauptschalter aus und |

attendre 5 minutes |

||||

minutes before |

warten sie 5 minuten, |

avantd’ ouvrir le capot |

principal y esperar 5 |

|||

opening this cover. |

bevor sie diese |

|

minutos antes de abrir |

|||

|

abdeckung ffnen. |

|

esta cubierta. |

|||

2

Moving parts may cause injury.

Operate with safety devices. Turn off main switch before threading, changing bobbin and needle, cleaning etc.

Safety devices Eye guard

Thread take-up cover

Thread take-up solenoid cover Belt cover

Frame side cover, etc.

3 |

High temperature warning display |

4Be sure to connect the ground. If the ground connection is not secure, you run a high risk of receiving a serious electric shock, and problems with correct operation may also occur.

2

5 |

Direction of operation |

5

3

Thread take-up cover

Frame Belt side cover cover

4 |

1042Q |

Thread take-up |

1 |

solenoid cover |

|

4 |

1 |

Eye guard |

|

2 |

|

1040Q

BAS-016B

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com |

iv |

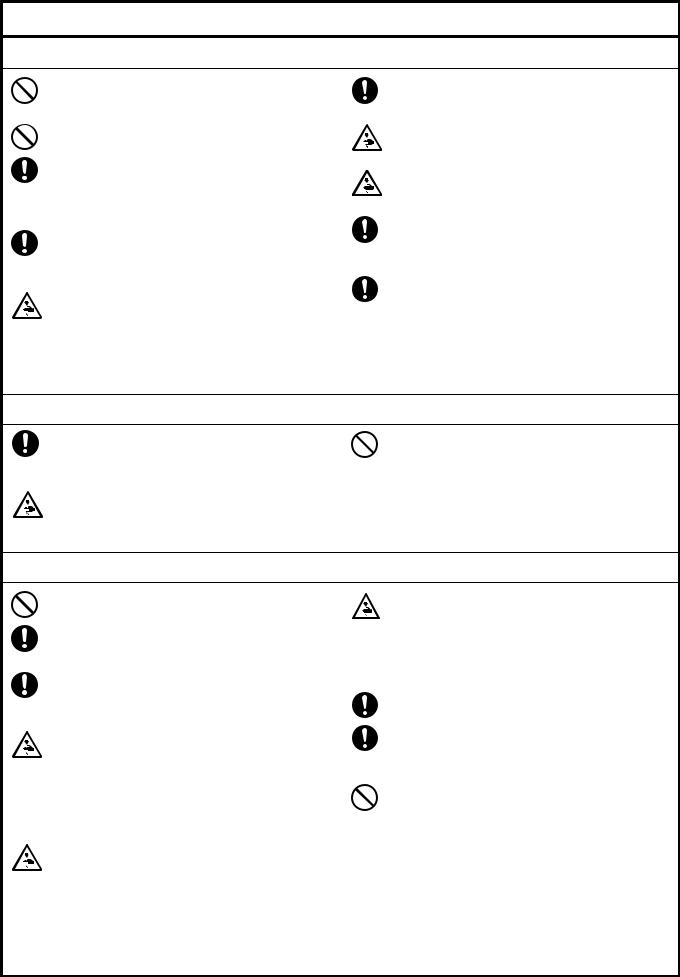

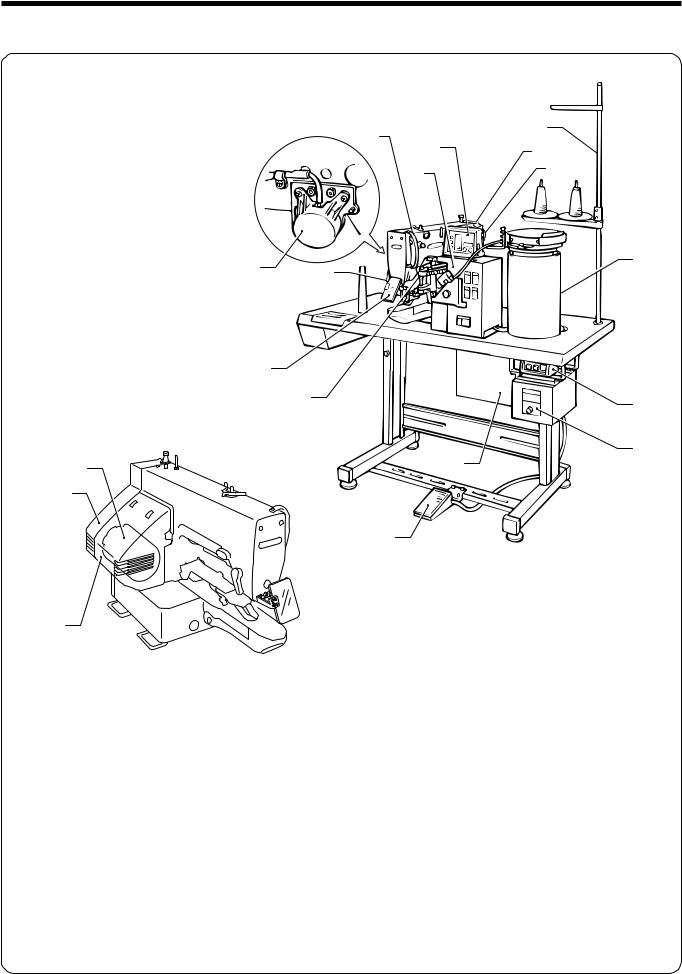

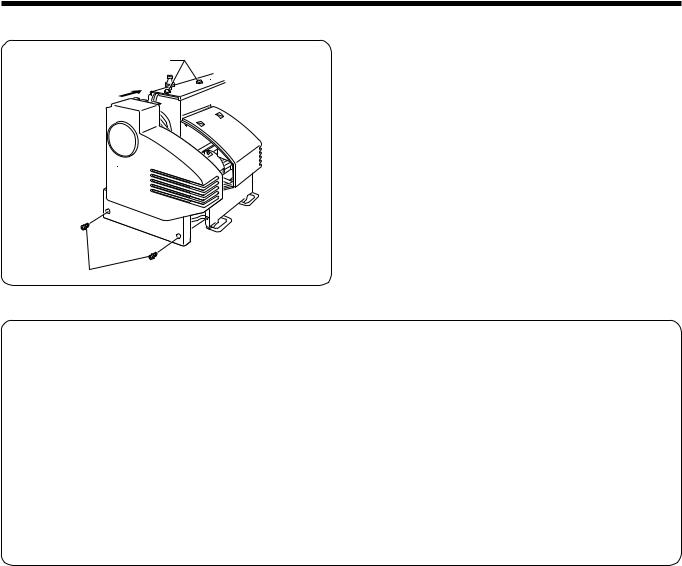

1.Name of each part

1. Name of each part

0436Q

!4

i e !5 !0 u

!7 |

!1 |

|

y |

||

|

!3

o |

q |

|

!2

t |

w |

|

|

!5 |

|

|

r |

!6

1043Q

qPower switch |

wControl box |

eOperation panel |

rFoot switch |

tMotor |

yTension release lever |

uPulley |

iSpool stand |

oThread take-up lever |

!0Button feeder |

!1Vibrating bowl |

!2Control box |

!3Eye guard |

!4Thread take-up cover |

!5Belt cover |

!6Frame side cover |

!7Thread take-up solenoid cover

BAS-016B |

1 |

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com |

|

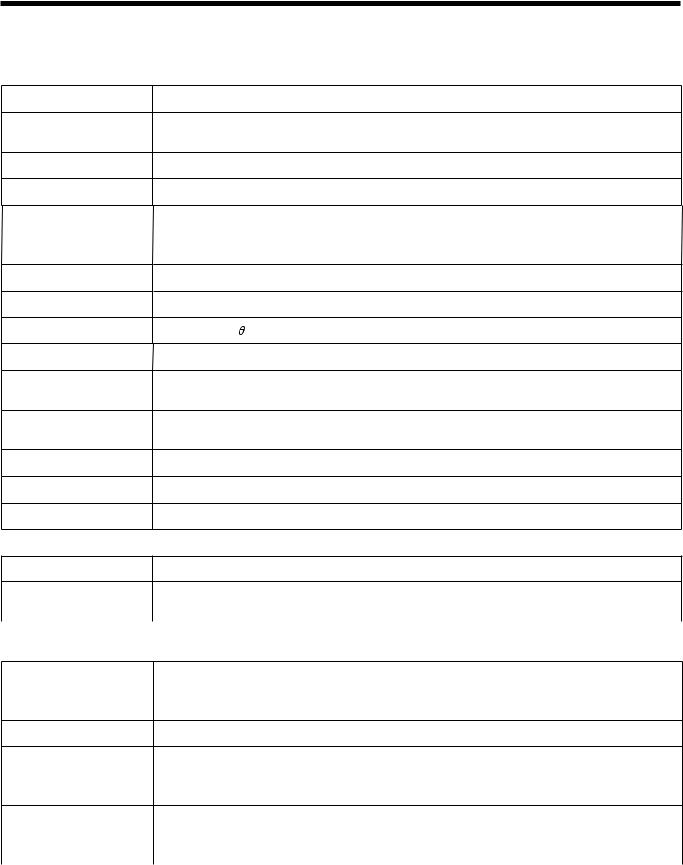

2. Specifications

2. Specifications

2-1. Specifications

|

Stitch formation |

|

Single needle lock stitch |

|

|

Maximum sewing |

|

2,500 rpm |

|

|

speed |

|

||

|

|

|

|

|

|

Maximum pattern size |

|

0 - 6.4 0 - 6.4 mm |

|

|

Needle |

|

TQ 1#12 |

|

|

Dimensions of buttons |

|

Outer diameter of button 9 - 22 mm |

|

|

that can be sewn |

|

Space between the button holes 2.5 - 6.4 mm |

|

|

Button clamp height |

|

10 mm (standard) |

|

|

Thread knot |

|

Knot tied by needle |

|

|

Feed mechanism |

|

R- intermittent feed mechanism (pulse-motor driven mechanism) |

|

|

Stitch length |

|

0.1 - 6.4 mm |

|

|

Number of stitches |

|

Variable (13, 15, 17, 19, 20, 22, 23, 24, 26, 27, 28, 30, 32, 34, 38 stitches |

|

|

|

pre-set) |

||

|

|

|

||

|

Maximum stitch |

|

20,000 stitches (including 10,000 stitches which can be added) |

|

|

number |

|

||

|

|

|

|

|

|

Work clamp lifter |

|

Solenoid type |

|

|

Rotary hook |

|

Shuttle hook |

|

|

Wiper device |

|

Standard equipment (Solenoid-type thread wiper (Option)) |

|

|

Thread trimmer device |

|

Standard equipment |

|

|

|

|

||

|

|

|

|

|

|

Data storage method |

|

P-ROM (Any sewing pattern can be added using BAS-PC/300.) |

|

|

Number of user |

16 |

|

|

|

programs |

|

||

|

|

|

|

|

|

|

|

|

|

|

Number of cycle |

|

4 |

|

|

programs |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Number of stored data |

|

49 sewing patterns are set already. |

|

|

|

(Up to 100 patterns can be added. Total number of stitches of stored data |

||

|

|

|

which can be added is within 10,000.) |

|

|

Motor |

|

Three-phase 400W induction motor |

|

|

Weights |

|

Machine head: 52kg, Operation panel: 0.6kg, |

|

|

|

Control box: 9 - 19kg (depending on destination) |

||

|

|

|

||

|

|

|

Button feeder: 37 kg |

|

|

|

|

Single-phase 220 - 230V |

|

|

Power source |

|

3-phase 220, 380, 400, 415V |

|

|

|

|

Maximum electric power consumption; 600VA |

|

|

|

|

|

|

BAS-016B

2 |

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com |

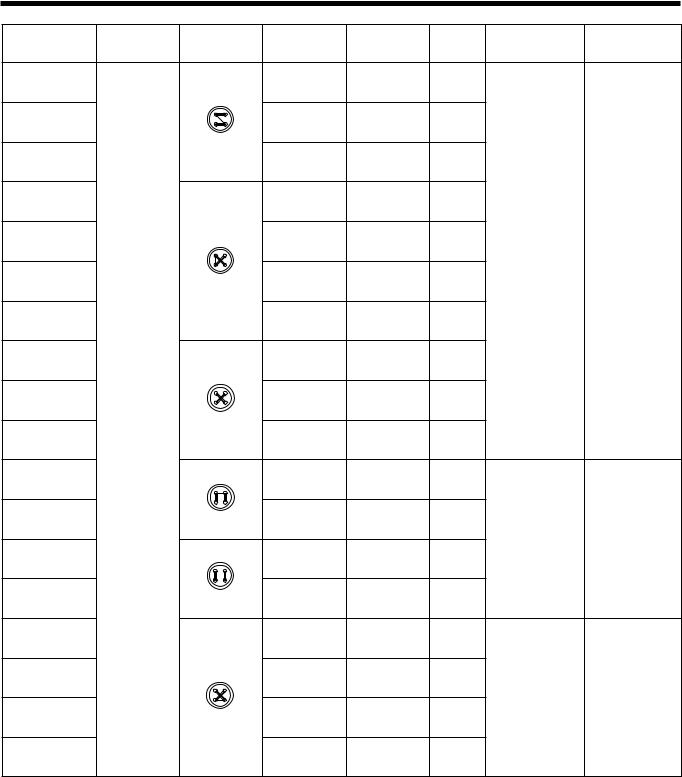

2. Specifications

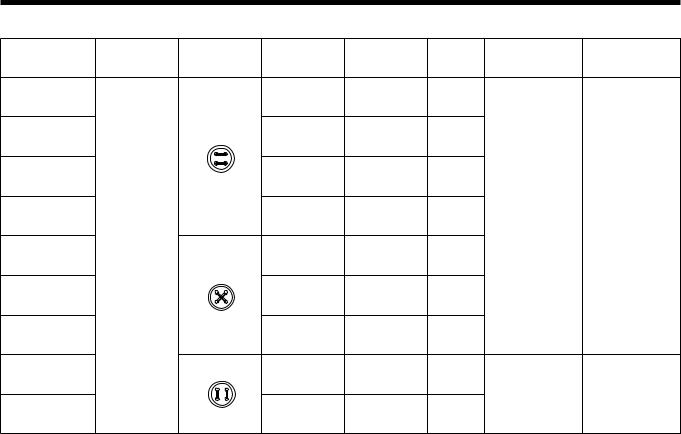

2-2. Program list

Sewing patterns are limited as shown in the table below.

(Any program is available as long as the needle drops down in the hole of the button.)

Program No. |

No. of |

Sewing |

No. of |

No. of |

No. of |

Standard |

Standard |

||||

crossover |

|||||||||||

button holes |

pattern |

threads |

stitches |

sewing length X |

sewing width Y |

||||||

|

stitches |

||||||||||

|

|

|

|

|

|

|

|

|

|

||

1 |

|

|

|

|

|

6 |

__ |

13 |

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

2 |

|

|

|

|

|

8 |

__ |

15 |

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

3 |

|

|

|

|

|

10 |

__ |

17 |

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

3.4 mm |

0 mm |

|

|

|

|

|

|

|

|

|

|

|||

4 |

|

|

|

|

|

12 |

__ |

19 |

|||

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

*1 |

2 |

|

|

|

|

16 |

__ |

23 |

|

|

|

5 |

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

*1 |

|

|

|

|

|

20 |

__ |

27 |

|

|

|

6 |

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

*2 |

|

|

|

|

|

6 |

__ |

13 |

|

|

|

7 |

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

*2 |

|

|

|

|

|

10 |

__ |

17 |

0 mm |

3.4 mm |

|

23 |

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

*2 |

|

|

|

|

|

12 |

__ |

19 |

|

|

|

8 |

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

*2 |

|

|

|

|

|

5-5-5 |

__ |

22 |

|

|

|

9 |

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

*2 |

|

|

|

|

|

7-7-7 |

__ |

28 |

|

|

|

24 |

|

|

|

|

|

|

|

|

|||

|

3 |

|

|

|

|

|

|

|

2.6 mm |

2.4 mm |

|

*2 |

|

|

|

|

5-5-5 |

__ |

22 |

||||

|

|

|

|

|

|

|

|||||

25 |

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

*2 |

|

|

|

|

|

7-7-7 |

__ |

28 |

|

|

|

26 |

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

*2 |

|

|

|

|

|

6-6 |

1 |

20 |

|

|

|

10 |

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

*2 |

|

|

|

|

|

8-8 |

1 |

24 |

|

|

|

11 |

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

*2 |

|

|

|

|

|

|

|

|

|

|

|

12 |

4 |

|

|

|

|

8-8 |

3 |

26 |

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

*2 |

|

|

|

|

|

10-10 |

1 |

28 |

|

|

|

13 |

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

*2 |

|

|

|

|

|

12-12 |

1 |

32 |

3.4 mm |

3.4 mm |

|

27 |

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

*3 |

|

|

|

|

|

6-6 |

0 |

26 |

|

|

|

14 |

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

*3 |

|

|

|

|

|

8-8 |

0 |

30 |

|

|

|

28 |

|

|

|

|

|

|

|

||||

|

4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

*3 |

|

|

|

|

10-10 |

0 |

34 |

|

|

||

|

|

|

|

|

|

|

|||||

15 |

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

*3 |

|

|

|

|

|

12-12 |

0 |

38 |

|

|

|

29 |

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

BAS-016B

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com |

3 |

2. Specifications

Program No. |

No. of |

Sewing |

No. of |

No. of |

No. of |

Standard |

Standard |

|

crossover |

||||||||

button holes |

pattern |

threads |

stitches |

sewing length X |

sewing width Y |

|||

|

stitches |

|||||||

|

|

|

|

|

|

|

||

16 |

|

|

6-5 |

1 |

19 |

|

|

|

17 |

|

|

8-7 |

1 |

23 |

|

|

|

30 |

|

|

10-9 |

1 |

27 |

|

|

|

*2 |

|

|

6-6 |

1 |

20 |

|

|

|

18 |

|

|

|

|

||||

*2 |

|

|

8-8 |

1 |

24 |

|

|

|

19 |

|

|

|

|

||||

*2 |

|

|

|

|

|

3.4mm |

3.4mm |

|

|

|

10-10 |

1 |

28 |

|

|

||

31 |

|

|

|

|

||||

*2 |

|

|

12-12 |

1 |

32 |

|

|

|

45 |

|

|

|

|

||||

*3 |

|

|

6-6 |

0 |

26 |

|

|

|

20 |

|

|

|

|

||||

*3 |

|

|

8-8 |

0 |

30 |

|

|

|

32 |

|

|

|

|

||||

*3 |

4 |

|

|

|

|

|

|

|

|

|

10-10 |

0 |

34 |

|

|

||

33 |

|

|

|

|

||||

*2 |

|

|

6-6 |

1 |

20 |

|

|

|

21 |

|

|

|

|

||||

*2 |

|

|

10-10 |

1 |

28 |

|

|

|

34 |

|

|

|

|

||||

*2*3 |

|

|

|

|

|

2.4mm |

3.4mm |

|

|

|

6-6 |

0 |

26 |

|

|

||

22 |

|

|

|

|

||||

|

|

|

|

|

|

|

||

*2*3 |

|

|

10-10 |

0 |

34 |

|

|

|

35 |

|

|

|

|

||||

|

|

|

|

|

|

|

||

46 |

|

|

6-6 |

1 |

20 |

|

|

|

47 |

|

|

8-8 |

1 |

24 |

|

|

|

|

|

|

|

|

|

3.4mm |

3.4mm |

|

48 |

|

|

10-10 |

1 |

28 |

|

|

|

49 |

|

|

12-12 |

1 |

32 |

|

|

*1 Check that the button hole diameter is 2 mm or greater before using the programs. *2 Do not use the button lifter spring.

*3 the presser foot lifts up once and the wiper operates, and then the other side is sewn, because there is no crossover thread to be sewn. (Operation will be different if the optional solenoid-type thread wiper is installed. [Refer to page 5].)

•If you want to sew a pattern other than one of the standard 24 patterns, you can create your original pattern using the BAS-PC/300.

Consult with your local Brother Sales Office for details.

BAS-016B

4 |

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com |

2. Specifications

■ The following programs require the solenoid thread wiper (OP).

|

No. of |

Sewing |

No. of |

No. of |

No. of |

Standard |

Standard |

|

Program No. |

crossover |

|||||||

button holes |

pattern |

threads |

stitches |

sewing length X |

sewing width Y |

|||

|

stitches |

|||||||

|

|

|

|

|

|

|

||

36 |

|

|

6-6 |

0 |

26 |

|

|

|

37 |

|

|

8-8 |

0 |

30 |

|

|

|

38 |

|

|

10-10 |

0 |

34 |

|

|

|

39 |

|

|

12-12 |

0 |

38 |

3.4mm |

3.4mm |

|

40 |

4 |

|

6-6 |

0 |

26 |

|

|

|

41 |

|

|

8-8 |

0 |

30 |

|

|

|

42 |

|

|

10-10 |

0 |

34 |

|

|

|

* |

|

|

6-6 |

0 |

26 |

|

|

|

43 |

|

|

|

|

||||

* |

|

|

|

|

|

2.4mm |

3.4mm |

|

|

|

10-10 |

0 |

34 |

|

|

||

44 |

|

|

|

|

||||

* Do not use the button lifter spring. |

|

|

|

|

|

|||

BAS-016B

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com |

5 |

3. Installation

3. Installation

CAUTION

CAUTION

Machine installation should only be carried out by a qualified technician.

Contact your Brother dealer or a qualified electrician for any electrical work that may need to be done.

The sewing machine head weighs more than 52 kg. The installation should be carried out by two or more people.

Do not connect the power cord until installation is complete, otherwise the machine may operate if the foot switch is depressed by mistake, which could result in injury.

Hold the machine head with both hands when tilting it back or returning it to its original position. Furthermore, after tilting back the machine head, do not push the face plate side or the pulley side from above, as this could cause the machine head to topple over, which may result in personal injury or damage to the machine.

All cords should be secured at least 25 mm away from any moving parts. Furthermore, do not excessively bend the cable or secure it too firmly staples, otherwise there is the danger that fire or electric shocks could occur.

Be sure to connect the ground. If the ground connection is not secure, you run the risk of receiving a serious electric shock, and problems with correct operation may also occur.

Install the belt covers to the machine head and motor.

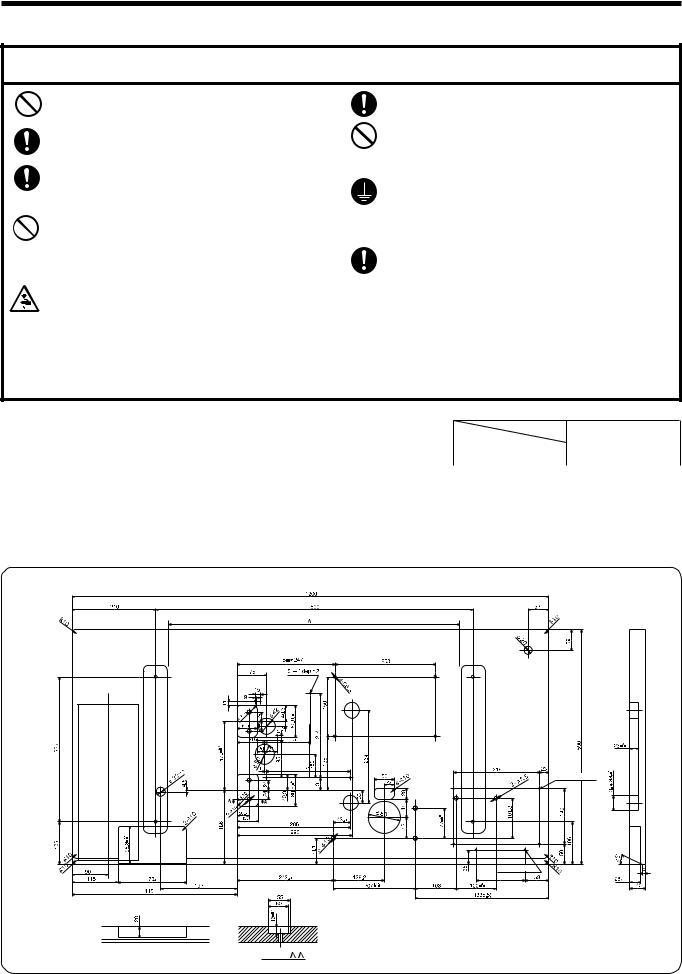

3-1. Power table

• Use the power table which has been specially designed for the BAS-016B. |

|

Model code |

|

* If using a commercially-available table, process it as shown in the illus- |

|

|

|

Table/ legs assembly |

127-Z48-50001 |

||

tration below. |

|||

|

|

||

|

|

NOTE: The thickness of the table should be at least 40 mm, and it should be strong enough to bear the weight and vibration of the sewing machine.

If the distance A between the insides of the legs is less than 740 mm, move the control box installation position to the left (B=247 mm).

Check that the control box is at least 10 mm away from the leg. If the control box and leg are touching, it could cause the sewing machine to operate incorrectly.

depth

depth

back

back

depth

depth

back

back

Section

1041Q

6 |

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com |

|

BAS-016B |

3. Installation

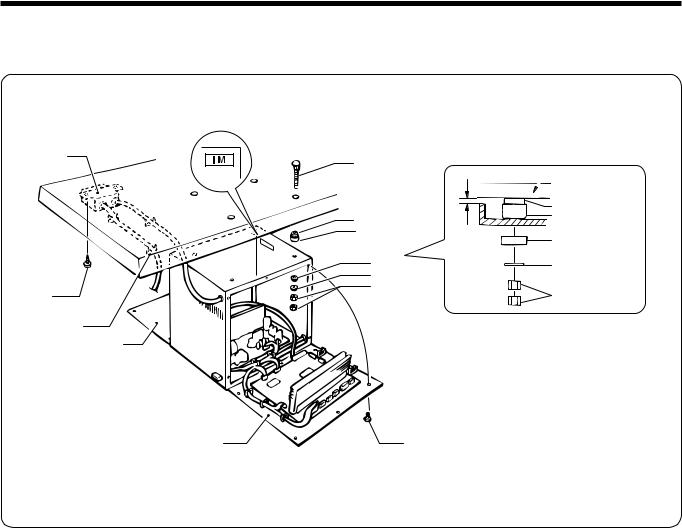

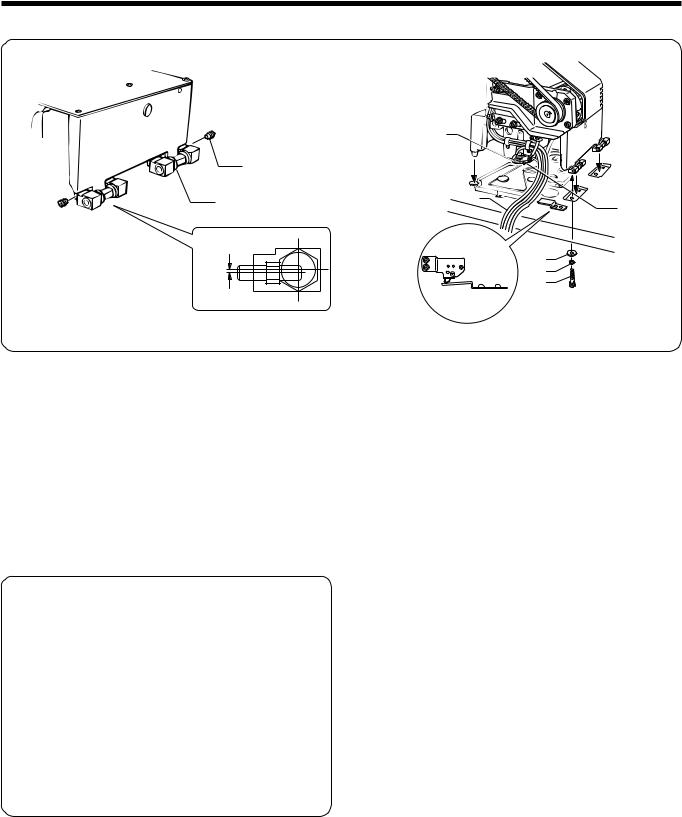

3-2. Installing the control box

Check that the IM sticker is attached to the side of the control box (in the position shown in the illustration). (BAS-016B machine heads can only be used with control boxes which have the IM sticker attached.)

!0 |

r |

|

|

|

t |

|

y |

|

u |

|

i |

!1 |

o |

|

|

!2 |

|

|

w |

e |

q |

0063Q

Table

Table

tCushions

yCushion collars

3 mm

u Rubber collers

i Flat washers

o Nuts

0051Q

1.Remove the 12 screws q, and then open the covers (panel mounting assembly w and main P.C. board mounting plate e).

NOTE:

When opening the cover, hold it securely so that it does not fall down.

2.Install the control box with the four accessory bolts r, cushions t, cushion collars y, rubber collars u, flat washers i and nuts o as shown in the illustration above. At this time, leave a gap of approximately 3 mm between the work table and the top of the box.

*Use two nuts o at each installation location, and make sure that both nuts are tightened.

3.Close the covers (panel mounting assembly w and main P.C. board mounting plate e), and tighten them with the screws q.

*The main P.C. board mounting plate e will be opened again during “3-13. Connecting the cords”, so provisionally tighten it with the screw q.

4.Install the power switch !0with the two screws !1.

5.Secure the power switch cord with the three staples !2.

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com |

7 |

BAS-016B |

|

3. Installation

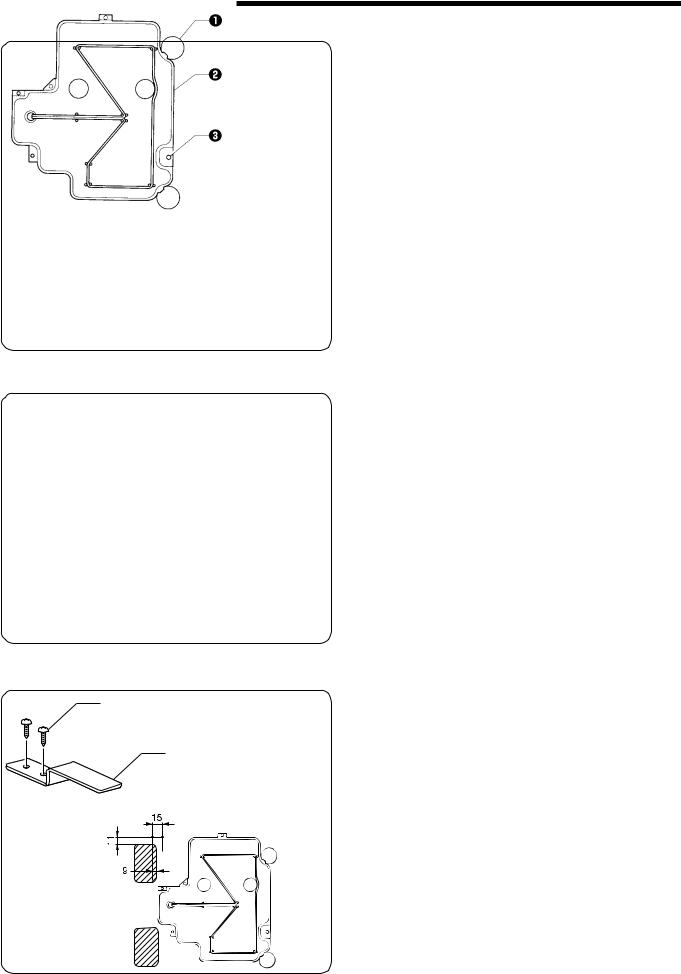

3-3. Installing the oil pan

0054Q 1. Insert the tabs of the oil pan w into the holes for the cushions q, and then secure it in place with the five nails e so that the oil pan w is not at an angle.

2. While pushing the oil pan w down from above, screw in the oil container r.

0055Q

3-4. Installing the cushions

e

w

q

1.Place the washers q and cushions w into the two holes in the work table.

*Adjust the height of the machine head to the button feeder by the number of the washers q.

2.After the height is decided, secure them with the nails e.

1044Q

3-5. Installing the switching plate

w

q

Install the switching plate q to the work table with the two wood screws w in the position shown in the illustration.

*The switching plate and the switch bracket which is attached to the machine head prevent the sewing machine from starting when the machine head is tilted back. Therefore, this means that the sewing machine will not start if the switching plate is not installed.

0471Q

8 |

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com |

|

BAS-016B |

3. Installation

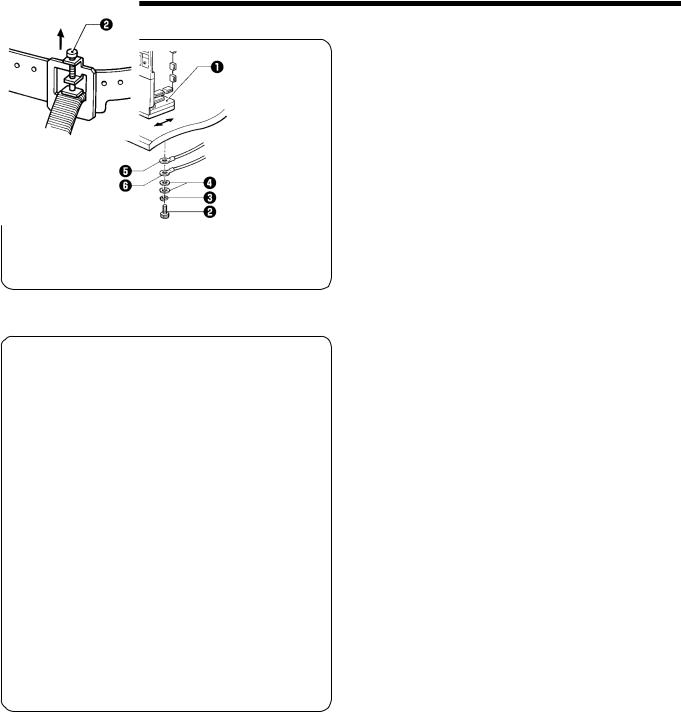

3-6. Installing the machine head

|

i |

|

w |

q |

e |

|

u |

1 mm |

r |

t |

|

|

y |

|

Fig. 1 |

1045Q |

1046Q |

1.Insert the two hinge assemblies q into the machine head so that they are parallel, and then secure them with the two set screw w.

2.Place the machine head gently on the table.

NOTE: Pull the cords e out as shown in the illustration above in order to prevent them from being clamped by the machine head.

3.Secure the two hinge assemblies q with the washers r, the spring washers t, and the bolts y, and install the machine head.

4.Check that the head position switch is turned on as shown in Figure 1.

5.Connect the motor cord connector u to the accessory cord connector i.

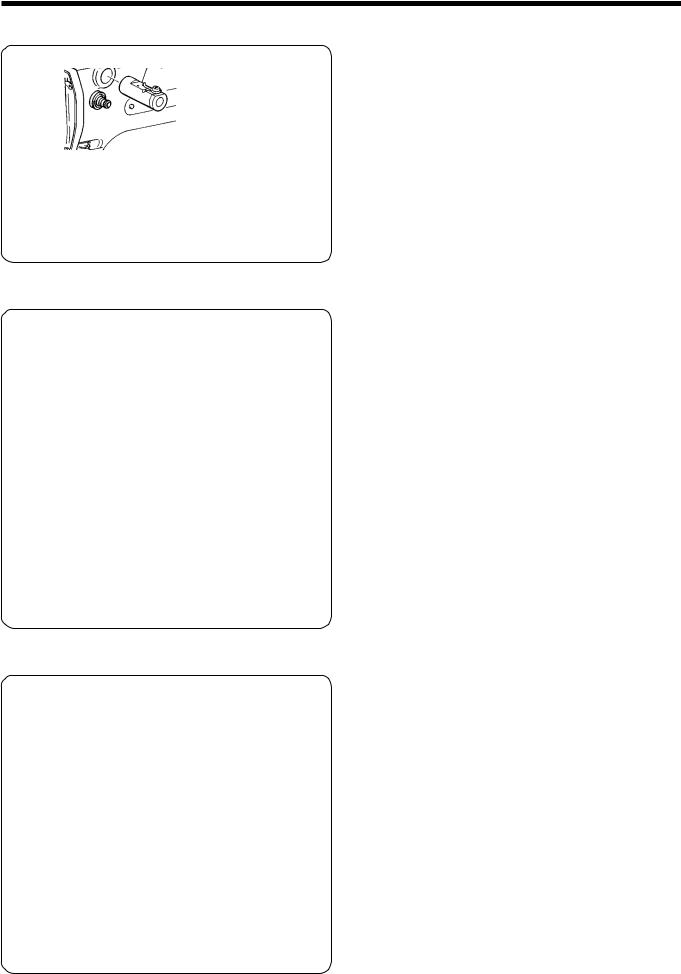

3-7. Installing the head rest

Tap the head rest q into the table hole.

NOTE:

Tap the head rest securely into the table hole.

0060Q

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com |

9 |

BAS-016B |

|

3. Installation

3-8. Installing the liquid cooling tank, optional

1. Remove the rubber plug, and then push the liquid cooling tank q.

2. Tighten it with the set screw w.

0061Q

3-9. Installing the vibrating bowl

1. Install the vibration bowl q with bolts w, spring washers e, and washers r.

2. Pass the wires from the vibration bowl q through the hole in the table.

1047Q

3-10. Installing the control box (for vibrating bowl)

1. Mount the control box q to the bottom of the box stay e with screws w.

2. Mount the control box stay e to the bottom of the work table with wood screws r.

1048Q

10 |

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com |

|

BAS-016B |

3. Installation

3-11. Installing the button feeder

1. Move button feeder base q to the front and rear and left and right as necessary to install it by using hole bolts w, spring washers e and washers r.

(And install ground wires ty.)

|

To vibrating bowl |

|

To control box |

|

(For vibrating bowl) |

|

1049Q |

3-12. Installing the shooter |

|

1050Q |

1. Raise the shooter lock pin w on the vibrating bowl q, |

|

and secure the shooter e by inserting the pin w, |

|

through the notch in the shooter. |

|

2. Secure the shooter e with thumb screw r on button |

|

feeder t. |

1051Q |

1052Q |

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com |

11 |

BAS-016B |

|

3. Installation

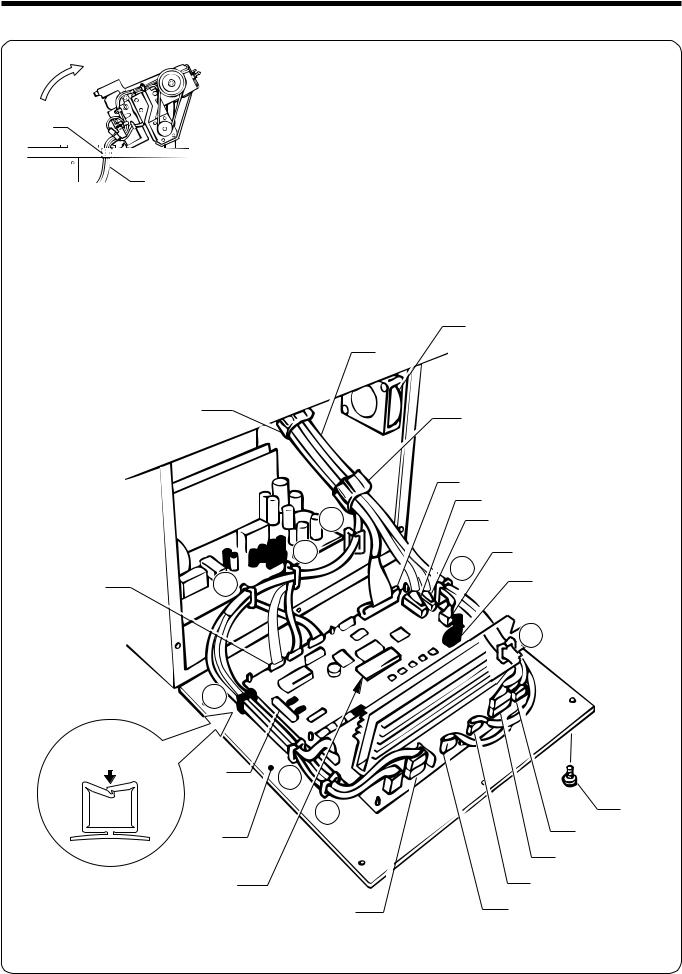

3-13. Connecting the cords

0065Q

w

!0

q

!1

q

!2

A

B

B

P15 C

D

Lock the cord clamp at the top.

P14 E

F

r

!5

P11

0066Q |

0068Q |

t

uy

o

i

!4

!3

P8

P1-B

P1-A

P2

G

P3

H

H

e

P4

P5

P6 (blue)

P7

1053Q

12 |

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com |

|

BAS-016B |

3. Installation

1.Gently tilt back the machine head.

NOTE:

After tilting back the machine head, do not push the face side or the pulley side from above.

2.Pass the cord bundle q from the machine head through the hole w in the work table.

3.Gently return the machine head to its original position.

4.Remove the six screws e, and then open the control box cover (main P.C. board mounting plate r).

NOTE:

When opening the cover, hold it securely so that it does not fall down.

5.Loosen the two screws t, and then open the cord presser plate y in the direction of the white arrow and pass the cord bundle q through the opening.

6.Remove the screw u, and then pass it through the terminal holes in the ground cord i from the machine head and the ground cord o from the operation panel. Then re-tighten the screw u so that the ground cords i and o are secured as shown in the illustration.

7.Remove the screw !0, and then pass it through the terminal hole in the ground cord !1from the upper shaft motor. Then re-tighten the screw !0so that the ground cord !1is secured as shown in the illustration.

NOTE:

Make sure that the ground connections are secure in order to ensure safety.

8.Securely connect connectors P1 to P8, P11, P14 and P15 as indicated in the table below.

NOTE:

Check that the connector is facing the correct way, and then insert it firmly until it locks into place. Furthermore, lock the cord clamp at the top.

Machine head connectors |

|

Connection location |

Cord clamps used |

|||

Connection location |

No. of pins |

Cord mark |

on circuit board |

|||

|

||||||

|

|

|

|

|

|

|

Head position switch |

9-pin |

1A |

P1 |

- A (ORG) |

None |

|

|

|

|

|

|

|

|

X, Y, Sewing sensor |

12-pin |

z |

P1 |

- B (ORG) |

None |

|

|

|

|

|

|

|

|

Synchronizer |

5-pin |

x |

P2 |

(SYNCHRO) |

G |

|

|

|

|

|

|

|

|

Machine specification |

8-pin |

c |

P3 |

(SELECT) |

None |

|

select connector |

||||||

|

|

|

|

|

||

|

|

|

|

|

|

|

Thread take-up solenoid |

5-pin |

v |

P4 |

(SOL2) |

G H |

|

|

|

|

|

|

|

|

Presser solenoid |

4-pin |

b |

P5 |

(SOL) |

G H |

|

Thread trimmer solenoid |

||||||

|

|

|

|

|

||

Pulse motor, Y |

4-pin (blue) |

n |

P6 |

(YPM) |

G H |

|

|

|

|

|

|

|

|

Pulse motor, X |

4-pin |

m |

P7 |

(XPM) |

G H |

|

|

|

|

|

|

|

|

Operation panel |

26-pin |

None |

P8 |

(PANEL) |

None |

|

|

|

|

|

|

||

Upper shaft motor |

3-pin |

None |

P11 (UVW) |

ABCDEF |

||

|

|

|

|

|

||

Button feeder |

1-pin |

None |

P14 |

ABCD |

||

|

|

|

|

|

||

Button feeder |

16-pin |

None |

P15 |

AB |

||

|

|

|

|

|

|

|

9.Secure the cord bundle q with the cord clamps !2and !3.

10.Close the cord presser plate y in the direction of the black arrow, and secure it by tightening the screws t.

NOTE:

Check that the cords do not get pulled when the machine head is tilted back gently.

11.Tighten the cover (main P.C. board mounting plate r) with the six screws e.

NOTE:

Check that the cords do not come into contact with the fan !4and that they are not clamped by the cover at this time.

NOTE:

Check that the main PROM !5 is version MN-G or later.

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com |

13 |

BAS-016B |

|

3. Installation

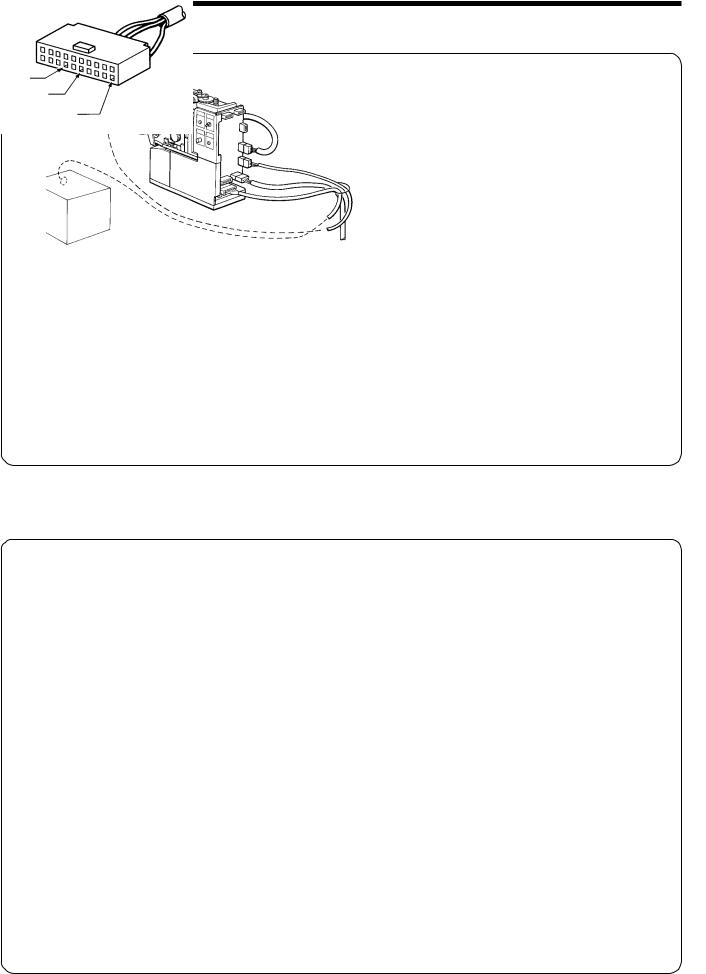

■Button feeder connection

Pull on the connector to make sure it will not come disconnected after connecting the pins.

1054Q |

1055Q |

20P connector

control box

Button feed |

6P |

Red |

|

|

|

sensor |

|

White |

|

|

|

|

|

9P |

|

|

|

|

7P |

Black |

|

|

|

|

|

|

|

|

|

|

20P |

|

|

|

|

|

|

7P connector |

|

|

|

6P connector |

9P connector |

|

control box |

|

|

|

(for vibrating bowl) |

||||

Botton stopper solenoid |

(machine head) |

Button feeder switch |

|

|

|

|

White |

|

|

|

|

White |

Black |

|

|

|

|

|

|

|

|

|

|

|

Red |

|

|

|

|

|

|

Black Red |

Brown |

Blue |

|

|

|

White Green |

Yellow |

1056Q |

|

|

|

|

|

||

■Control box (for vibrating bowl) connection

Connect the ground wire from the vibrating bowl to the bottom of the work table with the bolt of button feeder.

9P connector |

2P connector |

Red White Black |

|

Green |

Black |

|

White |

||

|

Brown Yellow 3P connector

Blue |

|

(male) |

9P connector (female) |

Black

Green/ White

Yellow

1057Q |

1058Q |

14 |

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com |

|

BAS-016B |

3. Installation

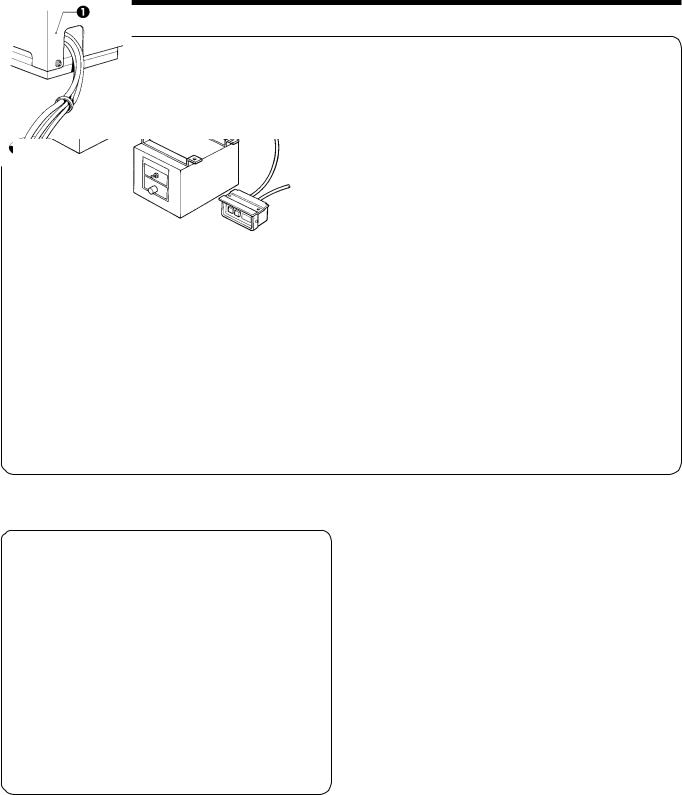

■ Power switch connection

B

A

1059Q

3-14. Installing the button feeder cover

1061Q |

1062Q |

Power switch connector (control box)

Control box (for vibrating Green/Yerrow Black

White

Red

Control box side A Green/Yerrow Black

White

Red

Control box side B Green/Yerrow Red

White

1060Q

Attach the button feeder cover q to the button feeder w with screws e, spring washers r, and washers t.

*Be sure to pass the wires through the hole in the cover when attaching the button feeder cover q.

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com |

15 |

BAS-016B |

|

3. Installation

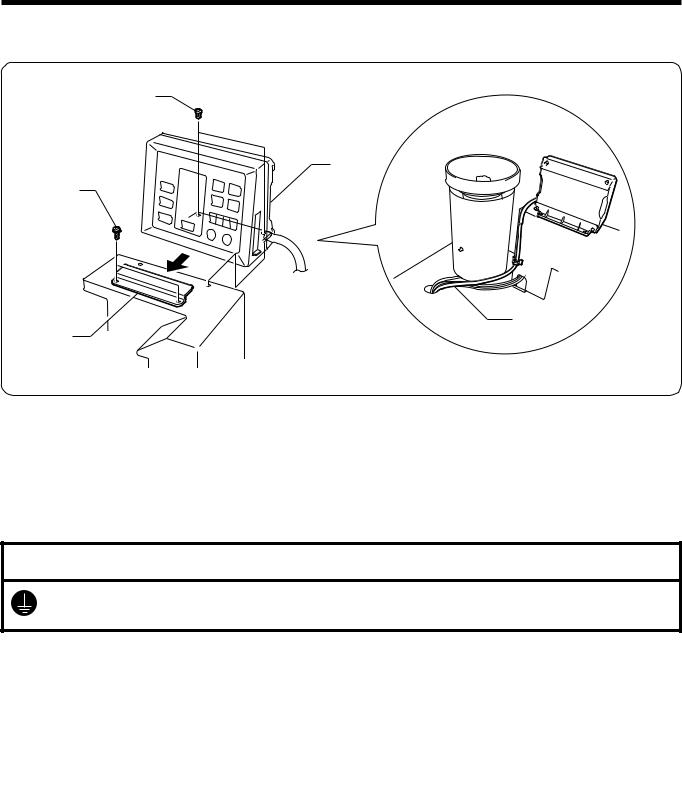

3-15. Installing the operation panel

The operation panel can be installed to either the top of the button feeder cover or bottom of the work table.

r

e

w

t

q

1063Q

1.Install the operation panel presser plate q to the top of the button feeder cover with the two screws w.

2.Insert the panel e into the operation panel presser plate q, and then secure it with the two screws r.

3.Insert the connector cord t into the control box through the hole at the side of the box. Refer to “3-13. Connecting the cords” for details on connecting the cord.

3-16. Connecting the ground wire

CAUTION

CAUTION

Be sure to connect the ground. If the ground connection is not secure, you run the risk of receiving a serious electric shock, and problems with correct operation may also occur.

Connect to the power switch. However, the black wire is insulated to the inside of the box and is not used.

Connect to ground

0445Q

16 |

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com |

|

BAS-016B |

3. Installation

3-17. Installing the belt cover

w

q

q

e

r |

0069Q |

1.Loosen the two screws w of the upper cover q.

2.Insert the belt cover e in the direction of the arrow, and then secure it with the two screws w and the two screws r.

*It is not necessary to remove the belt cover e when tilting back the machine head.

3-18. Installing the foot switch

|

[A] |

r |

|

|

|

y u |

!1 |

|

|

q |

i |

!0 |

|

e |

|

o |

|

|

|

w |

|

|

|

|

|

|

|

|

|

|

!2 t !3 |

!6 |

!4 !5 |

|

e |

[B] |

|

|

|

|

|

|

|

|

0070Q |

|

!7 |

|

!8 !9 |

|

|

|

|

|

0071Q

0072Q

1.Insert the connector of the foot switch e into the connector w of the control box q.

2.Install the foot switch e to the work table leg !2with foot switch support plate A r, foot switch support plate C t, the bolt y, spring washer u, flat washer i, bolt o, spring washer !0and flat washer !1as shown in Figure A.

♦ If foot switch support plate B !3is used in a back-to-front position, it can be used as shown in Figure B.

1.Remove the screw !4and rubber plug !5.

*Note that the spring !6will come out when the screw !4is removed.

2.Turn foot switch support plate B !3back to front, and then install it with the bolt !7, spring washer !8and flat washer !9as shown in Figure B.

NOTE:

If using the foot switch without installing it to the work table leg, move the foot switch at least 10 mm away from the leg. If the foot switch is not fully in contact with the work table leg when the foot switch is used, for example, if it is just hooked loosely onto the work table leg, it may cause the sewing machine to operate incorrectly.

If using the optional two-pedal foot switch, change the setting of DIP switch A on the oreration panel while referring to "Setting the presser mode" on page 56.

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com |

17 |

BAS-016B |

|

Loading...

Loading...