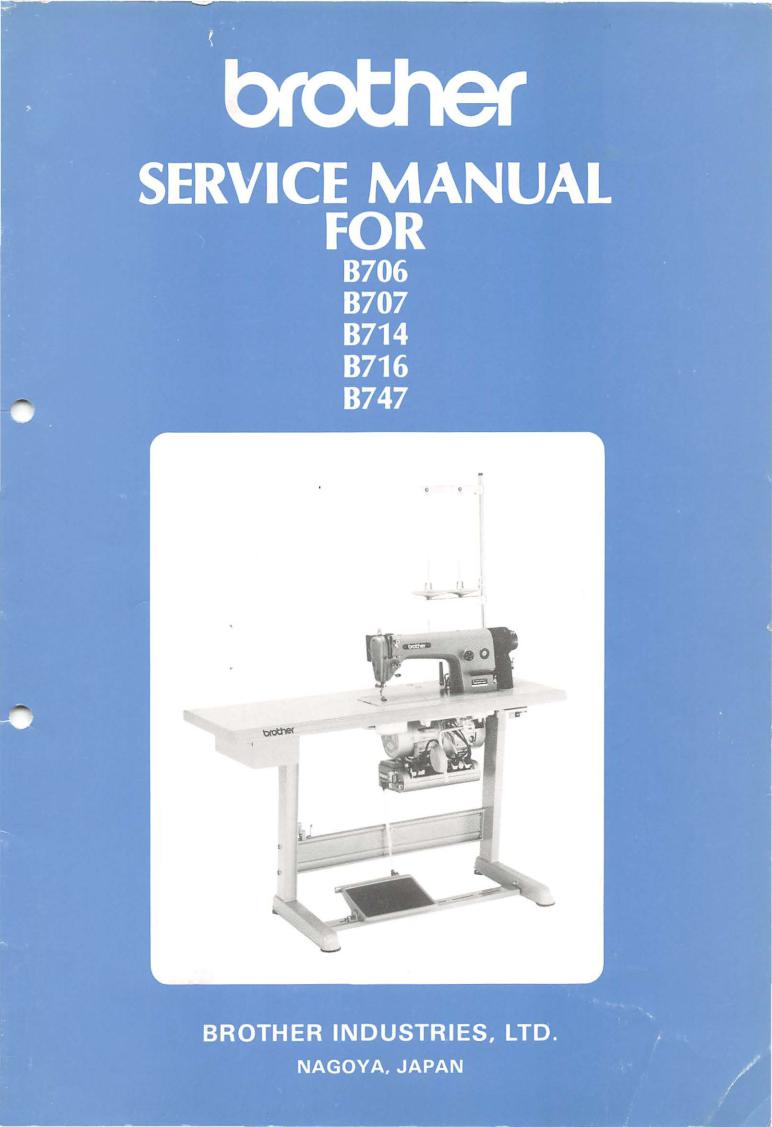

Brother B706, B707, B714, B716, B747 Service Manual

From the library of: Superior Sewing Machine & Supply LLC

CONTENTS

~MECHANISM~ .................................

|

OJ |

Upper shaft and needle bar mechanism |

|

|

|

[I] |

Lower shaft and rotary hook |

|

|

|

|

mechanism .......................................... .. |

|

|

|

[I] |

Feed mechanism ( 8714/ 8716/ 8747) .... |

2 |

|

|

[I] |

Feed mechanism (8706/ 8707) .............. |

3 |

|

0 |

Lubrication mechanism ........................ |

4 |

||

|

[I] |

Thread trimmer mechanism ................. |

6 |

|

[]] |

Thread tension release lever |

|

||

|

|

(8707/8716/8747)................................ |

9 |

|

|

[I] |

Thread wiper mechanism ..................... |

9 |

|

[!] |

Quick-back mechanism ........................ |

9 |

||

[]] |

Automatic presser lifter mechanism ..... |

9 |

||

|

|

|

|

|

~DISASSEMBLY~ |

10 |

|||

|

OJ |

Cover.................................................... |

10 |

|

|

I1J |

Presser.................................................. |

10 |

|

|

[I] |

Rotary hook ......................................... |

II |

|

0 |

Thread trimmer .................................... |

II |

||

|

[I] |

Feed. mechanism (8706/ 8707) .............. |

12 |

|

|

[I] |

Feedmechanism(8714/B716j8747) .... |

13 |

|

[]] |

Needle bar mechanism ......................... |

13 |

||

~ASSEMBLY~ ...................................... |

14 |

|

OJ |

Needle bar ............................................ |

14 |

[I] |

Feed mechanism (8706/ 8707) .............. |

15 |

I1J |

Feed mechanism (8714/ 8716/ 8747) .... |

16 |

[I] |

Thread trimmer .................................... |

17 |

0 |

Rotary hook......................................... |

18 |

[I] |

Presser mechanism ............................... |

19 |

[]] |

Cover.................................................... |

19 |

~ADJUSTMENTS~ ............................. |

20 |

|

OJ |

Needle and rotary hook timing |

|

|

adjustments .......................................... |

20 |

I1J |

Feed dog height adjustment ................. |

21 |

[I] |

Feed timing adjustment ........................ |

21 |

0 |

Presser height adjustment ..................... |

21 |

[I] |

Synchronizer adjustment ...................... |

22 |

[]] |

Thread trimmer ~djustment .................. |

23 |

[I] |

Tension release lever adjustment .......... |

24 |

[!] |

Thread wiper adjustment...................... |

24 |

[]] |

Automatic presser foot lifter adjustment |

|

|

(-900; electromagnetic type) ............... |

24 |

~TROUBLESHOOTING GUIDE~... |

25 |

|

From the library of: Superior Sewing Machine & Supply LLC

[I] Upper shaft and needle bar mechanism

I. When the pulley 0 turns in the direction indicated by the arrow, the movement is transmitted to the upper shaft

|

8 and causes the counter weight 8 to turn. |

2. |

The movement is transmitted to the needle bar connecting rod 8 via the needle bar crank 8 connected to the |

|

counter weight. |

3. |

The needle bar 8 connected to the needle bar clamp 8 is moved up and down. |

4. |

The needle bar is guided by needle bar bushing U 0 and needle bar bushing D 0. |

[I] Lower shaft and rotating hook mechanism

I. When the pulley 0 turns in the direction indicated by the arrow, the movement is transmitted by the upper shaft bevel gear 8 mounted to the upper shaft 8 to vertical shaft bevel gear U 8 mounted on the top of the vertical shaft G.

2. The movement is then transmitted by vertical shaft bevel gear D 8 mounted on the bottom of the vertical shaft 8 to the lower shaft 0 via the lower shaft bevel gear 8.

3. The rotary hook 0 is then caused to rotate in a full circle by the lower shaft 0.

- I -

From the library of: Superior Sewing Machine & Supply LLC

[I] Feed mechanism (8714/8716/8747)

•

------- ---- _...---

I.When the pulley 0 turns in the direction indicated by the arrow, vertical movement is transmitted by the feed

cam 8 mounted to the upper shaft 8 to the forked connector 8 via the feed cam sleeve G.

2. The horizontal feed rocker arm 8 connected to the forked connector 8 is then moved in a circular arc.

3.The feed bar 8 is moved back and forth by the horizontal feed bar shaft 0 mounted to the horizontal feed rocker shaft 8.

4.The crank rod fi) is moved up and down by the feed cam 8.

5. |

The horizontal feed shaft & connected to the crank rod ~ is then moved in i circular arc. |

6. |

The horizontal feed arm Cl connected to the feed shaft & is also moved in a circular arc. |

7. |

The movement of the feed dog mounted to the feed bar 8 is determined by the combined action of steps 3 and 6. |

-2-

From the library of: Superior Sewing Machine & Supply LLC

(}] Feed mechanism (8706/8707)

|

I. When the pulley 0 turns in the direction indicated by the arrow, the level feed connecting rod 8 is moved up |

||

|

|

and down by the level feed eccentric wheel 8 mounted to the upper shaft f). |

|

|

2. |

The feed rocker shaft arm 0 is moved in a circular arc by the level feed arm link assembly 0 mounted to the |

|

|

|

level feed connecting rod 8. |

|

|

3. |

The feed bar 0 is moved back and forth by the wick hanger 0 mounted to the feed rocker shaft f). |

|

|

4. |

The vertical feed connecting rod 6) is moved up and down by the vertical feed eccentric wheel Gi) mounted to the |

|

|

|

upper shaft f). |

|

|

5. |

The feed lifting rocker shaft arm • is moved in a circular arc by the vertical feed connecting rod 6). |

|

.~ |

6. |

The feed bar 0 is moved up and down by the feed lifting arm 4D mounted to the feed lifting rocker shaft G) . |

|

7. |

The movement oft he feed dog G) mounted to the feed bar 0 is determined by the combined action of steps 3 and |

||

|

|||

|

|

6. |

|

-3-

From the library of: Superior Sewing Machine & Supply LLC

[!] Lubrication mechanism

1. Upper shaft oil supply

Upper shaft

(I)The oil from the pump 8 passes through upper shaft bushing M 8, enters the center of the upper shaft, and from there is supplied to upper shaft bushing L 8 and upper shaft bushing R 8.

The oil dispersed in the arm column is supplied to the feed adjuster.

(2)An oil adjusting valve 8 is provided at the left end of the upper shaft, and oil is supplied to the thread take-up arm via the counterweight and needle bar crank.

(3)Felt is mounted on the needle bar crank in order to prevent excess oil discharge or oil clogging, and oil is supplied to the needle bar connecting rod.

(4)The oil that accumulates in the thread take-up shield is supplied to the needle barO and needle bar bushings U

|

and D via the oil wick 8. |

(5) |

The oil is held inside by the rubber stopper 8 in the pulley presser screw at the right end of the upper shaft. |

(6) |

The oil that accumulates at the dip in the arm is drawn back to the pump 8 via a felt and a tube. |

- 4 -

From the library of: Superior Sewing Machine & Supply LLC

2. Lower shaft oil supply

Lower shaft

(I) |

The oil is supplied by the pump to the lower shaft and lower shaft bushing L f). |

(2) |

Part of the oil from lower shaft bushing L f) flows through the lower shaft to the rotary hook. |

|

Also, the oil ejected from lower shaft bushing L f) is supplied to the horizontal feed rocker shaft 0 and the |

|

vertical feed shaft 8 via a wick. |

(3)The oil dispersed in the ar.,m column is supplied to lower shaft bushing R 0, the horizontal feed rocker shaft 0, and the vertical feed shaft 8 via the arm channel.

3. Pump mechanism

When the vanes at the bottom of the vertical shaft turn, the centrifugal force sucks the oil up through the hole in the center. The oil is then expelled from the outlets at the ends of the spinal chambers to the various oil tubes.

In addition, a plunger pump attached to the pump body draws oil which accumulates in the

dip in the arm back to the pump.

----Pump body

____ Rotating vanes

-5-

From the library of: Superior Sewing Machine & Supply LLC

(}] Thread trimmer mechanism

1 .Thread trimmer mechanism

As shown in the illustration, the thread trimmer mechanism consists of the movable knife 0, the fixed knife 0. a lower thread finger 8. the movable knife holder G. the knife holder assembly 8. the trimmer forked shaft 8. the trimmer cam lever assembly 8, the trimmer cam 0, and the trimmer solenoid 8.

2.Operation of the trimmer mechanism(The following illustrations are with the high-speed rotating hook removed.)

(I)Condition during high-speed operation

* Because the trimmer cam lever assembly 8 is kept pressed toward the trimmer 'solenoid 8 by the cam lever return spring f), the trimmer cam lever assembly 8 does not engage with the trimmer cam 0 and the movable knife holder 8 does not function. ,.

In addition, the trimmer lever 8 is pressed by the trimmer lever spring CD so that the movable knife holder 8 does not move.

(2) Condition when a trim signal is input

* When the foot Pedal is depressed again and the trim signal is input, the trimmer solenoid 8 pushes the trimmer cam lever shaft G). The roller shaft (right side) of the trimmer cam lever assembly 8 that is connected to the trimmer cam lever shaft G) moves around the outside of the trimmer cam 0.

- 6 -

From the library of: Superior Sewing Machine & Supply LLC

(3) Movement of the trimmer holder

* When the lower shaft turns and the trimmer cam 0 pushes the roller shaft (right side) upward, the movement is transmitted to the trimmer forked shaft 8 via the trimmer cam lever assembly 8.

* The movement is transmitted to the trimmer connecting rode and the movable knife holder 8 via the trimmer lever 0 mounted to the trimmer forked shaft 8.

* The movable knife 0 mounted to the movalbe knife holder 8 moves in the direction indicated by the arrow and overlaps with the fixed knife 8.

(4) Trimming completion and stop

* When the trim signal stops, t'he trimmer solenoid 8 returns, the trimmer cam lever assembly 8 is pushed by the cam lever return spring G), and the toller shaft ofthe trimmer cam lever assembly 8 separates from the trimmer came.

*The trimmer connecting rod fD and the movable knife holder 8 are returned to their original positions (in the directions indicated by the arrows) by the trimmer lever spring CD.

(5) Thread trimmer safety device

0

* If the moving knife 0 does not return to its original position, the return pin (left side) of the trimmer cam lever assembly 8 and the trimmer cam 8 function to return the movable knife 0 to a position where it will not come in contact with the needle.

-7-

From the library of: Superior Sewing Machine & Supply LLC

----~~

---

(I)The needle rises to a point 2.2 mm above the lowermost point and the tip of the rotary hook the loop formed by the needle.

(2)The trim signal is input. and the trimmer cam causes the movable knife to move. The needle thread is caught by the rotary hook and passes through the inner hook.

Bobbin thre~~

~ Movable knife

Fixed knife r |

~ Needle thread |

I |

|

I |

|

' |

(3) The tip of the movable knife goes into the triangular loop formed by the needle and bobbin threads divided by the tip of the rotary hook at the needle hole plate, and spreads the needle and bobbin threads.

At this time, the thread take-up is slightly above the lowermost position and the needle thread is separated by the movable knives as shown in the illustration.

If the timing for the above operation is too early. it will affect the loop spreading of the movable knives and errors in thread trimming may occur. ·'

Needle thread

(4)The needle and bobbin threads hooked by the movable knife in step (3) are spread out to a fan shape by the shape of the knife. and as they are spread out gradually by the thread spreader, they are cut by the tip of the fixed knife.

At this time, the thread take-up is almost at the uppermost position.

At the same time that the knife is spreading out the thread, the tension release lever functions to let the needle thread out smoothly and prevent excessive slack.

Note that the amount of thread determined at the movable knife becomes the length of thread remaining for the needle thread and in the bobbin case after thread trimming, and this in turn influences the composition of the stitch the next time sewing is begun.

-8-

From the library of: Superior Sewing Machine & Supply LLC

Loading...

Loading...